Evaluation of a 3.5-MW Floating Photovoltaic Power Generation System on a Thermal Power Plant Ash Pond

Abstract

1. Introduction

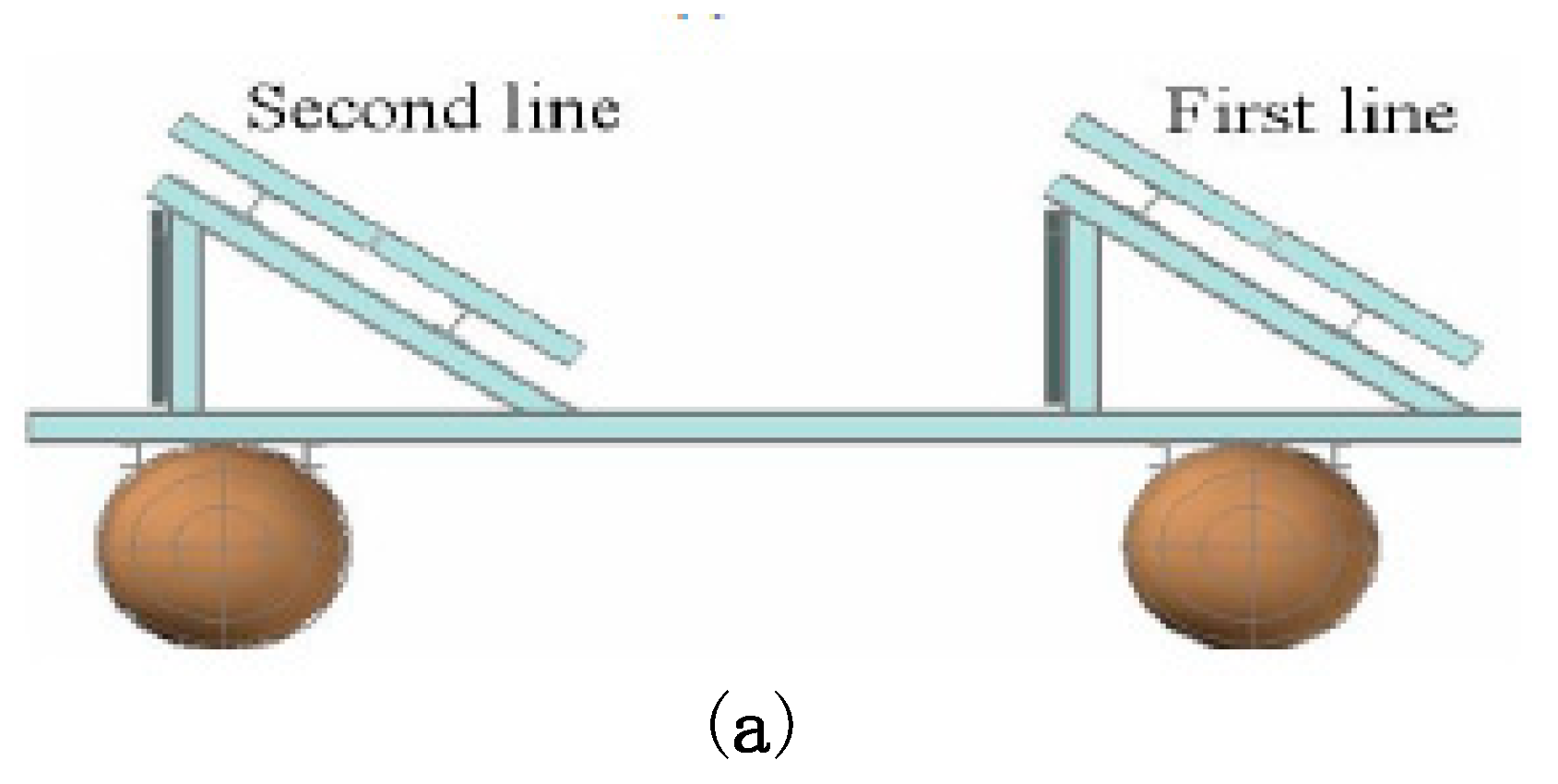

2. Proposed Floating PV Power Generation System

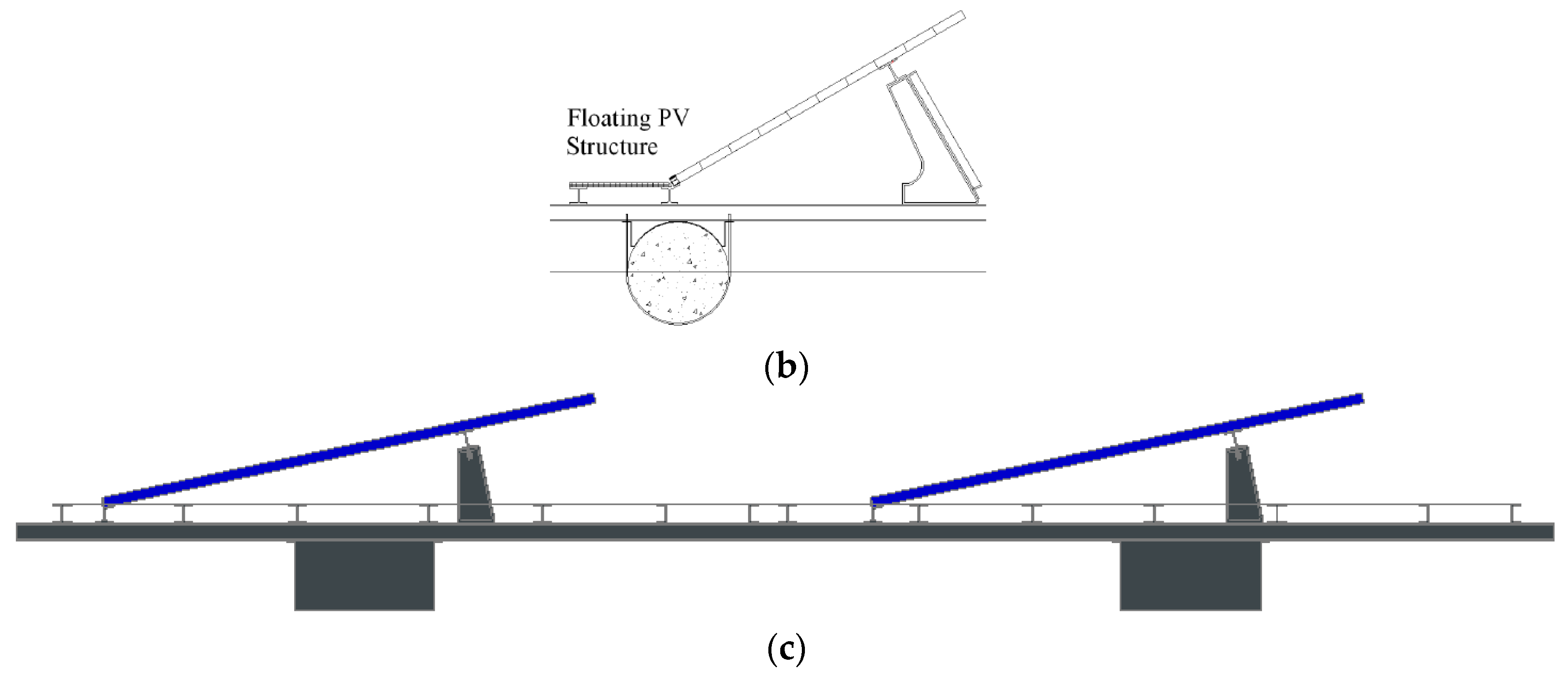

2.1. Mechanical Properties of FRP Members

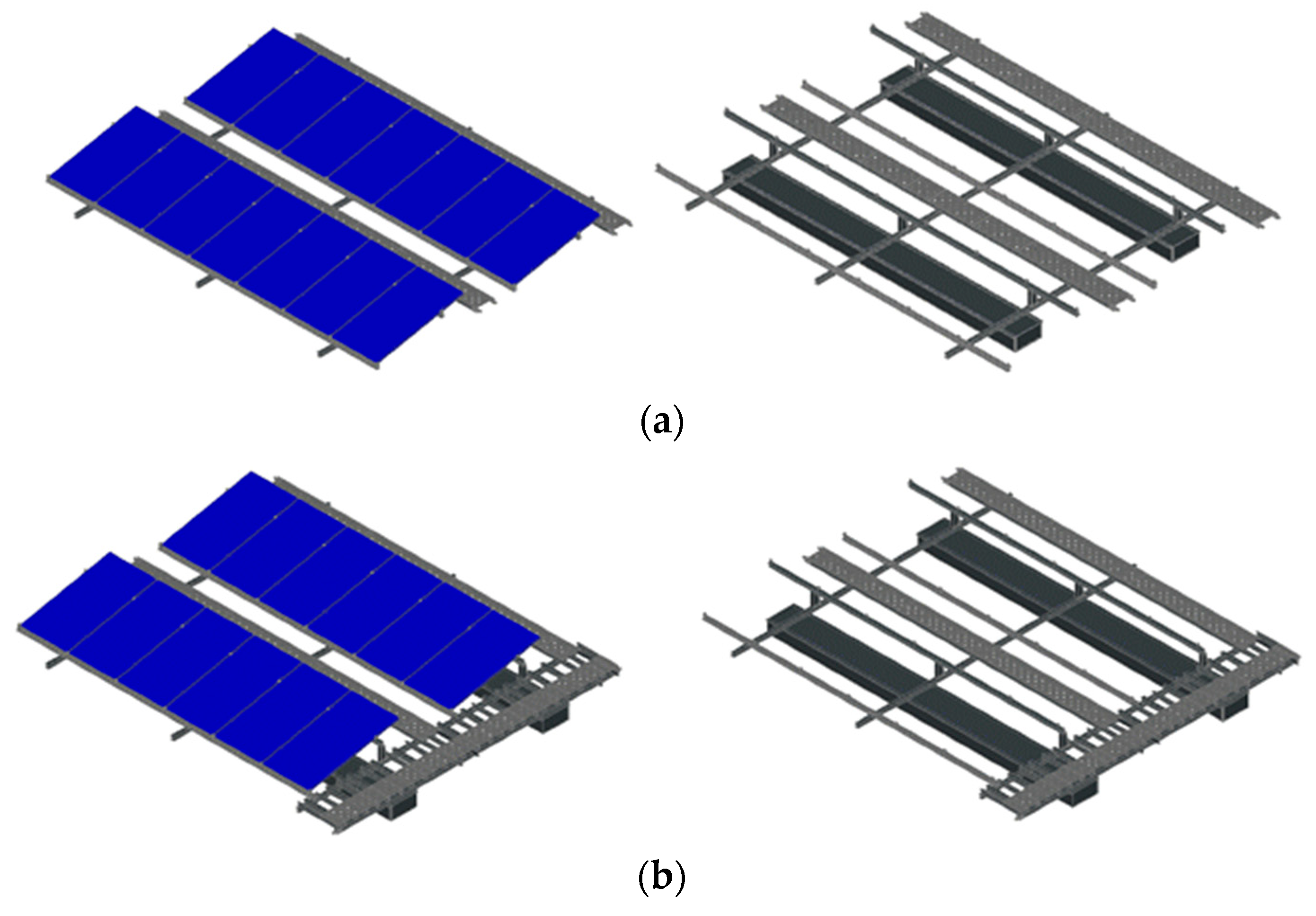

2.2. Components of the PV Power Generation Structure

2.3. Design Codes

2.4. Design Loading Conditions

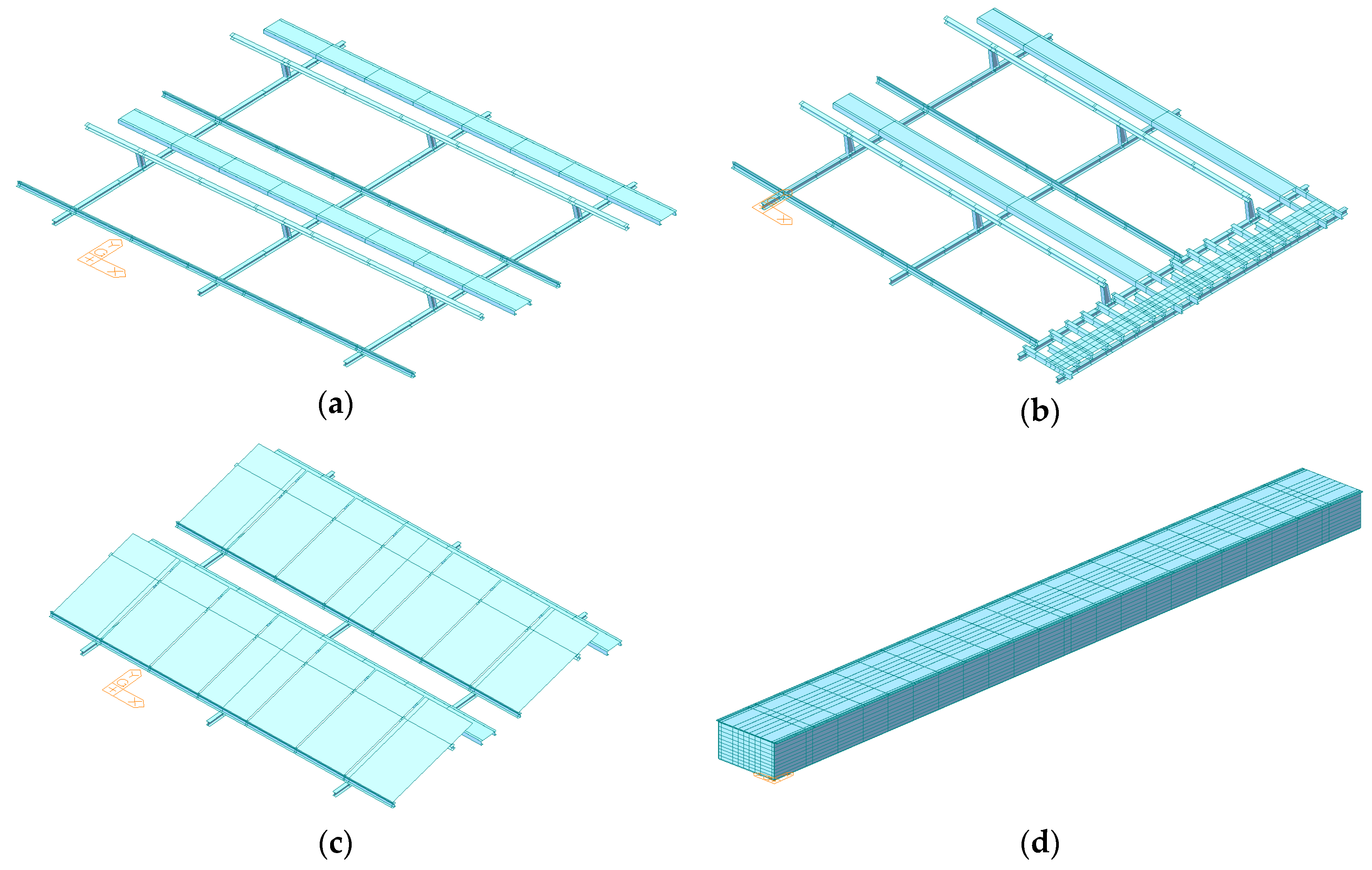

2.5. Finite Element Analysis

2.5.1. Modeling

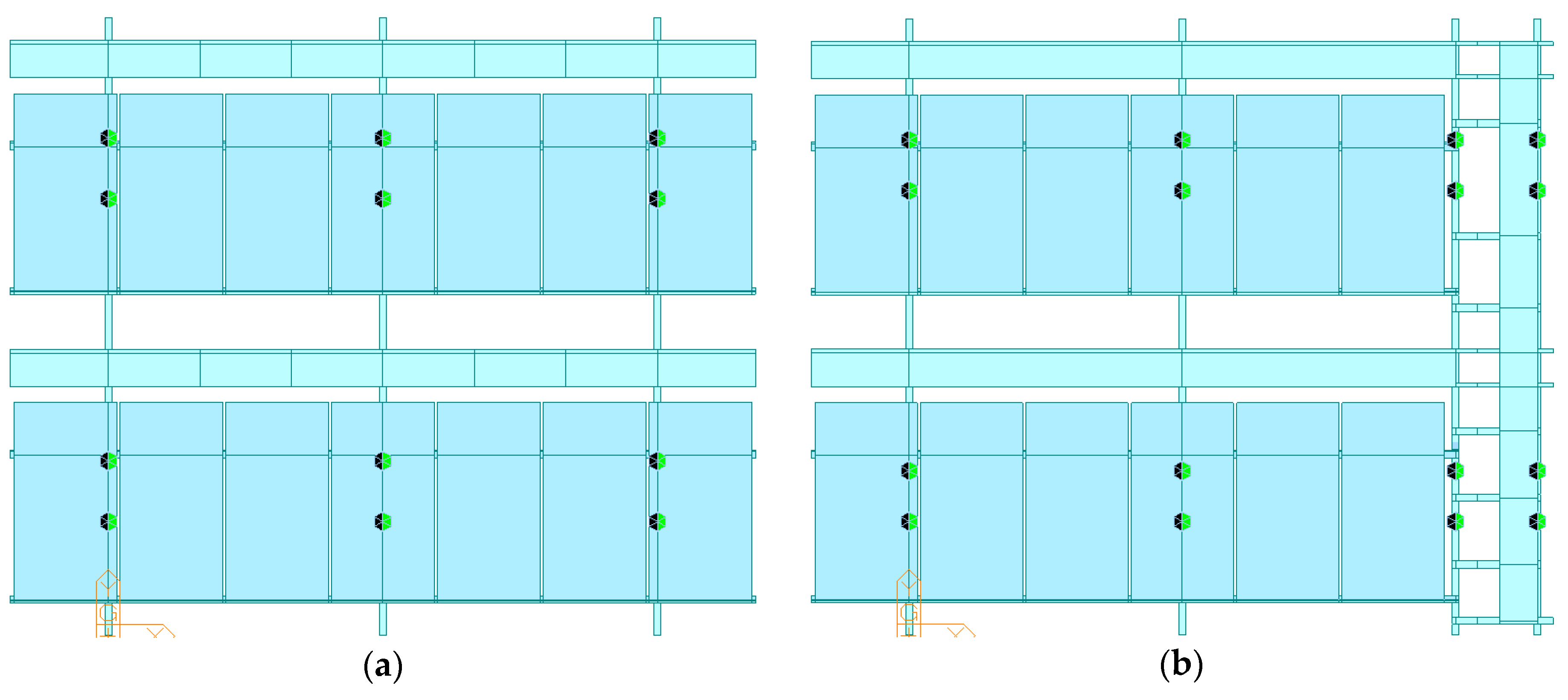

2.5.2. Loads and Boundary Conditions

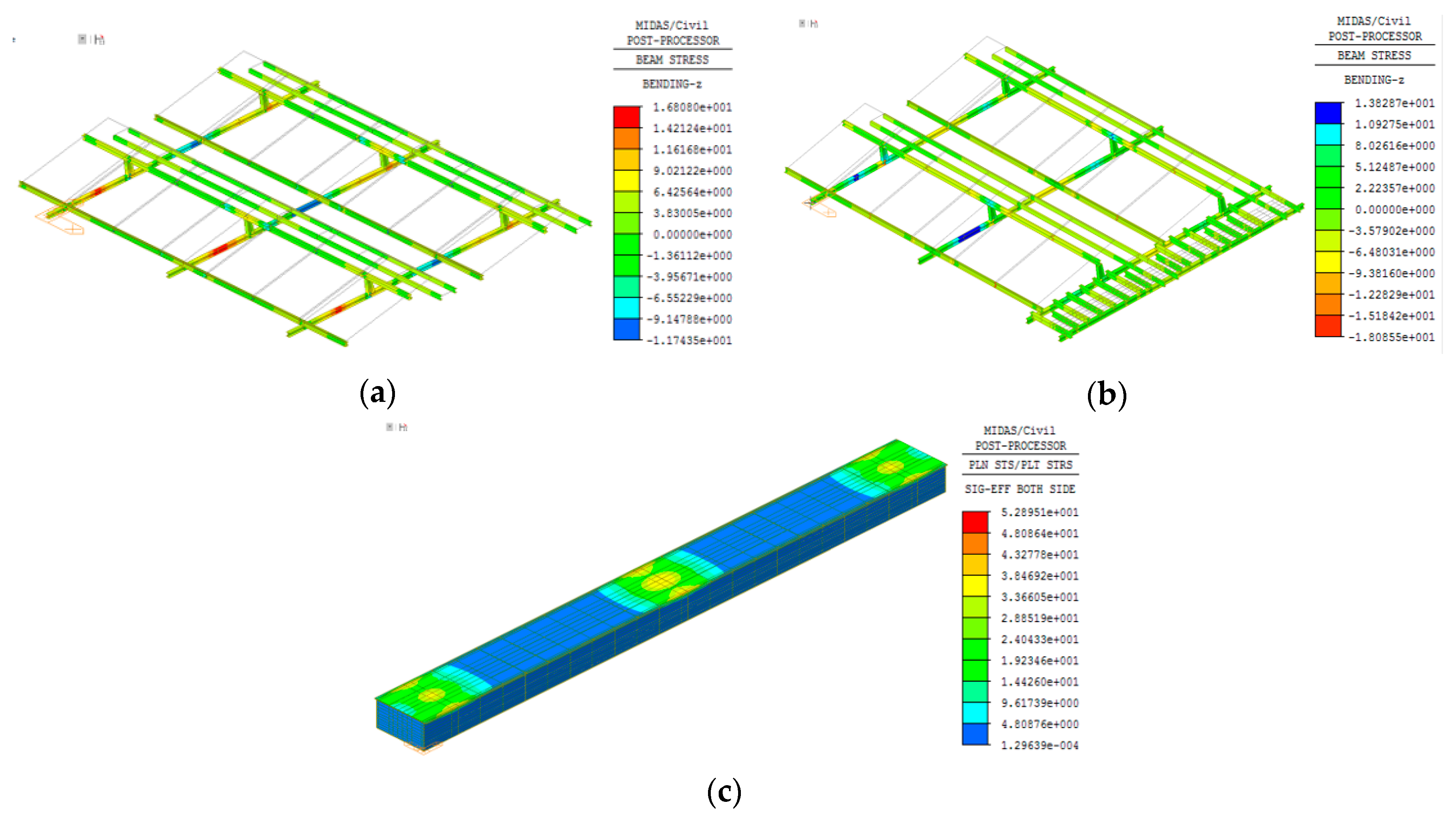

2.5.3. Results of the Finite Element Analysis

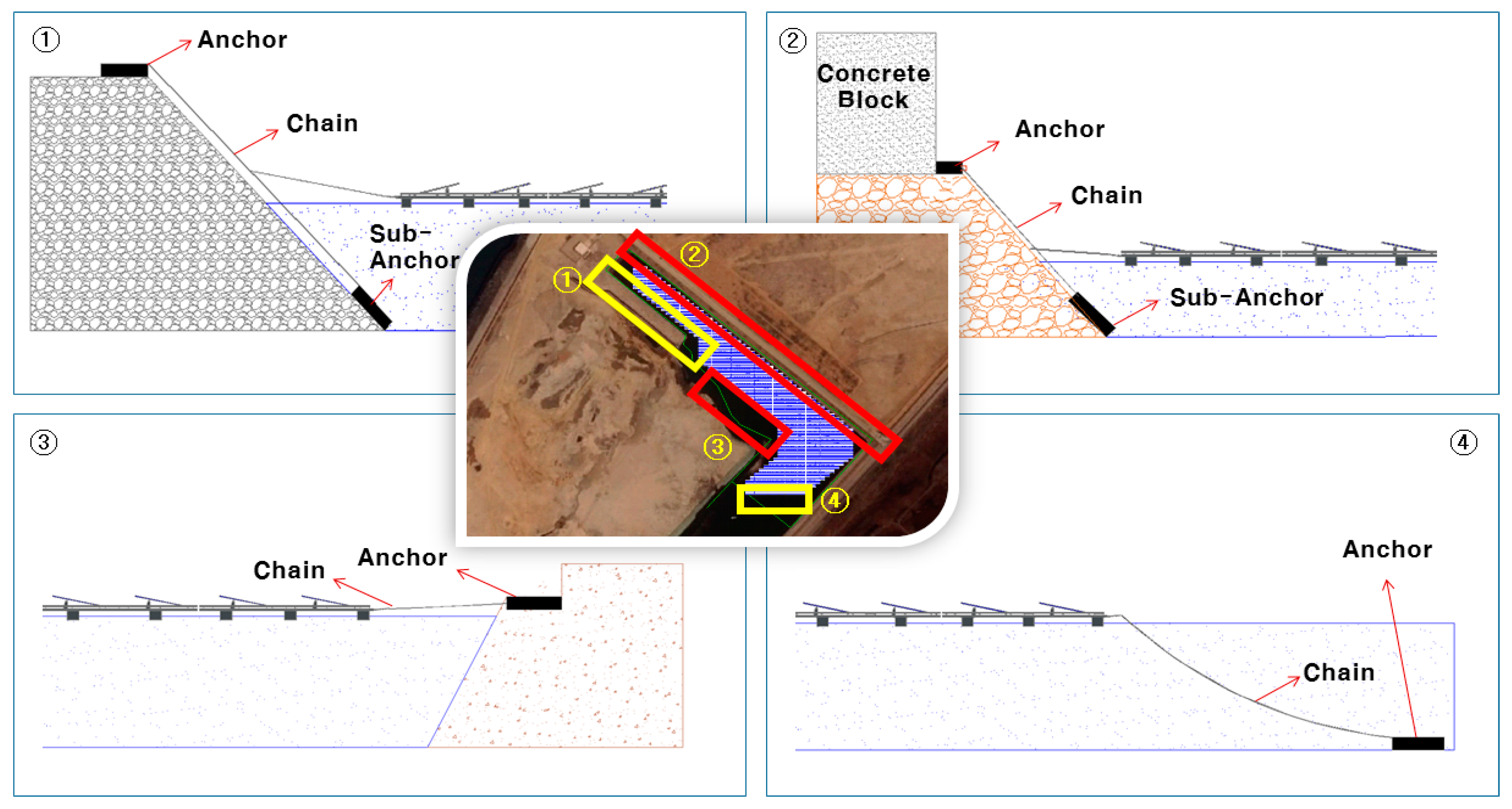

3. Proposed Mooring System

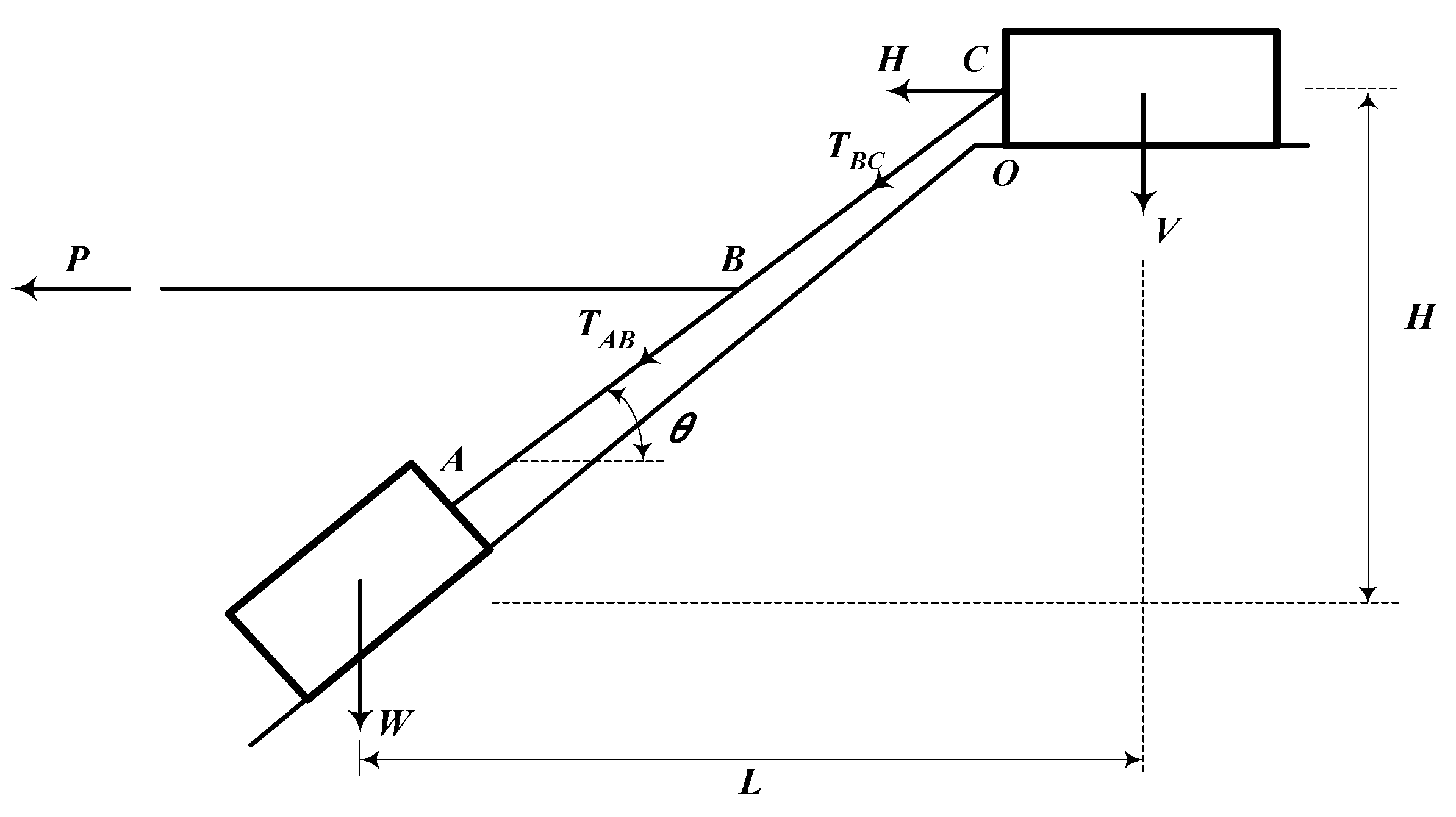

3.1. Mooring System Design

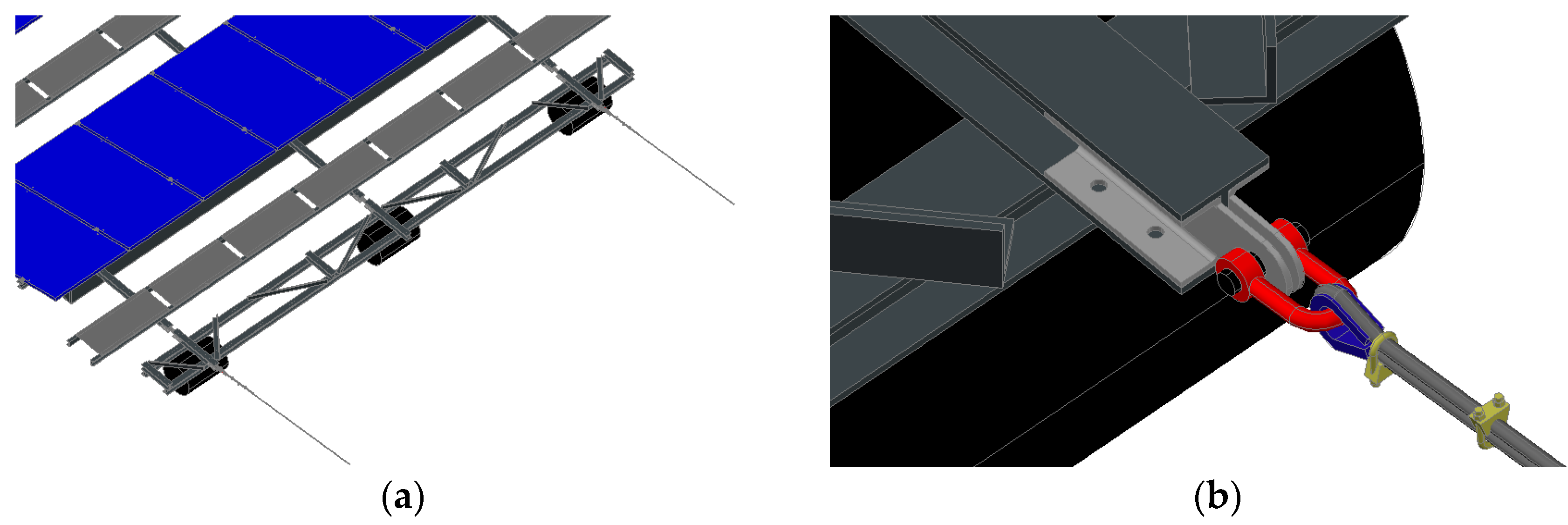

3.2. Mooring Hardware Design

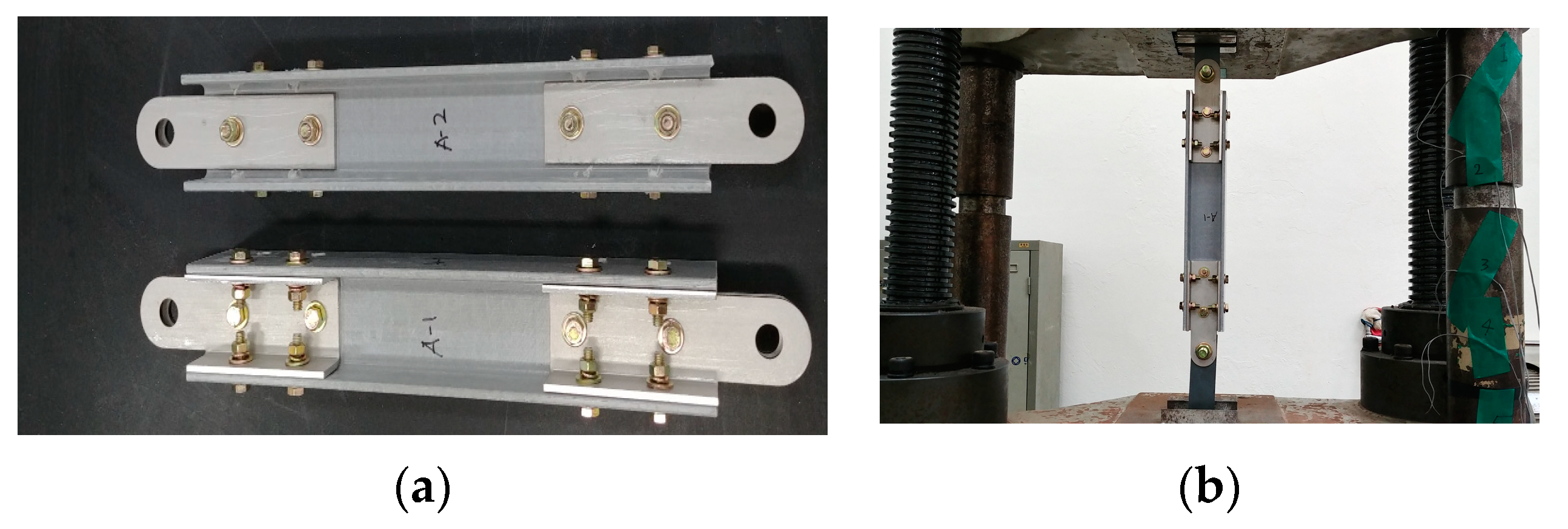

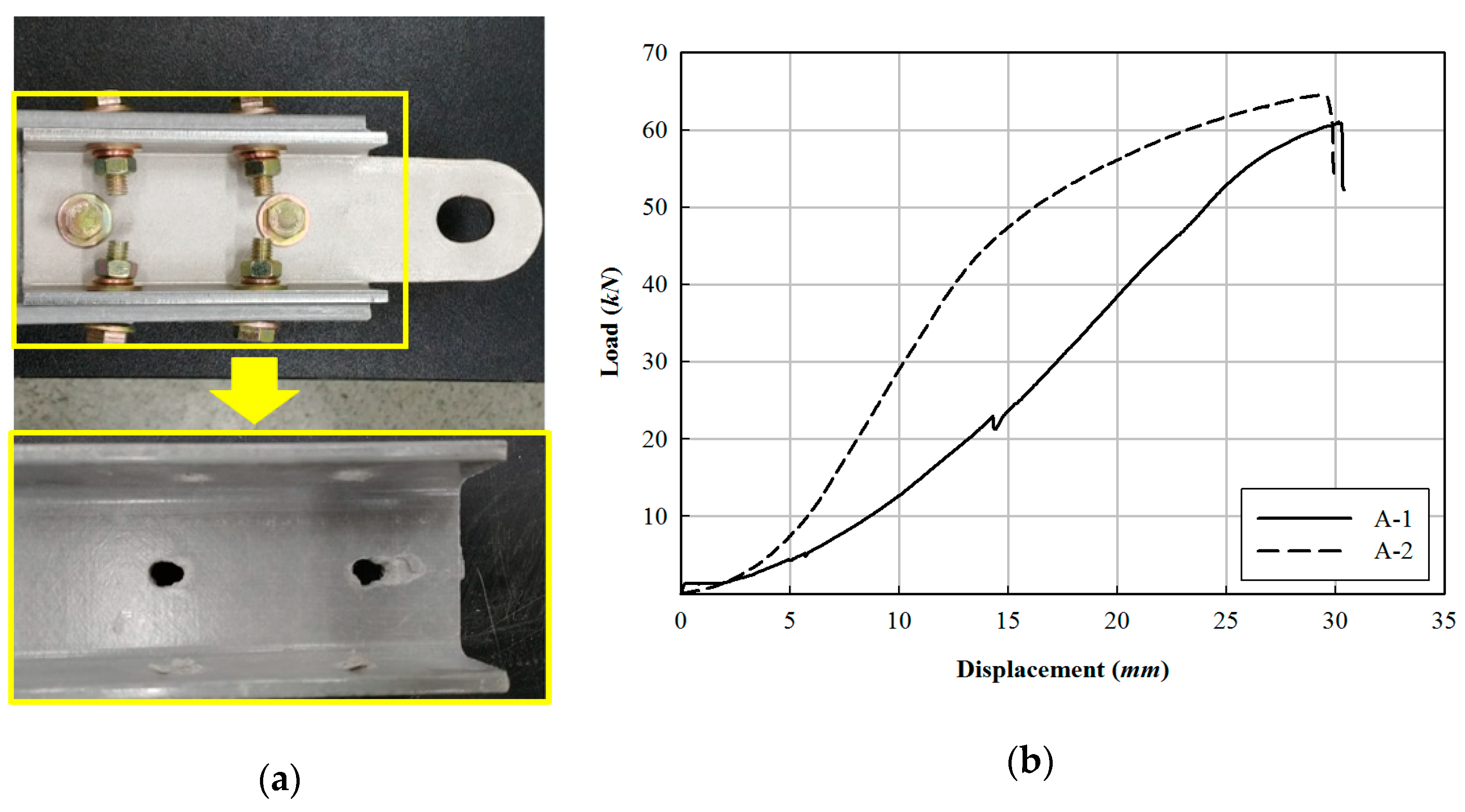

3.3. Mooring Connection Strength Testing

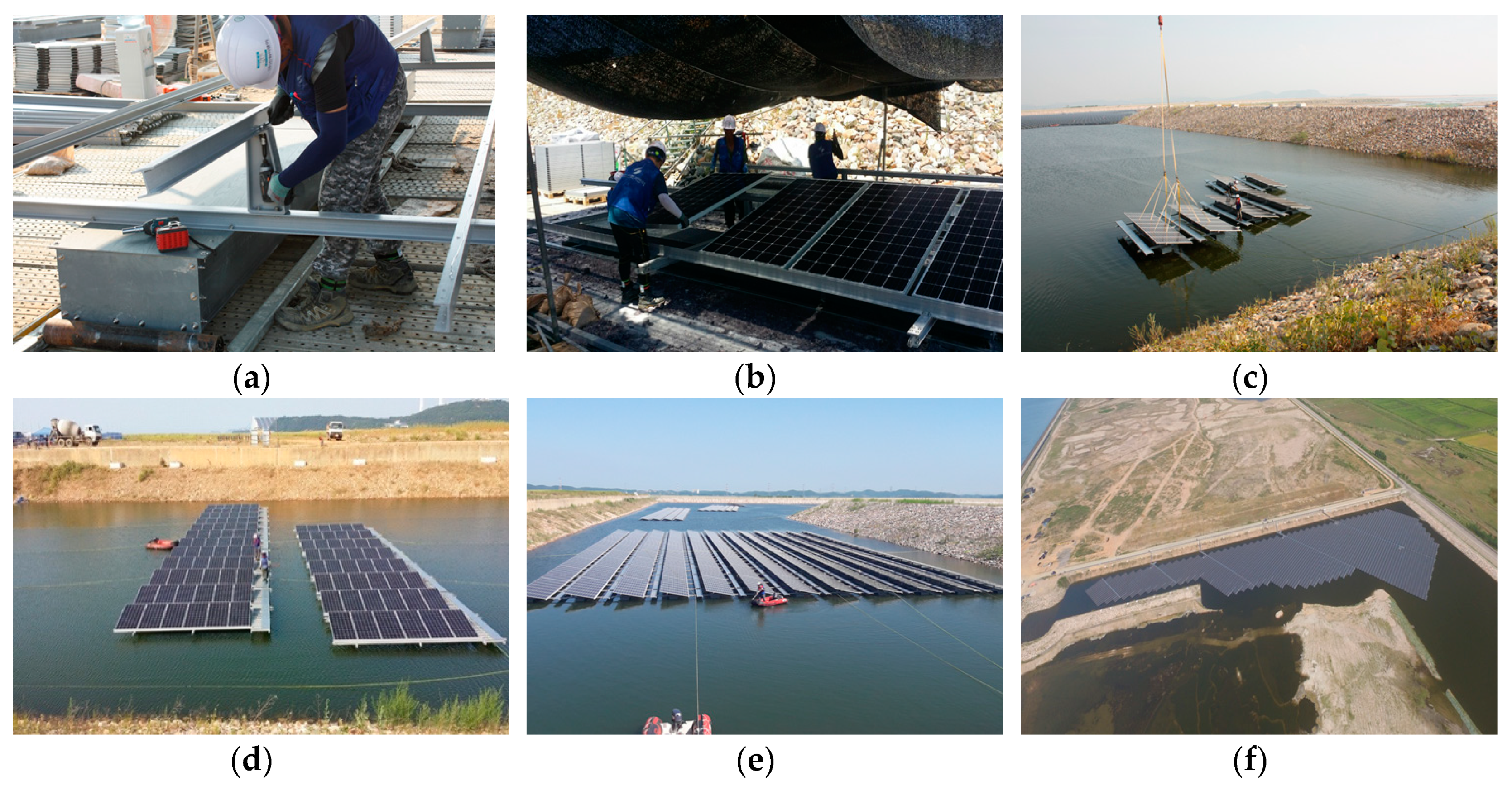

4. Installation of Proposed Floating PV Power Generation System

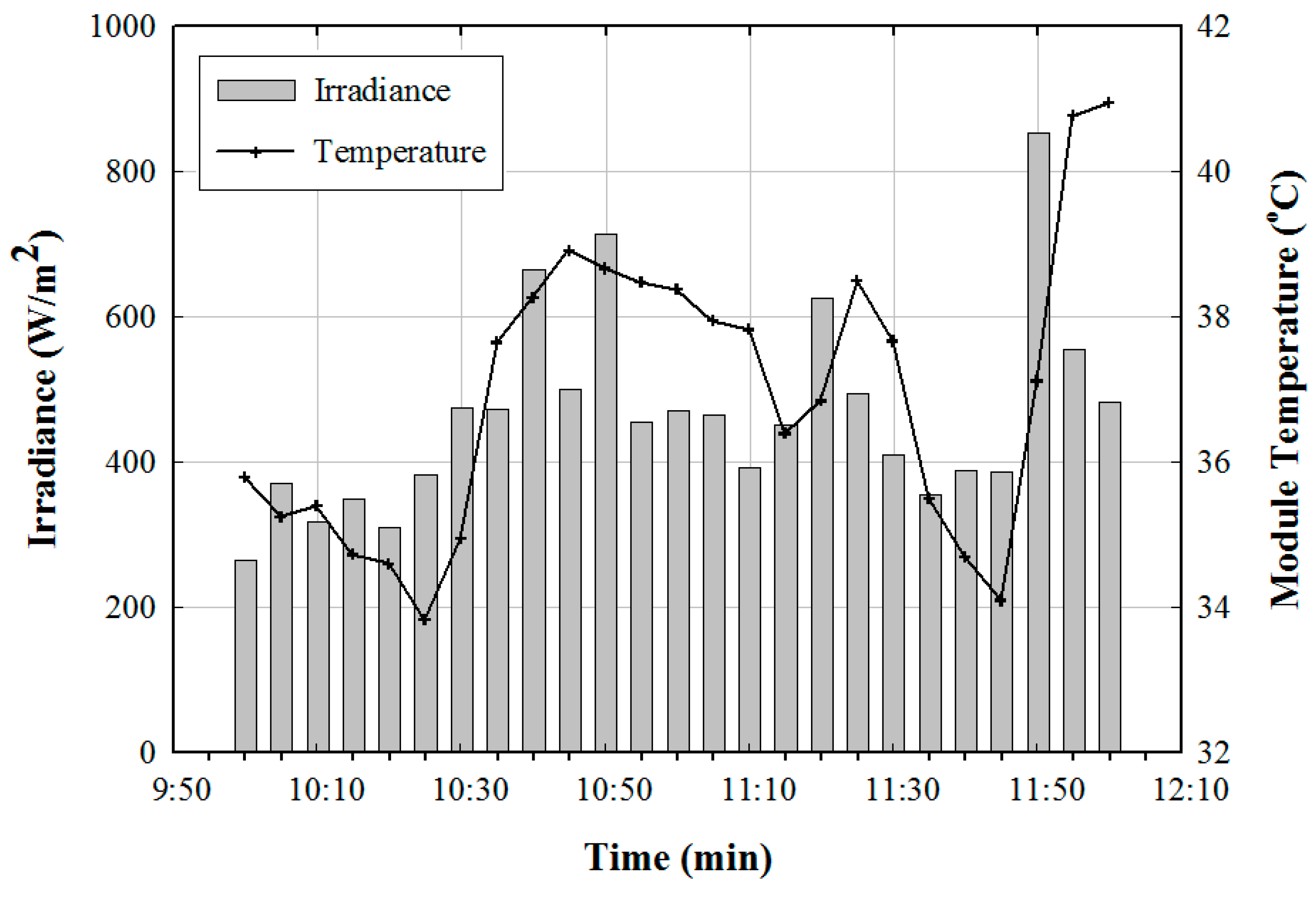

5. Performance of Proposed Floating PV Power Generation System

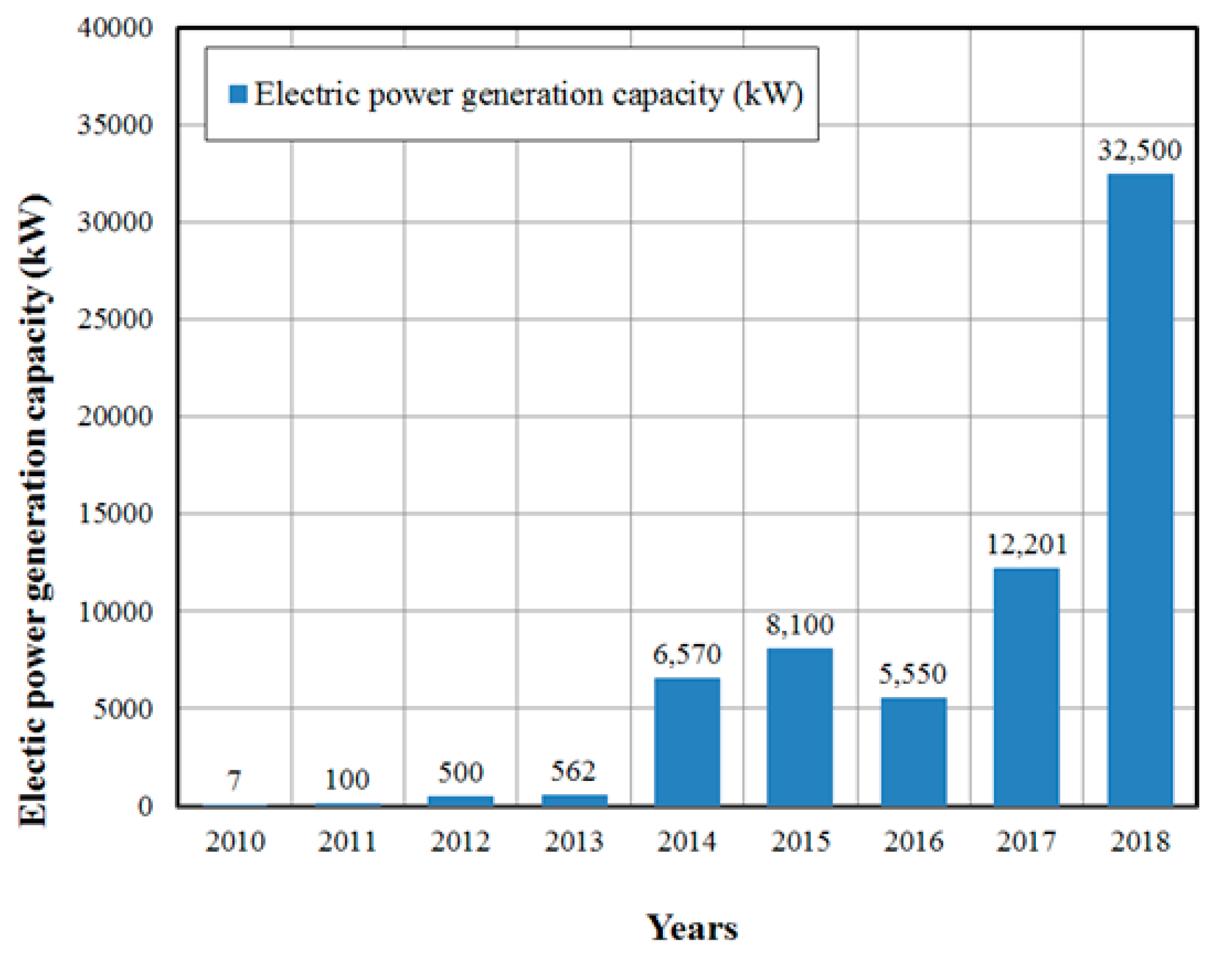

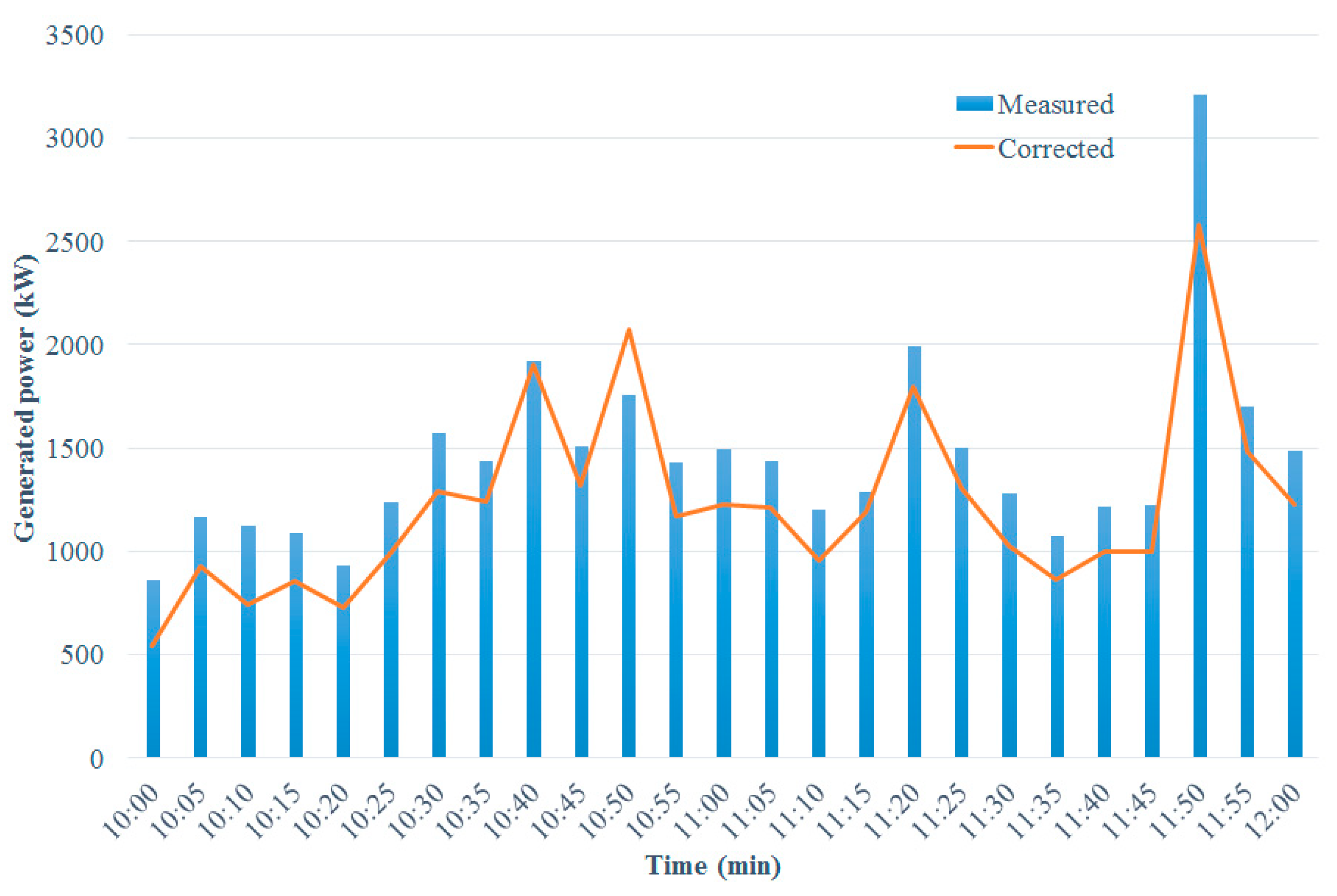

6. Production of PV Energy Generation of the System

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nam, J.H. Development of Floating Type Photovoltaic Energy Generation System Using the Pultruded Structural Members. Ph.D. Thesis, Hongik University, Seoul, Korea, 28 December 2010. [Google Scholar]

- Lee, Y.-G.; Joo, H.-J.; Yoon, S.-J. Design and installation of floating type photovoltaic energy generation system using FRP members. Sol. Energy 2014, 108, 13–27. [Google Scholar] [CrossRef]

- Choi Structural Performance Evaluation of Floating PV Power Generation Structure System. J. Korean Soc. Civ. Eng. 2014, 34, 1353–1362. [CrossRef]

- Kim, S.-H.; Yoon, S.-J.; Choi, W. Design and Construction of 1 MW Class Floating PV Generation Structural System Using FRP Members. Energies 2017, 10, 1142. [Google Scholar] [CrossRef]

- Ferrer-Gisbert, C.; Gozalvez, J.J.F.; Redón-Santafé, M.; Gisbert, P.F.; Sánchez-Romero, F.J.; Torregrosa-Soler, J.B. A new photovoltaic floating cover system for water reservoirs. Renew. Energy 2013, 60, 63–70. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Tina, G.M.; Nizetic, S. Floating photovoltaic plants and wastewater basins: An Australian project. Energy Procedia 2017, 134, 664–674. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Cicu, M.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M.; Ventura, C. Floating photovoltaic plants: Performance analysis and design solutions. Renew. Sustain. Energy Rev. 2018, 81, 1730–1741. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Q.; Lin, H.; Li, H.; Sun, Q.; Wennersten, R. Power Generation Efficiency and Prospects of Floating Photovoltaic Systems. Energy Procedia 2017, 105, 1136–1142. [Google Scholar] [CrossRef]

- Trapani, K.; Santafé, M.R. A review of floating photovoltaic installation: 2007–2013. Prog. Photovolt. 2015, 23, 524–532. [Google Scholar] [CrossRef]

- Lee, J.H. Preliminary Study on Development of Buoyant Body and Mooring System for Marine Solar Power lant; Korea Institute of Civil Engineering and Building Technology (KICT): Suwon, South Korea, 2018; p. 15. [Google Scholar]

- Choi, H.; Joo, H.J.; Nam, J.H.; Kim, K.S.; Yoon, S.-J. Structural Design for the Development of the Floating Type Photovoltaic Energy Generation System. Mater. Sci. Forum 2010, 654, 2803–2806. [Google Scholar] [CrossRef]

- Choi, J.-W.; Joo, H.-J.; Nam, J.-H.; Hwang, S.-T.; Yoon, S.-J. Performance Enhancement of Floating PV Generation Structure Using FRP. Compos. Res. 2013, 26, 105–110. [Google Scholar] [CrossRef]

- Ko, J.-W.; Yun, N.-R.; Min, Y.-K.; Jung, T.-H.; Won, C.-S.; Ahn, H.K. Prediction of Output Power for PV Module with Tilted Angle and Structural Design. Trans. Korean Inst. Electr. Eng. 2013, 62, 371–375. [Google Scholar] [CrossRef]

- Song, J.-H.; Yoon, J.-H.; An, Y.-S.; Kim, S.-G.; Lee, S.-J.; Choung, Y.-K. Power performance characteristics of transparent thin-film BIPV module depending on an installation angle. J. Korean Solar Energy 2008, 28, 58–63. [Google Scholar]

- Kakaomap. Available online: https://map.kakao.com/ (accessed on 7 December 2019).

- American Society of Civil Engineers. Pre-standard for Load and Resistance Factor Design (LRFD) of Pultruded Fiber Reinforced Polymer (FRP) Structures. Available online: http://dev1.kreysler.com/information/specifications/specs-resources/LRFD%20PreStandard%20-%20Revised%20FINAL%20-%20Nov%209%202010.pdf (accessed on 1 August 1996).

- Port and Fishing Port Design Standards. Ministry of Oceans and Fisheries (MOF). Available online: http://kpcs.portcals.go.kr/kc/mv_list.do (accessed on 1 July 2014).

- Structure and Equipment Standards for Floating Offshore Structures. Ministry of Oceans and Fisheries (MOF). Available online: http://mesis.krs.co.kr/Rules/Board/Ko/view.aspx?CurrPage=5&b_code=188&b_num=57&mode=M (accessed on 7 January 2011).

- Lee, K.-Y.; Kim, W.; Lee, J.-S. Review of Steel ratio Specifications in Korean Highway Bridge Design Code (Limit States Design) for the Design of RC Flexural Members. J. Korean Soc. Civ. Eng. 2017, 37, 277–287. [Google Scholar] [CrossRef]

- Korean Building Code (KBC). Architectural Institute of Korea: Seoul, Korea, 2016. Available online: http://r-nbck.or.kr/en/Sub/Sub_02_03.aspx (accessed on 8 August 2012).

- MIDAS Analysis Reference. MIDAS Information Technology Co., Ltd. (MIDAS IT): Seoul, Korea, 2012. Available online: https://kor.midasuser.com/civil/ (accessed on 8 August 2012). (In Korean).

- Lee, Y.-G.; Kim, S.-H.; Won, Y.-S.; Cheon, J.-U.; Shin, K.-Y.; Yoon, S.-J. Strength Evaluation of Bolt Arrangement in PFRP Bolted Connection with 2 Bolts. J. Korean Soc. Adv. Compos. Struct. 2014, 5, 17–22. [Google Scholar] [CrossRef][Green Version]

- Woo, S.-P.; Kim, S.-H.; Yoon, S.-J.; Choi, W. Effect of Bolt-Hole Clearance on Bolted Connection Behavior for Pultruded Fiber-Reinforced Polymer Structural Plastic Members. Int. J. Polym. Sci. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

| First-Generation PV Model | Second-Generation PV Model | Third-Generation PV Model | |

|---|---|---|---|

| No. of unit buoy (Each, EA.) | 2 | 9 | 2 |

| No. of structure (EA) | 940 | 360 | 736 |

| Module capacity (W) | 230 | 295 | 340 |

| Unit of generation capacity (kW) | 3.68 | 9.735 | 4.76 |

| Pultruded fiber reinforced polymer (PFRP) quantity (m3) | 0.536 | 1382.35 | 313.68 |

| Total capacity (MW) | 3.5 | ||

| Unit cost of structure (US$) | 2500 | 8250 | 1417 |

| Cost of structure (US$) | 2350,000 | 2970,000 | 1042,912 |

| Unit cost of buoy (US$) | 833 | 167 | 250 |

| Total No. of buoys (EA) | 1880 | 3240 | 1472 |

| Cost of buoys (US$) | 1566,040 | 541,080 | 368,000 |

| Total cost (US$) | 3916,040 | 3510,000 | 1410,833 |

| Material | Young’s Modulus (E, GPa) | Tensile Strength (ft, MPa) | Shear Strength (fv, MPa) | Poisson’s Ratio , mm/mm) | Specific Weight (G, kN/m3) |

|---|---|---|---|---|---|

| PFRP | 25.00 | 350.00 | 91.32 | 0.32 | 18.42 |

| SMC-FRP | 17.33 | 183.85 | 34.47 | 0.25 | 18.42 |

| Description | Design Wind Speed | Velocity Pressure Exposure Coefficient | Topographic Factor | Importance Factor |

|---|---|---|---|---|

| Value | 45 | 1.13 | 1.00 | 1.00 |

| Description | Snow Load | Roof Snow Load Factor | Exposure Factor | Temperature Factor | Importance Factor | Gradient Factor |

|---|---|---|---|---|---|---|

| Value | 0.65 | 0.7 | 0.8 | 1.2 | 1.2 | 1.05 |

| Member | Maximum Stress by FEA (MPa) ① | Allowable Stress (MPa) ② | Safety Factor ②/① | Status | |

|---|---|---|---|---|---|

| Type A | Tensile | 1.57 | 175.00 | 111.46 | OK |

| Compressive | 1.22 | 116.67 | 95.63 | OK | |

| Shear | 7.78 | 30.44 | 3.91 | OK | |

| Flexural | 16.81 | 140.00 | 8.32 | OK | |

| Type B | Tensile | 0.97 | 175.00 | 175.25 | OK |

| Compressive | 1.47 | 116.67 | 79.36 | OK | |

| Shear | 7.68 | 30.44 | 3.96 | OK | |

| Flexural | 18.09 | 140.00 | 7.73 | OK | |

| Pontoon | Flexural | 15.76 | 140.00 | 8.88 | OK |

| Description | Allowable Load (Pallow, kN)① | Horizontal Mooring Force (Pu, kN)② | Safety Factor ①/② |

|---|---|---|---|

| Bolt | 64.34 | 28.64 (=2.92 tonf) | 2.25 |

| Connection plate (steel) | 49.20 | 1.72 | |

| FRP member | 289.30 | 10.10 |

| Description | Maximum Load (kN)① | Maximum Displacement (mm) | Design Load (kN)② | Maximum Mooring Force (Pu, kN) | Safety Factor ①/② |

|---|---|---|---|---|---|

| A-1 | 61.03 | 30.41 | 49.20 | 28.64 | 1.24 |

| A-2 | 64.49 | 30.01 | 1.31 | ||

| Average | 62.76 | 30.21 | 1.28 |

| Month | Floating | ①/(0.93kW/3500 kW) (④, kWh) | ②/(1500kW/3500 kW) (⑤, kWh) | ③/④ | ③/⑤ | ||

|---|---|---|---|---|---|---|---|

| First-Type [2] (0.93 kW) (①, kWh) | Second-Type (1500 kW) (②, kWh) | Third-Type (3500 kW) (③, kWh) | |||||

| May | - | 114,025 | - | - | - | - | - |

| June | - | 121,324 | - | - | - | - | - |

| July | 52.6 | 117,562 | 379,020 | 49,489 | 274,311 | 7.65 | 1.38 |

| August | 55.8 | 107,499 | 282,192 | 52,500 | 250,831 | 5.37 | 1.12 |

| September | 46.5 | 98,364 | 253,414 | 43,750 | 229,516 | 5.79 | 1.10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.-Y.; Hwang, S.-T.; Kim, S.-H. Evaluation of a 3.5-MW Floating Photovoltaic Power Generation System on a Thermal Power Plant Ash Pond. Sustainability 2020, 12, 2298. https://doi.org/10.3390/su12062298

Choi J-Y, Hwang S-T, Kim S-H. Evaluation of a 3.5-MW Floating Photovoltaic Power Generation System on a Thermal Power Plant Ash Pond. Sustainability. 2020; 12(6):2298. https://doi.org/10.3390/su12062298

Chicago/Turabian StyleChoi, Jung-Youl, Seong-Tae Hwang, and Sun-Hee Kim. 2020. "Evaluation of a 3.5-MW Floating Photovoltaic Power Generation System on a Thermal Power Plant Ash Pond" Sustainability 12, no. 6: 2298. https://doi.org/10.3390/su12062298

APA StyleChoi, J.-Y., Hwang, S.-T., & Kim, S.-H. (2020). Evaluation of a 3.5-MW Floating Photovoltaic Power Generation System on a Thermal Power Plant Ash Pond. Sustainability, 12(6), 2298. https://doi.org/10.3390/su12062298