Abstract

To be sustainable and growing amongst uncertain environments and intensive global competition, supply-chain network leaders have established supply-chain management systems (SCMS) to leverage the resources and knowledge of their partners to achieve greater supply-chain capabilities (SCC) to respond to market changes and complexity. Although several studies have investigated the benefits to network leaders from these systems in various industries, little attention has been paid to the delivery of substantial benefits and advantages to its partners. Based on information technology (IT) applications and SCC literature, this paper proposes a model relating partners use of SCMS to benefits. Data from 168 partners using an SCMS implemented by a leading bicycle supply chain in Taiwan to test the hypotheses that SCC and operational performance has a mediating role linking SCMS use in order to affect a partner’s performance. The results indicate that SCMS implementation has a significant impact on SCC, which in turn create a significant positive effect on operational (sustainable) performance, ultimately leading to improved growth rate and profitability in partners. Another interesting finding of the research is that SCMS cannot directly affect financial performance. In addition, from sustainable performance aspects, it is revealed that IT enables supply chain management (SCM) to achieve environmental value through information sharing (up and down), process integration (vertical and horizontal) and automation (i.e., planning, operation and control). This finding highlights the importance for maximizing benefits and sustainability for the whole supply-chain partners, the IT implementation must be integrated with the sustainable development goals and inserted in the eco-operation supply-chain platform process. The results also contribute to the debate in prior studies by disclosing why so many partners could not find to gain benefit from these IT implementations. Furthermore, this study represents the first attempt to examine how partners benefit from IT use in SCC for traditional industry.

1. Introduction

Few firms currently possess all the skills and resources necessary to produce complex products entirely in-house. Thus, supply-chain management (SCM), which is primarily focused on managing relationships with suppliers and customers for providing and delivering the best product and service at a reasonable price [1], has become the dominant vehicle in business operation. For sustainability and growth, starting from the source of supply of raw materials through to the consumption of the product by the end customer, SCM should emphasize effective and efficient flows of both information and product or service to meet and satisfy customer requirements and service. Supply-chain capability (SCC) is defined as “the ability of an organization to identify, use, and assimilate both internal and external resources and information to facilitate entire supply-chain activities” [2]. While from an innovation goal viewpoint, Liao and Kuo [3] defined SCC as “coordinating and collaborating with upstream, midstream, and downstream supply-chain partners to create and realize overall value innovation.” Considering that different capabilities support different values, Lynch et al. [4] further divided SCCs into two categories, demand-driven value-added capabilities and supply-driven process capability.

With uncertain and complex environments, the accelerated pace of technological development, intensive global competition, rapid changes in customer demands mean that the supply chain should have the ability to sense, integrate and respond to market changes. Therefore, SCC is becoming increasingly crucial. Morash [5] even claims that SCC is the foundation of the supply-chain strategy and a source of competitive advantage for company success. Thus, supply-chain network leaders, with great enthusiasm, have rushed to collaborate and integrate the resources and knowledge of partnering organizations to achieve greater supply-chain capabilities to respond market changes such as Apple, Boeing, and Walmart. Rajaguru and Matanda [6] indicate that SCC is a high-level hierarchy of organizational capabilities and require wide information share for collaborating and coordinating with whole supply-chain partners. Supply-chain management systems (SCMS) or inter-organizational information systems (IOIS) are widely regarded by both researchers and practitioners as a crucial tool to manage business-to-business relationships [7]. SCMS is an integration of information systems across partnering organizations has been become the pillar of SCM, since it facilitates and enables information exchanging and sharing, accordingly enhancing organizational flexibility, agility and responsiveness [6].

Nowadays many scholars have focused on their research on the effect of SCMS on supply-chain capability and performance (detailed literature contributions are shown in the Appendix A). Wu et al. [2] examine the effect of information technology on supply-chain capabilities and company performance from the resource-based view in various industries. Considering that an agile firm can achieve critical first-mover and other competitive advantages over rivals, DeGroote and Marx [8] investigate IT impact on supply-chain ability to sense market changes, collect market information and execute coordinated responses, and impact on company performance. Recent, leveraging the process-based view of IT, Peng et al. [9] establish a theoretical framework to study the mediation effect of business process and supply-chain management capabilities on the impact between IT capabilities and performance in China’s manufacturing industry. Furthermore, based on empirical data from buyer-supplier dyads, Radhakrishnan et al. [10] examined the IOIS usage direct and indirect impact on capabilities. In addition, from intra-firm and inter-firm contexts, Prajogo et al. [11] examined the role of information management as a driving force for process management and its impact on operational performance. In fact, SCMS is a platform to facilitate information exchanging, communication, coordinating, and collaboration to gain substantial benefits among supply-chain partners. From a resource-based view, and using collected data from China’s manufacturing industry, Yu et al. [12] found that a data-driven supply chain has a significant positive effect on supply-chain capabilities, and in turn is positively and significantly related to financial performance. Furthermore, some studies reported a positive relationship between SCMS usage and network leaders’ performance in terms of reduce selling, general administrative expenses, and increased gross margin, inventory turnover, market share, and return on sales [13,14,15]. Furthermore, since blockchain technology is increasingly considered as a next generation information tool, researchers found that the use of blockchain in SCM activities can influence supply chain (SC) partnership efficiency and growth, thereby affecting SC performance outcomes [16]; in logistic activities this can improve order delay, damage to goods, errors, and multiple data entry [17]. However, some studies also showed that network leaders derive benefits at the expense of their partners [18]. Similarly, Clemons and Row [19] found only small benefits in the case of more general partners adopting SCMS championed by a major network leader. Furthermore, little prior academic attention has examined partners’ benefits from SCMS developed by network leaders, and what mechanisms enable partners to realize benefits [18,20]. Actually, it is not a problem of IT itself, but how companies integrate and utilize their IT with their strategic and goal partners. Therefore, the major problem confronting partners is always not whether they should use SCMS. The real question is how they should use these systems and benefit from them [18].

Furthermore, the different industries or firm sizse would affect the impact of information technology on supply-chain management capabilities, because they have different resources or information technology capabilities [21,22]. Especially in Taiwan, the traditional industries are regarded as a possessing a lack of resources and information technology capabilities. Hence, previous research that examined the benefits of these systems to network leaders in various industries could not show the actual supply-chain capability and its operating performance and financial performance of partners [18], especially for the traditional industry sector. Therefore, it is valuable to examine the impact of SCMS usage on performance from full supply chain rather than the network leader or one focus firm [10]. From a single industry (i.e., the bicycle industry) supply-chain viewpoint, this study intends to examine the effect of SCMS usage on supply-chain capability and operational performance, and ultimate financial performance. Furthermore, according to Hartono et al. [23] and Li et al. [24], operational performance plays a partial mediating role linking SCC to affect firm performance. However, other researchers have suggested that operational performance is not a mediating factor [25,26]. Such different results have caused confusion, and generated limited understanding and practices concerning actual SCMS implementation in supply-chain management.

In addition, Industry 4.0 and sustainability issues are recent, progressing exponentially in the supply chain. Undoubtedly, Industry 4.0 with its related technologies will reshape the way individuals live and work fundamentally, and the academic and industry remains optimistic regarding the opportunities Industry 4.0 may offer for sustainability. According to Beier et al. [27], and Kiron and Unruh [28], Industry 4.0 is really an enabler of sustainable development, but the convergence of digital transformation and sustainability remains underdeveloped. Recently, a lot of studies have identified several interlinks between Industry 4.0 technologies and sustainable operations, such as: discussing the influence of sustainable business models [29], exploring the potential impact, opportunities and challenges to sustainable development [30,31,32,33,34], enabling of sustainability [35,36,37], potentially contributing sustainable value creation [38], the effects on lean manufacturing practices for sustainable organizations [39,40], and presenting the dependence power of the determinants for Industry 4.0 implication in the sustainability context [41]. According to Vaio and Varriale [42], by adopting a sustainable supply-chain management (SSCM) perspective, firms tend to focus much more on searching for transparent information, coordination, integration, and effective sustainable practices, thus considering Industry 4.0 and its social, environmental, and economic impact. From this viewpoint, even scholars have paid attention to Industry 4.0, OM, and SCM from the perspective of sustainability, regarding SSCM, the contributions on this issue are still scarce, with most studies only referring to a single dimension of sustainability rather than to all dimensions of the Triple Bottom Line [31]. This area requires further exploration, especially in supply chains that have spare capacity at all stages, information transparency, energy and resource efficiency, higher levels of collaboration and cooperation, and highly horizontal and vertical integratration [42,43].

In Taiwan, the bicycle industry has been developing for about 30 years. Although the Taiwan bicycle industry is a traditional industry, it has complete information systems. Therefore, the Taiwan bicycle industry is used to study the effect of SCMS implementation on supply-chain integrated capability and sustainable benefits to its members.

From the above review the following questions arise: what are the mechanisms and relationships that enable partners to realize sustainable benefits from their SCMS use? what SCMS are used to support their supply-chain processes? Following the suggestion proposed by Tseng et al. [44], industries should effectively shape their processes and operations for sustainable development in an SC context. By adopting a sustainable supply-chain perspective based on IT applications and supply-chain capability literature, this paper proposes a model relating partners’ use of SCMS to enhance their supply-chain capabilities in terms of information exchange, coordination, integration as well as supply-chain responsiveness, and sustainable operation performance, with in turn bring benefits to firms. We test the hypotheses that supply-chain capabilities and sustainable operation performance perform as mediating role linking SCMS usage to firm performance, by analyzing data from 168 partners using SCMS implemented by Taiwan’s bicycle supply-chain network leader. The results indicate that SCMS implementation has a significant impact on SCC, which in turn creates a significant positive effect on operational (sustainable) performance, ultimately leading to improved growth rate and profitability in partners. Another interesting finding of the research is that SCMS cannot directly affect financial performance. That means if IT utilization cannot improve firms’ financial performance, they really need to check “Does it enhance the supply-chain capabilities and operational (sustainable) performance?” Do not let the “performance paradox” of SCMS occur. In addition, our findings also reveal that SCMS implementation has a significant impact on highly vertical and horizontal integrated supply-chain capabilities, which in turn enhance the sustainable outcomes of the entire supply-chain partners by maximizing the efficiency of SC processes, includes information sharing, thus ensuring on-time product delivery, supply network optimization, and logistics reliability. Furthermore, this finding highlights the importance of maximizing benefits and sustainability for all chain members. Supply-chain integrated capability and operational (sustainable) performance must be embedded in the check point of partnering organizations, and more attention must be paid to transparency of process, time to market, increasing resource efficiency, and reduction of waste, as well as reduction of wrong delivery for gaining competitive advantages [38,39]. According to these findings, our research contributes to the practice of supply-chain management, and specifically informs the question of how a supplier can more fully exploit their IT application path [23,24,25,26], and help managers develop more appropriate SCMS strategies. Finally, this study represents the first attempt to examine how partners benefit from SCMS use in supply-chain sustainable capability for traditional industry. It also adds significant value for bicycle industry trying to improve their performance though SCMS implementation.

The remainder of this report is arranged as follows: Section 2 is a literature review and hypothesis development section, which includes discussions of supply-chain management systems, Taiwan’s bicycle industry supply chain, supply-chain capability and hypothesis development in this study. In Section 3, we describe the research methodology. Section 4 reports the hypotheses testing of the research model. Finally, we conclude this paper in Section 5.

2. Literature Review and Hypothesis Development

2.1. Supply-Chain Management Systems

With the development of information technology (IT), especially the wide application of Internet, the environment for business operation around the world has fundamentally changed. This is because IT facilitates timely, freely, accurate and numerous flow of information and fast flow of products and services, as well as ensuring a collaboratory, coordinated and integrated supply chain. According to Singhry et al. [45], collaboration, coordination and integration of information systems across full supply-chain members can simplify and enhance the effectiveness and efficiency of their activities, and become the pillar of information sharing and flow of products or services in supply-chain management. Thus, the implementation of IT for SCM is becoming increasingly important in the context of an increasingly globalized and competitive economy. Supply-chain management systems (SCMS) offer a range of new features coordination and integration of information systems for aligning supply-chain management and information sharing, transformation, communication, and collaboration across organizational boundaries [18]”. Recently these systems have been widely used to support business-to-business transactions. According to researchers, SCMS across partnering organizations as an infrastructure not only motivates and provides timely, massive, accurate and reliable information sharing to support both the leader company and its partners in the supply chain, but also improves organizational agility, flexibility and responsiveness, thus minimizing risk and inventory costs [6,23]. It is recognized as a critical factor in the improvement of SCM [46]. There is no standard content of the SCMS. In general, it is an integrated information system which maybe include e-product collaboration development systems, customer relationship management (CRM), Internet-based electronic data interchange, supplier relationship management (SRM), e-procurement systems and other inter-organizational process automation systems that make use of common technology under a single ownership [6]. In recent decades, network leaders such as Apple, Ford, and Walmart have made significant efforts to use SCMS to derive the benefits of coordination, integration and collaboration with their suppliers and customers.

The benefit of IT has been a popular research topic for both management information system researchers and practitioners. For instance, leveraging the process-based view of IT, Peng et al. [9] revisited the question of how a firm’s performance was affected by information technology usage. They found that a firm’s IT effect on firm performance was fully mediated by the management capabilities in managing its internal and external business processes. The question arises: how do information technology capabilities contribute to firm performance? From a process point of view, Mithas et al. [47] examined the mediation effect of process management capability in the relationship between IT and performance. Using Korean steel suppliers as their sample, Youn et al. [48] found that the competitive advantage of the Korean steel industry is heavily influenced by the supply chain inter-organizational information system capabilities. Several empirical studies have shown a positively significant linkage between information system capabilities and the competitive process alignment and flexibility capabilities of small to medium-sized enterprises (SME) [49,50,51]. Using data collected from Australian retailing sectors, Rajaguru and Matanda [6] found that inter-organizational information system integration and supply chain capabilities were facilitated by cultural inter-organizational factors and inter-organizational technical and strategic compatibility. Nowadays in the era of industrial digitalization, companies are increasingly investing in Industry 4.0 and its related technologies, such as the Internet of Things, big data analytics, and cyber–physical systems, among others. Furthermore, there are continuous increasingly environmental and social awareness among citizens, thus the benefit of Industry 4.0 has been studied by researchers from the sustainable supply chain perspective. From the sustainability supply chain viewpoint, sustainable benefits can be obtained from the use of IT or Industry 4.0 related technologies as information systems integration improvement to enhance the supply chain information transparency and processing capability. Such benefits include: transparency of process, machinery, stock, or logistics data to facilitate traceability of commodity flow to increase resource and energy efficiency; reduction of waste, logistics process and delivery errors and damaged goods; shorter set-up and lead times as well as faster machine speed to facilitate faster and more flexible, efficient, and higher quality response to customer demands; reduction of time-to-market in new product design, thus supporting a firm to effectively and efficiently manage operational contingencies and enhance performance [29,30,31,32,33,34,35,36,37,38,39,40,41,42].

2.2. Taiwan’s Bicycle Industry Supply Chain

Taiwan’s bicycle industry is one of the traditional industries that can sell its products globally with its own brand. Taiwan’s bicycle industry originated during the Japanese occupation era, and acquired technology from its Japanese counterparts. Since then, Taiwan has begun to develop its own bicycle industry. Most of Taiwan’s bicycle companies are major suppliers, designers and manufacturers in the global market. Taiwan’s bicycle industry has been booming internationally for more than 30 years, became the world’s biggest bicycle exporting country from 1980, and enjoyed the fame of ’Bicycle kingdom’. However, rising labor costs and industrial structure changes, along with rapidly increasing manufacturing costs, mean that many bicycle manufacturers have shifted the production process to China or Southeast Asia countries where they may operate at lower cost. Facing uncertain environment, growing globalization and increasing threats from China, companies realized that the situation cannot be overcome with limited resources. Since 2003, in a strategy to bolster Taiwan’s bicycle competitive advantage, Giant and MERIDA, the two largest Taiwan bicycle assemblers, cooperated with 11 part suppliers to establish a bicycle alliance. After several years of upstream and downstream integration, the companies established a Taiwan cycling “A-Team alliance”. Their objective has been to improve the level of product development processes of customers, R&D, manufactories, and suppliers integration, and to share information to improve the coordination and collaboration between supply chain processes, enhancing supply chain integration level through the implementation of information systems and process reengineering. The ultimate hope is that these systems enhance the performance of the entire supply chain in terms of time to market, delivery speed, cost reduction and service level, and make the developers and suppliers the most successful.

According to the aims of A-Team alliance, A-Team developed an inter-organization information system which includes complementary cooperation and operational coordination to support the supply chain processes of A-Team alliance. This means that the A-Team alliance improves product technology and shares new market strategies together by using the inter-organizational information systems. In fact, in the international market, Taiwan’s bicycle industry needs to create value-added products and superior brand images to compete with European and American brands [52]. The development of A-Team provides a learning platform that enables businesses to easily access information and to subsequently enhance/streamline their operational structures. Now, Taiwan’s bicycle industry has become a boutique [53].

2.3. Supply Chain Management Systems Implement and Supply Chain Capability

Supply chain management systems (SCMS) refer to the network which connects partners’ information technologies in order to facilitate the sharing of information [54]. According to Chen and Paulraj [55], the SCMS implementation refers to electronic connection, communication and transactions utilizing SCMS resources across organizations and their customers and suppliers. A supply chain is a network of entities composed of suppliers’ suppliers, direct suppliers, primary producers, distributors, retailers, and consumers, through which material, product or service, money, and information flow [56]. Drawing from Rajaguru and Matanda [6], supply chain management can refer as “the systematic, strategic coordination, alignment and collaboration of business functions within a specific organization and across businesses within the supply chain to improve and enhance long-term organizational and whole supply chain performance”. In a more and more globalized and competitive economy, the implementation of information technology for supply chain management has become increasingly important.

From networking theory perspective, supply chain relationships where partners merge, integrate and reconfigure each other’s resources can facilitate co-creation of resources [57]. Thus, SCMS not only can facilitate and enhance sharing of valuable resources, such as information, technology, and markets [58], but also can improve effective and efficient integration to create incomparable capabilities, such as supply chain agility, provide timely, easily and fast communication and accurate exchange of existing resources [59]. According to Feng et al. [60], SCMS implementation can help firms develop new products because of its ability to store knowledge, to integrate different systems, and to improve the efficiency of product development. Furthermore, SCMS applications can forecast market trends and, thereby, help assess potential risks to reduce a firm’s operating costs. It also can enhance the efficiency of information management [61] and help cope with the effect of excessive demand in a quickly changing environment [62]. Hence, suppliers can share their information in a timely way, and make their information systems work interdependently. From an organizational information processing theory viewpoint, Premkumar et al. [63] found that the implementation of any kind of IT will facilitate streamlining a communication process, and enhance the sharing of information and knowledge between manufacturing firms and their suppliers and customers. This mean SCMS implementation can simplify product or service flow from major producers to consumers as well as information flow from consumers to producers, thus the supply chain capabilities can be facilitated by SCMS [64]. In general, digitization and interconnection of supply chain processes intended by SCMS are facilitated by information exchange, collaboration, resource sharing, inter-firm and intra-firm integration and data analytics [31]. Based on the literature review, we propose the following hypothesis:

H1:

SCMS implementation can positively affect the capability of supply chain.

2.4. Supply Chain Capability and Operational Performance

Adopting the definition from Rajaguru and Matanda [6], supply chain capability (SCC) is the organization’s ability to identify, use, integrate and assimilate internal and external resources and information to facilitate activities throughout the supply chain. Referencing the work of Wu et al. [2], Rajaguru and Matanda [6] further classify SCC into four sub-factors: information exchange, inter-firm coordination, inter-firm integration, and supply chain responsiveness. Several reports have revealed that information exchange can enable companies to obtain effective and efficient products and services, information flow [65], and make a competitive difference far from competitors [31,38,39,66]. Inter-firm coordination is the ability of a firm to coordinate transaction-related supply chain activities with customers and suppliers. Researchers have ascertained that supply chain partners’ coordination and collaboration is one of the most fundamental supply chain capabilities [2]. It can reduce potential conflicts and opportunistic behavior in the supply chain, incentivize companies and channel partners to focus and deploy resources, and help companies reduce transaction costs and delivery cycles, increase flexibility and agility to respond to high demand complexity and uncertainty [2], and lead to increase efficiency and effectiveness of new product development, and enhance operational effectiveness. Inter-firm activity integration is the ability to build strategic relationships between key companies and their customers and suppliers in managing cross-border business activities, including forecasting and planning, jointing new product development, and collaboration in purchasing and manufacturing [67,68,69]. Thus, Inter-firm activity integration creates opportunities to leverage the knowledge embedded in collaborative processes which can further reduce costs, create value, and improved delivery performance [38,39]. For sustainability and growth in today’s increasingly uncertain, complex and dynamic business environment, supply chain members must have competence to respond to changes in the environment. Thus, supply chain responsiveness is vital and has become a highly respected capability [70]. Supply chain responsiveness is the way in which supply chain managers can modify or change production and delivery quantities and product mix based on demand and supply changes.

Certain studies have found that SCC can develop a platform to share their knowledge and resources to improve supply chain visibility and enable companies to sense market changes in real time, effectively respond to the fast development of the technology, reducing the cost of demand dynamic, complexity and uncertainty [71,72]. Researchers [38,39] have acknowledged that the real-time information gathered from full supply chain: helps the partners efficiently allocate their manufacturing resources, such as materials, energy, and products; supports the reduction of energy consumption and inventory levels of raw material; effective use of capacity. Thus, SCC enables the firm to improve its efficiency and effectiveness of operations [21,38,39,40]. Based on the literature review, we propose the following hypothesis:

H2:

Supply chain capability can positively affect the operational performance.

2.5. Supply Chain Capability and Financial Performance

SCMS implementation can enhance the communication, coordination and collaboration among industry supply chain’s upstream and downstream vendors to improve supply chain capability (SCC). SCC is the organization’s ability to identify, absorb, align and use internal and external resources and information to facilitate activities throughout the supply chain. From the resource-based view (RBV), Wu et al. [2] have ascertained that IT-enabled SCC are company specific and difficult to replicate throughout the organization. With a higher SCC, companies can respond more flexibly and robustly to the needs of individual customers, reduce lead times, and reduce inventory, all of which can make the supply chain more efficient [73]. In the examining of the causality among SCM practice, corporate competitiveness, SCC level and corporate performance, Kim [74] found that a firm’s linking of its SCC strategy to its competitive strategy can improve firm performance. Drawing from the RBV, Yu et al. [12] investigated the causality between data-driven supply chain capabilities and financial performance. They found that supply chain coordination and responsiveness are positively related to financial performance. According to researchers [31,38,39,40], automation and digitization features of IT drive towards increasing transparency, interconnection and integration of processes and lead to strong contributions in terms of value creation, manufacturing flexibility, reduced lead times, lower manufacturing costs, superior quality, product customization, and increased customer satisfaction. Researchers [75,76] also have acknowledged that organizational supply chain capabilities are an important source of organizational operational strength and competitive performance. Thus, SCC enables the firm to reduce costs, improve sales and increase profitability [77]. Based on the literature review, we propose the following hypothesis:

H3:

Supply chain capability can positively affect the financial performance.

2.6. Operational Performance and Financial Performance

From the viewpoint of new product development, organization with high-level operational performance benefit from better product development, rapid product innovation and speed to market to become the market leader, thus they can enjoy higher market development, sales growth, market share, customer satisfaction and profit. On the other hand, from the product delivery viewpoint, high-level operational performance means an organization will be concerned with inventory, service levels or capacity needs in order to produce and deliver, thus driving financial performance in terms of better cash flow from operations, profitability, costs reduction and return on investment. Several studies have reported that an organization’s operational performance has a positive effect on financial performance. For example, in supply chain management, Li et al. [24] examined the effect of environmental uncertainty, intra-organizational relationships, and inter-organizational facilitators on information quality and information sharing, and found that compared with their competitors, organizations with operational excellence can often have one or more of the following capabilities: higher customer service, shorter time to market, faster market response time and shorter delivery time. These capabilities usually can, in turn, enhance the organization’s customer satisfaction, loyalty [78] and increase sales and profitability [79]. Considering the financial benefits of adopting an IT-based supply chain management system, Dehning et al. [80] proposed that higher-level operating revenues are associated with higher-level financial performance. Furthermore, Vazquez-Bustelo et al. [81] surveyed firms in Spain and found that the adoption of agile manufacturing has a positive effect on manufacturing intensity and thus improves business performance, so operational performance is considered to be a prerequisite for business performance. Similarly, Subramani [18], Hartono et al. [23] and Brah and Ying Lim [82] strongly emphasized the link between operational performance and overall company performance. Based on the literature review, we propose the following hypothesis:

H4:

Operational performance can positively affect the financial performance.

2.7. The Relationship among Supply Chain Capability, Operational Performance and Financial Performance

Nowadays many scholars have observed the impact of supply chain management systems on supply chain capability and firm performance [8,21]. Furthermore, several studies [13,83,84] have identified supply chain capability benefits which include operational performance and financial performance of an organization. It is expected to improve organizational performance mainly through innovation frequently, time to market, reduced lead time, delivery reliability, short delivery time and customer service. Based on social exchange theory, Homans [85] suggests that companies should exchange, coordinate and integrate resources and share information and knowledge with their supply chain partners to obtain short-term economic benefits and gain long-term competitive advantage. Therefore, ensuring and enhancing the high supply chain capability becomes a critical aspect of effective SCM [13].

Several empirical studies have shown the direct impact of SCC on financial performance [2,83,86,87]. However, Chang et al. [88] argued that operational performance mediates the relationship between SCC and financial performance. These are seemingly inconsistent ideas. This study views operational performance as a mediating variable that links the effect of SCMS to financial performance. We therefore hypothesize the following:

H5:

Operational performance mediates the relationship between supply chain management systems and financial performance.

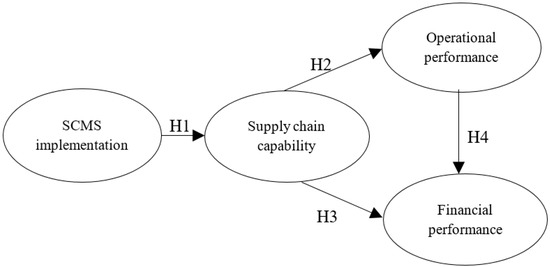

According to the above hypotheses development, the framework of the research as shown in Figure 1.

Figure 1.

The framework of the research. (SCMS: supply chain management systems)

3. Methodology

3.1. Questionnaire and Measurement Scale

This survey examines the impact of SCMS implementation on the supply chain capabilities, operational performance and firm performance in the Taiwan bicycle industry. The development of the questionnaire was based on an excessive review of literature related to IT application, supply-chain collaboration/integration, and performance management. Multiple item scales were used to measure each factor in this study. Factors including SCMS implementation, supply chain capabilities, operational performance, and financial performance were measured. SCMS implementations were adopted from Chen and Paulraj [55], Feng et al. [60] and DeGroote and Marx [8]. While supply chain capabilities were measured using a multi-item scale developed by Wu et al. [2], Flynn et al. [67], Cao and Zhang [89], Feng et al. [60] and DeGroote and Marx [8]. Operational performance was adopted from Wu et al. [2], Chen and Paulraj [55], DeGroote and Marx [8] and Flynn et al. [67]. Finally, financial performance was adopted from Wu et al. [2]; Cao and Zhang [89] and Flynn et al. [67]. In total, 38 items were used for measuring 11 constructs. All items in this study were measured by a 5-point Likert scale ranging from “strongly disagree” to “strongly agree”.

In order to increase the validity, the questionnaire was conducted through face-to-face interviews. Three senior managers with first-hand knowledge of supply chain operations and management in their respective companies were invited to interview. A survey instrument pretesting was conducted to confirm if the survey questions were clear and easy to understand in meaning and wording. After receiving feedback from respondents, appropriate adjustments were made to fit the context of SCMS usage in the whole supply chain (i.e., from upstream to downstream) management in Taiwan’s bicycle industry.

3.2. Data Collection

The population of this study were the members of the A-Team in Taiwan’s bicycle industry. The purposeful sampling was adopted because we aimed to examine the views of the A-Team’s major members. The data collection period was from 2 June 2019 to 2 July 2019. One hundred and eighty questionnaires were mailed to the firms, then follow-up telephone call were made to invite non-respondents to respond to questionnaire. Finally, one hundred and seventy five respondents completed and returned the questionnaires. Among the returned respondents who completed and returned the forms, one hundred and sixty eight of respondents were usable. The response rate was 97.2%. The large category (66%) of the respondents had worked in firms for more than 10 years. In regard to annual revenues, the companies were concentrated (91%) in 100 million NT dollars or above. 69.1% of the respondents worked in middle-sized companies (i.e., more than 300 but fewer than 5000 employees). It seems that the majority (54.8%) of the respondents’ position were department managers or senior managers who usually possessed a broad view and sufficient experience as well as first-hand knowledge concerning supply chain management practices of a company project.

3.3. Common Method Bias Test

Common Method Deviation (CMB) is the variance attributed to the measurement method rather than the construction. CMB occurs because all data are self-completed and collected through the same questionnaire through a cross-sectional study design over the same time period. For controlling the different sources of method bias, following the suggestion provided by Podsakoff et al. [90], the measures were taken in our questionnaire development: defining difficult terms in the questionnaire; in the questionnaire, examples were provided for complex items; avoiding extended questions, mainly based on prior test interviews.

Furthermore, we performed a check applying Harmon’s single-factor test [91] to confirm that this bias is not enough to undermine the validity of the results. According to the analysis process, all variables were entered into a principal components analysis with varimax rotation. According to Podsakoff and Organ [91], the common method variance may be present if one factor comes from the analysis, or one general factor has most of the covariance of the measure scores. The results of the analysis on data indicated that all the items could be categorized into 11 constructs, and the constructs with eigenvalues greater than 1.0 accounted for 74.24% of the variance, and the first construct accounted for 36.84% of the variance. Because no single factor comes from factor analysis, no general factor accounts for most of the variance among measures. Although an influence may exist to some extent, the results indicate that common method variance does not affect the results in the present study.

4. Analysis of Results

4.1. Construct Validity and Reliability

The proposed model was tested by structural equation model (SEM). SEM is a powerful two-step multivariate technique which consists of initial measurement model and subsequent structural model. The sufficiency of reliability and validity of the constructs of measurement model was tested by confirmatory factor analysis (CFA) first. Then, the structural model was applied to examine the direction and strength of the relationship among the theoretical constructs. In this study, AMOS 22—a useful statistical analysis software and has been applied in many investigation studies—was applied to evaluate the measurement and the structural models. The reliability of the scales was evaluated using composite reliability (CR) and Cronbach’s α [92]. The results of that analysis listed in Table 1. The Table 1 revealed that Cronbach’s α of the eleven constructs ranged between 0.779 and 0.943, exceeding the minimum hurdle level of 0.70 [93]. Furthermore, the CR of the eleven constructs ranged between 0.683 and 0.944 was exceeded the minimum hurdle level of 0.60 recommended by Bagozzi and Yi [92]. These values indicated that reliability was satisfactory.

Table 1.

Reliability and convergent validity test.

The validity of the scales was evaluated using convergent and discriminant validity. Fornell and Larcker [94] suggested that a variable having a standardized loading below 0.50 is unacceptable. Following this rule, three items should be deleted. Finally, 35 items were retained (listed in Table 1) after re-specifying the instruments. The standardized loadings of all items ranged from 0.559 to 0.949 on their proposed constructs which exceeds the cut-off point of 0.50 suggested by Hair et al. [95]. In addition, the average variance extracted (AVE) of eleven constructs ranged from 0.658 to 0.852, which exceeded the minimum hurdle level of 0.5 suggested by Fornell and Larcker [94], except the construct of delivery term, the value of which was 0.423, a little lower than threshold value. The instruments for assessing constructs were deemed to exhibit convergence reliability, as most reliability values (listed in Table 1) are above the suggested thresholds recommended by researchers.

Discriminant validity is tested by correlation estimates between constructs using variance extraction measures [96]. Although the square root of AVE value (0.650) of the factor, “delivery term”, was little lower than the correlation shared with exchanging information ability (0.663) and response sensitivity (0.717), all other values of the square root of AVE from a factor are higher than the correlation shared among the factors and other factors in the research model, as presented in Table 2. This indicates that each construct is statistically different from the other constructs. The preceding analysis showed that the measurement model tests including measures of convergent and discriminant validity are considered acceptable.

Table 2.

Discriminant validity test.

4.2. Tests of Structural Model

In this study, the structural equation model technique is used to measure parametric values (i.e., path coefficients) for each of the study hypotheses implemented on the basis of the IT applications and SCC to judge their respective significance. Following the assessing the measurement model, we assessed a primary theoretical model which has four constructs with one gamma path and three beta paths. In the hypothesis relationship evaluation, the structural equation model is first evaluated by examining the χ2 and the fitting indices. The results (shown in Table 3) revealed that χ2 = 92.59 with 40 degrees of freedom (p = 0.00039 < 0.001) which shows an insignificant χ2. According to researchers [97], sample size severely affects the chi-square, so other goodness-of-fit indicators can be used to assist model evaluation [98]. Therefore, some studies in the literature suggest a more comprehensive examination of the fit indices. For the hypothesized model (see Table 3), χ2/df = 2.301, less than the standard of 3 recommended by Bentler and Bonett [99]. The RMSEA was 0.087, a value a little higher than the requirement (less than 0.8) suggested by Hair et al. [95]. The GFI has a score of 0.913 exceeding the 0.9 recommended by Hair et al. [95]. The AGFI value was 0.856 which exceeded 0.8 recommended by Scott [100]. The NFI was 0.942, the TLI was 0.954, and the CFI was 0.966, exceeding the standard value of 0.9 recommended by Brown and Cudeck [101]. To summarize, these indicators consistently indicate an acceptable fit between the hypothesized model and the data.

Table 3.

Goodness-of-fit of structural equation model (N = 168).

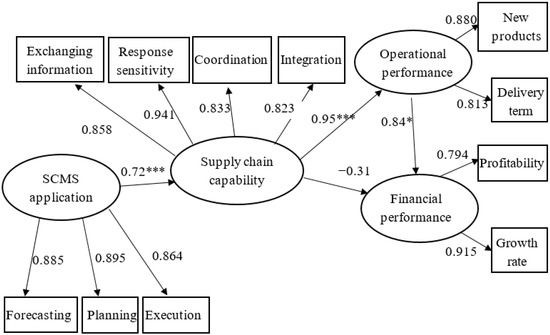

Table 4 shows the results of standardized parameter estimates for the structural model. As indicated in Table 4, the results supported the hypothesized relationships (H1, H2 and H4) between the endogenous constructs (supply chain capability, operational performance and financial performance) were supported at a significance level of 0.05. Consequently, supply chain capability was positively affected by SCMS implementation, as indicated by the completely standardized coefficient of 0.72 and p < 0.000; supply chain capability also positively affected operational performance, as indicated by the completely standardized coefficient of 0.95 and p < 0.000; moreover, financial performance was positively affected by operational performance, as indicated by the completely standardized coefficient of 0.84 and p < 0.05. Surprisingly, the supply chain capability did not have statistically significant effects on the financial performance (β = −0.31, p = 0.534). Figure 2 illustrates the results of the structural modeling analysis.

Table 4.

Standardized parameter estimates for structural model.

Figure 2.

Results of SEM analysis.

4.3. Mediating Effect Testing

Several studies have empirically demonstrated that SCC has a direct impact on financial performance [2,83,86,87]. However, Chang et al. [88] argued that operational performance mediates the relationship between SCC and financial performance. These are seemingly inconsistent ideas, so following the procedure proposed by Braon and Kenny [102], we checked the degree of the mediating effect of operational performance on the relationship between SCC and financial performance. They suggested that a variable functions as a mediator factor, which must meet the following requirements in the proposed direction: (i) The predictor variables (SCC) should impact the mediator (operational performance); (ii) The mediator (operational performance) should impact the dependent variable (financial performance); (iii) The predictor variables (SCC) should impact the dependent variable (financial performance); (iv) When controlling for the mediator (operational performance), it is full mediation if the impact of the predictor variables (SCC) on the dependent variable (financial performance) is not statistically significant, otherwise partial mediation if the impact is significantly reduced.

The mediating effect testing are listed in Table 5. The results in Model 1 indicate that the relationship between SCC and operational performance (β = 0.94, p < 0.001) and the relationship between operational performance with financial performance (β = 0.74, p < 0.001) are significant positive, which reveals the first and second requirements are met. In addition, the third requirement is met by Model 2. The relationship between SCC and financial performance is significant positive (β = 0.70, p < 0.001). Finally, controlling of the impact of the operational performance (mediator) in Model 3 reveals that SCC is not significantly related to financial performance (β = −0.31, p > 0.05). The foregoing analysis shows that the operational performance is a full mediation factor of the relation between SCC and financial performance and consistent with the findings of Chang et al. [88]. However, several studies [2,83,86,87] claim that the SCC directly impacts financial performance.

Table 5.

Tests of mediation results.

5. Conclusions and Implication

5.1. Conclusions and Discussion

The globalization era is characterized by shared standards and practices across the globe, as well as enormous complexities and uncertainties, and faced with these supply chain network leaders have established supply chain management systems (SCMS) to leverage the resources and knowledge of their partners to achieve greater supply chain capabilities (SCC) in order to respond to market changes and customers’ requirement change. The impact of SCMS implementationss on supply chains has been studied by many researchers and applied in various industries [8,103,104]. However, there is increasingly environmental and social awareness among citizens. Thus, the questions “what SCMS should they use to support their supply chain processes?” and “what mechanisms and relationships enable partners to realize sustainable benefits from their SCMS?” become more important, but are rarely studied. Therefore, this study empirically studied the impact of SCMS implementations on the industry supply chain capability, measured by the firm’s exchanging information ability, response sensitivity, coordinate ability and integration ability, and impact of operational (sustainable) performance, ultimately affecting firm performance within the bicycle industry in Taiwan.

The empirical results reveal that SCMS implement can enhance supply chain capability to sense market changes by improving the exchanging of information, and developing and executing a collaborated, coordinated and integrated response plan throughout the supply chain to respond to market changes and uncertainty. The results also indicate that supply chain capability improves the firm’s operating (sustainable) performance (innovation frequently, speed to market, reduce lead time, delivery reliability and customer service), ultimately enhancing financial performance (profit, sale volume, market share and rate of investment). In general, the SCMS implement has improved entire supply chain integration which enhances the sustainable outcomes of the entire supply chain partners by ensuring on-time product delivery, supply network optimization, and logistics reliability. From sustainability aspects, it also implied that the SCMS implementation in the Taiwan bicycle supply chain might induce partners to employ lean and agile management principles to attain a lean and agile virtual manufacturing network that connects all the partners in a single network, enabling the sharing of tangible (machines and equipment) and intangible assets (data, knowledge, and information) between the connected parties [105], thus helping them with planning, coordination, collaboration and integration to achieve the same output with fewer resources and higher efficiency. This would therefore reduce total energy consumption by maximizing the efficiency of SC processes such as scheduling, procurement, order fulfillment, engineering change, and design optimization. Agile manufacturing also promises to offer increased customization, flexibility and quality, reduce manufacturing waste, and decrease the manufacturing lead time [37,38,39,40,105]. Similarly, Gholami et al. [106] also found that IT implementation appear to influence the environmental value.

In addition, an industry supply chain possessing SCC can prevent itself from immediate competitive imitation and provide the basis of continuous competitive advantage since SCC are developed over time and are deeply plugged in to supply chain procedures [2,35]. These results reveal a strong message to managers for the strategic plan of SCMS to develop industry supply chain capability as a core competency to create competitive advantage. According to our research, the findings of the study are as follows:

In regard to the measurement instrument, the empirical results of confirmatory factor analysis coincide with the findings of previous studies (Chen and Paulraj [55], Feng et al. [60], DeGroote and Marx [8], Cao and Zhang [89]; Wu et al. [2]). Even if each construct retains its original characteristics, however, the indictor of “sense market changes in customer demand” (indicator a5) has been dropped from factor of forecasting with the number of reliable and appropriate items that can be used to measure this factor. It implies that sensing market changes in customer demand is the network leaders’ duty in Taiwan bicycle supply chain, and most supply chain partners just follow network leaders’ demand, so they do not use the mechanism in their work. These results are not fully consistent with the findings conducted by DeGroote and Marx [8]. Moreover, the indictor of “spends less time coordinating” (indicator b13) is also deleted from the factor of coordination ability. Such deletion does not comply with the findings reported by Wu et al. [2]. The differences might be due to the different level interaction and discussion mechanisms that play an important role in the determinants of coordination, thus it cannot be easy to achieve census opinion. In addition, the indicator of “outstanding on-time delivery” (indicator c 4) is also deleted from the factor of delivery term, which is also not consistent with the findings conducted by Flynn et al. [58]. The differences might be due to the fact that on-time delivery performance does not play so important role in the traditional bicycle industry compared to the IT industry.

For the hypothesized model, the overall empirical results of this study also provide tenable evidence that the proposed causal relationships model is acceptable, although one original hypothesis is not significant, e.g., supply chain capability on financial performance (H3). The results of the hypothesized model are as follows:

(a) The impact of SCMS implements on industry supply chain capability

The study results show that SCMS applications can promote the development of supply chain capabilities. This finding is consistent with the results provided by Wu et al. [2]. This finding suggests that using compatible information systems such as supply chain management systems to support a firm’s forecasts, plans and execution function with their key suppliers and customers to develop supply chain capabilities to respond to market uncertainty and changes is imperative. For developing strategy, managers must pay attention to facilitate information and knowledge sharing between the industry’s upstream and downstream, coordination, collaboration and integration for plan development and execution. Eventually, these SCMS implementations would play an important role in increasing the capacity of the supply chain. Furthermore, it also implied that vertical and horizontal integration done by SCMS implementations is an important enabler in driving supply chain sustainability, since coordination and collaboration with suppliers and customers in vertical and horizontal integration is essential for sustainable supply chain management [34,35,36]. However, to achieve the integration, managers and policy makers are needed to work together to create a real forum within their collaborative network in which there is a common culture and mutual trust [42].

(b) The impact of industry supply chain capability on firms’ operational performance

The results show that the development of supply chain capabilities can effectively improve new product development and delivery term, mainly through time to market, delivery reliability and customer satisfaction. This result is also consistent with previous findings [13,22], which suggested that with integrated supply chain information, the full supply chain members can virtually work together as a single entity, which enables complete coordination, collaboration and integration to quickly respond to market needs, and create the best value for customers. Furthermore, from and ecological viewpoint, the real-time information gathered from different market demand, along with an integrated production plan to help supply chain partners allocate their manufacturing resources, allows intelligent scheduling of tasks and manufacturing processes. This leads to reduced lead time and energy consumption; the number of wrong deliveries and unnecessary waiting time is reduced by data transparency throughout the entire supply chain, in turn enhancing delivery reliability and customer service. Additionally, by way of entire supply chain coordination, collaboration and integration, the product and manufacturing design was confirmed and improved through direct data interconnection from product usage back to design, thus improving product innovation frequency and speed to market. With the globalization, increasing rate of competition, technology development, customer expectations increasing, and market’s dynamic has made the supply chain become uncertainty and complexity which fills greater risks for companies. The SCC have provided new product development and delivery term opportunities for supply chain to gain competitive advantages today.

(c) The impact of firm’s operational performance on firm’s financial performance

The results of the study show that operational performance directly affects financial performance. The results consistent with previous studies [18,21,92], which strongly emphasized the link between firm operational performance and firm financial performance. Just as Dehning et al. [80] investigated the financial benefits of adopting IT-based SCMS, they found that higher levels of financial benefits came from higher levels of operational performance. This implies that SCMS implementation contributes information sharing and promotes the transparency and interconnection of processes, which allow partners’ coordination, collaboration, integration, optimization, increasing demand orientation, thus enabling produce efficiency, manufacturing flexibility, superior quality, lower manufacturing costs and product customization [31,32,37,38]. Additionally, this new business model based on novel value-creating mechanisms can achieve increasing customer satisfaction, market share and rate of investment [37]. Furthermore, among the statements of operational performance, “new products” is the most significant factor, as shown in Figure 2. This also implies that supply-chain members need to cooperate with one another and pay more attention to new product development for gaining competitive advantages. “Growth rate” is the most important factor for financial performance. That is, a firm’s long-term competitive advantage is based on market responses which, in large part, reflect customers’ satisfaction with designated products. Besides, it also implied that applying more efficient production processes, and achieving better productivity and economies of scale, might also result in increased economic sustainability.

(d) The operational performance mediates the relationship between SCC and financial performance

The results of the study show that operational performance mediates the relationship between SCC and financial performance. It indicates that financial performance may not be rewarded from SCC directly but from operational performance. The mediation effect of operational performance also implies that the inclusion of appropriate mediators may help to better explain the impact of SCC on financial performance. The present study provides some interpretations with regard to the inconsistent direct effects of SCC on financial performance [2,83,86,87] and consistent with the indirect effects of SCC on financial performance [23,24,88].

5.2. Managerial Implications

The results also provide some implications for those who manage the industry supply chain system, particularly for traditional industry. First, this study examines the effect of IT resources on full industry (upper, middle and downstream) supply chain capability and performance in the context of supply chain communication system (SCCS). The findings suggest that Taiwan’s bicycle industry needs to integrate SCMS implementations into its business functions. The findings also show that higher supply-chain capabilities can be created by the proper application of IT resources in SCCS, and realize benefits for the firm. Thus, managers should recognize the role of supply-chain capabilities, in terms of information exchange, activity coordination, activity integration as well as responsiveness, for fully realizing the value of IT application. As Barney [107] and Bonilla et al. [30] discuss, IT application can ensure sustainable benefits only when they are properly integrated with sustainable development goals and inserted in eco-operation supply chain platform processes. The results (Figure 2) show that the respondents in this study demonstrated high standardized parameter estimates in planning and forecast factors with regard to SCMS application; information exchange ability and responsive ability with regard to SCC; new product development with regard to operational performance; and growth rate with regard to financial performance. Thus, managers within the Taiwan bicycle industry should focus on the SCMS application in planning and forecast, such as developing a coordinated plan with supply chain partners based on the forecast of market changes in customer demand, competitor actions and technology trends. Furthermore, the information needs to be quickly and reliably shared and exchanged with the full supply chain for organizing and developing an appropriate plan to respond to the change and uncertainty in the market. The most effective responsive plan can be used to develop a new product to satisfy the change of customer demand. These findings are important for understanding why the Taiwan bicycle industry has a high market share and profit. Eventually, these SCMS implementations would play an important role in increasing the capability and capacity of the supply chain. This finding also be applied in other traditional industry supply chains, such as shoes, motorcycles, and garments.

Second, we discuss the mediating rode of operational performance. In this study, we explored the role of operational performance as a key mediator between SCC and financial performance. Results indicate that operational performance is able to transform SCC into higher value for a firm in terms of growth in sale, ROI, profit and market share. Through new product creation and product delivery embedding SCMS into full industry supply chain system, firms can enhance channel-specific assets through efficient and fast information exchange, better activity coordination, collaboration and integration with supply chain partners to appropriately respond to the market and changes in customer demand. The findings are very important in understanding why Taiwan bicycle manufacturers should enhance operational performance to improve financial performance. The results of the study also suggest a process that can assist managers to monitor and control their low financial performance problem. This means that if partners were found not to benefit from SCMS application, they really need to check “Does it enhance your supply chain capability and operational performance?”

In summary, the results indicate that IT application has a significant positive impact on supply chain capabilities, which subsequently links to a significant positive effect on operational performance and financial performance for full supply chain partners. This suggests that IT implementation does not merely consist of installing particular IS resources (e.g., SCMS), but that these IS resources are combined with embedded complementary organizational factors. Thus, effective SCMS implementation strategies require examining and improving previous patterns of organizational interactions, coordination, integration and application. Another interesting finding is that supply chain capabilities cannot directly affect financial performance. This study provides evidence of the mediating effect of operational performance on the relation between supply chain capabilities and financial performance. This finding also highlights the importance of improving firms’ supply chain capabilities. This implies that senior SC managers should pay closer attention to the importance of operational performance measures (e.g., innovation frequently, speed to market, reducing lead time, delivery reliability and customer service) in assessing the performance impacts of strategic initiatives such as SCMS implementation. Thus, the performance impact of SCMS implementation should be evaluated based on how these operational outcomes are first affected. Anyway, applying IT can serve as a vehicle to increase firms’ chances of being more effective in management and sustainability. Furthermore, the model is the first attempt to examine the impact of IT applications related to supply chain partners in the bicycle industry.

5.3. Limitations and Future Research

Although the study provides several significant findings for Taiwan’s bicycle industry, certain limitations need to be noted. First, the respondents of the study were in Taiwan’s bicycle industry. Therefore, the findings of the study are not applicable to other countries and industries. Second, the market in Taiwan is relatively small. As a result, a total of 168 vendors associated with bicycle firms were surveyed. Small sample size is a consideration of this study’s findings. Again, investigators need to exercise caution in terms of the generalization of the study results.

Further studies are needed because Taiwan’s bicycle industry is a model for the development of traditional industries. Bicycle firms need to integrate their resources across the board for the purpose of gaining competitive edges. The results of the study can serve as baseline data for further research. Based on the view of the authors, the following are the directions for future research. First, further studies could focus on verifying the impact of IT applications on other countries or industries. Second, this study is quantitative in nature. Further studies could combine both qualitative and quantitative methods in order to obtain deeper and richer insights concerning different perspectives of IT applications in Taiwan’s bicycle industry. Finally, nowadays in the era of industrial digitalization, companies are increasingly investing in Industry 4.0. Furthermore, there is increasing environmental and social awareness among citizens, and current research shows that there is still a lack of method-based and quantitative investigations of the impact of the implementation of Industry 4.0 and how it contributes to ecological protection and social justice.

Author Contributions

Conceptualization, J.L. and C.-W.C.; methodology, C.-W.C. and C.-H.W.; software, C.-H.W.; validation, J.L., C.-T.L. and C.-W.C.; formal analysis, C.-H.W.; investigation, H.-C.H.; data curation, H.-C.H.; writing—original draft preparation, J.L. and C.-W.C.; writing—review and editing, C.-T.L.; visualization, H.-C.H.; supervision, C.-T.L.; project administration, C.-T.L.; funding acquisition, J.L. and C.-T.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science and Technology of R.O.C (Taiwan), grant number MOST 108-2221-E-212-001-MY2.

Acknowledgments

Authors want to show acknowledgments to two reviewers for their valuable suggestions and comments. We also want to acknowledgments to all the respondents for their careful answer the questionnaire.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Summary of Prior Literature on the Study in Relationship between IT and Performance

| Authors | Study Aim | Investigate Object | Results |

| Wu et al. [2] | Examine the effect of information technology on supply chain capabilities and company performance. | Supply chain and logistics managers in various industries. | The total effects of IT advancement on market performance and financial performance are positive and significant. |

| DeGroote and Marx [8] | Investigate IT impact on supply chain agility and it impact on company performance. | Supply chain executives at U.S. manufacturing firms. | IT improves the supply chain’s ability to sense market changes and increases the supply chain’s ability to respond to market changes. |

| Peng et al. [9] | How information technology (IT) affects firm performance. | China’s manufacturing industry. | The coherent integration of IT capability with firm’s ability to optimize business processes and to improve management of supply chains can enhance firm performance. |

| Radhakrishnan et al. [10] | Examined the direct and indirect effect of IOS usage (through external integration) on the capabilities of a buyer -supplier dyad. | Buyer-supplier dyads. | External integration plays a mediating role in the relationship between IOS usage and capabilities of buyer - supplier dyad. |

| Prajogo et al. [11] | Examined the role of information management impact on operational performance. | Manufacturing firms in Australia. | Both internal information management and external information management have positive relationships with both internal process management and external process management. |

| Yu et al. [12] | The effect of data-driven supply chain capabilities on financial performance. | China’s manufacturing industry. | A data-driven supply chain significant impact on the four dimensions of supply chain capabilities and ultimately impact on financial performance. |

| Kim and Shin [16] | How the use of blockchain in SC influence SC partnership efficiency and growth, thereby affecting SC performance. | Various industries in Korean. | The blockchain technology characteristics have significant positive effects on partnership growth and marginal effects on partnership efficiency and firm performance. |

References

- Stevens, G.C. Integrating the supply chain. Int. J. Phys. Distrib. Mater. Manag. 1989, 19, 3–8. [Google Scholar] [CrossRef]

- Wu, F.; Yeniyurt, S.; Kim, D.; Cavusgil, S.T. The impact of information technology on supply chain capabilities and firm performance: A resource-based view. Ind. Mark. Manag. 2006, 35, 493–504. [Google Scholar] [CrossRef]

- Liao, S.H.; Kuo, F.I. The study of relationships between the collaboration for supply chain, supply chain capabilities and firm performance: A case of the Taiwan׳ s TFT-LCD industry. Int. J. Prod. Econ. 2014, 156, 295–304. [Google Scholar] [CrossRef]

- Lynch, D.F.; Keller, S.B.; Ozment, J. The effects of logistics capabilities and strategy on firm performance. J. Bus. Logist. 2000, 21, 47–68. [Google Scholar]

- Morash, E.A. Supply chain strategies, capabilities, and performance. Transp. J. 2001, 41, 37–54. [Google Scholar]

- Rajaguru, R.; Matanda, M.J. Effects of inter-organizational compatibility on supply chain capabilities: Exploring the mediating role of inter-organizational information systems (IOIS) integration. Ind. Mark. Manag. 2013, 42, 620–632. [Google Scholar] [CrossRef]

- Pereira, J.V. The new supply chain’s frontier: Information management. Int. J. Inf. Manag. 2009, 29, 372–379. [Google Scholar] [CrossRef]

- DeGroote, S.E.; Marx, T.G. The impact of IT on supply chain agility and firm performance: An empirical investigation. Int. J. Inf. Manag. 2013, 33, 909–916. [Google Scholar] [CrossRef]

- Peng, J.; Quan, J.; Zhang, G.; Dubinsky, A.J. Mediation effect of business process and supply chain management capabilities on the impact of IT on firm performance: Evidence from Chinese firms. Int. J. Inf. Manag. 2016, 36, 89–96. [Google Scholar] [CrossRef]

- Radhakrishnan, A.; Davis, J.S.; Sridharan, S.V.; Moore, D.W.; David, D. The impact of inter-organizational information systems-enabled external integration on capabilities of buyer–supplier dyads. Eur. Manag. J. 2018, 36, 558–572. [Google Scholar] [CrossRef]

- Prajogo, D.; Toy, J.; Bhattacharya, A.; Oke, A.; Cheng, T.C.E. The relationships between information management, process management and operational performance: Internal and external contexts. Int. J. Prod. Econ. 2018, 199, 95–103. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Jacobs, M.A.; Feng, M. Data-driven supply chain capabilities and performance: A resource-based view. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 371–385. [Google Scholar] [CrossRef]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Xue, L.; Ray, G.; Sambamurthy, V. The impact of supply-side electronic integration on customer service performance. J. Oper. Manag. 2013, 31, 363–375. [Google Scholar] [CrossRef]

- Qrunfleh, S.; Tarafdar, M. Supply chain information systems strategy: Impacts on supply chain performance and firm performance. Int. J. Prod. Econ. 2014, 147, 340–350. [Google Scholar] [CrossRef]

- Kim, J.S.; Shin, N. The impact of blockchain technology application on supply chain partnership and performance. Sustainability 2019, 11, 6181. [Google Scholar] [CrossRef]

- Tijan, E.; Aksentijević, S.; Ivanić, K.; Jardas, M. Blockchain technology implementation in logistics. Sustainability 2019, 11, 1185. [Google Scholar] [CrossRef]

- Subramani, M. How do suppliers benefit from information technology use in supply chain relationships? MIS Q. 2004, 28, 45–73. [Google Scholar] [CrossRef]

- Clemons, E.K.; Row, M.C. Limits to interfirm coordination through information technology: Results of a field study in consumer packaged goods distribution. J. Manag. Inf. Syst. 1993, 10, 73–96. [Google Scholar] [CrossRef]

- Rezaei, J.; Ortt, R.; Trott, P. How SMEs can benefit from supply chain partnerships. Int. J. Prod. Res. 2015, 53, 1527–1543. [Google Scholar] [CrossRef]

- Chen, C.D.; Fan, Y.W.; Farn, C.K. The Study of the Effects of Market-oriented Culture, Relationship-specific Investments and Process Integration Capabilities on Supply Chain Management Performance: The Moderating Role of Information Technology Competence. Int. J. Commer. Strategy 2011, 3, 81–99. [Google Scholar]

- Chen, C.J. A Study of Supply Chain Integration and Its Relations with ICT, Product Complexity, Involvement of SC Members, and SC Performance. J. E-Bus. 2011, 13, 241–247. [Google Scholar]

- Hartono, E.; Li, X.; Na, K.S.; Simpson, J.T. The role of the quality of shared information in interorganizational systems use. Int. J. Inf. Manag. 2010, 30, 399–407. [Google Scholar] [CrossRef]

- Li, S.; Ragu-Nathan, B.; Ragu-Nathan, T.S.; Rao, S.S. The impact of supply chain management practices on competitive advantage and organizational performance. Omega 2006, 34, 107–124. [Google Scholar] [CrossRef]

- Dobson, G.; Pinker, E.J. The value of sharing lead time information. IIE Trans. 2006, 38, 171–183. [Google Scholar] [CrossRef]

- Lee, H.L.; So, K.C.; Tang, C.S. The value of information sharing in a two-level supply chain. Manag. Sci. 2000, 46, 626–643. [Google Scholar] [CrossRef]

- Beier, G.; Niehoff, S.; Xue, B. More sustainability in industry through industrial internet of things? Appl. Sci. 2018, 8, 219. [Google Scholar] [CrossRef]

- Kiron, D.; Unruh, G. The Convergence of Digitalization and Sustainability. MIT Sloan Manag. Rev. 2018. [Google Scholar]

- de Man, J.C.; Strandhagen, J.O. An Industry 4.0 research agenda for sustainable business models. Procedia Cirp 2017, 63, 721–726. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R.; Terra da Silva, M.; Franco Gonçalves, R.; Sacomano, J.B. Industry 4.0 and sustainability implications: A scenario-based analysis of the impacts and challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia Cirp 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2019, 252, 119869. [Google Scholar] [CrossRef]

- Nagy, J.; Oláh, J.; Erdei, E.; Máté, D.; Popp, J. The role and impact of industry 4.0 and the internet of things on the business strategy of the value chain—The case of Hungary. Sustainability 2018, 10, 3491. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2018. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an enabler of sustainability diffusion in supply chain: An analysis of influential strength of drivers in an emerging economy. Int. J. Prod. Res. 2019, 58, 1505–1521. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the relation between lean manufacturing, Industry 4.0, and sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Determinants of information and digital technology implementation for smart manufacturing. Int. J. Prod. Res. 2019, 188, 1–22. [Google Scholar] [CrossRef]