LNG and Cruise Ships, an Easy Way to Fulfil Regulations—Versus the Need for Reducing GHG Emissions

Abstract

1. Introduction

- Methane slip is a recognized challenge when LNG is used as a fuel.

- While LNG 20 years ago gave large reductions in local pollution compared to conventional fuels, the much stricter air emission regulation, coming into effect from 2015 to 2021, has reduced the emission reduction potential of LNG as a ship fuel with more than 80% compared to conventional fuels both for NOx and SOx.

- In sensitive areas with a need for reducing emissions even bellow ECA requirements, state-of-the-art engine technology in combination with hybrid scrubbers or synthetic diesel (made from natural gas) can today deliver nearly similar performance as LNG.

- The LNG engine solution available for cruise and other ocean-going vessels using 4 stroke engines tends to come at a lower capex than alternative abatement options to fulfil IMO air emission regulations from 2020 [8].

- LNG is less expensive than MGO and is now, in some regions, becoming even cheaper than HFO [9].

- For the cruise industry, with its high public visibility, it is tempting to choose LNG as a fuel just due to its good reputation in the public opinion.

2. Materials and Methods

3. Results and Analysis

3.1. Well-to-Tank (WTT)

| Fuel Type | Id | Study | WTT- GWP100 | WTT- GWP100 Min | WTT- GWP100 Max | WTT- GWP20 |

|---|---|---|---|---|---|---|

| HFO <3.5% S (heavy fuel oil) | Brynolf (2014) [13,27] | 8.9 | 8.9 | |||

| 6 | Chryssakis and Stahl (2013) [24] | 9.2 | 9.2 | |||

| 2 | Lindstad (2019) [32] | 9.6 | 9.6 | 14.6 | ||

| 6 | DNV GL (2019) [35] | 9.8 | 9.8 | |||

| 5 | Verbeek et al. (2011) [23] | 9.8 | 9.8 | |||

| 1 | Thinkstep (2019) [31] Middle East | 11.7 | ||||

| 1 | Thinkstep (2019) [31] Global average | 13.5 | 11.1 | 18.8 | 18.5 | |

| 3 | ICCT (2020) [9] North America mix | 14.3 | 14.3 | 19.2 | ||

| VLSFO <0.5% S (very-low sulphur fuel oil) | 1 | Thinkstep (2019) [31] Global average | 13.2 | 10.8 | 18.4 | 18.2 |

| 2 | Lindstad (2019) [32] | 13.2 | 18.2 | |||

| 3 | ICCT (2020) [9] North America mix | 16.8 | 22.0 | |||

| MGO <0.1% S (marine gas oil) | 5 | Verbeek et al. (2011) [23] | 12.7 | |||

| 6 | DNV-GL (2019) [35] | 12.7 | ||||

| 1 | Thinkstep (2019) [31] Middle East | 13.5 | ||||

| 5 | Verbeek et al. (2013) [23] | 14.4 | ||||

| 6 | Chryssakis and Stahl (2013) [24] | 14.4 | ||||

| 1 | Thinkstep (2019) [31] Global average | 14.4 | 13.0 | 17.9 | 19.4 | |

| 2 | Lindstad (2019) [32] | 14.4 | 19.4 | |||

| 3 | ICCT (2020) [9] North America mix | 17.4 | 22.7 | |||

| LNG (liquified natural gas) | 6 | DNV-GL (2019) [35] Qatar | 7.7 | |||

| 6 | Chryssakis and Stahl (2013) [24] | 9.7 | ||||

| 6 | DNV-GL (2019) [35] Qatar–Europe | 10.7 | ||||

| 5 | Verbeek et al. (2011) [23] | 10.7 | ||||

| 5 | Verbeek et al. (2013) [37] Qatar–Europe | 17.0 | ||||

| 1 | Thinkstep (2019) [31] China | 17.3 | 24.5 | |||

| 4 | ICCT (2020) [9] Qatar–Europe (lit.) | 18.0 | ||||

| 1 | Thinkstep (2019) [31] Middle East | 18.2 | 25.9 | |||

| 1 | Thinkstep (2019) [31] Global average | 18.5 | 17.3 | 20.9 | 27.1 | |

| 2 | Lindstad (2019) [32] | 18.5 | 27.1 | |||

| 5 | Verbeek et al. (2015) [28] | 19.0 | ||||

| JRC–Eucar–Concawe (2014) [25] Europe | 19.4 | |||||

| GREET (2018) [34] USA LNG Supply | 19.7 | |||||

| NGVA (2017) [38] European LNG Supply | 19.9 | |||||

| 4 | ICCT (2020) [9] USA - N. America (lit.) | 20.0 | ||||

| 1 | Thinkstep (2019) [31] Europe | 20.9 | 29.5 | |||

| 4 | ICCT (2020) [9] Global average (lit.) | 21.2 | 14.7 | 28.6 | ||

| 3 | ICCT (2020) [9] North American mix | 21.5 | 35.6 | |||

| 4 | ICCT (2020) [9] Australia–Asia (lit.) | 22.0 | ||||

| Exergia (2015) [39] European LNG Supply | 24.6 | |||||

| Skone et al. (2014) [40] USA–Shanghai | 28.6 | 48.0 |

3.2. Engine Performance Including Methane Slip

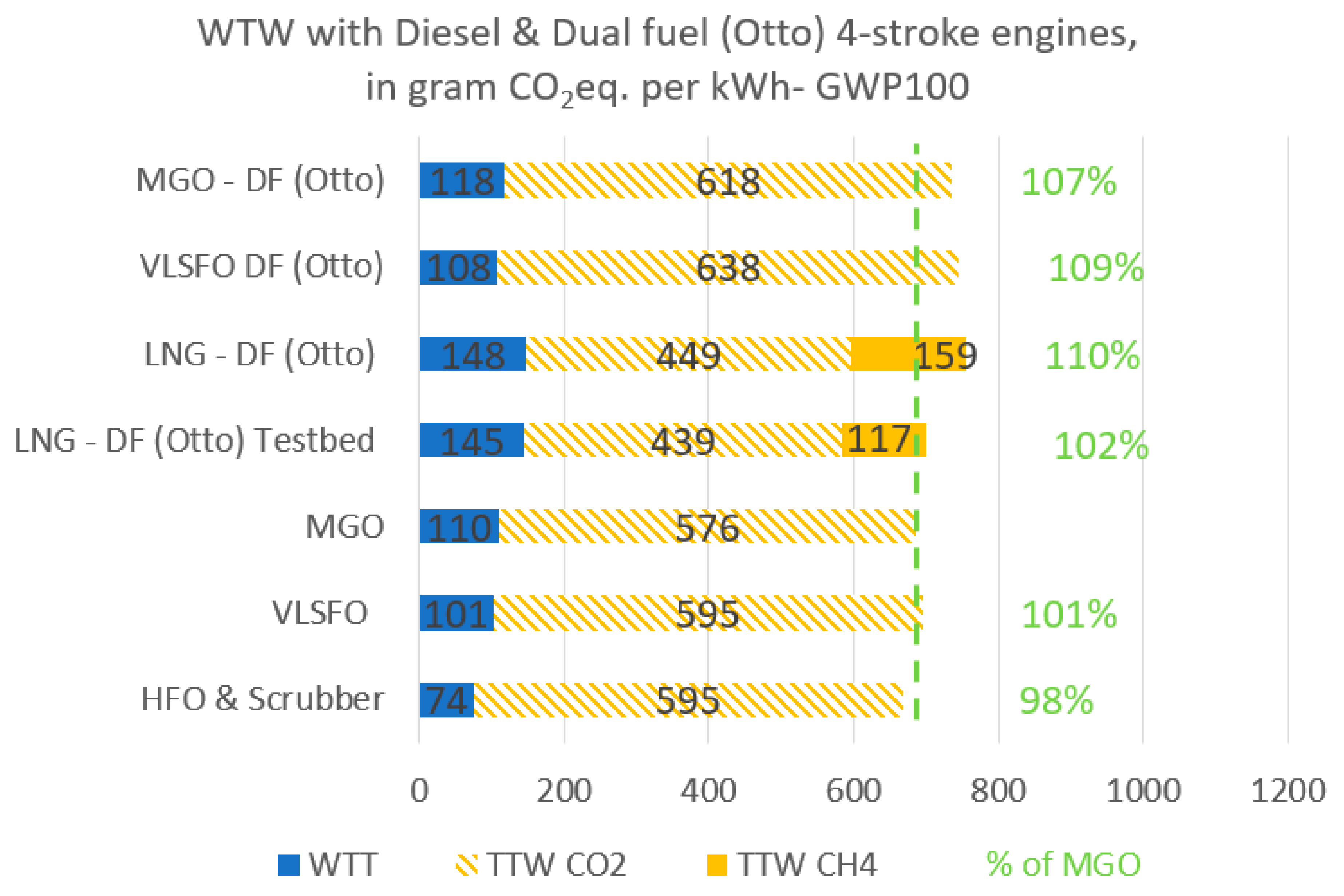

3.3. Well-to-Wake Emissions (WTW)

- The CO2 emissions factors and the low calorific value for each fuel.

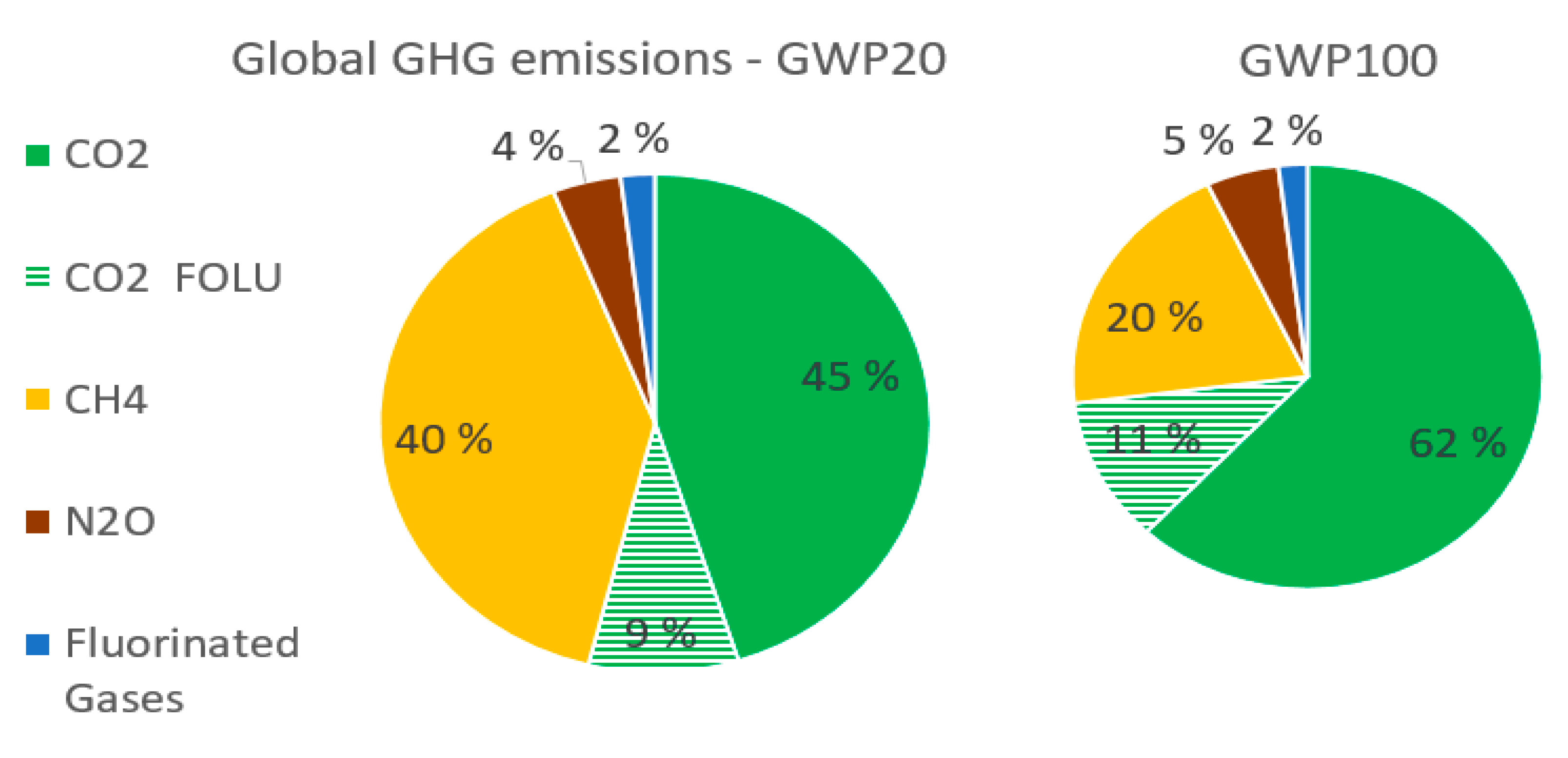

- The GWP factors for methane.

- The thermal engine efficiency.

- The specific fuel oil consumption (SFOC) calculated based on 1 and 2.

- The methane slips.

- TTW emissions are calculated based on fuel consumption and CO2 emission factors.

- WTT emissions calculated based on gram per MJ and the thermal efficiency for GWP100 and for GWP20.

- WTW emissions are given by adding up WTT with TTW emissions.

- WTW emissions in % of MGO are found by dividing WTW for each option on the MGO value both for GWP100 and for GWP20.

- First, LNG with a short-term horizon (GWP20) increases GHG emissions by 35–53% compared to the existing diesel options.

- Second, with a long-time horizon (GWP100), the increase is more modest, i.e., up to 10%, but LNG still gives no GHG emissions reduction, even in GWP100.

- Third, when the dual-fuel engines run purely on MGO or VLSFO, the GHG emissions increase by 7–9% compared to when diesel is burnt on a pure diesel engine. The reason is the lower thermal efficiency of the Otto dual-fuel engine compared to the pure diesel engine.

- Fourth, the potential GHG reduction with scrubbers are up to 2–4% compared to MGO, if we assume that HFO is the bottom of the barrel from standard oil refineries.

4. Comparing the Results with Previous Studies

- All studies that have investigated GWP20 confirm that LNG and dual-fuel (Otto) 4 stroke engines increase GHG emissions within a 20 year time horizon.

- For a 100 year time horizon, the figures from DNV-GL (2019) [35] and Thinkstep (2019) [31] indicate a small GHG reduction with LNG, i.e., 0–10%. This contrasts with ICCT (2020) [9], which indicates that GHG emissions with LNG could increase by 16%, with this study indicating an increase of up to 10%, and with Lindstad (2019) reporting a GHG emission increase of 6%.

- Thinkstep (2019) [31] has used a higher thermal efficiency for dual-fuel gas operations than for diesel. Furthermore, they have assumed (according to our interpretation) that all ships operate in ECAs according to the NOx Tier III requirements, which increases GHG emissions for conventional fuels due to the urea consumption required by the SCR (selective catalytic reduction) process to reduce the NOx content in the exhaust gas. This, despite that: first, NOx Tier III is only applicable to newbuilt ships after 2016/2021; second, newbuilt ships that generally have advanced engine control systems will operate in Tier II mode outside the ECAs to save fuel; third, the ECAs cover only a small part of the global oceans.

- ICCT (2020) [9] has used a higher CH4 factor, i.e., 36 instead of 30 for GWP100. It has also applied methane slip figures that are slightly higher than manufacturers’ test bed figures, and a higher lower calorific value for CH4, i.e., 50 instead of 49.2.

- Acknowledged WTT GHG emissions levels reported in published studies for production of LNG or conventional fuels, or both, and not on best-case assumption for one of the assessed fuels.

- The most recent knowledge published by IPCC through their Assessment Reports regarding GWP factors for the different GHG.

- Well-proven and accepted thermal efficiency for different 4 stroke engines.

- That the existing ocean-going fleet built up to 2016 will operate according to the NOx Tier II rules with no need for any NOx after treatment of the exhaust gas even for conventional fuels.

- That new ocean-going vessels will use today’s advanced engine control systems to operate in NOx Tier II mode outside the ECAs and operate in NOx Tier III mode only when in ECAs (with use of Urea in the SCR process or other NOx reduction means).

5. Discussion and Conclusions

- Comparable well-to-tank (WTT) GHG estimates, for LNG and conventional fuels.

- Transparent calculations of well-to-wake (WTW) GHG emissions for the investigated fuels.

- A transparent comparison of the results of this study with previous studies.

- Results indicating that increased use of dual-fuel (Otto) LNG engines (which are the current option for cruise vessels and other vessels using 4 stroke engines) will increase GHG emissions compared to conventional fuels (MGO, HFO & Scrubber, and VLSFO).

Author Contributions

Funding

Conflicts of Interest

References

- IMO (Ed.) Protocol of 1997 to Amend MARPOL 73/78: Annex VI of MARPOL 73/78: Regulations for the Prevention of Air Pollution from Ships, and Final Act of the 1997 MARPOL Conference, and the Technical Code on Control of Emission of Nitrogen Oxides from Marine Diesel Engines; International Maritime Organization (IMO): London, UK, 1997; p. 150. [Google Scholar]

- UN. Kyoto Protocol to the United Nations Framework Convention on Climate Change; COP3: Kyoto, Japan, 1997. [Google Scholar]

- IMO (Ed.) Resolution MEPC 203 (62) (Adopted on 15 July 2011) Amendments to the Annex of the Protocol of 1997 to Amend the International Convention for the Prevention of Pollution from Ships, 1973, as Modified by the Protocol of 1978 Relating There to (Inclusion of Regulations on Energy Efficiency for Ships in MARPOL Annex VI); IMO: London, UK, 2011. [Google Scholar]

- IPCC. Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects. Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Field, C.B., Barros, V.R., Dokken, D.J., Mach, K.J., Mastrandrea, M.D., Bilir, T.E., Chatterjee, M., Ebi, K.L., Estrada, Y.O., Genova, R.C., et al., Eds.; IPCC: Cambridge, UK; New York, NY, USA, 2014; p. 1132. [Google Scholar]

- Shine, K.P. The global warming potential-the need for an interdisciplinary retrial. Clim. Chang. 2009, 96, 467–472. [Google Scholar] [CrossRef]

- Balcombe, P.; Speirs, J.F.; Brandon, N.P.; Hawkes, A.D. Methane emissions: Choosing the right climate metric and time horizon. Environ. Sci. Process. Impacts 2018, 20, 1323–1339. [Google Scholar] [CrossRef] [PubMed]

- IPCC. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F.D., Qin, G.-K., Plattner, M., Tignor, S.K., Allen, J., Boschung, A., Nauels, Y., Xia, V.B., Midgley, P.M., Eds.; IPCC: Cambridge, UK; New York, NY, USA, 2013; p. 1535. [Google Scholar]

- Lindstad, E.; Eskeland, G.; Valland, A. The Importance of Encouraging and Rewarding Best Engine Technologies for Achieving Maritime GHG Reduction; 2020; (Unpublished; Manuscript in Preparation). [Google Scholar]

- The Climate Implications of Using LNG as a Marine Fuel; ICCT, International Council on Clean Transportation, 2020. Available online: https://theicct.org/publications/climate-impacts-LNG-marine-fuel-2020 (accessed on 7 February 2020).

- UN (Ed.) United Nations Framework Convention on Climate Change; Paris Agreement: FCCC/CP/2015/L.9/Rev.1.; United Nations: Paris, France, 2015. [Google Scholar]

- Campling, P.; Janssen, L.; Vanherle, K.; Cofala, J.; Heyes, C.; Sander, R. Specific Evaluation of Emissions from Shipping Including Assessment for the Establishment of Possible New Emission Control Areas in European Seas; Flemish Institute for Technological Research (VITO): Mol, Belgium, 2013; p. 34. [Google Scholar]

- Johansson, L.; Jalkanen, J.P.; Kalli, J.; Kukkonen, J. The evolution of shipping emissions and the costs of regulation changes in the northern EU area. Atmos. Chem. Phys. 2013, 13, 11375–11389. [Google Scholar] [CrossRef]

- Brynolf, S.; Magnusson, M.; Fridell, E.; Andersson, K. Compliance possibilities for the future ECA regulations through the use of abatement technologies or change of fuels. Transp. Res. Part D Transp. Environ. 2014, 28, 6–18. [Google Scholar] [CrossRef]

- Jiang, L.; Kronbak, J.; Christensen, L.P. The costs and benefits of sulphur reduction measures: Sulphur scrubbers versus marine gas oil. Transp. Res. Part D Transp. Environ. 2014, 28, 19–27. [Google Scholar] [CrossRef]

- Acciaro, M. Real option analysis for environmental compliance: LNG and emission control areas. Transp. Res. Part D Transp. Environ. 2014, 28, 41–50. [Google Scholar] [CrossRef]

- Lindstad, E.; Eskeland, G.S.; Psaraftis, H.; Sandaas, I.; Strømman, A.H. Maritime shipping and emissions: A three-layered, damage-based approach. Ocean Eng. 2015, 110, 94–101. [Google Scholar] [CrossRef]

- Lindstad, E.; Sandaas, I.; Strømman, A.H. Assessment of cost as a function of abatement options in maritime emission control areas. Transp. Res. Part D Transp. Environ. 2015, 38, 41–48. [Google Scholar] [CrossRef]

- Lindstad, E.; Eskeland, G.S. Environmental regulations in shipping: Policies leaning towards globalization of scrubbers deserve scrutiny. Transp. Res. Part D Transp. Environ. 2016, 47, 67–76. [Google Scholar] [CrossRef]

- Øberg, M.M. Life Cycle Assessment of Fuel Choices for Marine Vessels; NTNU, Norwegian University of Science and Technology: Trondheim, Norway, 2013. [Google Scholar]

- Silva, M. Life Cycle Assessment of Marine Fuel Production; NTNU, Norwegian University of Science and Technology: Trondheim, Norway, 2017. [Google Scholar]

- Buhaug, Ø.; Corbett, J.J.; Endresen, Ø.; Eyring, V.; Faber, J.; Hanayama, S.; Lee, D.S.; Lee, D.; Lindstad, H.; Markowska, A.Z.; et al. Second IMO GHG Study 2009; International Maritime Organization (IMO): London, UK, 2009. [Google Scholar]

- Bengtsson, S.; Andersson, K.; Fridell, E. Life Cycle Assessment of Marine Fuels: A Comparative Study of Four Fossil Fuels for Marine Propulsion; Chalmers University of Technology, Department of Shipping and Marine Technology, Division of Sustainable Ship Propulsion: Gothenburg, Sweden, 2011. [Google Scholar]

- Verbeek, R.; Kadijk, G.; van Mensch, P.; Wulffers, C.; van den Beemt, B.; Fraga, F. 2011 Environmental and Economic Aspects of Using LNG as a Fuel for Shipping in The Netherlands; TNO Report TNO-RPT-2011-00166; TNO: Delft, The Netherlands, 2011; p. 48. [Google Scholar]

- Chryssakis, C.; Stahl, S. Well-To-Propeller Analysis of Alternative Fuels for Maritime Applications. In Proceedings of the CIMAC 2013, Shanghai, China, 13–17 May 2013. [Google Scholar]

- Edwards, R.; Larive, J.-F.; Rickeard, D.; Weindorf, W.; Godwin, S.; Hass, H.; Krasenbrink, A.; Lonza, L.; Maas, H.; Nelson, R.; et al. WELL-TO-TANK Report Version 4.a: JEC WELL-TO-WHEELS ANALYSIS; JRC, EUCAR and CONCAWE; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Bengtsson, S.K.; Fridell, E.; Andersson, K.E. Fuels for short sea shipping: A comparative assessment with focus on environmental impact. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2014, 228, 44–54. [Google Scholar] [CrossRef]

- Brynolf, S.; Kuvalekar, S.; Andersson, K. Life Cycle Assessment of Methanol and Dimethyl Ether (DME) as Marine Fuels; Report 2014; Department of Shipping and Marine Technology, Chalmers University of Technology: Göteborg, Sweden, 2014. [Google Scholar]

- Verbeek, R.; Verbeek, M. LNG for Trucks and Ships: Fact Analysis Review of Pollutant and GHG Emissions; TNO: Delft, The Netherlands, 14 February 2015; p. 70. [Google Scholar]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Lindstad, E.; Bø, T.I. Potential power setups, fuels and hull designs capable of satisfying future EEDI requirements. Transp. Res. Part D Transp. Environ. 2018, 63, 276–290. [Google Scholar] [CrossRef]

- Thinkstep. Life Cycle GHG Emission Study on the Use of LNG as Marine Fuel. Available online: https://www.thinkstep.com/content/life-cycle-ghg-emission-study-use-lng-marine-fuel-1 (accessed on 30 November 2019).

- Lindstad, E. Increased Use of LNG Might Not Reduce Maritime GHG Emissions at all—June 2019. Transport & Environment’s (T&E). Available online: https://www.transportenvironment.org/sites/te/files/publications/2019_06_Dr_Elizabeth_Lindstad_commentary_LNG_maritime_GHG_emissions.pdf (accessed on 1 September 2019).

- Thinkstep. Available online: https://www.gabi-software.com (accessed on 30 June 2019).

- Argonne. GREET: Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) Model; Argonne National Laboratory: Lemont, IL, USA, 2018.

- DNV-GL. Assessment of Selected Alternative Fuels and Technologies. p. 56. Available online: https://www.dnvgl.com/maritime/publications/alternative-fuel-assessment-download.html (accessed on 30 November 2019).

- DNV-GL. Maritime Forecast to 2050, in ENERGY TRANSITION OUTLOOK 2019. Available online: https://eto.dnvgl.com/2019/Maritime/ (accessed on 30 November 2019).

- Verbeek, R.; Lingterink, R.; Meulenbrugge, J.; Kooneef, G.; Kroon, P.; de Wilde, H.; Kampman, B.; Croezen, H.; Aamink, S.; Verbeek, R.; et al. 2013 Natural Gas in Transport—An Assessment of Different Routes, TNO Report 4.818.1; TNO: Delft, The Netherlands, 2013; p. 172. [Google Scholar]

- NGVA. Greenhouse Gas Intensity of Natural Gas, Prepared by Thinkstep; NGVA Europe (European Natural & bio Gas Vehicle Association): Brussels, Belgium, 2017. [Google Scholar]

- EXERGIA; E3M-Lab; COWI. Study on Actual GHG Data for Diesel, Petrol, Kerosene and Natural Gas-Final Report, EXERGIA S.A.-E3M-Lab-COWI A/S, Members of COWI Consortium, Prepared for European Commission DG ENERGY; DG Energy: Brussels, Belgium, 2015; p. 549. [Google Scholar]

- Skone, T.J.; Cooney, G.; Jamieson, M.; Littlefield, J.; Marriott, J. Life Cycle Greenhouse Gas Perspective on Exporting Liquefied Natural Gas from the United States. Available online: https://www.energy.gov/fe/downloads/life-cycle-greenhouse-gas-perspective-exporting-liquefied-natural-gas-united-states (accessed on 29 May 2014).

- El-Houjeiri, H.; Monfort, J.-C.; Bouchard, J.; Przesmitzki, S. Life Cycle Assessment of Greenhouse Gas Emissions from Marine Fuels: A Case Study of Saudi Crude Oil versus Natural Gas in Different Global Regions. J. Ind. Ecol. 2018, 23, 374–388. [Google Scholar] [CrossRef]

- Shell. The Bunker Fuels Challenge: How Should You Respond? Technology Trends to Watch. Available online: http://www.shell.com/business-customers/global-solutions/industry-focus/the-bunker-fuels-challenge.html (accessed on 30 November 2016).

- Lindstad, H.E.; Rehn, C.F.; Eskeland, G.S. Sulphur abatement globally in maritime shipping. Transp. Res. Part D Transp. Environ. 2017, 57, 303–313. [Google Scholar] [CrossRef]

- Ushakov, S.; Stenersen, D.; Einang, P.M. Methane slip from gas fuelled ships: A comprehensive summary based on measurement data. J. Mar. Sci. Technol. 2019, 24, 1308–1325. [Google Scholar] [CrossRef]

- Smith, T.W.P.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’Keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. The Third IMO GHG Study; International Maritime Organization (IMO): London, UK, 2014. [Google Scholar]

- Fairplay. Pace Race—Slow Steaming Not Necessarily a Sulphur Cap Saviour; Fairplay Magazine: London, UK, 2018; pp. 24–26. [Google Scholar]

- IPCC. IPCC, Climate Change 2007: Synthesis Report. Contribution of Working Groups I, II and III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Pachauri, R.K., Reisinger, A., Eds.; IPCC: Geneva, Switzerland, 2007; p. 104. [Google Scholar]

- Stenersen, D.; Thonstad, O. GHG and NOx Emissions from Gas Fuelled Engines-Mapping, Verification, Reduction Technologies; OC2017 F-108; SINTEF Ocean: Trondhein, Norway, 2017. [Google Scholar]

| Thinkstep (2019) [31] North America | Thinkstep (2019) [31] Middle East | Thinkstep (2019) [31] Global Average | Lindstad (2019) [32] | ICCT (2020) [9] | GWP100 | |||

|---|---|---|---|---|---|---|---|---|

| LNG | 18.9 | 18.2 | 18.5 | 18.5 | 21.5 | gram of CO2eq per MJ | ||

| MGO | 17.9 | 13.5 | 14.4 | 14.4 | 17.4 | gram of CO2eq per MJ | ||

| HFO | 18.8 | 11.7 | 13.5 | 9.6 | 14.3 | gram of CO2eq per MJ | ||

| LNG/MGO | 135% | 128% | 128% | 124% | ||||

| LNG/HFO | 156% | 137% | 193% | 150% | ||||

| 4 Stroke Medium-Speed Engines. Comparing Pure Diesel Engines and Dual-Fuel (Otto) LNG Engines | HFO & Scrubber | VLSFO | MGO | LNG-DF (Otto-Engine)—Test Bed | LNG-DF (Otto-Engine) | VLSFO (Otto-Engine) | MGO (Otto-Engine) | |

|---|---|---|---|---|---|---|---|---|

| CO2 emission factors | 3.114 | 3.176 | 3.206 | 2.75 | 2.75 | 3.176 | 3.206 | |

| Lower calorific value | MJ/kg | 40.2 | 41.0 | 42.7 | 49.2 | 49.2 | 41 | 42.7 |

| CH4–GWP100 (CO2eq) | 30 | 30 | ||||||

| CH4–GWP20 (CO2eq) | 85 | 85 | ||||||

| Thermal engine efficiency | 47% | 47% | 47% | 45.8% | 45% | 44% | 44% | |

| Thermal engine efficiency for pure diesel engine | 47% | 47% | 47% | 47% | ||||

| Thermal engine efficiency compared to pure diesel engine | 97% | 96% | 94% | 94% | ||||

| Fuel consumption (SFOC) | Gram/kWh | 191 | 187 | 179.5 | 159.9 | 162.9 | 200 | 192.1 |

| Methane Slip | Gram/kWh | 3.9 | 5.3 | |||||

| TTW–GWP100 CO2eq | Gram/kWh | 595 | 595 | 576 | 556 | 608 | 638 | 618 |

| TTW–GWP20 CO2eq | Gram/kWh | 595 | 595 | 576 | 771 | 899 | 638 | 618 |

| WTT–GWP100 CO2eq | Gram/MJ | 9.6 | 13.2 | 14.4 | 18.5 | 18.5 | 13.2 | 14.4 |

| Gram/kWh | 74 | 101 | 110 | 145 | 148 | 108 | 118 | |

| WTT–GWP20–CO2eq | Gram/MJ | 14.1 | 19.6 | 20.8 | 27.9 | 27.9 | 19.6 | 20.8 |

| Gram/kWh | 108 | 150 | 159 | 219 | 223 | 160 | 170 | |

| WTW–GWP100–CO2eq | Gram/kWh | 668 | 696 | 686 | 701 | 756 | 746 | 736 |

| WTW–GWP20–CO2eq | Gram/kWh | 703 | 745 | 735 | 990 | 1122 | 798 | 789 |

| WTW GWP100 in % of MGO | % | 97% | 101% | 100% | 102% | 110% | 109% | 107% |

| WTW GWP20 in % of MGO | % | 96% | 101% | 100% | 135% | 153% | 109% | 107% |

| Comparing Results | Dual-Fuel (Otto) LNG 4 Stroke Engines | |

|---|---|---|

| GWP20 | GWP100 | |

| DNV-GL (2019) [35] Lowest | 90% | |

| DNV-GL (2019) [35] Highest | 100% | |

| Thinkstep (2019) [31] | 123% | 96% |

| This study, test bed | 135% | 102% |

| Lindstad (2019) [32] | 146% | 106% |

| This study | 153% | 110% |

| ICCT (2020) [9] | 162% | 116% |

| 4 Stroke Medium-Speed Engines. Comparing Pure Diesel Engines and Dual-Fuel (Otto) LNG Engines | MGO (Diesel Engine) | LNG-DF (Otto-Engine) – Test Bed | LNG-DF (Otto-Engine) | Why Previous Studies Have Shown Very Different GHG Impacts | |

|---|---|---|---|---|---|

| CO2 emission factors | 3.206 | 2.75 | 2.75 | LNG values in the range of 49.2–50 MJ/kg | |

| Low Caloric Value | MJ/kg | 42.7 | 49.2 | 49.2 | |

| CH4–GWP100 (CO2eq) | 30 | 30 | |||

| CH4–GWP20 (CO2eq) | 85 | 85 | |||

| Thermal engine efficiency | 47% | 45.8% | 45% | Thermal efficiency for LNG and dual-fuel engine with range going from 94 to 103% of pure diesel engine | |

| Thermal engine efficiency compared to pure diesel engine | 97% | 96% | |||

| Fuel consumption (SFOC) | Gram/kWh | 179.5 | 159.9 | 162.9 | Methane slip values in the |

| Methane Slip | Gram/kWh | 3.9 | 5.3 | range of 3.9–5.5 | |

| TTW - GWP100 CO2eq | Gram/kWh | 575 | 545 | 608 | |

| TTW - GWP20 CO2eq | Gram/kWh | 575 | 760 | 899 | |

| WTT - GWP100 CO2eq | Gram/MJ | 14.4 | 18.5 | 18.5 | Large variation with previous studies going from as low as 7.7 up to 28.6 g/MJ |

| Gram/kWh | 110 | 145 | 148 | ||

| WTT - GWP20 - CO2eq | Gram/MJ | 20.8 | 27.9 | 27.9 | GWP20 not covered by all studies |

| Gram/kWh | 159 | 219 | 223 | ||

| WTW - GWP100 - CO2eq | Gram/kWh | 686 | 701 | 756 | |

| WTW - GWP20 - CO2eq | Gram/kWh | 735 | 990 | 1122 | |

| WTW GWP100 in % of MGO | % | 100% | 102% | 110% | |

| WTW GWP20 in % of MGO | % | 100% | 135% | 153% | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindstad, E.; Rialland, A. LNG and Cruise Ships, an Easy Way to Fulfil Regulations—Versus the Need for Reducing GHG Emissions. Sustainability 2020, 12, 2080. https://doi.org/10.3390/su12052080

Lindstad E, Rialland A. LNG and Cruise Ships, an Easy Way to Fulfil Regulations—Versus the Need for Reducing GHG Emissions. Sustainability. 2020; 12(5):2080. https://doi.org/10.3390/su12052080

Chicago/Turabian StyleLindstad, Elizabeth, and Agathe Rialland. 2020. "LNG and Cruise Ships, an Easy Way to Fulfil Regulations—Versus the Need for Reducing GHG Emissions" Sustainability 12, no. 5: 2080. https://doi.org/10.3390/su12052080

APA StyleLindstad, E., & Rialland, A. (2020). LNG and Cruise Ships, an Easy Way to Fulfil Regulations—Versus the Need for Reducing GHG Emissions. Sustainability, 12(5), 2080. https://doi.org/10.3390/su12052080