Abstract

Enterprises of the supply chain are currently embedded in dynamic and turbulent environments, having to deal with the appearance of disruptive events. When an enterprise is affected by a disruptive event, the consequences of the disruption not only impact in the enterprise itself, but also influences on the other partners of the network to which it belongs. Thus, disruptive events exceed the capability of individual actors, impacting on the network performance. Consequently, network partners have to collaboratively make decisions to soften the negative impacts on the performance. In this regard, after a disruption takes place, network enterprises should be aware of activating a set of sustainable and resilience strategies that attenuate the performance loss and reduce the disruption recovery time. Nevertheless, the diverse nature of disruptions means that a wide range of varied and sometimes contradictory strategies can be formulated, resulting in conflict situations among the collaborative network (CN) partners. The current paper proposes an approach that makes it possible to collaboratively manage the strategies to activate when a disruptive event occurs, so that the selected strategies are aligned. The strategies alignment approach, proposed in the paper, makes it possible to select those strategies that have a positive impact, or a minimum negative impact, on the objectives defined, not only in the enterprise itself, but also in the objectives defined by the rest of CN partners. The alignment of strategies makes it possible to reduce the performance level loss when a disruption takes place. Thus, the strategies alignment approach aims at activating those strategies that maximize the performance of the CN, achieving levels of performance equal or higher than the levels previous to the disruption, limiting the adverse effects produced by the disruptive events, and contributing to a more sustainable–resilient CN. Finally, in order to validate the proposal, a case study is presented. The proposed model is validated to deal with a drop in demand due to a political embargo, in a textile CN.

1. Introduction

The current global business environment, characterised by being unpredictable and competitive, makes enterprises more exposed to disruptive events. This encourages enterprises to change the way they work, towards being more flexible and sustainable for recovering themselves against potential disruptions. The complexity and dynamicity associated with the disruptive events needs a high level of reactivity and adaptation within the affected enterprises. These restrictions became more limiting when the disruption affects to the collaborative network (CN) [1], and new challenges arise. According to [2], supply chain resilience (SCR) is “The ability of a system to return to its original state or move to a new, more desirable state after being disturbed”. In SCR, the efficacy and efficiency of the disruption management requires a sustainable approach, because disruptive events could have impacts in societal, environmental and economic dimensions.

CN enterprises are characterised by being autonomous entities, each one with different objectives. Therefore, the way of recovering from disruptive events is, consequently, not the same. Thus, in a CN, the enterprises can encounter a situation where the defined objectives and strategies, formulated to deal with a disruptive event, could be contradictory among the CN partners. These contradictions make it difficult to develop a unified scenario that captures the different objectives and strategies of the network enterprises. In the light of this, the benefits associated with the strategies’ alignment have a great influence on achieving a sustainable CN, becoming a relevant issue to obtain competitive advantages [3].

The formulation of sustainable resilience strategies enables enterprises to respond and adapt to disruptive events, taking into account sustainable factors, which make it possible to meet the needs of the present CN without compromising the its future operation. Sustainable resilience strategies allow the recovery and adjustment of the CN, and the enterprises that make it up, to return to the state before the event, or to attain new and better performance [4].

As disruptive events exceed the capacity and capability of individual actors, wider collaboration is required among the network partners [5]. Thus, the discipline of CN plays an important role, in the SC resilience perspective. In addition, such strategies can be proactively or reactively deployed [6]. Therefore, resilience in CN does not only depend on the proactive capacity to react to a disruptive event, but also the CN enterprises need to have reactive, adaptative and recovery capacities in order to recover the performance level achieved before the disruption occurred [7]. Some authors only focus on proactive solutions, which make it possible to improve the enterprises’ preparedness [8,9,10]; while others focus on proposing reactive and recovery management approaches [11,12,13]. In this context, the literature review carried out by [8] outlines as a future research line the consideration of an approach that supports the integration of proactive and reactive strategies. The authors argue that most models assume a single type of mitigation strategy, highlighting that, in practice, it can be quite effective to use multiple strategies, and especially to develop both proactive and reactive mitigation strategies simultaneously. Moreover, the developed literature review identifies the need for new models that mitigate disruptions in multi-echelon systems, such as CN environments.

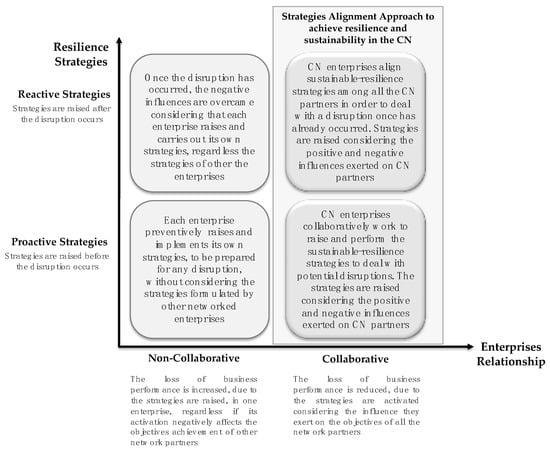

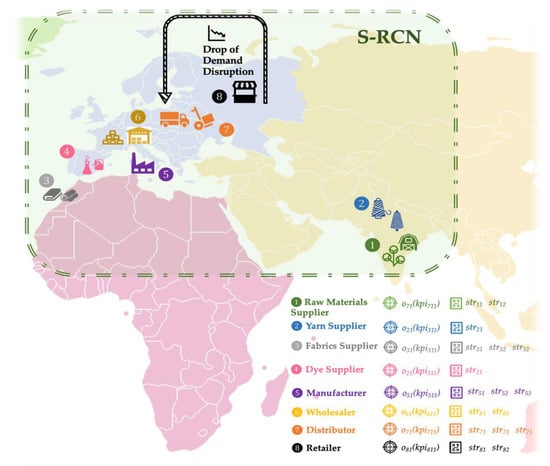

This paper focuses on the proposal of a collaborative approach to deal with the alignment of strategies formulated when disruptions appear, in order to achieve a sustainable–resilient CN (Figure 1). The proposed strategies alignment approach allows for representing all the objectives and sustainable resilience strategies set by all the CN enterprises, and the influences exerted among them. Moreover the strategies alignment approach makes it possible to simultaneously consider reactive and proactive strategies in the model, responding to the future research lines proposed by [8]. The model is based on the system dynamics method and promotes the activation of those strategies that positively influence all the CN partners, allowing them to reduce the loss of business performance and maintain the CN’s sustainability after a disruptive event occurs. The application of the strategies’ alignment approach will allow CN enterprises to increase their agility and resilience, using such qualities as an advantage for the network’s survival and sustainability. In the light of this, the paper is organized as follows: Section 2 introduces the materials and methods of the paper, including the state of the art on sustainable–resilient CN (S–RCN), the problem description, and the strategies alignment model proposed to deal with disruptions in an S–RCN. Section 3 validates the results of the proposed strategies alignment approach by its application in an Italian textile supply chain, consisting of eight echelons, from the raw materials supplier to the retailer, which is affected by a drop-in-demand disruption due to a political embargo. Finally, in Section 4, conclusions and future research lines are considered.

Figure 1.

Collaborative strategies alignment approach to achieve a sustainable–resilient supply chain.

2. Materials and Methods

2.1. State of the Art: Sustainable–Resilient CN (S–RCN)

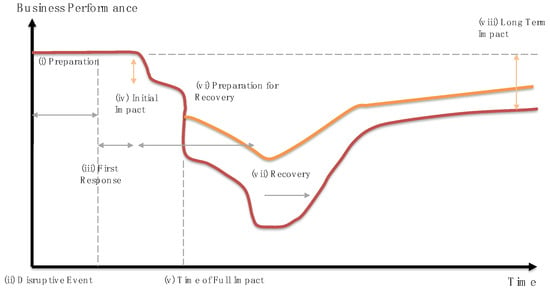

Enterprise resilience, responsiveness, robustness and flexibility are widely documented topics due to their relevance for reducing the negative effects derived from disruptions [14,15,16,17,18,19,20]. In this regard, the term “disruption”, outlined by [21], is defined as a predictable, or in most cases unpredictable, event that directly affects the common activity and stability of an enterprise, affecting its performance. The authors of [22] model the loss of business performance, defining the phases that enterprises experience when a disruption occurs (Figure 2). The disruptions classification is addressed by different authors making it possible to easily identify and overcome them. Thus, [22] address the classification from an enterprise perspective, whilst [23] focus on the potential disruptions identification from a SC perspective, using supply chain events management (SCEM). Other works addressing the research area of resilience from the SC context are developed in [17,24]. Similarly, [14] determines how disruptions propagate and affect SC, through the disruption analysis network (DA_NET) methodology.

Figure 2.

Disruption phases (Adapted from [22]).

A systematic literature review has been performed in the Scopus database with regard to SC resilience and sustainability using the following keywords: (TITLE-ABS-KEY (supply AND chain AND resilience) AND TITLE-ABS-KEY (sustainability)). A total of 155 documents were identified from 2008 to 2020, which indicates that SC resilience and sustainability has gained increased attention during the in the last decade. Nevertheless, there is still a gap on studying the inter-dependence between resilience and sustainability [25]. The definition of resilient SC and sustainable SC is described and documented in [26]. This author envisions the future of SC as obtaining trade-offs in the principles and practice of sustainability and resilience in SC, and introduces the concept of partition line that divides the sustainability-oriented upstream SC from the resilience-oriented downstream SC, opening up new insights into the concept of S–RCN. The authors of [27] state the importance of resilience to deal with disruptions and sustainability in the SC, identifying a clear gap between resilience and sustainability. The authors propose a hybrid approach for resilient and sustainable SC design, minimizing costs and maximizing SC sustainability. Work in [28,29] also addresses the supply chain network design problem from a resilient perspective, proposing an optimization model. Analytic methodologies [30] and simulation methods [31] are proposed in the literature to deal with sustainable–resilient supply chains. In this regard, [30] propose a network optimization model that considers sustainability, in terms of carbon footprints and emissions, and resilience, using a resilience index and a fuzzy multi-objective model under uncertainty. On the other hand, [31] demonstrates the intersections between resilience and SC sustainability, and presents a simulation study to deal with dynamics of SC structures and processes, identifying the influences of SC dynamics for achieving SC resilience. The author analyses the disruption propagation in the SC, taking into account the sustainability factors, namely reduction of the storage in SC facilities, in order to design resilient SC structures to mitigate the ripple effect and increase the SC sustainability. Multiple sourcing, high facility fortification, and high number of warehouses are some of the strategies proposed by [31] to deal with sustainability and resilience in SC. Although different approaches have been proposed in the literature to deal with sustainability and resilience, [25] outlined, as a future direction of research, the characterisation of the relation between resilience and sustainability, proposing to explore whether resilience is a necessary condition for sustainability and/or vice versa.

2.2. Problem Description

The literature has established resilience and sustainability concepts as key issues in the future continuity of CN operations [32,33,34,35]. Nevertheless, achieving S–RCN entails arduous efforts for researchers in the area, since there are still missing approaches to deal at the same time with sustainability and resilience in CN.

The problem to be solved in this paper follows this research line and deals with CN resilience and sustainability when a disruption takes place. In this regard, CN enterprises should be aware of activating in a short time period a set of sustainable resilience strategies that would reduce the performance loss when a disruptive event occurs. Nevertheless, the diverse nature of strategies may result in conflict situations, among the enterprises of the same CN. The main aim is to minimize the negative influences that the objectives experience when some specific strategies are activated. Accordingly, the enterprises have to align their own strategies with the strategies of their partners. To this extent, there is a need to develop an approach to support the decision of identifying which strategies to activate in order to be aligned, to quickly respond to the disruptive event and achieve S–RCN.

Consider two enterprises; each one defines one objective and formulates one strategy. Each objective is associated with a key performance indicator (KPI) to measure its achievement.

- Enterprise 1: defines objective1, which is associated with the KPI1, and formulates strategy1

- Enterprise 2: defines objective2, which is associated with the KPI2, and formulates strategy2.

The strategies formulated, strategy1 and strtrategy2, are considered to be fully aligned when (i) the activation of strategy1 exerts a positive influence on both objective1 and objective2. This means that the activation of strategy1 exerts an increase on the KPI defined to measure the objective of the same enterprise 1, , and exerts an increase on the KPI defined to measure the objective defined by the other enterprise 2, ; and (ii) simultaneously, in enterprise 2, the activation of strategy2 exerts a positive influence in both objective1 of enterprise 1 () and objective2 of enterprise 2 (). Accordingly, the strategies are aligned and the total benefit obtained is higher than the sum of the benefits obtained by the activation of each strategy individually [36].

The extensive literature review on resilience conducted by [37] define, as a future research line, the need for a collaborative tool to gain SC visibility, in order to evaluate the impact of disruptions on the SC. The authors conclude that there is a gap in the consideration of the duration of disruptions with the capacity of recovery and the costs of this recovery, identifying hybrid optimization-based simulation techniques as potential approaches to be applied to analyze recovery dynamics. The authors of [25] establish, as a future research line, the development of a common modelling and analysis framework for the success of S–RCN. Moreover, the authors propose to connect enterprise- and network-level properties and standardise key components of resilience and sustainability between such different contexts. The authors establish as a critical factor the proposal of a unified approach to address all dimensions and levels of resilience simultaneously. To this extent, [27] defines resilience strategies for SC and determines that the formulation and selection for its activation is crucial to maximize the supply performance and overall sustainability of the SC when a disruption occurs.

This paper proposes a strategies alignment approach that makes it possible to answer the future research lines aforementioned, enabling CN enterprises to quickly identify the strategies to be activated as a response to face the disruptions occurred, considering sustainable factors. Thus, rapid recovery strategies are formulated and activated to expedite stabilization and adaptation, in order to ensure the CNs’ continuity and reach long-term sustainability.

2.3. Strategies Alignment Model to Deal with Disruptions in a S–RCN

Assuming that the strategies are the set of actions raised to achieve the defined objectives, i.e., minimise the performance loss derived from a disruption, the strategies alignment concept is defined as the set of strategies whose activation positively influence the objectives achievement of all the CN enterprises, increasing the performance of the network. Consider two enterprises ei and ej; each one defines one objective (oi and oj) and formulates two strategies (stri and strj). The strategies stri and strj are considered to be aligned when the activation of stri exerts a positive influence on oi and oj; the same occurs with strj, which exerts a positive influence on oj and oi. Accordingly, this paper develops a model that allows identifying the strategies to activate, considering that they are aligned one with another from the global perspective of the CN. Assuming that the enterprises want to collaborate, the alignment of strategies is achieved when the activated strategies positively influence all the objectives defined by all the networked enterprises, and measured by key performance indicators (KPI). The alignment will enhance the performance of the objectives associated, reducing the margin of loss when a disruption takes place. The developed solution proposes a hybrid approach that considers system dynamics method in combination with a mathematical programming method.

The proposed strategies alignment model consists of a hybrid optimization-based system dynamics simulation technique, and serves as an analysis tool that allows companies in a CN to estimate the impacts of recovery measures. The sustainable resilience strategies formulated by each CN partner act as recovery measures raised to deal with the disruptions. The dynamic behavior of the recovery strategies is simulated according to the influence exerted by the disruption. The influences that the sustainable resilience strategies, formulated by the networked partners, have on their performance indicators are also represented in the proposed strategies alignment systems dynamic simulation model.

In order to reduce the performance loss and be more resilient against any disruption, enterprises are encouraged to collaborate and align their strategies [3,38]. In light of this, a model to collaboratively carry out the strategies’ alignment process is developed. The strategies alignment model is designed considering that, after a disruption occurs, the CN partners formulate a set of reactive strategies to manage this disruption, considering sustainability aspects such as delivery speed, adaptability, strategic partnerships, efficiency, lean management, labor equity, product life cycle costing, environmental issues, social issues, safety, and reverse logistics [26]. Moreover, we have also drawn on [26] to define resilience strategies, including transparency, operational capabilities, visibility reduction of uncertainty, integration, redundancy, collaboration, flexibility, responsiveness, reduction of complexity and agility. The strategies alignment model collaboratively works in order to identify, amongst all the strategies raised, those that are aligned, allowing the members to reduce the negative influences reflected in the key performance indicators (KPIs), contributing to achieving lower performance impact and sustainable CN. The strategies alignment model supports enterprises in deciding which strategies activate in order to align the own strategies with the strategies formulated by the other partners in the network.

2.3.1. Variables Definition

The definition of the variables used in the strategies alignment model is provided in Table 1 [3]. The model is subject to the following assumptions:

Table 1.

Nomenclature.

- The networked enterprises define a set of objectives (measured through KPIs) to minimize the disruption’s impacts. A maximum level of each KPI is determined in order to identify the extent to which the objectives are achieved.

- A set of sustainable resilience strategies are formulated by the enterprises in order to achieve the defined objectives. The strategies are raised to eliminate or reduce the negative effects, once the disruption has occurred.

- The use of KPIs allows computing the reduction of loss in the network performance.

The model proposed takes into account the further research work defined in [3] through:

- Considering a delay parameter (d1_stris), to model the fact that when a stris is activated, the kpiixk does not notice its influence until d1_stris passes

- Defining the decision variable ti_stris, which allows identifying the time instant in which stris is to be activated.

2.3.2. Objective Function and Restrictions

The strategies alignment model is hereafter developed. The objective function and the associated restrictions, representing the relations amongst all the defined variables, are proposed.

The objective of the model is to identify, amongst all the strategies defined, those strategies that are aligned, in order to positively influence all the objectives defined by the networked partners and reduce the performance loss resulting from a disruption. The model computes the KPIs improvement or worsening when a strategy is activated. Thus, the objective function (Equation (1)) maximizes the increase of the kpinet according to the units of strategies to be activated, u_stris, and the time in which activate the sustainable resilience strategies ti_stris.

The kpi’net is the homogenized global KPI at network level, computed through the average of all KPIs at enterprise level (Equation (2)).

The homogenized is computed considering all the increases experienced by all KPIs defined in the same enterprise (), by taking into account the importance associated to each kpiixk (wixk) (Equation (3)).

The is the dimensionless parameter of (Equation (4)). The allows comparing all the parameters one with another.

The parameters , and are homogenized. Allowing them to be compared, i.e., enables comparing all the KPIs defined in the same enterprise. The increase of the , when stris is activated, is calculated by (Equation (5)).

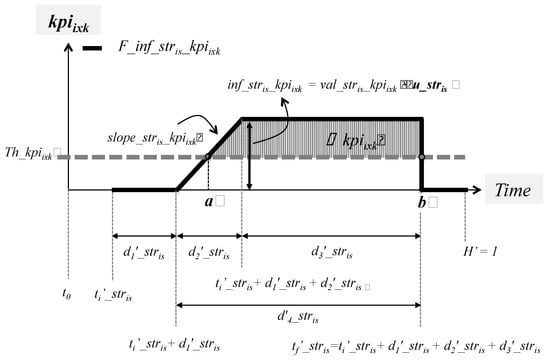

where, and b > a (b = tf_stris). The influence function F_inf_stris_kpiixk (Equation (6)) is a piecewise function (Figure 3).

Figure 3.

Influence function F_inf_stris_kpiixk represented as piecewise function.

The models the gradual influence that stris exerts on the kpiixk (Equation (7))

The maximum value achieved by F_inf_stris_kpiixk is represented by inf_stris_kpiixk (Equation (8)).

The number of strategy units ( is the decision variable that allows identifying which strategies activate; therefore if:

- u_stris = 0, stris must not be activated

- u_sis1, stris must be activated, and is characterized by being aligned; additionally, the variable u_stris identifies the degree of deployment of each strategy. For instance, we can define a strategy “stris: Invest 10 m.u. in research activities”; the completion of the whole strategy will be given by u_stris = 1 in which 10 m.u are invested. However, there may be a situation in which u_stris = 0.5, in this scenario, stris is implemented 50%, investing 5 m.u. On the other hand, u_stris = 5 indicates that 50 m.u. are to be invested. Accordingly, the total monetary units invested in one strategy are computed by Equation (9).

The time intervals of the piecewise function (F_inf_stris_kpiixk) are given by the duration parameters. All the durations are normalized to the unit (Equations (10), (11), (12) and (13)), as well as the horizon H’ = 1 (Equation (14)) and the points in time (Equations (15) and (16).

The capacity constraint (Equation (17)) models that the monetary units spent on the strategies’ activation will not exceed the budged.

The time constraint (Equation (18)) models that the instant time in which the strategy finishes will not be higher than the horizon (H).

where

The model application will result in the identification of which strategies activate and to what extent (u_stris), and when to initiate their activation (ti_stris), allowing sequencing the strategies in such a way that the network performance is maximized.

2.3.3. Systems Dynamic Method

Solving the strategies alignment model through analytical methods requires tedious procedures involving large number of iterations. For that reason, the use of the systems dynamic method is considered. The systems dynamic method, outlined by [39], makes it possible to analyze the characteristics of feedbacks in the represented system, allowing an understanding of how the elements belonging to the system interact with each other, influencing the performance of the system. Generally, systems dynamics allows an understanding of the causal relationships that produce the system’s behavior, by bringing together sets of elements that are interrelated in such a way that a change in one element affects the whole series of elements [40].

Particularly, systems dynamics allows representing the influences that the activated sustainable resilience strategies exert on the KPIs level; this relation of influence is represented in the strategies’ alignment process. Depending on the strategies activated, the KPIs level will be positively or negatively influenced: (i) positive loops will be depicted when the activation of a strategy generates an increase in the KPI level (likewise, when the non-activation of a strategy generates a reduction in the KPI level); (ii) negative loops will appear when the activation of a strategy implies a loss in the KPI level (similarly, when the non-activation of a strategy implies an increase in the KPI level). The systems dynamic method simultaneously considers positive and negative influences enhancing the system stabilization. The systems dynamic method makes it possible to simultaneously simulate all the elements of the system by changing at the same time all the decision variables, enabling the system to identify the appropriate strategies to be activated in order to exert positive influences on the achievement of all the KPIs defined by all the networked enterprises (for further details, the reader is invited to read [3]).

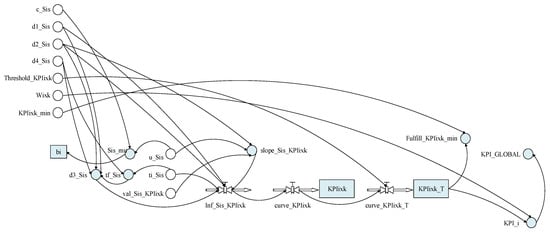

The causal loop diagram allows for representing the elements and relationships of the modelled system, based on causes having an influence on effects (+ and - loops). The flow diagram translates the information depicted in the causal loop diagram into a terminology that helps write equations in the computer. The representation of the flow diagram involves classifying the parameters and variables defined in the model into: stock variables (which are a mental photograph of the system), flow variables (elements determining the variation of levels), parameters and auxiliary variables. Accordingly, analogous to the strategies alignment model:

- Stock variables: bi, ;

- Flow variables: F_inf_stris_kpiixk, kpi’ixk;

- Parameters: wk, stris, u_stris, c_stris, val_stris_kpiixk, ti_stris, d’1_stris, d’2_stris, d’4_stris, Threshold_kpiixk;

- Dynamic variables: kpi’i, kpi’n, stris_mu, d’3_sis,tf_stris, slope_stris_kpiixk, inf_stris_kpiixk.

The parameters, identified to define the strategies alignment model (SAM), are transcribed in order to be applied in system dynamics (SD) domains (Table 2).

Table 2.

Elements of the system dynamics (SD) flow chart diagram.

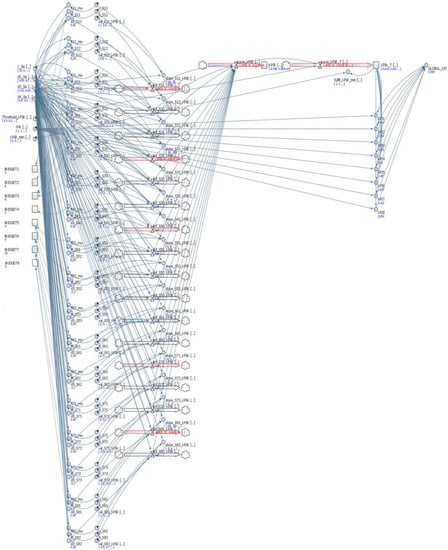

The creation of the SD flow diagram is described next and depicted in Figure 4 [36]. The stock variables are the elements related to the Budget, bi, of each enterprise participating in the SAM, and to the increase of the kpiixk before computing the Threshold_kpiixk (KPIixk) and after (KPIixk_T). The stock variables represent the situation of the SAM in all times. The flow variables, represented by the elements Inf_Sis_KPIixk, curve_KPIixk and curve_KPIixk_T, define the variation of stock variables. In this particular case, the flow variables represent the behavior of the kpiixk when a certain set of strategies stris are activated (Inf_Sis_KPIixk). Flow variables are defined by piecewise functions that depend on time. Auxiliary variables and parameters are given by: (i) the data that define the strategies, such as costs (c_Sis, Sis_mu) and duration (d1_Sis, d2_Sis, d3_Sis and d4_Sis); (ii) the data that affect the increase/decrease of the KPIs, such as the values of influence (val_Sis_KPIixk) and the slope (slope_Sis_KPIixk); (iii) the decision variables, represented by the elements u_Sis and ti_Sis; and (iv) the equations related to the KPIs both at Enterprise level, KPI_i, and at Network level, KPI_GLOBAL.

Figure 4.

SD Flow diagram modelling the strategies alignment collaborative process.

The schema represented in Figure 4 is be extended according to the number of enterprises, the number of KPIs defined and the strategies formulated, all of them belonging to the elements modelled to support the strategies alignment process.

The proposed systems dynamic method is used to solve the strategies alignment model. Particularly, the AnyLogic® simulation software [41] is used (AnyLogic 8 Personal Learning Edition 8.5.1), bringing together systems dynamics, simulation of discrete events and agent-based modelling approaches. The optimiser package included in AnyLogic® software allows obtaining the best set of parameter solutions while the system generates multiple scenarios in the simulation tool. The optimization process allows finding the optimal combination of parameters resulting in the best solution as regards the decision variables ti_stris, u_stris, in order to support enterprises in deciding which strategies activate to align them with the those defined by the networked partners.

3. Results: Validation of the Strategies Alignment Model

3.1. Case Study

The strategies alignment model was applied to an Italian supply chain that produces and delivers textile products. An Italian textile supply chain was considered as a case study, due to the authors’ extensive experience [4] on resilience in the fabric sector due to politician embargos and multiple disruptions affected by Italian textile supply chains. The study case was applied based on a realistic case occurring in an Italian textile network. The textile network consisted of eight enterprises located in different places of the world, including: the cotton supplier and yarn supplier, both located in India; the fabrics supplier, located in Morocco; the Spanish dye supplier; and the Italian manufacturer, wholesaler and distributor, which supply final products to the retailer located in Russia. During normal network operation, a disruption demand takes place due to a political embargo. Immediately after the occurrence of the disruptive event, each affected enterprise formulated a set of strategies to be potentially activated in order to mitigate and reduce the effects that the demand disruption has on the original equipment effectiveness (OEE) performance indicator of each enterprise, and on the global CN. From all the formulated strategies, the network partners have to identify the ones that are aligned for their activation. The strategies will enable them to achieve the objective of globally obtaining the maximum performance level of the CN (Figure 5).

Figure 5.

Textile supply chain network.

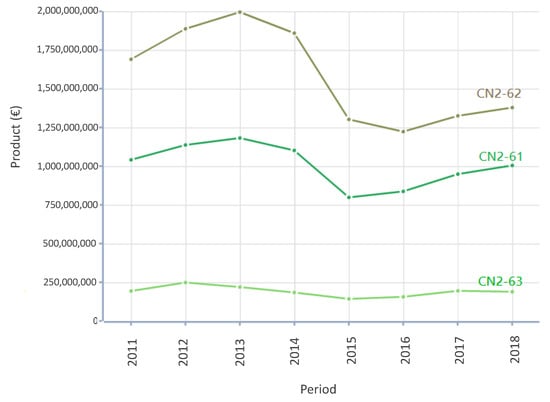

Generally, demand disruption causes a drop in demand that induces an overproduction during a certain period of time. Consequently, a certain quantity of the products, affected by the disruption, do not have the expected demand during a period of time and, therefore, cannot be distributed in the usual market for sale. The drop off demand disruption topic has been broadly analyzed in the literature, and can be generated by various causes. Focusing on the sector-side causes, we can find the risk of new entrants, or errors in forecasting demand. The textile industry falls indeed in the fashion sector, which is characterized, among other things, by high impulse purchasing by customers, short lifecycles and low predictability. This is why the last two mentioned can be considered a both high-impact and low/medium-probability risks. Focusing on the market-side, the drop in demand can be originated by macroeconomic factors, such as economic crises, healthcare crises, environmental issues or geopolitical interests. The textile business is extremely sensitive to economic situations and, as a result of the experience of the 2008 crisis, economic resilience has now become a property for many companies to cultivate [42,43,44]. Another factor that can critically influence the textile sector is the one related to the environment. Today’s consumers’ choices are increasingly driven by these issues, since they are aware of environmental protection, social responsibility, and economical sustainability [45]. As a result, companies in this sector are adopting the adaptive capacity in order to respond to these additional changes in clients’ behavior. Finally, the textile sector can also be dependent on political decisions, which in any moment could trigger embargos or non-tariff barriers to, i.e., textile garments by aggravated certification requirements [42]. A clear example of demand disruption can be seen through the measures adopted by the Russian government in response to the sanctions imposed, by USA and EU, for its support of the pro-Russian separatists that act in eastern Ukraine. The measures taken by Russian authorities have generated banning of products imports from the EU, USA, Australia, Canada, Japan and Norway (see Figure 6) In this regard, this embargo has so far cost Italian companies approximately EUR 12 billion, with companies in the Veneto region losing over EUR 2 billion: i.e., the textile sector has gone from an export of EUR 376 million to EUR 262 million [46].

Figure 6.

Export trends from EU28 to Russia of clothing and household textile products (CN groups 61-62-63). Adapted from EUROSTAT.

The network under study hereafter modelled deals with a drop in demand due to a political embargo coming from the government under which the retailer is located. The network global objective is defined as: “Reduce or eliminate the loss of business performance resulting from the demand disruption”. All the SC partners consider as a performance indicator the overall equipment effectiveness, to measure the objective’s achievement. The OEE is a framework for measuring the efficiency and effectiveness of a process, by breaking it down into three constituent components: (i) quality, which takes into account quality loss, tracking rejected parts; (ii) performance, which considers the performance loss due to factors that cause the process to operate at less than the maximum possible; and (iii) availability, which monitors the events that stop planned production for an appreciable length of time. The OEE will make it possible to measure the recovery degree when the drop in demand disruption occurs. For the achievement of the objectives, a set of strategies are formulated by each CN partner. Table 3 presents a description of the sustainable resilience strategies formulated, by each partner, to achieve and maximize the defined OEE performance indicator. The formulated strategies are extracted from a real Italian textile supply chain in which sustainable strategies are defined to deal with resilience against disruptions from a reactive perspective.

Table 3.

CN partners strategies definition.

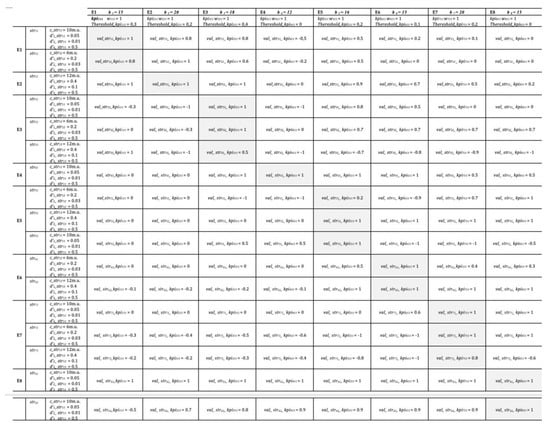

The influence that each strategy has on each objective is shown in Figure 7 (val_stris_kpiik). The data characterize (i) the strategies’ duration in time units normalized to the unit H’=1 (d’1_stris, d’2_ stris, d’4_stris) and cost in monetary units (c_stris); and (iii) the KPIs’ relevance (wxik) and threshold values (Thereshold_kpxxik). Above the Threshold_kpiixk value, the influence exerted by stris is considered; otherwise, below the threshold value, the influence is not considered. In the textile CN modelled, the parameter of strategies duration is defined by parameter d4_ stris, which equals to a six-month period, in which the disruptive event is expected to be controlled in order to allow all the CN partners to reach a balance between the produced and distributed products, and eliminate the overproduction generated resulting from the disruption of demand. The horizon to be simulated is H = 12 months. Since the strategies alignment model uses a normalized horizon of time (H’ = 1), the variables related to duration are also normalized, i.e., d’4_ stris = d4_ stris/H = 6/12 = 0.5 [u.t.]. All the numerical values have been extracted considering the strategies formulated and the OEE performance indicator. The expertise of the authors in collaborative networks, supply chains and resilience research areas, added to the experience of previous industrial applications of the strategies alignment model [47], has made it possible to give values to all the data related to strategies’ costs and duration, as well as the values of influence.

Figure 7.

Numerical Example Data.

According to the values of influence (val_stris_kpiixk) of Figure 7, the activation of str73, formulated as opening new markets and selling the products at a lower price, has a negative impact on all the KPIs defined by the CN partners, because opening new markets has associated additional costs, which would incur for all the stakeholders of the CN. Moreover, selling the products at a lower price depreciates the quality of raw materials, components and products manufactured and supplied along the CN, which would affect to CN quality status and sustainability. On the contrary, str81 has a positive impact in all the KPIs defined by the CN enterprises, due to the promotion of purchasing practices that guarantee the sustainability of the supply chain, which positively impacts on the sustainable and resilience values achieved by the CN partners.

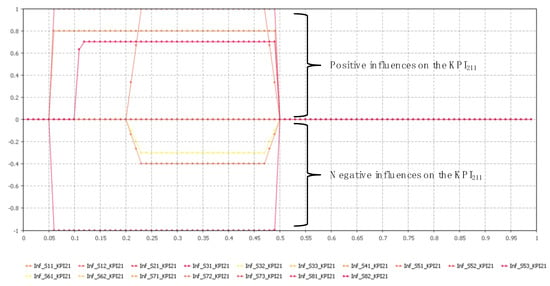

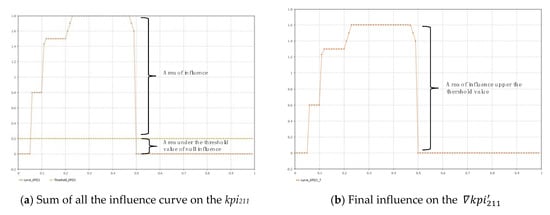

In a more detailed view, the influence experienced by the kpi211 when strategies of all the CN partners are activated is seen in Figure 8. Figure 8 depicts the graph with all the influence curves of the strategies that have an impact on the kpi211. Moreover, the graph depicted in Figure 9 gives a better insight into how the threshold value works for computing the influence on kpi211. In Figure 9a, the orange curve is the result of the sum of all the areas under the curves (depicted in the Figure 8), using the definite integral. The area below the threshold value (yellow line) is not counted for computing the when the strategies are activated. Finally, Figure 9b represents the increase that the kpi211 experiences as a consequence of the strategies’ activation, , by only considering the area under the Threshold_kpi211.

Figure 8.

Influence curves of each strategy on the kpi211.

Figure 9.

Influences on the kpi211.

3.2. Implementation and Resolution

The resolution of the strategies alignment model using the systems dynamic method allows identifying the number of units of each strategy (u_stris) and the time of activation (t_stris), which results in the maximum performance for the global S–RCN as a whole.

In systems dynamic method, the stock variable (Equation (19)) is computed through considering:

- The influence of the strategies activated in the same enterprise in which the kpiixk is defined (ei), F_inf_stris_kpiixk, and

- The influence of the strategies activated by the rest of enterprises of the network (ej), F_inf_strjs_kpiixk.

The flow chart diagram (Figure 10) allows representing the relations between the variables; AnyLogic® software is used. The collaborative scenario is depicted, taking into account the influences of all the strategies on the KPIs. In this specific model, the connections between the KPIs increase or decrease, and the strategies activated are depicted (F_inf_stris_kpiik). The increase in the number of units of strategy to be activated (u_stris) provokes an increase or decrease in the maximum influence variable (inf_stris_kpiixk), which depends on the value val_stris_kpiixk. If val_stris_kpiixk is positive, when stris is activated the receives a positive influence. Otherwise, if val_stris_kpiixk is negative, the influence experienced by the will be negative when the strategy stris is activated. The stock variable produces an increase in the same direction in the dynamic variable kpi’i, defined at enterprise level, and consequently in the kpi’net, defined at network level.

Figure 10.

Flow chart diagram in the collaborative scenario. Identifying the strategies to activate in AnyLogic® software.

3.3. Results

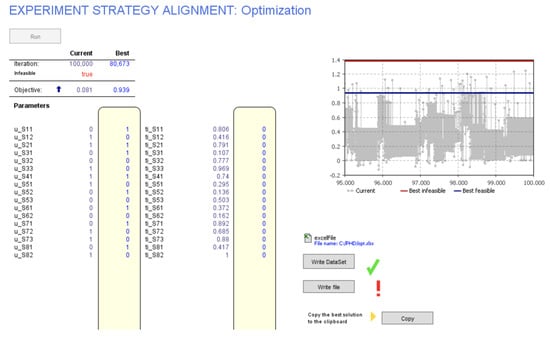

The optimization tool that AnyLogic® software brings allows identifying the decision variables (u_stris and ti_stris) that optimize the global KPI defined at network level (kpi’net). Two scenarios, the non-collaborative and the collaborative one, have been simulated in AnyLogic®. On the one hand, the non-collaborative scenario computes the alignment of strategies within each company in isolation, this is, without considering the influences that the strategies activated, for example by the manufacturer, have on the KPIs defined by the cotton supplier, yarn supplier, the fabrics supplier, the dye supplier, the, wholesaler and distributor and the retailer, and vice versa. Thus, the non-collaborative scenario only considers the influences that the strategies exert on the objectives defined in the same enterprise (see the light grey colored cells in Figure 7). On the other hand, in the collaborative scenario, apart from considering the alignment of the strategies within each enterprise, the networked enterprises align their own strategies with the strategies of their partners in the network; therefore, all the values depicted in Figure 7 are considered to compute the collaborative strategies’ alignment.

Figure 11 shows the optimal solution obtained in the collaborative scenario. Each dot in the graph corresponds to a single scenario with different solutions in the parameters’ scope. The optimization process carries out repetitive simulations of the system dynamic model introduced, by varying the values of the decision variables (u_stris and ti_stris), and, therefore, giving different values of the kpi’net parameter. The optimization experiment, in the simulation software used, is based on a combinatory resolution method. Depending on the number of enterprises, the performance indicators defined and the strategies formulated in the problem, the number of iterations required to solve the modelled problem varies. Therefore, the proper definition of the number of iterations is crucial in order to always obtain the same optimal solution. For this application, with eight partners of the textile CN, in which eight KPIs are defined and 17 strategies are formulated, the number of iterations used to solve the strategies alignment model is 100,000, obtaining the best feasible solution at iteration 80,673, with a global KPI of 0.939.

Figure 11.

Optimisation solution: collaborative scenario.

In the collaborative scenario, the optimization experiment results led the raw material supplier to activate str11, the yarn supplier activates str21, the fabric supplier activates str31, the dye supplier activates str41, the manufacturer activates str252, the wholesaler activates str61, the distributor activates str71, and finally, the retailer activates str81. The initial activation time of each strategy is also given, making it possible to logically activate the strategies in order not to disfavor their deployment. In this particular case, the strategies are to be activated simultaneously at ti_stris = 0, dealing with the disruptive event immediately after the disruption occurs and allowing the CN to be resilient and sustainable, due to the characteristics of the strategies selected for their activation. The model results suggest that strategies {str12, str32, str33, str51, str53, str62, str72, str73, str82} should not be activated, because their activation provokes a reduction in the global KPI defined by the network (kpi’net). The set of strategies {str11, str21, str31, str41, str252, str61, str71, str81} are characterized by being aligned, and their activation not only generates the KPI increases in the same enterprises in which they are defined, but also promotes positive increases in the KPIs defined by the rest of enterprises belonging to the S–RCN.

In order to have a better insight into how the collaborative scenario improves the dynamic variable kpi’net, both scenarios have been simulated. Figure 10 shows the flow diagram and Figure 11 depicts the optimization solution, both in the collaborative scenario. Table 4 summarizes the results derived from the experiments in the AnyLogic® simulation software considering the non-collaborative and collaborative scenarios. The collaborative scenario is characterized by the complete exchange of information, in which data related to the strategies and the objectives is shared among all the network partners. The collaborative scenario is characterized by implementing the strategies alignment model for all the enterprises of the network. This takes into account not only the influences exerted by the strategies formulated in the same enterprise but also considers the influences of the strategies formulated by the rest of enterprises. At the end of the simulation, the strategies alignment model makes it possible to identify the decision variables, [stris, ti_stris], … [strjs, ti_strjs], that refer to the strategies to be activated and aligned, and the time at which to initialize the activation of the strategies. Then the enterprises’ performance is computed for each CN partner [kpii, …, kpij]. Finally, the network performance, kpinet, is computed as the average of the enterprises’ performance. From Table 4, it can be deducted that the collaborative perspective view (taking into account the influences of the strategies on both CN enterprises) provides better performance levels than considering the enterprises in an isolated way in the non-collaborative scenario, in which the enterprise makes the decision of which strategies activate without considering the strategies of the other enterprises and how to affect to its own objectives.

Table 4.

Results: non-collaborative scenario vs. collaborative scenario.

The optimized solution of the collaborative scenario using the strategies alignment model generates a level of network performance significantly higher (9%) than the performance resulting from the solution obtained in the non-collaborative scenario (0.86). It can be observed that the performance at network level is higher in the collaborative scenario (0.939), but this does not necessarily mean that the performance indicators computed at the enterprise level improve when enterprises collaborate in the decision of determining which strategies to activate. It can be observed that enterprises E5 Manufacturer, E6 Wholesaler, and E7 Distributor achieve higher performance levels than in the non-collaborative scenario. To this extent, the network manager has to negotiate with the networked partners in order to adopt the solution that increases the performance level from a global perspective and not form an individual point of view. Assuming that all the enterprises collaborate, the strategies alignment model allows identifying amongst the 17 strategies formulated those that are aligned and that have positive impacts in the objectives defined by both enterprises. This results in a reduction of the performance loss to deal with the demand disruption and an activation of those strategies that enable the achievement of a sustainable CN. Through the comparison of both scenarios, it can be stated that the collaborative scenario gives better results than the non-collaborative one. The eight partners belonging to the textile CN have enabled validation of the usefulness of the collaborative strategies’ alignment model, with the main aim of reducing the loss of performance against any disruption, and ultimately, achieving a S–RCN.

4. Discussion and Conclusions

The competitiveness and dynamicity that characterises the current business environment increasingly triggers the occurrence of disruptions. When dealing with these disruptions, the SC partners have to decide whether to collaborate or not, knowing that companies involved in collaborative processes have major advantages in order to respond to unexpected changes in extreme situations. CN enterprises are affected by the loss of performance when a disruption occurs. Subsequently, the enterprises willing to collaborate have to opt for aligning their own strategies with the strategies of their CN partners, contributing to the network’s long-term operation and sustainability. The collaborative alignment of strategies permits a better management of disruptions, resulting in lower performance losses and higher capabilities within the CN partners to deal with sustainable challenges. Accordingly, this paper proposes, from a collaborative perspective, a strategies alignment model as a reactive solution to deal with the negative consequences derived from disruptive events. The developed model allows the networked enterprises to identify those strategies that, when activated, positively influence the attainment of the set objectives defined to deal the disruptive event occurred. The result consists of maximising the global network performance, reducing the performance loss when a disruptive event takes place, and ensuring a sustainable resilient collaborative network (S–RCN). The model has its background in the system dynamics method, which makes it possible to compute the influences between the strategies and the KPIs. The versatility of the proposed model makes it possible to reformulate the curve in order to model as many behaviors as the enterprises require, according to their needs and according to the way in which the strategies formulated influence the objectives defined.

The proposed strategies alignment approach has been validated in an Italian textile supply chain, in which an eight echelon network is considered, including the raw materials supplier, yarn supplier, fabrics supplier, dye supplier, manufacturer, wholesaler, distributor and retailer. From the application of the strategies alignment model, the results for the collaborative scenario provide higher levels of performance at the network level. Nevertheless, the application of the model has made it possible to see that the increase in the network performance could be sometimes given at the expense of the decrease in some enterprise’s performance. Therefore, negotiation processes can be conducted among the partners in order to obtain agreement with the potential set of aligned strategies. The validation of the negotiation process is set as s future research line to be conducted, in order to make the collaborative strategies alignment model a robust tool for achieving S–RCN. Moreover, the model application has made it possible to show CN enterprises another way of proceeding in the decision-making of selecting strategies based on the degree of alignment; that is, by considering not only the achievement of their own objectives but also the objectives of other enterprises of the CN.

The limitations of this study include the identification of the values of influence, val_strsi_kpixiz, which can be difficult and confusing to define due to the chaotic conditions that are associated after a disruption occurs. Future research lines include description of a detailed protocol to gather and share information after the disruption occurs, to accurately feed the strategies alignment model. In this regard, the impact of Industry 4.0 key technologies on supply chain resilience should be analyzed: this aspect is worth researching, since Industry 4.0 paradigms are becoming crucial to tackle disruptions and ameliorate vulnerability in links. Cloud collaborative environments and other technologies, including artificial intelligence, digital twins and blockchains can be embedded in the simulation software used. In this regard, AnyLogistix supply chain software supports the use of Industry 4.0 technologies, ensuring business KPIs continue to be best targeted as quickly as possible after a disruption occurs and enabling the S–RCN operation. Moreover, in order to give better insight into the usefulness of the strategies’ alignment model in the analyzed disruption context, it would be relevant to conduct future research experiments introducing uncertainty values to define the influences between the strategies and the performance indicators.

Author Contributions

This work forms part of the research of B.A., supervised by G.M., which proposes a collaborative tool to deal with the strategies alignment process when a disruption takes place, allowing to achieve a sustainable–resilient collaborative network (S–RCN). B.A. modelled the problem and G.M. proposed the data for the model validation. Conceptualization, B.A.; methodology, B.A.; software, B.A.; validation, B.A. and G.M.; formal analysis, B.A. and G.M.; investigation, B.A. and G.M; resources, G.M.; data curation, B.A. and G.M.; writing—original draft preparation, B.A. and G.M.; writing—review and editing, B.A. and G.M.; visualization, B.A.; supervision, B.A.; project administration, B.A.; funding acquisition, B.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ayuda Vali+D Formacion-Andres Navarro (ACIF/2012/006). (16/04/12–16/04/15) GENERALITAT VALENCIANA.

Acknowledgments

The research leading to these results was supported by the Spanish Ministry of Science, Innovation and Universities project entitled ‘Optimisation of zero-defects production technologies enabling supply chains 4.0 (CADS4.0)’ (RTI2018-101344-B-I00).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Camarinha-Matos, L.; Afsarmanesh, H. Collaborative networks: A new scientific discipline. J. Intell. Manuf. 2005, 16, 439–452. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the Resilient Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Andres, B.; Poler, R. A decision support system for the collaborative selection of strategies in enterprise networks. Decis. Support Syst. 2016, 91, 113–123. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Marcucci, G.; Mazzuto, G. Fuzzy cognitive maps approach for analysing the domino effect of factors affecting supply chain resilience: A fashion industry case study. Int. J. Prod. Res. 2019, 1–29. [Google Scholar] [CrossRef]

- Camarinha-Matos, L.; Afsarmanesh, H.; Boucher, X. The Role of Collaborative Networks in Sustainability. Nonlinear Model Predict. Control 2010, 336, 1–16. [Google Scholar]

- Chorn, N.H. The “Alignment” Theory: Creating Strategic Fit. Manag. Decis. 1991, 29, 20–26. [Google Scholar] [CrossRef]

- Starr, R.; Newfrock, J.; Delurey, M. Enterprise resilience managing risk in the networked economy. Strategy Bus. 2004, 30, 1–10. [Google Scholar]

- Snyder, L.V.; Atan, Z.; Peng, P.; Rong, Y.; Schmitt, A.J.; Sinsoysal, B. OR/MS Models for Supply Chain Disruptions: A Review. SSRN Electron. J. 2010, 48, 89–109. [Google Scholar] [CrossRef]

- Egbelakin, T.; Poshdar, M.; Walsh, K.Q.; Ingham, J.M.; Johnston, D.; Becker, J.; Mbachu, J.; Rasheed, E. Preparation of small to medium-sized enterprises to earthquake disaster. Bull. N. Z. Soc. Earthq. Eng. 2018, 51, 171–182. [Google Scholar] [CrossRef]

- Kimura, N.; Hoshino, S.; Onitsuka, K. Analyzing the Association Between Disaster Risk Preparedness and Environmental Consciousness of Small and Medium-Sized Enterprises: The Case of Sukagawa City, Fukushima Prefecture, Japan. J. Disaster Res. 2019, 14, 1047–1058. [Google Scholar] [CrossRef]

- Ivanov, D. Simulation-based ripple effect modelling in the supply chain. Int. J. Prod. Res. 2017, 55, 2083–2101. [Google Scholar] [CrossRef]

- Morrish, S.; Jones, R. Post-disaster business recovery: An entrepreneurial marketing perspective. J. Bus. Res. 2019, in press. [Google Scholar] [CrossRef]

- Tang, G. Research on transformation from “paired assistance” to “collaborative networks” in post-disaster recovery of 2008 Wenchuan Earthquake, China. Nat. Hazards 2019, 1–23. [Google Scholar] [CrossRef]

- Wu, T.; Blackhurst, J.; O’Grady, P. Methodology for supply chain disruption analysis. Int. J. Prod. Res. 2007, 45, 1665–1682. [Google Scholar] [CrossRef]

- Erol, O.; Sauser, B.J.; Mansouri, M. A framework for investigation into extended enterprise resilience. Enterp. Inf. Syst. 2010, 4, 111–136. [Google Scholar] [CrossRef]

- Nair, A.; Vidal, J.M. Supply network topology and robustness against disruptions—An investigation using multi-agent model. Int. J. Prod. Res. 2011, 49, 1391–1404. [Google Scholar] [CrossRef]

- Kim, Y.; Chen, Y.-S.; Linderman, K. Supply network disruption and resilience: A network structural perspective. J. Oper. Manag. 2014, 33, 43–59. [Google Scholar] [CrossRef]

- Kamalahmadi, M.; Parast, M.M. A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. Int. J. Prod. Econ. 2016, 171, 116–133. [Google Scholar] [CrossRef]

- Sanchis, R.; Poler, R. Enterprise Resilience Assessment—A Quantitative Approach. Sustain. 2019, 11, 4327. [Google Scholar] [CrossRef]

- Pei, J.; Liu, W. Evaluation of Chinese Enterprise Safety Production Resilience Based on a Combined Gray Relevancy and BP Neural Network Model. Sustainability 2019, 11, 4321. [Google Scholar] [CrossRef]

- Barroso, A.; Machado, V.; Cruz, V. Supply Chain Resilience Using the Mapping Approach. In Supply Chain Management; IntechOpen: London, UK, 2011; pp. 161–184. [Google Scholar]

- Sheffi, Y.; Rice, J.B. A Supply Chain View of the Resilient Enterprise. A Supply Chain View of the Resilient Enterprise. MIT Sloan. Manag. Rev. 2005, 47, 41–48. [Google Scholar]

- Ivanov, D.; Sokolov, B.; Dolgui, A.; Solovyeva, I. Application of control theoretic tools to supply chain disruption management. In Proceedings of the IFAC Proceedings Volumes; Elsevier BV: Amsterdam, The Netherlands, 2013; Volume 46, pp. 1926–1931. [Google Scholar]

- Craighead, C.W.; Elkins, D.; Handfield, R.B. An empirically derived agenda of critical research issues for managing supply-chain disruptions. Int. J. Prod. Res. 2005, 43, 4067–4081. [Google Scholar]

- Levalle, R.R.; Nof, S.Y. Resilience in supply networks: Definition, dimensions, and levels. Annu. Rev. Control. 2017, 43, 224–236. [Google Scholar] [CrossRef]

- Rajesh, R. On sustainability, resilience, and the sustainable–resilient supply networks. Sustain. Prod. Consum. 2018, 15, 74–88. [Google Scholar] [CrossRef]

- Jabbarzadeh, A.; Fahimnia, B.; Sabouhi, F. Resilient and sustainable supply chain design: Sustainability analysis under disruption risks. Int. J. Prod. Res. 2018, 56, 1–24. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and Resilient Supply Chain Network Design under Disruption Risks. Sustainability 2014, 6, 6666–6686. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, S.P. Sustainable procurement and logistics for disaster resilient supply chain. Ann. Oper. Res. 2016, 283, 1–46. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and Resilient Garment Supply Chain Network Design with Fuzzy Multi-Objectives under Uncertainty. Sustainability 2016, 8, 1038. [Google Scholar] [CrossRef]

- Ivanov, D. Revealing interfaces of supply chain resilience and sustainability: A simulation study. Int. J. Prod. Res. 2017, 56, 3507–3523. [Google Scholar] [CrossRef]

- Camarinha-Matos, L.M. Collaborative Networks: A Mechanism for Enterprise Agility and Resilience. Enterp. Interoperability VII 2014, 3–11. [Google Scholar]

- Andres, B.; Poler, R.; Sanchis, R. Collaborative Strategies Alignment to Enhance the Collaborative Network Agility and Resilience. Secur. Educ. Crit. Infrastruct. 2015, 463, 88–99. [Google Scholar]

- Barthe-Delanoë, A.M.; Montarnal, A.; Truptil, S.; Bénaben, F.; Pingaud, H. Towards the agility of collaborative workflows through an event driven approach—Application to crisis management. Int. J. Disaster Risk Reduct. 2018, 28, 214–224. [Google Scholar] [CrossRef]

- Zhu, W.; Wang, Z. The Collaborative Networks and Thematic Trends of Research on Purchasing and Supply Management for Environmental Sustainability: A Bibliometric Review. Sustainability 2018, 10, 1510. [Google Scholar] [CrossRef]

- Andres, B. An Approach to Support the Strategies Alignment Process in Collaborative Networks. Ph.D. Thesis, Universitat Politècnica de València, Valencia, Spain, 2016. [Google Scholar]

- Ivanov, D.; Sokolov, B.; Solovyeva, I.; Dolgui, A.; Jie, F. Dynamic recovery policies for time-critical supply chains under conditions of ripple effect. Int. J. Prod. Res. 2016, 54, 7245–7258. [Google Scholar] [CrossRef]

- Sanchis, R.; Poler, R. Definition of a framework to support strategic decisions to improve Enterprise Resilience. IFAC Proc. Vol. 2013, 46, 700–705. [Google Scholar] [CrossRef]

- Forrester, J.W. Industrial Dynamics; MIT Press: Cambridge, MA, USA, 1961. [Google Scholar]

- Campuzano, F.; Mula, J. Supply Chain Simulation. A System Dynamics Approach for Improving Performance; Springer: London, UK; Dordrecht, The Netherlands; Heidelberg, Germany; New York, NY, USA, 2011. [Google Scholar]

- AnyLogic. AnyLogic. 2020. Available online: https://www.anylogic.com/ (accessed on 25 March 2020).

- Abylaev, M.; Pal, R.; Torstensson, H. Resilience challenges for textile enterprises in a transitional economy and regional trade perspective - a study of Kyrgyz conditions. Int. J. Supply Chain Oper. Resil. 2014, 1, 54. [Google Scholar] [CrossRef]

- Li, W.-Y.; Chow, P.S.; Choi, T.-M.; Chan, H.-L. Supplier integration, green sustainability programs, and financial performance of fashion enterprises under global financial crisis. J. Clean. Prod. 2016, 135, 57–70. [Google Scholar] [CrossRef]

- Venkatesh, V.; Rathi, S.; Patwa, S. Analysis on supply chain risks in Indian apparel retail chains and proposal of risk prioritization model using Interpretive structural modeling. J. Retail. Consum. Serv. 2015, 26, 153–167. [Google Scholar] [CrossRef]

- Yang, S.; Song, Y.; Tong, S. Sustainable Retailing in the Fashion Industry: A Systematic Literature Review. Sustainability 2017, 9, 1266. [Google Scholar] [CrossRef]

- Sanctions against Russia and the Russian Embargo: Billions of Euros Damage to ‘Made in Italy’ Products. 2018. Available online: http://www.europarl.europa.eu/doceo/document/E-8-2018-002225_EN.html (accessed on 20 February 2020).

- Andres, B.; Pole, R. Supporting the Strategies Alignment Process in Collaborative Networks. In Doctoral Conference on Computing, Electrical and Industrial Systems; Springer: Cham, Switzerland, 2017; Volume 499. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).