Recyclable Architecture: Prefabricated and Recyclable Typologies

Abstract

1. Introduction

2. The History of Prefabrication Towards Recyclable Buildings

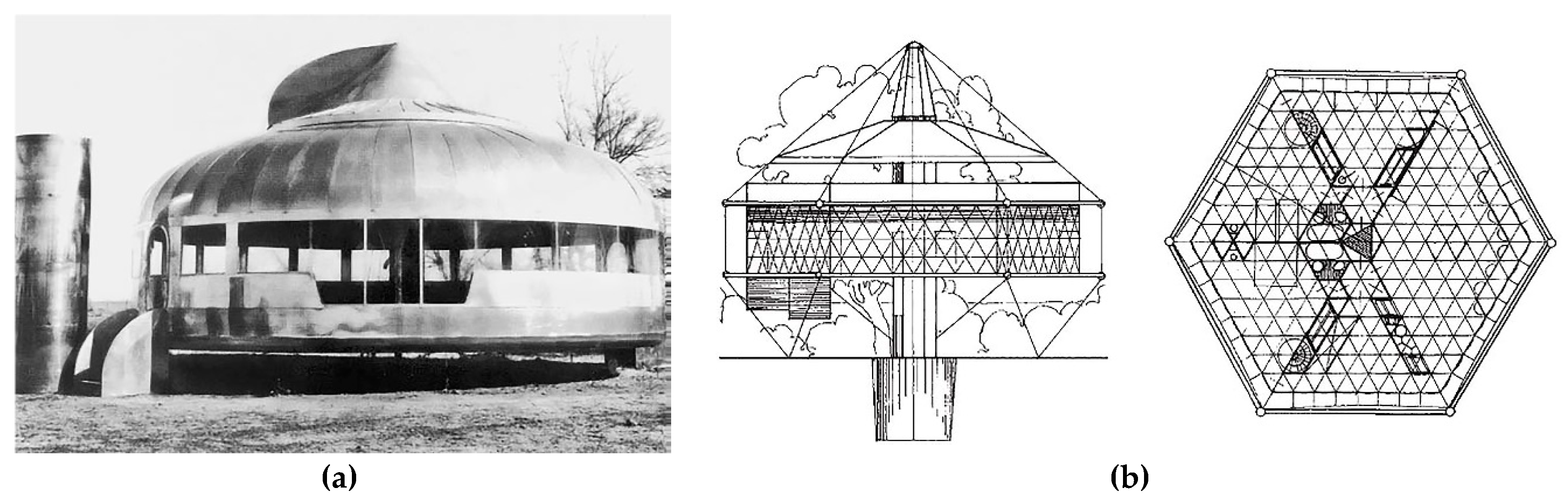

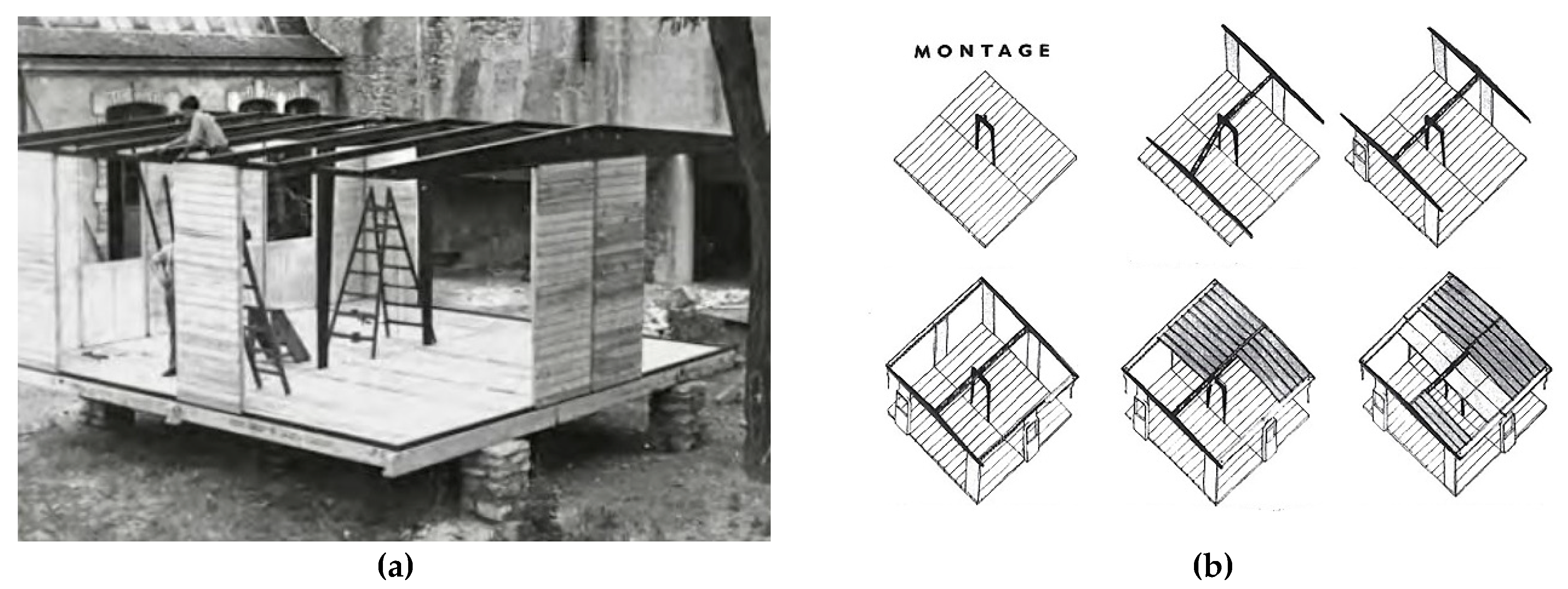

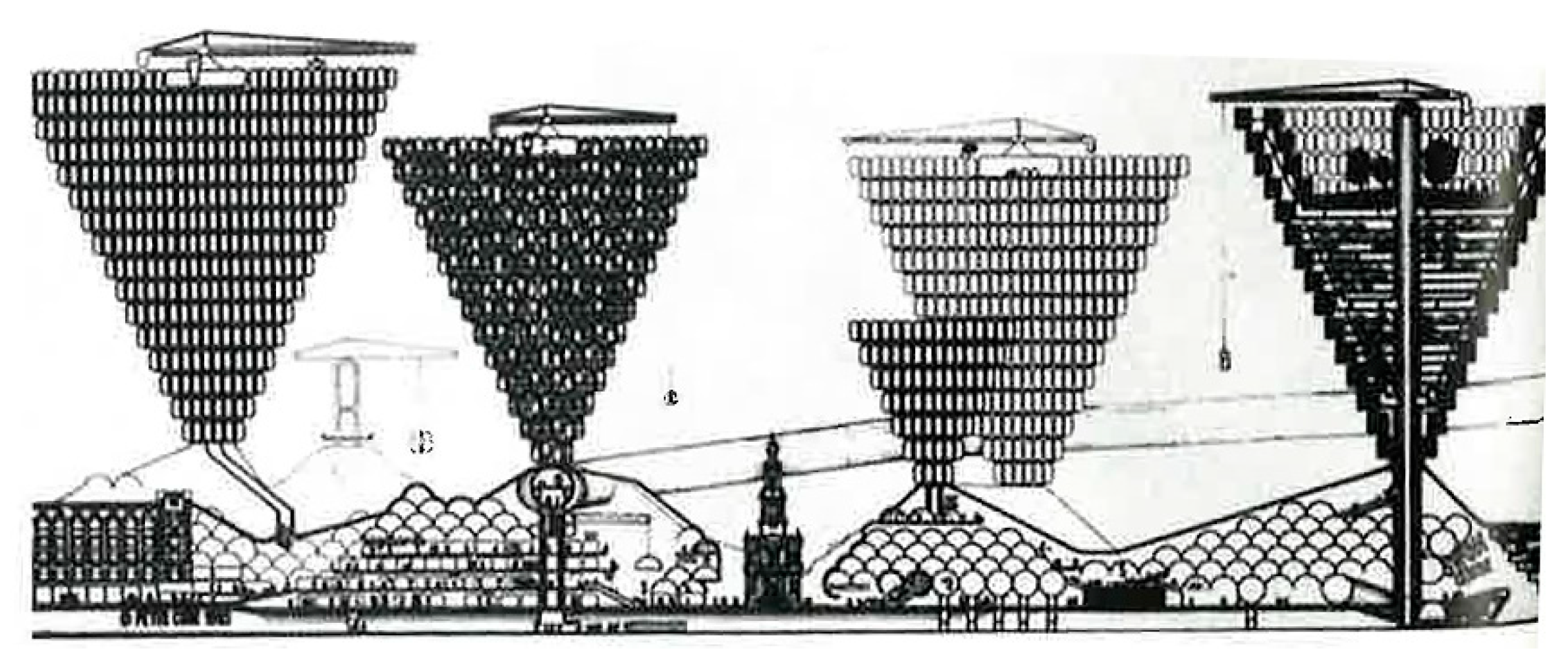

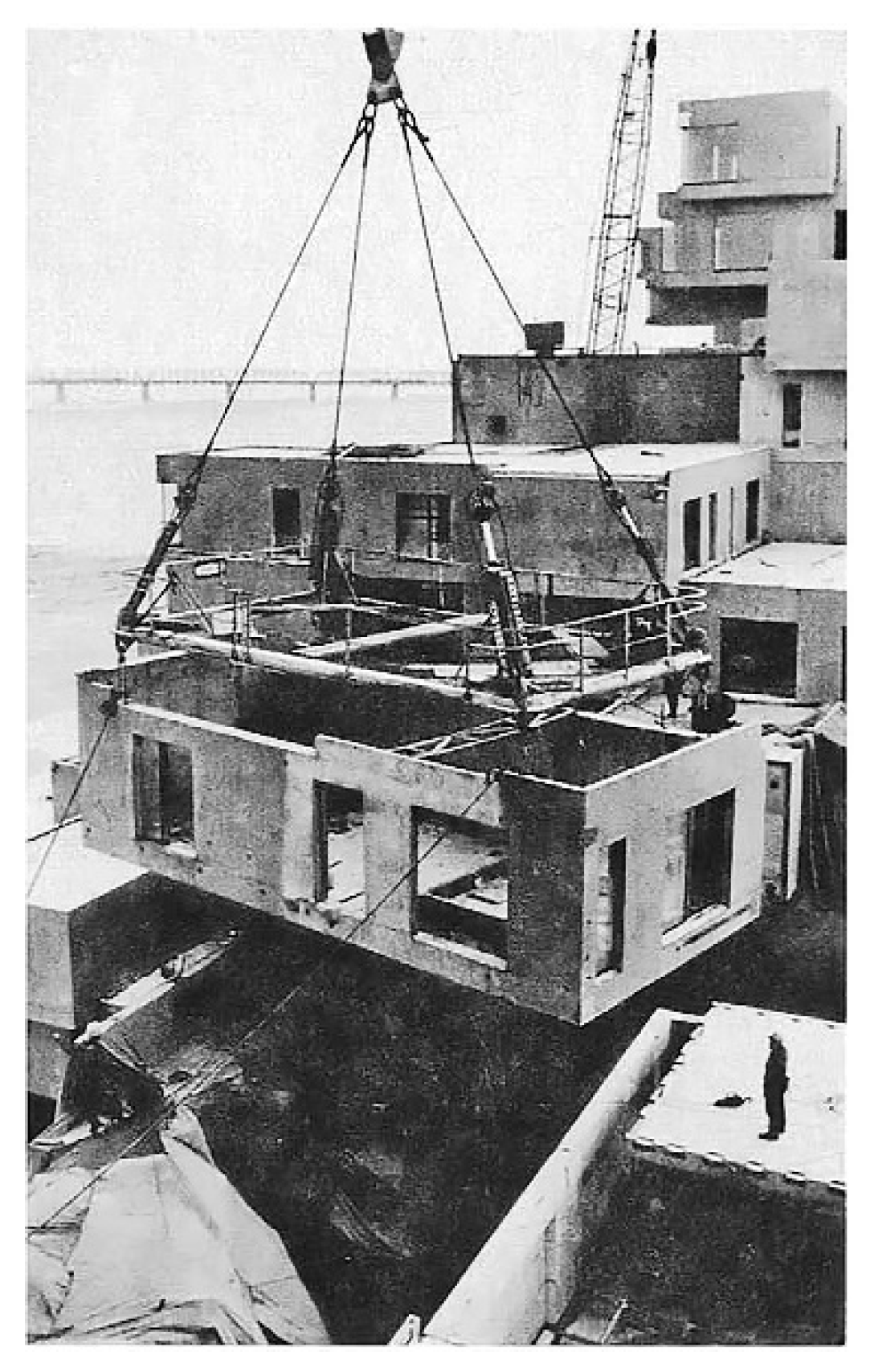

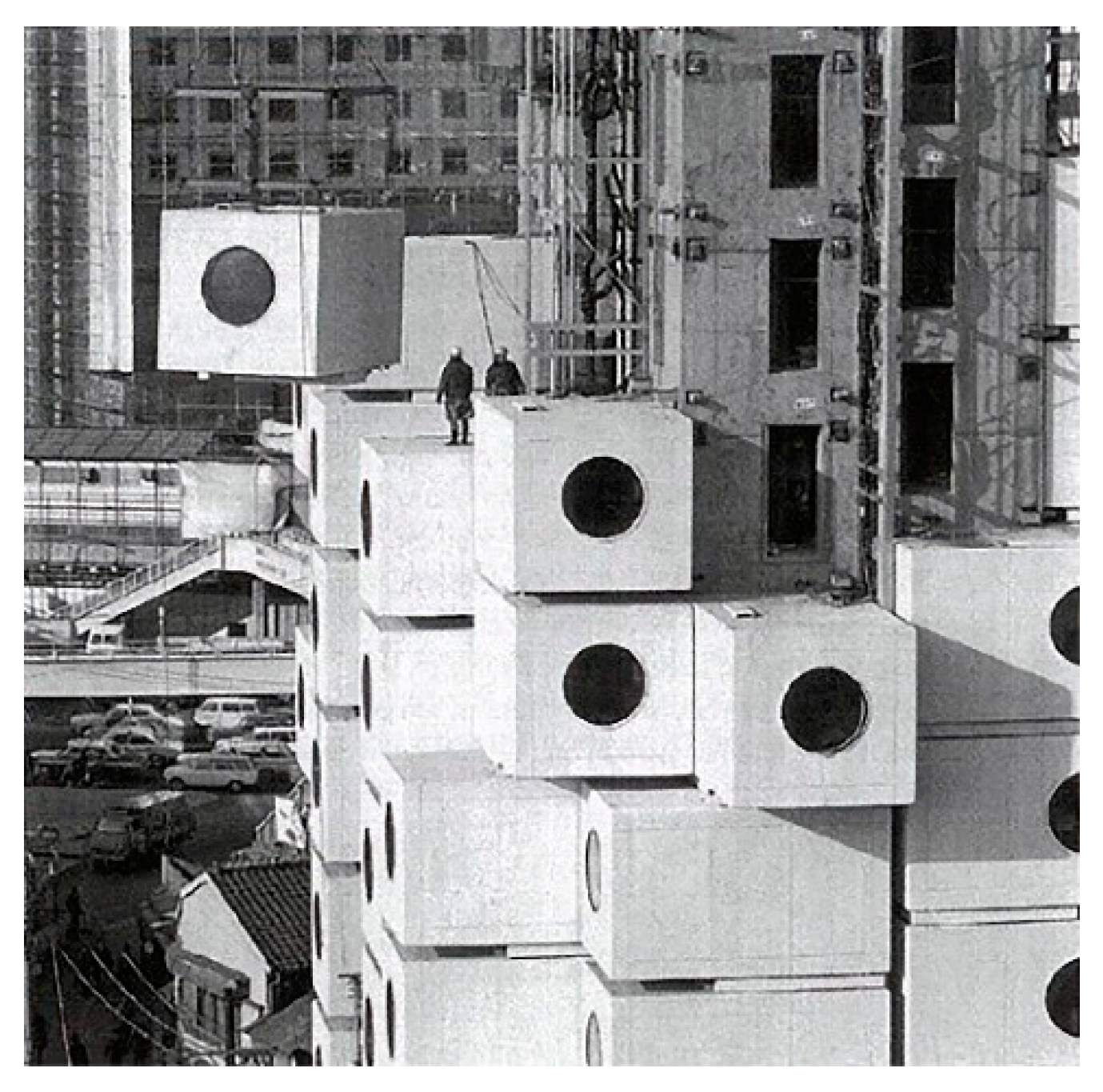

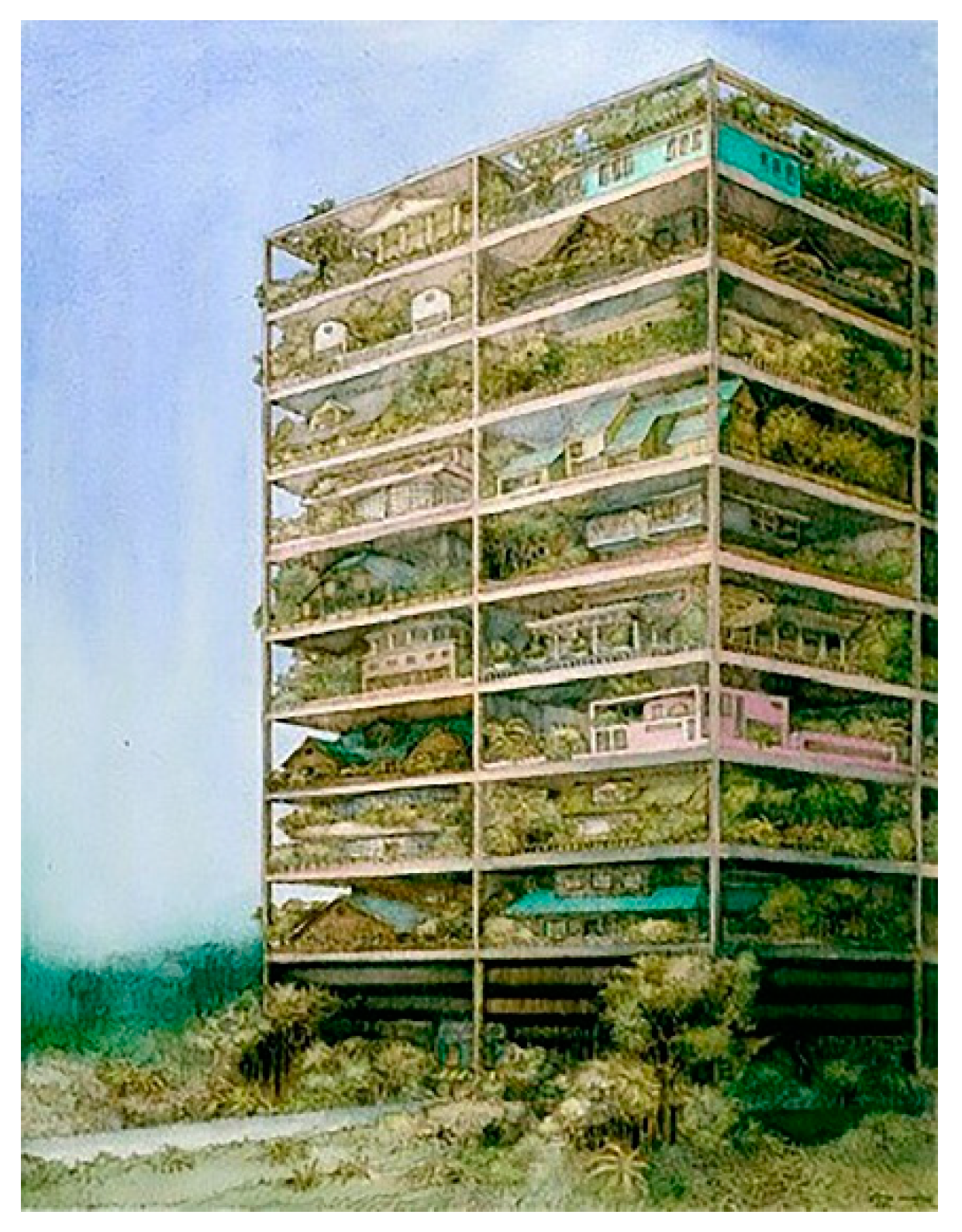

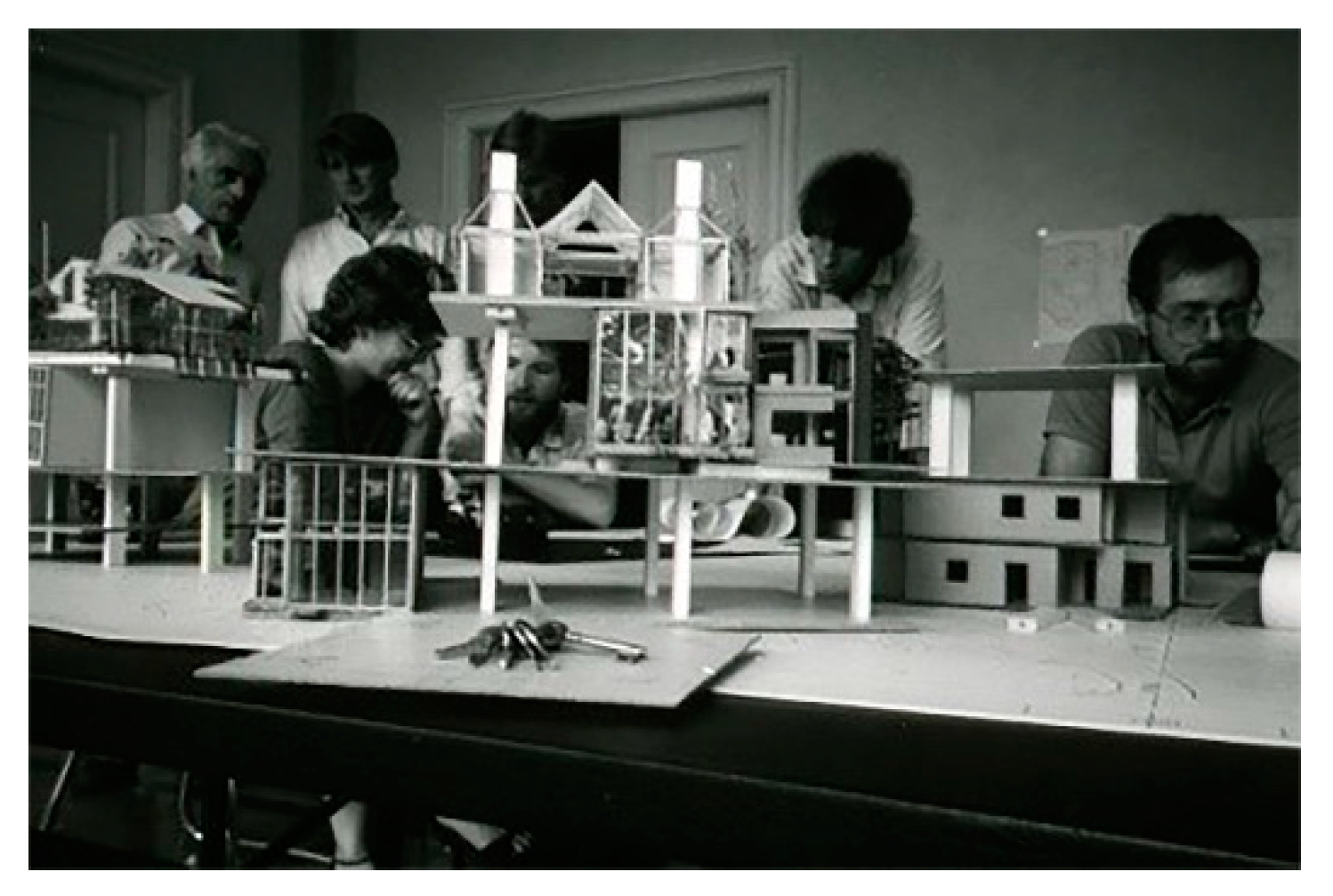

2.1. Prefabricated Buildings

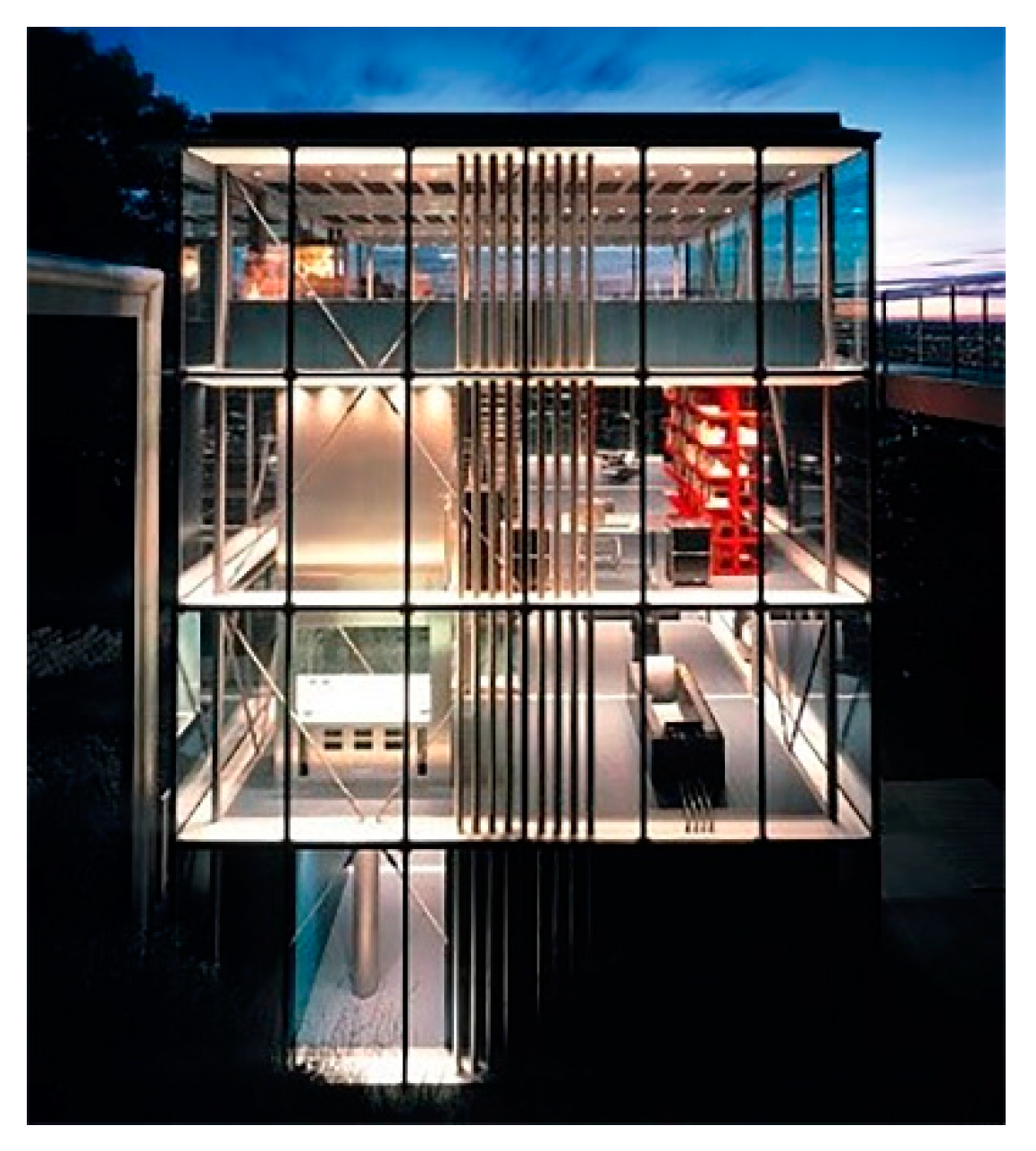

2.2. Ecological and Recyclable Buildings

2.3. Discussion

3. Proposed Architectural Typologies

3.1. The Principles

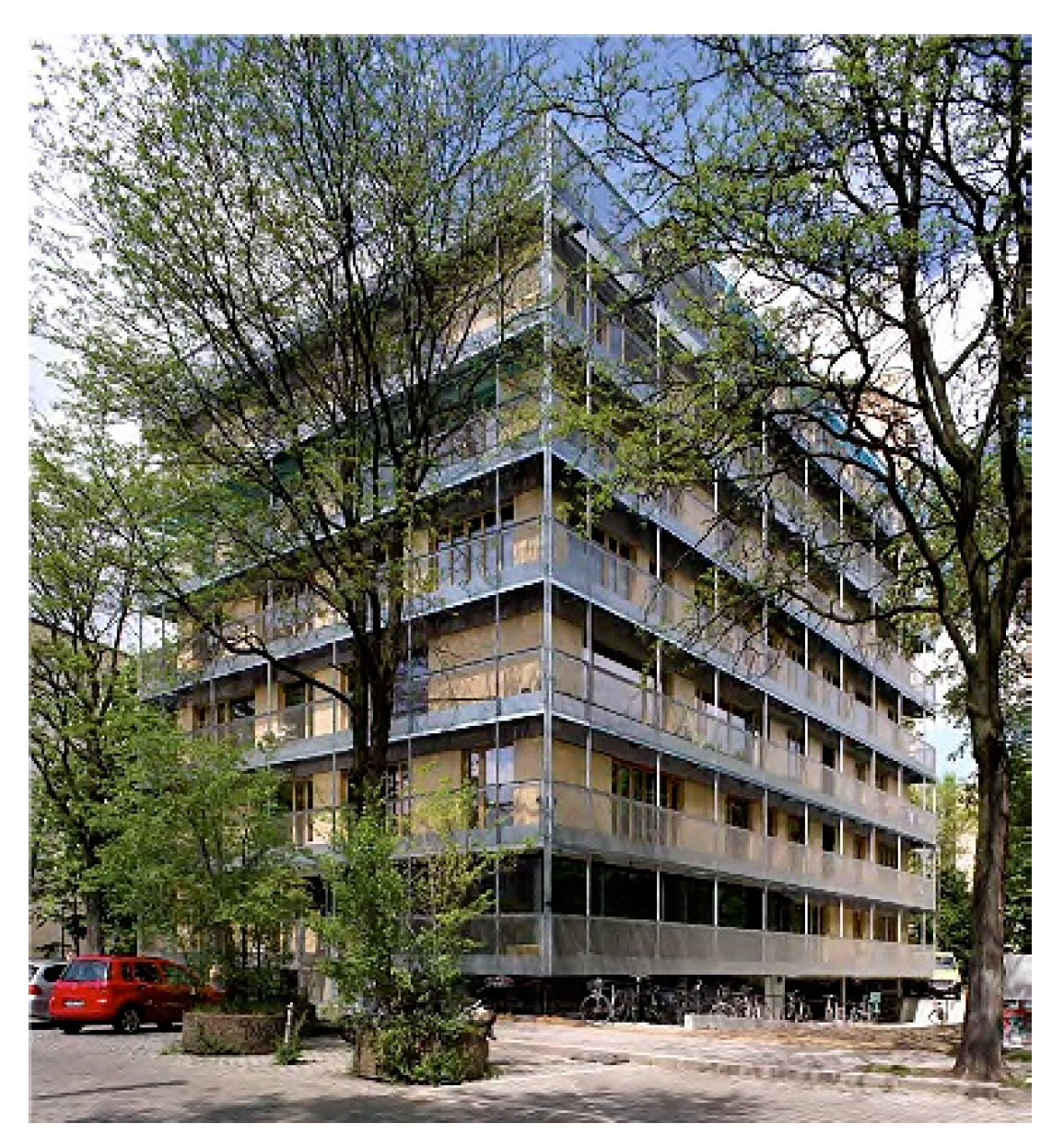

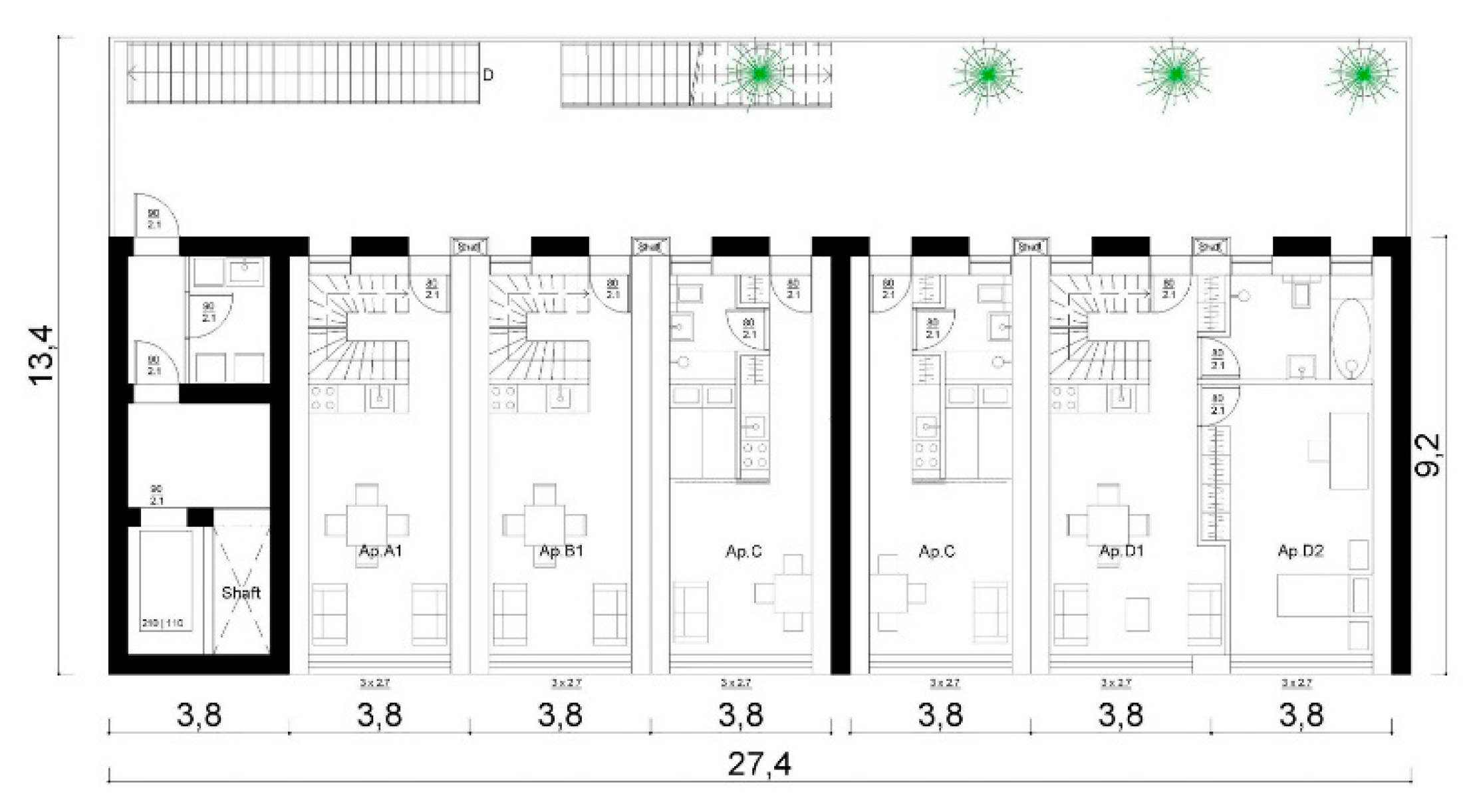

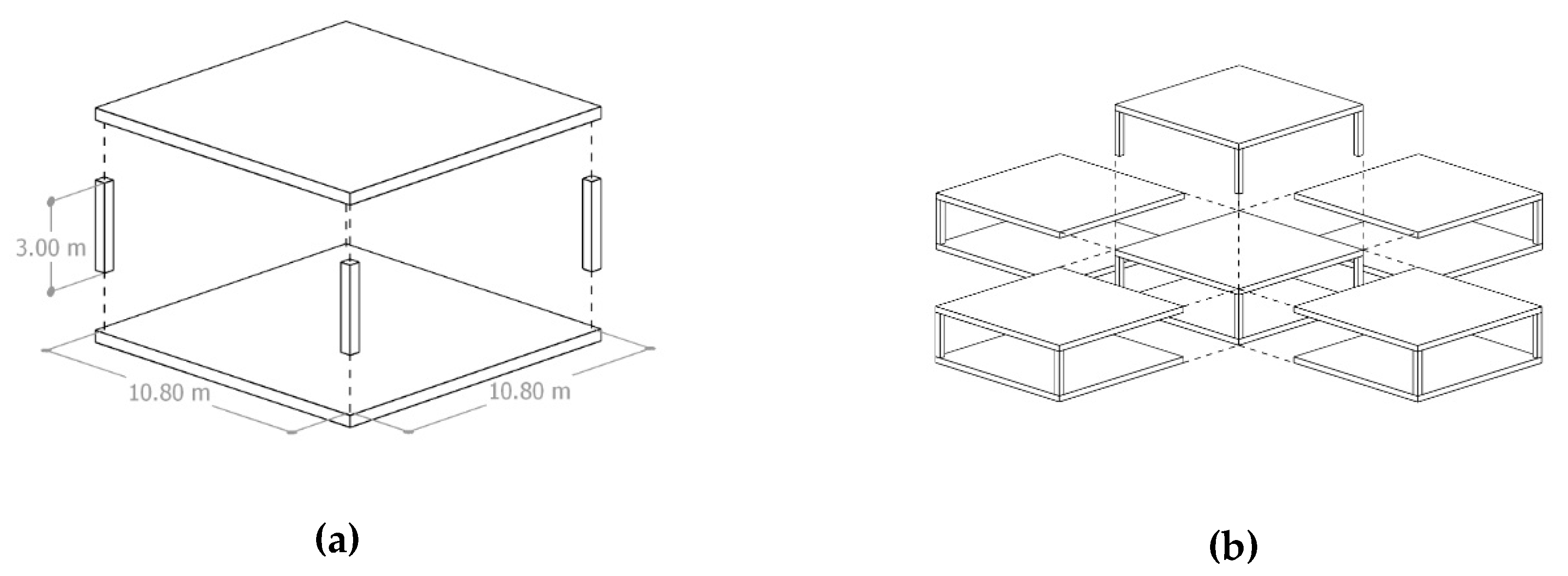

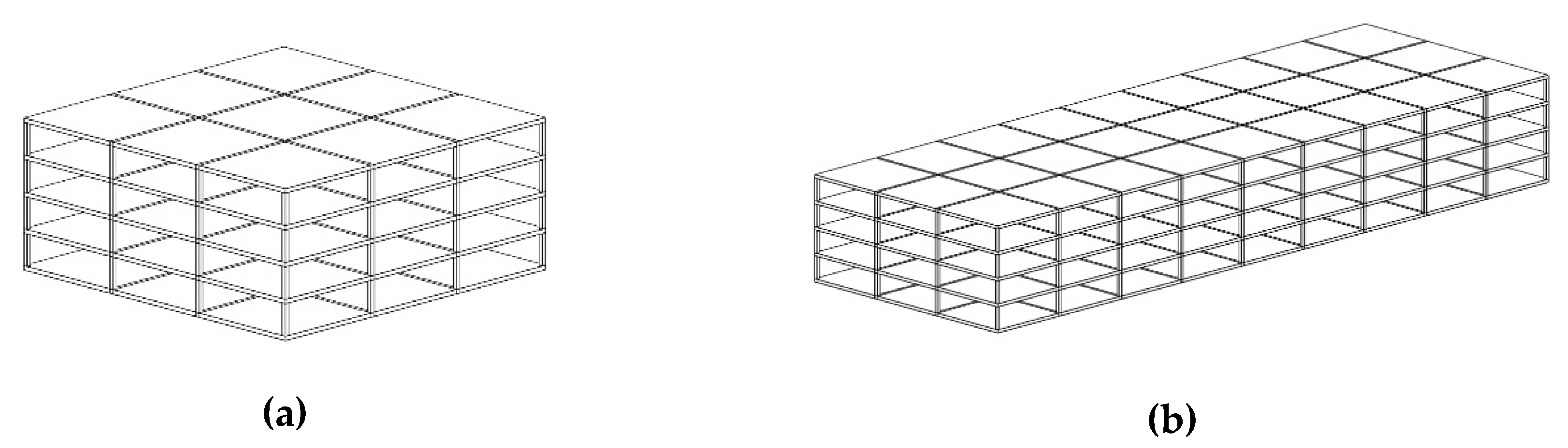

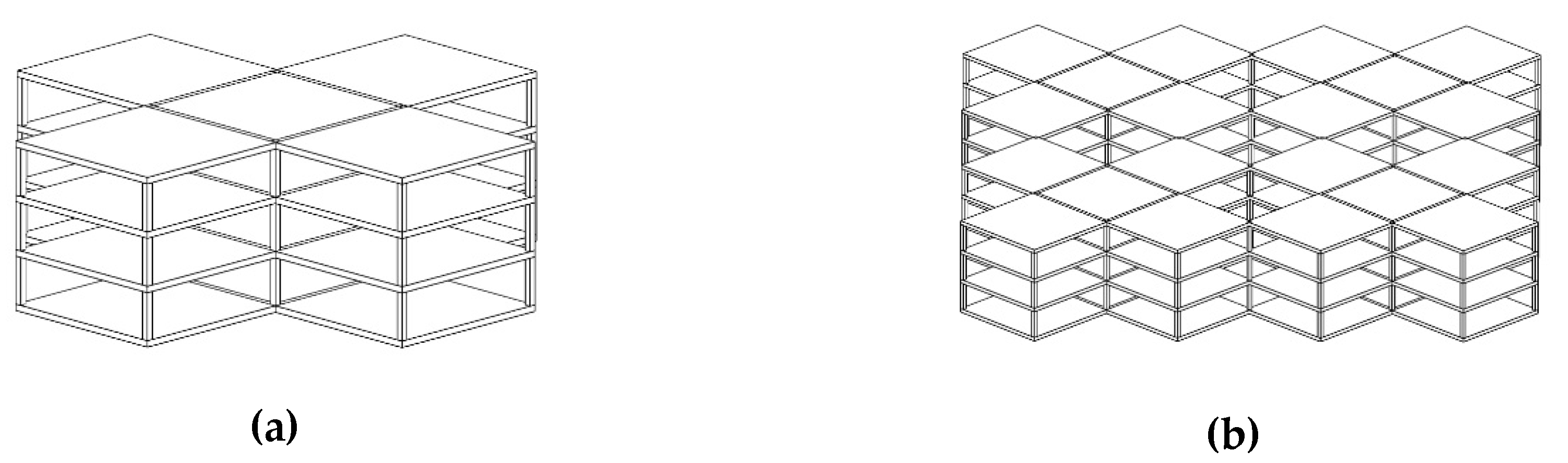

3.2. Prototype 1: Slab

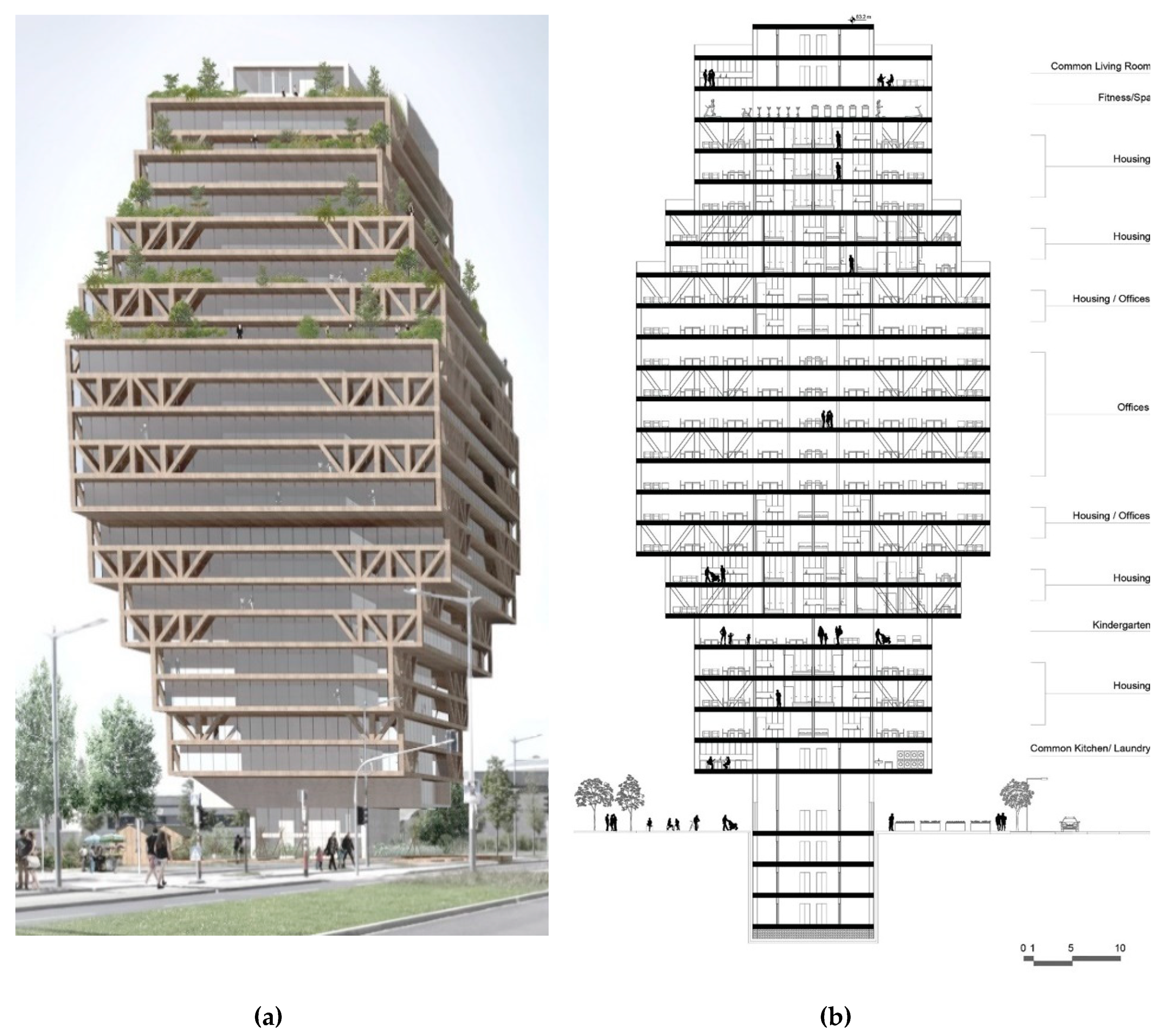

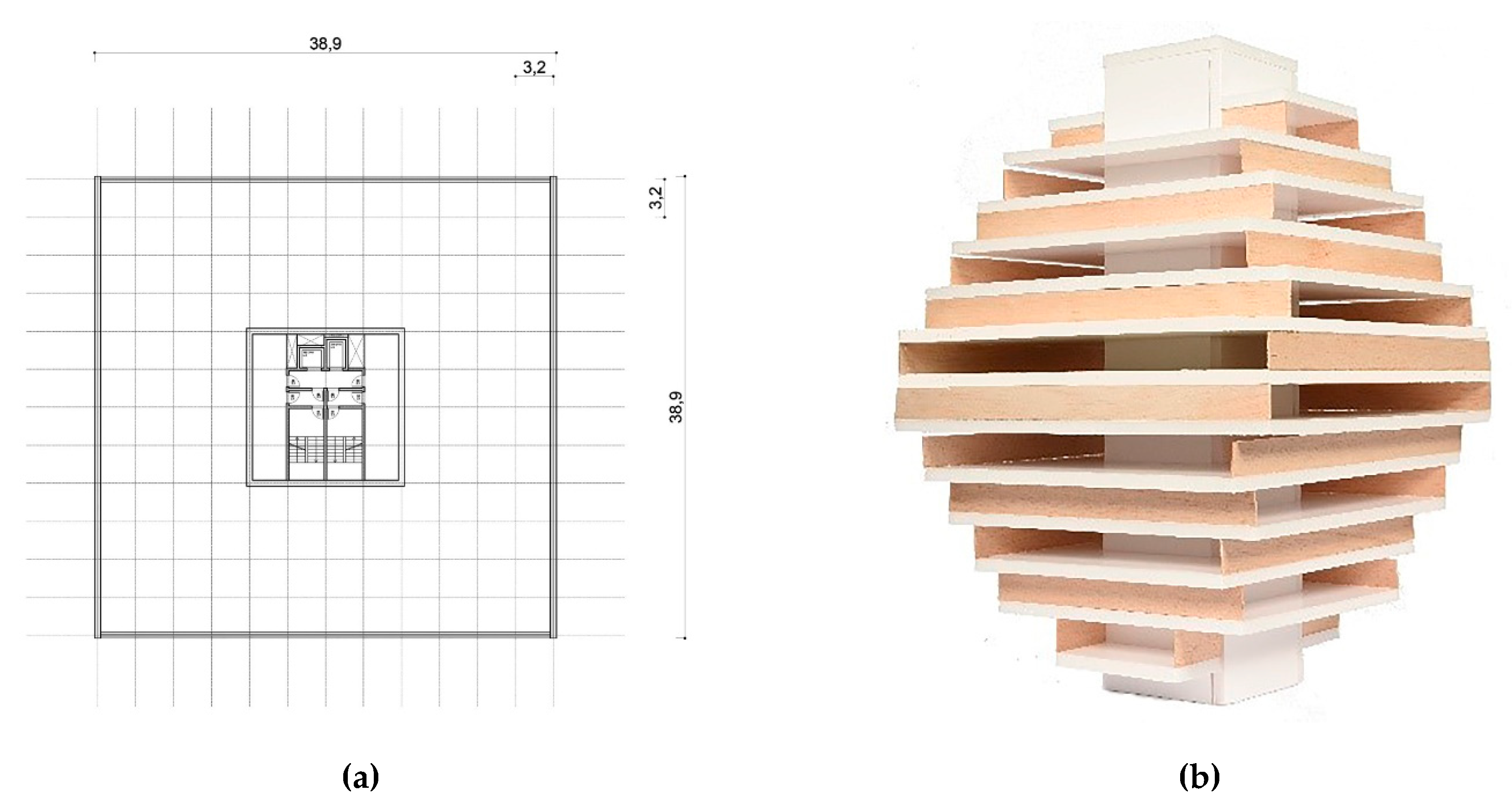

3.3. Prototype 2: Tower

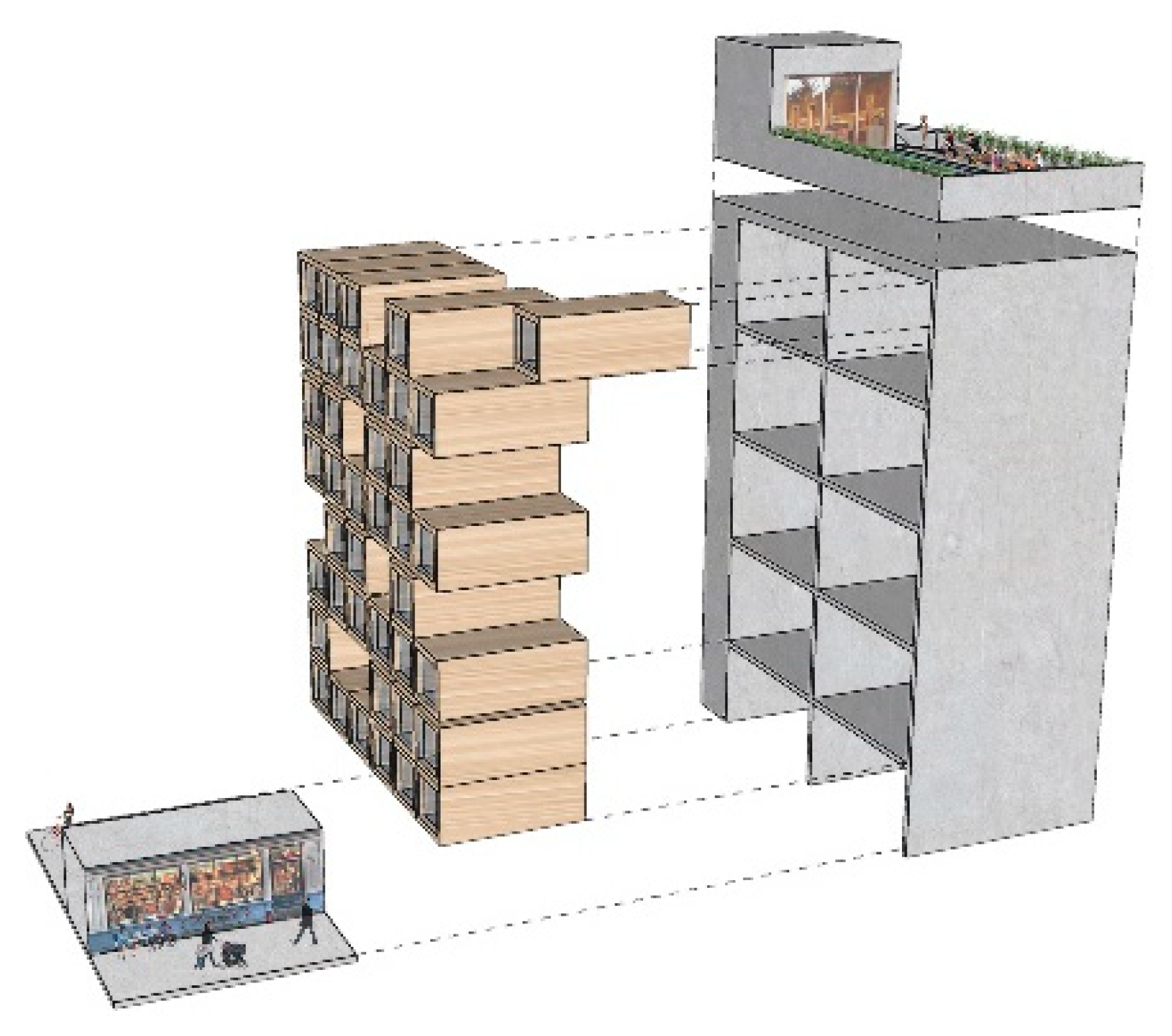

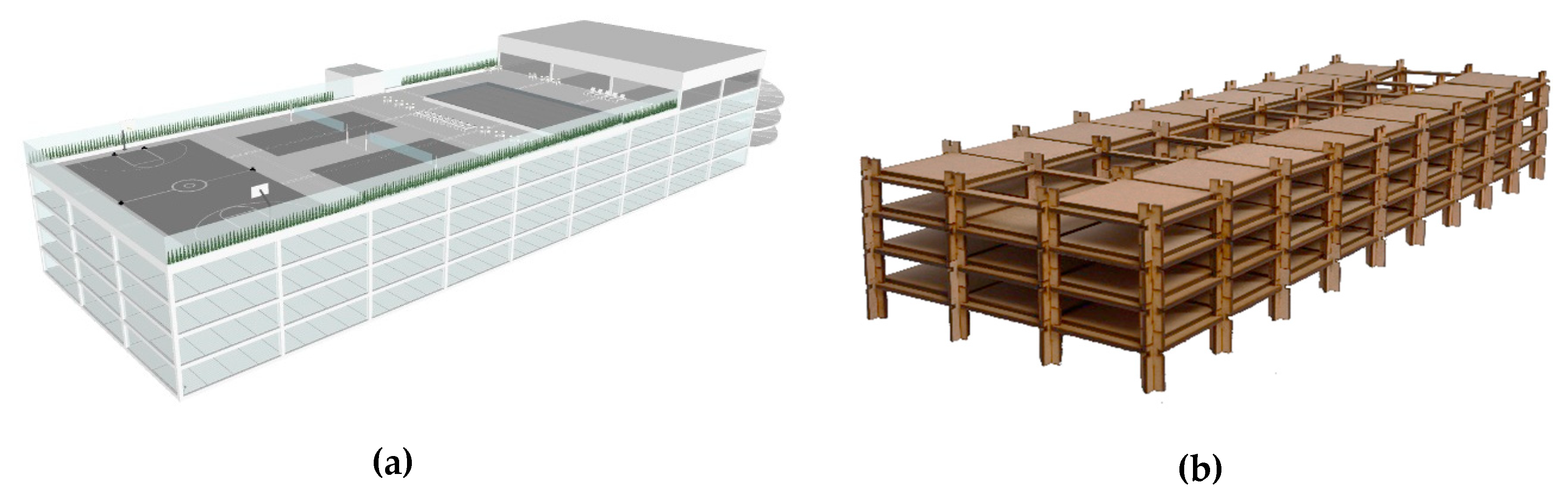

3.4. Prototype 3: Demountable

3.5. Discussion and Benefits of the New Recyclable Prototypes

- The design brings more value to the construction and to the life of the residents. As an example it could be mentioned that this design provides more communal space inside the buildings. In the Tower prototype, the common areas are localized in the upper and lower floors. In the Slab prototype, the rooftop and corridors are the shared spaces. Moreover, the Demountable prototypes have a public access rooftop, and the ground floors of all Prototypes are public spaces. These strategies integrate living, working and leisure in the same building.

- The open design enables home expansion according to the needs of the resident. In the Slab building, the modules can be pluged in and out and connected. In the Tower and Demountable buildings, the open slabs without walls can change the layout easily. As a result, the floors can be adapted to different uses, e.g., the slabs can accommodate apartments and later on the interior layout can be changed to become offices.

- The use of primary resources and waste is reduced by proposing in the earliest stages of architectural design, for all the three prototypes, the use of recycled materials, and by predicting changes and disassembly that may occur over the useful life of the building or at the end of the first cycle.

- To complement the above, the transition of structure reconfiguration, additions, and subtractions through time is facilitated because the structure is separated from the liming. The housing modules are separated from the infrastructure in the Slab typology, and the walls are separated from the bolted structure in the Tower and Demountable.

- All prototypes serve as material banks for the construction of future buildings, considering that from the beginning, all the elements of the buildings can be traced and are designed to be separated and reused in other constructions, by adopting raw materials, exposed structures, and systems that can be plugged in and out, which keeps the loop of materials closed. For example, the Slab housing modules can be used in other building and their wood reused in other structures. Secondly, the structure of the Tower can be demounted and reused since it is build entirely in timber and the walls can be relocated. Finally, the Demountable prototype was designed to be entirely demountable, so beams, walls, slabs and walls can be reused in different constructions.

- Parallel disassembly is allowed to minimize time onsite, for instance, the removal of modules or prefabricated slabs where parts can be detached later.

- Mechanical, electrical and plumbing systems are consolidated into core units to minimize runs and hence unnecessary entanglement.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations. The World’s Cities in 2018—Data Booklet (ST/ESA/ SER.A/417); United Nations: New York, NY, USA, 2018; p. 34. [Google Scholar]

- United Nations. UN World Population Prospects The 2017 Revision; United Nations: New York, NY, USA, 2017; Volume 136. [Google Scholar]

- Ellen Macarthur Foundation. Cities in the Circular Economy: An Initial Exploration; Ellen Macarthur Foundation: Cowes, UK, 2017. [Google Scholar]

- Kibert, C.J. Deconstruction: The start of a sustainable materials strategy for the built environment. Ind. Environ. 2003, 26, 84–88. [Google Scholar]

- Rashid, A.F.A.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- European Commission Eurostat. Waste statistics. 2014. Available online: https://ec.europa.eu/eurostat/statisticsexplained/ (accessed on 24 July 2019).

- Otto, F.; Songel, J.M. Conversation with Frei Otto; Princeton Architectural Press: New York, NY, USA, 2010. [Google Scholar]

- Petzet, M.; Heilmeyer, F. Reduce, Reuse, Recycle. In Architecture as Resource; Hatje Cantz: Berlin, Germany, 2012; ISBN 978-3-7757-3425-7. [Google Scholar]

- Smith, R. Prefab Architecture: A Guide to Modular Design and Construction; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 9780470275610. [Google Scholar]

- Akbarnezhad, A.; Ong, K.C.G.; Chandra, L.R. Economic and environmental assessment of deconstruction strategies using building information modeling. Autom. Constr. 2014, 37, 131–144. [Google Scholar] [CrossRef]

- Chen, T.Y.; Burnett, J.; Chau, C.K. Analysis of embodied energy use in the residential building of Hong Kong. Energy 2001, 26, 323–340. [Google Scholar] [CrossRef]

- Heinlein, F.; Sobek, W. Recyclable by Werner Sobek; Avedition Gmbh: Stuttgart, Germany, 2019. [Google Scholar]

- Guy, B.; Ciarimboli, N. DfD: Design for Disassembly in the Built Environment: A Guide to Closed-Loop Design and Building; Hamer Center for Community Design: State College, PA, USA, 2005. [Google Scholar]

- Mule, J.Y. Design for Disassembly Approaches on Product Development. Int. J. Sci. Eng. Res 2012, 3, 996–1000. [Google Scholar]

- Hensel, M.U. Introduction to design innovation for the built environment—research by design and the renovation of practice. In Design Innovation for the Built Environment: Research by Design and the Renovation of Practice; Routledge: Abingdon-on-Thames, UK, 2012. [Google Scholar]

- Staib, G.; Dörrhöfer, A.; Rosenthal, M. Components and Systems: Modular Construction—Design, Structure, New Technologies; Walter de Gruyter: Berlin, Germany, 2008; ISBN 978-3-0346-1566-2. [Google Scholar]

- Lambert, A.J.D.; Gupta, S.M. Disassembly Modeling for Assembly, Maintenance, Reuse and Recycling; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Hearn, J. The Prefab Museum Education Pack: Post War Prefabs. 2018. Available online: https://www.prefabmuseum.uk/content/history/education-pack-2 (accessed on 29 October 2019).

- Arif, M.; Egbu, C. Making a case for offsite construction in China. Eng. Constr. Archit. Manag. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef]

- Kruft, H.-W. A History of Architectural Theory: From Vitruvius to the Present; Princeton Architectural Press: New York, NY, USA, 1994. [Google Scholar]

- Berthier, S. Timber in the buildings of Jean Prouvé: An industrial material. Constr. Hist. Soc. 2015, 30, 87–106. [Google Scholar]

- Jean Prouvé/Maison démontable 6 × 6—Adaptation Roger Stirk Harbour + Partners. Available online: https://issuu.com/patrickseguin/docs/maison-6x6-rshp (accessed on 23 December 2019).

- Cook, P. Archigram; Princeton Architectural Press: New York, NY, USA, 1999. [Google Scholar]

- Tamari, T. Metabolism: Utopian Urbanism and the Japanese Modern Architecture Movement. Theoryculture Soc. 2014, 31, 201–225. [Google Scholar] [CrossRef]

- Galeria de Clássicos da Arquitetura: Nakagin Capsule Tower/Kisho Kurokawa—2. Available online: https://www.archdaily.com.br/br/01-36195/classicos-da-arquitetura-nakagin-capsule-tower-kisho-kurokawa/36195_36197 (accessed on 23 December 2019).

- Rifkin, J. The Third Industrial Revolution: How Lateral Power Is Transforming Energy, the Economy, and the World; St. Martin’s Griffin: New York, NY, USA, 2011. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Kyoto Protocol Reference Manual: On accounting of emisions and assigned amount. UNFCCC, 2008. Available online: https://unfccc.int/resource/docs/publications/08_unfccc_kp_ref_manual.pdf (accessed on 4 December 2019).

- SITE High-Rise of Homes. Available online: https://www.siteenvirodesign.com/content/high-rise-homes (accessed on 11 November 2019).

- The Okohaus—Frei Otto’s participative experiment in Berlin. Available online: http://www.the-offbeats.com/articles/building-together-the-okohaus-frei-otto-collective-improvisation/ (accessed on 19 November 2019).

- Mok, K. The Modern House Bus: Mobile Tiny House Inspirations; The Countryman Press: New York, NY, USA, 2018. [Google Scholar]

- R128. Available online: https://www.wernersobek.de/en/projects/focus-en/design-en/r128/ (accessed on 24 December 2019).

- Heide & von Beckerath. Available online: https://heidevonbeckerath.com/single/r50-cohousing (accessed on 22 December 2019).

- Werner Sobek Group R128. Available online: https://www.wernersobek.de/en/projects/focus-en/design-en/r128/ (accessed on 14 November 2019).

- Jaffe, E. Available online: https://www.sidewalklabs.com/blog/when-affordable-housing-starts-in-a-factory/ (accessed on 15 November 2019).

- Kumar Dhar, T.; Maruf Hossain, M.S.; Rubayet Rahaman, K. How does flexible design promote resource efficiency for housing? A study of Khulna, Bangladesh. Smart Sustain. Built Environ. 2013, 2, 140–157. [Google Scholar] [CrossRef]

- Gijsbers, R.; Lichtenberg, J.; Erkelens, P. A new approach to flexibility-in-use: Adaptability of structural elements. Proc. SASBE 2009, 9, 15–19. [Google Scholar]

- Leatherbarrow, D. The project of design research. In Design Innovation for the Built Environment: Research by Design and the Renovation of Practice; Routledge: Abingdon-on-Thames, UK, 2012. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira Silva, M.; Jayasinghe, L.B.; Waldmann, D.; Hertweck, F. Recyclable Architecture: Prefabricated and Recyclable Typologies. Sustainability 2020, 12, 1342. https://doi.org/10.3390/su12041342

Ferreira Silva M, Jayasinghe LB, Waldmann D, Hertweck F. Recyclable Architecture: Prefabricated and Recyclable Typologies. Sustainability. 2020; 12(4):1342. https://doi.org/10.3390/su12041342

Chicago/Turabian StyleFerreira Silva, Marielle, Laddu Bhagya Jayasinghe, Daniele Waldmann, and Florian Hertweck. 2020. "Recyclable Architecture: Prefabricated and Recyclable Typologies" Sustainability 12, no. 4: 1342. https://doi.org/10.3390/su12041342

APA StyleFerreira Silva, M., Jayasinghe, L. B., Waldmann, D., & Hertweck, F. (2020). Recyclable Architecture: Prefabricated and Recyclable Typologies. Sustainability, 12(4), 1342. https://doi.org/10.3390/su12041342