Biocorrosion of Concrete Sewers in Greece: Current Practices and Challenges

Abstract

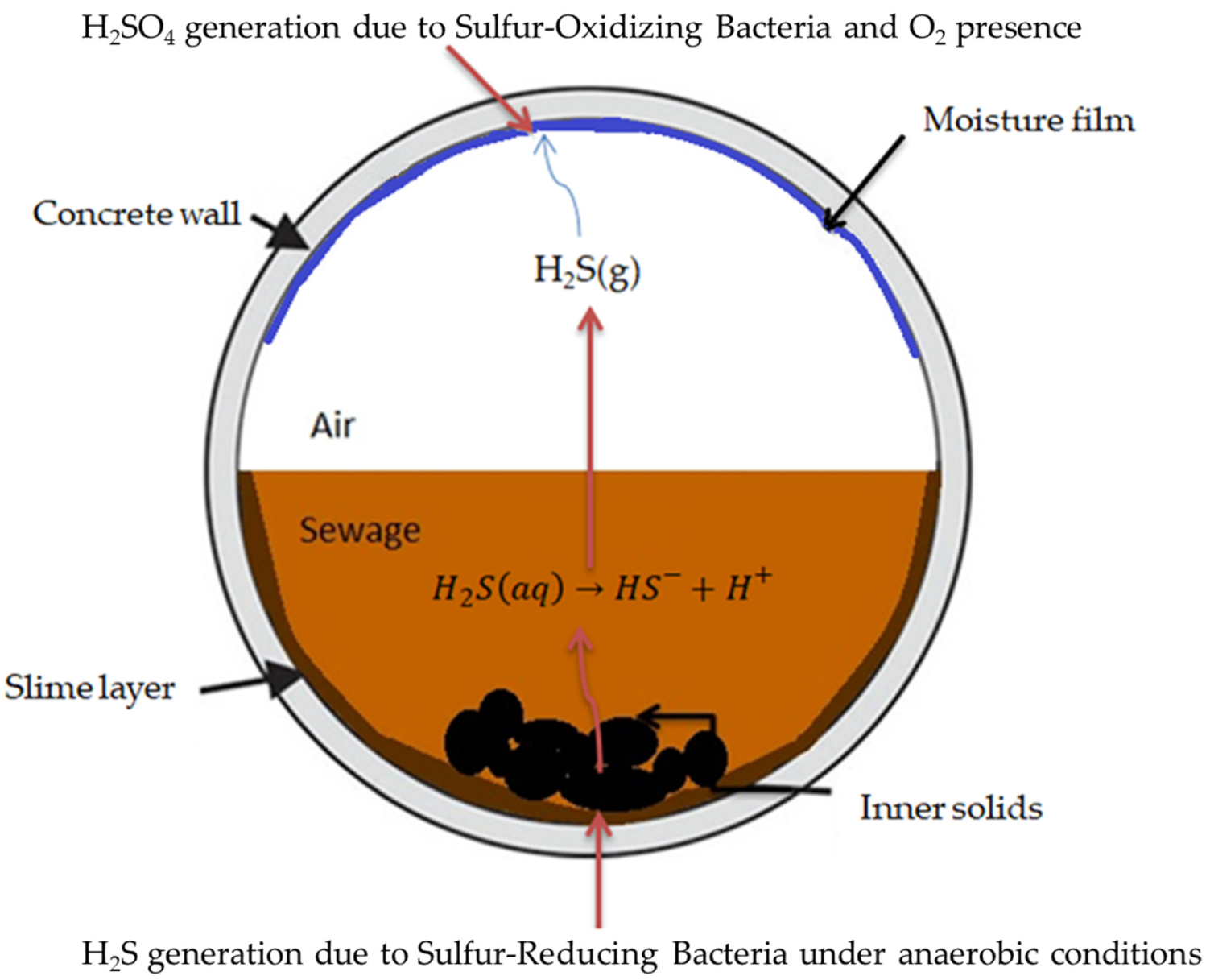

1. Introduction

2. Materials and Methods

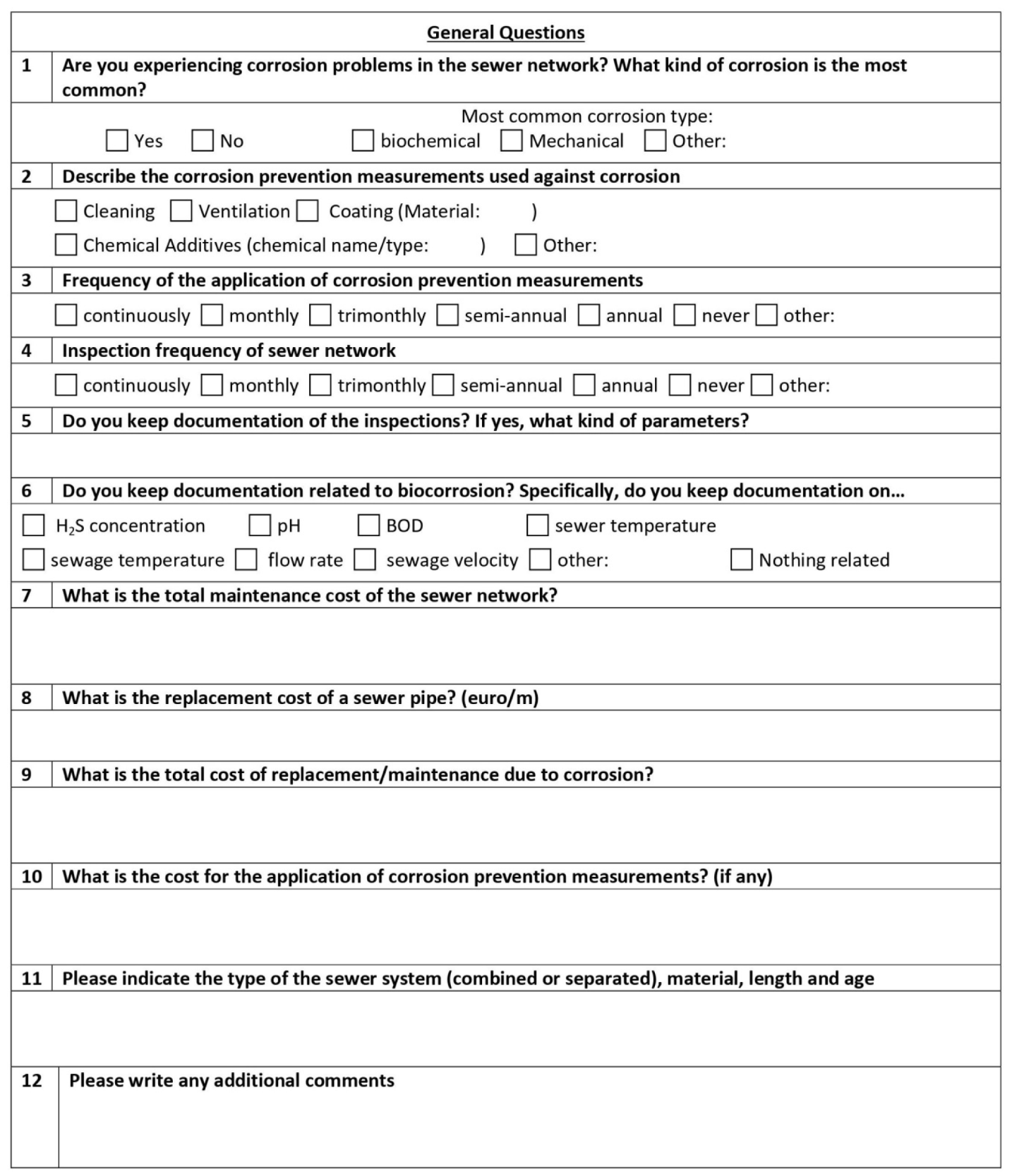

2.1. Questionnaire Development

- the overall state of the sewer network,

- the extent to which the corrosion of sewer pipes is generally recognized as a problem and how it is addressed,

- the extent to which different types of corrosion, especially biocorrosion, are identified as problems with different causes and how they are dealt with,

- the frequency of sewer network inspections and corrosion inhibitions measurements,

- a first estimate of the cost of network maintenance related to corrosion.

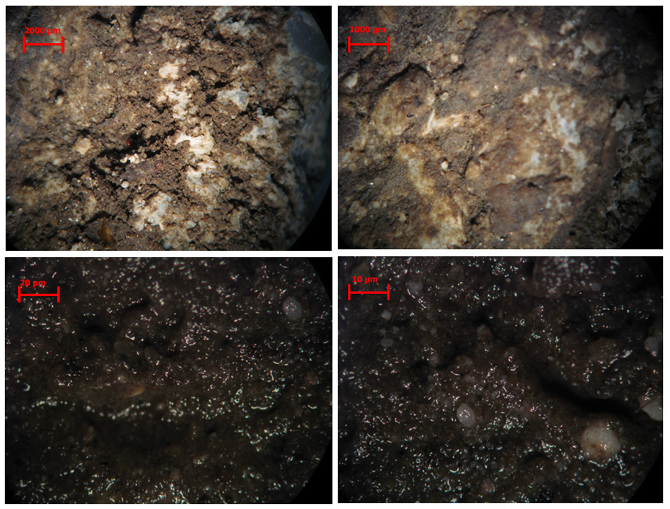

2.2. Analysis of Samples

2.3. Molecular Genetic Analysis of Bacterial Slime

3. Results

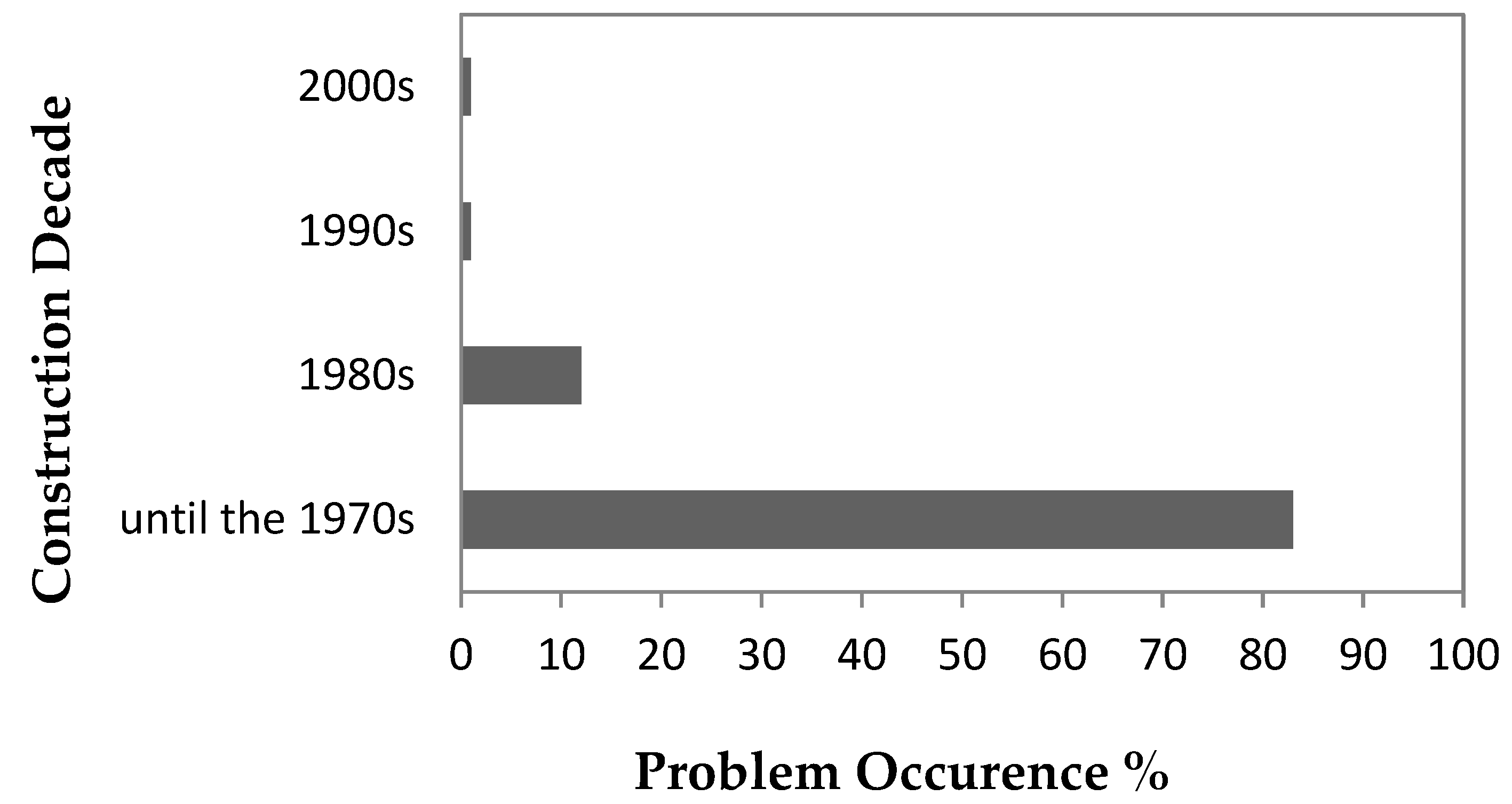

3.1. Survey Results

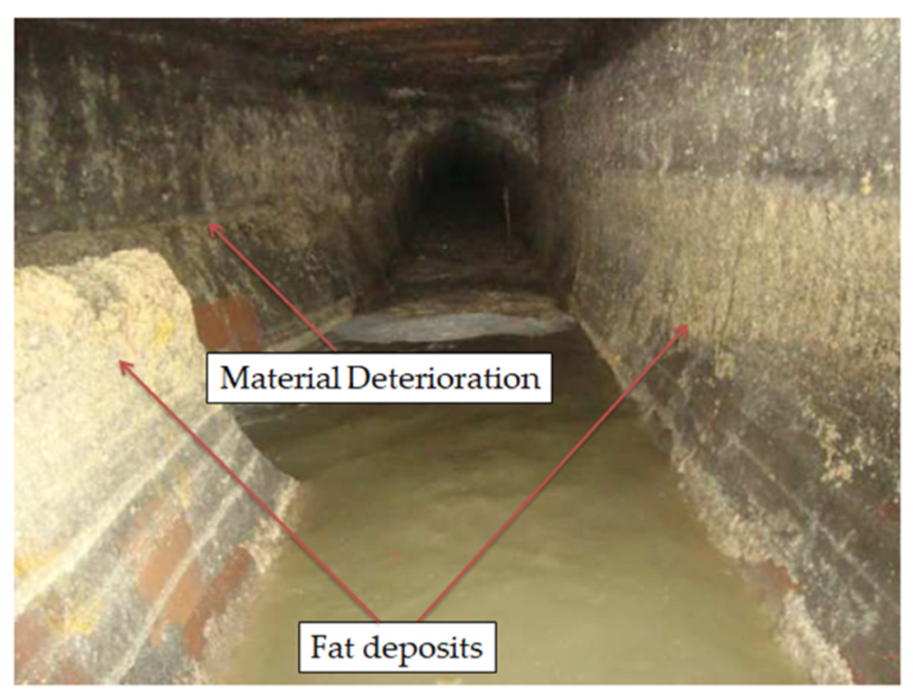

3.2. Field Measurements Results

3.2.1. Gas Analysis

3.2.2. Liquid Analysis

3.2.3. Concrete Analysis

3.2.4. Slime Genetic Analysis

4. Recommendations

- The regular measurement and recording of H2S concentrations, pH, COD, sewage temperatures, effluents properties, and flow rates. These are all parameters that, together with the geometrical characteristics of the network, can be used for calculations of hydrogen sulfide production and risk.

- Use of mobile units equipped with cameras for regular inspections.

- Surface washes with water. Although flushing with high-pressure water removes the corrosion deposits from the concrete surface and increases the surface pH, the effects are short term, i.e., one month [24], or two to four months [25] and for a long-term protection, frequent flushing with high-pressure water is necessary.

- Treatment of the concrete surface so as to be less susceptible to corrosion. This can be done by using spray-on coatings, e.g., Mg(OH)2 based coatings.

- Application of polyethylene (PE) liner.

- Inhibition of the biological activity, e.g., with biocides.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- O’Dea, V. Understanding biogenic sulfide corrosion. Mater. Perform 2007, 46, 36–39. [Google Scholar]

- Wu, L.; Hu, C.; Liu, W.V. The sustainability of concrete in sewer tunnel—A narrative review of acid corrosion in the city of Edmonton, Canada. Sustainability 2018, 10, 517. [Google Scholar] [CrossRef]

- Yamanaka, T.; Aso, I.; Togashi, S.; Tanigawa, M.; Shoji, K.; Watanabe, T.; Watanabe, N.; Maki, K.; Suzuki, H. Corrosion by bacteria of concrete in sewerage systems and inhibitory effects of formates on their growth. Water Res. 2002, 36, 2636–2642. [Google Scholar] [CrossRef]

- Mori, T.; Nonaka, T.; Tazaki, K.; Koga, M.; Hikosaka, Y.; Noda, S. Interactions of nutrients, moisture, and pH on microbial corrosion of concrete sewer pipes. Water Res. 1992, 26, 29–37. [Google Scholar] [CrossRef]

- Okun, D.A.; Wang, L.K.; Shammas, N.K. Water Supply and Distribution and Wastewater Collection; JohnWiley and Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Bowker, R.P.; Smith, J.M. Odor and Corrosion Control in Sanitary Sewerage Systems and Treatment Plants; U.S. Environmental Protection Agency: Washington, DC, USA, 198 e sewer pipes. Water Res. 1992, 26, 29–37. [Google Scholar]

- Vincke, E. Biogenic Sulfuric Acid Corrosion of Concrete: Microbial Interaction, Simulation and Prevention. Ph.D. Thesis, Faculty of Bio-engineering Science, University Ghent, Ghent, Belgium, 2002; pp. 7–9. [Google Scholar]

- Zhang, L.; De Schryver, P.; De Gusseme, B.; De Muynck, W.; Boon, N.; Verstraete, W. Chemical and biological technologies for hydrogen sulfide emission control in sewer systems: A review. Water Res. 2008, 42, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Karageorgos, P.; Latos, M.; Kotsifaki, C.; Lazaridis, M.; Kalogerakis, N. Treatment of unpleasant odors in municipal wastewater treatment plants. Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 2010, 61, 2635–2644. [Google Scholar] [CrossRef] [PubMed]

- Mathioudakis, L.V.; Vaiopoulou, E. Addition of nitrate for odor control in sewer networks: Laboratory and field experiments. Glob. NEST J. 2006, 8, 37–42. [Google Scholar]

- Nikolopoulos, C.V. A mushy region in concrete corrosion. Appl. Math. Model. 2010, 34, 4012–4030. [Google Scholar] [CrossRef]

- Nikolopoulos, C.V. Macroscopic models for a mushy region in concrete corrosion. J. Eng. Math. 2015, 91, 143–163. [Google Scholar] [CrossRef]

- Henze, M.; Comeau, Y. Wastewater characterization. Biological Wastewater Treatment: Principles, Modelling and Design; IWA Publishing: London, UK, 2008; Volume 7, pp. 33–52. [Google Scholar]

- Nielsen, A.H.; Lens, P.; Vollertsen, J.; Hvitved-Jacobsen, T. Sulfide–iron interactions in domestic wastewater from a gravity sewer. Water Res. 2005, 39, 2747–2755. [Google Scholar]

- Jayaraman, A.; Mansfeld, F.B.; Wood, T.K. Inhibiting sulfate-reducing bacteria in biofilms by expressing the antimicrobialpeptides indolicidin and bactenecin. J. Ind. Microbiol. Bio Technol. 1999, 22, 167–175. [Google Scholar] [CrossRef]

- Crownmag. Innovative Coating Materials for Corrosion Protection of Sewer Network Pipes. Available online: http://crownmag.gr/en/ (accessed on 10 January 2020).

- Dorji, U.; Tenzin, U.M.; Dorji, P.; Wangchuk, U.; Tshering, G.; Dorji, C.; Shon, H.; Nyarko, K.B.; Phuntsho, S. Wastewater management in urban Bhutan: Assessing the current practices and challenges. Process Saf. Environ. Prot. 2019, 132, 82–93. [Google Scholar] [CrossRef]

- Wastewater Treatment Plants. Monitoring Database. Special Secretariat for Water. Ministry of Environment and Energy. Available online: http://astikalimata.ypeka.gr/Services/Pages/WtpViewApp.aspx (accessed on 10 January 2020).

- Available online: http://www.maps-of-europe.net/maps-of-greece/ (accessed on 22 January 2020).

- Available online: https://www.eyath.gr/sewerage/?lang=en (accessed on 24 January 2020).

- Available online: https://www.eydap.gr/en/TheCompany/DrainageAndSewerage/NetworkMaintenance/ (accessed on 24 January 2020).

- Metcalf & Eddy, Inc. Wastewater Engineering: Treatment and Reuse; McGraw-Hill: Boston, MA, USA, 2003. [Google Scholar]

- Kelly, D.P.; Wood, A.P. The Family Acidithiobacillaceae. In The Prokaryotes; Rosenberg, E., DeLong, E.F., Lory, S., Stackebrandt, E., Thompson, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Nielsen, A.H.; Vollertsen, J.; Jensen, H.S.; Wium-Andersen, T.; Hvitved-Jacobsen, T. Influence of pipe material and surfaces on sulfide related odor and corrosion in sewers. Water Res. 2008, 42, 4206–4214. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Jiang, G.; Chiu, T.H.; Zhou, M.; Keller, J.; Bond, P.L. Effects of surface washing on the mitigation of concrete corrosion under sewer conditions. Cem. Concr. Compos. 2016, 68, 88–95. [Google Scholar] [CrossRef]

- Song, Y.H.; Yun, R.; Lee, E.H.; Lee, J.H. Predicting sedimentation in urban sewer conduits. Water 2018, 10, 462. [Google Scholar] [CrossRef]

| Town | Town Number on Map | Peak Population Equivalent | Type of System | Corrosion Problems | Type of Corrosion | Corrosion Prevention Measurement | Inspection Frequency | Prevention Measures Frequency |

|---|---|---|---|---|---|---|---|---|

| Athens | 1 | 5200000 | Combined | Yes | mainly Mechanical | Cleaning, Ventilation | continuously | Semi-annual |

| Thessaloniki | 2 | 900000 | Combined | Yes | Biochemical/Mechanical | Cleaning, Ventilation | Semi-annual | Semi-annual |

| Ioannina | 3 | 142000 | Separate | Yes | Biochemical/Mechanical | Cleaning | trimontly | Trimontly |

| Serres | 4 | 79000 | Combined | Yes | Biochemical/Mechanical | Cleaning, Ventilation | montly | Montly, n.s. |

| Lamia | 5 | 78200 | Separate | No | n/a | Cleaning | trimontly | n/a |

| Komotini | 6 | 72000 | Separate | No | n/a | Cleaning | Annual, n.s. | n/a |

| Kozani | 7 | 46000 | Combined | Yes | Biochemical/Mechanical | Cleaning, Chemical Additives | montly | Montly |

| Agios Nikolaos | 8 | 25000 | Separate | Yes | Biochemical | Cleaning, Other | Annual | Annual |

| Florina | 9 | 20000 | Separate | Yes | Biochemical | Cleaning, Ventilation | montly | Semi-annual |

| Tyrnavos | 10 | 10900 | Separate | No | n/a | Cleaning | trimontly, n.s. | n/a |

| Chortiatis | 11 | 4800 | Combined | Yes | Mechanical | Cleaning, Other | montly | Semi-annual |

| Place | Measured Gas | ||

|---|---|---|---|

| H2S (ppm) | CH4 (%) | O2 (%) | |

| 1 | 2 | 0.04 | 21 |

| 2 | 1 | 0.03 | 20.3 |

| 3 | 1 | 0 | 20.9 |

| 4 | 0 | 0.08 | 21.1 |

| 5 | 0 | 0005 | 21 |

| 6 | 1 | 0.16 | 20.9 |

| 7 | 1 | 0.03 | 20.9 |

| 8 | 2 | 0.03 | 20.5 |

| 9 | 2 | 0.2 | 20.6 |

| 10 | 1 | 0.09 | 20.8 |

| 11 | 1 | 0.04 | 20.4 |

| 12 | 1 | 0.03 | 20.2 |

| 13 | 1 | 0.02 | 20.9 |

| Sewage Chemical Parameters | mg/L |

|---|---|

| Chemical Oxygen Demand (COD) | 910 |

| Total Organic Carbon (TOC) | 238,7 |

| Total Nitrogen | 49 |

| Total Phosphorus | 5,1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fytianos, G.; Baltikas, V.; Loukovitis, D.; Banti, D.; Sfikas, A.; Papastergiadis, E.; Samaras, P. Biocorrosion of Concrete Sewers in Greece: Current Practices and Challenges. Sustainability 2020, 12, 2638. https://doi.org/10.3390/su12072638

Fytianos G, Baltikas V, Loukovitis D, Banti D, Sfikas A, Papastergiadis E, Samaras P. Biocorrosion of Concrete Sewers in Greece: Current Practices and Challenges. Sustainability. 2020; 12(7):2638. https://doi.org/10.3390/su12072638

Chicago/Turabian StyleFytianos, Georgios, Vasilis Baltikas, Dimitrios Loukovitis, Dimitra Banti, Athanasios Sfikas, Efthimios Papastergiadis, and Petros Samaras. 2020. "Biocorrosion of Concrete Sewers in Greece: Current Practices and Challenges" Sustainability 12, no. 7: 2638. https://doi.org/10.3390/su12072638

APA StyleFytianos, G., Baltikas, V., Loukovitis, D., Banti, D., Sfikas, A., Papastergiadis, E., & Samaras, P. (2020). Biocorrosion of Concrete Sewers in Greece: Current Practices and Challenges. Sustainability, 12(7), 2638. https://doi.org/10.3390/su12072638