Empowering Sustainable Consumption by Giving Back to Consumers the ‘Right to Repair’

Abstract

1. Introduction

- What are the most relevant barriers consumers face today when they want to repair their products?

- How can repairability make a substantial contribution to sustainable consumption and the emergence of circular economies?

- What are the main actors and elements interacting in the repairability ecosystem?

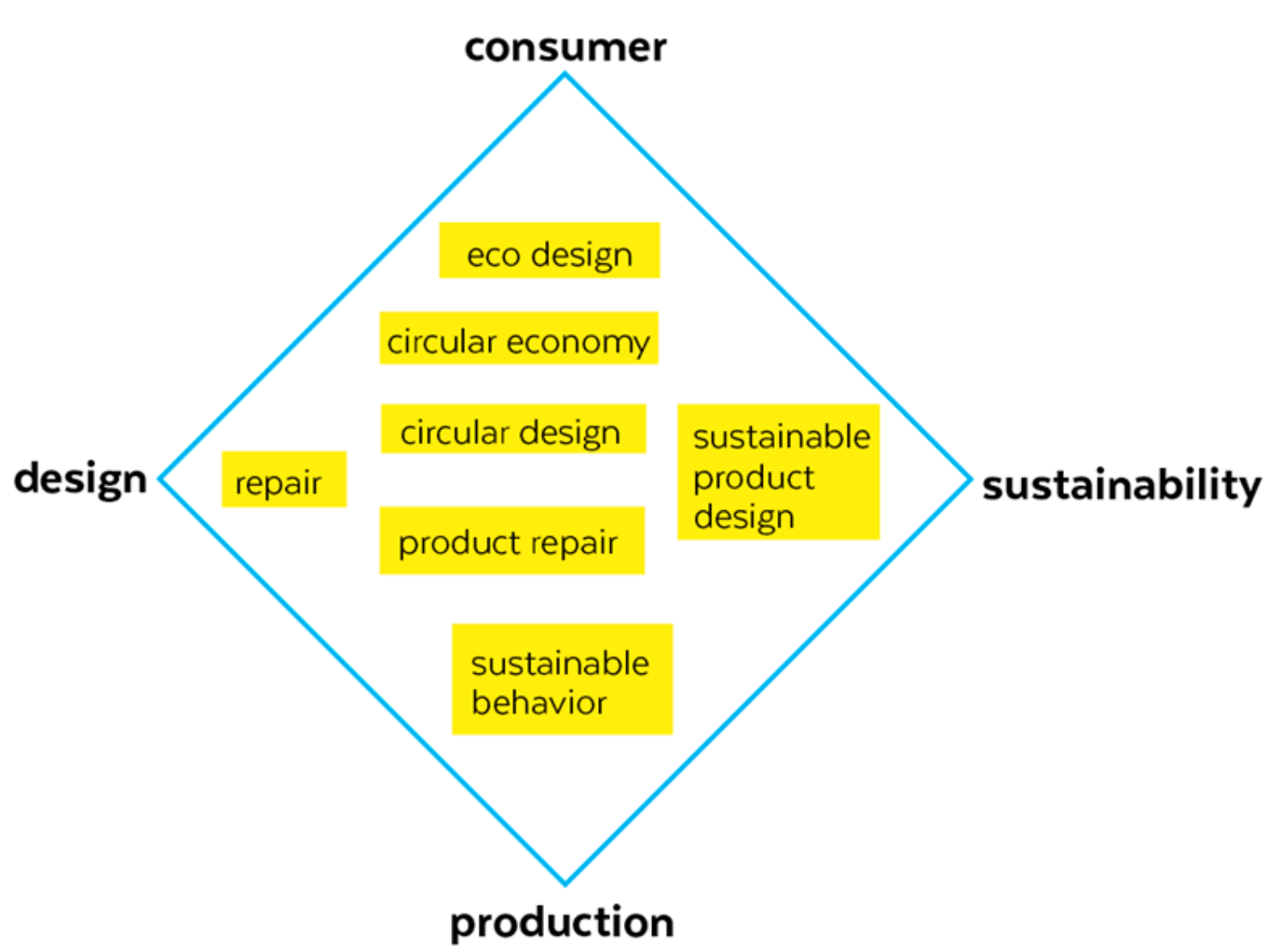

2. Transformation towards Circular Economy

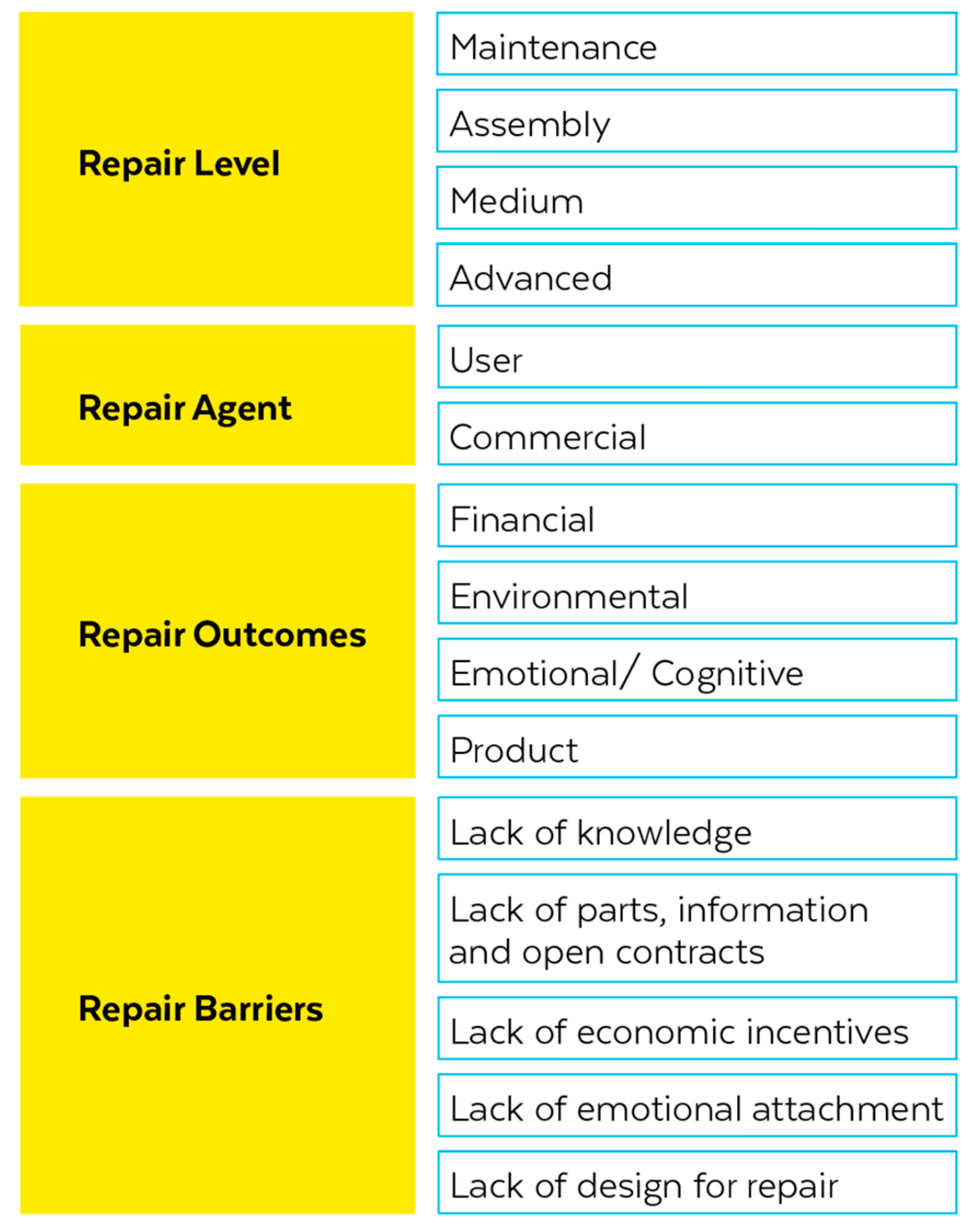

3. Repairability from a Consumer Point of View

- Assembly repair: This repair type does not require any skill or knowledge. A good example here would be putting product parts together, gluing, or binding them.

- Medium level repair: This repair type consists of activities which require some level of skill and knowledge like glue knowledge, material knowledge.

- Advanced level repair: This repair type includes activities that require advanced skills and knowledge, such as changing the screen of a laptop.

3.1. Repairing, an Opportunity for Industry

3.2. Design for Repair

3.3. Factors Inhibiting Repairability

3.3.1. Lack of Knowledge on How Products Work

3.3.2. Lack of Spare Parts, Technical Information, and Restricted Contracts

3.3.3. Lack of Economic Incentives to Repair a Product

3.3.4. Lack of Emotional and Economic Attachment to Products

3.3.5. Lack of Design and Manufacturing Features Allowing Repairs

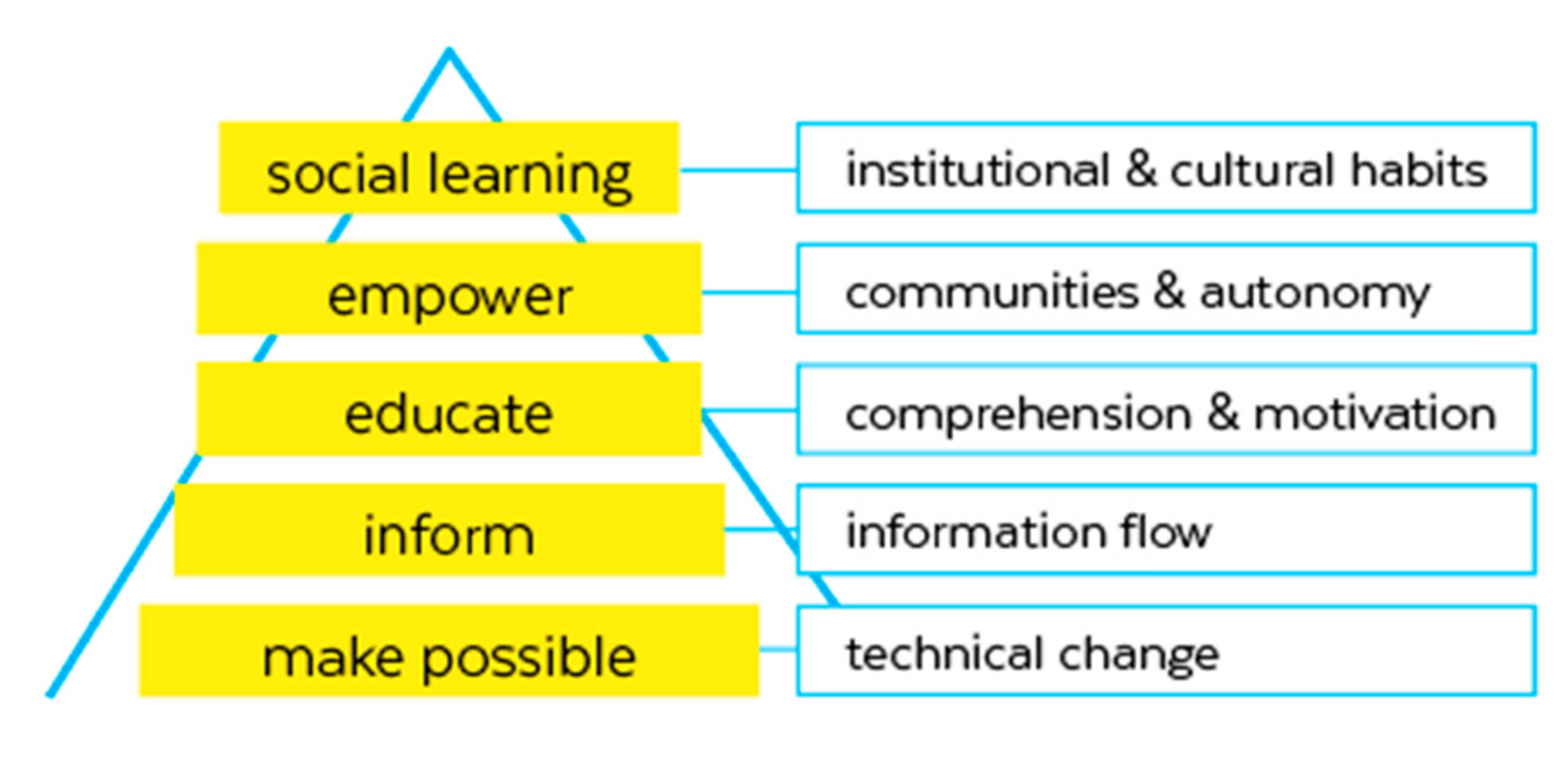

4. ‘Right to Repair’ a Push Forward Sustainable Consumption

´Right to Repair´

5. Discussion: Guidelines for a More Comprehensive "Right to Repair"

- Producers should support repair done by the users, providing a market of spare parts, technical information, and avoiding obstacles like specialized tooling required to perform the repair.

- Producers should allow third parties to perform repairs of their products for the benefit of the users and also as a business strategy to build networks that facilitate the development of circular systems of production and consumption. This will, in turn, open up new challenges to redesign legal responsibilities and economic obligations (e.g. warranties) around repaired products.

- Businesses should consider repairability as a desired condition of their products. Instead of perceiving repairability as a potential risk for their economic survival, they should design business models where repairability constitutes a new stream of income and an attractive way to approach and get to know their users and their own products better. This change will likely be motivated by new political directives and increased awareness of consumers. It must be noted that an increase of repair services could have significant effects on the economy overall. It is estimated that an increase of 1% of this sector would increase the EU Gross Domestic Product (GDP) by 7.9 billion EUR through direct and indirect impacts [36].

- New directives about repairability as a viable alternative to extend the lifespan of products and keep them rotating in circular systems should influence curriculums and academic programs. This influence should be manifested by designers and engineers being better prepared to make products that will be repaired, make products that people want to take care of and are motivated to repair for emotional and economic reasons, and to understand repairability as part of a larger system (circular economy).

- Laws and directives should provide physical and digital infrastructure to promote repairs. It means spaces to perform repairs, to share knowledge and experiences, to hold tools and develop strong community relationships around repair. Some of these initiatives already exists, like repair cafes, and websites like ifixit. These have proven to be attractive initiatives for tech savvies and also for novice users. They have to prove that repair communities are not a niche issue, as we argue that all people benefit from a better repair space. A recent EU report showed that 64% of over 12,000 EU nationals who participated in a survey repair broken products and 12% have previously self-repaired products [44]. It is a myth that overall repair is a niche issue.

- Product design should consider embedding features that facilitate repairs, giving, for example, information to the user when a product is failing, or when a part needs to be replaced. This information system can go directly into the product or in supporting services.

- Warranty contracts should be more flexible to allow third parties to participate in the repair process without punishing the user for doing so.

- Markets should be regulated to avoid the emergence of perverse incentives favoring replacement of products over repairing. In economic terms, to repair a product should be cheaper than to by a new one. This condition can be different in some cases, but in general, materials and energy embedded into a product should be protected, keeping the products in the system for the longest time possible.

- Directives and institutions should help re-frame repair as an exciting and innovation-driven activity. It is often the case that the language of innovation is reserved for the new “bright and shiny tools” [13] (p. 227) and not for conservation and maintenance duties. Integral repair policies should help to change our usual perceptions of repair as a tedious and mechanical experience by stimulating innovation and creative ways to showcase and practice repair.

Author Contributions

Funding

Conflicts of Interest

References

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cox, UK, 2012. [Google Scholar]

- Hernandez, R.J. Designing Sustainable Product Service Systems: A Business Framework for SME Implementation; Loughborough University: Loughborough, UK, 2012. [Google Scholar]

- Bhamra, T.; Lofthouse, V. Design for Sustainability: A Practical Approach; Cooper, R., Ed.; Gower Publishing Limited: Hampshire, U K, 2007. [Google Scholar]

- Ackermann, L. Design for Product Care: Enhancing Consumers’ Repair and Maintenance Activities. Des. J. 2018, 21, 543–551. [Google Scholar] [CrossRef]

- Brezet, J.C.; van Hemel, C. Ecodesign: A Promising Approach to Sustainable Production and Consumption; United Nations Environment Programme, Rathenau Institute, and Delft University of Technology: Paris, France, 1997. [Google Scholar]

- Lilley, D. Design for sustainable behaviour: Strategies and perceptions. Des. Stud. 2009, 30, 704–720. [Google Scholar] [CrossRef]

- Hernandez, R.J.; Bhamra, T.; Bhamra, R. Sustainable Product Service Systems in Small and Medium Enterprises (SMEs): Opportunities in the Leather Manufacturing Industry. Sustainability 2012, 4, 175–192. [Google Scholar] [CrossRef]

- Mestre, A.; Cooper, T. Circular Product Design. A Multiple Loops Life Cycle Design Approach for the Circular Economy. Des. J. 2017, 20, S1620–S1635. [Google Scholar] [CrossRef]

- European Parliament Council Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32009L0125:EN:NOT (accessed on 20 November 2019).

- OECD. Extended Producer Responsibility: a guidance manual for governments; OECD Publications Service: Paris, France, 2001. [Google Scholar]

- Bhamra, T.; Hernandez, R.J.; Mawle, R. Sustainability: Methods and Practices. In The Handbook of Design for Sustainability; Bloomsbury Publishing Plc: London, UK, 2013; pp. 106–120. [Google Scholar]

- Braungart, M.; McDonough, W. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Jackson, S.J. Rethinking Repair. In Media Technologies; Gillespie, T., Boczkowski, P.J., Foot, K.A., Eds.; The MIT Press: Cambridge, MA, USA, 2014; pp. 221–240. [Google Scholar]

- Graham, S.; Thrift, N. Out of Order: Understanding Repair and Maintenance. Theory Cult. Soc. 2007, 24, 1–25. [Google Scholar] [CrossRef]

- Terzioğlu, N.; Brass, C.; Lockton, D. Understanding User Motivations and Drawbacks Related to Product Repair. In Proceedings of the Sustainable Innovation 2015, Epsom, UK, 9–10 November 2015. [Google Scholar]

- Huang, J.; Esmaeilian, B.; Behdad, S. Design for Ease-of-Repair: Insights from Consumers Repair Experiences. In Proceedings of the 21st Design for Manufacturing and the Life Cycle Conference, 10th International Conference on Micro-and Nanosystems, Charlotte, North Carolina, USA, 21–24 August 2016; Volume 4. [Google Scholar]

- Whiteley, N. Toward a Throw—Away Culture. Consumerism, Style Obsolescence and Cultural Theory in the 1950s and 1960s. Oxf. Art J. 1987, 10, 3–27. [Google Scholar] [CrossRef]

- Cooper, T. Inadequate Life?Evidence of Consumer Attitudes to Product Obsolescence. J. Consum. Policy 2004, 27, 421–449. [Google Scholar] [CrossRef]

- Adler, L.; Hlavacek, J.D. The Relationship between Price and Repair Service for Consumer Durables. J. Mark. 1976, 40, 80–82. [Google Scholar] [CrossRef]

- McCollough, J. The effect of income growth on the mix of purchases between disposable goods and reusable goods. Int. J. Consum. Stud. 2007, 31, 213–219. [Google Scholar] [CrossRef]

- McCollough, J. Factors impacting the demand for repair services of household products: The disappearing repair trades and the throwaway society. Int. J. Consum. Stud. 2009, 33, 619–626. [Google Scholar] [CrossRef]

- Sabbaghi, M.; Behdad, S. Design for Repair: A Game Between Manufacturer and Independent Repair Service Provider. In Proceedings of the ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Cleveland, OH, USA, 6–9 August 2017; Volume 2A. [Google Scholar]

- Sabbaghi, M.; Esmaeilian, B.; Cade, W.; Wiens, K.; Behdad, S. Business outcomes of product repairability: A survey-based study of consumer repair experiences. Resour. Conserv. Recycl. 2016, 109, 114–122. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; Den Hollander, M. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Scott, K.A.; Weaver, S.T. To Repair or Not to Repair: What is the Motivation? J. Res. Consum. 2014, 26, 42–44. [Google Scholar]

- Lefebvre, M.; Lofthouse, V.; Wilson, G. Towards a Circular Economy: Exploring factors to repair broken electrical and electronics products by users with pro-environmental inclination. In Proceedigns of the DRS Design Research Society Conference, Catalyts, University of Limerick, Limerick, Ireland, 25–28 June 2018; Design Research Soceity: London, UK, 2018; Volume 5, pp. 2032–2046. [Google Scholar]

- Tukker, A.; Tischner, U. New Business for Old Europe: Product-Service Development, Competitiveness and Sustainability; Tukker, A., Tischner, U., Eds.; Greenleaf Pub: Sheffield, South Yorkshire, UK, 2006. [Google Scholar]

- Roy, R. Sustainable product-service systems. Futures 2000, 32, 289–299. [Google Scholar] [CrossRef]

- Hernandez, R.J. Sustainable Product-Service Systems and Circular Economies. Sustainability 2019, 11, 5383. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.D.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A.; et al. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1543–1552. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, Q.; Zhang, Y.; Li, T.; Zhang, H.-C. Sustainability of 3D Printing: A Critical Review and Recommendations. In Proceedings of the ASME 2016 11th International Manufactufing Science and Engineering Conference, Materials Biomanufacturing; Properties, Applications and Systems; Sustainable Manufacturing, Blacksburg Virginia, USA, 17 June–1 July 2016; Volume 2. [Google Scholar]

- Lofthouse, V.; Prendeville, S. Human-Centred Design of Products And Services for the Circular Economy —A Review. Des. J. 2018, 21, 451–476. [Google Scholar] [CrossRef]

- Chapman, J. Emotionally Durable Design: Objects, Experiences and Emphaty; Earthscan: London, UK, 2005. [Google Scholar]

- Vezzoli, C.; Manzini, E. Design for environmental sustainability; Springer: London, UK, 2008. [Google Scholar]

- Grinvald, L.C.; Tur-Sinai, O. Intellectual Property Law and the Right to Repair. SSRN Electron. J. 2019, 19, 1–66. [Google Scholar] [CrossRef]

- Montalvo, C.; Peck, D.; Rietveld, E. A Longer Lifetime for Products: Benefits for Consumers and Companies. Study Intern. Market Consum. Prot. Comm. 2016. [Google Scholar]

- European Commission. The New Ecodesign Measures Explained. In European Commission—Questions and Answers. Available online: https://ec.europa.eu/commission/presscorner/detail/it/qanda_19_5889. (accessed on 4 December 2019).

- Reitdorf, L.; Itkonen, A.-K. New rules make household appliances more sustainable. Available online: https://ec.europa.eu/commission/presscorner/detail/it/ip_19_5895. (accessed on 14 November 2019).

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Arnstein, S.R. A Ladder Of Citizen Participation. J. Am. Inst. Plann. 1969, 35, 216–224. [Google Scholar] [CrossRef]

- Collins, K.; Ison, R. Jumping off Arnstein’s ladder: Social learning as a new policy paradigm for climate change adaptation. Environ. Policy Gov. 2009, 19, 358–373. [Google Scholar] [CrossRef]

- Wenger, E. Communities of Practice and Social Learning Systems: The Career of a Concept. In Social Learning Systems and Communities of Practice; Springer: London, UK, 2010; pp. 179–198. [Google Scholar]

- Reed, M.S.; Evely, A.C.; Cundill, G.; Fazey, I.; Glass, J.; Laing, A.; Newig, J.; Parrish, B.; Prell, C.; Raymond, C.; et al. What is Social Learning? Ecol. Soc. 2010, 15, 4. [Google Scholar] [CrossRef]

- Cerulli-Harms, A.; Suter, J.; Landzaat, W.; Duke, C.; Rodriguez Diaz, A.; Porch, L.; Svatikova, K. Behavioural Study on Consumers’. Engagement in the Circular Economy: Luxemburg, 2018. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernandez, R.J.; Miranda, C.; Goñi, J. Empowering Sustainable Consumption by Giving Back to Consumers the ‘Right to Repair’. Sustainability 2020, 12, 850. https://doi.org/10.3390/su12030850

Hernandez RJ, Miranda C, Goñi J. Empowering Sustainable Consumption by Giving Back to Consumers the ‘Right to Repair’. Sustainability. 2020; 12(3):850. https://doi.org/10.3390/su12030850

Chicago/Turabian StyleHernandez, Ricardo J, Constanza Miranda, and Julian Goñi. 2020. "Empowering Sustainable Consumption by Giving Back to Consumers the ‘Right to Repair’" Sustainability 12, no. 3: 850. https://doi.org/10.3390/su12030850

APA StyleHernandez, R. J., Miranda, C., & Goñi, J. (2020). Empowering Sustainable Consumption by Giving Back to Consumers the ‘Right to Repair’. Sustainability, 12(3), 850. https://doi.org/10.3390/su12030850