Waste Valorization through Additive Manufacturing in an Industrial Symbiosis Setting

Abstract

1. Introduction

2. Background

2.1. AM Industry within a Circular Economy Context

- Energy use: at a process or machine level, most AM processes use more energy than traditional processes. However, AM allows us to produce complex parts on a single step. AM makes it easier to use renewable energies and enables distributed manufacturing.

- Waste: it is expected that AM uses less material and produces less waste. However, little information is available about the quantity and origin of the waste that is generated during AM processes.

- Flexible manufacturing strategies: AM production systems are based on strategies that may support the minimization of transportation needs and can reduce the number of logistics activities.

- Maintenance interventions and hard repair: the spare parts can be manufactured by AM processes only if the necessity of using them arises. This can lead to savings in storage and space costs related to spare parts.

- Material savings: due to the absence of tooling, AM enables material savings. Using the almost exact amount of material needed to manufacture the product, AM allows reducing waste generation and the use of raw materials.

- Design-based economy: AM characteristics may decrease the barriers related to the product’s and manufacturing process knowledge since parts can be manufactured directly from 3D CAD files without requiring manufacturing expertise.

- Extended product life span: due to the specific technical improvements given by the AM technology and also due to easier access to parts’ repair interventions instead of manufacturing new parts, the product’s life span may increase.

2.2. The Industrial Symbiosis Setting and Resource Exchange

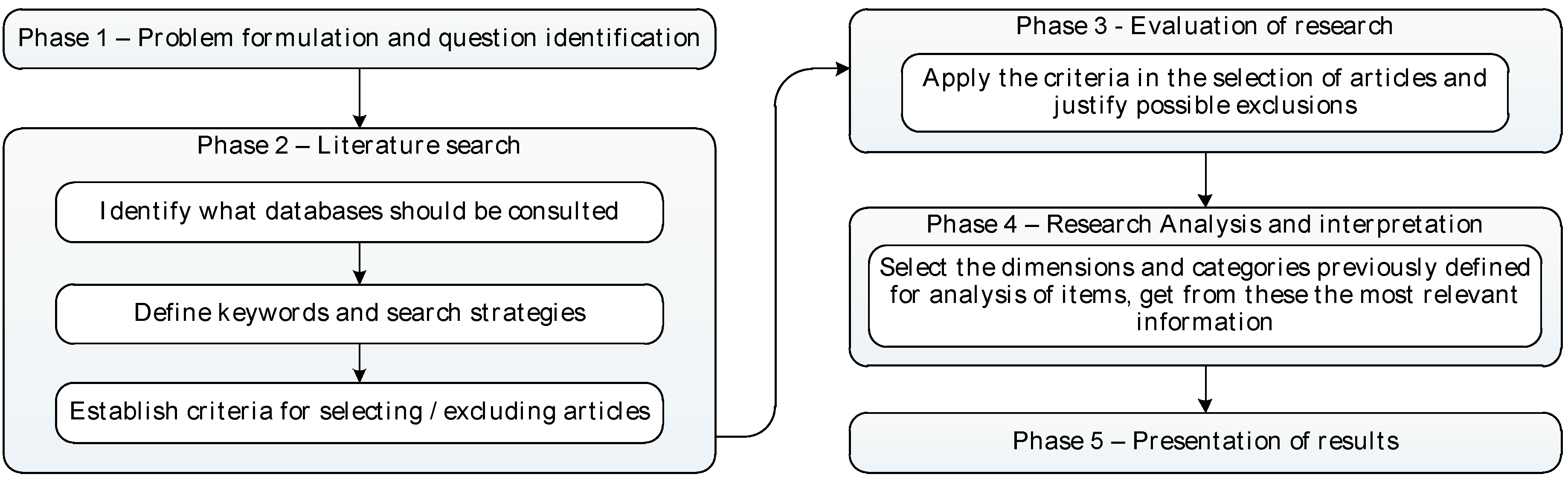

3. Materials and Methods

3.1. Problem Formulation

3.2. Literature Search

3.3. Evaluation of Research

3.4. Research Analysis and Interpretation

4. Results

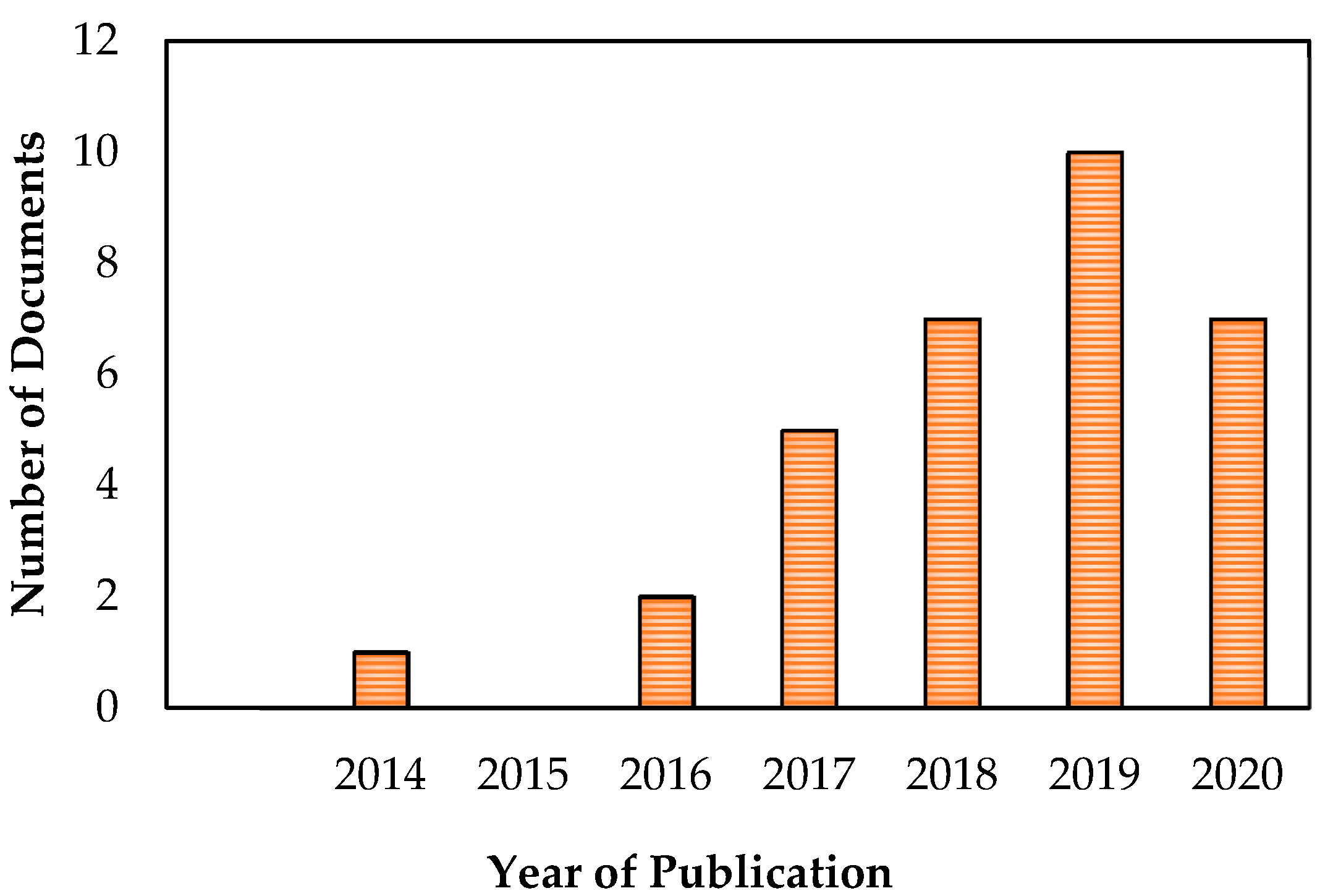

4.1. Bibliometric Analysis

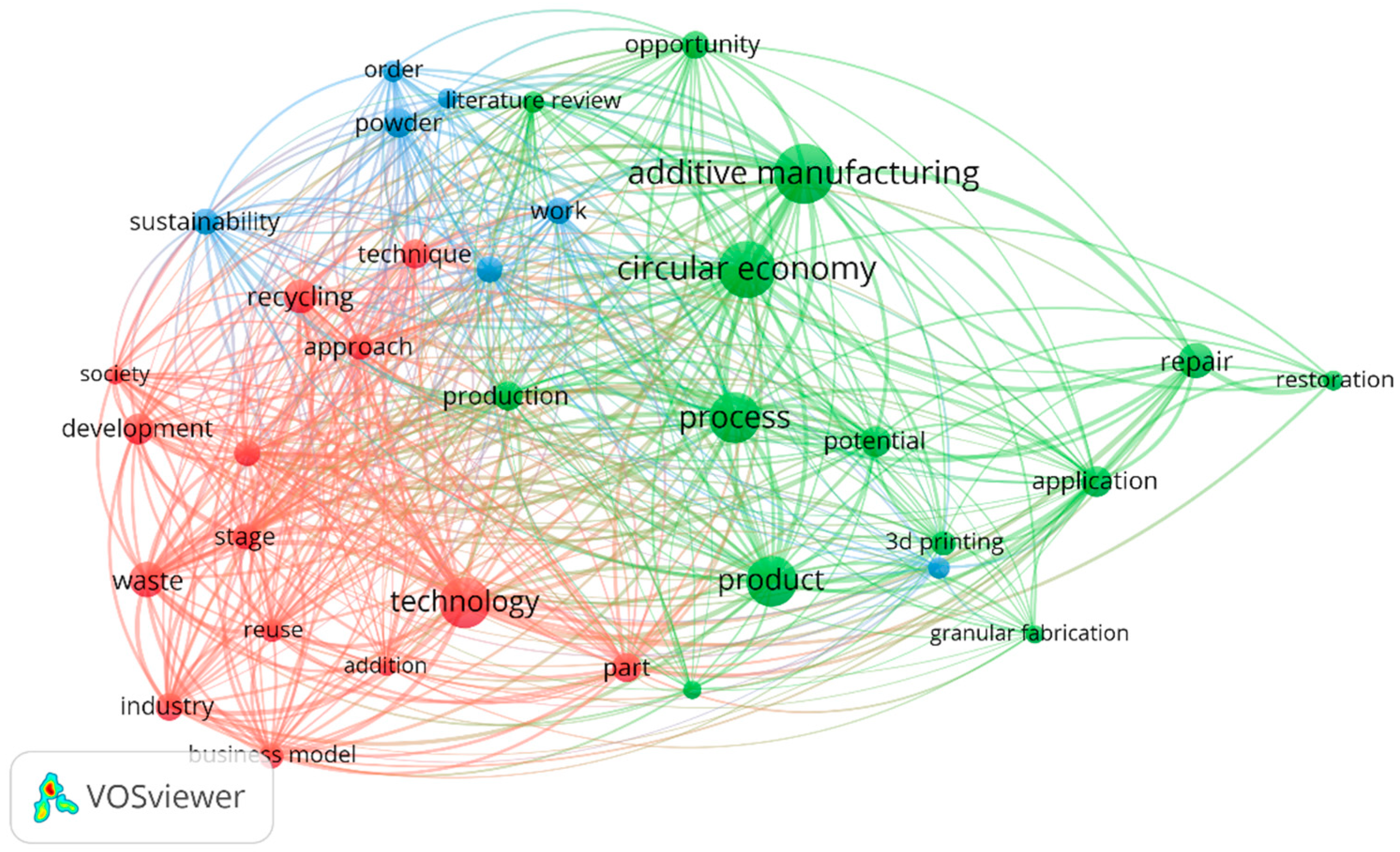

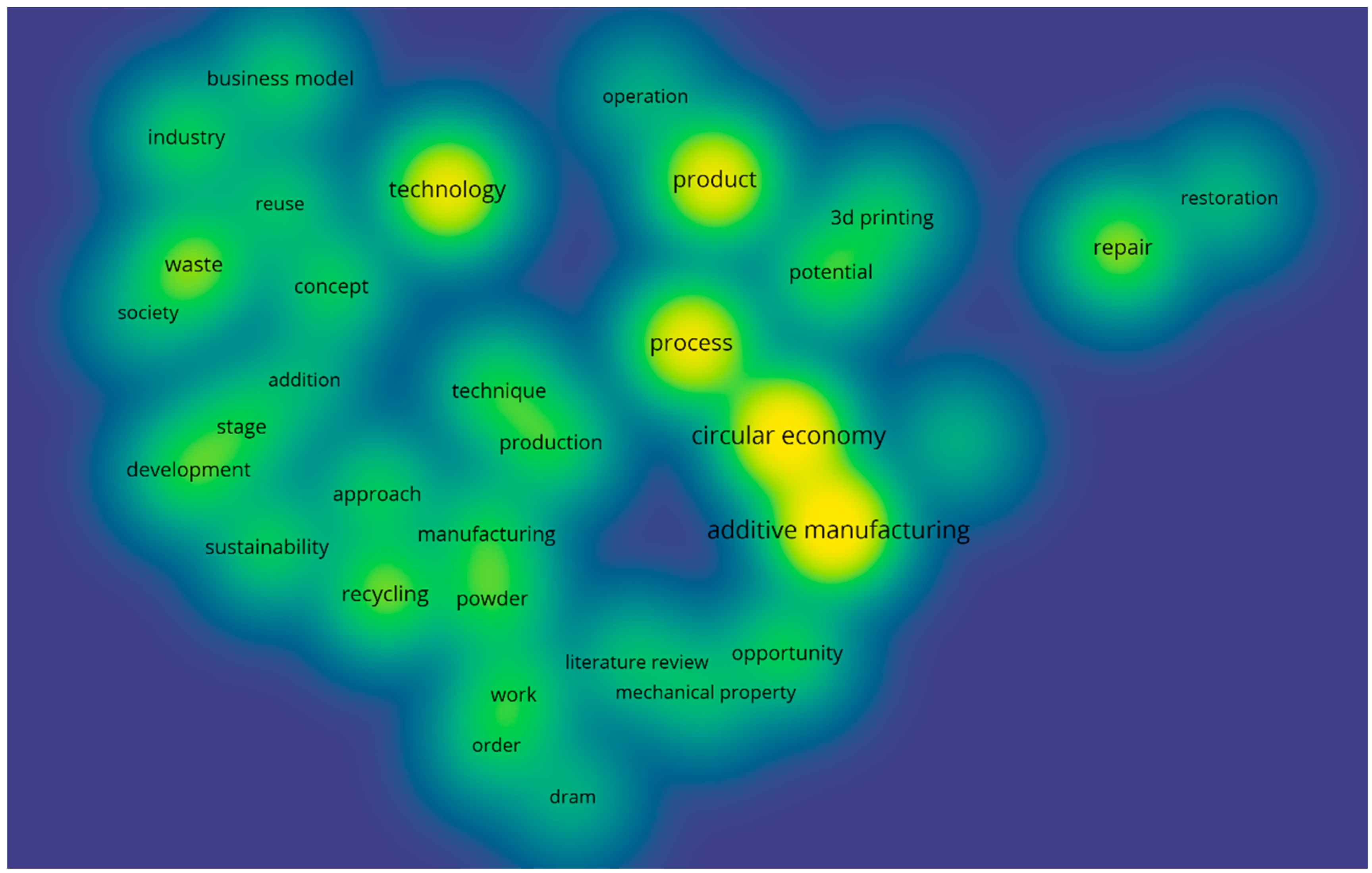

Analysis of Keywords in the Sample

- Green cluster: composed of documents that analyze how the circular economy concept is explored and promoted within the AM context, mostly through repairing and restoration activities and through the product and process innovation and development.

- Red cluster: includes studies that relate technology innovation with recycling activities and waste management and also includes documents that focus on business models for firms that are willing to adopt new technologies focusing on circular economy applications.

- Blue cluster: characterized by the presence of articles focusing on sustainability and specific AM technologies, namely, AM technologies using powder.

- In [49], the authors explored the possibility of using industrial 3D printers capable of fused particle fabrication/fused granular fabrication printing directly from waste plastic streams (external wastes) through the intervention of Green Fab Labs that could act as recycling centers for converting plastic waste into valuable products for their communities. As an example, the authors studied the Gigabot X printer, which is an open-source industrial 3D printer. Acrylonitrile butadiene stryrene (ABS) and polypropylene (PP) were the plastic waste streams that were used for printing three consumer-grade products: a skateboard, kayak paddles, and snowshoes. The results of this study showed that AM technology is capable of producing large high-value sports products with plastic waste streams.

- In [53], the authors developed an approach that aims to support the search and use of local materials (external wastes) as material input for AM and also materials that are recyclable to serve multiple lifecycles. The authors explored the possibility of adapting mussel shell waste into AM material. Mussel shells can be considered waste that is not suitable for composting, and printing mussel shell waste results in a ceramic-like material; therefore, a flowerpot was considered a suitable initial product application to demonstrate the current applicability.

- In [48], the authors explored the potential of using recycled polymers (external wastes) in 3D printing, namely, in fused particle fabrication or fused granular fabrication. The authors analyzed one of the possibilities to overcome the artificial cost barrier to distribute AM through the upcycled of plastic waste, namely, polycarbonate (PC) plastic regrind, into 3D printing filament with an open-source waste plastic extruder (designated by Recyclebot). The study extended the potential to high-performance polymers and analyzed the material properties of the 3D-printed products. Three case study applications were explored: (i) using PC waste to successfully manufacture it into a mold that can be used for rapid molding of a lower melting thermoplastic point; (ii) using a home floor steamer whose outer plastic had become brittle and disintegrated but for which a replacement was designed to be optimized for ease in 3D printing, allowing a new steamer head to be printed from PC waste that performed the same function; and (iii) an open-source car window ice scraper with interchangeable blades was printed and tested—the handle was printed via polylactic acid (PLA) and the blade was printed in recycled PC. This study showed that recycled PC particles may be a useful and inexpensive material to be considered for use in AM on particle material extrusion 3D printers—external.

- In [52], the open source Gigabot X printer was used to develop a method in order to optimize fused particle fabrication or fused granular fabrication for recycled materials. The authors analyzed and compared virgin PLA pellets with recycled polymers that included the two most popular printing materials and the two most common plastic wastes. The results showed that the Gigabot X and similar printers may use a wide range of recycled polymer materials with no significant post processing.

- In [58], the authors applied the circular economy concept into AM through the recovery of metallic scrap generated in the AM process (internal wastes) to the feedstock material for selective laser melting. Powder from 100% scrap feedstock was prepared following two routes: (i) gas atomization of solid scrap without extra alloying and (ii) mechanical milling of agglomerated residue powder. The properties of the powder were tested and analyzed to determine the mechanical properties and were compared to commercial reference powder. The study showed that recycled powder properties entirely comparable to the reference can be reached.

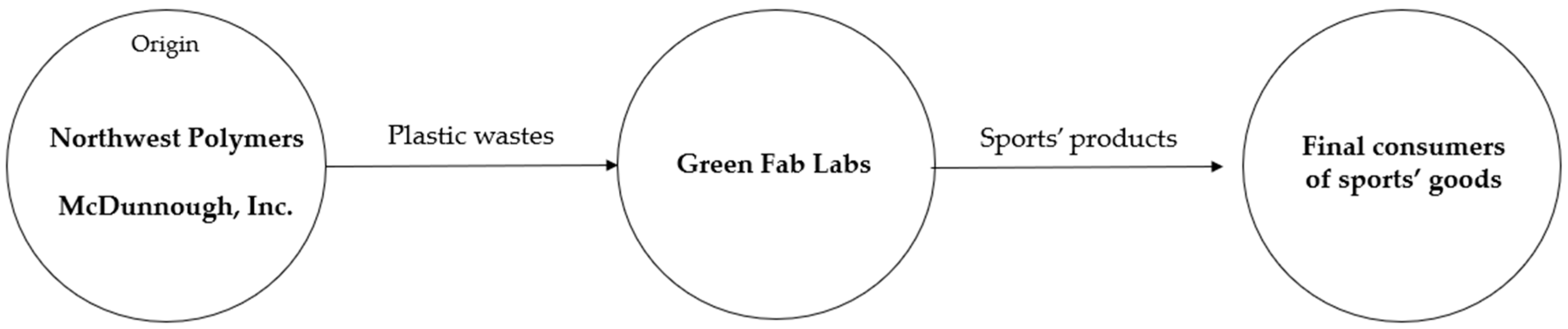

- In [49], the origin of the wastes used in the 3D printer (ABS and PP) came from two different entities: Northwest Polymers and McDunnough, Inc., respectively. There is an intermediary entity that allows the incorporation of these wastes in a 3D printer and converts them into consumer-grade products. This intermediary entity is the Green Fab Lab, which acts like a recycling center. The products resulting from printing the plastic waste corresponded to sports mobility products that would be sell to the final consumers.The industrial symbiosis network that could be developed for this process was created, considering only the three direct partners that exchange physical materials between them. As an example of how the initial configuration of the symbiosis network would be, we present the network in Figure 5.

- In [53], the authors highlight that approximately 50 million kilograms of mussels are produced in the Netherlands. The shells of the mussels are waste, and their origin came from the entity that represents the mussels’ breeders. These wastes can be used as material input by entities that use a binder jetting additive manufacturing process. These entities would be responsible for the necessary treatment of the wastes before incorporating them in AM processes. By the end the process, and since the mussel shell print mainly consists of calcium carbonate, ceramic-like materials can be printed (in [53], for example, a flowerpot was produced).

- In [52], the source of the recycled polymers that were used in the 3D printer came from different entities: Nature Works LLC, McDonnough Plastics, Northwest Polymers, and CiorC. These polymers can be used as material input by other entities that work or own an open source Gigabot X printer, which is a large scale recycled plastic 3D printer. From this process, a large variety of polymers can be printed at a lower print time when compared to the traditional fused filament fabrication process. These polymers can then be used internally or can be sold to other entities.

- In [48], the entity responsible for providing the recycled PC regrind as the waste to be incorporated was the McDonnough Plastics. As identically described in the previous process entities that work or own a Gigabot X printer can use these polymers to produce filament, which can also be used internally or can be sell to other entities.

- In [58], the focus was on the recovery of process side-streams back to feedstock material. In fact, there is not an industrial symbiosis network inherent to this process. However, if other entities that use selective laser melting as AM processes would have interest in it, the entity responsible for incorporating the process side-streams into feedstock material could sell the service to these other entities or even use the process side-stream from other entities, creating an industrial symbiosis network.

5. Critical Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Giurco, D.; Littleboy, A.; Boyle, T.; Fyfe, J.; White, S. Circular Economy: Questions for Responsible Minerals, Additive Manufacturing and Recycling of Metals. Resources 2014, 3, 432–453. [Google Scholar] [CrossRef]

- Piller, F.T.; Weller, C.; Kleer, R. Business Models with Additive Manufacturing—Opportunities and Challenges from the Perspective of Economics and Management. In Proceedings of the Advances in Production Technology; Brecher, C., Ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 39–48. [Google Scholar]

- Proyecto RecWood3D, la Innovación y la Economía Circular al Servicio de la Impresión 3D—Aclima. Available online: https://aclima.eus/en/proyecto-recwood3d-la-innovacion-y-la-economia-circular-al-servicio-de-la-impresion-3d/ (accessed on 27 December 2020).

- Eco-Designed 3D Filaments for Sustainable Creativity|OWA. Available online: https://www.armor-owa.com/3d-printing (accessed on 14 August 2020).

- Oettmeier, K.; Hofmann, E. Additive manufacturing technology adoption: An empirical analysis of general and supply chain-related determinants. J. Bus. Econ. 2017, 87, 97–124. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Rahito; Wahab, D.A.; Azman, A.H. Additive Manufacturing for Repair and Restoration in Remanufacturing: An Overview from Object Design and Systems Perspectives. Processes 2019, 7, 802. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Barz, A.; Buer, T.; Haasis, H.-D. A Study on the Effects of Additive Manufacturing on the Structure of Supply Networks. IFAC-PapersOline 2016, 49, 72–77. [Google Scholar] [CrossRef]

- Faludi, J.; Baumers, M.; Maskery, I.; Hague, R. Environmental Impacts of Selective Laser Melting: Do Printer, Powder, Or Power Dominate? J. Ind. Ecol. 2017, 21, S144–S156. [Google Scholar] [CrossRef]

- Rejeski, D.; Zhao, F.; Huang, Y. Research needs and recommendations on environmental implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef]

- Khorram Niaki, M.; Nonino, F.; Palombi, G.; Torabi, S.A. Economic sustainability of additive manufacturing: Contextual factors driving its performance in rapid prototyping. JMTM 2019, 30, 353–365. [Google Scholar] [CrossRef]

- Matos, F.; Jacinto, C. Additive manufacturing technology: Mapping social impacts. J. Manuf. Technol. Manag. 2018, 30, 70–97. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Angioletti, C.M.; Sisca, F.G.; Luglietti, R.; Taisch, M.; Rocca, R. Additive Manufacturing as an Opportunity for Supporting Sustainability through Implementation of Circular Economies. Available online: https://www.semanticscholar.org/paper/Additive-Manufacturing-as-an-opportunity-for-the-of-Angioletti-Sisca/491abfa423df8d96e5983a3ce81e0aacc84b2218 (accessed on 27 December 2020).

- Sauerwein, M.; Doubrovski, E.; Balkenende, R.; Bakker, C. Exploring the potential of additive manufacturing for product design in a circular economy. J. Clean. Prod. 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

- Ferreira, I.D.A.; de Castro Fraga, M.; Godina, R.; Souto Barreiros, M.; Carvalho, H. A Proposed Index of the Implementation and Maturity of Circular Economy Practices—The Case of the Pulp and Paper Industries of Portugal and Spain. Sustainability 2019, 11, 1722. [Google Scholar] [CrossRef]

- Ferreira, I.A.; Barreiros, M.S.; Carvalho, H. The industrial symbiosis network of the biomass fluidized bed boiler sand—Mapping its value network. Resour. Conserv. Recycl. 2019, 149, 595–604. [Google Scholar] [CrossRef]

- Jiao, W.; Boons, F. Toward a research agenda for policy intervention and facilitation to enhance industrial symbiosis based on a comprehensive literature review. J. Clean. Prod. 2014, 67, 14–25. [Google Scholar] [CrossRef]

- Kosmol, L.; Esswein, W. Capturing the Complexity of Industrial Symbiosis. In Proceedings of the Advances and New Trends in Environmental Informatics; Bungartz, H.-J., Kranzlmüller, D., Weinberg, V., Weismüller, J., Wohlgemuth, V., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 183–197. [Google Scholar]

- European Commission Directive 2008/98/EC on Waste (Waste Framework Directive)—Environment—European Commission. Available online: https://ec.europa.eu/environment/waste/framework/ (accessed on 11 December 2020).

- European Commission End-of-Waste Criteria—Environment—European Commission. Available online: https://ec.europa.eu/environment/waste/framework/end_of_waste.htm (accessed on 11 December 2020).

- Chertow, M.R. “Uncovering” Industrial Symbiosis. J. Ind. Ecol. 2008, 11, 11–30. [Google Scholar] [CrossRef]

- Xiang, P.; Yuan, T. A collaboration-driven mode for improving sustainable cooperation in smart industrial parks. Resour. Conserv. Recycl. 2019, 141, 273–283. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D., Bryman, A., Eds.; Sage Publications Ltd.: London, UK, 2009; pp. 671–689. [Google Scholar]

- Rousseau, D.M.; Manning, J.; Denyer, D. Evidence in Management and Organizational Science: Assembling the Field’s Full Weight of Scientific Knowledge Through Syntheses. Acad. Manag. Ann. 2008, 2, 475–515. [Google Scholar] [CrossRef]

- Correia, E.; Carvalho, H.; Azevedo, S.G.; Govindan, K. Maturity Models in Supply Chain Sustainability: A Systematic Literature Review. Sustainability 2017, 9, 64. [Google Scholar] [CrossRef]

- Broome, M.E.; Rodgers, B.L.; Knafl, K.A. Integrative Literature Reviews for the Development of Concepts. In Concept Development in Nursing: Foundations, Techniques and Applications; W. B. Saunders Company: Philadelphia, PA, USA, 2000; pp. 231–250. [Google Scholar]

- Rosato, P.F.; Caputo, A.; Valente, D.; Pizzi, S. 2030 Agenda and sustainable business models in tourism: A bibliometric analysis. Ecol. Indic. 2021, 121, 106978. [Google Scholar] [CrossRef]

- Pizzi, S.; Caputo, A.; Corvino, A.; Venturelli, A. Management research and the UN sustainable development goals (SDGs): A bibliometric investigation and systematic review. J. Clean. Prod. 2020, 276, 124033. [Google Scholar] [CrossRef]

- Ji, B.; Zhao, Y.; Vymazal, J.; Mander, Ü.; Lust, R.; Tang, C. Mapping the field of constructed wetland-microbial fuel cell: A review and bibliometric analysis. Chemosphere 2021, 262, 128366. [Google Scholar] [CrossRef]

- Meyer, T.K.; Tanikella, N.G.; Reich, M.J.; Pearce, J.M. Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite. Sustain. Mater. Technol. 2020, 25, e00169. [Google Scholar] [CrossRef]

- Northwood, D.O.; Faldu, N. Corrosion: The Circular Materials Economy and Design for Sustainability. In Proceedings of the Australasian Corrosion Association’s Annual Conference: Corrosion and Prevention, Melbourne, Australia, 24–27 November 2019. [Google Scholar]

- DePalma, K.; Walluk, M.R.; Murtaugh, A.; Hilton, J.; McConky, S.; Hilton, B. Assessment of 3D printing using fused deposition modeling and selective laser sintering for a circular economy. J. Clean. Prod. 2020, 264, 121567. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Dertinger, S.C.; Gallup, N.; Tanikella, N.G.; Grasso, M.; Vahid, S.; Foot, P.J.S.; Pearce, J.M. Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades. Resour. Conserv. Recycl. 2020, 157, 104810. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Ukar, O.; Ostolaza, M.; Mugica, A. Study of the Environmental Implications of Using Metal Powder in Additive Manufacturing and Its Handling. Metals 2020, 10, 261. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Sundqvist, J.; Samarjy, R.S.M. High-speed imaging of droplet behaviour during the CYCLAM drop-deposition technique. Procedia Manuf. 2019, 36, 208–215. [Google Scholar] [CrossRef]

- Kuzman, M.K.; Kariz, M.; Ayrilmis, N.; Šernek, M.; Žigon, J.; Xu, Q. Fire Behaviour of 3D Printed PLA and Wood/PLA Composites. In Proceedings of the 12th WoodEMA Annual International Scientific Conference on Digitalisation and Circular Economy: Forestry and Forestry Based Industry Implications, Varna, Bulgaristan, 11–13 September 2019; pp. 149–154. [Google Scholar]

- Ravindran, A.; Scsavnicki, S.; Nelson, W.; Gorecki, P.; Franz, J.; Oberloier, S.; Meyer, T.K.; Barnard, A.R.; Pearce, J.M. Open Source Waste Plastic Granulator. Technologies 2019, 7, 74. [Google Scholar] [CrossRef]

- Turner, C.; Moreno, M.; Mondini, L.; Salonitis, K.; Charnley, F.; Tiwari, A.; Hutabarat, W. Sustainable Production in a Circular Economy: A Business Model for Re-Distributed Manufacturing. Sustainability 2019, 11, 4291. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci.-Basel 2019, 9, 3316. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef]

- Byard, D.J.; Woern, A.L.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Green fab lab applications of large-area waste polymer-based additive manufacturing. Addit. Manuf. 2019, 27, 515–525. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. J. Manuf. Technol. Manag. 2019. [Google Scholar] [CrossRef]

- Woern, A.L.; Pearce, J.M. 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing. Inventions 2018, 3, 78. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Sauerwein, M.; Doubrovski, E.L. Local and recyclable materials for additive manufacturing: 3D printing with mussel shells. Mater. Today Commun. 2018, 15, 214–217. [Google Scholar] [CrossRef]

- Unruh, G. Circular Economy, 3D Printing, and the Biosphere Rules. Calif. Manag. Rev. 2018, 60, 95–111. [Google Scholar] [CrossRef]

- Voet, V.S.D.; Strating, T.; Schnelting, G.H.M.; Dijkstra, P.; Tietema, M.; Xu, J.; Woortman, A.J.J.; Loos, K.; Jager, J.; Folkersma, R. Biobased Acrylate Photocurable Resin Formulation for Stereolithography 3D Printing. ACS Omega 2018, 3, 1403–1408. [Google Scholar] [CrossRef]

- Clemon, L.M.; Zohdi, T.I. On the tolerable limits of granulated recycled material additives to maintain structural integrity. Constr. Build. Mater. 2018, 167, 846–852. [Google Scholar] [CrossRef]

- Lahrour, Y.; Brissaud, D. A Technical Assessment of Product/Component Re-manufacturability for Additive Remanufacturing. Procedia Cirp 2018, 69, 142–147. [Google Scholar] [CrossRef]

- Reijonen, J.; Jokinen, A.; Puukko, P.; Lagerbom, J.; Lindroos, T.; Haapalainen, M.; Salminen, A. Circular Economy Concept in Additive Manufacturing. In Proceedings of the Euro PM2017 Proceedings; European Power Metallurgy Association EPMA: Milan, Italy, 2017. [Google Scholar]

- Angioletti, C.M.; Despeisse, M.; Rocca, R. Product Circularity Assessment Methodology. In Proceedings of the Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing; Lödding, H., Riedel, R., Thoben, K.-D., von Cieminski, G., Kiritsis, D., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 411–418. [Google Scholar]

- Alghamdi, A.; Prickett, P.; Setchi, R. A Conceptual Framework to Support Decision-Making in Remanufacturing Engineering Processes. In Proceedings of the Sustainable Design and Manufacturing 2017; Campana, G., Howlett, R.J., Setchi, R., Cimatti, B., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 222–232. [Google Scholar]

- Sauerwein, M.; Bakker, C.A.; Balkenende, R. Additive Manufacturing for Circular Product Design: A Literature Review from a Design Perspective. In Proceedings of the PLATE 2017: Product Lifetimes and the Environment, Delft, The Netherlands, 8–10 November 2017. [Google Scholar]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Virolainen, S. Hydrometallurgical Recovery of Valuable Metals from Secondary Raw Materials; Lappeenranta University of Technology: Lappeenranta, Finland, 2013. [Google Scholar]

- Sillani, F.; Kleijnen, R.G.; Vetterli, M.; Schmid, M.; Wegener, K. Selective laser sintering and multi jet fusion: Process-induced modification of the raw materials and analyses of parts performance. Addit. Manuf. 2019, 27, 32–41. [Google Scholar] [CrossRef]

- Kasmi, F. Industrial Symbiosis and Territorial Development: The Cross-Fertilization of Proximity Dynamics and the Role of Information and Knowledge Flows. J. Knowl. Econ. 2020. [Google Scholar] [CrossRef]

- Santander, P.; Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M. Closed loop supply chain network for local and distributed plastic recycling for 3D printing: A MILP-based optimization approach. Resour. Conserv. Recycl. 2020, 154, 104531. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A comprehensive review of industrial symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

| AM Principles | Example of AM Technology | Basic Principles |

|---|---|---|

| Powder bed fusion | Direct metal laser sintering | Fusion of a specific coordinate in a small region of the powder bed using focused thermal energy. |

| Selective laser sintering | ||

| Melting | ||

| Direct energy deposition | Laser engineered net shaping | Deposition of powder materials that coincides with focused thermal energy to melt it. |

| Plasma arc melting | ||

| Laser cladding | ||

| Binder jetting | 3D inkjet technology | Liquid printing binder deployed onto specific coordinate, layer by layer of material powder that sticks at the particle. |

| Sheet lamination | Laminated object manufacturing | Attachment of sheets of materials. |

| Ultrasound consolidation | ||

| Ultrasound | ||

| Vat photo polymerization | Stereo lithography Digital light processing | Focused light-curing towards liquid polymer in a vat. |

| Material extrusion | Fused deposition modelling | Precipitation of building materials droplets through a heated nozzle. |

| Fused filament fabrication | ||

| Fused granular fabrication | ||

| Fused particle fabrication | ||

| 3D inkjet technology | ||

| Cold spray | Multi-metal deposition | Injected powder at high velocity to build material, caused by adhesion. |

| Category | Subcategories |

|---|---|

| Document identification | Authors—list of authors Publication date—year of publication Publication type—international journal or conference name Language—English or other |

| Domain | Research field—may include among other subcategories such as “Engineering”, “Materials Science”, “Science and Technology”, “Environmental Sciences” |

| Research methods | Analytical—conceptual (e.g., conceptual models or future research/scenarios) |

| Empirical—case studies, content analysis, statistical sampling (e.g., expert panels or surveys), mixed methods, experimental design (experimental empirical design) | |

| Others | |

| Circular economy principles—4Rs (a) | Reduce, Reuse, Recycle, Recover |

| Industrial symbiosis characteristics (b) | Exchange of resources—it takes the value “yes” if there is an exchange of some type of resources, or the value “no” |

| Type of resource—it includes waste, sub-product, by-product, raw material, product, energy, residue, material, services, structures, secondary raw material | |

| Type of technology (c) | AM technology—for example direct metal laser sintering, selective laser, sintering/melting, laser engineered net shaping, plasma arc melting, 3D inkjet technology, among the ones cited in Table 1 |

| Type of material (d) | Materials input for AM processes—containing the type of the material used in as input for the AM process as it is described in the document |

| Paper ID | Year | Pub. Type | Journal/Conference | Domain | Research Methods | Circular Economy Principles 4Rs | Potential Industrial Symbiosis Characteristics | Technology | Material Used | |

|---|---|---|---|---|---|---|---|---|---|---|

| Exchange of Resources | Type of Resource | |||||||||

| [36] | 2020 | Int. Journal | Sustainable Materials and Technologies | Materials Science; Engineering | E | Recycle | No | N/A | N/A | Plastic waste (a) |

| [37] | 2020 | Conf. | Australasian Corrosion Association’s Annual Conf. | Materials Science; Physics | E | Reuse, recycle | No | N/A | N/A | N/A |

| [38] | 2020 | Int. Journal | J. Cleaner Production | Science and Technology—Environmental Sciences and Ecology | A | Recycle | No | N/A | Selective laser sintering/fused deposition modeling | Plastic waste (b) |

| [39] | 2020 | Int. Journal | J. Cleaner Production | Science and Technology Engineering; Environmental Sciences and Ecology | E | Recycle | No | N/A | N/A | N/A |

| [40] | 2020 | Int. Journal | Resources, Conservation & Recyling | Engineering; Environmental Sciences and Ecology | E | Recylce | No | N/A | Fused filament fabication/fused particle fabrication | Thermoplastic composite (c) |

| [41] | 2020 | Int. Journal | Metals | Materials Science; Metallurgy and Metallurgical Engineering | E | Reuse, recycle | No | N/A | N/A | Metal powders |

| [42] | 2020 | Int. Journal | Resources, Conservation & Recyling | Engineering; Environmental Sciences and Ecology | E | Recycle | No | N/A | N/A | N/A |

| [43] | 2019 | Conf. | Procedia Manufacturing | Engineering | A | Recycle | No | N/A | Laser cuting | Metal waste |

| [44] | 2019 | Conf. | WoodEMA Annual International Scientific Conf. | Sciences and Technology; Mechanics and Tecnology; Engineering | E | Recycle | No | N/A | Fused deposition modeling | Wood plastic composites (d) |

| [45] | 2019 | Int. Journal | Technologies | Engineering | E | Recycle | No | N/A | Fused particle fabrication/fused granular fabrication | Post-consumer waste, 3D printed products, and 3D printer wastes |

| [10] | 2019 | Int. Journal | Processes | Engineering | E | Reuse, recycle | No | N/A | Direct energy deposition/powder bed fusion/cold spray technology | N/A |

| [46] | 2019 | Int. Journal | Sustainability | Science and Technology; Environmental Sciences and Ecology | E | Reduce, reuse | No | N/A | Selective laser sintering | N/A |

| [47] | 2019 | Int. Journal | Applied Sciences—Basel | Chemistry; Engineering; Materials Science; Physics | E | Reuse | No | N/A | Direced energy deposition | N/A |

| [19] | 2019 | Int. Journal | J. Cleaner Production | Science and Tecnology; Engineering; Environmental Sciences and Ecology | E | Reduce | No | N/A | N/A | N/A |

| [48] | 2019 | Int. Journal | Materials | Materials Science | E | Recycle | Yes | Waste | Fused particle fabrication/fused granular fabrication | Plastic waste (e) |

| [49] | 2019 | Int. Journal | Additive Manufacturing | Engineering; Materials Science | E | Recycle | Yes | Waste | Fused particle fabrication/fused granular fabrication | Plastic waste (f) |

| [50] | 2019 | Int. Journal | J. Manufacturing Technology Management | Business and Economics; Engineering | E | Reuse, recycle | No | N/A | Selective laser sintering | N/A |

| [51] | 2018 | Int. Journal | Inventions | Materials Science; Engineering | E | Recycle | No | N/A | Fused granular fabrication/fused particle fabrication | Plastic waste (g) |

| [52] | 2018 | Int. Journal | Materials | Materials Science | E | Recycle | Yes | Waste | Fused particle fabrication/fused granular fabrication | Plastic waste (h) |

| [53] | 2018 | Int. Journal | Materials Today Communications | Materials Science | E | Reuse | Yes | Materials and waste | Binder jetting | Locally sourced materials (i) |

| [54] | 2018 | Int. Journal | California Management Review | Business and Economics | O | Reduce, reuse, recycle, recover | No | N/A | N/A | N/A |

| [55] | 2018 | Int. Journal | ACS Omega | Chemistry | E | Reduce | No | N/A | Stereolithography apparatus | Biobased acrylate resins |

| [56] | 2018 | Int. Journal | Construction and Building Materials | Construction and Building Technology; Engineering; Materials Science | O | Recycle | No | N/A | N/A | N/A |

| [57] | 2018 | Conf. | Cirp Life Cycle Engineering Conf. | Science and Tecnology; Engineering | O | Recycle | No | N/A | N/A | N/A |

| [58] | 2017 | Conf. | International Powder Metallurgy Congress and Exhibition | Engineering | E | Recycle | Yes | Waste | Selective laser melting | Scrap feedstock |

| [59] | 2017 | Conf. | IFIP Advances in Information and Communication Technology | Decision Sciences | A | Reduce, reuse, recycle | No | N/A | N/A | N/A |

| [17] | 2017 | Int. Journal | Technological Forecasting and Social Change | Business and Economics, Public Administration | O | Reduce, reuse recycle, recover | No | N/A | N/A | N/A |

| [60] | 2017 | Conf. | Sustainable Design and Manufacturing | Engineering | O | Recycle | No | N/A | Direct energy deposition/powder bed fusion | N/A |

| [61] | 2017 | Conf. | Product Lifetimes and The Environment (Plate) | Business and Economics; Science and Technology | E | Reduce, reuse, recycle | No | N/A | N/A | N/A |

| [18] | 2016 | Conf. | Smart Innovation, Systems and Technologies | Decision Sciences | E | Reuse, recycle | No | N/A | N/A | N/A |

| [62] | 2016 | Int. Journal | Laser Assisted Net Shape Engineering 9 International Conf. | Engineering; Optics; Physics | E | Reduce, reuse, recycle | No | N/A | Direct energy deposition/powder bed fusion | N/A |

| [4] | 2014 | Int. Journal | Resources | Environmental Science | A | Reuse | No | N/A | N/A | N/A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, I.A.; Godina, R.; Carvalho, H. Waste Valorization through Additive Manufacturing in an Industrial Symbiosis Setting. Sustainability 2021, 13, 234. https://doi.org/10.3390/su13010234

Ferreira IA, Godina R, Carvalho H. Waste Valorization through Additive Manufacturing in an Industrial Symbiosis Setting. Sustainability. 2021; 13(1):234. https://doi.org/10.3390/su13010234

Chicago/Turabian StyleFerreira, Inês A., Radu Godina, and Helena Carvalho. 2021. "Waste Valorization through Additive Manufacturing in an Industrial Symbiosis Setting" Sustainability 13, no. 1: 234. https://doi.org/10.3390/su13010234

APA StyleFerreira, I. A., Godina, R., & Carvalho, H. (2021). Waste Valorization through Additive Manufacturing in an Industrial Symbiosis Setting. Sustainability, 13(1), 234. https://doi.org/10.3390/su13010234