Review of Optimization Dynamically Applied in the Construction and the Application Potential of ICT

Abstract

1. Introduction

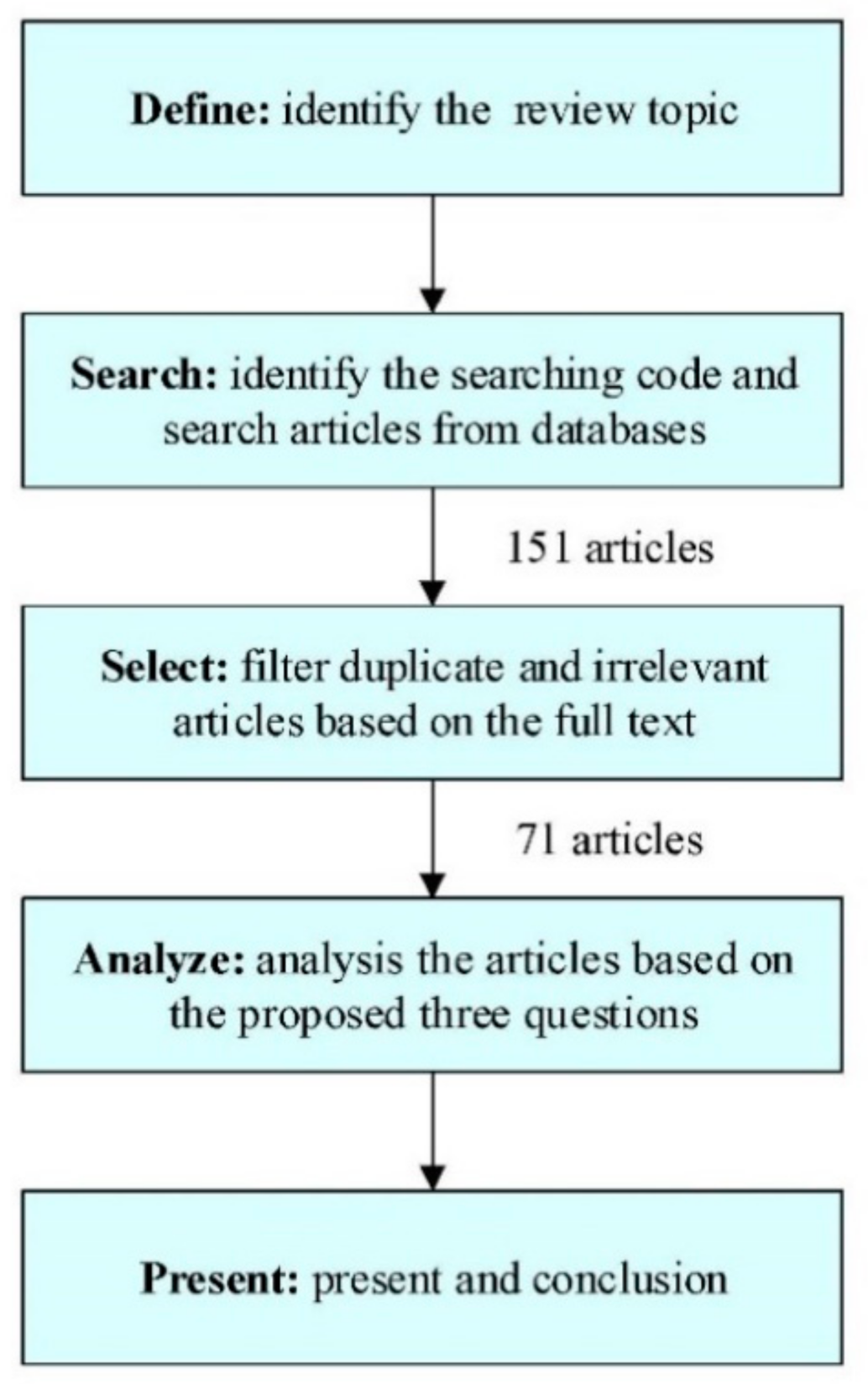

2. Review Method

- (1)

- How the optimization method realizes dynamics;

- (2)

- What data drive its dynamics;

- (3)

- Whether these data can be collected by ICT.

3. Event Mode

3.1. Rescheduling

3.2. Adapt Algorithm

3.3. Event Accepted by Agents

3.4. Conclusion and the Potential to Combine ICT Technology and Apply Real Data

- (1)

- The algorithm begins with several potential solutions that encoded according to the current optimization object;

- (2)

- Then they are substituted into the “fitness function” to calculate which of them is relatively optimal;

- (3)

- The optimal ones are more likely to be taken as the blueprints to generate the new solutions, different optimization algorithm has a different way to generate new solutions like that GA generates new individuals by mimicking the mutation and crossover of genes;

- (4)

- Repeat step 2, iterate until the extremum or achievement of optimization goal.

| Article | Dynamic Data | Dynamic Data Resource | Optimization Topic | Algorithm |

|---|---|---|---|---|

| Rescheduling | ||||

| [17] | orders change, machine failures | randomly trigger | production scheduling | GA |

| [18] | orders change, machine failures | randomly trigger | production scheduling | PSO |

| [19] | machine failures, newly jobs | randomly trigger | production scheduling | EO |

| [20] | demand change of PCs | pre-scheduled | production scheduling | GA |

| [21] | material delays | pre-scheduled | construction scheduling | CP |

| [22] | productivity modification | pre-scheduled | construction scheduling | CP |

| [23] | job insertion | pre-scheduled | construction scheduling | ACO |

| [24] | machine failures, production delay | pre-scheduled | construction scheduling | SA |

| Adapt algorithm | ||||

| [6] | order and workers change | randomly trigger | construction scheduling | GA |

| [25] | machine failure and job insertion | randomly triggered | construction scheduling | VNSA |

| [26] | assembly sequence change | randomly trigger | construction scheduling | GA |

| Event accepted by agents | ||||

| [27] | machine failures, resource change | randomly trigger | production scheduling | GA |

| [28] | truck breakdowns | randomly trigger | equipment scheduling | EA |

4. Periodic Mode

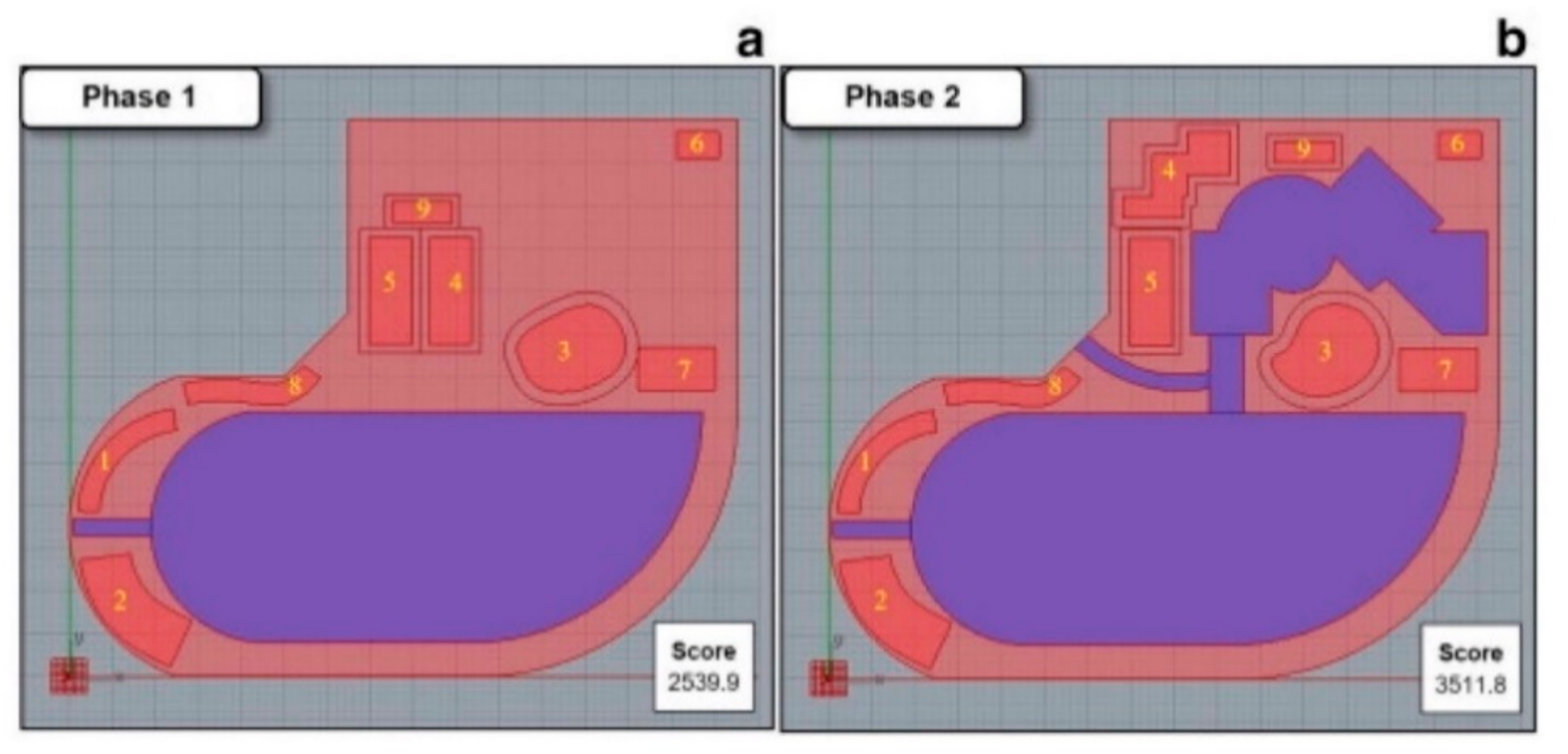

4.1. Dynamic Construction Site Layout Planning Problem

4.2. Dynamic Material and Temporary Facility Layout Problem

4.3. Other Periodic Updates for Dynamics

4.4. Conclusion and the Potential to Combine ICT

| Dynamic Data | Dynamic Data Resource | Optimization Topic | Algorithm | |

|---|---|---|---|---|

| Dynamic Construction Site Layout Planning Problem | ||||

| [39] | site status | project documents | DCSLP | MMAS |

| [40] | site status | project documents | DCSLP | ACO |

| [34] | site status | project documents | DCSLP | GA |

| [35] | facilities’ demand | project documents | facilities planning | LP |

| [36] | site status | project documents | DCSLP | PSO |

| [41] | dynamic site status | project documents | facility relocation | GA |

| [37] | dynamic site status | project documents | tower crane planning | SA |

| [38] | dynamic facilities’ demand | BIM model | DCSLP | GA |

| [44] | dynamic site status | project documents | DCSLP | DP |

| [45] | dynamic site status | project documents | DCSLP | GA/ADP |

| [42] | dynamic site status | project documents | DCSLP | LFA |

| [43] | dynamic site status | project documents | DCSLP | MEP |

| [47] | dynamic site status | project documents | transportation planning | PSO |

| [48] | dynamic material’s demand | project documents | material supply chain | stochastic programs |

| [46] | dynamic material’s demand | project documents | transportation planning | mathematic method |

| [49] | dynamic site status | unmanned aerial vehicle | DCSLP | LP |

| Dynamic material and temporary facility layout problem | ||||

| [50] | arrival/departure of material | project records | material inventory | GA |

| [51] | incoming/outgoing materials | Predetermined | material inventory | GA |

| [31] | arriving time, type, quantity of material | GNSS and RFID | material inventory | GA |

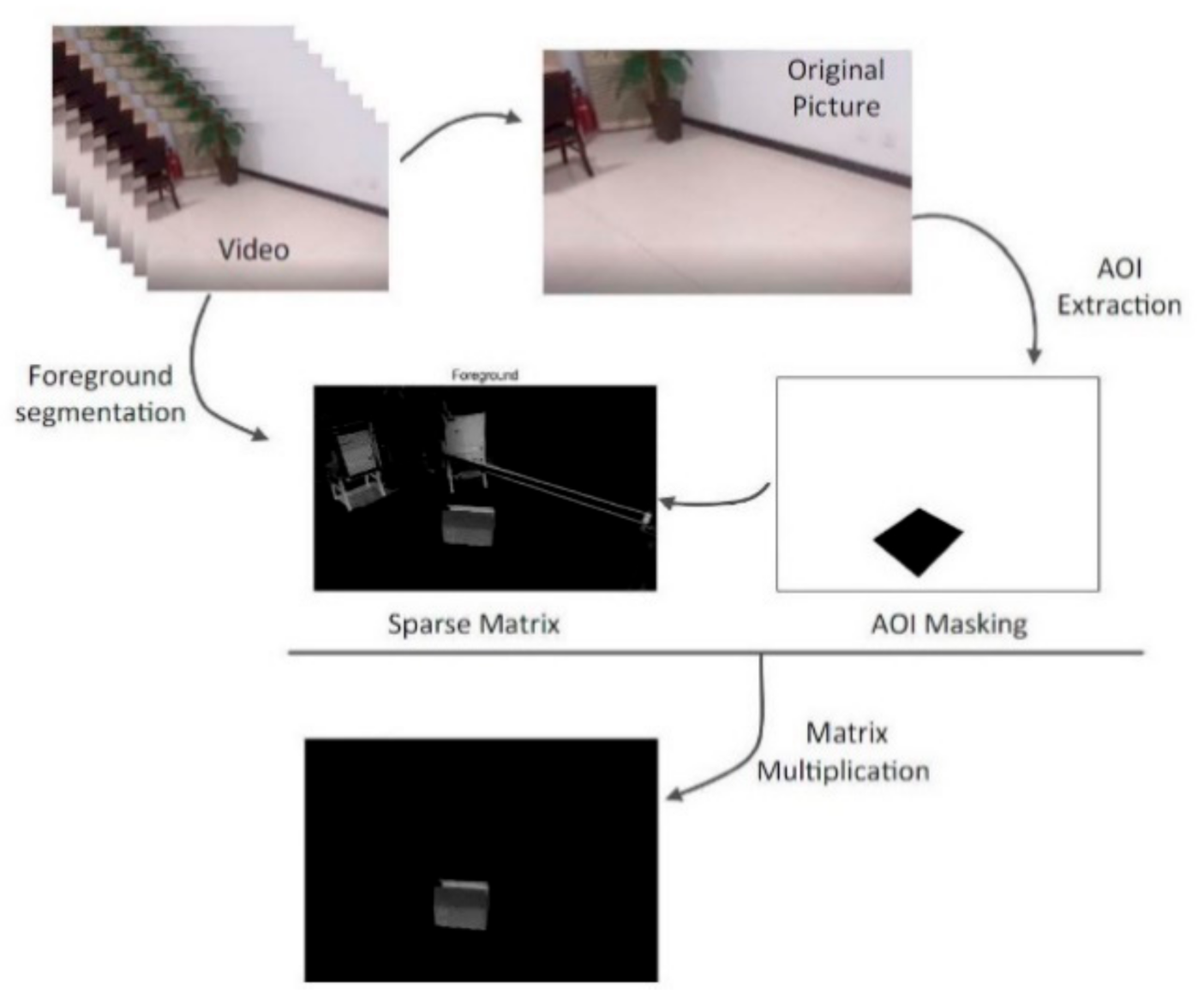

| [52] | material supply, yard availability | imaging technology | material inventory | GA |

| [53] | material supply and demand | imaging technology, BIM | material inventory | EA |

| Other periodic updates for dynamics | ||||

| [54] | equipment failures | project records | equipment allocation | PSO |

| [55] | drop, rise of water level | project records | construction dewatering | mathematic method |

| [56] | dynamic construction process | project documents | schedule optimization | GA |

| [58] | evolving project constraints | prescheduled | construction Scheduling | CP |

| [57] | dynamic constraints | project documents | schedule optimization | GA |

| [59] | change of resource | project documents | schedule optimization | mathematic method |

| [60] | equipment productivity | GPS-sensors | equipment allocation | GA |

| [10] | location and status of equipment | data sensor | equipment allocation | SBO |

5. Uncertain Relationships

| Article | Dynamic Data | Dynamic Data Resource | Optimization Topic | Algorithm |

|---|---|---|---|---|

| [68] | dynamic linkage between tasks, cranes, and supply locations | predetermined | layout optimization | PSO |

| [69] | dynamics of resource sharing | production data | layout optimization | metaheuristics |

| [70] | uncertain routes and loading points | predetermined | material supply chain | GA |

| [71] | multiple duration/resource execution modes | predetermined | planning and scheduling | GA |

| [72] | fuzzy logic between facilities | predetermined | facilities planning | GA |

| [73] | dynamic resource allocation | predetermined | Project scheduling | heuristic |

6. Uncertain Parameter

6.1. Probabilistic Distribution

6.2. Mathematic Model

6.3. Fuzzy Theory

6.4. Conclusion and the Potential to Combine ICT

| Dynamic Data | Dynamic Data Resource | Optimization Topic | Algorithm | |

|---|---|---|---|---|

| Probabilistic distribution | ||||

| [77] | material delay, equipment failures | known distribution | project scheduling | robust optimization |

| [75] | activity durations | known distribution | project scheduling | EA |

| [76] | activity durations | known distribution | project scheduling | heuristic algorithm |

| [78] | crew production rates | known distribution | project scheduling | GA |

| [74] | activity duration, weather condition | randomly trigger | project scheduling | GA |

| [79] | idle rates of equipment, activity duration | known distribution | concrete placing scheduling | GA |

| [80] | triangular distribution of activity durations | known distribution | project scheduling | DES-GA hybrid |

| [81] | task floating time | known distribution | material layout | SOSA |

| Mathematic model | ||||

| [82] | duration and cost | predetermined | project scheduling | GA |

| [83] | task duration | predetermined | project scheduling | SBO |

| [84] | cost–time function | predetermined | project scheduling | GA |

| [85] | space–time float | predetermined | optimize the duration | LP |

| [86] | quality, cost and schedule function | predetermined | schedule cost optimization | GA |

| [87] | weights between time, cost, quality and resources | predetermined | project Scheduling | PSO |

| [88] | geometries of facilities | predetermined | facilities layout | GA |

| [89] | resources uncertainties | predetermined | project Scheduling | PSO |

| Fuzzy theory | ||||

| [90] | task duration, material supply | predetermined | material supply chain | LP |

| [91] | work quantities, crews’ productivities and costs | predetermined | project Scheduling | GA |

| [92] | crew productivity | predetermined | project Scheduling | GA |

| [93] | time and cost | predetermined | project Scheduling | GA |

| [94] | human bias and uncertainty | predetermined | resource-allocation | SBO |

| [95] | equipment failure rate | predetermined | project Scheduling | DP-based GA |

| [96] | interaction cost and operating cost of facilities | predetermined | project Scheduling | PSO |

| [97] | transportation cost of facilities | predetermined | project Scheduling | DP-based PSO |

7. Research Gap Identification

8. Conclusions

- (1)

- Dynamic data of the event mode are mainly about the events that affect the encoding status, constraints and results of fitness function of optimization algorithms. The rescheduling (event-driven), adapt algorithm, and event accepted by agents are three ways adopted to deal with events. However, their data sources are mainly from the default event schedule and random triggering that lacking the application of real-time events. So far, ICT can monitor and identify the events in real-time, which means that they have the great potential to be combined with dynamic optimization.

- (2)

- In the periodic mode, the optimization method is applied periodically with the system status update. Research has proven the huge application value of ICT in DCSLP. As for the dynamic material and facility layout problem, more ICT such as RFID, imaging techniques are applied to identify the current status of the site, which makes dynamic optimization have more practical significance in construction and reflects the great application value of ICT technology in dynamic optimization.

- (3)

- The uncertain relationship dynamics are pre-determined when the model is established, so it is not easy to use the real data continually during construction. Uncertain parameter brings dynamics into optimization by a probability distribution, fuzzy theory and mathematic model. This form of dynamics is more forward-looking than events and periodic mode. Although almost no ICT technology is used in this type of optimization, the uncertain parameter can be updated during construction by using real construction data in process control and prediction studies, etc., which shows the great application potential of ICT in it.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACO | Ant Colony Optimization |

| ADP | Approximate Dynamic Programming |

| BIM | Building Information Modelling |

| CP | Constraint Programming |

| DCSLP | Dynamic Construction Site Layout Planning |

| DES | Discrete Event Simulation |

| DP | Dynamic Programming |

| EA | Evolution Algorithm |

| EO | Evolutionary Optimization |

| GA | Genetic Algorithm |

| GNSS | Global Navigation Satellite System |

| ICT | Information and Communication Technologies |

| LFA | Levy Flights Algorithm |

| LP | Linear Programming |

| MEP | Minimum Energy Principles |

| MMAS | Max–min Ant System |

| PSO | Particle Swarm Optimization |

| SA | Simulated Annealing |

| SBO | Simulation-based Optimization |

| VNSA | Variable Neighborhood Search Algorithm |

References

- Ding, Z.; Zuo, J.; Wu, J.; Wang, J. Key factors for the BIM adoption by architects: A China study. Eng. Constr. Arch. Manag. 2015, 22, 732–748. [Google Scholar] [CrossRef]

- Choi, J.; Xuelei, J.; Jeong, W. Optimizing the Construction Job Site Vehicle Scheduling Problem. Sustainability 2018, 10, 1381. [Google Scholar] [CrossRef]

- An, H.; Byon, Y.-J.; Cho, C.-S. Economic and Environmental Evaluation of a Brick Delivery System Based on Multi-Trip Vehicle Loader Routing Problem for Small Construction Sites. Sustainability 2018, 10, 1427. [Google Scholar] [CrossRef]

- Leśniak, A.; Zima, K. Cost Calculation of Construction Projects Including Sustainability Factors Using the Case Based Reasoning (CBR) Method. Sustainability 2018, 10, 1608. [Google Scholar] [CrossRef]

- Ghasemi, F.; Sari, M.H.M.; Yousefi, V.; Falsafi, R.; Tamošaitienė, J. Project Portfolio Risk Identification and Analysis, Considering Project Risk Interactions and Using Bayesian Networks. Sustainability 2018, 10, 1609. [Google Scholar] [CrossRef]

- Shan, S.; Hu, Z.; Liu, Z.; Shi, J.; Wang, L.; Bi, Z. An adaptive genetic algorithm for demand-driven and resource-constrained project scheduling in aircraft assembly. Inf. Technol. Manag. 2017, 18, 41–53. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. A Concept for Automated Construction Progress Monitoring: Technologies Adoption for Benchmarking Project Performance Control. Arab. J. Sci. Eng. 2018, 44, 4993–5008. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Ali, Z.H.; Salih, S.Q.; Al-Ansari, N. Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model. Sustainability 2020, 12, 1514. [Google Scholar] [CrossRef]

- Sardroud, J.M. Perceptions of automated data collection technology use in the construction industry. J. Civ. Eng. Manag. 2015, 21, 54–66. [Google Scholar] [CrossRef]

- Lu, M.; Dai, F.; Chen, W. Real-time decision support for planning concrete plant operations enabled by integrating vehicle tracking technology, simulation, and optimization algorithms. Can. J. Civ. Eng. 2007, 34, 912–922. [Google Scholar] [CrossRef]

- Soltani, M.M.; Zhu, Z.; Hammad, A. Skeleton estimation of excavator by detecting its parts. Autom. Constr. 2017, 82, 1–15. [Google Scholar] [CrossRef]

- Kim, H.; Han, S. Accuracy Improvement of Real-Time Location Tracking for Construction Workers. Sustainability 2018, 10, 1488. [Google Scholar] [CrossRef]

- Jia, M.; Komeily, A.; Wang, Y.; Srinivasan, R.S. Adopting Internet of Things for the development of smart buildings: A review of enabling technologies and applications. Autom. Constr. 2019, 101, 111–126. [Google Scholar] [CrossRef]

- Xu, W.; Wang, T.-K. Dynamic safety prewarning mechanism of human–machine–environment using computer vision. Eng. Constr. Arch. Manag. 2020, 27, 1813–1833. [Google Scholar] [CrossRef]

- Wolfswinkel, J.F.; Furtmueller-Ettinger, E.; Wilderom, C.P. Using grounded theory as a method for rigorously reviewing literature. Eur. J. Inf. Syst. 2013, 22, 45–55. [Google Scholar] [CrossRef]

- Fahmy, A.; Hassan, T.; Bassioni, H.; McCaffer, R. Dynamic scheduling model for the construction industry. Built Environ. Proj. Asset Manag. 2019, 10, 313–330. [Google Scholar] [CrossRef]

- Kundakcı, N.; Kulak, O. Hybrid genetic algorithms for minimizing makespan in dynamic job shop scheduling problem. Comput. Ind. Eng. 2016, 96, 31–51. [Google Scholar] [CrossRef]

- Li, J.X.; Wen, X.N. Construction and Simulation of Multi-Objective Rescheduling Model Based on PSO. Int. J. Simul. Model. 2020, 19, 323–333. [Google Scholar] [CrossRef]

- Liu, F.; Wang, S.; Hong, Y.; Yue, X. On the Robust and Stable Flowshop Scheduling Under Stochastic and Dynamic Disruptions. IEEE Trans. Eng. Manag. 2017, 64, 539–553. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H. Dynamic response to demand variability for precast production rescheduling with multiple lines. Int. J. Prod. Res. 2018, 56, 5386–5401. [Google Scholar] [CrossRef]

- Liu, J.; Lu, M. Constraint Programming Approach to Optimizing Project Schedules under Material Logistics and Crew Availability Constraints. J. Constr. Eng. Manag. 2018, 144, 04018049. [Google Scholar] [CrossRef]

- Liu, S.-S.; Shih, K.-C. Construction rescheduling based on a manufacturing rescheduling framework. Autom. Constr. 2009, 18, 715–723. [Google Scholar] [CrossRef]

- Liu, X.; Ni, Z.; Qiu, X. Application of ant colony optimization algorithm in integrated process planning and scheduling. Int. J. Adv. Manuf. Technol. 2016, 84, 393–404. [Google Scholar] [CrossRef]

- Chen, W.; Zhao, Y.; Yu, Y.; Chen, K.; Arashpour, M. Collaborative Scheduling of On-Site and Off-Site Operations in Prefabrication. Sustainability 2020, 12, 9266. [Google Scholar] [CrossRef]

- Wen, Y.; Xu, H.; Yang, J. A heuristic-based hybrid genetic-variable neighborhood search algorithm for task scheduling in heterogeneous multiprocessor system. Inf. Sci. 2011, 181, 567–581. [Google Scholar] [CrossRef]

- Wang, Y.W.; Yuan, Z.M.; Sun, C.S. Research on assembly sequence planning and optimization of precast concrete buildings. J. Civ. Eng. Manag. 2018, 24, 106–115. [Google Scholar] [CrossRef]

- Du, J.; Dong, P.; Sugumaran, V.; Castro-Lacouture, D. Dynamic decision support framework for production scheduling using a combined genetic algorithm and multiagent model. Expert Syst. 2021, 38. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Tran, D.-H. Integrating Chaotic Initialized Opposition Multiple-Objective Differential Evolution and Stochastic Simulation to Optimize Ready-Mixed Concrete Truck Dispatch Schedule. J. Manag. Eng. 2016, 32, 04015034. [Google Scholar] [CrossRef]

- Cheng, C.-F.; Rashidi, A.; Davenport, M.A.; Anderson, D.V. Activity analysis of construction equipment using audio signals and support vector machines. Autom. Constr. 2017, 81, 240–253. [Google Scholar] [CrossRef]

- Cho, C.; Lee, Y.-C.; Zhang, T. Sound Recognition Techniques for Multi-Layered Construction Activities and Events. In Computing in Civil Engineering 2017; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2017; Volume 2017, pp. 326–334. [Google Scholar]

- Liu, D.; Li, X.; Chen, J.; Jin, R. Real-Time Optimization of Precast Concrete Component Transportation and Storage. Adv. Civ. Eng. 2020, 2020, 5714910. [Google Scholar] [CrossRef] [PubMed]

- Memarzadeh, M.; Golparvar-Fard, M.; Niebles, J.C. Automated 2D detection of construction equipment and workers from site video streams using histograms of oriented gradients and colors. Autom. Constr. 2013, 32, 24–37. [Google Scholar] [CrossRef]

- Tajeen, H.; Zhu, Z. Image dataset development for measuring construction equipment recognition performance. Autom. Constr. 2014, 48, 1–10. [Google Scholar] [CrossRef]

- Farmakis, P.M.; Chassiakos, A.P. Genetic algorithm optimization for dynamic construction site layout planning. Organ. Technol. Manag. Constr. Int. J. 2017, 10, 1655–1664. [Google Scholar] [CrossRef]

- Al Hawarneh, A.; Bendak, S.; Ghanim, F. Dynamic facilities planning model for large scale construction projects. Autom. Constr. 2019, 98, 72–89. [Google Scholar] [CrossRef]

- Li, Z.; Shen, W.; Xu, J.; Lev, B. Bilevel and multi-objective dynamic construction site layout and security planning. Autom. Constr. 2015, 57, 1–16. [Google Scholar] [CrossRef]

- Wu, K.; De Soto, B.G.; Zhang, F. Spatio-temporal planning for tower cranes in construction projects with simulated annealing. Autom. Constr. 2020, 111, 103060. [Google Scholar] [CrossRef]

- Kumar, S.S.; Cheng, J.C. A BIM-based automated site layout planning framework for congested construction sites. Autom. Constr. 2015, 59, 24–37. [Google Scholar] [CrossRef]

- Ning, X.; Lam, K.-C.; Lam, M.C.-K. Dynamic construction site layout planning using max-min ant system. Autom. Constr. 2010, 19, 55–65. [Google Scholar] [CrossRef]

- Ning, X.; Lam, K.-C.; Lam, M.C.-K. A decision-making system for construction site layout planning. Autom. Constr. 2011, 20, 459–473. [Google Scholar] [CrossRef]

- Farmakis, P.M.; Chassiakos, A.P. Dynamic multi-objective layout planning of construction sites. Procedia Eng. 2017, 196, 674–681. [Google Scholar] [CrossRef]

- Yahya, M.; Saka, M. Construction site layout planning using multi-objective artificial bee colony algorithm with Levy flights. Autom. Constr. 2014, 38, 14–29. [Google Scholar] [CrossRef]

- Andayesh, M.; Sadeghpour, F. Dynamic site layout planning through minimization of total potential energy. Autom. Constr. 2013, 31, 92–102. [Google Scholar] [CrossRef]

- El-Rayes, K.; Said, H. Dynamic Site Layout Planning Using Approximate Dynamic Programming. J. Comput. Civ. Eng. 2009, 23, 119–127. [Google Scholar] [CrossRef]

- Said, H.; El-Rayes, K. Performance of global optimization models for dynamic site layout planning of construction projects. Autom. Constr. 2013, 36, 71–78. [Google Scholar] [CrossRef]

- Lan, Y.C.; Xia, G.P. The Application of the Simulation-Based Optimization for the Material Planning in Large-Scale Water Conservancy Projects. 2008. Available online: https://www.researchgate.net/publication/290657736 (accessed on 12 January 2008).

- Zhang, H.; Yu, L. Dynamic transportation planning for prefabricated component supply chain. Eng. Constr. Arch. Manag. 2020, 27, 2553–2576. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K. Data-Driven Rolling Horizon Approach for Dynamic Design of Supply Chain Distribution Networks under Disruption and Demand Uncertainty. Decis. Sci. 2020. [Google Scholar] [CrossRef]

- Jiang, W.; Zhou, Y.; Ding, L.; Zhou, C.; Ning, X. UAV-based 3D reconstruction for hoist site mapping and layout planning in petrochemical construction. Autom. Constr. 2020, 113, 103137. [Google Scholar] [CrossRef]

- Alanjari, P.; Razavialavi, S.; Abourizk, S.M. A simulation-based approach for material yard laydown planning. Autom. Constr. 2014, 40, 1–8. [Google Scholar] [CrossRef]

- Alanjari, P.; Razavialavi, S.; Abourizk, S. Hybrid Genetic Algorithm-Simulation Optimization Method for Proactively Planning Layout of Material Yard Laydown. J. Constr. Eng. Manag. 2015, 141, 06015001. [Google Scholar] [CrossRef]

- Li, K.; Luo, H.; Skibniewski, M.J. A non-centralized adaptive method for dynamic planning of construction components storage areas. Adv. Eng. Inform. 2019, 39, 80–94. [Google Scholar] [CrossRef]

- Chen, Q.; De Soto, B.G.; Adey, B. Transshipment approach to coordinate materials for a contractor’s project portfolio. Int. J. Constr. Manag. 2020, 1–12. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, Z. Applying Optimal Control Model to Dynamic Equipment Allocation Problem: Case Study of Concrete-Faced Rockfill Dam Construction Project. J. Constr. Eng. Manag. 2011, 137, 536–550. [Google Scholar] [CrossRef]

- Shi, C.-H.; Cao, C.-Y.; Lei, M.-F.; Peng, L.-M.; Jiang, J. Optimal design and dynamic control of construction dewatering with the consideration of dewatering process. KSCE J. Civ. Eng. 2017, 21, 1161–1169. [Google Scholar] [CrossRef]

- Hegazy, T.; Petzold, K. Genetic Optimization for Dynamic Project Control. J. Constr. Eng. Manag. 2003, 129, 396–404. [Google Scholar] [CrossRef]

- Lin, C.W.R.; Hsiau, H.J. A genetic algorithm approach for optimizing chemical towers construction project scheduling with dynamic resources constraints. Int. J. Ind. Eng. Theory Appl. Pract. 2010, 17, 128–141. [Google Scholar]

- Abuwarda, Z.; Hegazy, T. Work-Package Planning and Schedule Optimization for Projects with Evolving Constraints. J. Comput. Civ. Eng. 2016, 30, 04016022. [Google Scholar] [CrossRef]

- Zhang, S.P.; Qi, S.J.; Chen, X.; Chu, X.J. Study on Theory of Real-Time Dynamic Scheduling Optimization under the Drive of Construction Resource. 2009. Available online: https://d.wanfangdata.com.cn/conference/WFHYXW377268 (accessed on 30 August 2010).

- Correia, A.G.; Parente, M. Coupled ICT and Dynamic Optimization Tools Toward an Integrated Earthwork Management System. In Proceedings of the GeoShanghai 2018 International Conference: Transportation Geotechnics and Pavement Engineering, Shanghai, China, 27 May 2018; pp. 136–143. [Google Scholar]

- Yang, J. Enhancing action recognition of construction workers using data-driven scene parsing. J. Civ. Eng. Manag. 2018, 24, 568–580. [Google Scholar] [CrossRef]

- Zhang, J.; Zi, L.; Hou, Y.; Wang, M.; Jiang, W.; Deng, D. A Deep Learning-Based Approach to Enable Action Recognition for Construction Equipment. Adv. Civ. Eng. 2020, 2020, 8812928. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Yang, B.; Wu, T.; Lei, K.; Zhang, B.; Fang, T. Vision-Based Framework for Automatic Progress Monitoring of Precast Walls by Using Surveillance Videos during the Construction Phase. J. Comput. Civ. Eng. 2021, 35, 04020056. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, Z.; Hammad, A.; Ahmed, W. Vision-Based Excavator Activity Recognition and Productivity Analysis in Construction. In Computing in Civil Engineering 2019; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2019; Volume 2019, pp. 241–248. [Google Scholar]

- Chen, C.; Zhu, Z.; Hammad, A. Automated excavators activity recognition and productivity analysis from construction site surveillance videos. Autom. Constr. 2020, 110, 103045. [Google Scholar] [CrossRef]

- Vahdatikhaki, F.; Hammad, A. Framework for near real-time simulation of earthmoving projects using location tracking technologies. Autom. Constr. 2014, 42, 50–67. [Google Scholar] [CrossRef]

- Zhu, Z.; Ren, X.; Chen, Z. Integrated detection and tracking of workforce and equipment from construction jobsite videos. Autom. Constr. 2017, 81, 161–171. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H. Simulation-based optimization for dynamic resource allocation. Autom. Constr. 2004, 13, 409–420. [Google Scholar] [CrossRef]

- Khodabandelu, A.; Park, J.; Arteaga, C. Crane operation planning in overlapping areas through dynamic supply selection. Autom. Constr. 2020, 117, 103253. [Google Scholar] [CrossRef]

- Sonmez, R.; Gürel, M. Hybrid Optimization Method for Large-Scale Multimode Resource-Constrained Project Scheduling Problem. J. Manag. Eng. 2016, 32, 04016020. [Google Scholar] [CrossRef]

- Xu, J.; Liu, Q.; Lei, X. A fuzzy multi-objective model and application for the discrete dynamic temporary facilities location planning problem. J. Civ. Eng. Manag. 2016, 22, 357–372. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Abbasi, B.; Lee, E.; Minas, J. Off-site construction optimization: Sequencing multiple job classes with time constraints. Autom. Constr. 2016, 71, 262–270. [Google Scholar] [CrossRef]

- Gu, Q.; Xie, H.; Issa, R.R.A.; Lu, C. Location Optimization with Uncertainty for Industrial Project Using Discrete Block Model and Spatial Meshing Algorithm. J. Comput. Civ. Eng. 2019, 33, 04018064. [Google Scholar] [CrossRef]

- Kerkhove, L.-P.; Vanhoucke, M. Optimised scheduling for weather sensitive offshore construction projects. Omega 2017, 66, 58–78. [Google Scholar] [CrossRef]

- Li, H.; Wang, M.; Dong, X. Resource Leveling in Projects with Stochastic Minimum Time Lags. J. Constr. Eng. Manag. 2019, 145, 04019015. [Google Scholar] [CrossRef]

- He, L.; Zhang, L. Dynamic priority rule-based forward-backward heuristic algorithm for resource levelling problem in construction project. J. Oper. Res. Soc. 2013, 64, 1106–1117. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Aurisicchio, M.; Angeloudis, P. Risk-averse supply chain for modular construction projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

- Hassan, A.; El-Rayes, K.; Attalla, M. Optimizing the scheduling of crew deployments in repetitive construction projects under uncertainty. Eng. Constr. Arch. Manag. 2020. [Google Scholar] [CrossRef]

- Nadoushani, Z.S.M.; Akbarnezhad, A.; Rey, D. Optimization of concrete placing operation based on competing carbon footprint, cost and production rate objectives. Eng. Constr. Arch. Manag. 2018, 25, 938–957. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J. Framework for modeling operational uncertainty to optimize offsite production scheduling of precast components. Autom. Constr. 2018, 86, 69–80. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Chang, N.-W. Dynamic construction material layout planning optimization model by integrating 4D BIM. Eng. Comput. 2018, 35, 703–720. [Google Scholar] [CrossRef]

- He, W.; Shi, Y.; Kong, D. Construction of a 5D duration and cost optimisation model based on genetic algorithm and BIM. J. Eng. Des. Technol. 2019, 17, 929–942. [Google Scholar] [CrossRef]

- Ma, G.; Liu, X. Model and Algorithm for Dependent Activity Schedule Optimization Combining with BIM. Adv. Civ. Eng. 2020, 2020, 9727256. [Google Scholar] [CrossRef]

- Ke, H.; Liu, B. Project scheduling problem with stochastic activity duration times. Appl. Math. Comput. 2005, 168, 342–353. [Google Scholar] [CrossRef]

- Roofigari-Esfahan, N.; Razavi, S. Uncertainty-Aware Linear Schedule Optimization: A Space-Time Constraint-Satisfaction Approach. J. Constr. Eng. Manag. 2017, 143, 04016132. [Google Scholar] [CrossRef]

- Xu, Y.; Wei, Y. Study on trade-off of time-cost-quality in construction project based on BIM. In 2015 International Conference on Economics, Social Science, Arts, Education and Management Engineering; Atlantis Press: Paris, France, 2015; Volume 38, pp. 864–870. [Google Scholar]

- Zhou, R.; Ye, C.-M.; Ma, H.-M. Model Research of Multi-Objective and Resource-Constrained Project Scheduling Problem. In The 19th International Conference on Industrial Engineering and Engineering Management; Springer: Berlin/Heidelberg, Germany, 2013; Volume 2013, pp. 991–1001. [Google Scholar]

- Abotaleb, I.; Nassar, K.; Hosny, O. Layout optimization of construction site facilities with dynamic freeform geometric representations. Autom. Constr. 2016, 66, 15–28. [Google Scholar] [CrossRef]

- Huang, Y.; Qiu, Z.; Zhang, W. Network comprehensive optimization for schedule and cost in project construction based on PSO algorithm. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008; Volume 2008, pp. 1260–1264. [Google Scholar]

- Jaśkowski, P.; Sobotka, A.; Czarnigowska, A. Decision model for planning material supply channels in construction. Autom. Constr. 2018, 90, 235–242. [Google Scholar] [CrossRef]

- Bakry, I.; Moselhi, O.; Zayed, T. Optimized scheduling and buffering of repetitive construction projects under uncertainty. Eng. Constr. Arch. Manag. 2016, 23, 782–800. [Google Scholar] [CrossRef]

- Roghabadi, M.A.; Moselhi, O. Optimized crew selection for scheduling of repetitive projects. Eng. Constr. Arch. Manag. 2020. [Google Scholar] [CrossRef]

- Yildirim, H.A.; Akcay, C. Time-cost optimization model proposal for construction projects with genetic algorithm and fuzzy logic approach. Rev. Constr. 2019, 18, 554–567. [Google Scholar] [CrossRef]

- Pan, N.-H. A hybrid optimization mechanism for constructing a dynamic simulation system—An operational behavior analysis of a moving scaffolding system. Autom. Constr. 2009, 18, 881–893. [Google Scholar] [CrossRef]

- Xu, J.; Meng, J.; Zeng, Z.; Wu, S.; Shen, M. Resource Sharing-Based Multiobjective Multistage Construction Equipment Allocation under Fuzzy Environment. J. Constr. Eng. Manag. 2013, 139, 161–173. [Google Scholar] [CrossRef]

- Xu, J.; Li, Z. Multi-Objective Dynamic Construction Site Layout Planning in Fuzzy Random Environment. Autom. Constr. 2012, 27, 155–169. [Google Scholar] [CrossRef]

- Xu, J.; Feng, C. Two-stage based dynamic earth-rock transportation assignment problem under fuzzy random environment to earth-rock dam construction. J. Civ. Eng. Manag. 2015, 21, 775–797. [Google Scholar] [CrossRef]

- Zhong, D.; Ren, B.; Li, M.; Wu, B.; Li, M. Theory on real-time control of construction quality and progress and its application to high arc dam. Sci. China Ser. E Technol. Sci. 2010, 53, 2611–2618. [Google Scholar] [CrossRef]

- Hu, W.; Zhong, D.; Wu, B.; Li, Z. Construction phase oriented dynamic simulation: Taking RCC dam placement process as an example. J. Civ. Eng. Manag. 2019, 25, 654–672. [Google Scholar] [CrossRef]

- Akhavian, R.; Behzadan, A.H. Construction equipment activity recognition for simulation input modeling using mobile sensors and machine learning classifiers. Adv. Eng. Inform. 2015, 29, 867–877. [Google Scholar] [CrossRef]

- Špačková, O.; Straub, D. Dynamic Bayesian Network for Probabilistic Modeling of Tunnel Excavation Processes. Comput. Civ. Infrastruct. Eng. 2012, 28, 1–21. [Google Scholar] [CrossRef]

- Gelisen, G.; Griffis, F.H. Automated Productivity-Based Schedule Animation: Simulation-Based Approach to Time-Cost Trade-Off Analysis. J. Constr. Eng. Manag. 2014, 140, B4013007. [Google Scholar] [CrossRef]

- Srour, F.J.; Kiomjian, D.; Srour, I.M. Automating the Use of Learning Curve Models in Construction Task Duration Estimates. J. Constr. Eng. Manag. 2018, 144, 04018055. [Google Scholar] [CrossRef]

- Damnjanovic, I.; Reinschmidt, K. Bayesian Revision of Probability Estimates. In Data Analytics for Engineering and Construction Project Risk Management; Springer: Cham, Switzerland, 2020; pp. 207–233. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Yang, B.; Xiao, J.; Zhu, D.; Zhang, B.; Wang, Z.; Dong, M. Review of Optimization Dynamically Applied in the Construction and the Application Potential of ICT. Sustainability 2021, 13, 5478. https://doi.org/10.3390/su13105478

Liu B, Yang B, Xiao J, Zhu D, Zhang B, Wang Z, Dong M. Review of Optimization Dynamically Applied in the Construction and the Application Potential of ICT. Sustainability. 2021; 13(10):5478. https://doi.org/10.3390/su13105478

Chicago/Turabian StyleLiu, Boda, Bin Yang, Jianzhuang Xiao, Dayu Zhu, Binghan Zhang, Zhichen Wang, and Miaosi Dong. 2021. "Review of Optimization Dynamically Applied in the Construction and the Application Potential of ICT" Sustainability 13, no. 10: 5478. https://doi.org/10.3390/su13105478

APA StyleLiu, B., Yang, B., Xiao, J., Zhu, D., Zhang, B., Wang, Z., & Dong, M. (2021). Review of Optimization Dynamically Applied in the Construction and the Application Potential of ICT. Sustainability, 13(10), 5478. https://doi.org/10.3390/su13105478