Carbonization Durability of Two Generations of Recycled Coarse Aggregate Concrete with Effect of Chloride Ion Corrosion

Abstract

1. Introduction

1.1. Carbonation Durability of Recycled Concrete: Effects of Recycled Coarse Aggregate

1.2. Carbonation Durability of Recycled Concrete: Effects of Water Reducing Admixtures and Mineral Additions

1.3. Carbonization Durability of Recycled Aggregate Concrete Assessed by Permeability-Related Properties

1.4. The Effect of Chloride Ion Corrosion on the Carbonization Durability of RAC

1.5. Significance of the Research

2. Materials and Methods

2.1. Materials

2.2. Mixture Design

2.3. Measurements

3. Results

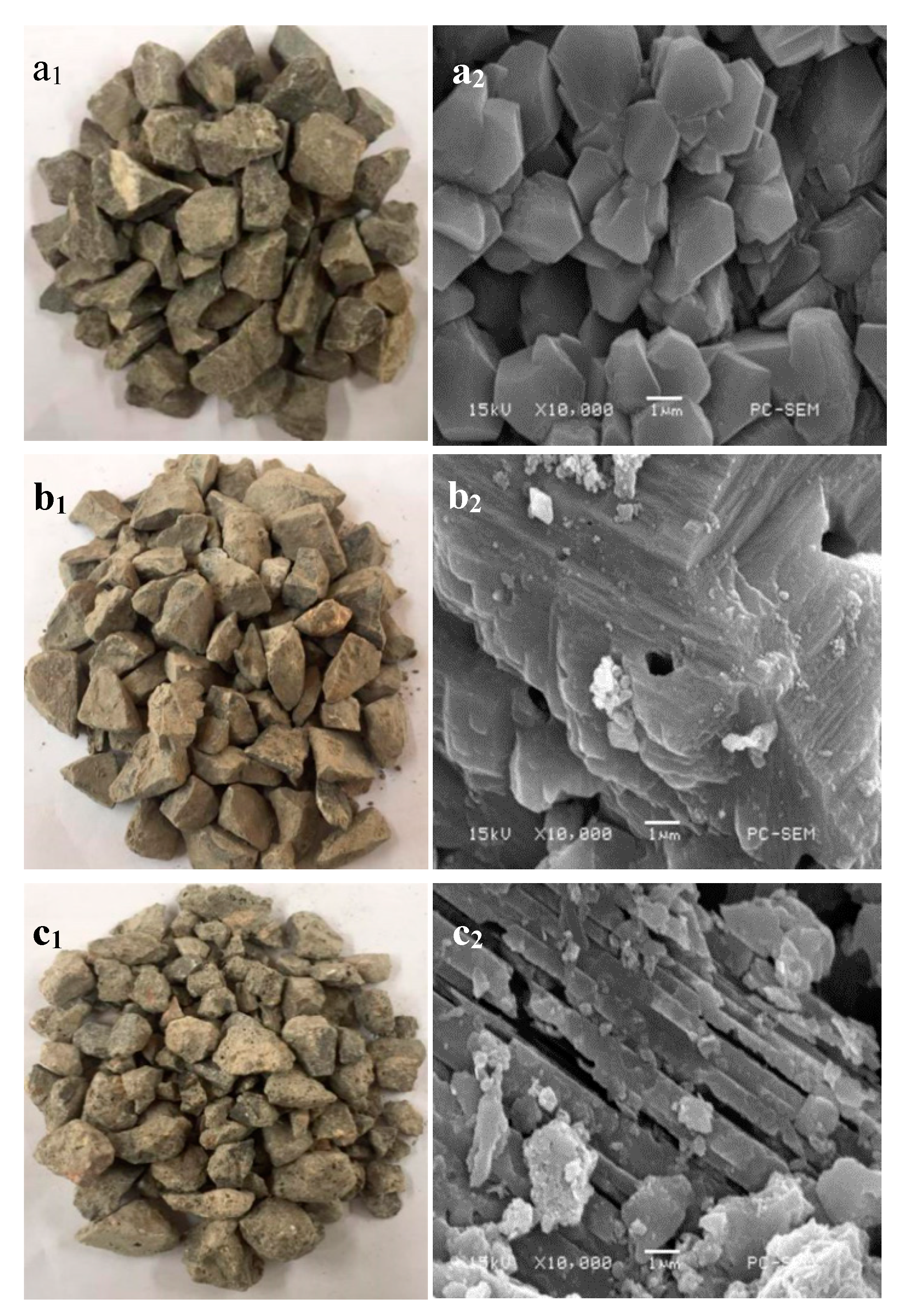

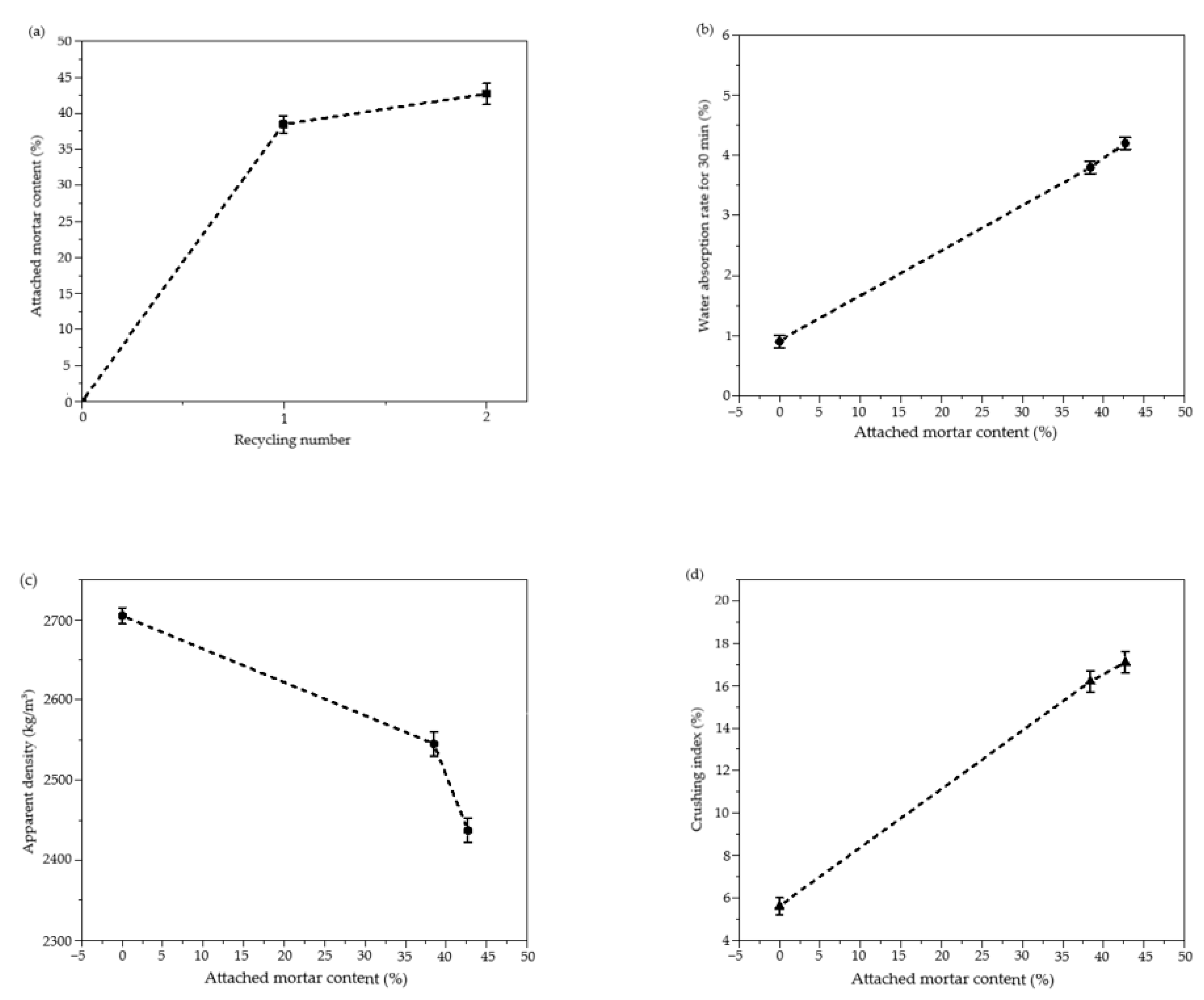

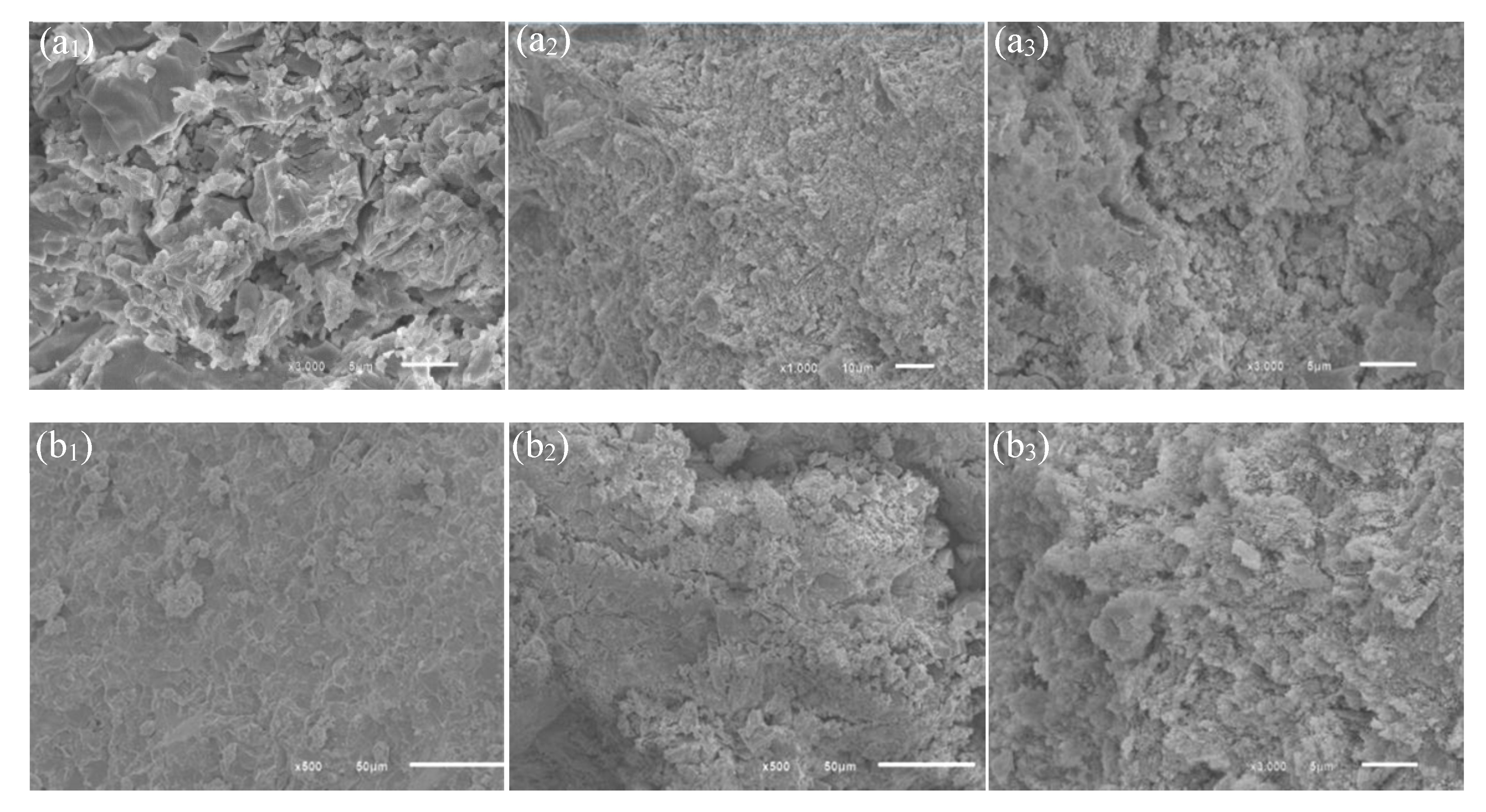

3.1. Natural and Recycled Coarse Aggregate

3.2. Carbonation Resistance

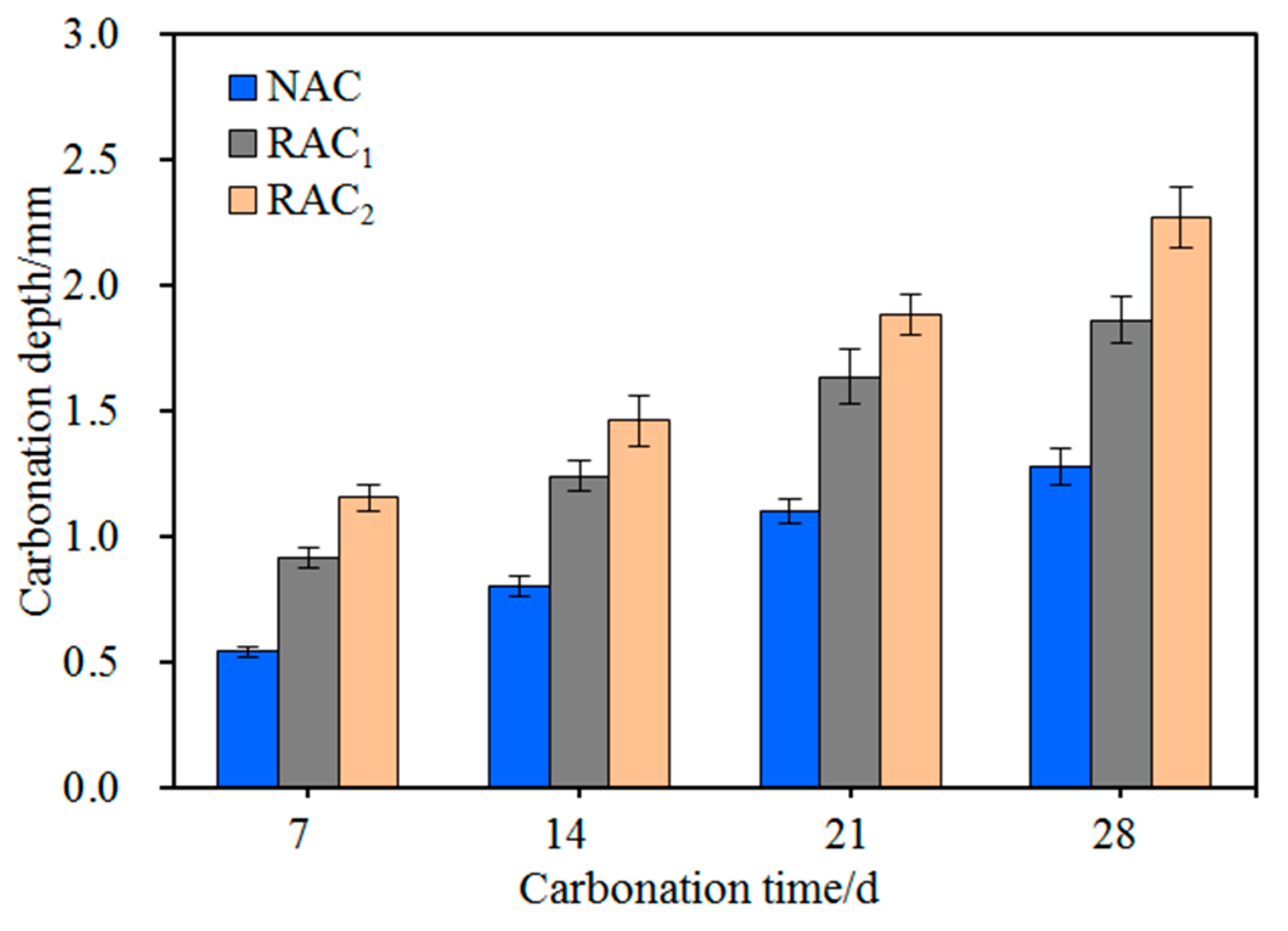

3.2.1. Carbonation Resistance without Effect of Chloride Ion Corrosion

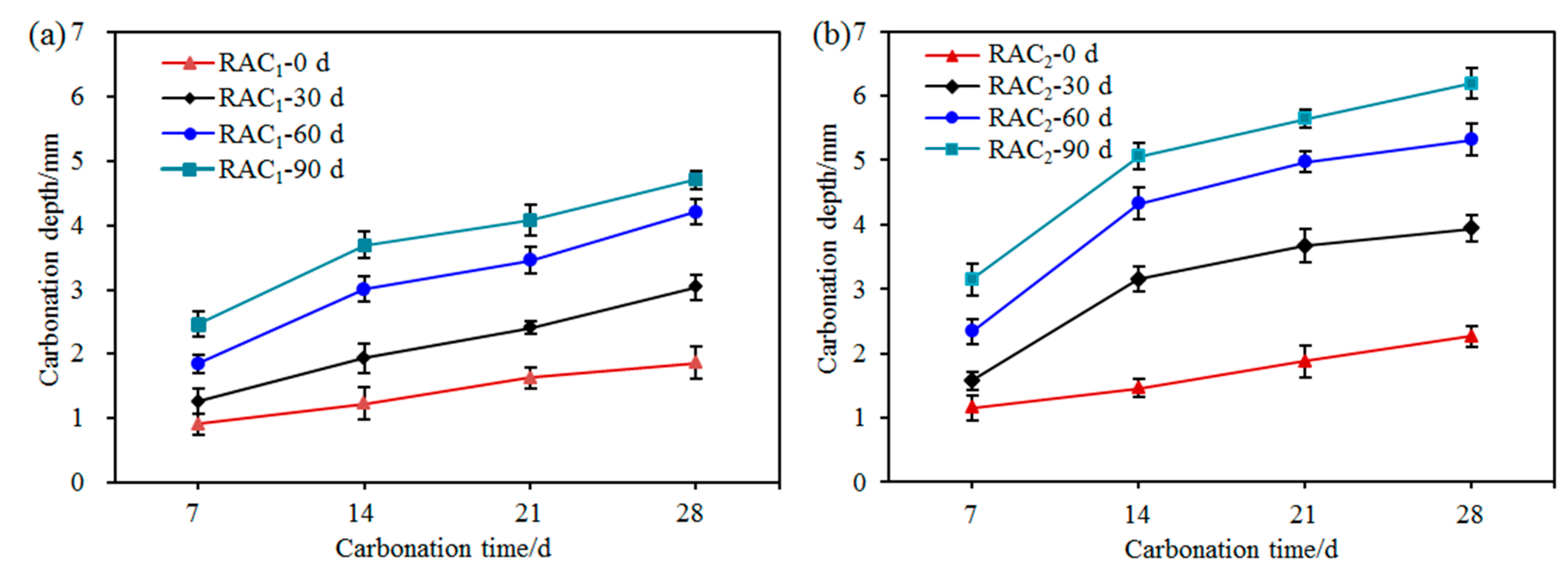

3.2.2. Carbonation Resistance with Effect of Chloride Ion Corrosion

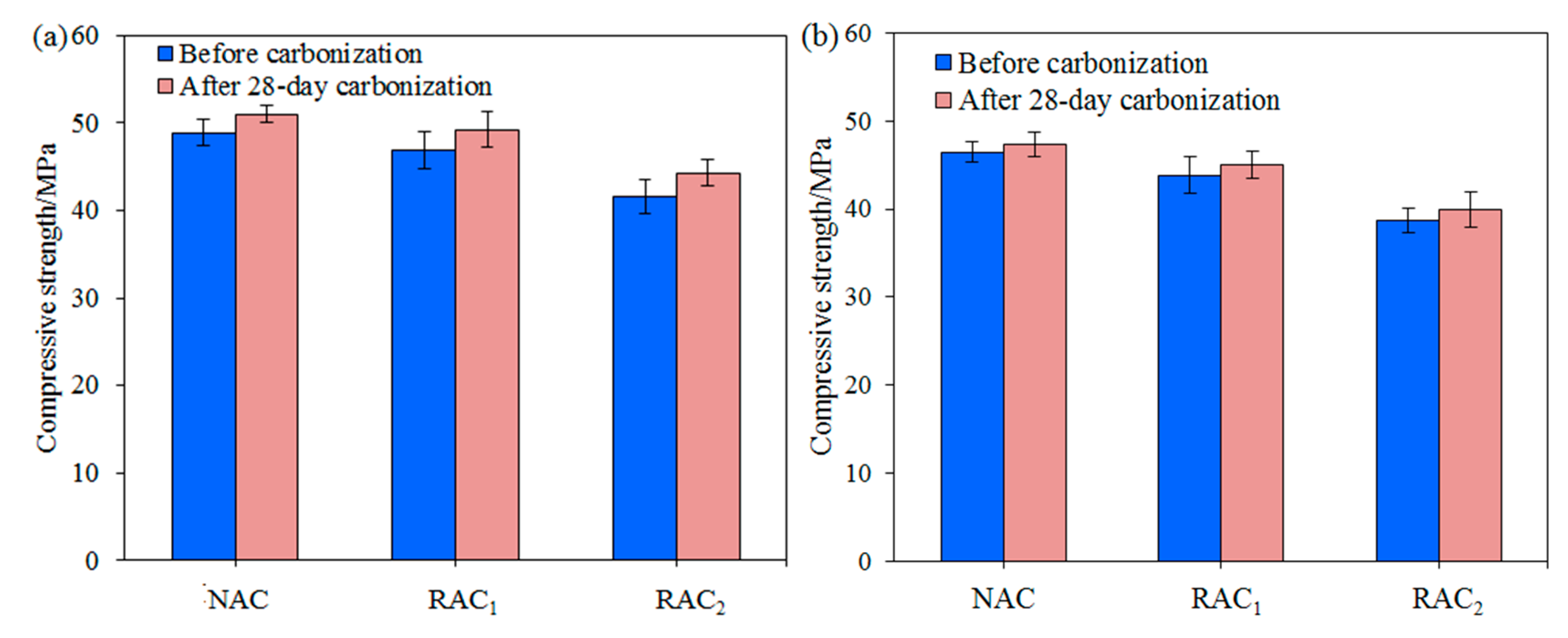

3.3. Compressive Strength

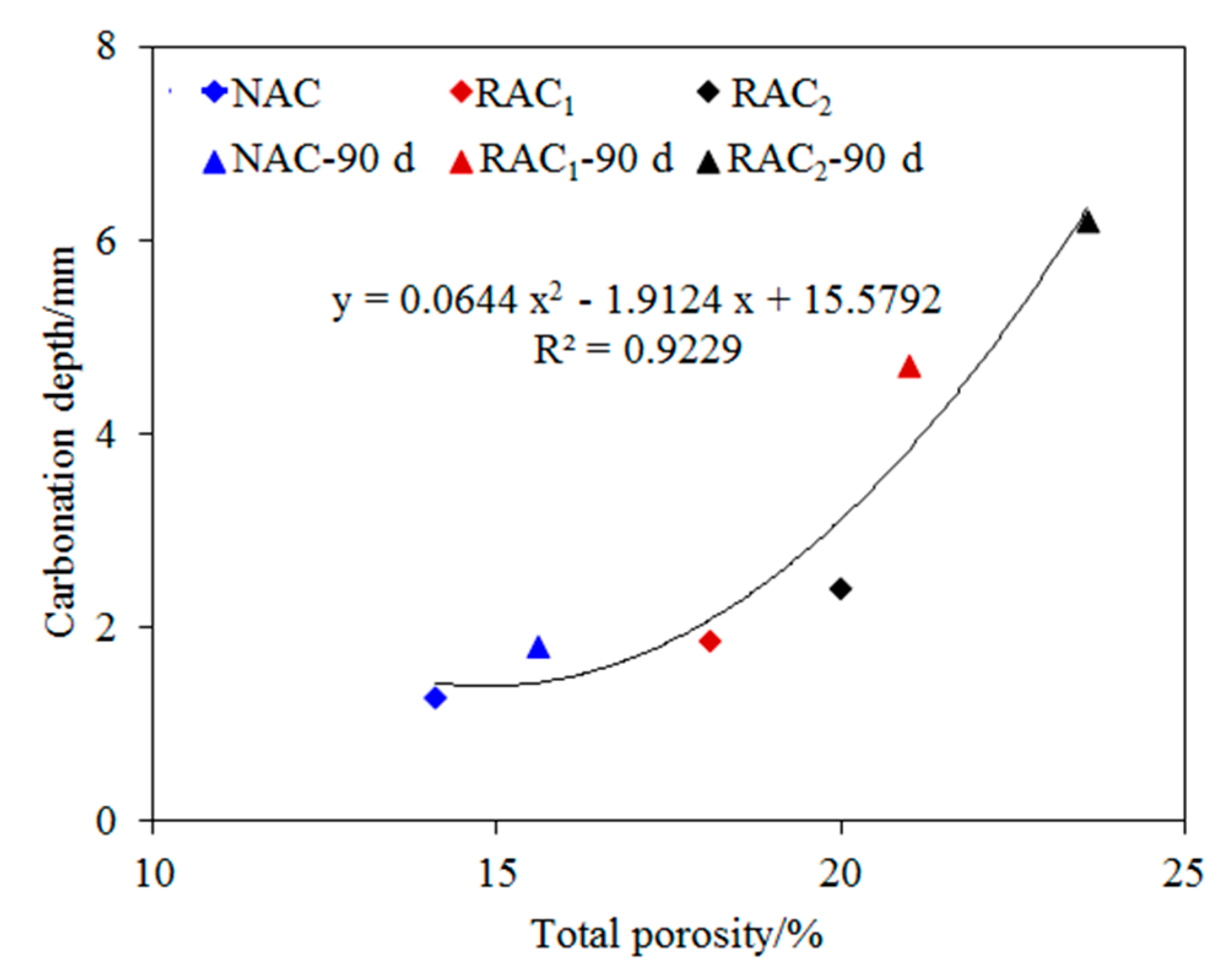

3.4. Concrete Porosity and Permeability

4. Conclusions

- The recycling number was the factor to affect the deterioration degree of properties of RCA, and the content of the attached mortar was the key one. Although the quality of RCA prepared in this study decreased with the increase of recycling number, all of them still can meet the requirements used for structural concrete.

- The carbonation depth of concrete specimens without chloride ion corrosion increased as the recycling cycles increased, and compared to NAC, the carbonation depth of RAC1 and RAC2 at 28 days increased 46% and 78% than that of NAC.

- Chloride ion corrosion negatively affected the carbonation resistance of RAC and the negative effect was more severe with the increase of corrosion time and recycling cycles. Chloride ion corrosion led to the increase of porosity of RAC, which was the fundamental reason for the carbonation resistance deterioration.

- The equation of concrete total porosity and carbonation depth was established, which could effectively judge the deterioration of carbonation resistance of RAC.

- Based on the Chinese standard JGJ/T193-2009, the carbonation durability of RAC1 and RAC2 with the effect of chloride ion corrosion can fully meet the requirements for structural concrete to be used for 50 years. According to the carbonation durability, the application of multi-recycled coarse aggregate in structural concrete under the chloride environment is feasible.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huda, S.B.; Alam, M.S. Mechanical behavior of three generations of 100% repeated recycled coarse aggregate concrete. Constr. Build. Mater. 2014, 65, 574–582. [Google Scholar] [CrossRef]

- Zhu, P.; Hao, Y.; Liu, H.; Wei, D.; Liu, S.; Gu, L. Durability evaluation of three generations of 100% repeatedly recycled coarse aggregate concrete. Constr. Build. Mater. 2019, 210, 442–450. [Google Scholar] [CrossRef]

- Salesa, Á.; Pérez-Benedicto, J.Á.; Esteban, L.M. Physico-mechanical properties of multi-recycled self-compacting concrete prepared with precast concrete rejects. Constr. Build. Mater. 2017, 153, 364–373. [Google Scholar] [CrossRef]

- Pavlů, T.; Kočí, V.; Hájek, P. Environmental assessment of two use cycles of recycled aggregate concrete. Sustainability 2019, 11, 6185. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Amaral, R.E.; Brito, J.; Buckman, M.; Drake, E.; Ilatova, E.; Rice, P.; Sabbagh, C.; Voronkin, S.; Abraham, Y. Waste Management and Operational Energy for Sustainable Buildings: A Review. Sustainability 2020, 12, 5337. [Google Scholar] [CrossRef]

- Li, H.; Guo, Q.J.; Wang, J.B.; Zhang, K. Meso-/Micro-structure of interfacial transition zone and durability of recycled aggregate concrete: A review. Mater. Rev. 2020, 34, 13050–13057. [Google Scholar]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Taboada, G.L.; Seruca, I.; Castro-Lopes, F.; Pereira, Á. Exploratory Data Analysis and Data Envelopment Analysis of Construction and Demolition Waste Management in the European Economic Area. Sustainability 2020, 12, 4995. [Google Scholar] [CrossRef]

- Talukdar, S.; Banthia, N.; Grace, J.R. Carbonation in concrete infrastructure in the context of global climate change—Part 1: Experimental results and model development. Cem. Concr. Compos. 2012, 34, 924–930. [Google Scholar] [CrossRef]

- Gholizadeh-Vayghan, A.; Bellinkx, A.; Snellings, R.; Vandoren, B.; Quaghebeur, M. The effects of carbonation conditions on the physical and microstructural properties of recycled concrete coarse aggregates. Constr. Build. Mater. 2020, 257, 119486. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Bacon, J. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. J. Clean. Prod. 2011, 19, 272–277. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Soares, D.; De Brito, J.; Ferreira, J.G.; Pacheco, J. Use of coarse recycled aggregates from precast concrete rejects: Mechanical and durability performance. Constr. Build. Mater. 2014, 71, 263–272. [Google Scholar] [CrossRef]

- Silva, R.; Neves, R.; De Brito, J.; Dhir, R. Carbonation behaviour of recycled aggregate concrete. Cem. Concr. Compos. 2015, 62, 22–32. [Google Scholar] [CrossRef]

- Amorim, P.; de Brito, J.; Evangelista, L. Concrete Made with Coarse Concrete Aggregate: Influence of Curing on Durability. ACI Mater. J. 2012, 109, 195–204. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Xiao, J.; Lei, B.; Zhang, C. On carbonation behavior of recycled aggregate concrete. Sci. China Ser. E Technol. Sci. 2012, 55, 2609–2616. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, K.; Hu, K. Carbonation Behavior of Repeated Recycled Fine Aggregate Concrete under Bending Load. KSCE J. Civ. Eng. 2019, 23, 729–736. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on the compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 46. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Matias, D.; De Brito, J.; Rosa, A.; Pedro, D. Durability of Concrete with Recycled Coarse Aggregates: Influence of Superplasticizers. J. Mater. Civ. Eng. 2014, 26, 06014011. [Google Scholar] [CrossRef]

- Kurda, R.; De Brito, J.; Silvestre, J.D. Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2. J. CO2 Util. 2019, 29, 12–19. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef]

- Bhashya, V.; Bharatkumar, B.H. Carbonation, Shrinkage and Long-Term Studies on Recycled Aggregate Concrete. In Recent Advances in Structural Engineering; Springer: Singapore, 2018; Volume 1, pp. 703–713. [Google Scholar]

- Singh, N.; Singh, S.P. Improving the carbonation resistance of self-compacting concrete containing recycled concrete aggregates using blended cements. Indian Concr. J. 2019, 93, 46–60. [Google Scholar]

- Neville, A.M.; Brooks, J.J. Concrete Technology, 2nd ed.; Pearson: London, UK, 2010. [Google Scholar]

- Evangelista, L.; De Brito, J. Durability of crushed fine recycled aggregate concrete assessed by permeability-related properties. Mag. Concr. Res. 2019, 71, 1142–1150. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of recycled aggregate treatment techniques on the durability of concrete: A comparative evaluation. Constr. Build. Mater. 2020, 264, 120284. [Google Scholar] [CrossRef]

- Dodds, W.; Goodier, C.; Christodoulou, C.; Austin, S.; Dunne, D. Corrosion risk assessment of structural concrete with coarse crushed concrete aggregate. Proc. Inst. Civ. Eng. Constr. Mater. 2020, 173, 57–69. [Google Scholar] [CrossRef]

- Ye, H.; Jin, X.; Fu, C.; Jin, N.; Xu, Y.; Huang, T. Chloride penetration in concrete exposed to cyclic drying-wetting and carbonation. Constr. Build. Mater. 2016, 112, 457–463. [Google Scholar] [CrossRef]

- Kuosa, H.; Ferreira, R.M.; Holt, E.M.; Leivo, M.; Vesikari, E. Effect of coupled deterioration by freeze–thaw, carbonation and chlorides on concrete service life. Cem. Concr. Compos. 2014, 47, 32–40. [Google Scholar] [CrossRef]

- Xu, C.; Wang, C.K.; Jin, W.L. Interaction effect of chloride attack and carbonization in concrete. J. Build. Mater. 2011, 14, 376–380. [Google Scholar]

- Del Bosque, I.S.; Heede, P.V.D.; De Belie, N.; De Rojas, M.S.; Medina, C. Carbonation of concrete with construction and demolition waste based recycled aggregates and cement with recycled content. Constr. Build. Mater. 2020, 234, 1–17. [Google Scholar] [CrossRef]

- Leemann, A.; Loser, R. Carbonation resistance of recycled aggregate concrete. Constr. Build. Mater. 2019, 204, 335–341. [Google Scholar] [CrossRef]

- Pan, H.; Yang, Z.; Xu, F. Study on concrete structure’s durability considering the interaction of multi-factors. Constr. Build. Mater. 2016, 118, 256–261. [Google Scholar] [CrossRef]

- Puatatsananon, W.; Saouma, V.E. Nonlinear Coupling of Carbonation and Chloride Diffusion in Concrete. J. Mater. Civ. Eng. 2005, 17, 264–275. [Google Scholar] [CrossRef]

- Zhu, P.; Wu, J.; Zhang, X.; Wang, X. Performance degradation of the repeated recycled aggregate concrete with 70% replacement of three-generation recycled coarse aggregate. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 989–995. [Google Scholar] [CrossRef]

- Chen, J.K.; Wang, D.M. New mix design method for HPC-overall calculation method. J. Chin. Chem. Soc. 2008, 28, 194–198. [Google Scholar]

- Tam, V.W.; Tam, C.; Wang, Y. Optimization on proportion for recycled aggregate in concrete using two-stage mixing approach. Constr. Build. Mater. 2007, 21, 1928–1939. [Google Scholar] [CrossRef]

- GB/T 50080-2016. Standard for Test Method of Performance on Ordinary Fresh Concrete; China Building Industry Press: Beijing, China, 2016. [Google Scholar]

- GB/T 50082-2009. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; China Building Industry Press: Beijing, China, 2009. [Google Scholar]

- Wu, X.H.; Yue, P.J. Experimental study on chloride ion penetration into recycled aggregate concrete. J. Build. Mater. 2011, 14, 381–384. [Google Scholar]

- Wu, Z.W.; Lian, H.Z. High Performance Concrete; China Railway Publishing House: Beijing, China, 1999; pp. 64–68. [Google Scholar]

- GB/T 14685-2010. Standard for Pebble and Crushed Stone for Construction; China Building Industry Press: Beijing, China, 2010. [Google Scholar]

- GB/T 25177-2010. Standard for Recycled Coarse Aggregate for Concrete; China Building Industry Press: Beijing, China, 2010. [Google Scholar]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Yi, Y.; Zhu, D.; Guo, S.; Zhang, Z.; Shi, C. A review on the deterioration and approaches to enhance the durability of concrete in the marine environment. Cem. Concr. Compos. 2020, 113, 103695. [Google Scholar] [CrossRef]

- JIS A5023-2006. Recycled Concrete Using Recycled Aggregate Class L; Japanese Industrial Standards Committee: Tokyo, Japan, 2006. [Google Scholar]

- RILEM TC 121-DRG. Specifications for concrete with recycled aggregates. Mater. Struct. 1994, 27, 557–559. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Ghahari, S.A.; Esmaeili, M. Effect of combined carbonation and chloride ion ingress by an accelerated test method on microscopic and mechanical properties of concrete. Constr. Build. Mater. 2014, 58, 138–146. [Google Scholar] [CrossRef]

- Abed, M.; Nemes, R.; Tayeh, B.A. Properties of self-compacting high-strength concrete containing multiple use of recycled aggregate. J. King Saud Univ. Eng. Sci. 2020, 32, 108–114. [Google Scholar] [CrossRef]

- Lotfi, S.; Deja, J.; Rem, P.; Mróz, R.; Van Roekel, E.; Van Der Stelt, H. Mechanical recycling of EOL concrete into high-grade aggregates. Resour. Conserv. Recycl. 2014, 87, 117–125. [Google Scholar] [CrossRef]

- Lü, Q.; Qiu, Q.; Zheng, J.; Wang, J.; Zeng, Q. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar] [CrossRef]

- Zhang, J.; Bian, F.; Zhang, Y.; Fang, Z.; Fu, C.; Guo, J. Effect of pore structures on gas permeability and chloride diffusivity of concrete. Constr. Build. Mater. 2018, 163, 402–413. [Google Scholar] [CrossRef]

- Kim, N.; Kim, J.; Yang, S. Mechanical Strength Properties of RCA Concrete Made by a Modified EMV Method. Sustainability 2016, 8, 924. [Google Scholar] [CrossRef]

- Ma, Z.; Li, W.; Wu, H.; Cao, C. Chloride permeability of concrete mixed with activity recycled powder obtained from C&D waste. Constr. Build. Mater. 2019, 199, 652–663. [Google Scholar] [CrossRef]

- Ismail, S.; Kwan, W.H.; Ramli, M. Mechanical strength and durability properties of concrete containing treated recycled concrete aggregates under different curing conditions. Constr. Build. Mater. 2017, 155, 296–306. [Google Scholar] [CrossRef]

- JGJ/T193-2009. Standard for Inspection and Assessment of Concrete Durability; China Building Industry Press: Beijing, China, 2009. [Google Scholar]

| Chemical Composition (%) | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | MnO | K2O | TiO2 | LOI 1 |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 60.79 | 21.22 | 7.29 | 3.78 | 1.8 | 1.17 | 0.63 | 0.27 | 1.75 |

| Slag | 3.72 | 51.5 | 29.33 | 3.77 | 1.15 | 0.21 | 1.71 | 0.99 | 1.69 |

| FA | 25.68 | 31.92 | 16.80 | 1.41 | 7.93 | 0.51 | 0.89 | 0.79 | 0.69 |

| SF | 0.27 | 87.03 | 1.12 | 0.97 | 0.88 | 0.14 | - | - | 0.86 |

| Cement | 60.79 | 21.22 | 7.29 | 3.78 | 1.8 | 1.17 | 0.63 | 0.27 | 1.75 |

| Concrete Types | Cement | NCA | Sand | RCA | Slag | FA | SF | PCA | PP | Water |

|---|---|---|---|---|---|---|---|---|---|---|

| NAC | 293 | 1037 | 689 | - | 45 | 90 | 23 | 8.1 | 0.45 | 171 |

| RAC1 | 293 | - | 689 | 1037 | 45 | 90 | 23 | 8.1 | 2.25 | 218 |

| RAC2 | 293 | - | 689 | 1037 | 45 | 90 | 23 | 8.1 | 2.25 | 225 |

| Aggregate Types | Apparent Density (kg/m3) | Water Absorption Rate for 30 min (%) | Crushing Index (%) | Attached Mortar Content (%) |

|---|---|---|---|---|

| NCA | 2705 | 0.9 | 5.6 | - |

| RCA1 | 2545 | 3.8 | 16.2 | 38.5 |

| RCA2 | 2437 | 4.2 | 17.1 | 42.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Liu, R.; Zhu, P.; Liu, H.; Wang, X. Carbonization Durability of Two Generations of Recycled Coarse Aggregate Concrete with Effect of Chloride Ion Corrosion. Sustainability 2020, 12, 10544. https://doi.org/10.3390/su122410544

Chen C, Liu R, Zhu P, Liu H, Wang X. Carbonization Durability of Two Generations of Recycled Coarse Aggregate Concrete with Effect of Chloride Ion Corrosion. Sustainability. 2020; 12(24):10544. https://doi.org/10.3390/su122410544

Chicago/Turabian StyleChen, Chunhong, Ronggui Liu, Pinghua Zhu, Hui Liu, and Xinjie Wang. 2020. "Carbonization Durability of Two Generations of Recycled Coarse Aggregate Concrete with Effect of Chloride Ion Corrosion" Sustainability 12, no. 24: 10544. https://doi.org/10.3390/su122410544

APA StyleChen, C., Liu, R., Zhu, P., Liu, H., & Wang, X. (2020). Carbonization Durability of Two Generations of Recycled Coarse Aggregate Concrete with Effect of Chloride Ion Corrosion. Sustainability, 12(24), 10544. https://doi.org/10.3390/su122410544