Firstly, the causal relationship and causal weight of each index were learned through the fuzzy cognitive graph method. Secondly, the ingress and egress of the indicators were calculated according to the adjacency matrix of the fuzzy cognitive graph to obtain the structural relationship and influence degree between the indicators. The next step is to analyze the indicators and choose a decision path. Finally, the sensitivity of each path index is calculated, and the key index and the key path are determined.

The fuzzy cognitive map method has been widely used in economic systems, management decision-making, stock analysis, policy analysis, and control systems. Applying a fuzzy cognition map to study the influencing factors of the Shandong chemical enterprise’s transformation and upgradation, we can use fuzzy logic for clear and intuitive expression of the causal relationship between influencing factors. This article uses FCM interpretation and feedback to mitigate errors caused by expert experience and knowledge.

STEP1: Determine the indicator system and establish a model of the influencing factors on the transformation and upgradation of chemical enterprises.

STEP2: Collect time-series data and perform equalization and normalization.

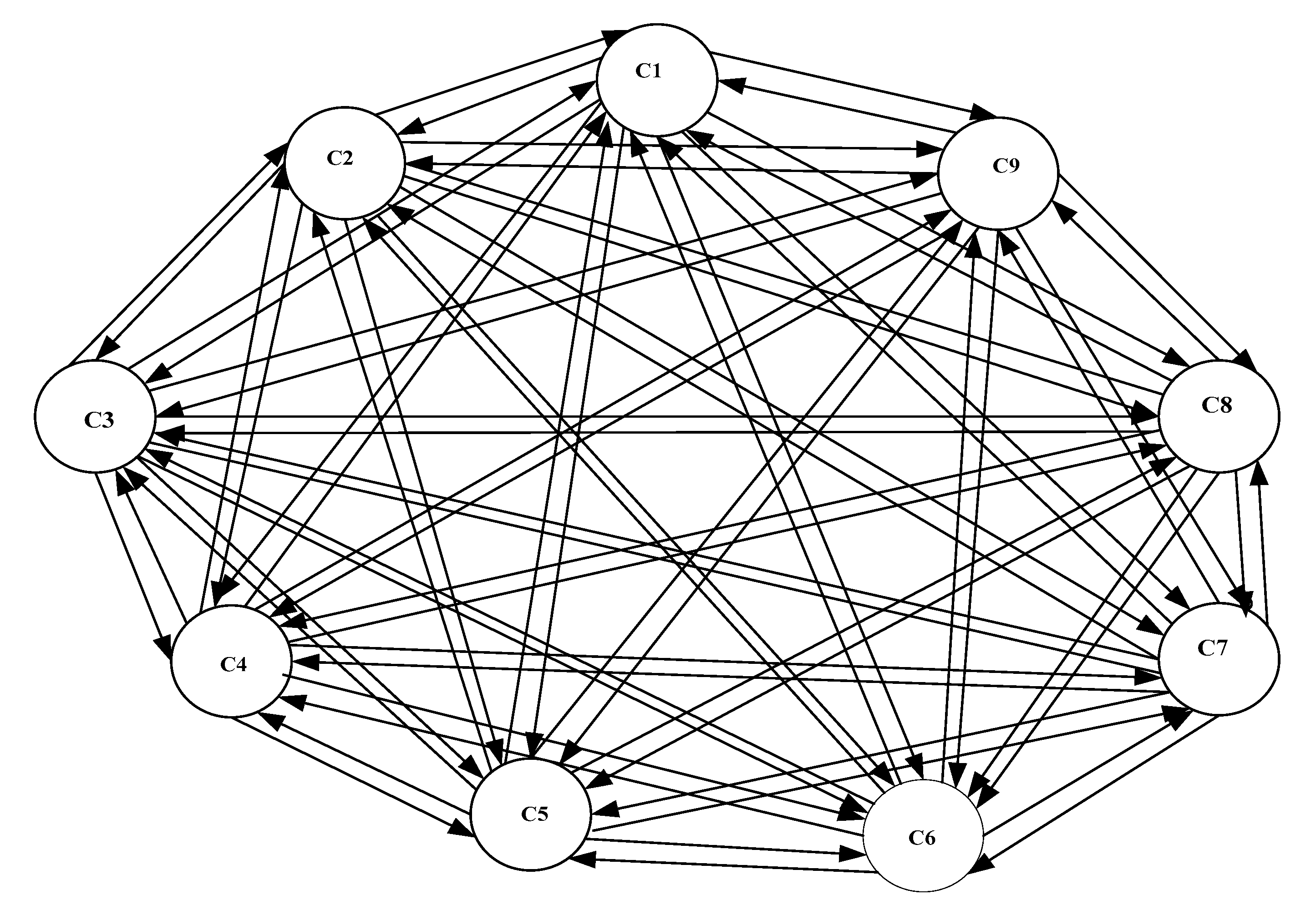

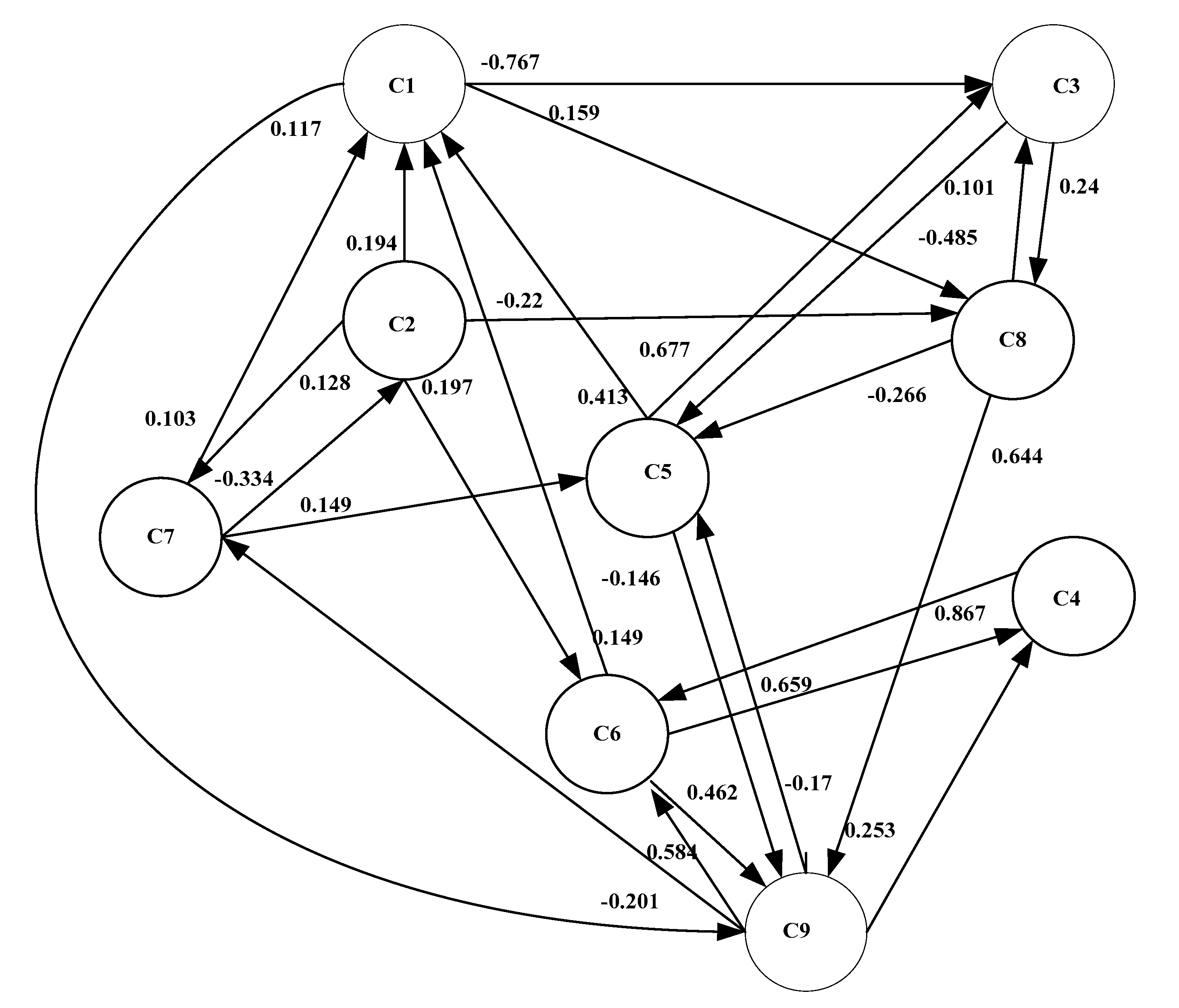

STEP3: The genetic algorithm is used to solve the relationship weights. A fuzzy cognitive map is drawn to reflect the interaction between the indicators.

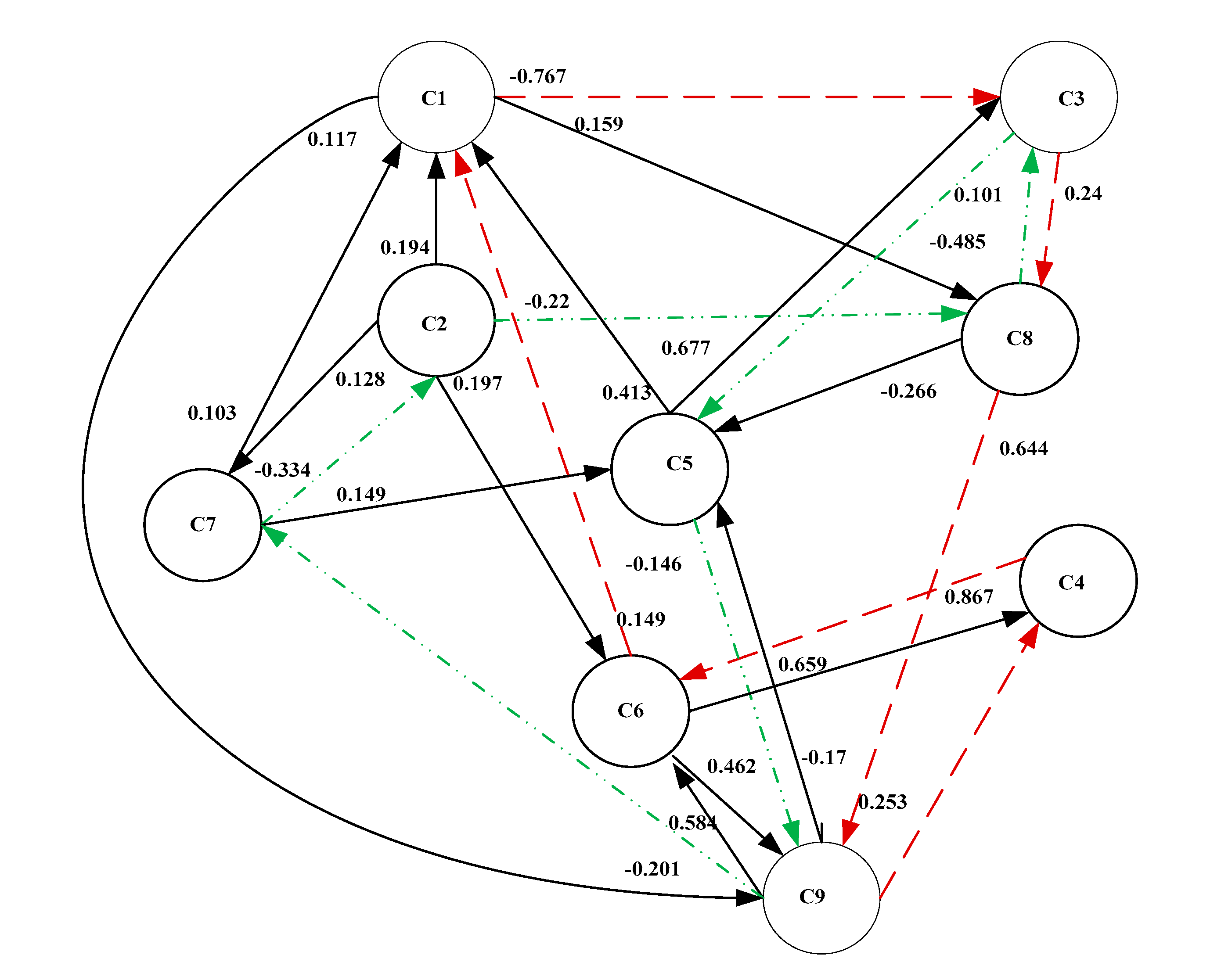

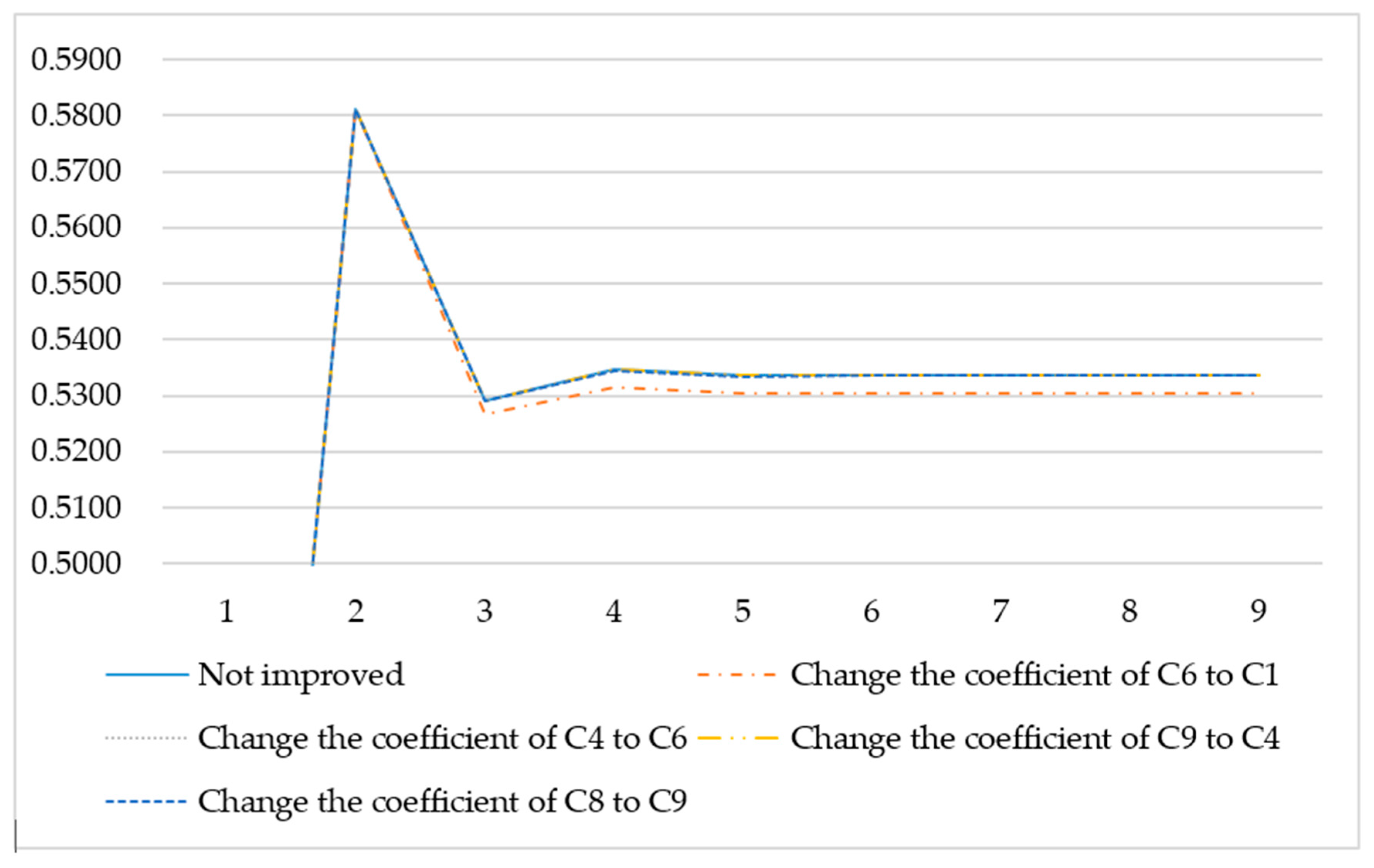

STEP4: Calculate the ingress and egress of each indicator, determine the system goals, and choose the path of transformation and upgradation.

STEP5: Perform sensitivity analysis on each indicator to determine key indicators and critical paths.

3.2.1. Building an Indicator System

According to the previous research and the “Notice on Printing and Distributing the Overall Work Plan for the Special Action for the Transformation and Upgradation of Chemical Industry Safety in Shandong Province” issued by the General Office of the Provincial Party Committee, this paper considers economic benefits, technological innovation capabilities, green environmental protection, and policies. It establishes an indicator system that affects the factors that transform and upgrade enterprises in Shandong’s chemical industry.

Economic benefits reflect the relationship between GDP and production costs. These are the main objectives of investment project production and operation. Economic efficiency is the key to measure the core competitiveness of an enterprise. Improving industrial efficiency means improving investment efficiency and resource utilization efficiency, which is also the goal of enterprise transformation and upgradation. Zhang [

32] uses the total industrial output value, leading business income, and overall profit to reflect the economic benefits of the company. Wu [

33] and Lu [

34] studied the impact of ROI on commercial interests. Ye [

35] believes that the ex-factory price of industrial producers is an important indicator reflecting the price level and trend of industrial enterprises. Additionally, according to their study, it can also indicate price gain and industrial booms. According to data collection and the actual situation, this paper selects the total industrial output value, leading business income, return on investment, and industrial producers’ ex-factory price to represent the economic benefits of the enterprise.

The work plan emphasizes strengthening the construction of modern enterprise systems, improving the level of process technology equipment and products, and achieving innovative development, transformation, and upgradation. Many scholars believe that innovation ability is the source of the core competitiveness of enterprises. Innovation is the driving force for the transformation and upgradation of enterprises and is the critical measure to realize “Made in China” and “Create in China.” A company’s ability to innovate is often measured by quantitative indicators such as R&D expenditures, R&D activities, number of patent applications, and gross industrial output [

36,

37,

38]. As a traditional process manufacturing enterprise, the chemical industry needs innovation to drive its development. Due to the limitations of the data, the innovation indicators selected in this paper are R&D expenditures and R&D activities. R&D expenditure is an important indicator reflecting the scientific and technological strength of the chemical industry and an essential basis for improving the core competitiveness of enterprises. The number of R&D personnel reflects the input strength of innovative resources from the perspective of human resources.

The highly polluting and energy-intensive industries in the chemical industry and the development trend of the contemporary green economy have led to a green transformation, which will ease the pressure on resources and environment while ensuring steady growth in output value. Xu [

15] explored the relationship between energy consumption, emissions of three wastes, and total industrial output value. He believes that with the change in industrial output value, material consumption and pollutant emissions will change in the opposite direction. Therefore, in terms of environmental protection, this paper selects two indicators of energy consumption coefficients and environmental consumption per unit of output value.

Government intervention is also of considerable significance to the success of enterprise transformation and upgradation. However, the policy and its impacts are challenging to quantify. This paper selects the loan benchmark interest rate to study the effects of government policies on enterprise transformation and upgradation.

Selected in this paper are industrial gross output value, primary business income, energy consumption coefficient, R&D personnel, producer ex-factory price index, R&D expenditure private expenditure, loan benchmark interest rate, and investment return. Rate (ROI) and unit production value consumption encompass nine indicators. The established indicator system and the explanation of each indicator are shown in

Table 1:

3.2.3. Data Collection and Processing

To ensure the integrity and authenticity of the data, this paper takes the data of Shandong as an example to study the influencing factors and path of the transformation and upgradation of chemical enterprises. Combining the data of the Shandong Statistical Yearbook, we replaced the chemical industry data with data on five industries: petrochemical; coking and nuclear fuel processing; chemical raw materials and chemical product manufacturing; pharmaceutical manufacturing; chemical fiber manufacturing for rubber and plastic products. According to the indicators of transformation and upgradation of chemical industry enterprises formulated in the previous section, the data from 2001 to 2016 was obtained from Shandong Statistical Yearbook.

1. Equivalence calculation

Funds have time values, and at different times, they have different values. This is why they cannot be directly compared. Therefore, the index data for leading business income and other monetary amounts are equivalently converted based on 2001 currency values. The calculation method is as follows.

The total industrial output value is based on the producer’s appearance price index, because PPI is the price factor that constitutes the total industrial output value. The industrial output values of other years are then adjusted to the base year level. The entire industrial output value of the base year is

, the total industrial output value of the year is

, the producer price index of the producer in the base year is

, and the producer price index of the producer is

. The formula for calculating the total industrial output value of the year is:

The internal expenditure of R&D funds is based on the GDP deflator. The internal expenditure of R&D funds in other years is the base year level. The internal expenditure of the benchmark R&D expenditure is

. The internal expenditure of the R&D expenditure for the year is

, the benchmark GDP deflator is

, and the GDP deflator for the year is

. The internal expenses of R&D funds for the year were:

2. Normalized Processing

The normalization process aims to remove the dimension and harmonize the evaluation criteria. The normalization formula used here is:

where

represents the normalized value of the original data;

represents the original data value;

represents the maximum value in the raw data of the indicator, and

represents the minimum value in the raw data of the indicator.

3.2.4. Solving the Relationship Weight

Natural genetics, initially inspired by the origins and principles of genetic algorithms (GA), performs optimization and search tasks in many problem areas. Genetic algorithms have many characteristics such as adaptability, parallelism, global optimization, randomness, universality, etc., and have great potential in solving complex problems, especially NP-hard problems and adaptive design systems. Real-coded genetic (RCGA) algorithm is an extended algorithm of genetic algorithm (GA). Processing function optimization is an essential direction of genetic algorithm application. Since real-coded coding does not require codec decoding, it is closer to the problem, and it is easier to combine with other search techniques. Therefore, processing function optimization is increasingly using real-coded genetic algorithms [

39,

40].

1. Chromosome Structure

RCGA defines each chromosome as a floating-point vector. Its length corresponds to the number of variables in each problem. Each element of the vector is referred to as a gene. With FCM learning, each chromosome consists of N(N–1) genes, which are floating-point numbers from the range [−1, 1], defined as follows:

C represents a chromosome; is a gene on a chromosome.

Each chromosome must be decoded back to the candidate FCM. This process involves copying the weight values from the chromosomes into corresponding units in the connection matrix, which defines the connection matrix of the FCM model. The number of chromosomes in the population is constant for each generation and is specified by the population size parameter.

2. Reasoning Mechanism

The state of the FCM model is determined by the value of the concept node after iteration t times. The initial state vector is inputted into the dynamic FCM model, and the current time state vector is multiplied by the adjacency matrix of the dynamic FCM model to obtain the next time state vector as the input value for the next iteration. Repeat this process until a steady state is reached. The mathematical model of FCM reasoning is:

where

represents the state value of the conceptual node

at time t;

represents the state value of the conceptual node

at time t+1; t represents the discrete time, t = 0, 1, 2, 3, ..., T; F is a conversion function that normalizes the value of the concept node to the appropriate range. This article uses the sigmoid function as a conversion function; the function is as follows:

C represents the experimental parameters, .

3. Fitness Function

The essential thing in genetic algorithms is to design a fitness function for the problem. The state obtained by the fuzzy cognitive graph at this moment is compared with the actual state value at that moment to receive an error function:

where

is the expected output value of node i at time t;

is the actual output value of node i at time t; and

, N is the number of conceptual nodes in the system.

, k is the total number of training samples.

The fitness function used in this algorithm is:

4. Stop Condition

The proposed stop condition considers two scenarios in the learning process:

–Learning is successful; the sequence of state vectors obtained by simulating the candidate FCM is near the input data. The similarity between the actual state value and the real state value is described by the fitness function value of each generation of the best chromosome. Therefore, learning should be terminated when the fitness function value reaches the threshold max_fitness.

–Learning is unsuccessful, but the maximum number of iterations defined by the max_generation parameter has been reached.

5. RCGA Learning Process

The chromosome edge weight matrix in the initialization population is evaluated; that is, the new time state value reasoned by the FCM reasoning mechanism is compared with the actual result in the data source. If the end condition is reached, the optimal FCM edge weight matrix is obtained. Otherwise, the chromosome weight matrix is crossed and mutated, and the chromosome weight matrix with high fitness is selected to generate a new generation group to enter the next round. This process is iterated multiple times until the termination condition is reached. The specific learning process is as follows:

STEP1: Assign values to the parameters, including the population size m, the number of variables n, the crossover probability pc, the mutation probability pm, and the maximum algebra T allowed by the genetic calculation.

STEP2: Generation of the initial population. The initial population is randomly generated, and the population size m is set to 100.

STEP3: Calculate the individual fitness value. Calculate the fitness of each chromosome in the population according to Formulas (8) and (9).

STEP4: Selection. The selection operator uses roulette selection to calculate the cumulative probability for each individual based on the fitness of each individual.

STEP5: Intersection. Using a single-point crossover method, the populations are randomly paired first, then the intersections are randomly set, and, finally, some genes are exchanged between the paired chromosomes. The crossover probability is .

STEP6: Variation. The mutation calculation is performed by the method of significant position variation. First, the position of the genetic modification of each individual is determined, and then the genetic value of the variation point is reversed according to a certain probability. The probability of variation is .

The relationship weight training pseudocode is as follows:

Initialize parameters such as , , m, T, and max_generation. Randomly generate the first generation population pop.

Do

{

Calculate the fitness of each individual in the population pop F(i)

Initialize empty population newpop

Do

{

Select two individuals from the population pop according to the fitness by the proportional selection algorithm

If(random (0,1) < pc)

{Intersection of 2 individuals by crossover probability}

If(random (0,1) < pm)

{For two individuals to perform mutation operations according to mutation probability}

Add 2 new individuals to the population new pop

}until (M children are created)

}until (any chromosome fitness value exceeds max_fitness, or breeding algebra exceeds m)