1. Background

The circular economy enables sustainable development, and the common circular economy practices within the manufacturing industry are end-of-use strategies, including recycling, remanufacturing, repairing, and reusing. However, it is widely accepted that the majority of products and components that are currently recirculated via end-of-use strategies have not been designed for circulation of any sort, whereas these end-of-use strategies are greatly dependent on the very beginning stage of the product lifecycle, i.e., product design and development [

1,

2]. This phenomenon could be attributed to the lack of structured and integrated design guidelines for circularity, as well as a lack of companies actively engaging with the circular economy. Consequently, circular product design and development have not been well established in the domain of the circular economy, and circularity aspects are not yet properly considered in the design phase. Products have to be designed and manufactured to keep the products, components, and materials circulating through several lifecycles and lasting each lifecycle. This approach will contribute to resource efficiency, less waste generation, and overall fewer environmental effects.

To enable the circular economy, it is vital that designers consider circularity aspects in early product design and development to enhance these products’ circularity potential. Additionally, publications and reports such as towards the circular economy [

3], establishing a framework for the setting of eco-design requirements for energy-related products [

4], and closing the loop—an EU action plan for the circular economy [

5] have promoted the value enhancement of products through design guidelines for circularity in terms of product durability, repairability, reusability, and recyclability.

This paper, within the field of the circular economy [

3], aims to present a set of generic circular design guidelines to map companies’ circular product design initiatives in the early stages of product design and development. These guidelines have proved to support decision-making and enhance the circularity of products.

The proposed guidelines are generic but can be tailored and detailed depending on the product type, material used, product development process, environmental management system, environmental and circularity goals, the adopted business model innovation, and the circular strategies and production system of companies.

2. Theoretical Framework

Although eco-design [

6] and the circular economy [

3] are not entirely new concepts, past literature and research on the circular economy have focused mainly on the domain of new circular business models, (for example, see [

7,

8,

9]) and closing the loop solutions (for example, see [

10,

11]). However, circular economy business models and closing the loop can be functional only if the products and services are designed for circularity, e.g., to be easily disassembled and segregated into different components and materials to facilitate the exchange of faulty components to increase the lifespan of products in different ways. Therefore, there is a need to focus on the domain of circular product design and development. Previous literature has, to some extent, covered frameworks of design for the environment [

12,

13], design for disassembly [

14,

15], design for remanufacturing [

16,

17], and design for recycling [

18,

19]. Nevertheless, these design studies do not systematically cover circular design guidelines for all circular strategies in one picture.

The main focus of environmental design (also called eco-design) has been on the harmful ecological impacts of products in terms of reducing the toxicity and harmfulness of input substances into the products and the emission of hazardous output substances into the environment, which is usually measured in the form of global warming and greenhouse effects [

12]. In design for disassembly, guidelines include mainly minimizing the number of parts and disassembly movements to reduce the disassembly time and increase efficiency [

20]. In design for remanufacturing, the main goal has been on nondestructive dismantling and reassembly of the product via modular design and interchangeability [

21]. In design for recycling, the ease of mechanical dismantling of similar components and materials, preferably in one single module, has been the focus to facilitate shredding, regeneration, and recycling [

22].

Among the limited literature on circular design guidelines, [

23] presents a methodology in which circularity design guidelines found through a literature review could be incorporated into new product designs for the improvement of product circularity. Although their methodology can be applied for any product category, the results presented are tested only on electrical and electronic appliances. Kjaer [

24] also used a lifecycle assessment (LCA) approach and proposed a set of guidelines with six steps to evaluate the environmental performance of product-service systems (PSS). Their guidelines aimed to reduce the risk of biased results, predictable rebound effects, and significant cut-off errors. In another study in the domain of product-service systems, [

25] proposed design guidelines based on software engineering methods and theory (SEMAT) that have two essential characteristics, including actor networks and continuous improvement, and four steps, including arrangement, evaluation, definition, and discussion. Our literature search also found a D4N tool [

26] that provides guidelines for redesign and enables the integration of environmental aspects in the design phase by accessing existing electronically stored 3D CAD data.

3. Circular Strategy Scanner

The concept of the circular economy has recently received much attention, and consequently, several approaches and strategies to work towards the circular economy have been developed and discussed in the literature, which in turn has brought controversies and confusion [

27] and blurred the concept due to different worlds of thought [

28]. In short, the strategies and approaches towards a circular economy include the choice of the correct business model, product design and development, green manufacturing, material sourcing, and the recirculation of parts and components, as well as materials (end-of-use strategies) to prolong product use, among other strategies.

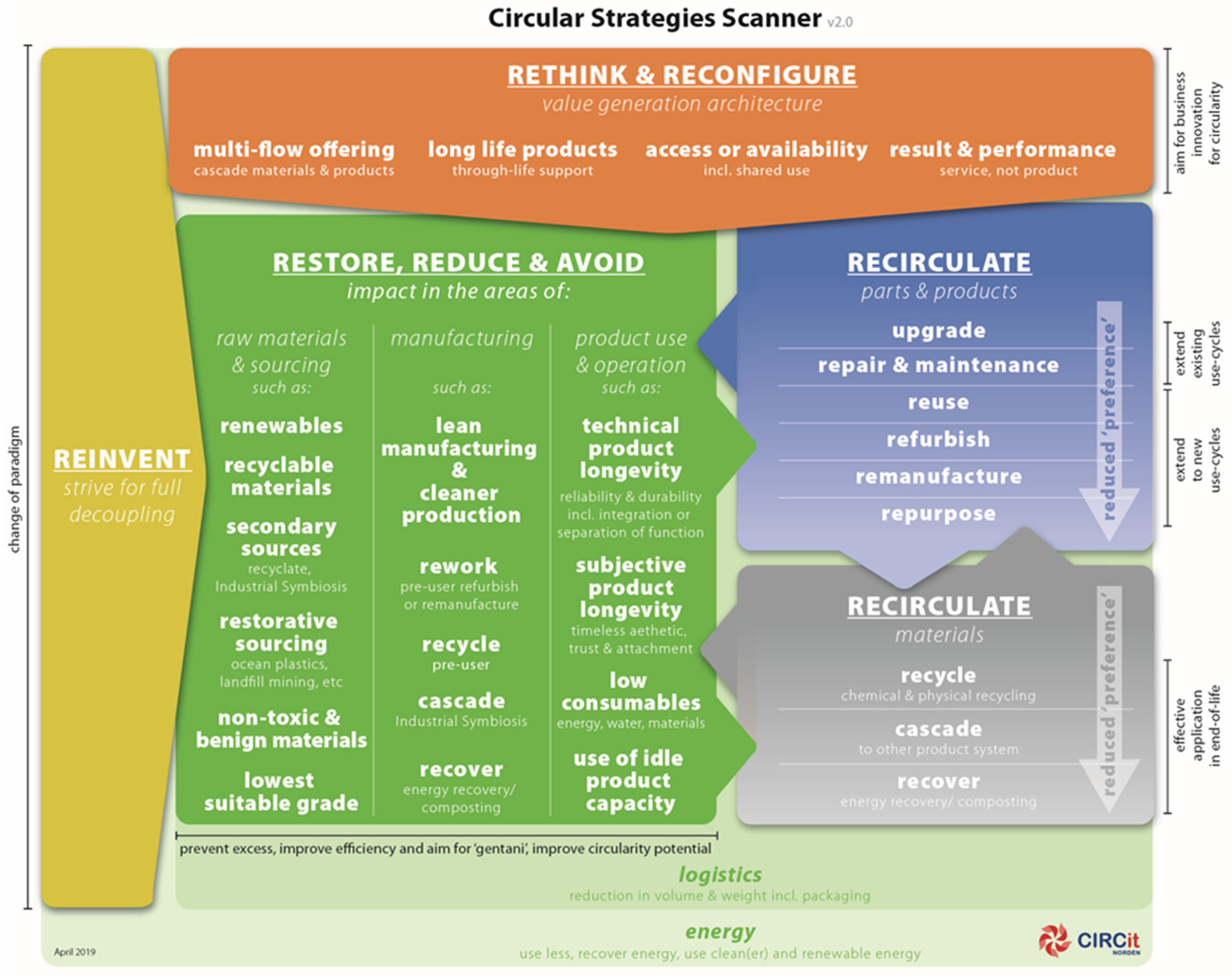

In the CIRCit project and our previously published paper [

29], all these different strategies were identified and mapped in a “circular strategies scanner” (see

Figure 1). The circular strategies scanner is a framework that introduces a taxonomy of circular strategies in a comprehensive set of definitions to increase clarity and provide a heuristic for the manufacturing context. See

Supplementary Materials for defitions of circular strategies.

The color-coding of these strategies is an attempt to categorize the strategies to enhance clarity. The “reinvent” strategy (yellow) on the left is related to changes in paradigms and the dematerialization by which physical products become redundant by offering the same function, usually enabled by radically different products and/or technologies. The “rethink and reconfigure” strategy (orange) relates to business model innovation, function, and value delivery/proposition to the market and how a customer or user can use, interact and experience the products. All strategies within green area relate to typical and traditional supply chains (take, make, use, and logistics) and aim to prevent excess consumption, improve efficiency, make products last longer, and illuminate the real minimum resources needed to carry out a process. The strategies within the blue and gray areas relate to the end-of-use phase (dispose) and the closing-the-loop phase, where the blue areas address the recirculation of parts and components, and the gray areas focus on the recirculation of materials.

4. Materials and Methods

The research presented in this paper was carried out as a part of a Nordic research project, CIRCit (Circular Economy Integration in the Nordic Industry for Enhanced Sustainability and Competitiveness). The project aims to “conceptualize, develop and implement a set of tools and approaches that will enable Nordic industry to accelerate the transition towards a sustainable society by means of the circular economy”. However, this paper, which falls within the area of the circular economy, [

3] focuses on circular product design and development in the early stages. This paper contributes to industry and academia by adding value to the circular economy literature by presenting a set of generic guidelines for circular product design and development for the different circular strategies presented in the previous chapter and in

Figure 1. In addition, the guidelines are linked to circularity strategies to map companies’ circular product design initiation in the early stages of product design and development. These guidelines have proved to support decision-making and enhance the circularity of products.

The research began with a literature review on guidelines for circular product design. The literature search included peer-reviewed publications from scientific databases, as well as institutional reports and gray literature from non-academic resources. The literature selection method used a keyword search regarding relevant guidelines for circular product design and development, followed by an abstract review and a full-text reading. The search incorporated the keywords “eco-design”, “circular product design”, “product design and development”, “design for circularity”, “design for remanufacturing”, “design for X”, “design for recycling”, and “design for the environment”, along with combinations with the terms “circular economy”, “guidelines”, and “frameworks”. This search was then extended through a qualitative upstream and downstream search of the references in the selected articles. This approach resulted in a long list of guidelines that were then iteratively reviewed and revised together with the help of practitioners from the companies. Some guidelines were combined, and some were removed for several reasons, such as being too detailed or being very industry-, product-, or material-specific.

The empirical part of the research presented in this article followed an action research approach with the participating companies and organizations over one and a half years of collaborative research. The action research was an iterative process of codeveloping guidelines and testing as well as inviting the participative and collaborative engagement of authors with companies for several months to promote organizational learning related to circular product design and development. The overall aim of the action research approach is to enable Nordic industry to (1) understand the overall potential for circular economy implementation in different areas; (2) ensure the commitment of companies at the strategic level, in addition to the full customization of the transition path; (3) develop circular products and services that support value maximization throughout multiple life cycles; (4) facilitate closing the loop at the end-of-use; (5) enable circular business models and innovative value propositions. The action research at each company followed several structured and iterative steps, including identifying the issue, planning action, implementing the action, and assessing the action in different cycles [

30]. Each company’s engagement and collaboration took between 2 and 6 months, and regular follow-ups were scheduled afterwards to review the changes and progress at each company. The action-research approach made industrial companies effectively become co-researchers in the project [

30], which in turn enabled organizational learning for both companies and researchers such that expertise and capabilities were transferred from one to another.

The companies that participated in this research (see

Table 1) are from different manufacturing industries, including urban furniture, coffee brewery machines, orthopedic equipment, and hand tools. The companies vary in terms of size, production volume, complexity, and environmental management systems. They are also located in different Nordic countries, while their products are sold worldwide. The company selection was based on the companies’ interest in the research project and their intention to move towards a circular economy, particularly in terms of circular product design and development.

Empirical data were gathered by means of direct observations, discussions, and meetings with the experts at each company and document reviews. The direct observations included visiting companies and discussing issues related to product design and development with product designers, product owners, research and development, and environmental management, among others. There were also several online meetings and remote discussions to follow up on their progress and to exchange information and knowledge. For each company, product design and development-related documents and reports were reviewed. The guideline development was a back-and-forth process between the researchers and the companies, where modifications were made according to feedback in a “systematic combining” manner [

31]. The results for each company were afterwards compared and analyzed in an iterative manner to maintain consistency between the cases and with the literature and to increase the understanding and generalizability of the empirical findings.

To better understand the collected data and validate the empirical findings, empirically collected data were compounded with internal discussions with CIRCit project members from different institutes and countries. This approach helped capture a broad understanding of circular product design and development, particularly in connection to other circular economy perspectives in the CIRCit project, including innovative business models, waste management and closing-the-loop, sustainability management and key performance indicators, digitalization, the internet of things and information and communications technology, and circular value chains.

5. Design Guidelines for Circularity

Based on the foundation of the circular strategy scanner [

29] (see

Figure 1), a set of generic design guidelines (in the left column) for circular product design and development were developed and correlated to the circular strategy (in the top row) in

Table 2. The definition of each strategy has been given in our previously published paper [

29]. The proposed guidelines (see

Supplementary Materials for defintions) were intentionally developed to be generic and applicable to any industry and product, as it is impossible to prescribe a set of detailed guidelines suiting all product types, materials, manufacturing systems, and industries. Even depending on the adopted business model innovation and circular strategies at each company (e.g., selling or renting out or aiming for recycling or reuse), the guidelines will differ in their details. For this reason,

Table 2 has been developed to generally guide practitioners to relate guidelines to circular strategies. However, the generic design guidelines can be tailored, added, or removed and further detailed technically. The changes depend on the product type, material used, product development process, environmental management system, environmental and circularity goals, adopted business model innovation and circular strategies, and the companies’ production system. The selection, tailoring, and detailing process can be carried out through workshops and deep discussions with relevant functions such as designers, manufacturing, product owners, and environmental coordinators.

The connections between the guidelines and circular strategies are also presented in

Table 2. The black cells indicate a direct connection (effect) of the guideline to a specific circular strategy; the gray cells, however, indicate an indirect connection (effect) on a specific circular strategy. For example, “design using recyclable and secondary (recycled) materials” is closely connected to (and affects) the “raw materials and sourcing”, “recycling”, and “cascade” strategies; therefore, it is imperative to consider when designing these strategies. In addition, “design using recyclable and secondary (recycled) materials” has an indirect connection to the “remanufacturing” and “refurbishment” strategies, which means that it has either a relatively minor influence or has situational influence depending on the product type.

Note that

Table 2 presents general connections (effects) between the guidelines and circular strategies, and additional connections between other guidelines and other strategies are possible depending on the company and product type. Therefore, when using the guidelines, certain key points should be taken into consideration: (a) there is no specific design guideline for each of the circular strategies, and the design guidelines for different circular strategies overlap with each other to some extent, i.e., similar design guidelines might be applied to several circular strategies. For instance, “make exchanging of faulty components easily accessible” is a common guideline among many circularity strategies; (b) there can be similarities between circular strategies. However, the main focus area differs. For example, “design for repair and maintenance” and “design for reuse” share similar design guidelines; the former focuses more on the exchangeability of parts, and the latter focuses more on the durability of parts, even though both share several similar guidelines. (c) Although there is no clear line between circular strategies and they might share some common design guidelines, the same design guidelines might slightly differ at the core and fulfillment levels. For example, “use durable and robust components and materials” is a common design guideline among “design for repair and maintenance” and “design for reuse”. However, in “design for reuse”, it is important that all components have the same durability, while in “design for repair”, it is not vital that all components have the same lifespan because faulty parts are designed to be removed and replaced. (d) A design guideline may simultaneously (positively and/or negatively) affect several circularity strategies or other design guidelines, although the nature and intensity might differ among them. For instance, “design using recyclable and secondary (recycled) materials” influences “design for recycling” and “design for remanufacturing”, although the effect on the latter strategy is lower. Additionally, “design using recyclable and secondary (recycled) materials” influences both “make it easy to clean the product and components” and “use durable and robust components and materials”. (e) Some design guidelines are generally applicable to several circular strategies, such as “focus mainly on functionality and quality performance” and “focus on fulfilling the customer’s requirements and value creation”, which are both core parts of any circularity strategy. However, both are more central to the “rethink” strategy than to the other strategies. (f) More design guidelines will be identified during the design process and analysis of a specific product concept. These guidelines might be added to

Table 2. (g) Facilitating end-of-use collection and transportation should be considered for a majority of circular strategies. (h) Design for recycling should be considered under all circumstances; as one product eventually fails completely after several lifecycles, recycling is its final fate. (i) There are consistencies and dependencies between the circular strategies. It is important to have a broad overview considering several circular strategies simultaneously when designing. One activity may make other circularity activities too difficult or expensive to carry out. The changes in design can be both major and minor, although the product’s function must be the same. Hence, the guidelines must be used comprehensively as a whole, and then specific design guidelines should be referred to (if needed).

6. Empirical Results

The proposed guidelines were developed through a back-and-forth process with several companies engaged in the project. However, only four companies have been included in the research presented in this paper because the authors had in-depth contact with these four companies for an extended period of time and with a specific focus on circular product design and development. The engagement in the guideline development loop at each company consisted of presenting the initial guidelines (from the literature search), tailoring them accordingly and trying them out within the product development process and for a new product/service (if possible). Afterwards, through several meetings and discussions regarding the companies’ product design and development and the application of guidelines, revisions, and additions to the guidelines were conducted. The end results and guidelines certainly differed as products and processes at each company were different.

The guidelines (

Table 2) have been designed to be used by key stakeholders working on product design and development, such as designers, engineers, research and development professionals, and product owners. It can also support a variety of functions within manufacturing, marketing, environmental management, and general management, as well as sustainable development and circular economy. Guidelines have been developed to map the circular product design initiatives of companies in the early stages of product design and development, although they can also be used for later stages of product design and development, where the product concepts and prototypes are already developed. However, in this respect, the purpose would be to evaluate the design in terms of circularity and revision and improve future designs. Nevertheless, this guideline is a means of supporting decision-making and enhancing the circularity of products.

The guidelines (

Table 2) were used at the studied companies for which the authors had in-depth contact for an extended period of time; this contact focused on their circular strategies and how to support the design and development of their products and services with increased circularity potential.

Table 3 presents the focal companies, their industry, and their main and secondary circular strategies. The selection of circular strategies at each company occurred during a half-day workshop with relevant stakeholders and was based on their business model innovation, environmental and circularity goals, and the nature of their products. The companies were certain to pursue a main circular strategy, while several secondary strategies were discussed simultaneously (consistent with point (i) in

Section 5).

Afterwards, when the relevant circular strategy at each company was discussed and selected, generic design guidelines were reviewed and discussed with relevant stakeholders during another half-day workshop. In this workshop, through discussion with stakeholders, the generic design guidelines were tailored, added or removed, or further detailed based on their product type, material used, product development process, environmental management system, environmental and circularity goals, adopted business model innovation, selected circular strategies, and production system. These design guidelines were then used (as the results are shown in

Table 4) to map the companies’ circular product design initiatives and to correlate them with circular strategies. The mapping procedure included going through the guidelines one by one and discussing them with stakeholders to see whether each specific guideline is now being applied/considered at the company. If the guideline has already been considered in the product design and development process, the purpose and correlation to circular strategies should have been specified. For instance, we asked, “Do you make your product out of recycled material?”; if the answer was yes, then we asked the following follow-up questions: “Why do you use recycled material?”, “How does using recycled material in your products contribute to the circular economy and circular strategies?”

A, B, C, and D in

Table 4 represent where each company adopted design considerations with regard to a specific circular strategy and a guideline. For instance, Company B considers using digitalization and information and communication technologies when designing and developing their products to not only provide their products as a service instead of selling them (rethink and reconfigure as their main circular strategies) but also to facilitate upgrades, repairs, reuse, refurbishment, and remanufacture (as their secondary circular strategies); see also

Table 3. Company B also uses digitalization and information and communication technologies to monitor the use phase of its products worldwide to enable condition-based and preventive maintenance to avoid product breakdowns or business slowdowns for several hours. Moreover, Company B, inspired by the developed guidelines and through several discussions, designed a coffee machine with a brewing tube on top as a module that enabled easy access to the exchangeable component with simple tools and in a nondestructive way. Components were also designed to be standardized across several models to ease the dismantling and exchangeability of components in terms of efficiency and time savings.

7. Analysis and Discussion

With a focus on repair and maintenance as their main circular strategy, Company A fulfilled ease of inspection, cleaning, accessibility, and dismantling to some extent, although further improvements are possible. It also now uses standardized components across several products and models and uses standardized tools for dismantling and assembly. Company A has very good control over incoming sourcing, in which renewable energy from hydroelectric power, renewable and environmentally friendly materials (e.g., PEFC-certified Scandinavian pine), and 20% recycled steel are supplied for production. Company A’s products are also designed for durability and longer lifespans through wood impregnated with natural linseed oil for protection against rot and hot-dip galvanized steel in liquid zinc to ensure rust-proofing and cathodic protection. The company also promises to supply spare parts for all its product ranges even after the production of a particular model ceases.

With a focus on rethinking and reconfiguration as its main circular strategies, Company B successfully changed its business model innovation and adopted a product-service system to deliver functionality and value to customers. Simultaneously, Company B managed to make several circularity improvements in its new product series, in which the majority of design guidelines were considered and included. The main circularity enabler of the new product series at Company B was the integration of information and communications technology (ICT) to monitor user behavior and product performance during the use phase. ICT empowered Company B’s products and services through condition-based and preventive maintenance. Consequently, products, components, and performance can be measured via online monitoring parameters such as vibrations, temperature and noise levels, and potential failures can be identified and prevented by exchanging parts before coffee machine breakdown. Furthermore, the new product series was designed by taking recirculation strategies into account through standardized components and tools as well as modular construction. The brewing tube on the top of the coffee machine is set as a module that can be simply and nondestructively opened via only two screws.

With a focus on remanufacturing as its main circular strategy, Company C reevaluated its designs and concepts to ease inspection, cleaning, and accessibility. There were several back-and-forth discussions on designing standardized components across several models and on the use of standardized tools to ease dismantling, although, ultimately, some glue had to be used in its products for technical and functionality reasons. Company C’s products are made of robust and durable materials as their customers are heavily dependent on the functionality of the product, and any slight failure has immediate and high health risk consequences. Company C is the only company among the four cases that firmly takes “laws and regulations” into consideration since their products are categorized as medical devices and must, therefore, follow strict standards, legislation, and regulations. In addition, due to the nature of the products of Company C and the fact that the product is in contact with the human body, particularly human skin, the environmental profile of the material and its toxicity and effects were rigorously reviewed.

Company D focused on the product use phase above everything else as its customers are professionals who use hand tools within construction and industry. Therefore, the design concentration was on functionality, reliability, precision, user-friendliness, and durability in all situations. Company D truly considered timeless design and product emotional attachment, where the tools must feel right in craftsmen’s hands at all times. Products from this company are manufactured to be durable to withstand different conditions and function for long lifespans. Within this research project, Company D also began initial considerations and evaluations to change the business model from sales to product-service systems (rethink and reconfiguration) since their products are reliable and durable enough. The initial design concepts for the new business model focused on modularity (e.g., with exchangeable knife blades), although no concrete change has been approved yet. However, Company D is less mature in the end-of-use phase of their products, since hand tools are difficult to collect from a variety of end-customers at different qualities and in different industries and since these products have lower prices than other cases presented in this paper.

Looking at the individual cells of

Table 4, where the circular product design initiatives of the studied companies have been mapped, it can be concluded that all four companies share three circular strategies and three guidelines as common approaches to circular product design. This can be seen in

Table 4, where the cells include “ABCD”. This finding shows that companies have already established systems where raw materials sourcing (in the form of the “raw materials and sourcing” strategy and the “using recyclable and secondary materials” and “consider toxicity and environmental aspects” circular design guidelines) and recycling opportunities are widely considered when designing (circular) products. The same reality can be pinpointed for the “durability and robust components and materials” for “product use and operation”. The main reason for the former can be existing standards, legislation, and regulations such as REACH and Roche, and black and gray lists for materials and chemicals.

While all four companies currently consider recycling as a vital scenario for their products’ fate (in accordance with point (h)), several other recirculation strategies are also being slowly taken into consideration, e.g., Company C focusing on remanufacturing and Company A focusing on repair and maintenance. Company B has the broadest consideration for recirculation strategies.

There are some circular strategies, such as “repurpose”, “manufacturing”, “cascade”, and “reinvent”, where no product design initiative can be found in the mapping results. The absence of the “cascade” can be attributed to the confusion among companies in distinguishing cascading and recycling. The absence of the “reinvent” strategy and its relevant guidelines are basically due to the nature of this strategy and of the studied companies and of their products, where the probability of an extraordinary innovative change to their products is extremely rare. The absence of the “repurpose” strategy can be linked to the fact that repurposing is usually an act of creativity where the end customer individually reuses the product in another way. Hence, this strategy is difficult to follow after the end-of-use phase. The absence of the “manufacturing” strategy concerns the delimitations of this research, where measuring production systems, manufacturing machines and equipment, as well as pre-consumer waste such as scraps was outside the scope of this study.

According to the mapping results, there is also an absence of design initiatives for material identification, for example, by codifying the components. Although the main reason for this lack needs to be further investigated through in-depth interviews with designers, it can be speculated that there are no standards, regulations, or mandates on marking materials with, for example, R codes or RFID technology.

As shown in

Table 4, Company B is the most active company that applies the most circular design guidelines and strategies. The main reason for this is that Company B changed its business model innovation (adopting product service systems), and while doing so, several product design changes (including circularity aspects) were also considered simultaneously. This is the best possible approach to move towards a circular economy, although it might not be practical for all companies to change not only their business model but also their products.

8. Concluding Points

Product design and development are key to moving towards a circular economy that affects different areas, such as the value chain, innovative business model, and waste management. However, circular product design and development have not been well established in the domain of the circular economy, and circularity aspects are not yet properly considered in the design phase. This paper presents a set of generic design guidelines and connects them to different circular strategies (

Table 1). The guidelines are then used to map companies’ circular product design initiatives in the early stages of product design and development. The guidelines have proved to support decision-making and enhance the circularity of products. Although the guidelines are generic in their current form, they can be used to identify more design guidelines during the design process and analysis.

A design guideline may simultaneously (positively and/or negatively) affect several circularity strategies or other design guidelines, although the nature and intensity of these effects might differ among them. Since there are consistencies and dependencies between the circular strategies, it is important to have a broad overview considering several circular strategies simultaneously when designing. One activity may make any other circularity activities too difficult or expensive to carry out. Hence, the guidelines must be used comprehensively as a whole, and then, specific design guidelines should be referred (if needed).

The results from mapping the current product design initiation at the studied companies show that sourcing raw materials, recycling, and ensuring the robustness of components and products for the use phase to make them last longer are the most common strategies used by the studied companies. However, there is a slow transition towards other recirculated strategies, such as repair, remanufacture, and reuse. In addition, changing product design to fit the business model innovation is the best approach to move towards a circular economy.