Opportunities for Cleaner Production (CP) Using Process Flow Analysis: Case Study of a Furniture Manufacturer in the City of Palhoça (SC, Brazil)

Abstract

1. Introduction

2. Literature Review

Cleaner Production (CP), Layout, and the Furniture Industry

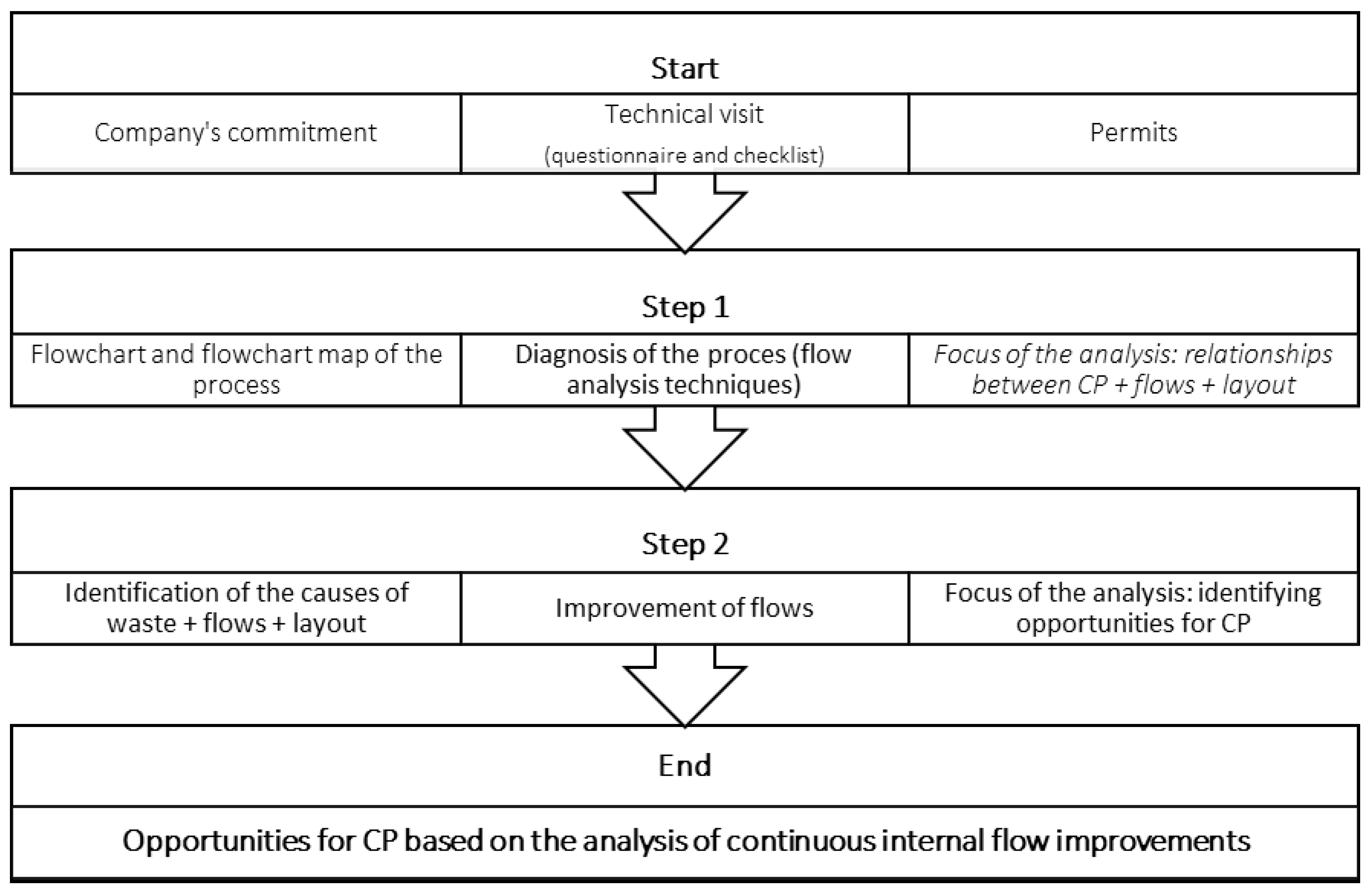

3. Methodological Approach

4. Results

4.1. Description of the Company Used as a Case Study

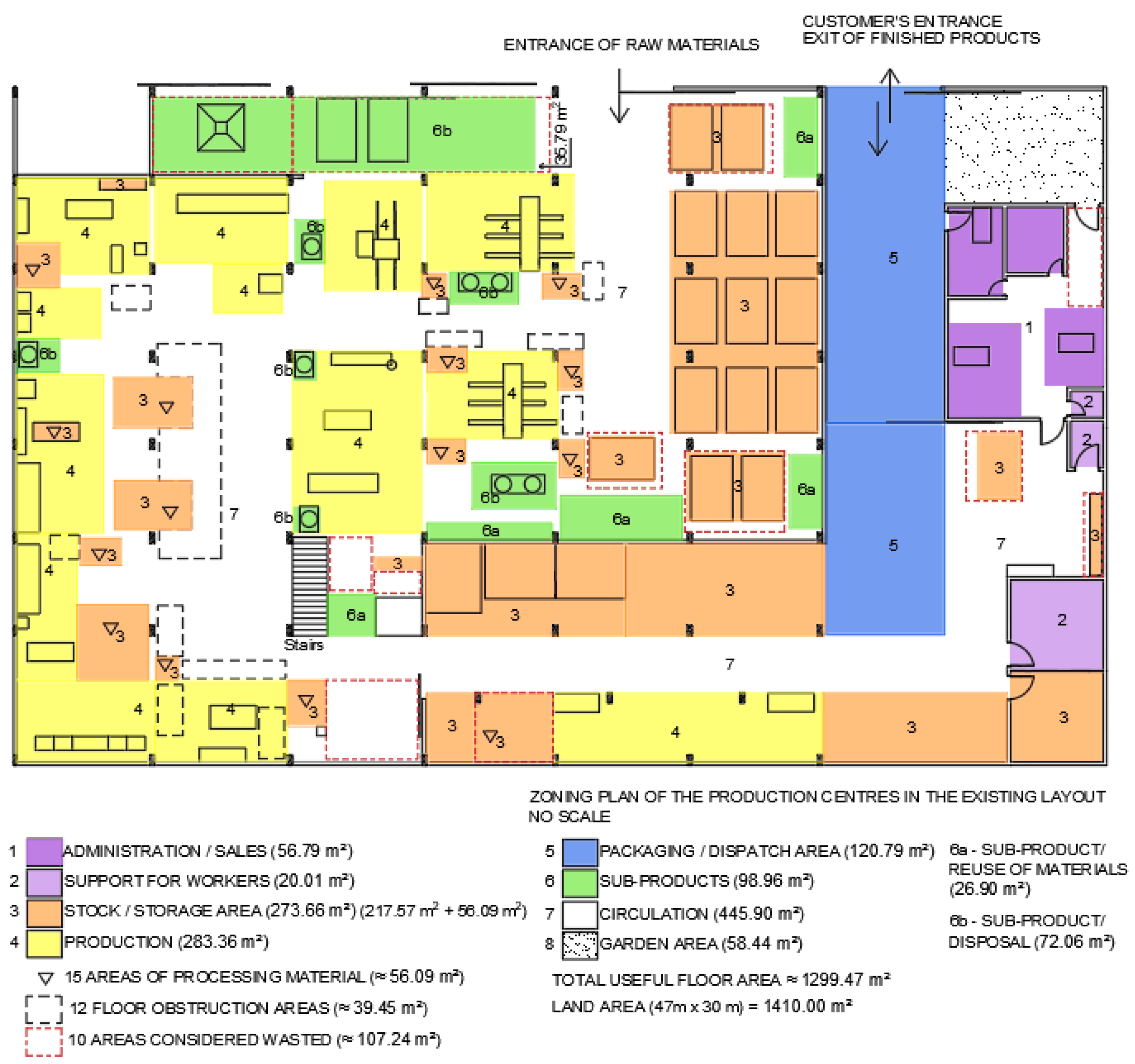

4.1.1. Zoning of the Areas from the Existing Layout

4.1.2. Production Centres and Sectorization of the Existing Layout

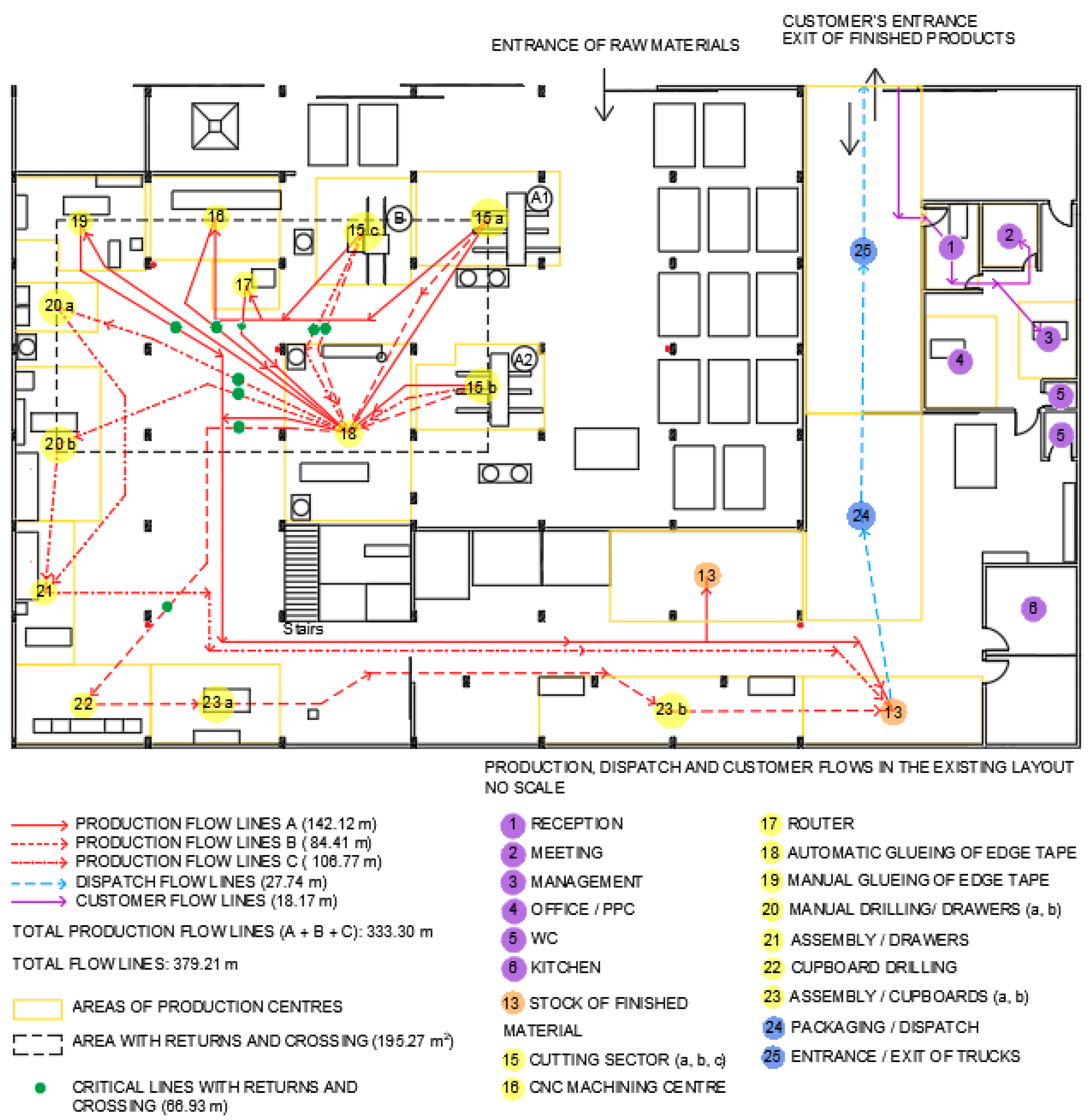

4.1.3. Process Flow and Supply in the Existing Layout

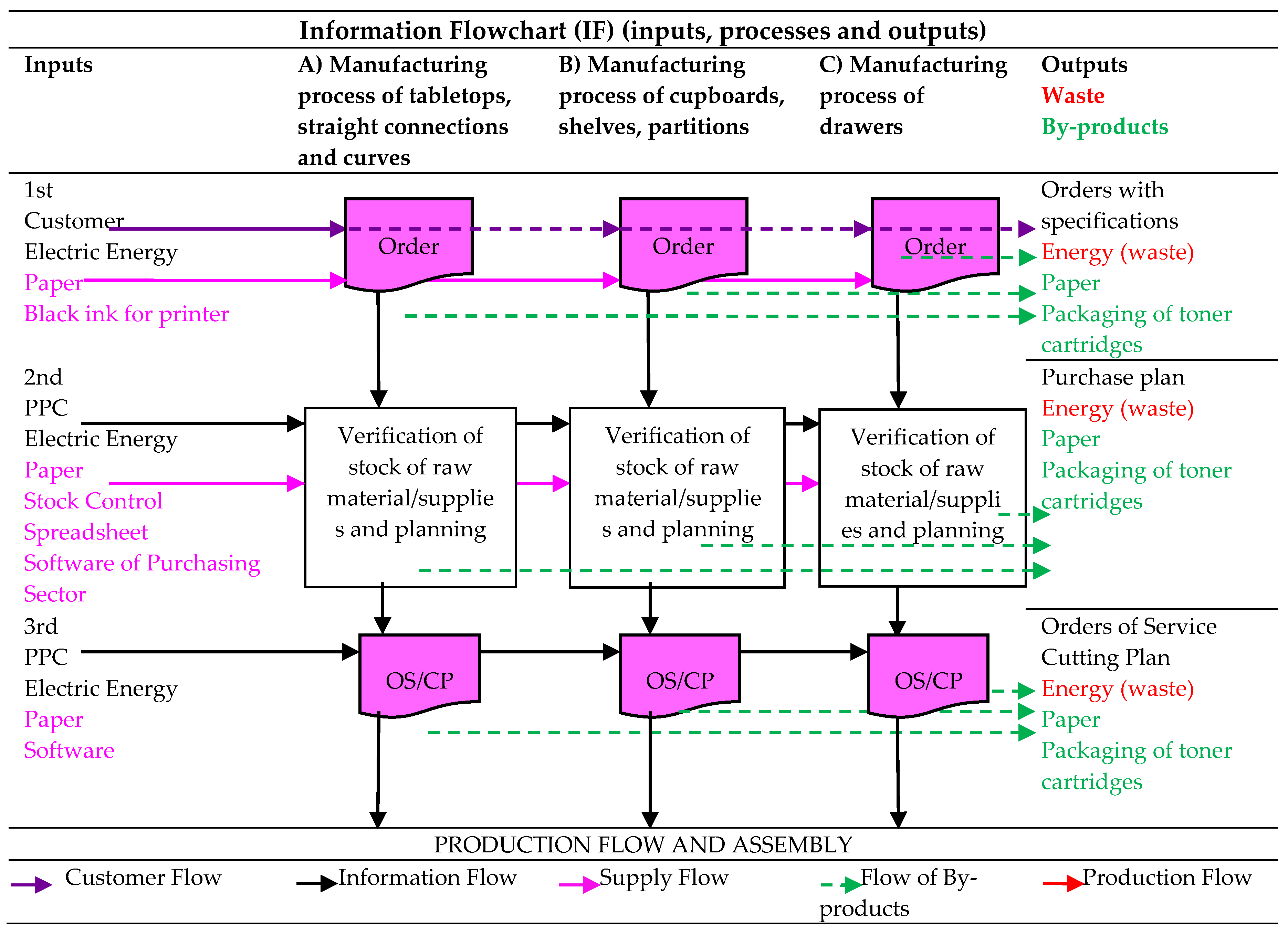

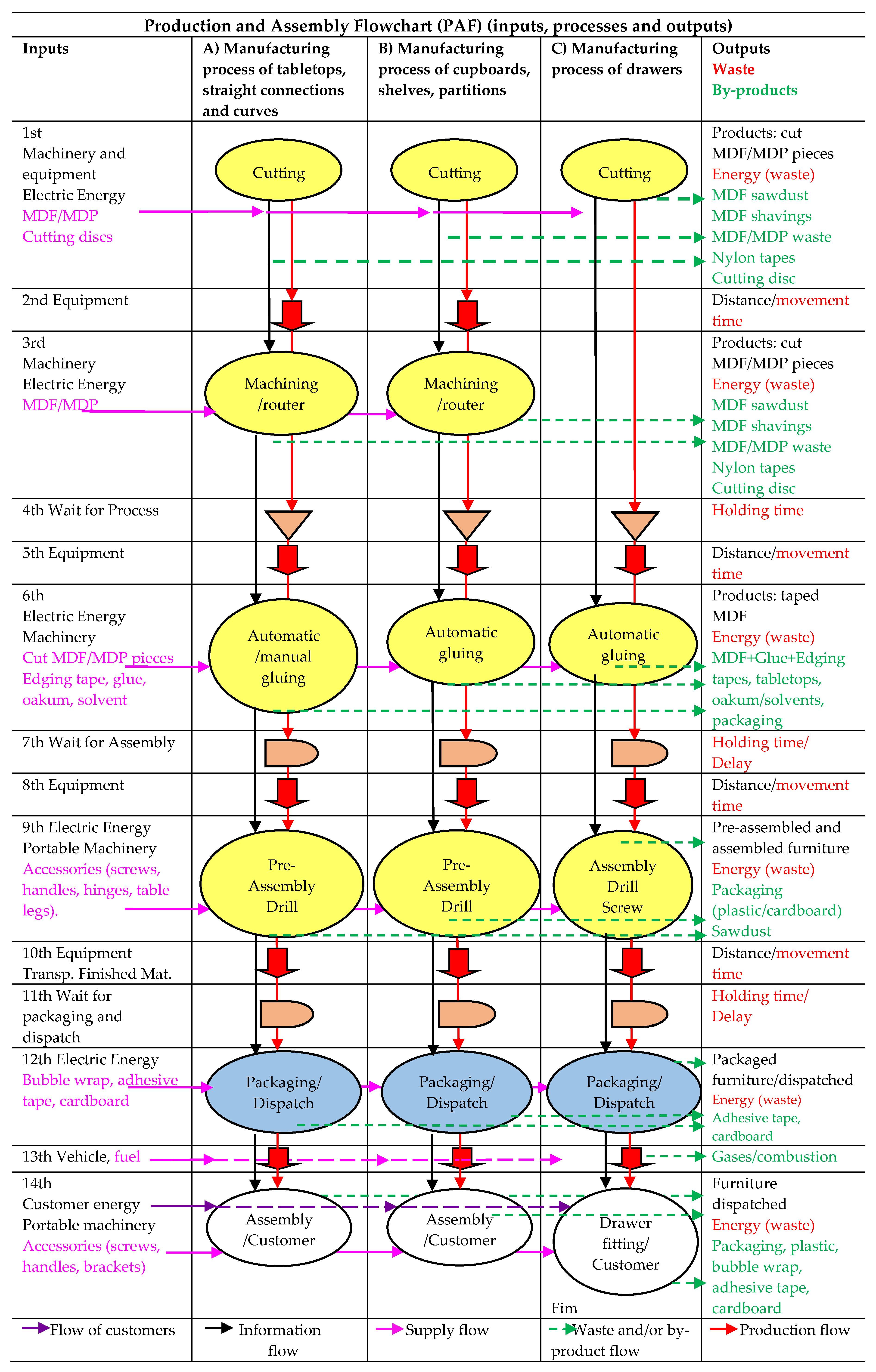

4.1.4. Information, Production, and Assembly Flowchart with Material Input and Output

4.1.5. Assignment and Destination of By-Products

4.2. CP Opportunities from the Process Flow Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stefano, N.M.; Ferreira, A.R. Ecodesign referencial teórico e análise de conteúdo: Proposta inicial para estudos futuros. Revista Estudos em Design 2013, 21, 01–22. (In Portuguese) [Google Scholar]

- Yoshimochi, A.P.; Dalto, F.; Bortoletti, M.; Britschka, N.N.; Cavini, R.; Garcia, R.L. Guia PCS, Produção e Consumo Sustentáveis, Tendência e Oportunidades para o Setor de Negócios; PNUMA/FIESP: São Paulo, Brazil, 2015; Available online: https://nacoesunidas.org/wp-content/uploads/2015/06/PNUMA_Guia-de-Produ%C3%A7%C3%A3o-e-Consumo-Sustent%C3%A1veis.pdf (accessed on 26 April 2019). (In Portuguese)

- Silva, A.L.E.; Moraes, J.A.R.; Machado, Ê.L. Proposal for cleaner production oriented practices ecodesign and reverse logistics. Revista Engenharia Sanitária e Ambiental 2015, 20, 29–37. (In Portuguese) [Google Scholar] [CrossRef]

- BMBF. Federal Report on Research and Innovation 2018; Bundesministerium für Bildung und Forschung /Federal Ministry of Education and Research (BMBF): Bonn, Germany, 2018. Available online: https://www.bmbf.de/upload_filestore/pub/Bufi_ (accessed on 26 April 2019).

- Silva, A.N.; Araújo, A.V.; Godoy, L.C.; Minette, L.J.; Suzuki, J.A. Contribution of Computational Simulation for Layout Analysis in a Wooden Furniture Industry. Revista Árvore 2017, 41, 1–8. [Google Scholar] [CrossRef]

- Prado, M.V. Brasil Móveis. Relatório Setorial da Indústria de Móveis no Brasil 2018; IEMI/ABIMÓVEL: Brasília, Brasil, 2018; pp. 40–41, (In Portuguese and in English). [Google Scholar]

- Brainer, M.S.D.C.P. Setor Moveleiro: Aspectos Gerais e Tendências no Brasil e na Área de Atuação do BNB. Caderno Setorial ETENE, Year 3, 34, June, 2018. Available online: https://www.bnb.gov.br/documents/80223/3585904/moveis_34-2018.pdf/f0e0657f-a6c2-db33-f139-04d95692453e (accessed on 3 January 2020). (In Portuguese)

- Rapôso, A.; César, S.F.; Kiperstok, A. Design do Ciclo de Vida do Produto e Produção mais Limpa: Uma reflexão aplicada à produção de estofados. Revista Estudos em Design 2013, 21, 01–25. (In Portuguese) [Google Scholar]

- Aguilar, C.M.G.; Panameño, R.; Velazquez, A.P.; Álvarez, B.E.A.; Kiperstok, A.; César, S.F. Cleaner Production Applied in a Small Furniture Industry in Brazil: Addressing Focused Changes in Design to Reduce Waste. Sustainability 2017, 9, 1–17. (In English) [Google Scholar]

- Hillig, É.; Schneider, V.E.; Pavoni, E.T. Geração de resíduos de madeira e derivados da indústria moveleira em função das variáveis de produção. Production 2009, 19, 292–303. (In Portuguese) [Google Scholar] [CrossRef]

- Massote, C.H.R.; Santi, A.M.M. Implementation of a cleaner production program in a Brazilian wooden furniture factory. J. Clean. Prod. 2013, 46, 89–97. (In English) [Google Scholar] [CrossRef]

- Panameño, R.; Aguilar, C.M.G.; Angel, B.E.; César, S.F.; Kiperstok, A. Cleaner Production and LCA as Complementary Tools in Environmental Assessment: Discussing Tradeoffs Assessment in a Case of Study within the Wood Sector in Brazil. Sustainability 2019, 11, 5026. [Google Scholar] [CrossRef]

- United Nations Environment Programme. UNEP. Resource Efficient and Cleaner Production. 2019. Available online: http://www.unep.fr/scp/cp/ (accessed on 26 April 2019). (In English).

- Da Silva, G.C.S.; de Medeiros, D.D. Cleaner production implementation in services using checkland’s methodology. Gestão Produção 2006, 13, 411–422. (In Portuguese) [Google Scholar]

- Tavares, A.C.S.; Vanalle, R.M.; Camarotto, J.A. Influence of Green Initiatives on Environmental, Economic and Operational Outcomes: The Case of the Brazilian Packaging Supply Chain. Sustainability 2019, 11, 430. (In English) [Google Scholar] [CrossRef]

- Schneider, P.; Oswald, K.; Riedel, W.; Meyer, A.; Schiller, G.; Bimesmeier, T.; Thi, V.A.P.; Khac, L.N. Engineering Perspectives and Environmental Life Cycle Optimization to Enhance Aggregate Mining in Vietnam. Sustainability 2018, 10, 525. [Google Scholar] [CrossRef]

- Neto, G.C.O.; Leite, R.R.; Shibao, F.Y.; Lucato, W.C. Framework to overcome barriers in the implementation of cleaner production in small and medium-sized enterprises: Multiple case studies in Brazil. J. Clean. Prod. 2017, 142, 50–62. [Google Scholar] [CrossRef]

- Fernandes, J.V.G.; Gonçalves, E.; Andrade, J.C.S.; Kiperstok, A. Introduzindo práticas de produção mais limpa em sistemas de gestão ambiental certificáveis: Uma proposta prática. Revista Engenharia Sanitária e Ambiental 2001, 6, 157–164. (In Portuguese) [Google Scholar]

- Centro Nacional de Tecnologias Limpas. CNTL. Implementação de Programas de Produção mais Limpa (Série Manuais de Produção mais Limpa). 2003. Available online: www.pha.poli.usp.br/LeArq.aspx?id%5Farq=7985 (accessed on 10 April 2019). (In Portuguese).

- Centro Nacional de Tecnologias Limpas. CNTL. Diagnóstico Ambiental e de Processo (Série Manuais de Produção mais Limpa). 2003. Available online: https://www.senairs.org.br/documentos/serie-manuais-de-producao-mais-limpa-diagnostico-ambiental-e-de-processo (accessed on 10 April 2019). (In Portuguese).

- United States Environmental Protection Agency. EPA. Facility Pollution Prevention Guide. Washington: 1992. Available online: https://nepis.epa.gov/Exe/ZyPDF.cgi/200132N4.PDF?Dockey=200132N4.PDF (accessed on 10 April 2019). (In English)

- Conselho Empresarial Brasileiro para o Desenvolvimento Sustentável. CEBDS. Guia da Produção mais Limpa Faça Você Mesmo. 2005, pp. 1–58. Available online: https://d335luupugsy2.cloudfront.net/cms/files/14773/1560693095Guia-Pratico-de-PmaisL.pdf (accessed on 22 January 2020). (In Portuguese).

- Marujo, L.G.; Carvalho, D.; Leitão, M.N. Otimização de layout utilizando-se o SLP combinado com teoria das filas: Um estudo de caso em uma oficina de rodas e freios de aeronaves. Revista Gestão Industrial 2010, 6, 93–109. (In Portuguese) [Google Scholar] [CrossRef][Green Version]

- Saravanan, M.; Arulkumar, P.V. An artificial bee colony algorithm for design and optimize the fixed area layout problems. Int. J. Adv. Manuf. Technol. 2015, 78, 2079–2095. (In English) [Google Scholar] [CrossRef]

- Camarotto, J.A. Projetos de Unidades Produtivas; Universidade de São Carlos: São Carlos, Brasil, 2006. (In Portuguese) [Google Scholar]

- Olivério, J.L. Projeto de fábrica produtos processos e instalações industriais, 1st ed.; IBLC-Instituto Brasileiro do Livro Científico Ltda.: São Paulo, Brasil, 1985; pp. 192–216. (In Portuguese) [Google Scholar]

- Muther, R. Planejamento do layout:Sistema SLP; Edgard Blucher LTDA: São Paulo, Brasil, 1978. (In Portuguese) [Google Scholar]

- Tseng, M.L.; Lin, Y.H.; Chiu, A.S.F. Fuzzy AHP-based study of cleaner production implementation in Taiwan PWB manufacturer. J. Clean. Prod. 2009, 17, 1249–1256. (In English) [Google Scholar] [CrossRef]

- Nunes, J.R.R.; Silva, J.E.A.R.D.; Moris, V.A.D.S.; Giannetti, B.F. Cleaner production in small companies: Proposal of a management methodology. J. Clean. Prod. 2019, 218, 357–366. (In English) [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. (In English) [Google Scholar] [CrossRef]

- Schneider, V.E.; Nehme, M.C.; Ben, F. Pólo Moveleiro da Serra Gaúcha: Sistemas de Gerenciamento Ambiental na Indústria Moveleira; Educs: Caxias do Sul, Brasil, 2006; p. 19. (In Portuguese) [Google Scholar]

- Kravchenko, G.A.; Pasqualetto, A.; Ferreira, E.D.M. Aplicação de princípios da ecologia industrial nas empresas moveleiras de Goiás. Revista Engenharia Sanitária Ambiental 2016, 21, 283–294. (In Portuguese) [Google Scholar] [CrossRef]

- Da Costa, M.A.F.; Costa, M.D.F.B.D. Projeto de Pesquisa: Entenda e Faça, 6th ed.; Editora vozes: Petrópolis, Brasil, 2015. (In Portuguese) [Google Scholar]

- Cauchick-Miguel, P.A.; Sousa, R. Metodologia de Pesquisa em Engenharia de Produção e Gestão de Operações, 3rd ed.; Coordenação de Cauchick-Miguel, P.A., Ed.; Elsevier: Rio de Janeiro, Brasil, 2018. (In Portuguese) [Google Scholar]

- Bernards, E.; Muniz Junior, J.; Nakano, D.N. Pesquisa qualitativa em engenharia de produção e gestão de operações; Atlas: São Paulo, Brasil, 2019. (In Portuguese) [Google Scholar]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. (In English) [Google Scholar] [CrossRef]

- Tubino, D.F. Planejamento e Controle da Produção: Teoria e Prática, 2nd ed.; Atlas: São Paulo, Brasil, 2009; p. 1. (In Portuguese) [Google Scholar]

- Serviço Brasileiro de Apoio às Micro e Pequenas Empresas. SEBRAE. 2019. Available online: https://m.sebrae.com.br/sites/PortalSebrae/estudos_pesquisas/quem-sao-os-pequenos-negociosdestaque5,7f4613074c0a3410VgnVCM1000003b74010aRCRD (accessed on 10 September 2019).

- Instituto Brasileiro de Geografia Estatística. IBGE. 2019. Available online: https://www.ibge.gov.br/cidades-e-estados/sc/palhoca.html? (accessed on 30 September 2019).

- Associação Brasileira de Normas Técnicas. ABNT NR-23: Proteção Contra Incêndios; Mai: Rio de Janeiro, Brasil, 2011. [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NR-11: Transporte, Movimentação, Armazenagem e Manuseio de Materiais; Abr: Rio de Janeiro, Brasil, 2016. [Google Scholar]

| References | CP | Layout | Design Requirements from the Questionnaire and Checklist | |

|---|---|---|---|---|

| Criteria | Attributes | Layout Design Factors | ||

| Muther [27] Olivério [26] Tseng, Lin and Chiu [28] CNTL [19] CNTL [20] | Training and staff | Cultural change | Changes | Management commitment, objectives, needs and preventive positioning (permits). |

| Systems and technologies | + | Changes * | Commitment/preventive positioning (monitoring and release of information). | |

| + | Workforce * | Number of staff members, roles, needs, team importance, labor risks, healthy conditions. | ||

| Tools and technologies | Services | Benefits/difficulties/structural support to staff and customers, location of support infrastructure. | ||

| Materials | Type of raw materials, specifications, reception and type of stocking; waste, residue, by-products, dust particles in the air; control of raw materials and by-products, space occupied, location of suppliers. | |||

| Machinery and equipment | Types, specifications, safety and maintenance, location and space occupied. | |||

| Building | Measurements of physical spaces, location of machinery, equipment, furniture and people. | |||

| Analysis and improvement of process flows | Wait | Location of stock of raw material, finished material and material being processed, waste, delays, waste and by-product stocks, stock control, space occupied | ||

| Movement | Measurements of the flow of material during processing, description of processes, need of inter-relationships between areas and sectors, waste, crossings and floor obstruction with materials, by-products, machinery or equipment | |||

| O-1 | Update machines and equipment to comply with the work safety standards and obtain greater productivity. Replace old sliding table saw with a new one that complies with the norms and with energy-efficiency label. |

| O-2 | Create cleaning and preventive maintenance procedures in the machines and production area. |

| O-3 | Reorganize sawdust ducts and seal the silo from its surroundings. Suggest changes to the waste collection company in terms of covering the dumpster for sawdust collection. |

| O-4 | Set up a board at each workstation to organize the portable machines and tools. |

| O-5 | Eliminate wasted space (clearing the floor) by improving layout planning in all production areas and reduce material on hold, optimizing the tasks in the production centres. |

| O-6 | Eliminate material flow crossings. |

| O-7 | Reorganize and record the practices and procedures of each workstation, associated to CP. |

| O-8 | Optimize the cutting plan of MDF/MDP panels to minimize amounts of by-products and waste, maximizing the use of raw material. |

| O-9 | Execute joint cutting plans to maximize the used material. |

| O-10 | Keep record of by-products generated with the respective specifications of the material to be used, sold or exchanged with other partner companies (Simbiose Industrial), including width and size of the material. |

| O-11 | Place the collectors with indication of the respective material next to the production sector for selective waste collection and internal and/or external [re]cycling. |

| O-12 | Set up shelves to accommodate any waste by-products from the selective waste collection and for previously catalogued MDF/MDP for internal and external use. |

| O-13 | Carry out a [re]layout project of each workstation considering the principles of optimized movement (of people and material), ergonomics, safety and flow of material. |

| O-14 | Carry out a [re]layout project to optimize and integrate the production areas. Eliminate waste from areas and flow, and circulation crossings. |

| O-15 | Minimize energy consumption. Promote the efficient use of natural light by using translucent roofing tiles, as well as alternative energy. |

| O-16 | Create and execute an electric and luminotechnical project; divide the electric circuits in order to sectorize the lighting in the different spaces, reducing energy consumption. |

| O-17 | Create flow maps of by-products for the internal and external spaces. |

| O-18 | Store material according to their characteristics and needs to avoid damage, waste and losses. And close to the production areas to avoid waste of flows. |

| O-19 | Facilitate the entry, movement and exit of materials; and stock control and traceability processes, facilitating product Life Cycle Analysis (LCA). |

| O-20 | Optimize the layout of storage spaces to avoid obstruction of floor areas, waste and loss of material and time; seek visual solutions which can be easily controlled. |

| O-21 | Assign shelves for by-products, in order to promote easier handling and reuse for each process, with the shelves being located within easy-reach to other companies, avoiding obstruction of the floor area. |

| O-22 | Prioritize suppliers with environmental certification and from nearby regions, avoiding the generation of gas emissions from transport. |

| O-23 | Optimize the delivery of finished material to avoid unnecessary costs with transport and greater emissions. Use a shared cargo and route system. |

| O-24 | Modify the entrance to the building in order to separate the access for customers from the exit of finished material. Prioritize safety, marketing and information management. |

| O-25 | Prepare a packaging project using Ecodesign and CP principles; and project to implement an eco-seal aimed at the furniture sector. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lins, P.S.; Cunha, R.D.A.; Kiperstok, A.; Rapôso, Á.L.Q.R.e.S.; César, S.F. Opportunities for Cleaner Production (CP) Using Process Flow Analysis: Case Study of a Furniture Manufacturer in the City of Palhoça (SC, Brazil). Sustainability 2020, 12, 863. https://doi.org/10.3390/su12030863

Lins PS, Cunha RDA, Kiperstok A, Rapôso ÁLQReS, César SF. Opportunities for Cleaner Production (CP) Using Process Flow Analysis: Case Study of a Furniture Manufacturer in the City of Palhoça (SC, Brazil). Sustainability. 2020; 12(3):863. https://doi.org/10.3390/su12030863

Chicago/Turabian StyleLins, Patrícia Soares, Rita Dione Araujo Cunha, Asher Kiperstok, Áurea Luiza Quixabeira Rosa e Silva Rapôso, and Sandro Fábio César. 2020. "Opportunities for Cleaner Production (CP) Using Process Flow Analysis: Case Study of a Furniture Manufacturer in the City of Palhoça (SC, Brazil)" Sustainability 12, no. 3: 863. https://doi.org/10.3390/su12030863

APA StyleLins, P. S., Cunha, R. D. A., Kiperstok, A., Rapôso, Á. L. Q. R. e. S., & César, S. F. (2020). Opportunities for Cleaner Production (CP) Using Process Flow Analysis: Case Study of a Furniture Manufacturer in the City of Palhoça (SC, Brazil). Sustainability, 12(3), 863. https://doi.org/10.3390/su12030863