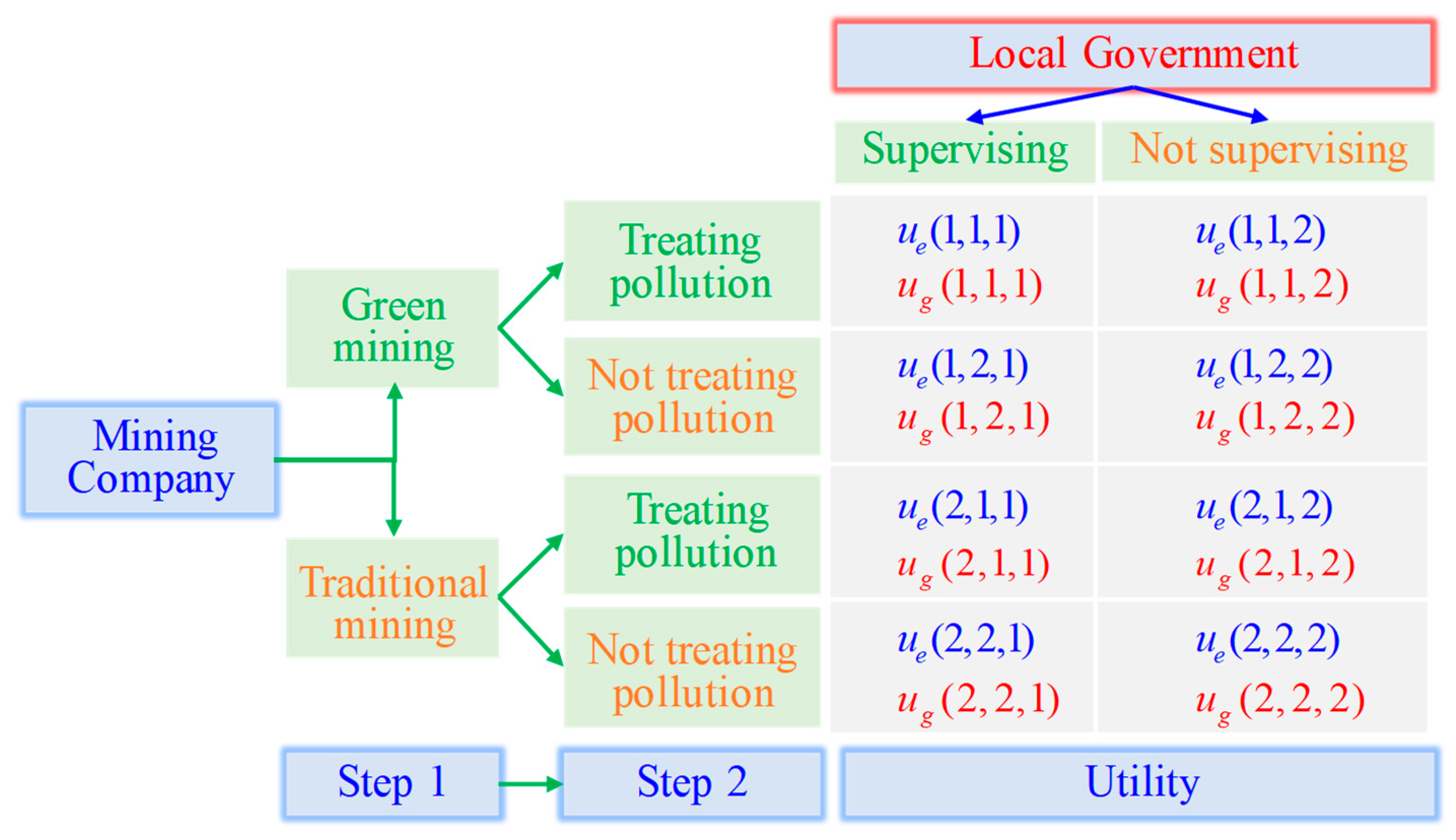

Nowadays, the Chinese central government is implementing the strictest environmental protection policies, making the environmental situation an important indicator of the local government’s performance. Ft has increased greatly following improvement in the environmental standard, with the cost of supervision declining sharply through the application of satellite and aerial photography technology. Therefore, ΔUg in both Equations (19) and (20) is positive. In this case, since supervision is the local government’s dominant strategy, it will certainly supervise the mining company.

A company supervised by the local government will certainly have to treat pollution, but need not necessarily adopt the green mining mode. In the following section, we examine the impacts of the various parameters in Equation (17) on the mining company’s decision.

4.1. Value of Parameters in the Game Model

The parameters in Equation (17), except for

QR, can be categorized into two constant parameters and green mining technology-level parameters. As shown in

Table 5, the constant parameters include

F0,

τ0,

p0,

Tp, and

Ft, and the green mining technology-level parameters are

τg,

R,

r,

Fg, and

pg.

To quantitatively analyse the impact of the different parameters in Equation (17) on the mining company’s decision, we first determine the values of all parameters shown in

Table 5 by analysing the data from the China Tendering and Bidding Public Service Platform, government documents, and related research papers. The values of these parameters are mainly based on the data of metal mines, especially gold mines. The specific parameter determination processes are provided below, and the raw data can be found in the

Supplementary Materials.

Tailing storage is the conventional approach to handling tailings in China, with the disposal cost including the storage and emission costs. The per unit mass tailing storage cost can be calculated by dividing the tailing storage construction investment by the designed storage capacity; its value is about 15–25 CNY/t. Tailing discharge has two kinds of technology: Slurry disposal and dry stacking. While the slurry disposal cost is about 5 CNY/t, the dry stacking cost is about 15 CNY/t. Therefore, the conventional approach’s cost to dispose of tailings, F0, is about 20–40 CNY/t in China. The harmless tailing storage technology is based on the conventional dry stacking technology and increases the seepage prevention and tailing consolidation process. The calculation of project construction shows that the additional cost of disposing of storage tailings using environmentally friendly methods, Fg, is about 10–20 CNY/t.

The TWR yield rate

τ is based on the TWR discharge intensity in gold mines [

38]. The waste rocks when mining one ton of gold ore,

ω, is about 1.2 tons; the concentrate yield of gold ore,

γ, is about 3%; the yield rate of TWR under conventional mining in gold mines

τ0 is about 2.2. From the report,

ω can be reduced to zero through the use of low-waste mining technology, but since the concentrate yield,

γ, cannot be easily changed in the short term, the lowest that

τ can reach is 0.97.

The area of land polluted by unit mass TWR,

p, can be estimated from the tailing storage floor area. From the Chinese tailing storage data, a tailing storage facility with an area of 10 hm can store about 3 million tons of tailings, which means that one square meter can store 30 tons of tailings. The areas surrounding tailing storage facilities are always polluted by heavy metals. A sampling survey in a typical Pb–Zn mining area in South China shows that the surface soil in about one kilometer diameter of tailing impoundment is severely polluted, with the equivalent diameter of tailing impoundment close to 0.5 km [

39]. Thus, the equivalent radius of the contaminated land is twice that of the tailings storage, and the area of land polluted by unit mass TWR under conventional mining,

p0, is 0.13 m

2/t. When the mine adopts a harmless disposal technology, the radius of pollution impact area is equal to the equivalent radius of the tailing storage area, so

pg is 0.03 m

2/t.

The Chinese central government introduced the environmental tax in 2018; the present environmental tax on tailings,

Tp, is 15 CNY/t. Note that comprehensively utilized tailings are exempt from environmental tax [

40].

From the

China Resources Comprehensive Utilization Annual Report and

China Environmental Statistics Yearbook data, the comprehensive utilization rate of tailings in China,

R, is from 10% to 35%. Different comprehensive utilization approaches have different profits. Underground space filling, building material production, and reconcentration are three main comprehensive tailing utilization approaches in China, accounting for 53%, 43%, and 3% of all utilization approaches, respectively, in 2013 [

41]. When tailings are used for filling underground space, if no ore pillars need to be mined, the filling will cost only about 20 CNY/t. Therefore, 20 CNY/t can be saved compared to storing tailings on the ground. The profit from using tailings to produce building materials such as blocks, baking-free bricks, cement, and artificial stone is about 40–100 CNY/t. The profit from tailing reconcentration is related to the gold grade of the tailings. Since the gold grade of old tailings produced in the 20th century is more than 1 g/t, the profit from old tailing reconcentration is above 200 CNY/t [

42]. However, since the gold grade of new tailings is only about 0.25 g/t, the profit from reconcentration of new tailings will be less than 10 CNY/t unless beneficiation technology makes great progress [

43]. Because the profit from reconcentration of new tailings is far less than that from filling underground space and building material production, the comprehensive TWR utilization profit ranges from 20 CNY/t to 100 CNY/t.

The cost of treatment per contaminated unit area land in China, Ft, can be estimated mainly from the total investment and treatment area of the abandoned mine environmental remediation project since 2018. Ft ranged from 25 CNY/m2 to 100 CNY/m2 according to the project requirements and degree of land pollution. If the project has to build new tailing storage and wastewater treatment facilities, its investment will increase to 200 or even 300 CNY/m2. Since the construction cost of a tailing storage facility has been considered in F0, Ft is valued at 25–100 CNY/m2 in this paper.

4.2. Impact of Green Mining Technology

To analyze how the level of green mining technology affects the company’s decision under supervision, we re-write Equation (17) as follows:

where

Ae is the company’s increased profit from mining one ton of ore under the green mining mode. This can be calculated as follows:

where

A1,

A2,

A3, and

A4 represent the increased profit from environmental tax, tailing disposal, pollution treatment, and comprehensive TWR utilization, respectively.

Since QR in Equation (21) is positive, we can use Ae to determine whether adopting the green mining mode is the dominant strategy of the mining company.

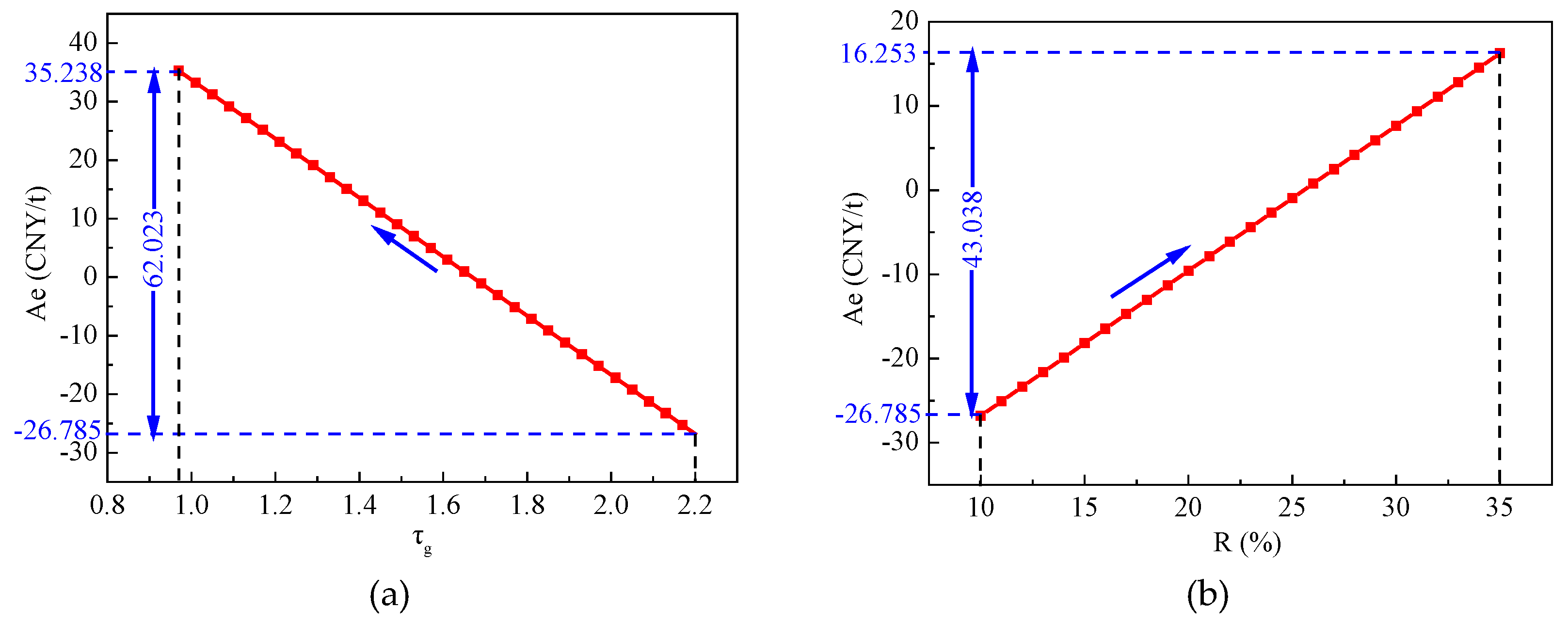

In

Section 4.1, we determined value ranges of five parameters,

τg,

R,

r,

Fg, and

pg, which reflect the company’s green mining technology level; their values are shown in

Table 5. When

Fg,

R,

r, and

Ft are at their minimum, from Equation (21),

Fg is at its maximum,

τg = τ0, and

pg = p0, and these parameters are at their worst. Furthermore, at this point,

Ae reaches its minimum value of −26.785 CNY/t. In this case, green mining is the dominated strategy of the company. Now, by improving the level of the green mining technology parameters, we can increase the value of

Ae and, in turn, improve the mining companies’ approach towards adopting the green mining mode, although the different parameters will have different effects on

Ae.

We analyzed the effect of each parameter on

Ae by improving each parameter in turn, keeping the other parameters at their worst value and studying the relationship between the development of green mining technology and the company’s profit. The analysis results are presented in

Figure 2.

As shown in

Figure 2, by reducing

τg or increasing

R,

Ae can be changed from negative to positive and green mining can be turned from a dominated strategy to a dominant strategy; the three measures of reducing

Fg, increasing

r, and reducing

pg can improve the revenue of green mining, but if used alone, cannot change

Ae from negative to positive. In the following, we discuss the reasons for this phenomenon in detail.

In Equation (22), τg and R are two parameters existing in all terms. This means that both of them can affect A1, A2, A3, and A4 simultaneously. Therefore, a reduction in τg or increase in R will quickly increase Ae. In fact, these two measures will reduce the amount of TWR, which needs to be disposed, from the source, and so the environmental taxes, cost of tailing disposal, and pollution treatment costs will decrease.

Fg can impact

A2, as shown in Equation (22), and can be reduced from 20 CNY/t to 10 CNY/t, as shown in

Table 5.

Fg has limited scope to be reduced because the cost of harmless disposal measures in China, such as laying seepage-prevention layers at the tailing storage’s bottom, adding alkaline material into acid tailings, or adding a hardener into tailings, is sufficiently cheap. Therefore, a reduction in

Fg alone cannot change

Ae from negative to positive.

From

Figure 2d,

Ae increases by only 17.6 CNY/t when

r is increased from 20 CNY/t to 100 CNY/t, the maximum value of

r under the current technology level in China. From Equation (22), the effect of

r on

A4 depends on the value of

τg and

R. As

Figure 2a,b show,

τg and

R are respectively negatively and positively correlated with

Ae; this means that improving

r alone will not increase

Ae effectively until

R is high enough.

From Equation (22), a reduction in

pg can improve

A3, which represents increased profit from pollution treatment. Since the impact of

pg on

A3 is related to

Ft,

pg will have more effect on

A3 when

Ft is higher. The value of

Ft depends mainly on the land reclamation standards and TWR storage method. According to the

Completion Standards on Land Reclamation Quality published by the Chinese central government, the main measure for the reclamation of polluted land is the isolation of harmful TWR. The cost of reclaiming the abandoned land would be only 25 CNY/m

2 if no new tailing storage facilities or sewage treatment facilities need to be built. Moreover, the value of

pg cannot be lower than that of the area required for stacking per unit mass TWR, that is, 0.03 m

2/t. Thus, as shown in

Figure 2e,

pg has only a limited effect on

Ae.

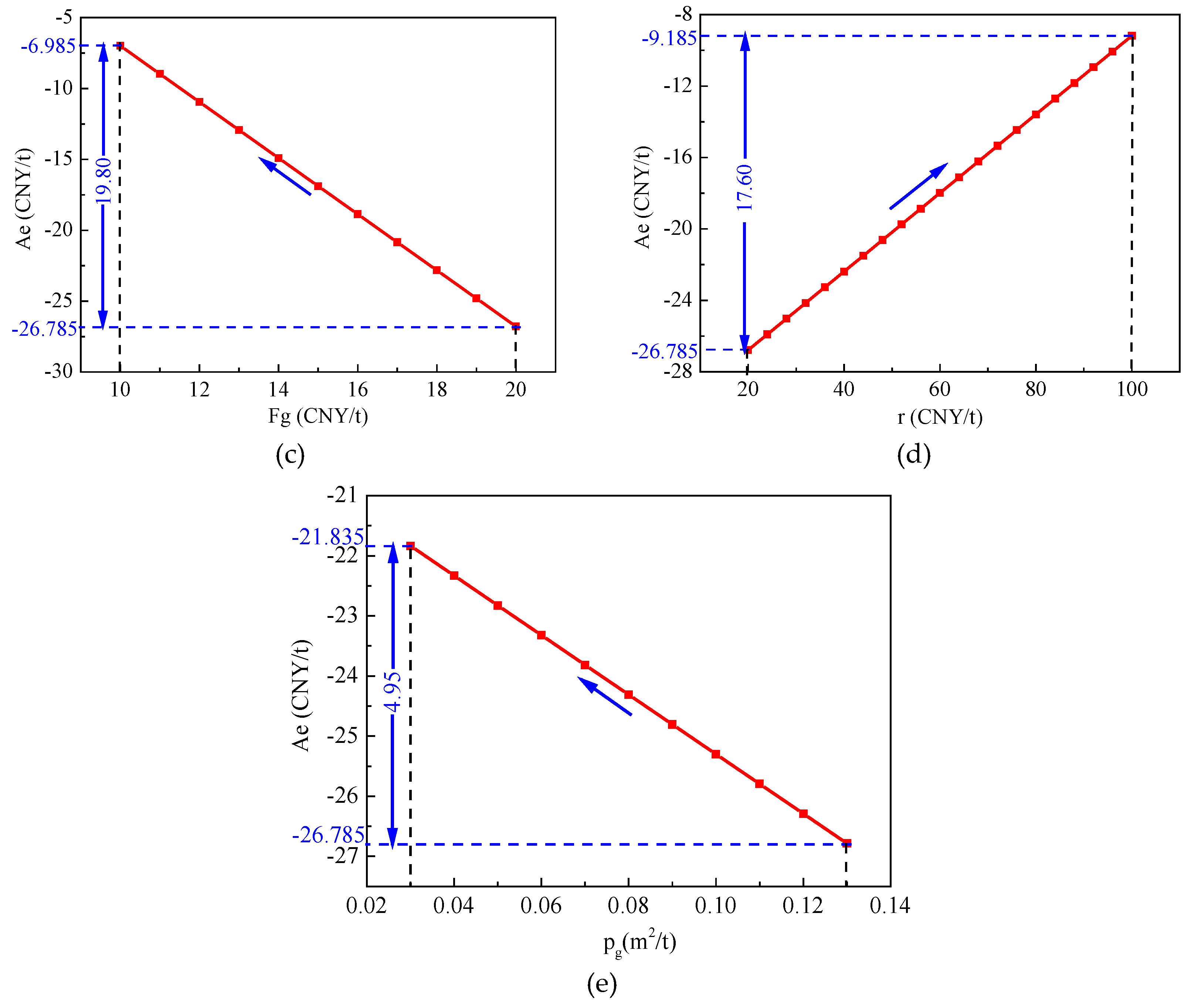

In order to find the sort orders of each parameter’s influence degree, we conduct a sensitivity analysis using

τg,

R,

r,

Fg, and

pg as independent variables and

Ae as the dependent variable. From the value ranges of these independent variables shown in

Table 5, we set their base values at their median values, 1.58, 22.5%, 60 CNY/t, 15 CNY/t, and 0.08 m

2/t, respectively, with the variation coefficients of the independent variables set at ±5%, ±10%, ±15%, and ±20%, respectively.

As shown in

Figure 3, the sort orders of each parameter’s degree of influence on green mining are as follows:

τg >

R >

r >

Fg >

pg. This once again proves that the reduction in

τg and increase in

R are the two most effective approaches to improving

Ae and eventually improving the mining companies’ inclination towards adopting the green mining mode.

4.3. Impact of Production Scale

From behavior analysis of a company in

Section 4.1, the production scale of a mine can affect the company’s inclination to upgrade technology. In this section, we discuss this phenomenon in more detail.

Taking a gold mine as an example, the minimum annual output,

QR, should be more than 15,000 t in China. A mine that can produce more than 150,000 t of gold ore per annum belongs to the group of large mines, as shown in

Table 6. The largest gold mine in China is in Shandong province, with an annual ore output of over 3.6 million t in 2018.

To quantify the green mining technology level, we divide the technical level into five grades by percentage (see

Table 7). The values of five green mining technical parameters (

τg,

R,

r,

Fg, and

pg) at each grade are calculated proportionally.

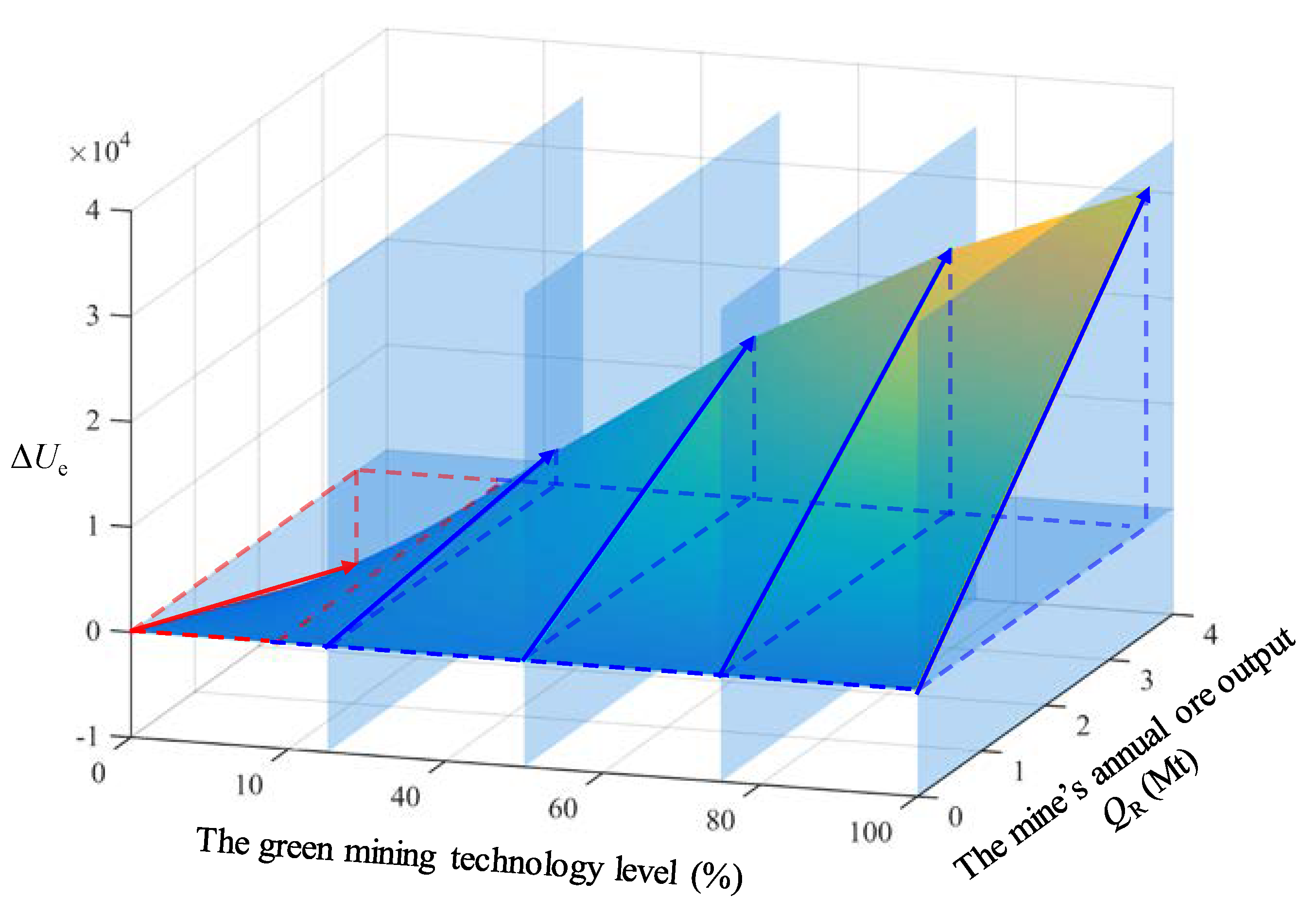

We calculate the company’s increased profits from adopting green mining, ∆

Ue, under different green mining technology levels by inserting the data from

Table 6 and

Table 7 into Equations (21).

Figure 4 plots the results as a 3D curved surface graph, using the green mining technology level, the mine’s annual ore output, and ∆

Ue as the x-axis, y-axis, and z-axis, respectively.

From

Figure 4 and Equation (22), an increase in

QR can raise ∆

Ue when

Ae is greater than zero. By comparing the change in ∆

Ue with the green mining technology level and

QR, we find that ∆

Ue changes when the green mining technology level increases with

QR. If mining companies with different scales invest similarly to upgrade their green mining technology level, return on investment of small mines will be less, with a longer investment payoff period than that of large mines. Thus, large mines have more motivation to innovate on technology and upgrade the level of green mining technology than small mines.

Green mining can be graded into three modes as follows, based on the green technology level of each mining production link: The light green mode, where the green technologies adopted in most of the production links are of a low level, the medium green mode, where the green technologies adopted in nearly half of the production links are advanced, and the deep green mode, where the green technologies adopted in most of the production links are advanced and industry-leading. From the above analyses, large mines invest in green technology development and innovation to increase their own income and also to improve the technical level of the entire industry, but small mines investing too heavily in technology development may face investment risks due to the long payback period. Therefore, in the promotion of green mining, small mines, medium mines, and large mines are suitable for the light green, medium green, and deep green mining modes, respectively.

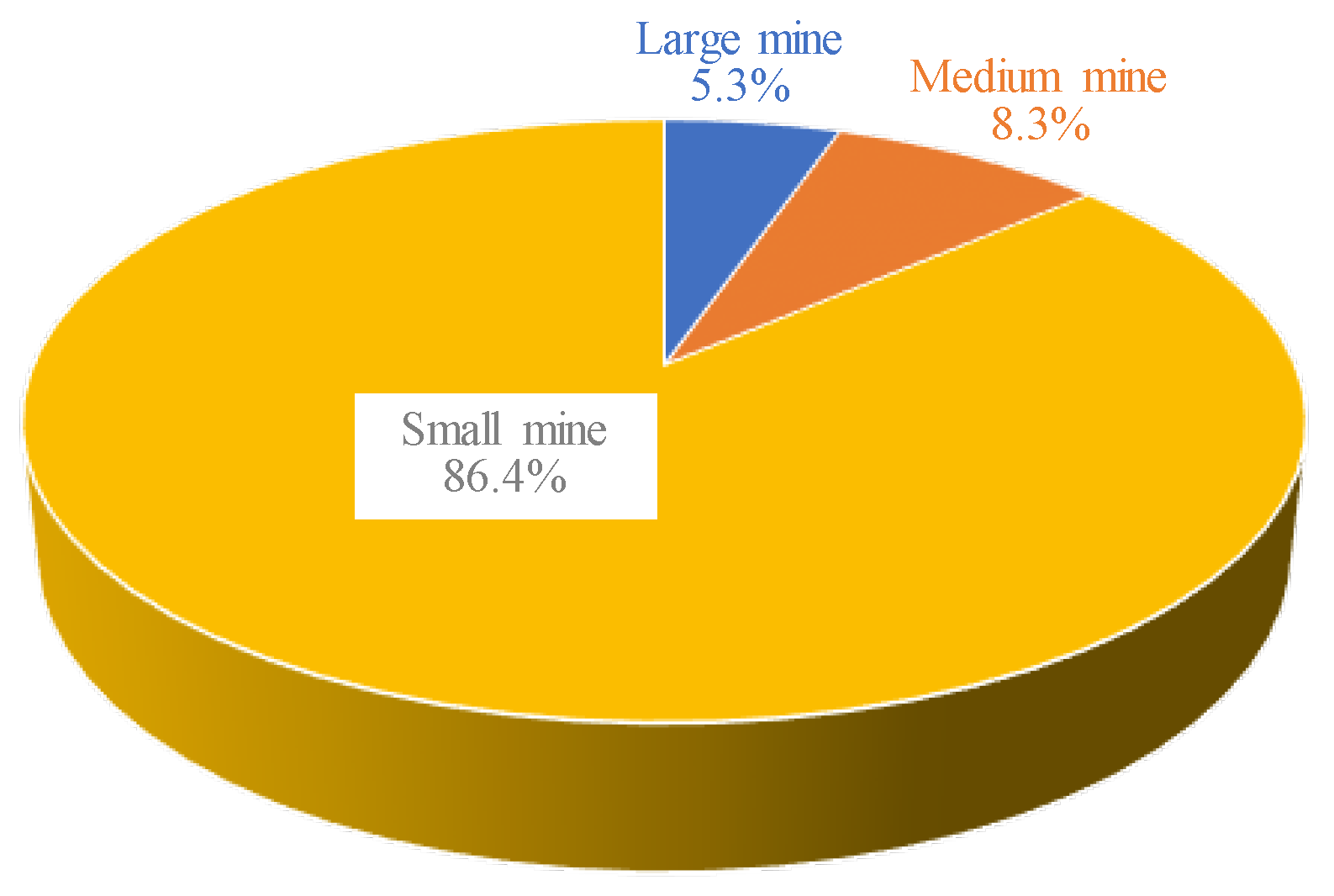

From the Chinese land and resources data, small mines accounted for more than 85% of the total mining companies in 2016 [

8], as shown in

Figure 5. To achieve cleaner production in the Chinese metal mining industry and to change all mines into green mines, improving small mines is a critical task. Since small mines lack the motivation for technical innovation, the Chinese central government should design subsidy policies and encourage mining associations or research institutes to promote mature green mining technology applicable to small mines. Some large mines can sell their own green mining technology and the total solutions to small mines, and develop themselves from simple ore production and processing companies to technology companies.