Carbon Footprint Assessment of Construction Waste Packaging Using the Package-to-Product Indicator

Abstract

1. Introduction

2. Materials and Methods

2.1. Construction Products

2.2. Packaging Materials and Types

2.3. Life Cycle Assessment

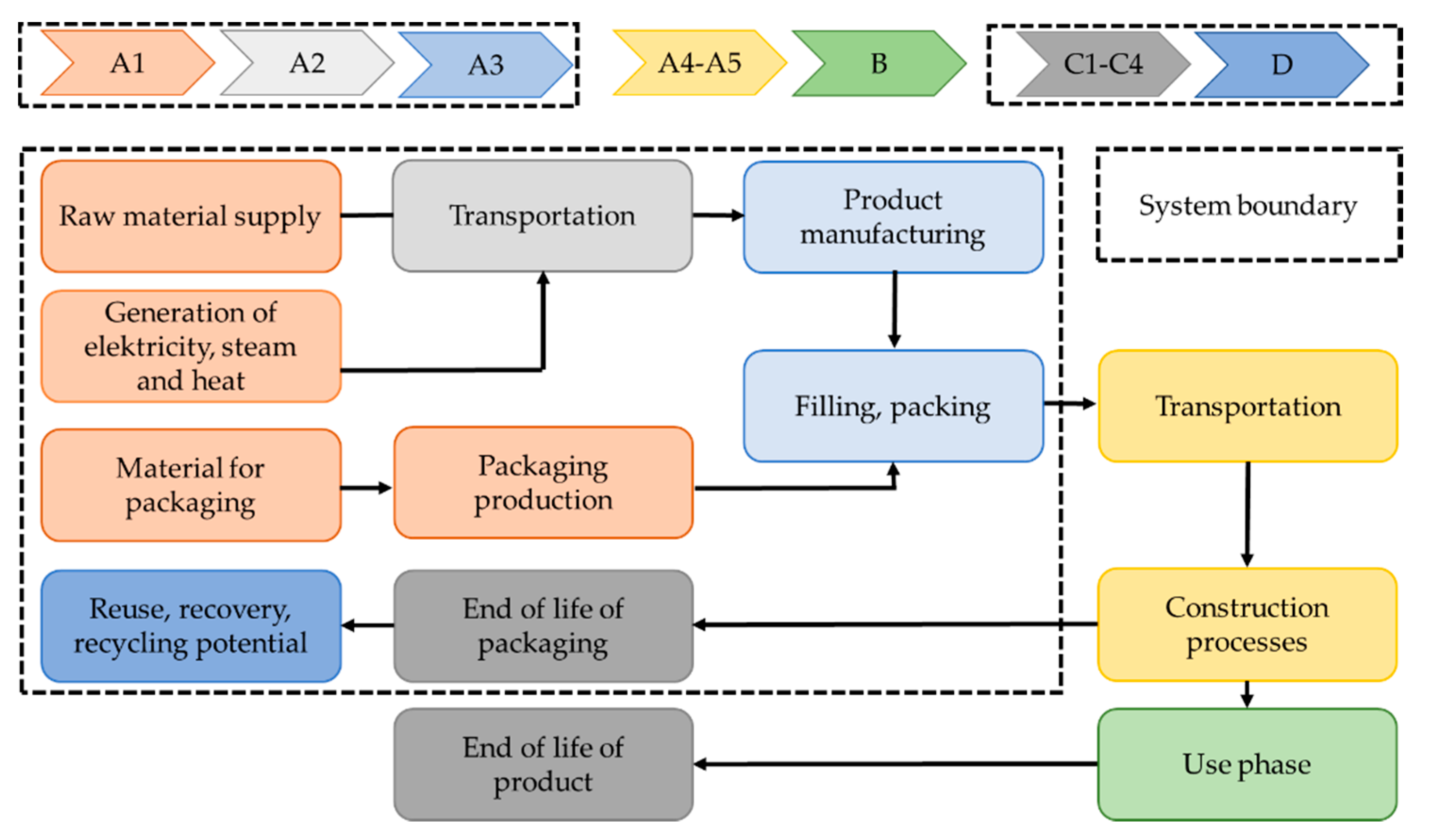

2.3.1. System Boundaries and Functional Unit

2.3.2. Assumption Accepted in the Study

- The process describing the Czech energy mix was used according to data from reference year 2016.

- Wooden pallets were assumed to be used 25 times.

- Other materials such as straps, labels, and stickers were neglected for packaging.

- Transport: the distance for transporting the packaging from the packaging manufacturer was set to 230 km, while the distance for the transporting of the packaging to the removal site was set in the scenarios as follows: 50 km for landfilling, 150 km for energy recovery, 250 km for material recovery.

2.3.3. Scenarios Modelling the End-of-Life Phase

2.3.4. Life Cycle Inventory

2.4. Calculation of PtP Indicator Focused on Carbon Footprint

2.5. Uncertainty Analysis

3. Results

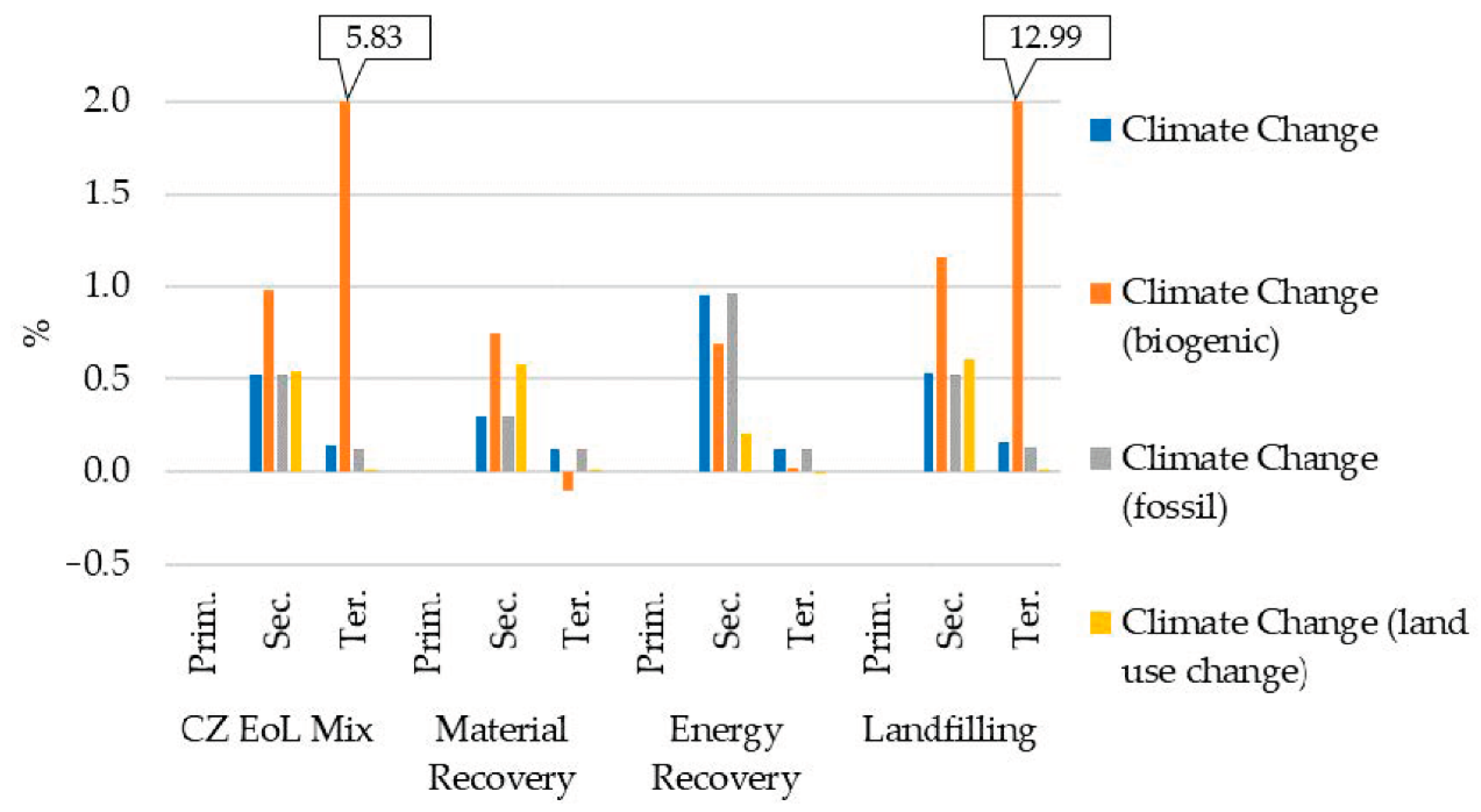

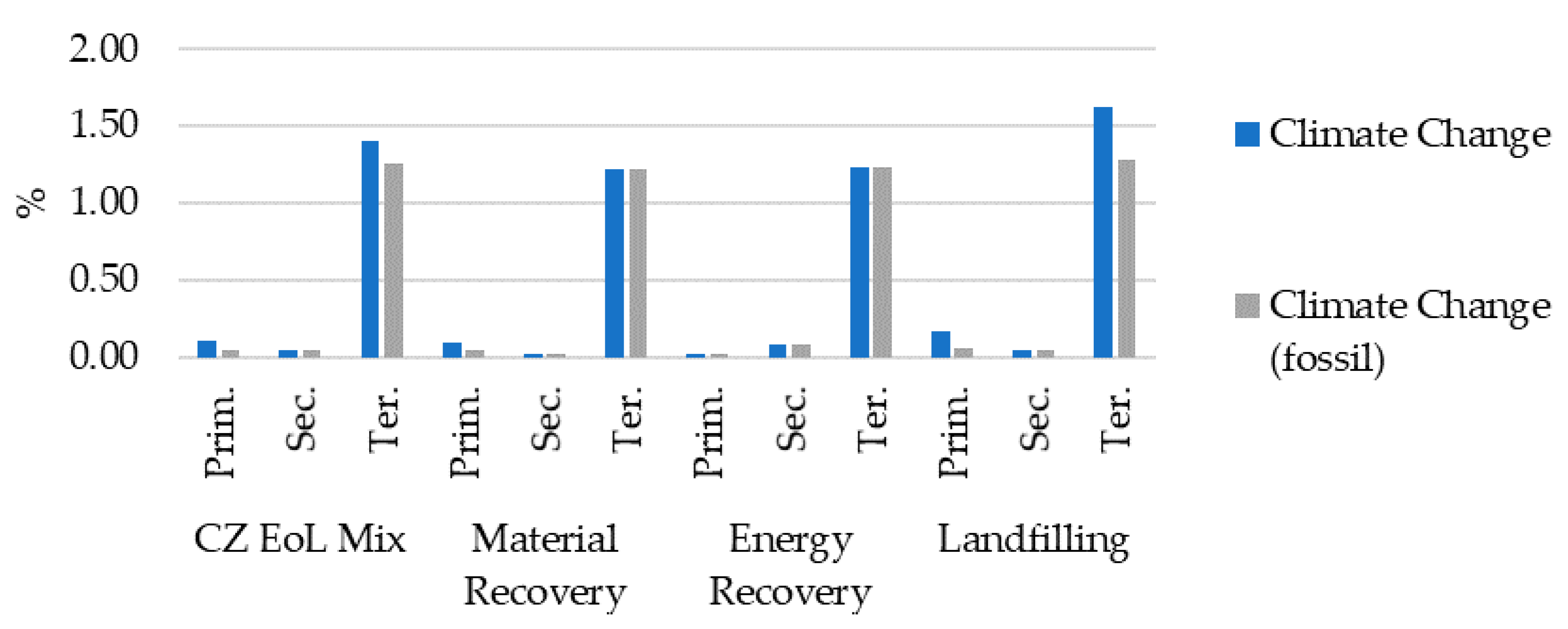

3.1. Aerated Concrete Block Element and Its Packaging

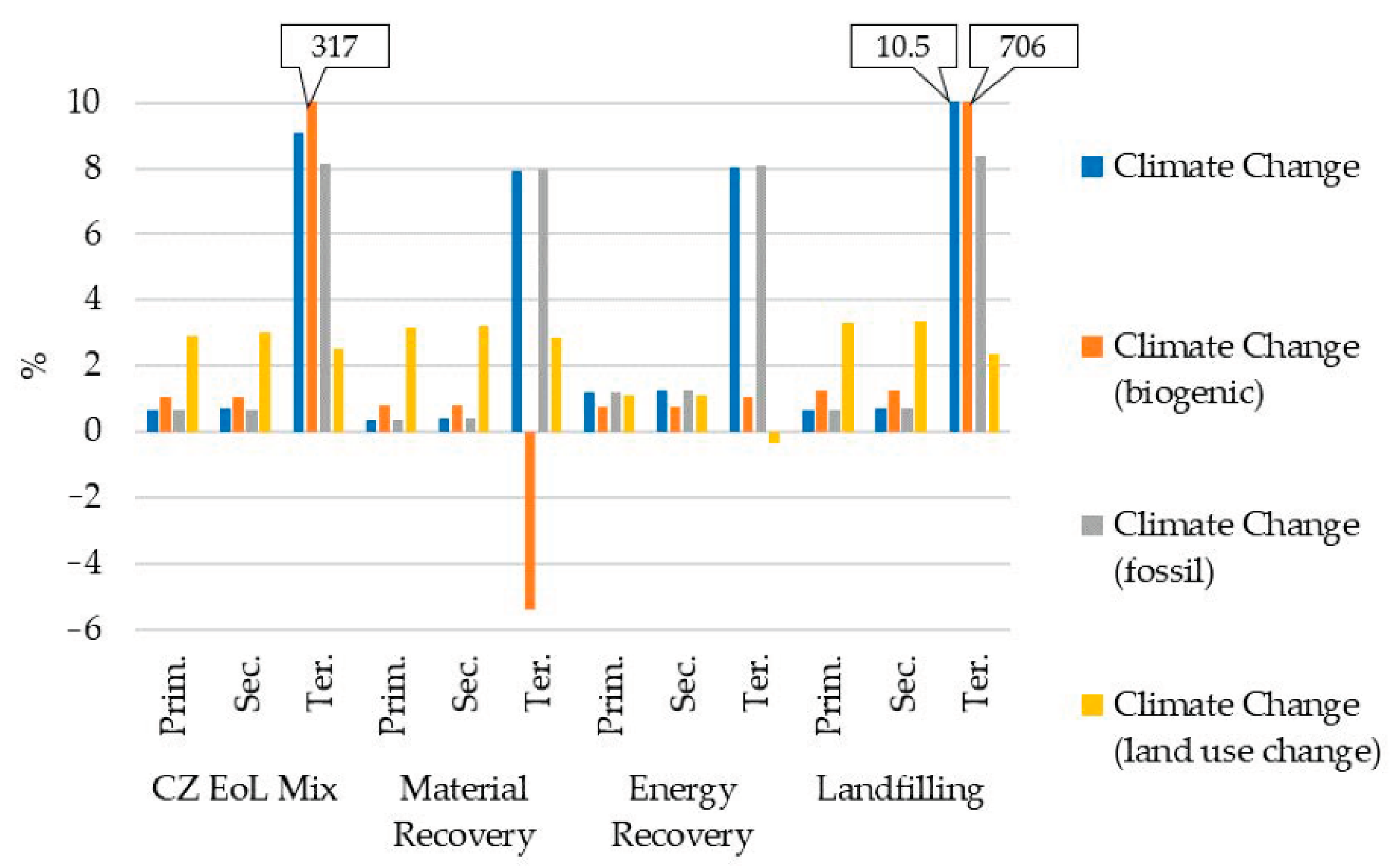

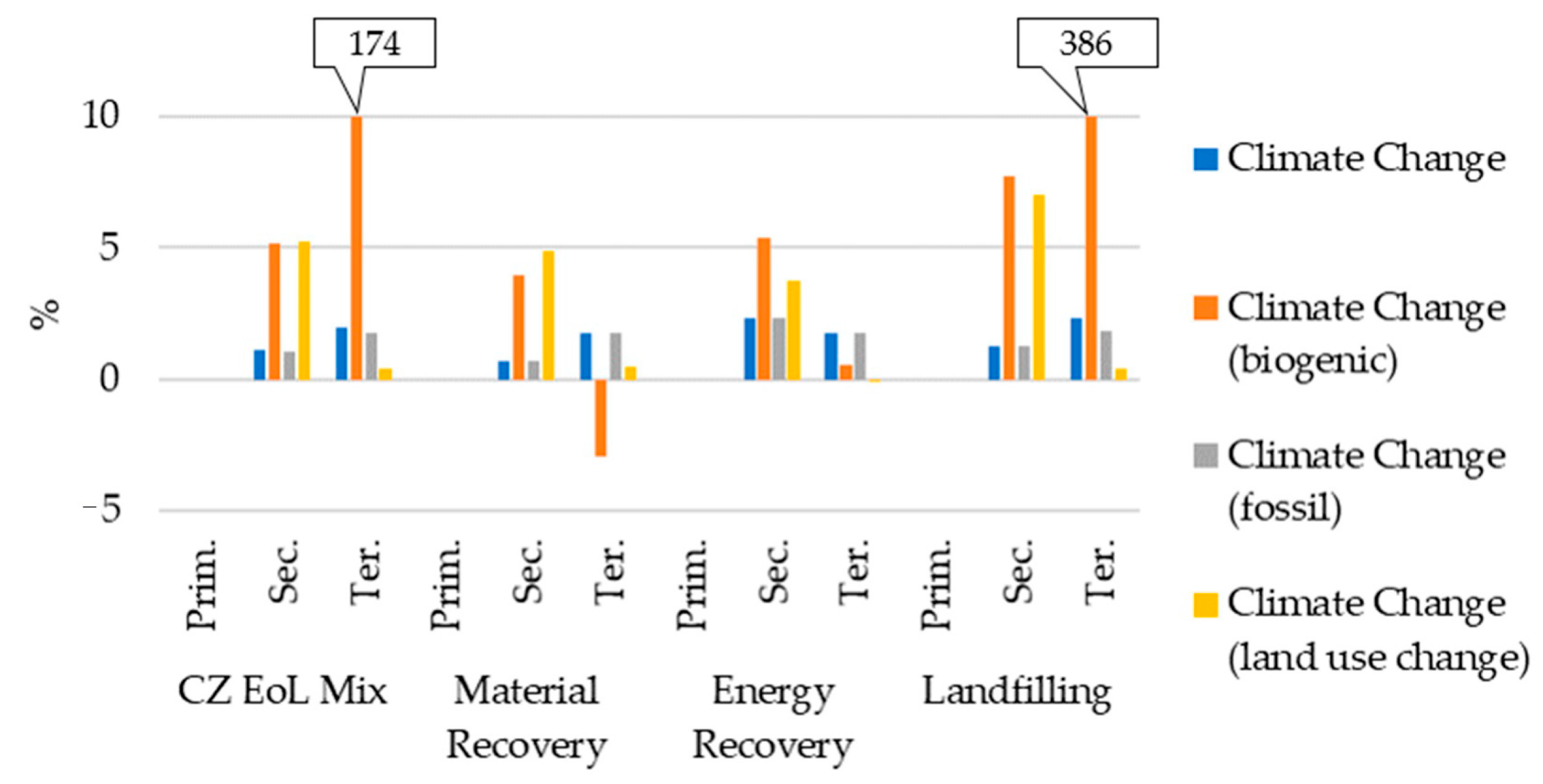

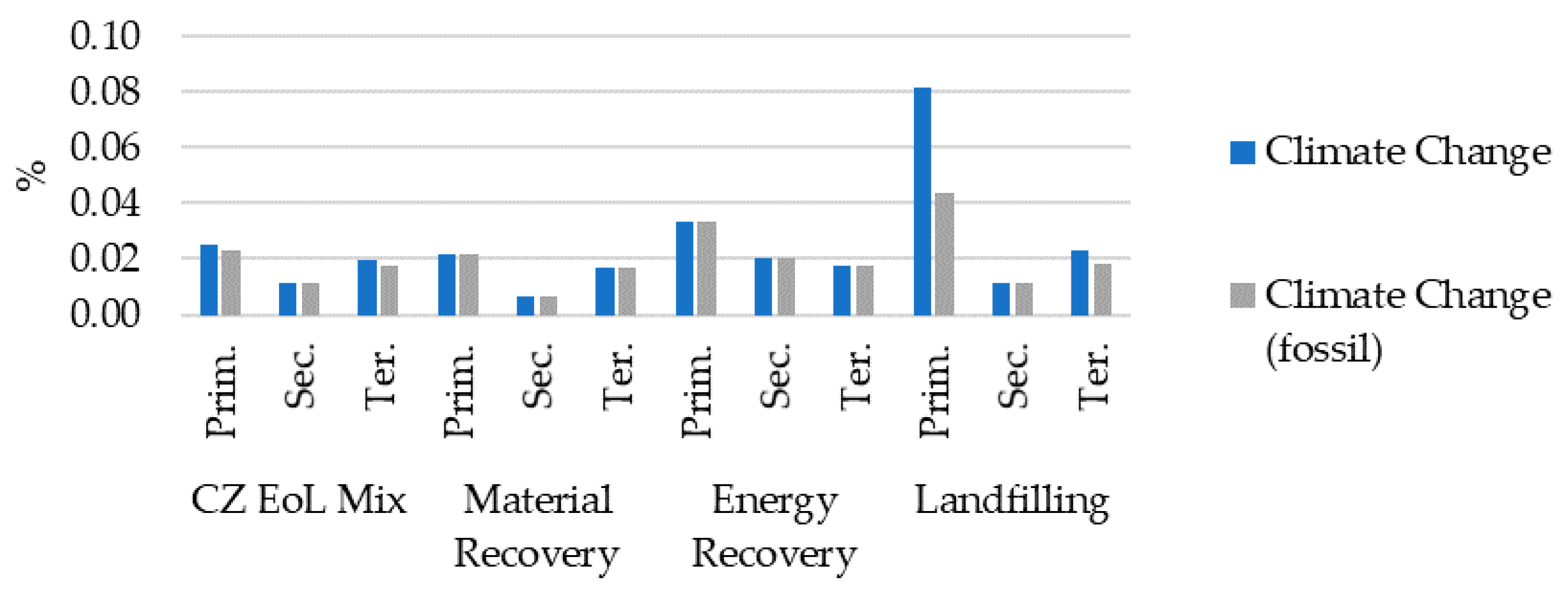

3.2. Expanded Polystyrene and Its Packaging

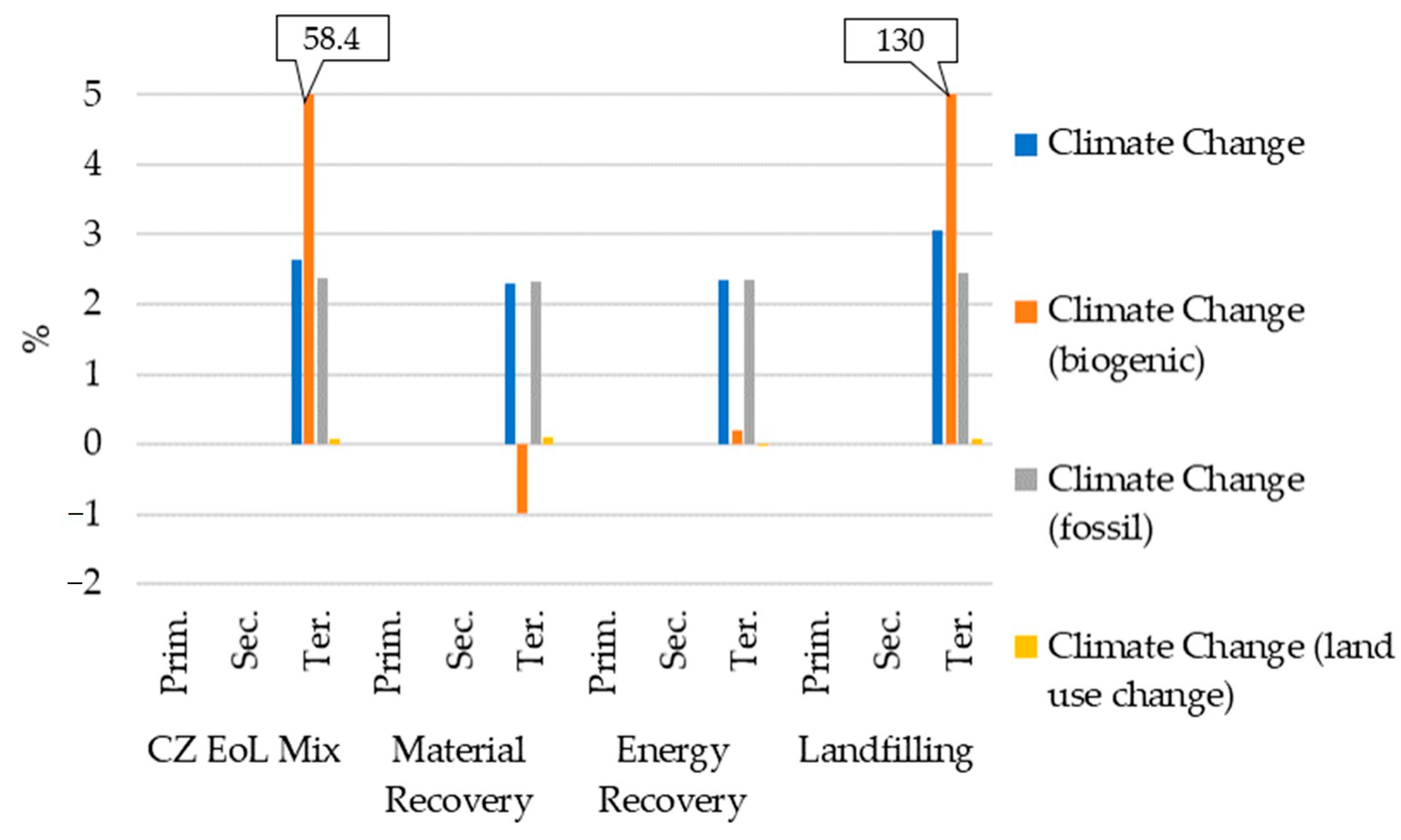

3.3. Gypsum Plasterboard and Its Packaging

3.4. Cement and Its Packaging

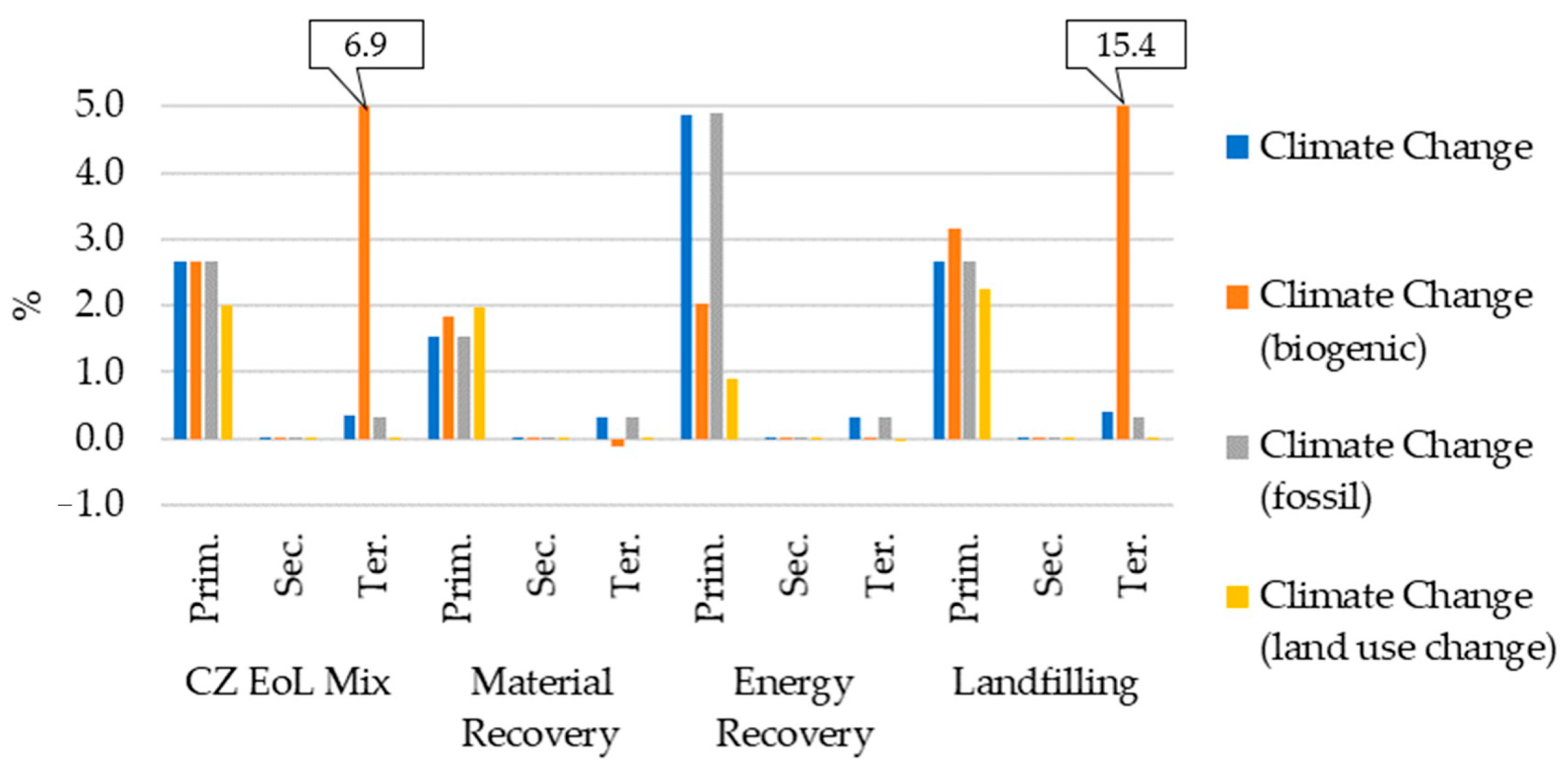

3.5. Clay Brick and Its Packaging

3.6. Ceramic Facade Panel and Its Packaging

3.7. Paint Emulsion and Its Packaging

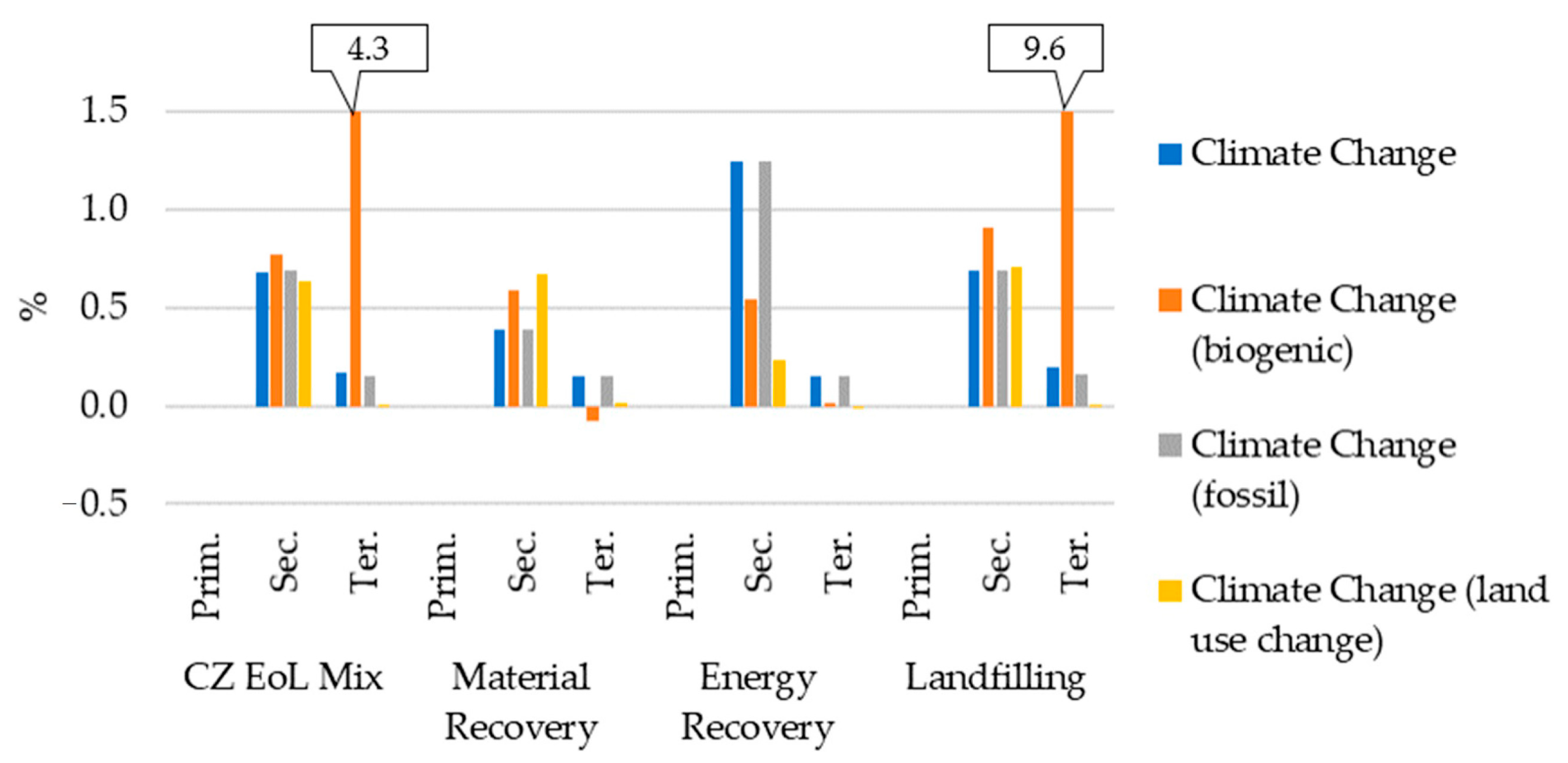

3.8. Mineral Wool and Its Packaging

3.9. Roof Tile and Its Packaging

3.10. Mineral Reinforcement Mortar and Its Packaging

3.11. Results of Monte Carlo Analysis

4. Discussion

Study Limitation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EU Construction and Demolition Waste Protocol and Guidelines. Available online: https://ec.europa.eu/growth/content/eu-construction-and-demolition-waste-protocol-0_en (accessed on 10 January 2020).

- Pericot, N.G.; Sáez, P.V.; Merino, M.D.R.; Carrasco, O.L. Production patterns of packaging waste categories generated at typical Mediterranean residential building worksites. Waste Manag. 2014, 34, 1932–1938. [Google Scholar] [CrossRef] [PubMed]

- Muthu, S.S.; Li, Y.; Hu, J.Y.; Mok, P.Y. An Exploratory Comparative Study on Eco-Impact of Paper and Plastic Bags; Textile Bioengineering and Informatics Symposium Proceedings, Vols 1 and 2; Hong Kong Polytechnic University: Kowloon, Hong Kong, 2009; ISBN 977-1-94234-300-5. [Google Scholar]

- Tichá, M. Environmental Assessment of The Milk Life Cycle: The Effect of Packaging Selection and The Variability of Milk Production Data. Porovnání evironmentálních dopadů nápojových obalů v ČR metodou LCA. 2009. Available online: https://is.muni.cz/el/1431/jaro2015/Bi6920/um/LCA_napojove_obaly_zaverecna_zprava.pdf (accessed on 10 October 2020).

- Xie, M.H.; Qiao, Q.; Sun, Q.H.; Zhang, L.L. Life cycle assessment of composite packaging waste management-a Chinese case study on aseptic packaging. Int. J. Life Cycle Assess. 2013, 18, 626–635. [Google Scholar] [CrossRef]

- Meneses, M.; Pasqualino, J.; Castells, F. Environmental assessment of the milk life cycle: The effect of packaging selection and the variability of milk production data. J. Environ. Manag. 2012, 107, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Cole, R.J.; Valdebenito, M.J. The importation of building environmental certification systems: International usages of BREEAM and LEED. Build. Res. Informat. 2013, 41, 662–676. [Google Scholar] [CrossRef]

- Tencar, J.; Vonka, M. Practical Experience With Sbtoolcz Certification; Sustainable Building and Refurbishment for Next Generations; Czech Technical University Prague: Prague 6, Czech Republic, 2013; ISBN 978-80-247-5015-6. [Google Scholar]

- Guinee, J. Handbook on life cycle assessment—Operational guide to the ISO standards. Int. J. Life Cycle Assess. 2001, 6, 255. [Google Scholar] [CrossRef]

- Tornese, F.; Carrano, A.L.; Thorn, B.K.; Pazour, J.A.; Roy, D. Carbon footprint analysis of pallet remanufacturing. J. Clean Prod. 2016, 126, 630–642. [Google Scholar] [CrossRef]

- Koci, V. Comparisons of environmental impacts between wood and plastic transport pallets. Sci. Total Environ. 2019, 686, 514–528. [Google Scholar] [CrossRef]

- Accorsi, R.; Baruffaldi, G.; Manzini, R.; Pini, C. Environmental Impacts of Reusable Transport Items: A Case Study of Pallet Pooling in a Retailer Supply Chain. Sustainability 2019, 11, 13. [Google Scholar] [CrossRef]

- CEN EN 15804:2012+A2:2019 Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. Available online: https://standards.cen.eu/dyn/www/f?p=204:110:0::::FSP_PROJECT:70014&cs=1CFE7BDC38149F238F05C4C13E0E3B4C2 (accessed on 27 November 2020).

- Yang, D.; Fan, L.; Shi, F.; Liu, Q.; Wang, Y.J. Comparative study of cement manufacturing with different strength grades using the coupled LCA and partial LCC methods-A case study in China. Resour. Conserv. Recycl. 2017, 119, 60–68. [Google Scholar] [CrossRef]

- Werner, F.; Richter, K. Wooden building products in comparative LCA. Int. J. Life Cycle Assess. 2007, 12, 470–479. [Google Scholar] [CrossRef]

- Islam, H.; Jollands, M.; Setunge, S.; Ahmed, I.; Hague, N. Life cycle assessment and life cycle cost implications of wall assemblages designs. Energy Build. 2014, 84, 33–45. [Google Scholar] [CrossRef]

- Pesta, J.; Pavlu, T.; Fartova, K.; Koci, V. Sustainable Masonry Made from Recycled Aggregates: LCA Case Study. Sustainability 2020, 12, 1581. [Google Scholar] [CrossRef]

- Monteiro, H.; Freire, F. Life-cycle assessment of a house with alternative exterior walls: Comparison of three impact assessment methods. Energy Build. 2012, 47, 572–583. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Idris, J.; Yusoff, S. Environmental Impact Analysis on Residential Building in Malaysia Using Life Cycle Assessment. Sustainability 2017, 9, 329. [Google Scholar] [CrossRef]

- Marinkovic, S.; Habert, G.; Ignjatovic, I.; Dragas, J.; Tosic, N.; Brumaud, C. Life Cycle Analysis of Recycled Aggregate Concrete with Fly Ash as Partial Cement Replacement. Expand. Boundaries Syst. Think. Built Environ. 2016, 2016, 390–396. [Google Scholar]

- Jiang, M.H.; Chen, X.J.; Rajabipour, F.; Hendrickson, C.T. Comparative Life Cycle Assessment of Conventional, Glass Powder, and Alkali-Activated Slag Concrete and Mortar. J. Infrastruct. Syst. 2014, 20, 9. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; Enrique Garcia-Muina, F.; Settembre-Blundo, D. Building a Sustainability Benchmarking Framework of Ceramic Tiles Based on Life Cycle Sustainability Assessment (LCSA). Resources-Basel 2019, 8, 11. [Google Scholar] [CrossRef]

- Lozano-Miralles, J.A.; Hermoso-Orzaez, M.J.; Martinez-Garcia, C.; Rojas-Sola, J.I. Comparative Study on the Environmental Impact of Traditional Clay Bricks Mixed with Organic Waste Using Life Cycle Analysis. Sustainability 2018, 10, 17. [Google Scholar] [CrossRef]

- Zimele, Z.; Sinka, M.; Korjakins, A.; Bajare, D.; Sahmenko, G. Life Cycle Assessment of Foam Concrete Production in Latvia. Environ. Clim. Technol. 2019, 23, 70–84. [Google Scholar] [CrossRef]

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A comparative life cycle assessment (LCA) of different insulation materials for buildings in the continental Mediterranean climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- Grabois, T.M.; Caldas, L.R.; Julião, N.R.; Toledo Filho, R.D. An Experimental and Environmental Evaluation of Mortars with Recycled Demolition Waste from a Hospital Implosion in Rio de Janeiro. Sustainability 2020, 12, 8945. [Google Scholar] [CrossRef]

- Onn, C.C.; Mo, K.H.; Radwan, M.K.H.; Liew, W.H.; Ng, C.G.; Yusoff, S. Strength, Carbon Footprint and Cost Considerations of Mortar Blends with High Volume Ground Granulated Blast Furnace Slag. Sustainability 2019, 11, 8945. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Alba, J.; del Rey, R.; Crespo-Amorós, J.E.; Guillén-Guillamón, I. Life-Cycle Assessment and Acoustic Simulation of Drywall Building Partitions with Bio-Based Materials. Polymers 2020, 12, 1965. [Google Scholar] [CrossRef]

- Carrano, A.L.; Thorn, B.K.; Woltag, H. Characterizing the Carbon Footprint of Wood Pallet Logistics. For. Prod. J. 2014, 64, 232–241. [Google Scholar] [CrossRef]

- Gasol, C.M.; Farreny, R.; Gabarrell, X.; Rieradevall, J. Life cycle assessment comparison among different reuse intensities for industrial wooden containers. Int. J. Life Cycle Assess. 2008, 13, 421–431. [Google Scholar] [CrossRef]

- Šerešová, M.; Kočí, V. Methodics PtP (Package-to-Product); Poznan University of Technology: Poznan, Poland, 2019. [Google Scholar]

- Šerešová, M.; Kočí, V. Proposal of Package-to-Product Indicator for Carbon Footprint Assessment with Focus on the Czech Republic. Sustainability 2020, 12, 3034. [Google Scholar] [CrossRef]

- He, B.; Shao, Y.W.; Wang, S.; Gu, Z.C.; Bai, K.J. Product environmental footprints assessment for product life cycle. J. Clean Prod. 2019, 233, 446–460. [Google Scholar] [CrossRef]

- ISO Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040:2006). Available online: https://www.iso.org/standard/37456.html (accessed on 1 October 2020).

- ISO Environmental management—Life Cycle Assessment—Requirements and guidelines (ISO 14044:2006). Available online: https://www.iso.org/standard/38498.html (accessed on 1 October 2020).

- Product Environmental Footprint (PEF) Guide. Available online: https://ec.europa.eu/environment/archives/eussd/pdf/footprint/PEF%20methodology%20final%20draft.pdf (accessed on 7 October 2020).

- Life Cycle Assessment LCA Software: Gabi Software. Available online: http://www.gabisoftware.com/ (accessed on 30 October 2020).

- GaBi Database and Modelling Principles. Available online: http://www.gabi-software.com/fileadmin/gabi/Modelling_Principles/Modeling_Principles_-_GaBi_Databases_2020_2.pdf (accessed on 1 December 2020).

- Watkiss, P.; Downing, T. The Impacts and Costs of Climate Change. Available online: https://ec.europa.eu/clima/sites/clima/files/strategies/2020/docs/final_report2_en.pdf (accessed on 10 October 2020).

- Fazio, S.; Secchi, M.; Castellani, V.; Sala, S.; Schau, E.M.; Diaconu, E.; Zampori, L. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Method. Available online: https://publications.jrc.ec.europa.eu/repository/bitstream/JRC109369/jrc109369_final.pdf (accessed on 1 October 2020).

- WRAP Reusable Packaging in Construction. Available online: http://www.wrap.org.uk/sites/files/wrap/RTP%20briefing%20note%20for%20suppliers%20-%20Final.pdf (accessed on 10 January 2020).

- Huang, C.C.; Ma, H.W. A multidimensional environmental evaluation of packaging materials. Sci. Total Environ. 2004, 324, 161–172. [Google Scholar] [CrossRef]

| Construction Product | Primary Packaging | Secondary Packaging | Tertiary Packaging | |||

|---|---|---|---|---|---|---|

| Material | Weight of Pack. Per 1 kg of Product [g] | Material | Weight of Pack. Per 1 kg of Product [g] | Material | Weight of Pack. Per 1 kg of Product [g] | |

| Cement (CEM I 32.5) | Paper bag | 0.46 | HDPE foil | 0.07 | Wooden pallet | 0.69 |

| Mineral reinforcement mortar | Paper bag | 4.00 | HDPE foil | 0.07 | Wooden pallet | 0.80 |

| Clay brick | LDPE | 1.11 | Wooden pallet | 0.67 | ||

| Roof Tile | HDPE foil | 11.20 | Wooden pallet | 0.09 | ||

| Mineral wool | HDPE foil | 3.79 | Wooden pallet | 0.36 | ||

| Ceramic facade panels | Cardboard | 0.39 | HDPE foil | 0.05 | Wooden pallet | 0.03 |

| Expanded Polystyrene (PS 30) | HDPE foil | 7.26 | HDPE foil | 7.41 | Wooden pallet | 37.0 |

| Aerated concrete block element | HDPE foil | 0.97 | Wooden pallet | 0.10 | ||

| Paint emulsion (building, exterior, white) | PP foil | 20.2 | HDPE foil | 0.04 | Wooden pallet | 1.00 |

| Gypsum plasterboard | Wooden pallet | 0.79 | ||||

| Indicator | Unit | Description |

|---|---|---|

| Climate Change | kg CO2 eq. | This indicator describes the impact on climate change caused by emissions of greenhouse gases (GHGs). |

| Climate Change (biogenic) | kg CO2 eq. | Carbon is removed from the atmosphere because of the process of growing biomass. This indicator described the impact on climate change, which is allocated to the carbon released from the biomass (for example by the burning of biomass) and the carbon removed from the atmosphere due to the growth of biomass. |

| Climate Change (fossil) | kg CO2 eq. | The result of this indicator corresponds to the impact of emissions from fossil sources, such as the burning of fossil fuels. It also includes removals of carbon from the atmosphere. |

| Climate Change (land use change) | kg CO2 eq. | The land use and land use change influence the carbon stock in the land. This indicator represents the impact of carbon, which is released to the atmosphere because of the change of carbon stocks in the land. |

| Construction Product | Description of Considered Processes |

|---|---|

| Cement (CEM I 32.5) | The process includes the excavation of primary resources, the production of clinker, and the grinding of cement. The cement is marked according to EN 197-1. |

| Mineral reinforcement mortar | The process includes the life cycle stages of the production of primary products, mining, processing operations and input secondary materials (e.g., recycling processes), their transport to the factory, and the production itself, including the provision of all supplies and materials, energy, and the complete waste treatment or landfilling of residual waste during the production stage. |

| Clay Bricks | Bricks made of clay with the following production steps: extraction of clay, processing and moulding of clay, drying, and firing in a furnace. |

| Roof Tile | Roof tile production covers the cradle-to-gate phase, that is, the production of raw and auxiliary materials as well as the production of the roof tiles, including plant operation. The main raw material is clay. |

| Mineral wool | Datasets describe mineral wool and glass fibre production using sedimentary or igneous rocks and various recycled materials. These materials are melted and then fibres are made. |

| Ceramic facade panels | This dataset represents the production of ceramic facade panels, which includes material and energy production, the transportation of raw materials and the actual production phase of the ceramic wall plate. |

| Expanded Polystyrene (PS 30) | The production of expanded polystyrene (EPS) takes place with the following steps: frothing of the granulate, treatment in a block foaming machine in dimensions for various products, post-foaming, cutting, and piling. |

| Aerated concrete block element | The dataset represents the following process steps: preparation, mixing of primary materials, production and installation of the corrosion protective reinforcement (for reinforced components), casting, driving, rubbing and cutting of the block, hardening using steam |

| Paint emulsion (building, exterior, white) | The dataset includes the manufacturing of raw and auxiliary materials as well as the processing at the construction site (solvent emissions). |

| Gypsum plasterboard | The dataset represents the pre-processing of the gypsum feedstock, the thermal process of calcination, mixing stucco with water and casting it together with paperboards. It also includes the cutting of boards. |

| Aerated Concrete Block Element | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 4.87 × 10−1 | 0.00 | 2.55 × 10−3 | 6.86 × 10−4 | 0.00 | 1.45 × 10−3 | 5.97 × 10−4 |

| Climate Change (biogenic) [kg CO2 eq.] | 1.27 × 10−3 | 0.00 | 1.24 × 10−5 | 7.41 × 10−5 | 0.00 | 9.46 × 10−6 | −1.26 × 10−6 |

| Climate Change (fossil) [kg CO2 eq.] | 4.85 × 10−1 | 0.00 | 2.54 × 10−3 | 6.12 × 10−4 | 0.00 | 1.43 × 10−3 | 5.98 × 10−4 |

| Climate Change (land use change) [kg CO2 eq.] | 3.02 × 10−4 | 0.00 | 1.63 × 10−6 | 2.76 × 10−8 | 0.00 | 1.75 × 10−6 | 3.13 × 10−8 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 0.00 | 4.64 × 10−3 | 6.05 × 10−4 | 0.00 | 2.57 × 10−3 | 7.93 × 10−4 | |

| Climate Change (biogenic) [kg CO2 eq.] | 0.00 | 8.73 × 10−6 | 2.45 × 10−7 | 0.00 | 1.47 × 10−5 | 1.65 × 10−4 | |

| Climate Change (fossil) [kg CO2 eq.] | 0.00 | 4.64 × 10−3 | 6.05 × 10−4 | 0.00 | 2.55 × 10−3 | 6.29 × 10−4 | |

| Climate Change (land use change) [kg CO2 eq.] | 0.00 | 6.09 × 10−7 | −3.96 × 10−9 | 0.00 | 1.83 × 10−6 | 2.58 × 10−8 | |

| Expanded Polystyrene | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 2.86 | 1.91 × 10−2 | 1.95 × 10−2 | 2.60 × 10−1 | 1.08 × 10−2 | 1.10 × 10−2 | 2.26 × 10−1 |

| Climate Change (biogenic) [kg CO2 eq.] | 8.84 × 10−3 | 9.31 × 10−5 | 9.50 × 10−5 | 2.81 × 10−2 | 7.08 × 10−5 | 7.22 × 10−5 | −4.77 × 10−4 |

| Climate Change (fossil) [kg CO2 eq.] | 2.85 | 1.90 × 10−2 | 1.94 × 10−2 | 2.32 × 10−1 | 1.07 × 10−2 | 1.10 × 10−2 | 2.27 × 10−1 |

| Climate Change (land use change) [kg CO2 eq.] | 4.16 × 10−4 | 1.22 × 10−5 | 1.25 × 10−5 | 1.05 × 10−5 | 1.31 × 10−5 | 1.33 × 10−5 | 1.19 × 10−5 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 3.48 × 10−2 | 3.55 × 10−2 | 2.30 × 10−1 | 1.92 × 10−2 | 1.96 × 10−2 | 3.01 × 10−1 | |

| Climate Change (biogenic) [kg CO2 eq.] | 6.54 × 10−5 | 6.67 × 10−5 | 9.30 × 10−5 | 1.10 × 10−4 | 1.12 × 10−4 | 6.24 × 10−2 | |

| Climate Change (fossil) [kg CO2 eq.] | 3.47 × 10−2 | 3.54 × 10−2 | 2.30 × 10−1 | 1.91 × 10−2 | 1.95 × 10−2 | 2.39 × 10−1 | |

| Climate Change (land use change) [kg CO2 eq.] | 4.56 × 10−6 | 4.66 × 10−6 | −1.50 × 10−6 | 1.37 × 10−5 | 1.40 × 10−5 | 9.78 × 10−6 | |

| Gypsum Plasterboard | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 2.08 × 10−1 | 0.00 | 0.00 | 5.52 × 10−3 | 0.00 | 0.00 | 4.80 × 10−3 |

| Climate Change (biogenic) [kg CO2 eq.] | 1.02 × 10−3 | 0.00 | 0.00 | 5.96 × 10−4 | 0.00 | 0.00 | −1.01 × 10−5 |

| Climate Change (fossil) [kg CO2 eq.] | 2.07 × 10−1 | 0.00 | 0.00 | 4.93 × 10−3 | 0.00 | 0.00 | 4.81 × 10−3 |

| Climate Change (land use change) [kg CO2 eq.] | 2.65 × 10−4 | 0.00 | 0.00 | 2.22 × 10−7 | 0.00 | 0.00 | 2.52 × 10−7 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 0.00 | 0.00 | 4.87 × 10−3 | 0.00 | 0.00 | 6.39 × 10−3 | |

| Climate Change (biogenic) [kg CO2 eq.] | 0.00 | 0.00 | 1.97 × 10−6 | 0.00 | 0.00 | 1.32 × 10−3 | |

| Climate Change (fossil) [kg CO2 eq.] | 0.00 | 0.00 | 4.87 × 10−3 | 0.00 | 0.00 | 5.06 × 10−3 | |

| Climate Change (land use change) [kg CO2 eq.] | 0.00 | 0.00 | −3.19 × 10−8 | 0.00 | 0.00 | 2.07 × 10−7 | |

| Cement | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 8.28 × 10−1 | 4.82 × 10−4 | 1.63 × 10−4 | 4.82 × 10−3 | 4.47 × 10−4 | 1.07 × 10−4 | 4.19 × 10−3 |

| Climate Change (biogenic) [kg CO2 eq.] | 8.88 × 10−4 | 2.83 × 10−4 | 7.99 × 10−7 | 5.20 × 10−4 | 2.55 × 10−4 | 7.02 × 10−7 | −8.82 × 10−6 |

| Climate Change (fossil) [kg CO2 eq.] | 8.27 × 10−1 | 1.98 × 10−4 | 1.62 × 10−4 | 4.30 × 10−3 | 1.91 × 10−4 | 1.06 × 10−4 | 4.20 × 10−3 |

| Climate Change (land use change) [kg CO2 eq.] | 2.25 × 10−4 | 8.91 × 10−7 | 1.19 × 10−7 | 1.94 × 10−7 | 8.80 × 10−7 | 1.30 × 10−7 | 2.20 × 10−7 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 1.25 × 10−4 | 3.45 × 10−4 | 4.25 × 10−3 | 7.68 × 10−4 | 1.90 × 10−4 | 5.57 × 10−3 | |

| Climate Change (biogenic) [kg CO2 eq.] | 1.94 × 10−7 | 6.48 × 10−7 | 1.72 × 10−6 | 5.10 × 10−4 | 1.09 × 10−6 | 1.16 × 10−3 | |

| Climate Change (fossil) [kg CO2 eq.] | 1.24 × 10−4 | 3.44 × 10−4 | 4.25 × 10−3 | 2.57 × 10−4 | 1.89 × 10−4 | 4.42 × 10−3 | |

| Climate Change (land use change) [kg CO2 eq.] | 7.76 × 10−7 | 4.52 × 10−8 | −2.78 × 10−8 | 9.84 × 10−7 | 1.36 × 10−7 | 1.81 × 10−7 | |

| Clay Brick | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 2.35 × 10−1 | 0.00 | 2.57 × 10−3 | 4.69 × 10−3 | 0.00 | 1.67 × 10−3 | 4.08 × 10−3 |

| Climate Change (biogenic) [kg CO2 eq.] | 2.90 × 10−4 | 0.00 | 1.50 × 10−5 | 5.06 × 10−4 | 0.00 | 1.15 × 10−5 | −8.58 × 10−6 |

| Climate Change (fossil) [kg CO2 eq.] | 2.35 × 10−1 | 0.00 | 2.55 × 10−3 | 4.18 × 10−3 | 0.00 | 1.65 × 10−3 | 4.08 × 10−3 |

| Climate Change (land use change) [kg CO2 eq.] | 4.32 × 10−5 | 0.00 | 2.28 × 10−6 | 1.89 × 10−7 | 0.00 | 2.10 × 10−6 | 2.14 × 10−7 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 0.00 | 5.43 × 10−3 | 4.13 × 10−3 | 0.00 | 3.05 × 10−3 | 5.42 × 10−3 | |

| Climate Change (biogenic) [kg CO2 eq.] | 0.00 | 1.57 × 10−5 | 1.67 × 10−6 | 0.00 | 2.25 × 10−5 | 1.12 × 10−3 | |

| Climate Change (fossil) [kg CO2 eq.] | 0.00 | 5.41 × 10−3 | 4.13 × 10−3 | 0.00 | 3.03 × 10−3 | 4.30 × 10−3 | |

| Climate Change (land use change) [kg CO2 eq.] | 0.00 | 1.62 × 10−6 | −2.71 × 10−8 | 0.00 | 3.02 × 10−6 | 1.76 × 10−7 | |

| Ceramic Facade Panel | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 1.13 | 2.81 × 10−4 | 1.26 × 10−4 | 2.22 × 10−4 | 2.42 × 10−4 | 7.15 × 10−5 | 1.93 × 10−4 |

| Climate Change (biogenic) [kg CO2 eq.] | 0.00 | 2.07 × 10−5 | 6.16 × 10−7 | 2.40 × 10−5 | −9.20 × 10−7 | 4.68 × 10−7 | −4.07 × 10−7 |

| Climate Change (fossil) [kg CO2 eq.] | 1.13 | 2.61 × 10−4 | 1.26 × 10−4 | 1.98 × 10−4 | 2.44 × 10−4 | 7.10 × 10−5 | 1.94 × 10−4 |

| Climate Change (land use change) [kg CO2 eq.] | 0.00 | −8.55 × 10−7 | 8.09 × 10−8 | 8.95 × 10−9 | −9.38 × 10−7 | 8.64 × 10−8 | 1.01 × 10−8 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 3.78 × 10−4 | 2.30 × 10−4 | 1.96 × 10−4 | 9.23 × 10−4 | 1.27 × 10−4 | 2.57 × 10−4 | |

| Climate Change (biogenic) [kg CO2 eq.] | −7.10 × 10−7 | 4.32 × 10−7 | 7.93 × 10−8 | 4.31 × 10−4 | 7.27 × 10−7 | 5.33 × 10−5 | |

| Climate Change (fossil) [kg CO2 eq.] | 3.79 × 10−4 | 2.29 × 10−4 | 1.96 × 10−4 | 4.92 × 10−4 | 1.26 × 10−4 | 2.04 × 10−4 | |

| Climate Change (land use change) [kg CO2 eq.] | −1.13 × 10−7 | 3.02 × 10−8 | −1.28 × 10−9 | 6.26 × 10−8 | 9.04 × 10−8 | 8.34 × 10−9 | |

| Paint Emulsion | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 1.95 | 5.21 × 10−2 | 1.05 × 10−4 | 7.03 × 10−3 | 3.00 × 10−2 | 5.96 × 10−5 | 6.11 × 10−3 |

| Climate Change (biogenic) [kg CO2 eq.] | 1.10 × 10−2 | 2.91 × 10−4 | 5.13 × 10−7 | 7.59 × 10−4 | 2.02 × 10−4 | 3.90 × 10−7 | −1.29 × 10−5 |

| Climate Change (fossil) [kg CO2 eq.] | 1.94 | 5.17 × 10−2 | 1.05 × 10−4 | 6.27 × 10−3 | 2.97 × 10−2 | 5.92 × 10−5 | 6.13 × 10−3 |

| Climate Change (land use change) [kg CO2 eq.] | 1.87 × 10−3 | 3.73 × 10−5 | 6.74 × 10−8 | 2.83 × 10−7 | 3.69 × 10−5 | 7.20 × 10−8 | 3.21 × 10−7 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 9.53 × 10−2 | 1.92 × 10−4 | 6.20 × 10−3 | 5.19 × 10−2 | 1.06 × 10−4 | 8.13 × 10−3 | |

| Climate Change (biogenic) [kg CO2 eq.] | 2.24 × 10−4 | 3.60 × 10−7 | 2.51 × 10−6 | 3.48 × 10−4 | 6.06 × 10−7 | 1.69 × 10−3 | |

| Climate Change (fossil) [kg CO2 eq.] | 9.50 × 10−2 | 1.91 × 10−4 | 6.20 × 10−3 | 5.16 × 10−2 | 1.05 × 10−4 | 6.44 × 10−3 | |

| Climate Change (land use change) [kg CO2 eq.] | 1.69 × 10−5 | 2.51 × 10−8 | −4.06 × 10−8 | 4.23 × 10−5 | 7.53 × 10−8 | 2.64 × 10−7 | |

| Mineral Wool | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 1.46 | 0.00 | 9.98 × 10−3 | 2.52 × 10−3 | 0.00 | 5.65 × 10−3 | 2.19 × 10−3 |

| Climate Change (biogenic) [kg CO2 eq.] | 6.31 × 10−3 | 0.00 | 4.86 × 10−5 | 2.72 × 10−4 | 0.00 | 3.69 × 10−5 | −4.62 × 10−6 |

| Climate Change (fossil) [kg CO2 eq.] | 1.45 | 0.00 | 9.93 × 10−3 | 2.25 × 10−3 | 0.00 | 5.61 × 10−3 | 2.20 × 10−3 |

| Climate Change (land use change) [kg CO2 eq.] | 1.01 × 10−3 | 0.00 | 6.39 × 10−6 | 1.02 × 10−7 | 0.00 | 6.82 × 10−6 | 1.15 × 10−7 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 0.00 | 1.81 × 10−2 | 2.23 × 10−3 | 0.00 | 1.00 × 10−2 | 2.92 × 10−3 | |

| Climate Change (biogenic) [kg CO2 eq.] | 0.00 | 3.41 × 10−5 | 9.00 × 10−7 | 0.00 | 5.74 × 10−5 | 6.05 × 10−4 | |

| Climate Change (fossil) [kg CO2 eq.] | 0.00 | 1.81 × 10−2 | 2.22 × 10−3 | 0.00 | 9.96 × 10−3 | 2.31 × 10−3 | |

| Climate Change (land use change) [kg CO2 eq.] | 0.00 | 2.38 × 10−6 | −1.46 × 10−8 | 0.00 | 7.14 × 10−6 | 9.48 × 10−8 | |

| Roof Tile | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 3.33 × 10−1 | 0.00 | 2.94 × 10−2 | 6.27 × 10−4 | 0.00 | 1.66 × 10−2 | 5.45 × 10−4 |

| Climate Change (biogenic) [kg CO2 eq.] | 1.08 × 10−3 | 0.00 | 1.43 × 10−4 | 6.77 × 10−5 | 0.00 | 1.09 × 10−4 | −1.15 × 10−6 |

| Climate Change (fossil) [kg CO2 eq.] | 3.31 × 10−1 | 0.00 | 2.92 × 10−2 | 5.60 × 10−4 | 0.00 | 1.65 × 10−2 | 5.46 × 10−4 |

| Climate Change (land use change) [kg CO2 eq.] | 1.98 × 10−4 | 0.00 | 1.88 × 10−5 | 2.53 × 10−8 | 0.00 | 2.01 × 10−5 | 2.86 × 10−8 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 0.00 | 5.34 × 10−2 | 5.53 × 10−4 | 0.00 | 2.95 × 10−2 | 7.25 × 10−4 | |

| Climate Change (biogenic) [kg CO2 eq.] | 0.00 | 1.00 × 10−4 | 2.24 × 10−7 | 0.00 | 1.69 × 10−4 | 1.50 × 10−4 | |

| Climate Change (fossil) [kg CO2 eq.] | 0.00 | 5.33 × 10−2 | 5.53 × 10−4 | 0.00 | 2.93 × 10−2 | 5.75 × 10−4 | |

| Climate Change (land use change) [kg CO2 eq.] | 0.00 | 7.01 × 10−6 | −3.62 × 10−9 | 0.00 | 2.10 × 10−5 | 2.36 × 10−8 | |

| Mineral Reinforcement Mortar | CZ EoL Mix | Material Recovery | |||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 4.00 × 10−1 | 4.19 × 10−4 | 1.90 × 10−4 | 5.63 × 10−3 | 3.88 × 10−4 | 1.07 × 10−4 | 4.89 × 10−3 |

| Climate Change (biogenic) [kg CO2 eq.] | 0.00 | 2.46 × 10−4 | 9.23 × 10−7 | 6.07 × 10−4 | 2.22 × 10−4 | 7.02 × 10−7 | −1.03 × 10−5 |

| Climate Change (fossil) [kg CO2 eq.] | 4.00 × 10−1 | 1.72 × 10−4 | 1.89 × 10−4 | 5.02 × 10−3 | 1.66 × 10−4 | 1.06 × 10−4 | 4.90 × 10−3 |

| Climate Change (land use change) [kg CO2 eq.] | 0.00 | 7.75 × 10−7 | 1.21 × 10−7 | 2.26 × 10−7 | 7.65 × 10−7 | 1.30 × 10−7 | 2.57 × 10−7 |

| Energy Recovery | Landfilling | ||||||

| Prim. | Sec. | Ter. | Prim. | Sec. | Ter. | ||

| Climate Change [kg CO2 eq.] | 1.09 × 10−4 | 3.45 × 10−4 | 4.96 × 10−3 | 6.68 × 10−4 | 1.90 × 10−4 | 6.50 × 10−3 | |

| Climate Change (biogenic) [kg CO2 eq.] | 1.69 × 10−7 | 6.48 × 10−7 | 2.01 × 10−6 | 4.43 × 10−4 | 1.09 × 10−6 | 1.35 × 10−3 | |

| Climate Change (fossil) [kg CO2 eq.] | 1.08 × 10−4 | 3.44 × 10−4 | 4.96 × 10−3 | 2.23 × 10−4 | 1.89 × 10−4 | 5.15 × 10−3 | |

| Climate Change (land use change) [kg CO2 eq.] | 6.75 × 10−7 | 4.52 × 10−8 | −3.25 × 10−8 | 8.55 × 10−7 | 1.36 × 10−7 | 2.11 × 10−7 | |

| Product System (Including Packaging) | Mean Value of the Climate Change (Total) Indicator [kg CO2 eq.] | Standard Deviation [%] |

|---|---|---|

| Aerated concrete block element | 0.49 | 0.009 |

| Expanded polystyrene | 3.16 | 0.093 |

| Gypsum plasterboard | 0.21 | 0.030 |

| Cement | 0.83 | 0.008 |

| Clay brick | 0.24 | 0.041 |

| Ceramic facade panel | 1.13 | 0.002 |

| Paint emmulsion | 2.01 | 0.042 |

| Mineral Wool | 1.47 | 0.011 |

| Roof tile | 0.36 | 0.130 |

| Mineral reinforcement mortar | 0.41 | 0.018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pešta, J.; Šerešová, M.; Kočí, V. Carbon Footprint Assessment of Construction Waste Packaging Using the Package-to-Product Indicator. Sustainability 2020, 12, 10094. https://doi.org/10.3390/su122310094

Pešta J, Šerešová M, Kočí V. Carbon Footprint Assessment of Construction Waste Packaging Using the Package-to-Product Indicator. Sustainability. 2020; 12(23):10094. https://doi.org/10.3390/su122310094

Chicago/Turabian StylePešta, Jan, Markéta Šerešová, and Vladimír Kočí. 2020. "Carbon Footprint Assessment of Construction Waste Packaging Using the Package-to-Product Indicator" Sustainability 12, no. 23: 10094. https://doi.org/10.3390/su122310094

APA StylePešta, J., Šerešová, M., & Kočí, V. (2020). Carbon Footprint Assessment of Construction Waste Packaging Using the Package-to-Product Indicator. Sustainability, 12(23), 10094. https://doi.org/10.3390/su122310094