Condition Monitoring of DC-Link Electrolytic Capacitors in PWM Power Converters Using OBL Method

Abstract

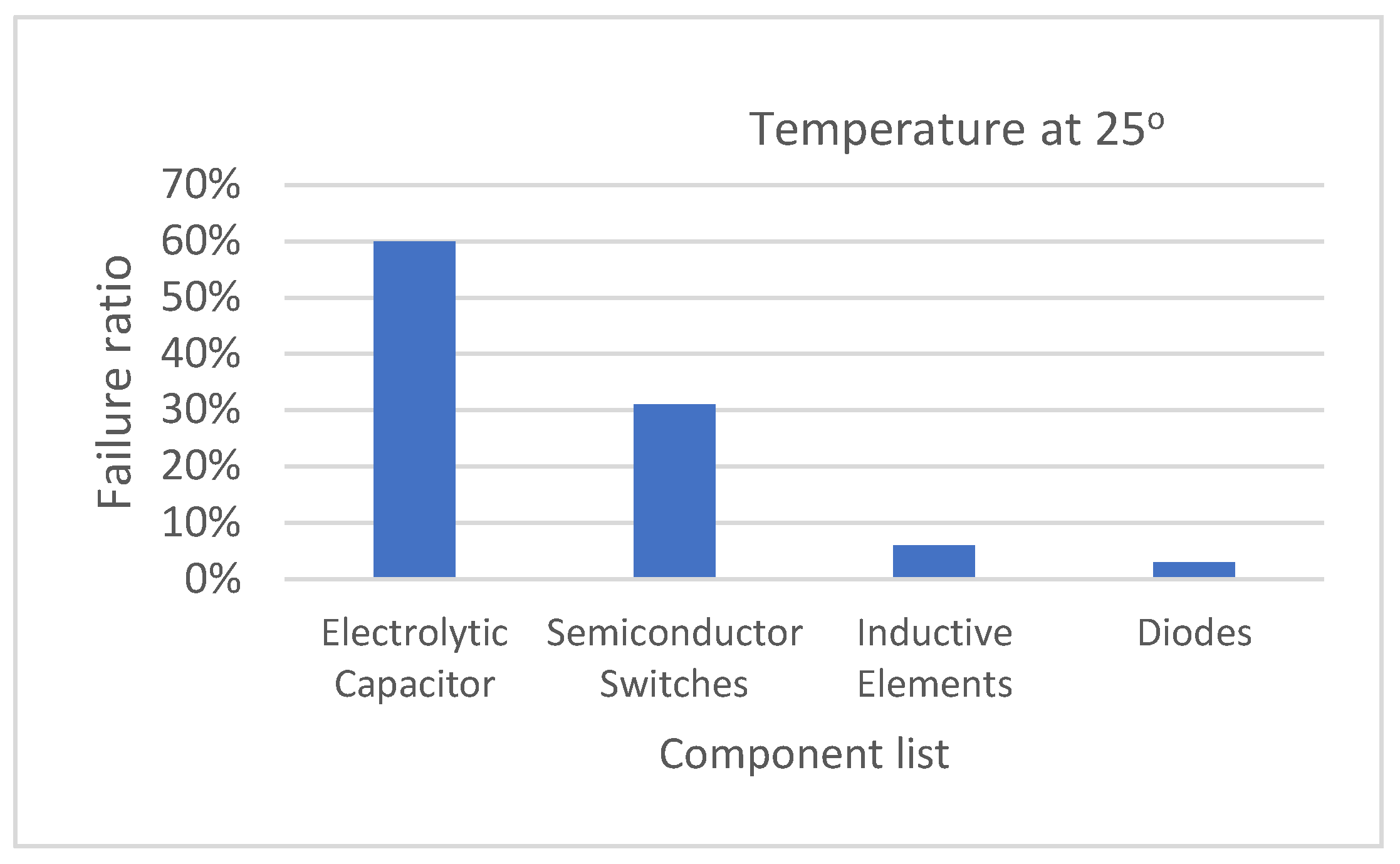

1. Introduction

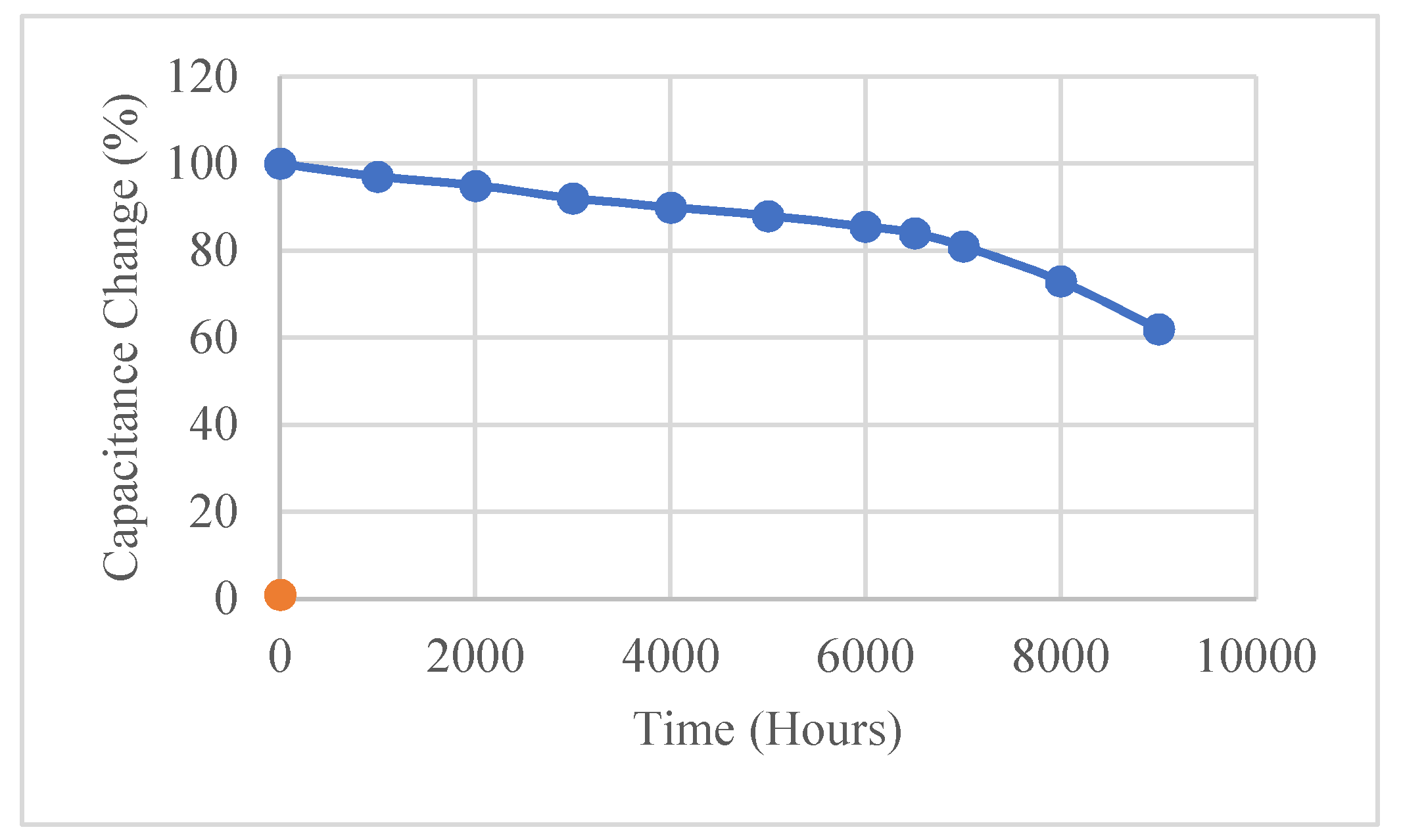

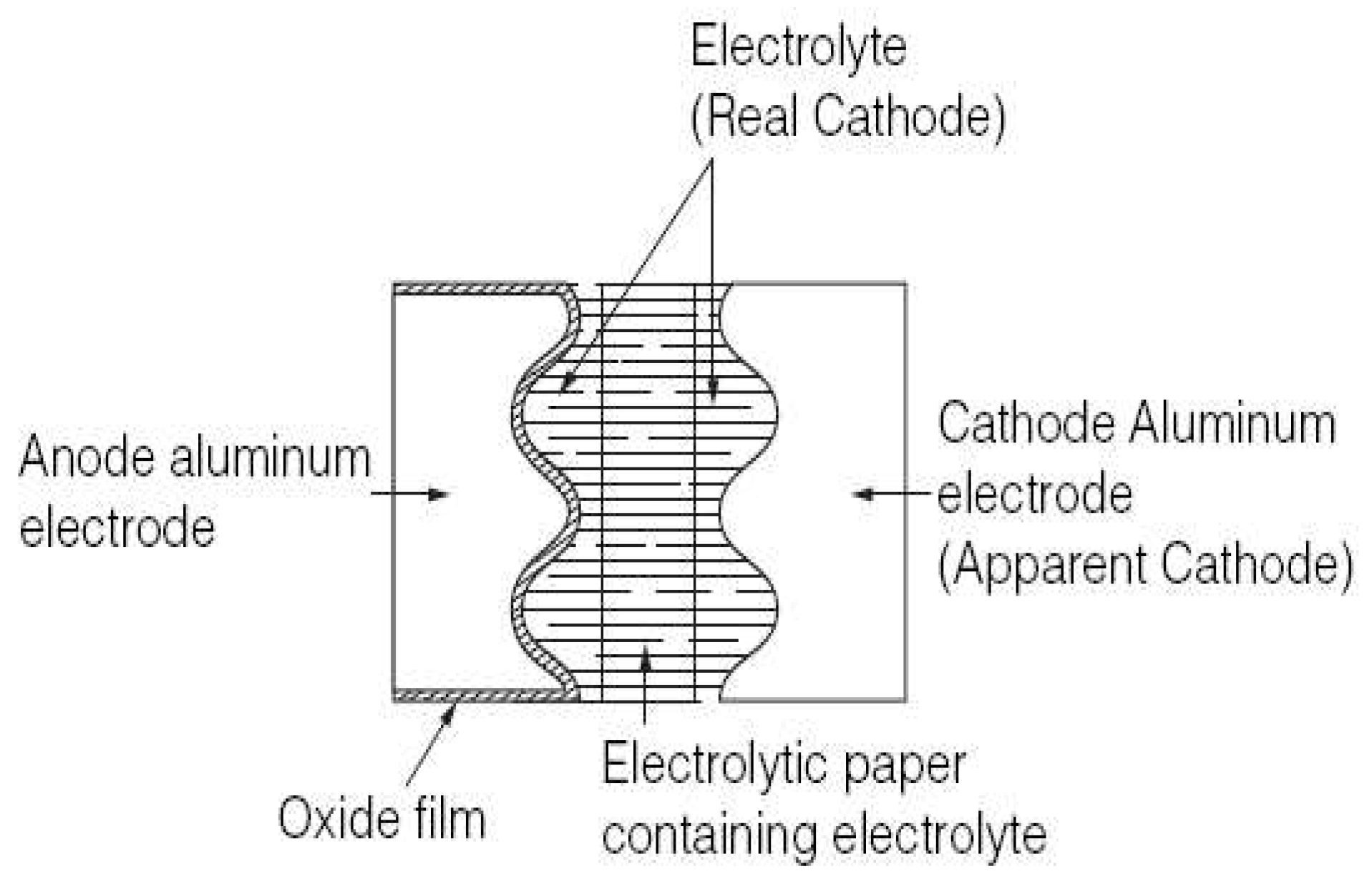

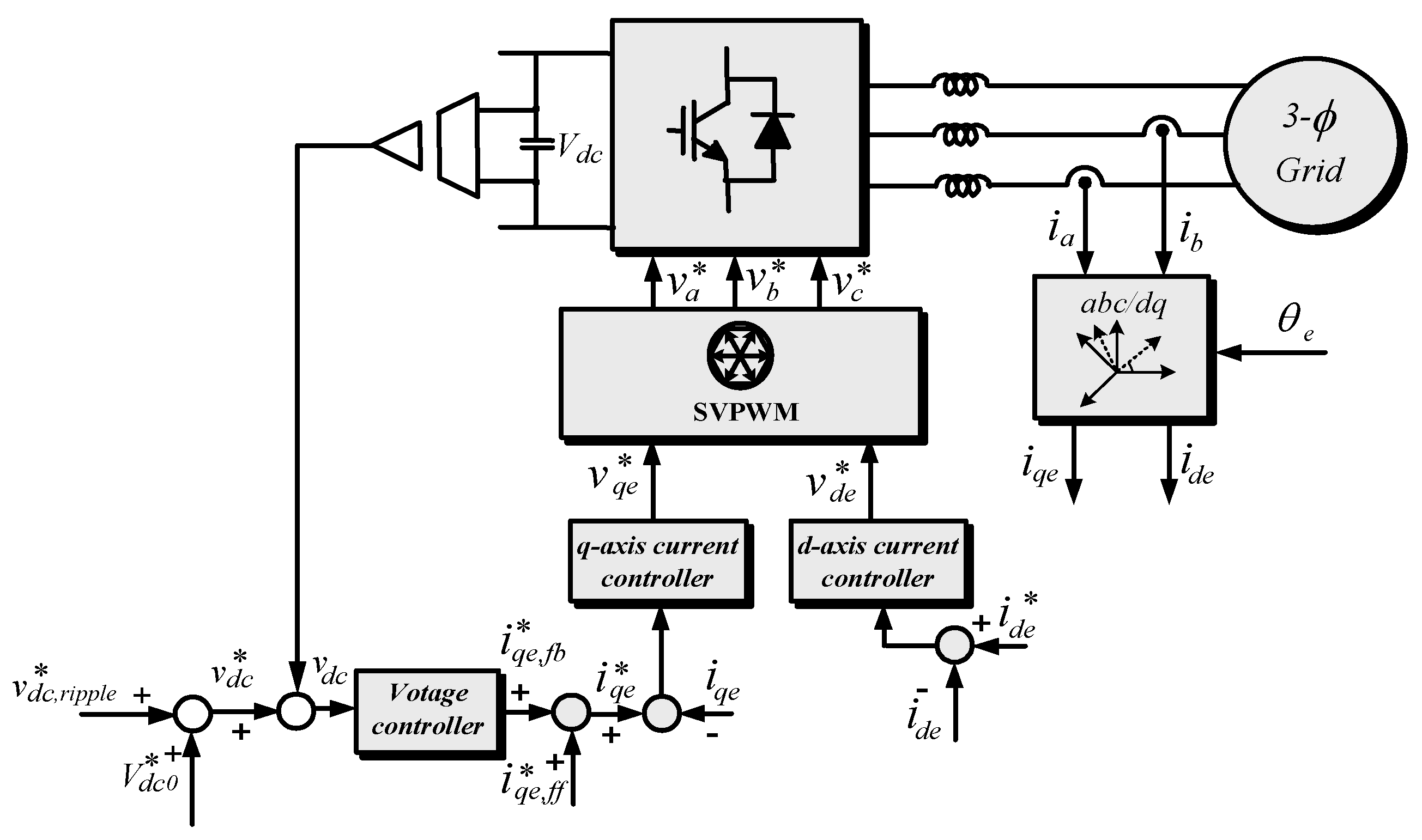

2. Capacitance Lifetime Monitoring

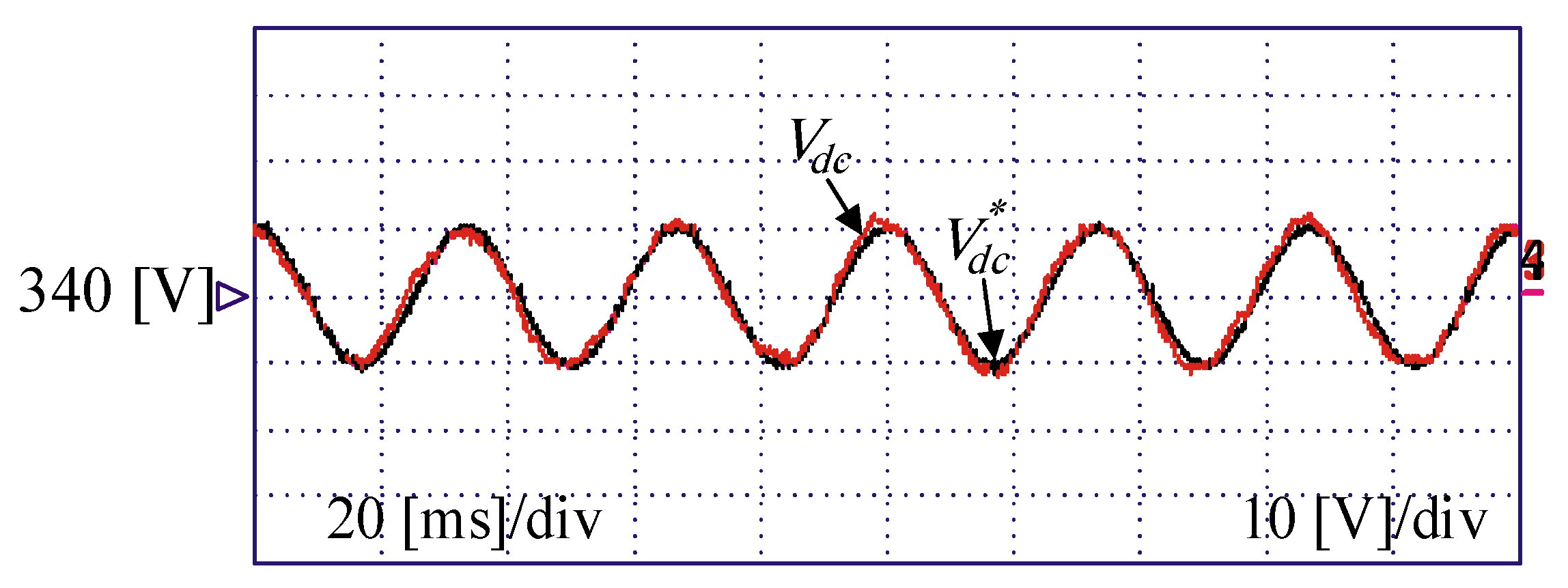

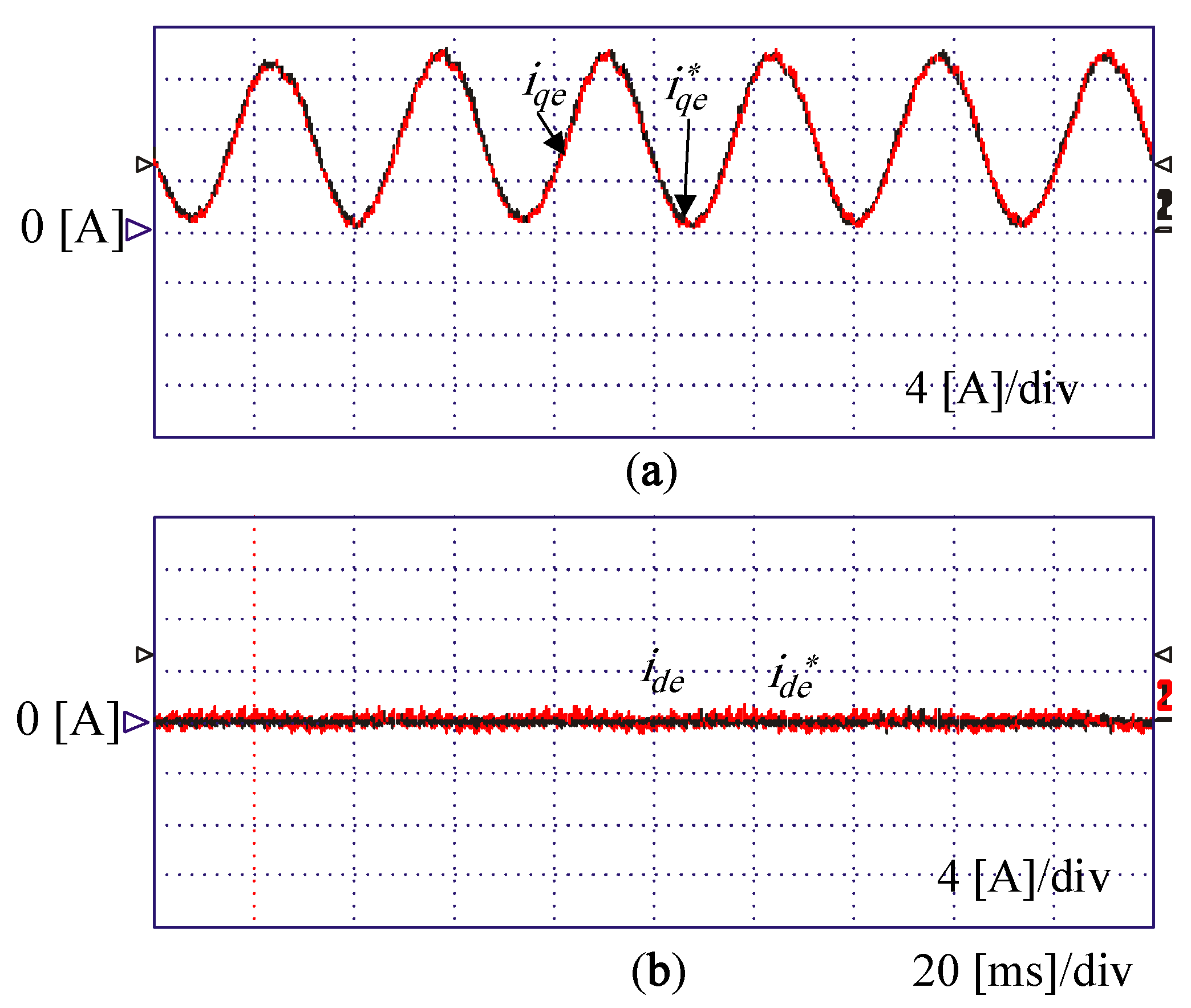

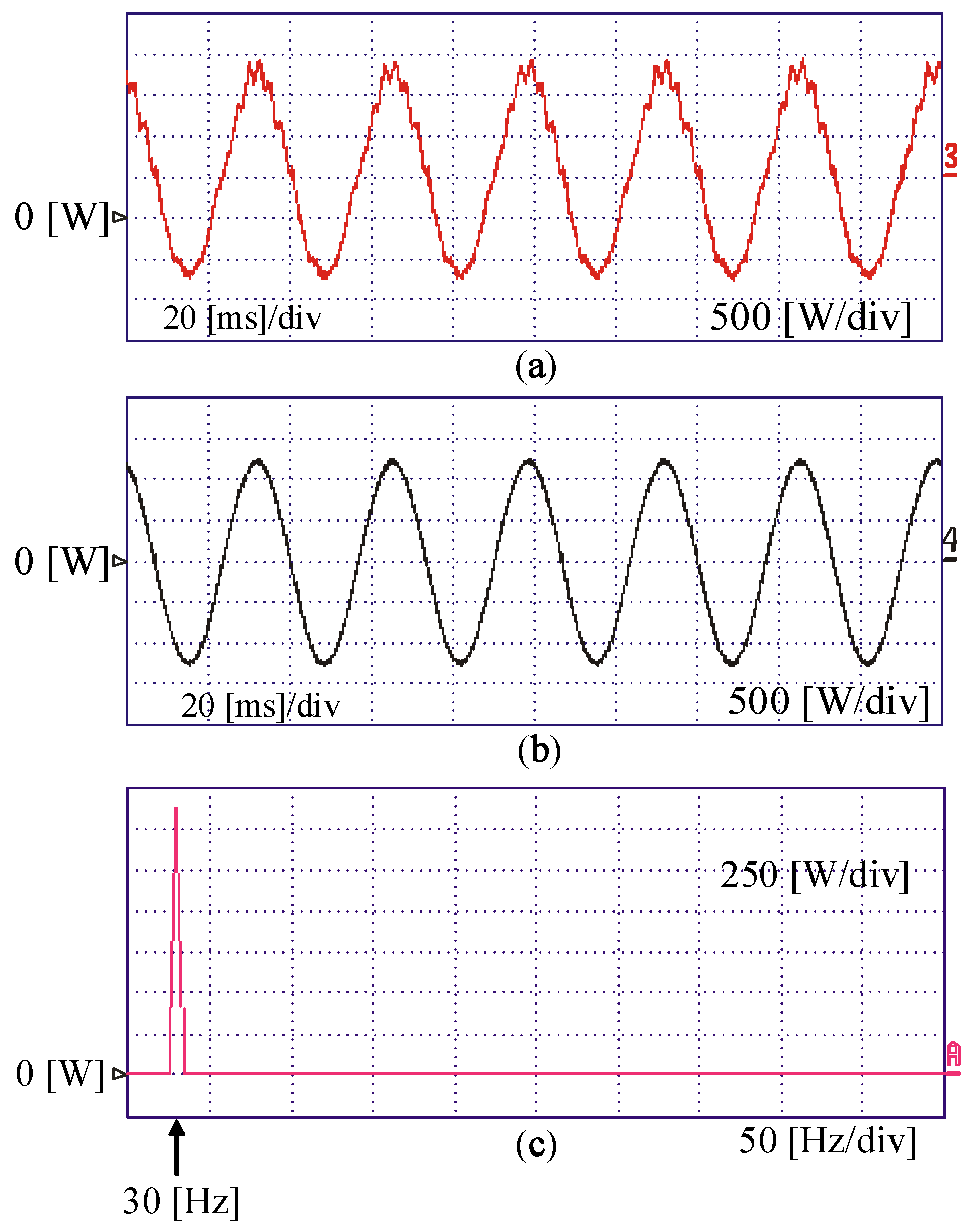

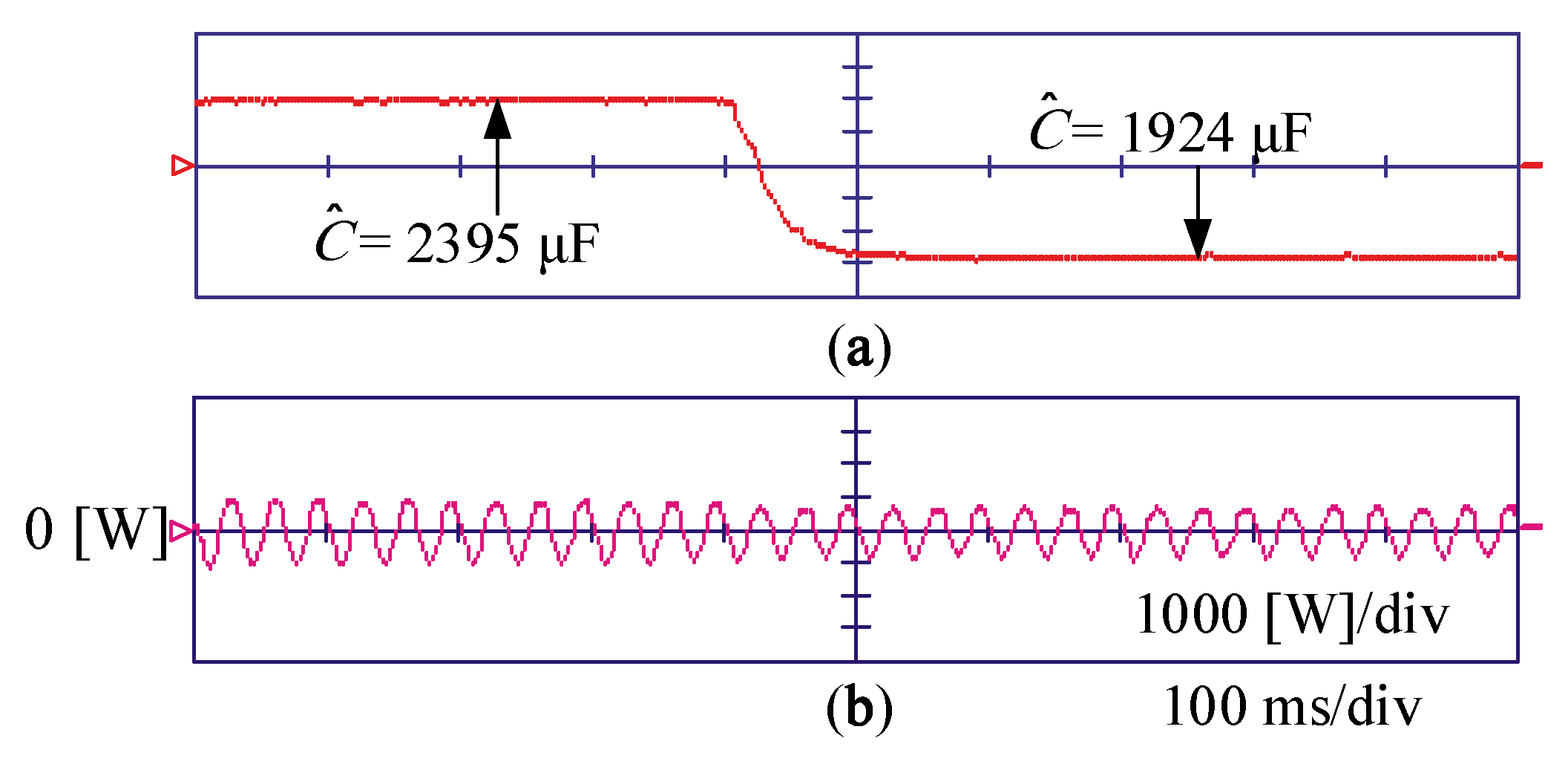

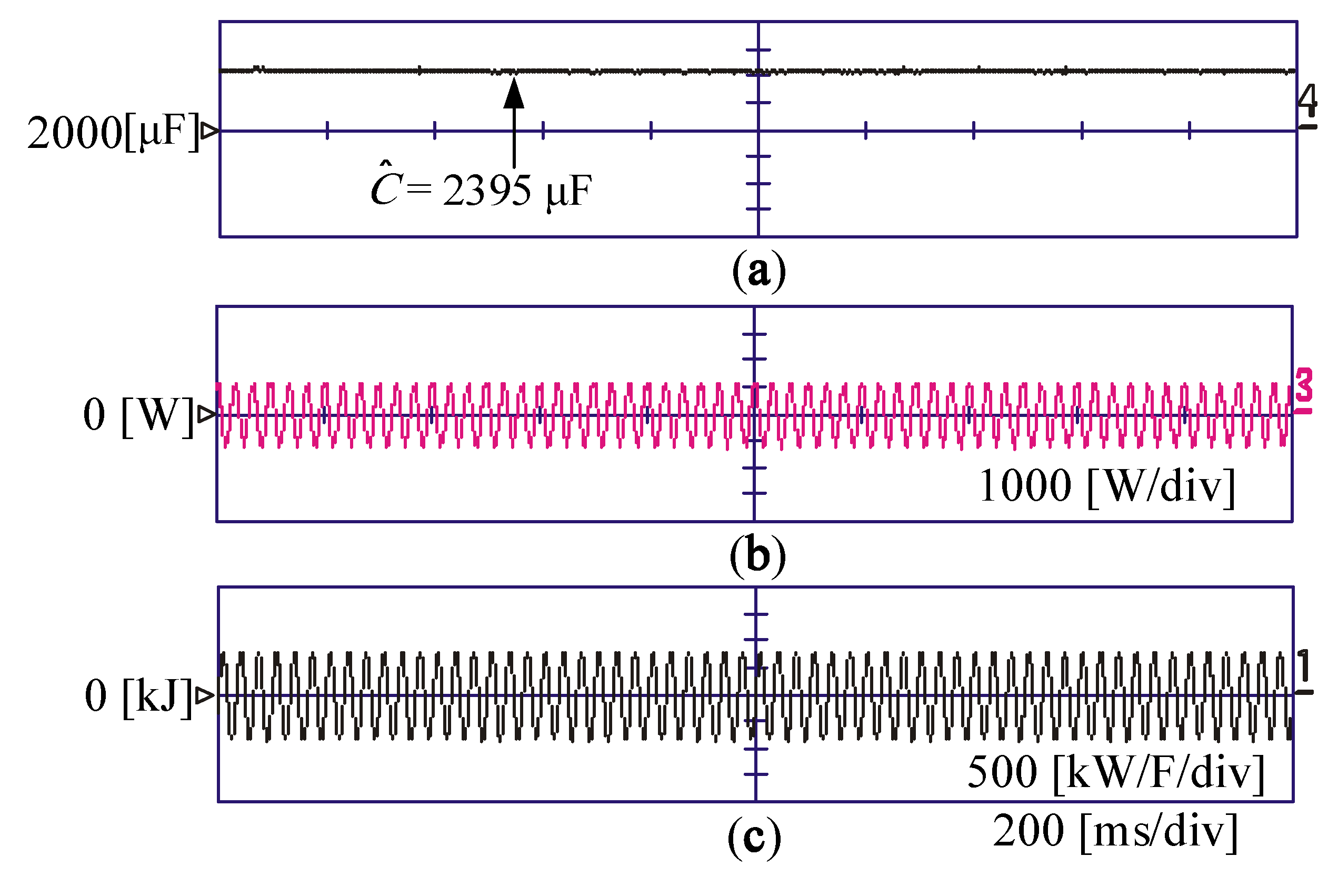

3. Capacitance Estimation Using OPSO-SVFR

3.1. Support Vector Regression (SVR)

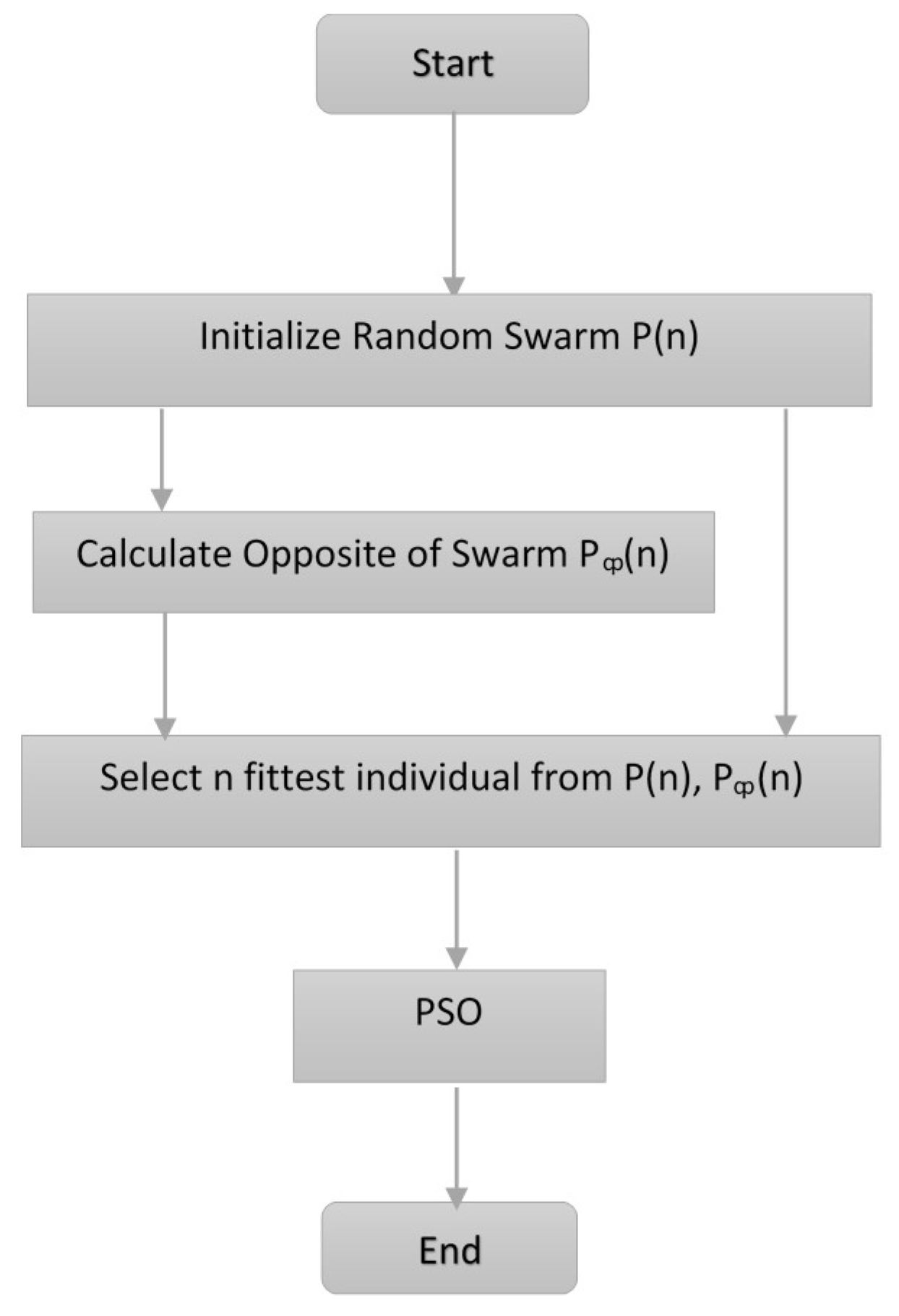

3.2. The O-Particle Swarm Optimization

- Enter the original data for estimation, known as the data preparation step.

- Initialize and update the particles using standard PSO and then repeat the same step using the opposite numbers.

- Update the position and velocity components by using standard and opposition PSO formulas to get the accurate SVR parameters.

- Perform an offline training process for SVR with training samples assessing each particle fitness value of the OPSO for the SVR.

- Update each particle velocity and position until the termination condition is satisfied.

- Construct and retrain the SVR estimation model based on the optimal parameters.

3.3. Capacitance Estimation Using OPSO-SVR

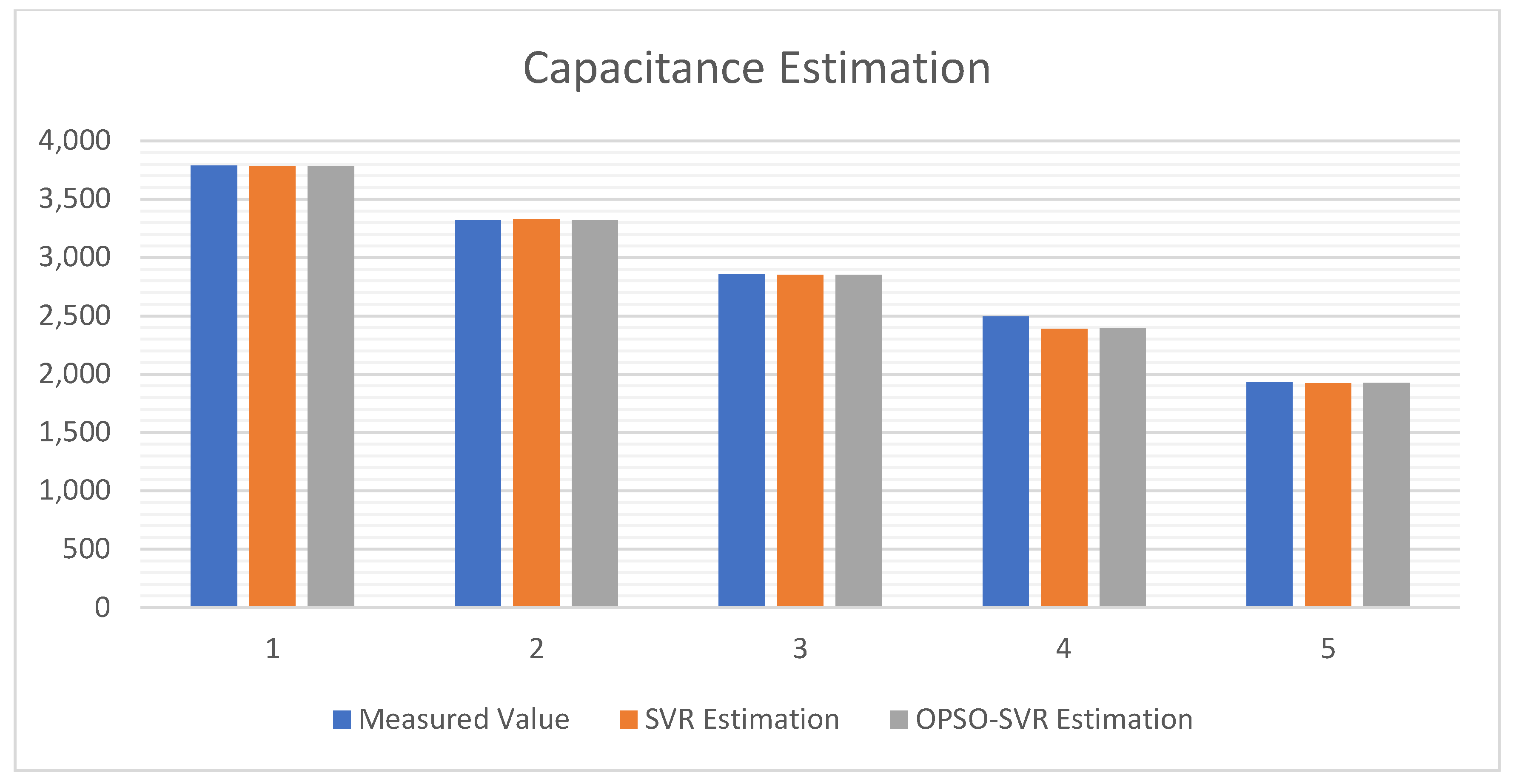

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Vac | the peak voltage of the injected AC voltage |

| ωin | the angular frequency |

| C | the DC-link capacitance |

| Rleak | Capacitor leakage resistance |

| vdc | the DC- link voltage |

| pin | the line side converter input power |

| pout | the load side converter output power |

| , | the line side d-q axis voltages |

| , | the line side d-q axis currents |

| , | the load side d-q axis voltages |

| , | the load side d-q axis currents |

| E | the magnitude of the source voltage |

| W | the weight vector |

| B | the bias |

| the nonlinear function | |

| and | random functions |

| the variance | |

| and | personal and social learning factors |

| the inertia weight |

References

- Shoyama, M.; Deriha, F.; Ninomiya, T. Steady-state characteristics of resonance switched capacitor converters. Trans. KIPE 2005, 5, 206–212. [Google Scholar]

- Nippon Chemicon Co. Judicious Use of Aluminum Electrolytic Capacitors. Available online: http://www.chemi-con.co.jp/e/catalog/pdf/al-e/al-sepa-e/001-guide/al-technote-e-120701.pdf (accessed on 1 January 2013).

- Kemet Electronics Co. Electrolytic Capacitors. Available online: http://www.kemet.com/kemet/web/homepage/kechome.nsf/weben/322E1646C60C72B285257713006ADB65/$file/F3304.pdf (accessed on 8 October 2016).

- Lee, K.; Kim, M.; Yoon, J.; Lee, S.B.; Yoo, J. Condition Monitoring of DC Link Electrolytic Capacitors in Adjustable Speed Drives. IEEE Trans. Ind. Appl. 2008, 44, 1606–1613. [Google Scholar]

- Harada, K.; Katuski, A.; Fujiw, M. Use of ESR for deterioration diagnosis of electrolytic capacitors. IEEE Trans. Power Electron. 1993, 8, 1199–1207. [Google Scholar] [CrossRef]

- Aeloiza, E.; Kim, J.H.; Enjeti, P.; Ruminot, P. A real time method to estimate electrolytic capacitor condition in PWM adjustable speed drives and uninterruptible power supplies. In Proceedings of the 2005 IEEE 36th Power Electronics Specialists Conference, Recife, Brazil, 16 June 2005; pp. 2867–2872. [Google Scholar]

- Abo-Khalil, A.G.; Lee, D.C. DC-Link Capacitacne Estimation using Support Vector Regression in AC/DC/AC PWM Converters. Korean Inst. Electr. Eng. J. 2007, 56, 81–87. [Google Scholar]

- Parler, S.G., Jr. Improved Spice models of aluminum electrolytic capacitors for inverter applications. IEEE Trans. Ind. Appl. 2003, 39, 929–935. [Google Scholar] [CrossRef]

- Gasperi, M.L. Life prediction modeling of bus capacitors in AC variable-frequency drives. IEEE Trans. Ind. Appl. 2005, 41, 1430–1435. [Google Scholar] [CrossRef]

- Abo-Khalil, A.G.; Lee, D.C. DC-Capacitance Estimation of DC-Link Capacitors using AC Voltage Injection in AC/DC/AC PWM Converters. In Proceedings of the Forty-First IAS Annual Meeting, Tampa, FL, USA, 8–12 October 2006; Volume 4, pp. 2095–2100. [Google Scholar]

- Lee, K.-W. Fault Diagnosis of a Electrolytic Capacitor for Inverter DC-Link Voltage Smoothing. Trans. Korean Inst. Power Electron. 2007, 12, 372–377. [Google Scholar]

- Ertl, H.; Wiesinger, T.; Kolar, J.W.; Zach, F.C. A simple active method to avoid the balancing losses of DC Link Capacitor. In Proceedings of the 24th International Conference on Power Electronics (PCIM), Nürnberg, Germany, 20–22 May 2003; pp. 459–464. [Google Scholar]

- Abo-Khalil, A.G.; Lee, D.C. DC-link capacitance estimation in AC/DC/AC PWM converters using voltage injection. IEEE Trans. Ind. Appl. 2008, 44, 1631–1637. [Google Scholar] [CrossRef]

- Abo-Khalil, A.G. Current Injection-Based DC-link Capacitacne Estimation Using Support Vector Regression. IET J. Power Electron. 2012, 5, 53–58. [Google Scholar] [CrossRef]

- Amaral, A.; Buatti, G.; Ribeiro, H.; Cardoso, A. Using DFT to obtain the equivalent circuit of aluminum electrolytic capacitors. In Proceeding of 2007 7th International Conference on Power Electronics and Drive Systems, Bangkok, Thailand, 27–30 November 2007; pp. 434–438. [Google Scholar]

- Amaral, A.; Cardoso, A. Using Newton-Raphson method to estimate the condition of aluminum electrolytic capacitors. In Proceeding of the 2007 IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007; pp. 827–832. [Google Scholar]

- Amaral, A.; Cardoso, A. Simple experimental techniques to characterize capacitors in a wide range of frequencies and temperatures. IEEE Trans. Instrum. Meas. 2010, 59, 1258–1267. [Google Scholar] [CrossRef]

- Amaral, A.; Cardoso, A. An experimental technique for estimating the ESR and reactance intrinsic values of aluminum electrolytic capacitors. In Proceedings of the 2006 IEEE Instrumentation and Measurement Technology Conference, Sorrento, Italy, 24–27 April 2006; pp. 1820–1825. [Google Scholar]

- Imam, A.; Divan, D.; Harley, R.; Habetler, T. Real-time condition monitoring of the electrolytic capacitors for power electronics applications. In Proceedings of the 22nd Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 25 February–1 March 2007; pp. 1057–1061. [Google Scholar]

- Venet, P.; Perisse, F.; El-Husseini, M.; Rojat, G. Realization of a smart electrolytic capacitor circuit. IEEE Ind. Appl. Mag. 2002, 8, 16–20. [Google Scholar] [CrossRef]

- Soliman, H.; Wang, H.; Gadalla, B.; Blaabjerg, F. Condition monitoring for DC-link capacitors based on artificial neural network algorithm. In Proceedings of the IEEE 5th International Conference on Power Engineering, Energy and Electrical Drives (POWERENG), Riga, Latvia, 11–13 May 2015. [Google Scholar]

- Abo-Khalil, A.G.; Alyami, S.; Alhejji, A.; Awan, A.B. Real-Time Reliability Monitoring of DC-Link Capacitors in Back-to-Back Converters. Energies 2019, 12, 2396. [Google Scholar] [CrossRef]

- Park, J.; Sandberg, I.W. Universal approximation using radial basis-function networks. Neural Comput. 1991, 3, 246–257. [Google Scholar] [CrossRef] [PubMed]

- Qiao, W.; Harley, R.G. Optimization of radial basis function widths using particle swarm optimization. In Proceedings of the 2006 IEEE Swarm Intelligence Symposium, Indianapolis, Indiana, 12–14 May 2006; pp. 55–60. [Google Scholar]

- Bazzani, A.; Bevilacqua, A.; Bollini, D.; Brancaccio, R.; Campanini, R.; Lanconelli, N.; Riccardi, A.; Romani, D. An SVM classifier to separate false signals from icrocalcifications in digital mammograms. Phys. Med. Biol. 2001, 46, 1651–1663. [Google Scholar] [CrossRef] [PubMed]

- Nuller, K.R.; Smola, A.; Ratrch, G.; Scholkopf, B.; Kohlmargen, J.; Vapnik, V. Predicting time series with support vector machine. In Proceedings of the 1997 International Conference on Artificial Neural Networks, Lausanne, Switzerland, 8–10 October 1997; Springer: Berlin/Heidelberg, Germany, 1997; pp. 999–1004. [Google Scholar]

- Rastgoufard, S.; Charalampidis, D. Tuned support vector regression by modified particle swarm optimization for online power system static security evaluation. In Proceedings of the 2018 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 8–9 February 2018; pp. 1–6. [Google Scholar]

- Schölkopf, B.; Burges, C.J.C.; Smola, A.J. Using support vector support machines for time series prediction. In Advances in Kernel Methods; MIT Press: Cambridge, MA, USA, 1999; pp. 242–253. [Google Scholar]

- Cherkassky, V.; Miller, F. Learning from Data Concepts, Theory and Methods; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Yu, B.; Abo-Khalil, A.G.; So, J.; Yu, G. Support Vector Regression Based Maximum Power Point Tracking for PV Grid-Connected System. In Proceedings of the 2009 34th IEEE Photovoltaic Specialists Conference (PVSC), Philadelphia, PA, USA, 7–12 June 2009. [Google Scholar]

- Abo-Khalil, A.G.; Alyami, S.; Sayed, K.; Alhejji, A. Dynamic Modeling of Wind Turbines Based on Estimated Wind Speed under Turbulent Conditions. Energies 2019, 12, 1907. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Al-Saud, M.S.; Abokhalil, A.G.; Farh, H.M. Photovoltaic maximum power point tracking under dynamic partial shading changes by novel adaptive particle swarm optimization strategy. Trans. Inst. Meas. Control 2020, 42, 104–115. [Google Scholar] [CrossRef]

- Lee, K.; El-Sharkawi, M. Modern Heuristic Optimization Techniques; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Rastgoufard, S.; Charalampidis, D. Parameter selection of multi-class SVM with evolutionary optimization methods for static security evaluation in power systems. In Proceedings of the 2016 IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016. [Google Scholar]

- Lin, S.W.; Ying, K.C.; Chen, S.C.; Lee, Z.J. Particle swarm optimization for parameter determination and feature selection of support vector machines. Expert Syst. Appl. 2008, 35, 817–1824. [Google Scholar] [CrossRef]

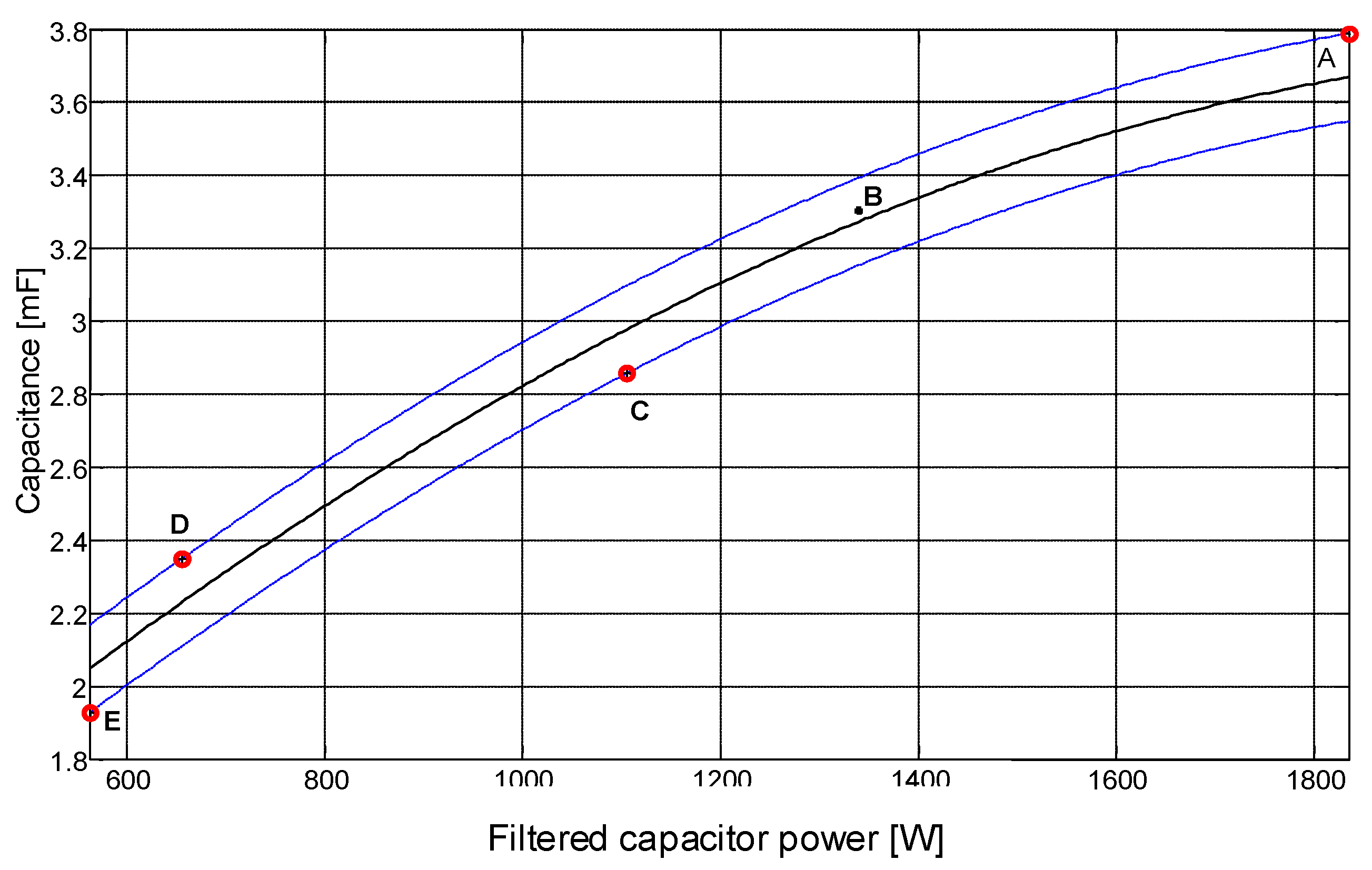

| Measured Value | SVR Estimated Value | OPSO-SVR Estimated Value | |

|---|---|---|---|

| A | 3789 | 3786 | 3787 |

| B | 3323 | 3320 | 3320 |

| C | 2857 | 2855 | 2856 |

| D | 2394 | 2393 | 2395 |

| E | 1928 | 1922 | 1924 |

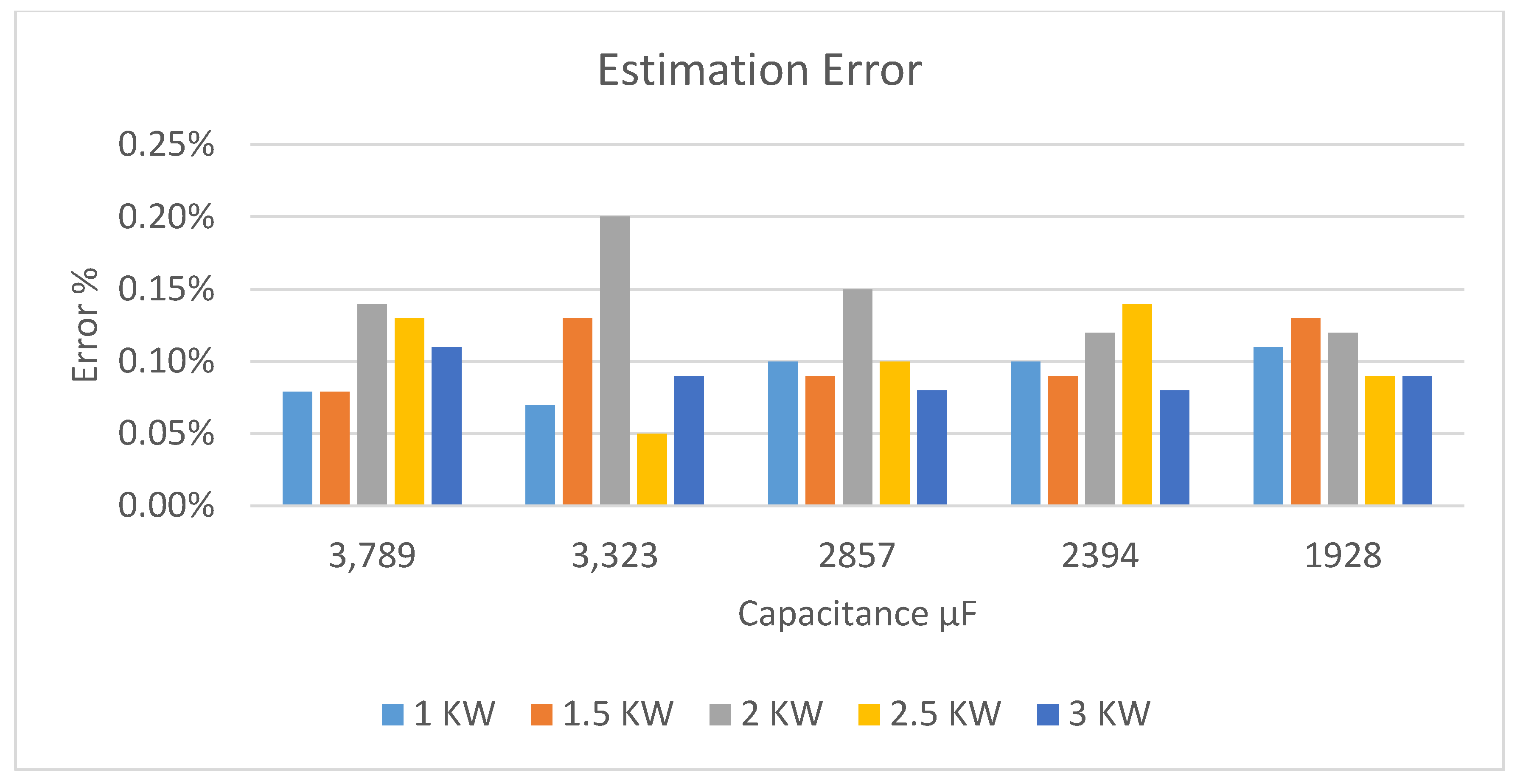

| Measured Capacitance | Power = 1 kW | Power = 1.5 kW | Power = 2 kW | Power = 2.5 kW | Power = 3 kW | Mean | Max | Min | STD |

|---|---|---|---|---|---|---|---|---|---|

| Error | Error | Error | Error | Error | |||||

| 3789 | 0.08% | 0.09% | 0.14% | 0.125% | 0.11% | 0.000917186 | 0.14% | 0.09% | 0.00037 |

| 3323 | 0.07% | 0.13% | 0.2% | 0.05% | 0.09% | 0.001609477 | 0.13% | 0.03% | 0.0045 |

| 2857 | 0.1% | 0.09% | 0.15% | 0.1% | 0.08% | 0.000960228 | 0.15% | 0.08% | 0.0004 |

| 2394 | 0.1% | 0.085% | 0.115% | 0.14% | 0.075% | 0.001053874 | 0.14% | 0.075% | 0.00023 |

| 1928 | 0.112% | 0.13% | 0.12% | 0.09% | 0.085% | 0.002759459 | 0.13% | 0.085% | 0.0195 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abo-Khalil, A.G.; Al-Qawasmi, A.-R.; Eltamaly, A.M.; Yu, B.G. Condition Monitoring of DC-Link Electrolytic Capacitors in PWM Power Converters Using OBL Method. Sustainability 2020, 12, 3719. https://doi.org/10.3390/su12093719

Abo-Khalil AG, Al-Qawasmi A-R, Eltamaly AM, Yu BG. Condition Monitoring of DC-Link Electrolytic Capacitors in PWM Power Converters Using OBL Method. Sustainability. 2020; 12(9):3719. https://doi.org/10.3390/su12093719

Chicago/Turabian StyleAbo-Khalil, Ahmed G., Abdel-Rahman Al-Qawasmi, Ali M. Eltamaly, and B. G. Yu. 2020. "Condition Monitoring of DC-Link Electrolytic Capacitors in PWM Power Converters Using OBL Method" Sustainability 12, no. 9: 3719. https://doi.org/10.3390/su12093719

APA StyleAbo-Khalil, A. G., Al-Qawasmi, A.-R., Eltamaly, A. M., & Yu, B. G. (2020). Condition Monitoring of DC-Link Electrolytic Capacitors in PWM Power Converters Using OBL Method. Sustainability, 12(9), 3719. https://doi.org/10.3390/su12093719