1. Introduction

One of the goals of the European Union (EU) is to stimulate the creation of a competitive low carbon economy that is able to provide a reduction of 80%–95% greenhouse gas (GHG) in Europe by 2050 [

1]. Energy production is an important sector where changes can be made in order to reach this ambitious target. Shifting from fossil-based energy to renewable sources of energy can lead to GHG reductions, provided the value chains for the renewable energy sources can lead to better overall environmental performance. A careful evaluation of new renewable energy pathways has previously been recommended [

2] and various studies have shown wide ranges for GHG emissions of renewable energy systems [

3,

4]. Moreover, and particularly relevant to biomass based renewable energy, in some cases lower GHGs are not accompanied by lower emissions of other environmentally concerning emissions, such as those contributing to eutrophication, acidification, and human/ecosystem toxicity [

5,

6]. Within the various renewable energy sources, biomass is important as in 2015 it already supplied 10% of the global demand for primary energy consumption [

7]. In Europe, demand for electricity biomass, heating, and transport was around 5010 PJ in 2012 and it is estimated to rise to 7437 PJ in 2020 in order to meet renewable energy targets in the EU. Thereby, it is important to consider additional renewable energy with holistic perspectives that can quantify the environmental performance of renewable energy from biomass resources. Life cycle assessment (LCA) is an internationally recognized, standardized tool with a mature methodology capable of assessing large systems and giving a complete assessment of environmental impacts [

8]. As such, LCA has been used widely and is aligned with the sustainable development goals (SDGs) developed by the United Nations [

9], which incorporate life cycle thinking into, for example, goal number 12 (sustainable production and consumption patterns) [

10]. Under the umbrella of SDGs, decoupling economic growth from the unsustainable use of resources is of prime importance so that future generations may enjoy precious natural resources. Thus, measuring progress towards these goals is necessary from both an economic and environmental perspective, which makes the use of mixed assessments necessary.

Out of the estimated 7437 PJ demand for biomass energy in 2020, 887 PJ are expected to come from biogas [

11]. Biogas production has increased significantly in the EU, from 92 PJ in 2000 to 654 PJ of primary energy in 2015, with a total of 17,400 installed biogas plants [

7]. Anaerobic digestion (AD) is a versatile technology for many reasons, one being that it is possible to install decentralized plants near agricultural sources of feedstock. In terms of biomass resources, AD can utilize various types of organic waste aside from agricultural residues, including industrial wastes such as slaughterhouse wastes and residues from food production, sewage sludge and the organic fraction of municipal solid waste. The produced biogas can be valorized in several ways, such as for heat and electricity production in combined heat and power engines (CHP); injection into the natural gas grid after an upgrade to biomethane; or use in the transport sector. It is at least in part due to this versatility that AD can serve as a successful platform for the bioeconomy. In addition, the latest developments in biogas technology expand the platform beyond energy into materials production [

12]. While some of the advances focus on optimizing energy extraction, such as wet explosion pretreatment aimed at unlocking the lignocellulosic fraction of waste [

13], or adding a separate dark fermentation step before methanization so as to increase hydrogen content of the biogas [

14], other innovation allows for the production of biopolymers via the modification of the AD process [

15]. By isolating the volatile fatty acids (VFAs) produced during the AD process and feeding them to microbes in a multi-stage process, intracellular polymer, such as polyhydroxybutyrate (PHB) of the polyhydroxyalkanoates (PHAs) family of biodegradable polymers can be produced and later extracted from the bacteria. In this way, it is possible to turn biogas plants into chemical platforms, which can expand the acting field of AD to new utilization and valorization opportunities.

Needless to say, biogas relies on available biomass and by definition is constrained to these finite resources. Various studies have focused on mapping out the availability of biomass in Europe for the production of energy and biogas [

16,

17,

18,

19,

20,

21]. Though the quantified potentials vary widely due to methodological selections and database choice, it is generally acknowledged that the extraction of biomass must be done with care to avoid competition with food resources and unwanted market effects, such as increases on land and maize prices [

22,

23]. Still, Scarlat et al. [

11] warns that even though domestic biomass supply in the EU is enough to satisfy the demand required to accomplish national renewable targets, as much as a quarter of the biomass demand may be sourced from third countries (outside of the EU) in 2020. Since this is due to market effects, it is imperative to take economics as well as environmental aspects into account so that the appropriate support systems are in place for the development of a sustainable renewable energies market and thereby a sustainable biogas sector. In this regard, it is important to determine if the emerging biogas innovations mentioned are environmentally sound and lead to environmental performance improvements in comparison to the status quo. As has been pointed out before, the prefix bio does not guarantee sustainability [

24]. Biogas capacity already built in Europe is an important aspect when analyzing any additional capacity that may be built in an area, e.g., considering that 50% of the EU’s biogas capacity is in Germany [

7]. As has been pointed out by Bojesen [

25] and colleagues, who estimated service areas for existing and future biogas plants in Denmark, the availability of feedstock in relation to plant location is an important aspect. An inadequate assessment of a plant’s sourcing ability may lead to high operation costs from increased transport demand or inadequate sourcing of feedstock [

25]. In turn, high transport distances may negate the environmental benefits brought about by biorefineries, as shown in Croxatto Vega et al. [

26] which applied the territorial metabolism-LCA approach (TM-LCA) [

27] and found distances of 50 km to be the upper limit.

This study performs a step-wise assessment starting from individual plant level and investigates the implementation potential of the PHB and AD-Booster technologies in two different plant scales. A techno-economic assessment (TEA) and LCA are carried out for this aim. The results from the TEA-LCA are used to structure implementation of the technologies at the regional level. The TEA relates the plant scale and processing capacity to capital expenditure (CapEx) and operational expenditure (OpEx) of the plant, and to the break-even prices of products. In the LCA, the environmental aspects of different technologies are quantified. The implementation of the two technologies is analyzed for two regions defined by the nomenclature of territorial units for statistics (NUTS) from Eurostat’s definition of regions (NUTS2 regions): Bavaria, Germany and Veneto, Italy. We analyze the potential impacts of the two innovative technologies (PHB and AD-Booster) against the current level of biogas implementation for the regions. First, we use TEA to analyze the effect of scale on the economic potential considering relevant plant sizes. Concurrently, we provide a mass flow analysis for the regions to better understand the energetic potential of agricultural residues produced within the regions (i.e., both the residues already in use for biogas and not yet exploited) as well as the level of development of the biogas sector (i.e., installed capacity). Finally, we use the results from the TEA of each technology to perform a TM-LCA, which will be able to tell us the possible environmental improvements (or deterioration) potentials for the whole region, if all of the residues are processed with the new technologies. We place special attention on the repercussions for the farmer, especially from installation of large biogas plants, which can potentially monopolize biomass resources over a large area. Vice versa, we explore the possible needs and constraints for biogas developers in the two regions. In this way, we seek to explore new biotechnological implementation potentials from a stakeholder’s perspective.

3. Results and Discussion

3.1. Regional Feedstock Availability and Potential Bioenergy Production

A complete table of the sustainable/technical feedstock potential is presented in

Appendix B,

Table A7, for Bavaria and Veneto. These amounts were used for the TEA-LCA as the regional feedstock mix, though with a 1% cut-off based on the energetic potential of the feedstock.

When graphed on a % wt basis (

Figure 4), a relatively large proportion of production of energy crops is evident in Bavaria. Both regions are rich in cattle manure and have a noteworthy amount of swine manure. After energy crops, the most abundant residues are cereal straw for Bavaria and sugar beet straw and soybean residues for Veneto. The regions notably differ from each other, in particular with regard to the production of certain crops, for example sugar beet, soya and grapes. The grapes, represented by pomace, are much more prominent in the Veneto region.

In comparison to Veneto, Bavaria has a much larger share of energy crops, mainly maize silage. This greater share of energy crops is explained by feed incentives given to biogas plants using energy crops in Germany during 2004–2008 [

82]. Although maize production has been capped by several German rulings, from 60% by mass input in 2014 lowered to 50% in 2018 and 44% by 2021, the combination of a high animal density and fodder production means that growing of maize has increased exponentially with unintended consequences, such as increasing land prices [

22,

82]. In Veneto, the feedstock mix exhibits more variability and the expansion of energy crops has not been as dramatic. This may likely be due to the Biogasdoneright™ concept promoted by the Italian Biogas Association, which originates in northern Italy, under which sequential crop cultivation is practiced, where the primary food crop goes to its intended purpose, and a secondary cover crop serves as feedstock for biogas plants [

83].

Nevertheless, in energy terms, the potential of the feedstock mix is different than the availability based on mass, mostly due to the poor methane potential of some of the feedstocks. Without subtracting the feedstock that is already being used in the installed capacity of these regions, the energetic potential (based on electrical power) is seen in

Figure 5. The largest share of potential is dominated by different feedstocks in the two regions. In Bavaria, the largest share can be obtained from energy crops, while in Veneto the largest share can come equally from cattle manure or energy crops. As a rough estimate, 153 PJ and 38 PJ remain as unexploited feedstock. This represents 31% and 54% of the total available feedstock potential, in Bavaria and Veneto, respectively, which is estimated as described in

Section 2.3.4. However, for the LCA, all of the feedstock in the region was assumed to be utilized by the technologies, since in theory biogas plants can be retrofitted with the additional equipment needed for implementation of the AD + Booster technology and PHB production.

3.2. TEA Results

Based on the technical description of the different technologies and the different feedstock compositions, the flow sizes, flow compositions, production of electricity, heat, and crude PHB were estimated. Linking these process parameters to the economic parameters results in the TEA in

Table 8.

In all scenarios, the financing, maintenance, labor-related, and feedstock costs are in the same order of magnitude. The contributions of these cost aspects to the total cost vary between 19% and 34%. The small-scale scenarios have, relative to annual production, a larger CapEx compared to the industrial scale, therefore financing and maintenance costs increase the break-even prices for the small-scale scenarios. This results in a break-even price are 34% higher for electricity and 27% higher for crude PHB for the small-scale scenarios, compared to the industrial scale scenarios. As all cost aspects are in the same order of magnitude, the extra required labor in the AD + PHB scenarios results in a significant contribution to the total costs. Logically, the extra labor related costs increase the break-even price of crude PHB. Compared to the feedstock costs of the studied plants, the regional level feedstock in both Bavaria and Veneto have a slightly higher contribution to the costs and to the break-even prices. In the Bavaria scenarios, the revenues of the thermal energy cause a reduction to the break-even prices of 8% for the small scale and 6% for the industrial scale, relative to scenarios that do not utilize the thermal energy.

For the 1 MW AD plant scenarios the average estimated break-even price for electricity is €0.22/kWh. For the AD + Booster scenarios, the average estimated break-even price for electricity is €0.19/kWh, a reduction of 12% in comparison to AD alone. Using the break-even for electricity of regular AD in the AD + PHB scenarios results in an estimated break-even price for crude PHB in the range €4.3/kg to €4.7/kg. When the purification costs of €1.8/kg are included, the break-even price range for PHB is in the range €6.1/kg to €6.5/kg. Due to the difference between market price and the break-even prices, as outlined in

Section 2.4 (

Table 6), it is clear that both electricity and PHB require large subsidy contributions to be profitably produced in AD plants. Relative to their respective market prices, the required amount of subsidy for the production of PHB is smaller compared to the subsidy for the production of electricity. Nevertheless, the production of PHB requires the co-production of electricity (

Table 8).

3.3. LCA Results

3.3.1. Midpoint Results

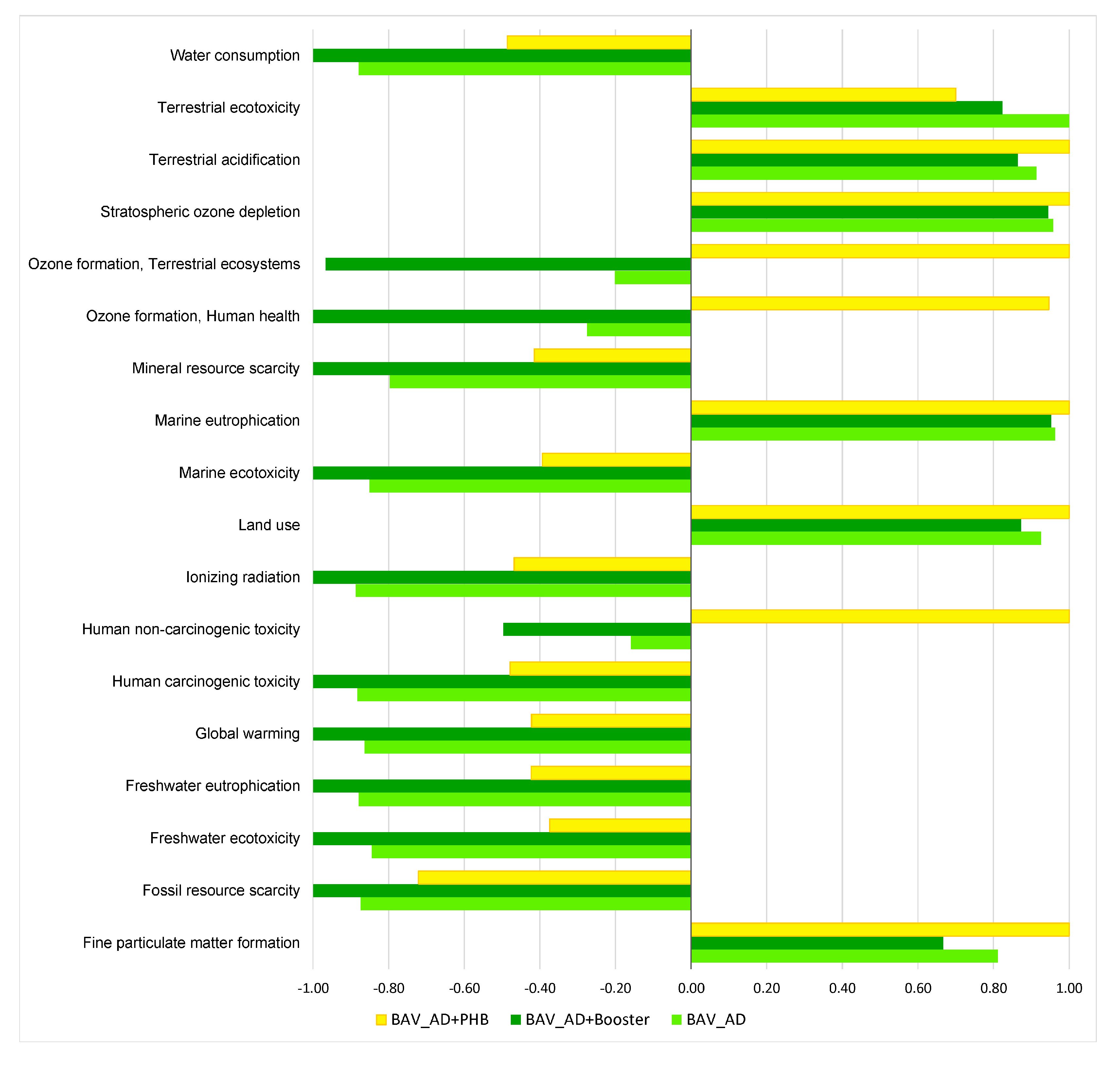

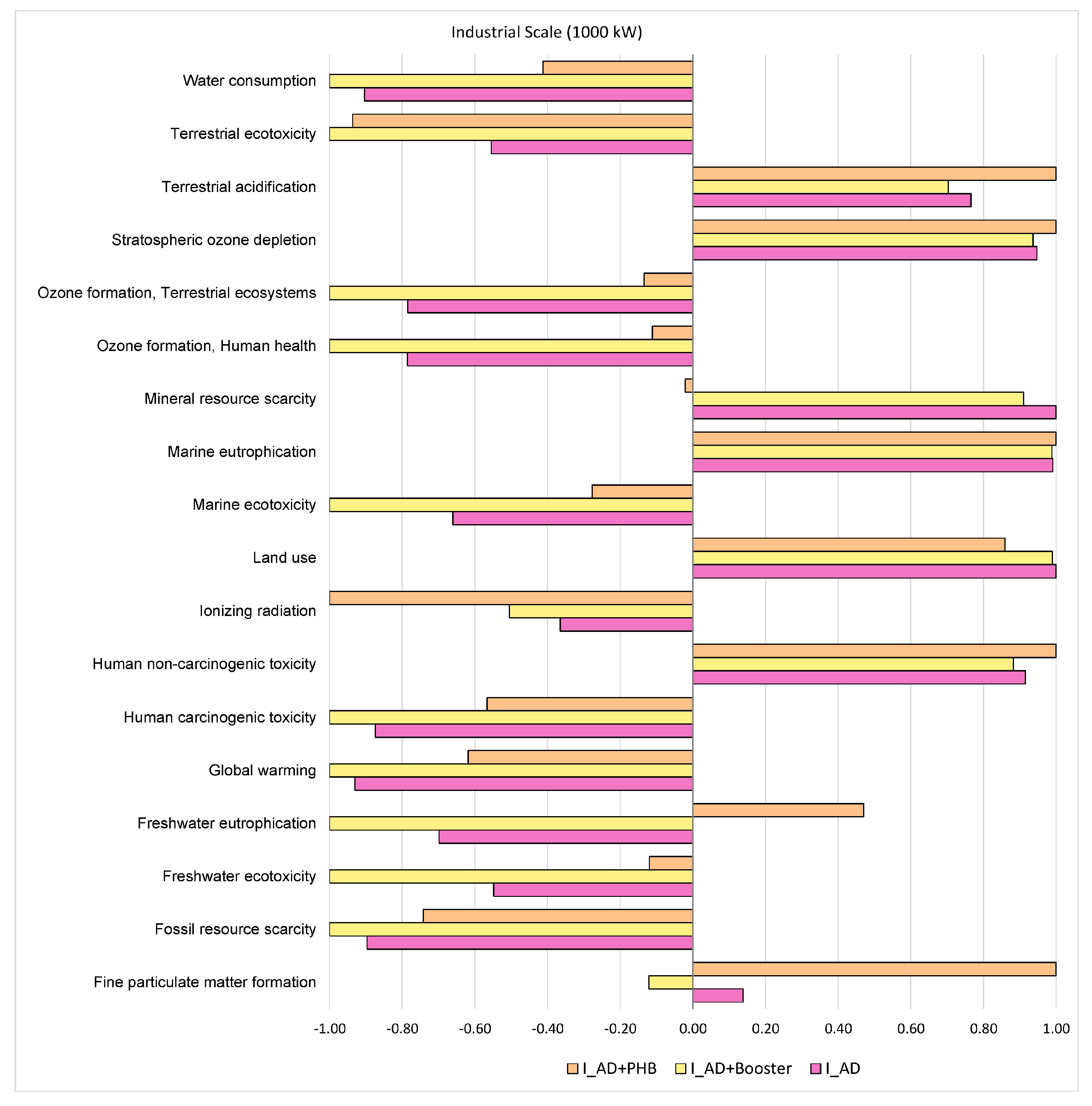

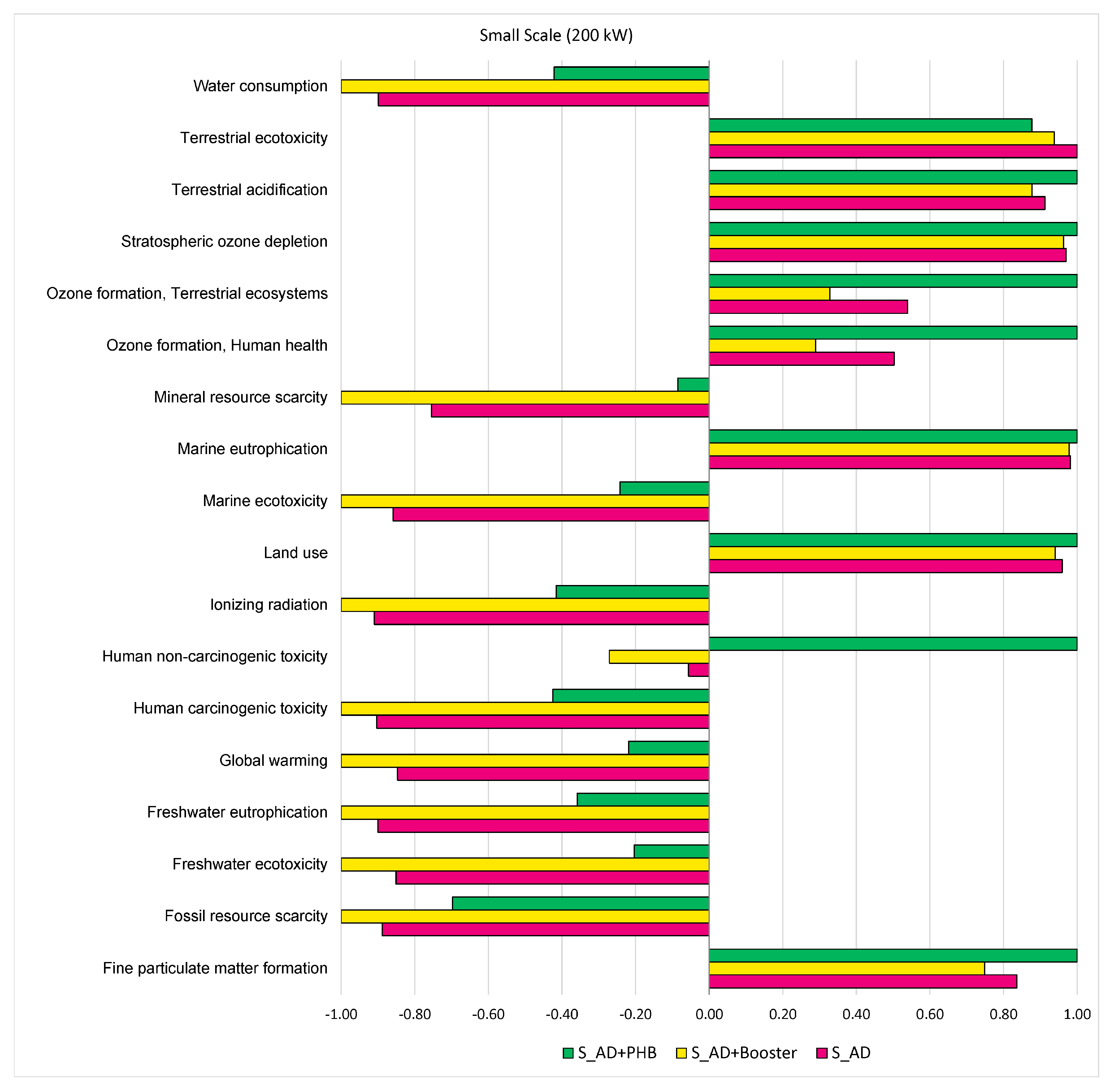

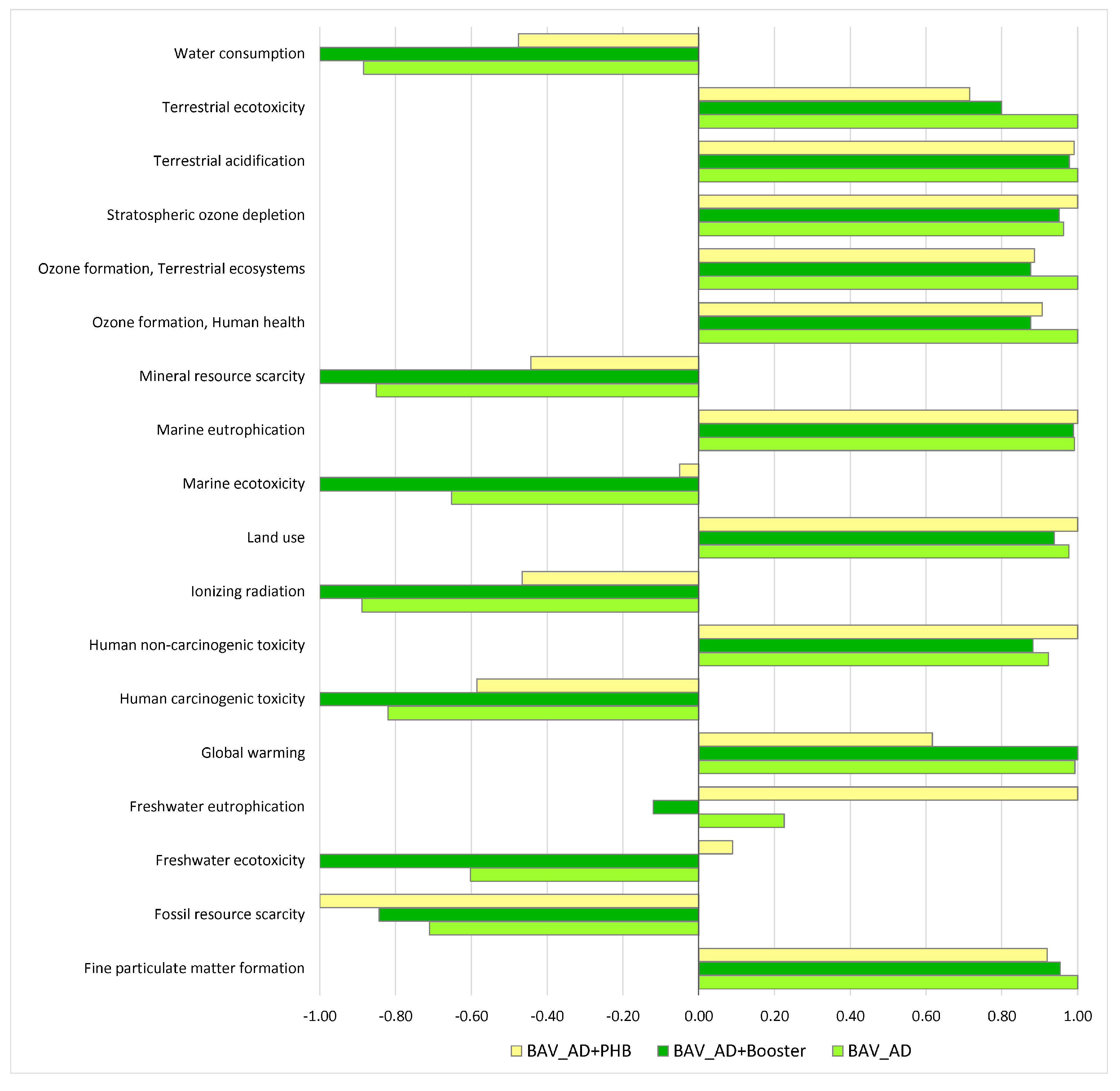

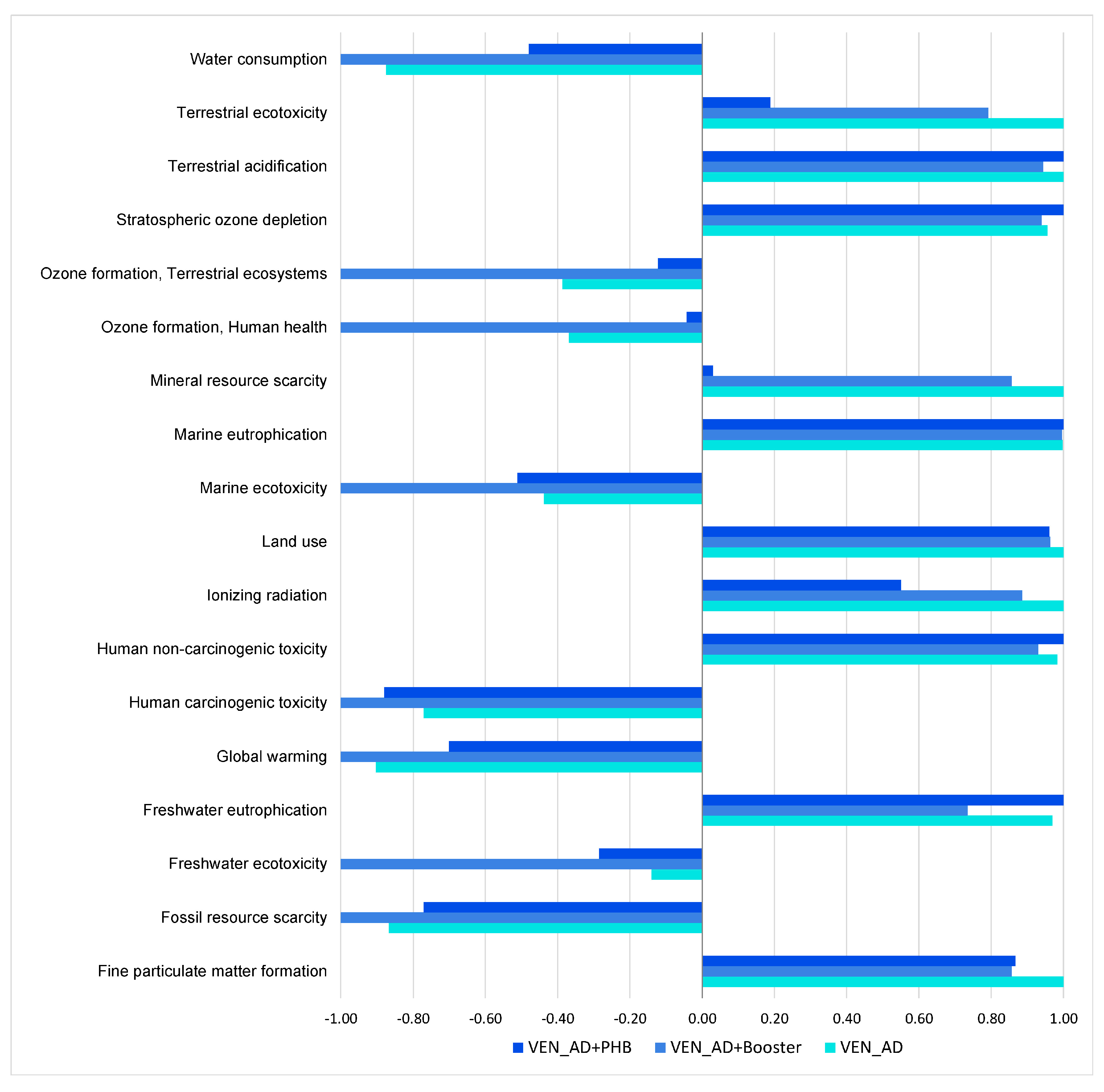

Results were obtained both at midpoint and endpoint level, using the ReCiPE 2016 (H) LCIA methodology. The results were internally normalized and ranked relative to the best-performing technology scenario. Midpoint level results for both regions and scales showed, for the most part, the same technology preference, pointing to AD + Booster as the best performer across impact categories (ICs), followed by AD and lastly AD + PHB. In the Veneto region, slightly more variation is observed across impact categories (

Figure 6) and AD + PHB can at times be the best performer, as seen in the Ionizing Radiation, Land Use, and the Mineral Resource Scarcity ICs. The importance of this variation was tested with TOPSIS and is discussed further in

Section 3.4.

Midpoint results for the two farms assessed the small scale 200 kW farm in Bavaria and the 1000 kW farm in the Veneto region showed identical preference to the regional assessment when ranked within geographical location. However, more rank switching is observed when ranking is done across scales; this is explored further and discussed in

Section 3.4., where rank reversal is checked thoroughly for both regional and scale assessments. Figures of normalized midpoint impacts for the Bavarian region, small and industrial scale are shown in

Appendix B (

Figure A1,

Figure A2 and

Figure A3), as well as tables of raw midpoint/endpoint results (

Table A8,

Table A9,

Table A10 and

Table A11).

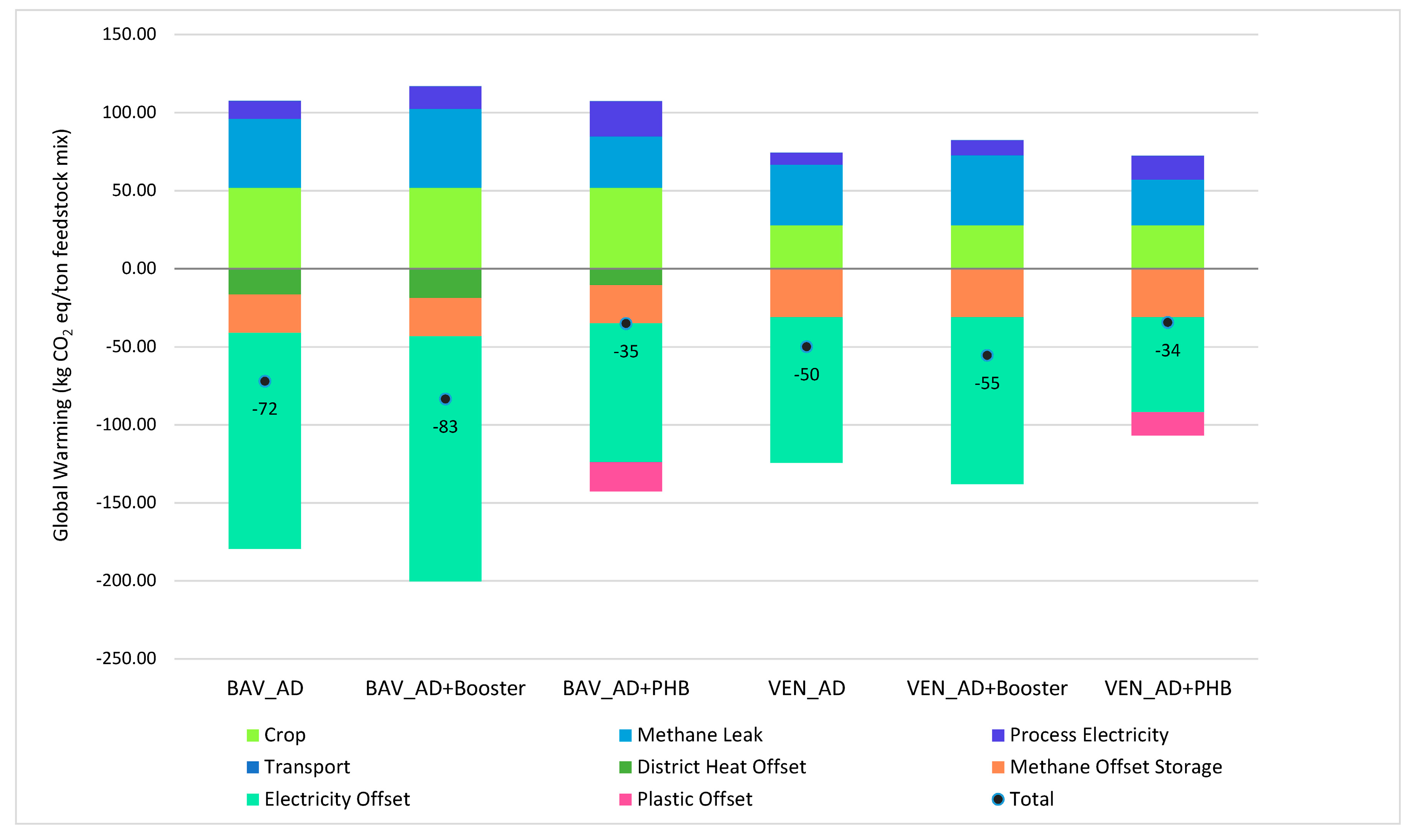

3.3.2. Global Warming

As mentioned previously, global warming potential (GWP) shows the same technology preference as other ICs, with AD + Booster performing better than AD, which in turn performs better than AD + PHB. Looking at the contribution to GWP from the various elements that make up the system, it is possible to understand this preference. As can be seen in

Figure 4, the higher energy production of the AD + Booster induces a higher electricity offset, which is largely responsible for the technology preference exhibited by the results. It is also evident that the offset for substituting plastic in the market for the AD + PHB options is very moderate and occurs on account of lower energy production, resulting overall in the lowest GWP savings out of all technology options.

Figure 4 also shows the difference between the two regions on a per ton feedstock mix basis. An important difference can be observed in the crop mixture used for each region, where it is evident that Bavaria uses a more burdensome mix than Veneto. Other than crop differences, methane leaks from the facilities, here assumed to be 3% of the biogas produced, is an important source of GHGs. This is worth noting, as it can diminish the savings intended by these technologies. On the other hand, an important savings is attained by degassing animal manures, which would otherwise sit in storage facilities for a longer period producing methane that would be released to the atmosphere. This benefit can be seen in

Figure 7 as the “methane offset storage” and is higher for Veneto due to the higher availability of animal manures on a %wt basis in this region.

Figure 8A,B, shows total GWP savings for both Veneto and Bavaria, respectively. As a total, the Bavaria region is capable of obtaining GWP savings 7.4, 7.7, and 5.4 times higher than in the Veneto region for AD, AD + Booster, and AD + PHB, respectively, on an annual basis. This is explained in part by the scale of the regions, feedstock density of the regions, as well as the energy density of each feedstock employed in the mix. While Veneto is also the smaller of the two regions, the lower GWP savings are partly due to an average 25% lower feedstock mass production per area relative to Bavaria. Moreover, the regional feedstock mix in Bavaria contains ca. 7% more crops and crop residues, among which maize silage is a prominent one, whilst Veneto contains ca. 7% more animal manures, which have a low methane/VFA productivity. The feedstock mix of Bavaria results in a higher electricity offsets, even though its feedstock mix contains a higher share of primary production (1st Generation) feedstock, i.e., maize silage, rather than secondary production such as straw. In addition, the utilization of waste heat in the Bavarian system for district heating gives an extra considerable impact offset to the region. If the heat were to be utilized in Veneto, then an extra 23%–25% savings in GWP could be attained there.

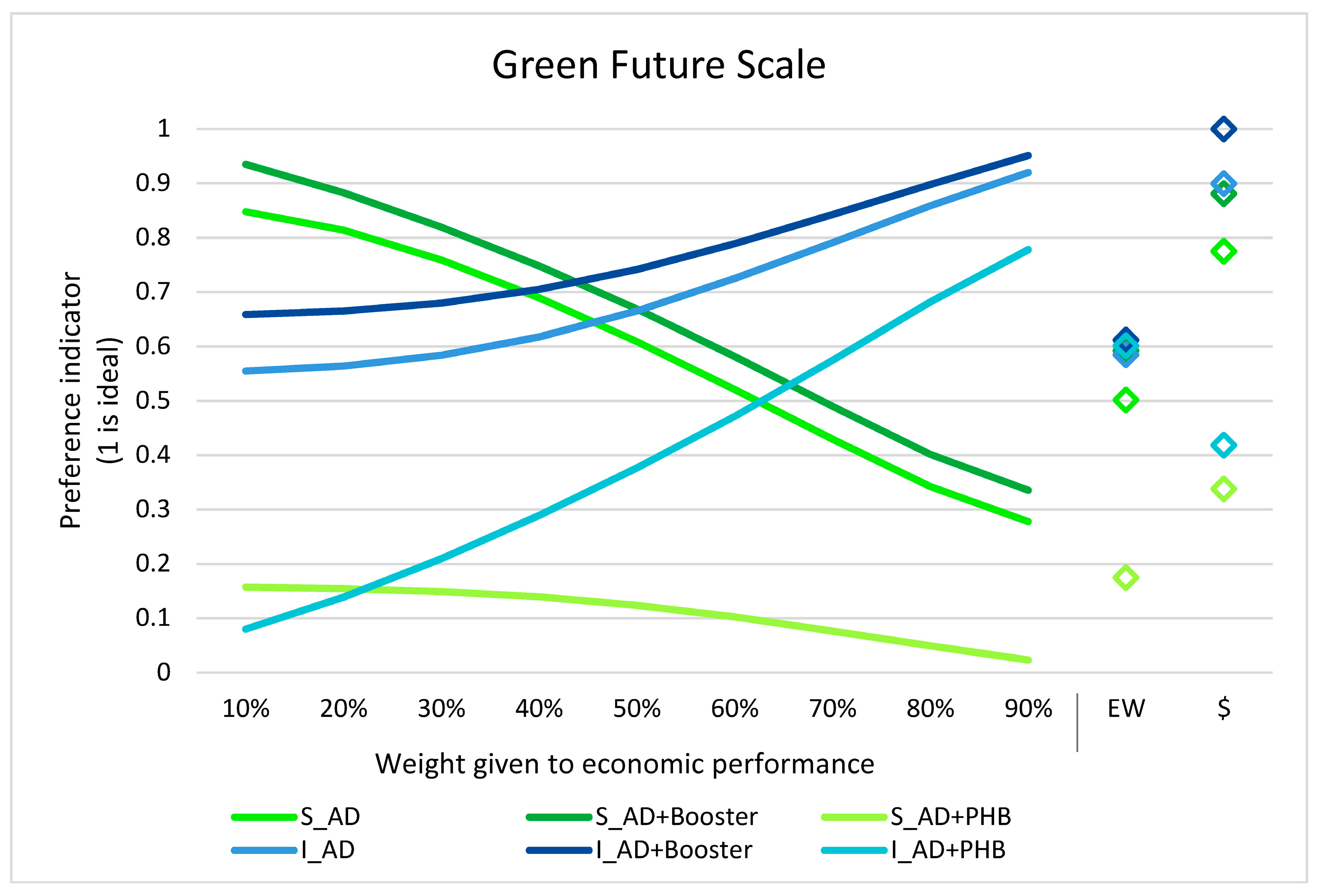

The pattern of feedstock efficiency is repeated when comparing the technologies on a scale basis. In fact, using more energy dense feedstock, i.e., feedstock that has a higher methane potential, leads to higher GWP savings for the small-scale facility (S + technology scenario), on a per ton feedstock basis, than for the industrial scale (I + technology scenario) (

Figure 9). This is true even though the feedstock mix used in the small scale is more burdensome in terms of GWP, due to the cultivation phase of the feedstocks. The industrial scale facility still incurs savings to GWP, albeit lower, due to the poor characteristics of the feedstock utilized, which in this case is ca. 80% cow manure. Technology preference largely stays the same for both scales, though it is worth mentioning that a friendlier feedstock mix, i.e., with less first generation feedstocks, such as the one in the industrial scale is more important for the AD + PHB option, as can be observed when comparing S_AD + PHB and I_AD + PHB, which have savings of −15 and −25 kg CO

2 eq/ton, respectively.

3.3.3. Sensitivity

Two parameters were tested to assess the sensitivity of the results: transport distance of the feedstock and the effect of a theoretical future green energy mix in the system.

The effect of transport varies depending on how well the technologies perform. The initial results, which include a 1 km transport distance were varied and transport was added up to 100 km. The result can be observed in

Figure 10, where it is evident that a further transport distance can be allowed for the AD + Booster technology in both regions since this is the best performing technology. The point at which each technology scenario goes from GWP saving to GWP burden can also be seen in the graph. This point (the y-intercept) is 86, 99, and 42 kilometers respectively for BAV_AD, BAV_AD + Booster and BAV_AD + PHB, in Bavaria. In Veneto these distances are lower, because of the lower performance of the technologies in this region, where a transport distance below 59, 65, and 41 kilometers for VEN_AD, VEN_AD + Booster, and VEN_AD + PHB respectively, would ensure that the technologies continue to induce GWP savings. Needless to say, the lower the transport distances for the feedstock, the better the technologies perform.

The effect of switching the current production mix for the provisioning of process electricity and electricity offset with a future energy mix mainly composed of renewable sources is substantial for GWP results. For the regional assessment in Bavaria, all technology options result in impact burdens for GWP, while they continue to be impact savings for Veneto (

Figure 11). This is due to the feedstock mix emissions in Bavaria, which are no longer counterbalanced by high emissions savings from offsetting of electricity. As has been shown before [

26,

84], offsets from replacing GHG intensive sources of electricity production such as coal, diminish as ‘green’ energy sources are implemented in the energy grid. The implications of this are very important for technologies producing renewable fuels, as their potential to produce savings will be bound to this future component.

On the other hand, BAV_AD + Booster, which is the worst performing scenario in terms of GWP continues to be the best performing scenario for most other impact categories in the green energy future SA (normalized midpoint results in

Appendix B,

Figure A4 and

Figure A5). As this clearly points to burden shifting the results were subjected to two single indicator interpretation methods to clarify the results.

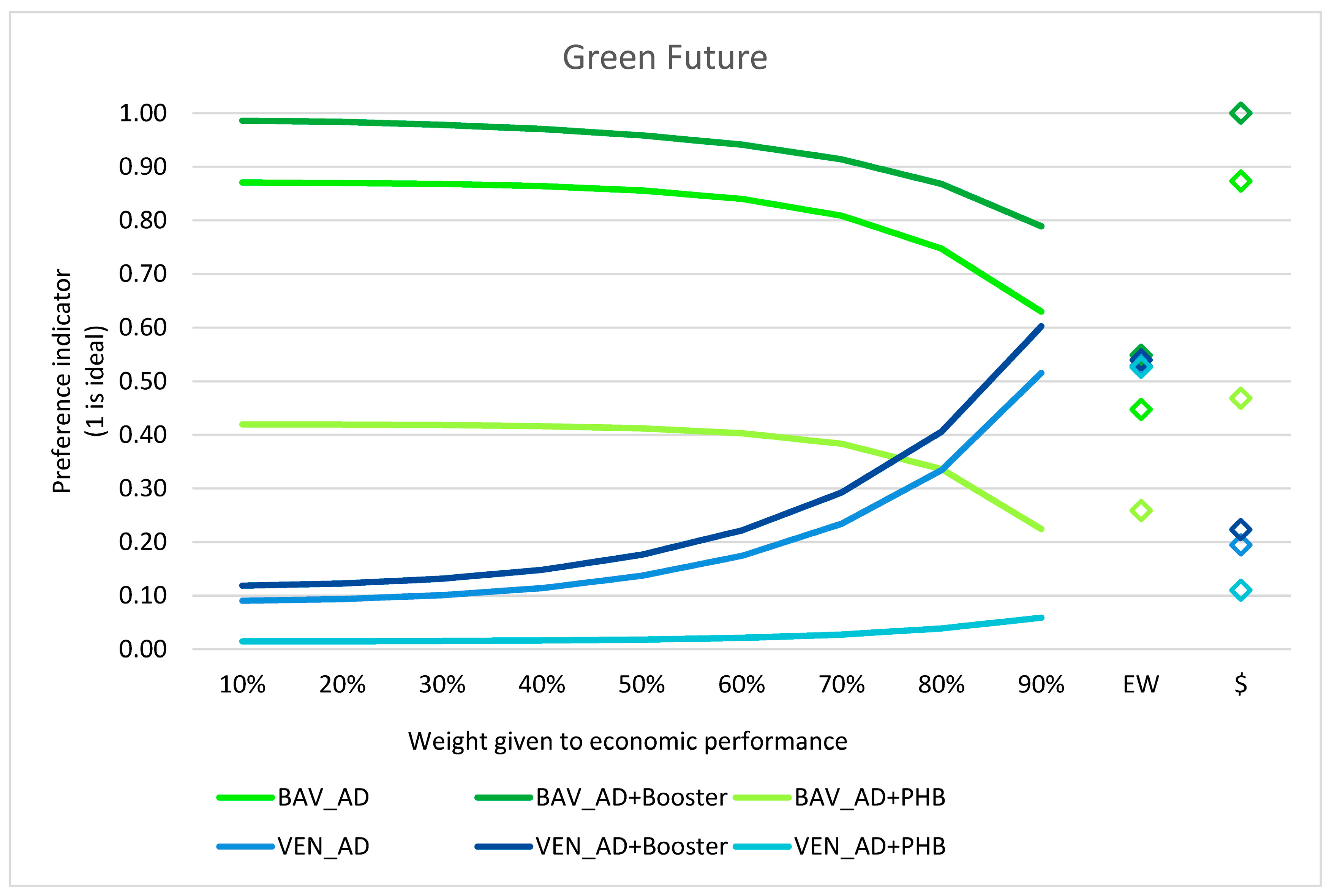

3.4. Single Score Interpretations

Single score results, via TOPSIS developed by applying the ArgCW-LCA methodology [

75], with environmental weights relating the results to a European’s consumption patterns, and an economic weight derived from the TEA are discussed in this section. When assessed through TOPSIS (

Figure 12), the initial regional results are very clear. Technology preference does not change within each region no matter which weighting is given to the results. AD + Booster is always the preferred choice, whether there are equal weights and high or low weight is given to economics. Furthermore, when impacts are monetized (

$) so that the costs of environmental protection are visualized, these results also agree with the ArgCW-LCA and equal weights (EW) TOPSIS results. From the figure it is clear that the AD + Booster is also the best performer in terms of economic preference in Veneto (going up to 90% econ level), and on the contrary AD + PHB appears to be the worst. However, it is worth noting that in the Veneto region, if environmental concerns are weighed more heavily (<55% econ level), it is not easy to single out one of the technologies as unequivocally the best performing option, since the results perform close to equally well. This is not the case for Bavaria where the more burdensome feedstocks result in a more indisputable preference for the AD + Booster option, which produces the most energy. The implication of these results, namely that the more burdensome the energy production is, the more important the energy offsets become, is even more obvious for the plant level assessment. Here we see that though the technology preference is always the same (AD + Booster > AD > AD + PHB), the relative difference between the options becomes smaller the higher the economic weight (approaching 90%) for the Industrial plant in Veneto. This is a different pattern than the one observed for the regional level, where the distance between options, with and without PHB, increases with economic weight, and as supported by the assessment of midpoint results, the technology scenarios are closer to each other when the feedstock mix contains more animal manures than crop residues (see

Figure 9). The same trend is seen for the small-scale plant in Bavaria, where the distance between the AD + Booster and AD + PHB option decreases with increasing economic weight. Though in this case, the plant’s economic performance, which is very low in comparison to the industrial plant, is an important factor pulling all technology options further from the ideal.

The green energy future sensitivity was also checked with the single indicator methodology. The results again showed to be robust in terms of technology preference for the assessment (

Figure A6 and

Figure A7). It is important to point out, however, that if the decision was based solely on GWP, then when looking at the green energy future one would choose AD + PHB in Bavaria, but continue to choose the AD + Booster in Veneto (

Figure A6,

Appendix B).

Overall the results are robust, though some clear patterns emerge. The single indicator results clearly highlight the dependency on the energy extraction efficiency of the options, which have increasing importance for regions with a more burdensome production, i.e., in the cultivation of energy crop for biogas production (the BAV and S scenarios). In this case, the electricity offsets are very important, not only for GWP, but all impact categories considered in an LCA, as evidenced by the single indicator preference. There are trade-offs when production utilizes a higher share of energy crops. On the one hand, electricity production is higher and with today’s electricity mixes offsetting this type of production is highly valuable. On the other hand, it is worth noting that sustainability criteria for biofuels and biomass fuels might limit this type of production even more in the future. As it stands today, the renewable energy directive II sets out a cap on energy crops for renewable fuels and national caps are also present in various member states. The EC has also singled out feedstock of high potential for indirect land use change (iLUC), so that renewable fuels do provide the GHG reductions they are meant to bring. Though small plants are exempt from this cap (ca. <500 kW electric), one needs only to look at the German case, where around 50% of plants are small, as an example of how many small biogas plants can in fact have large consequences for how agricultural land is used.

The assessment also shows that varied production, i.e., not only energy, can be a viable option for plants with a high content of manures in the mix. In a future with an optimized PHB production this might be even more beneficial, also if we are to avoid the impacts of microplastic pollution, which are yet to be included in LCA studies. For now, strong subsidies are needed to increase technology penetration in the market with constant revision on sustainability targets. Continuing to green the energy grid should be a top priority by making as much energy as possible and fomenting technologies that increase the energy that can be obtained from biomass (like the AD booster). Future research on the possible synergies between technologies such as the AD-Booster + PHB could be interesting to explore.