1. Introduction

Day by day, severe traffic conditions, such as more traffic volume and loads based on industry developments, are becoming critical to asphalt pavements. Global warming is also one of the factors which accelerates asphalt pavement deterioration. As such, traffic volume, traffic load, and weather conditions are factors that have a significant influence on the defects of asphalt pavements [

1,

2]. Due to limited budget and time, achieving a more extended service period of asphalt pavements is one of the transportation industry’s primary goals. It can significantly reduce maintenance cost and time. In general, three types of failure mode are considered: rutting, fatigue cracking, and thermal cracking. Even though all kinds of deficiencies are critical to the pavement service life, cracking has more impact on reducing pavement service life, eventually leading to a severe failure mode of the asphalt pavement [

3]. There are two types of cracking: (i) fatigue and (ii) thermal cracking. In general, fatigue cracking occurs due to repetitive traffic loads at an intermediate temperature, and thermal cracking is due to a rapid temperature change and cycle. As a result, it is necessary to develop a sustainable asphalt binder which is highly resistant to cracking under intermediate temperatures.

Several kinds of polymer additives have been utilized to produce durable asphalt binders. Thermoplastic polyurethane (TPU) is a type of polymer with rigid and flexible properties based on a molecule that contains hard and soft segments [

4]. TPU has been widely used in many fields, mainly in foam plastics, elastomers, and adhesives [

5,

6,

7]. TPU can improve the flexibility as well as the strength of a modified asphalt system as a polymer modifier [

8,

9]. Its compatibility can also be enhanced through the reaction of the functional group of TPU with the fundamental asphalt component to improve the rheological properties considering rutting and cracking performances [

10,

11,

12]. There are few research works that have been conducted on TPU-modified asphalt binders.

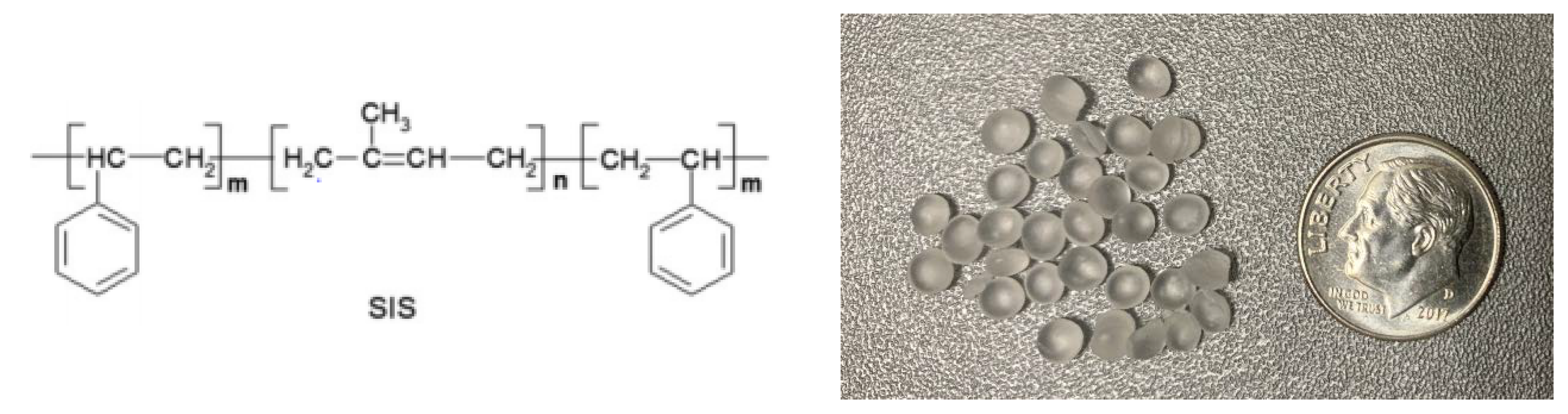

Styrene-isoprene-styrene (SIS) is relatively new and is considered a potential additive to overcome the challenge of pavement problems [

13,

14]. The molecular chain of isoprene increases the complex modulus of SIS at high temperatures. It has better toughness and compatibility with other materials due to the branched methyl of the isoprene group [

15,

16]. SIS dispersion in asphalt binders is relatively homogeneous, though it requires specific temperature control and mixing times. The molecular structure of an asphalt binder can be modified by completely dispersed polymers [

17]. Even though SIS addition is beneficial to produce a more robust binder, it increases binder viscosity. Furthermore, it has problems such as high fuel consumption and poor workability due to the high melting temperature. In addition, the percentage increase in polymer additives does not significantly improve cracking properties compared to rutting properties. Thus, there is a need to increase the content to have better cracking resistance and, at the same time, maintain binders with less viscosity.

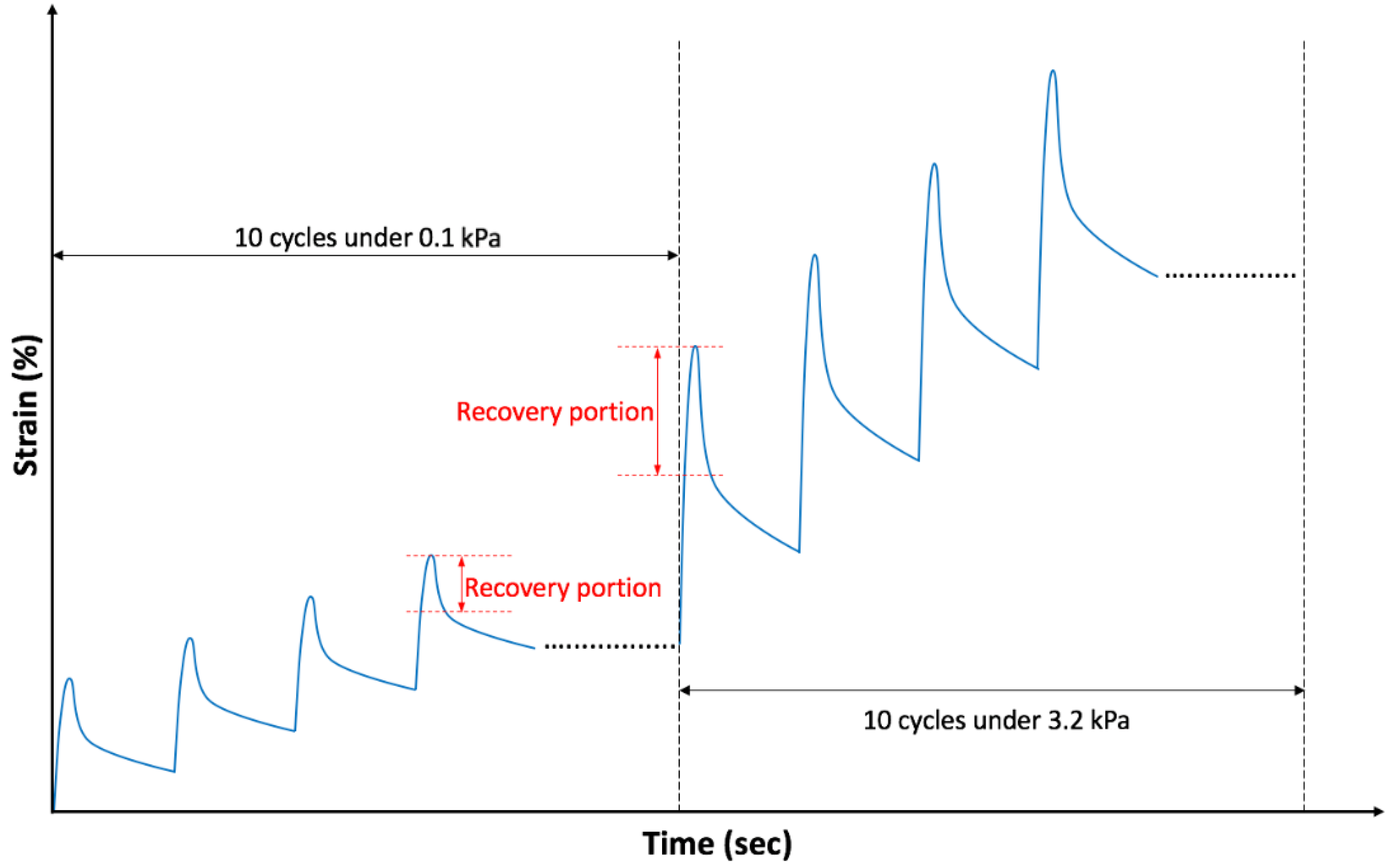

The purpose of this study is to evaluate the performance characteristics of sustainable polymer-modified asphalt (PMA) binders containing TPU and SIS. The rolling thin film oven (RTFO) and pressure aging vessel (PAV) procedures were applied to produce artificially aged binder samples. A series of Superpave binder tests were carried out to investigate the PMA binders in three aging states (original, short aging, and long aging). Additionally, the multiple stress creep recovery (MSCR) test was used to assess the deformation properties of SIS-modified binders with TPU more effectively.

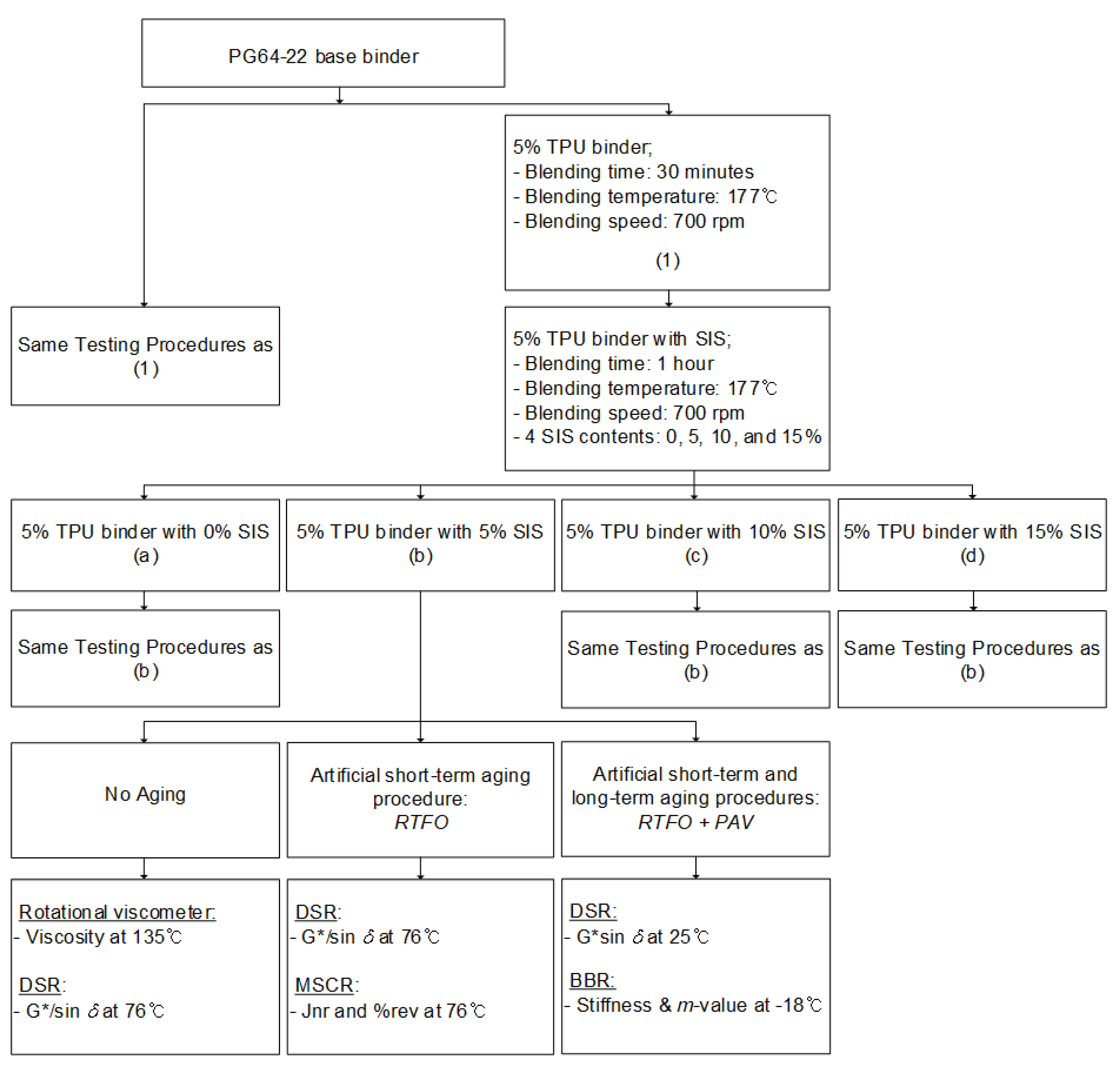

Figure 1 shows the research procedure.

4. Summary and Conclusions

The performance characteristics of polymer-modified asphalt binders, improved by the addition of TPU and SIS, were evaluated. The study was conducted with a 5% TPU content set, and three different percentages of SIS contents were applied. All binders were prepared by a wet process and aged using RTFO and PAV. A series of Superpave asphalt binder tests were performed using a rotational viscometer, DSR, and BBR in order to evaluate the physical and rheological properties of the binders. In addition, the plastic deformation characteristics were assessed through an MSCR test. From the results, the following conclusions were drawn:

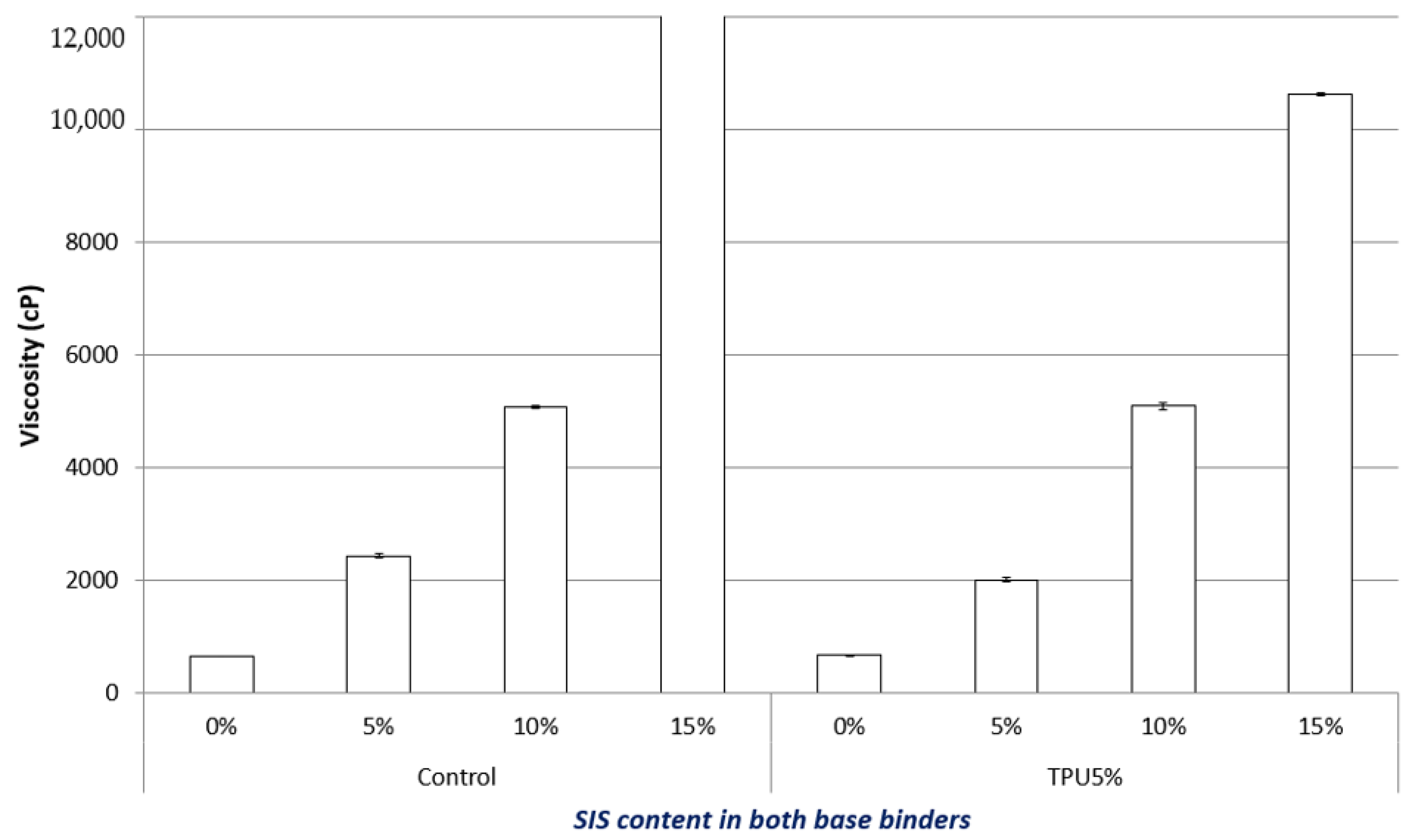

The SIS modifier significantly increased the binder viscosity, but the addition of TPU had an insignificant effect on viscosity. This means that unlike conventional polymeric materials, TPU makes it possible to produce improved mixtures without increasing the binder viscosity.

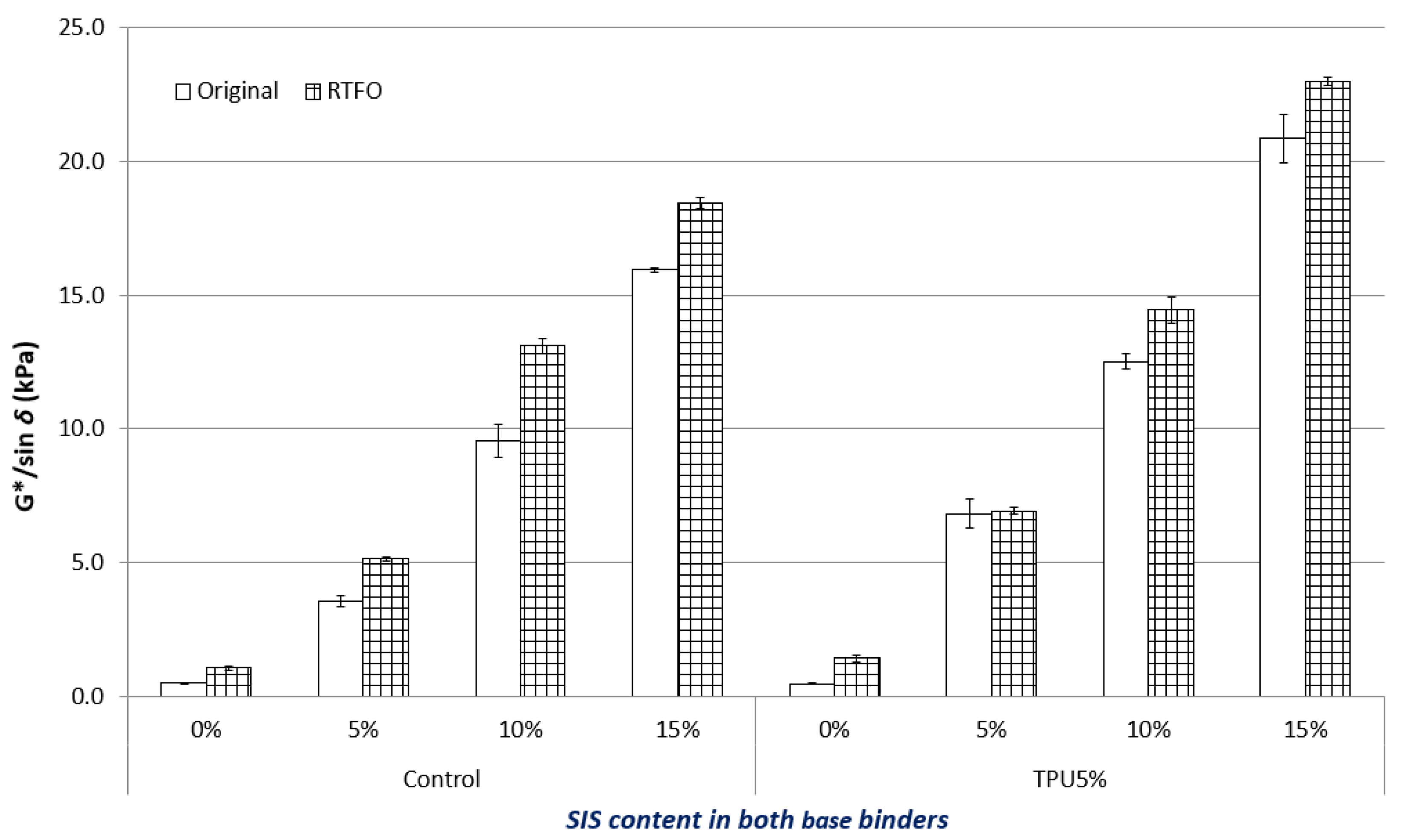

The results of G*/sin δ values showed that the addition of TPU and SIS significantly improved the rutting resistance of the PMA binders.

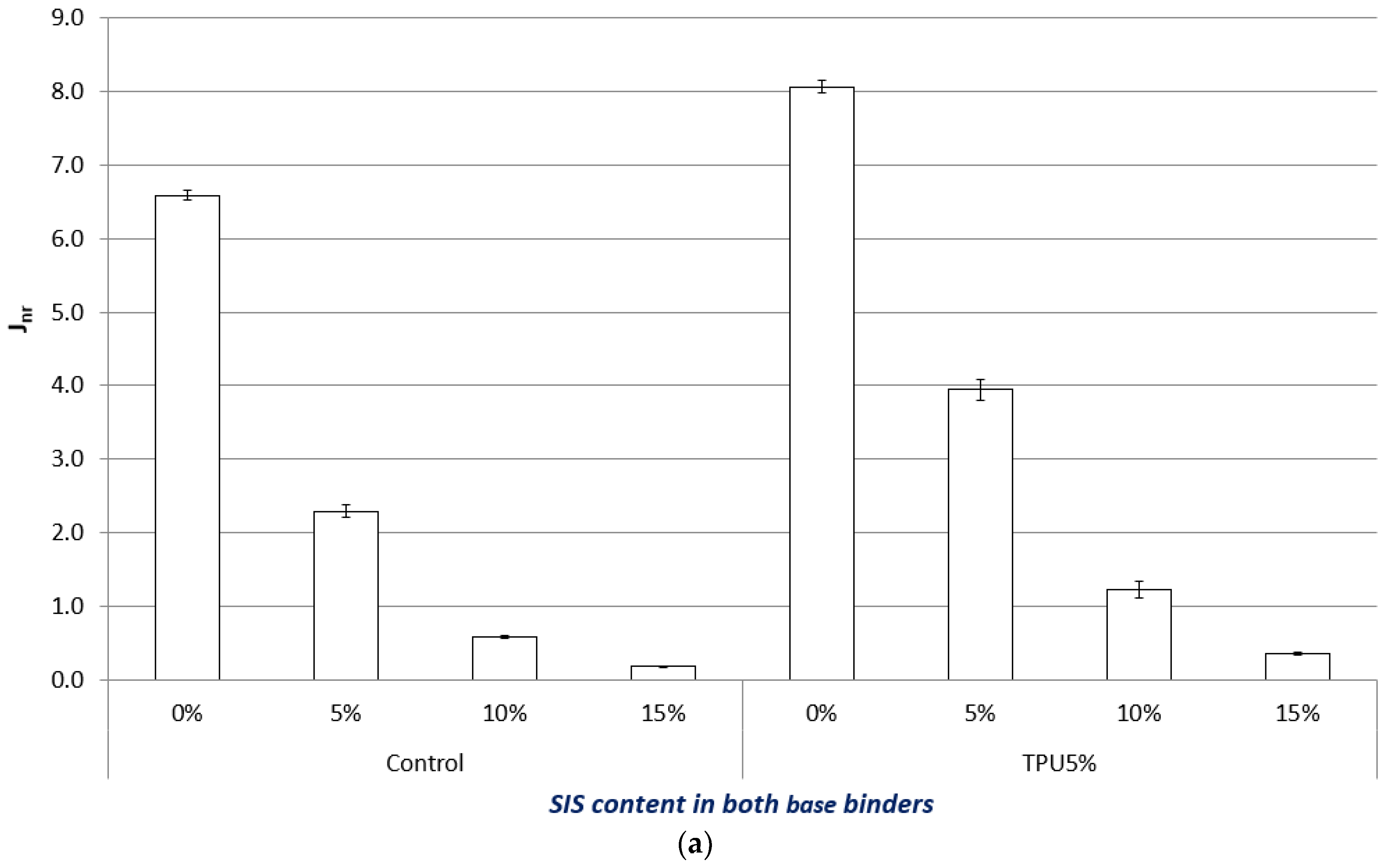

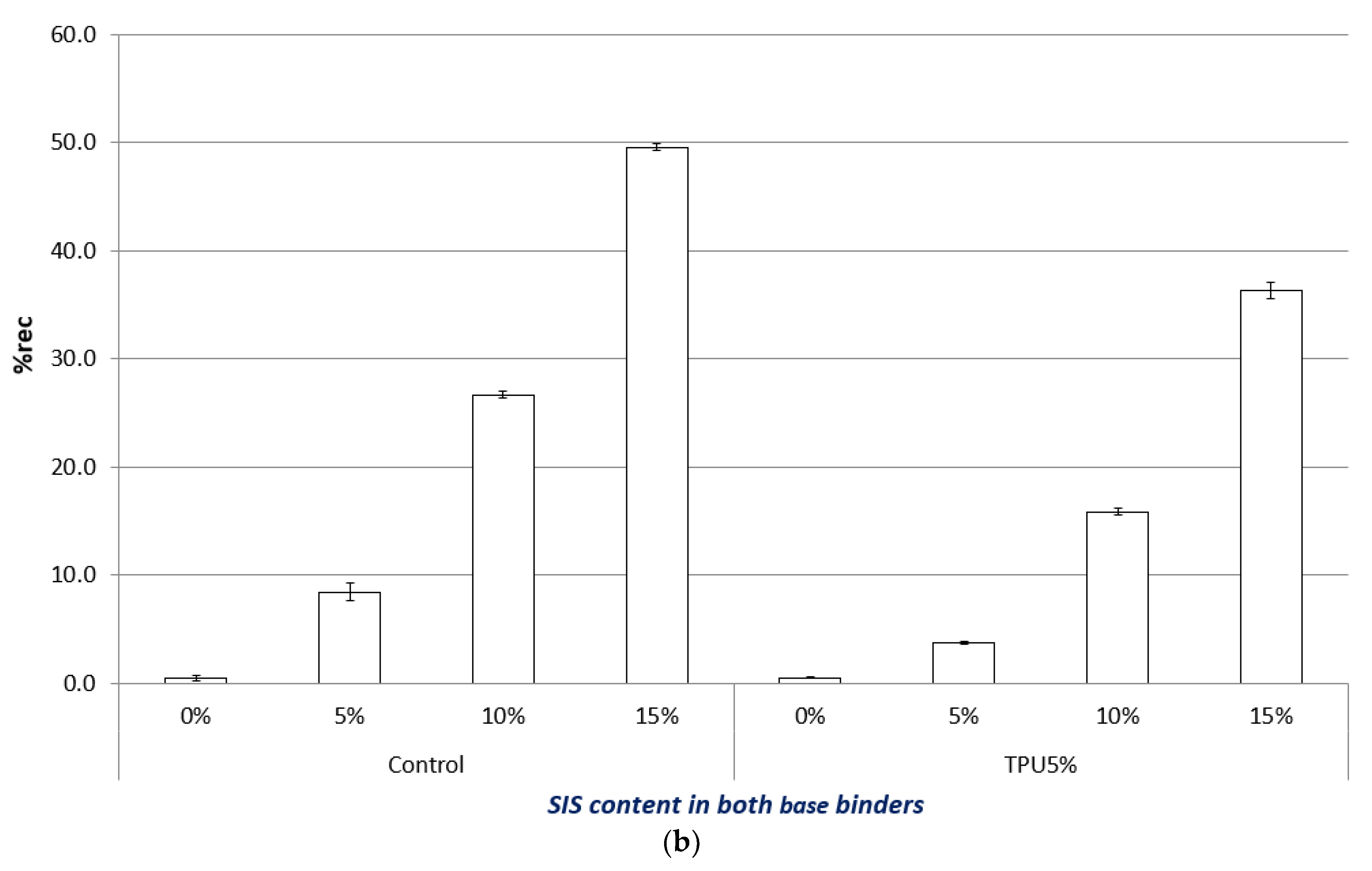

In the MSCR test results, as the SIS content increased, the Jnr value significantly decreased. Furthermore, it was observed that TPU had little influence on improving binder elasticity.

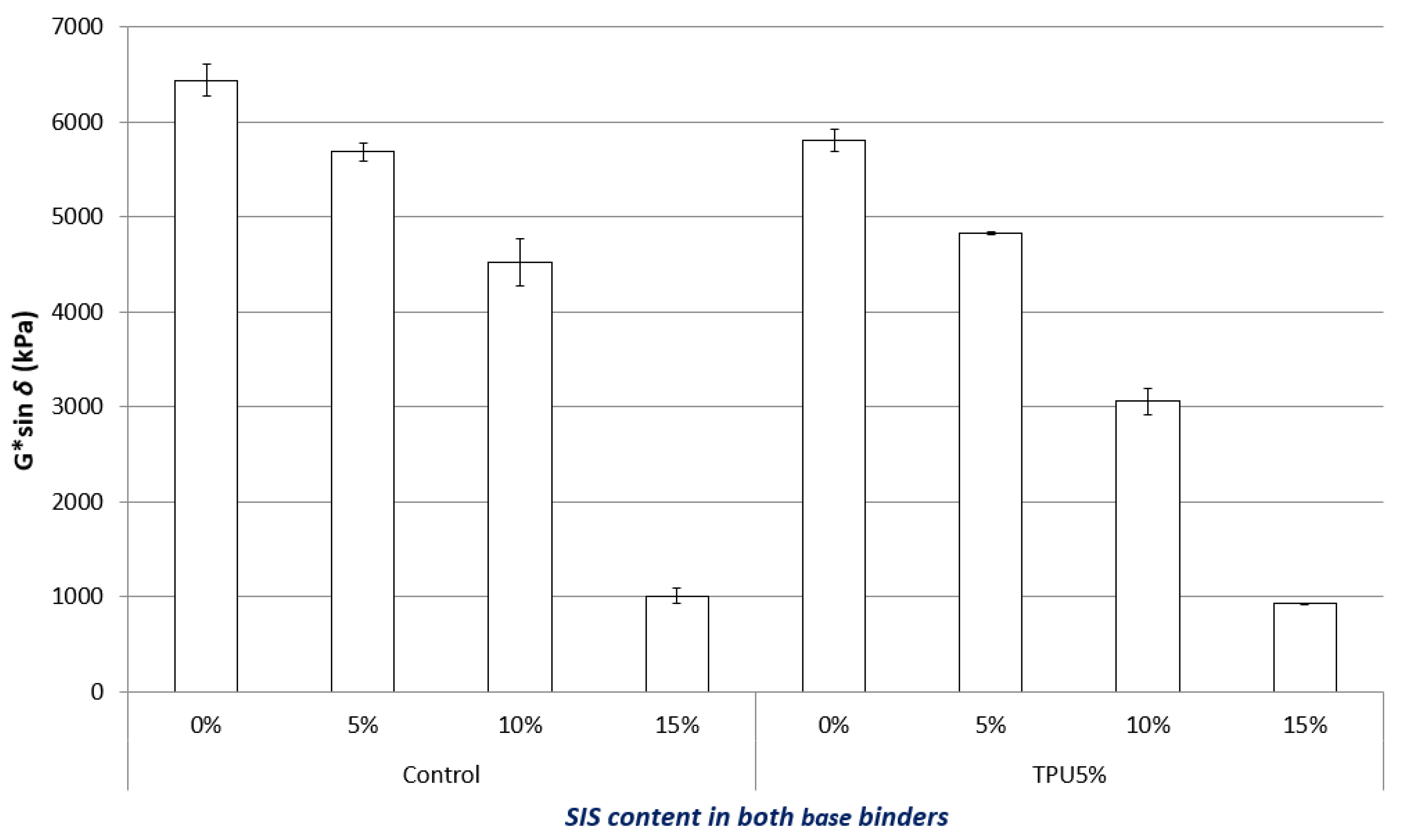

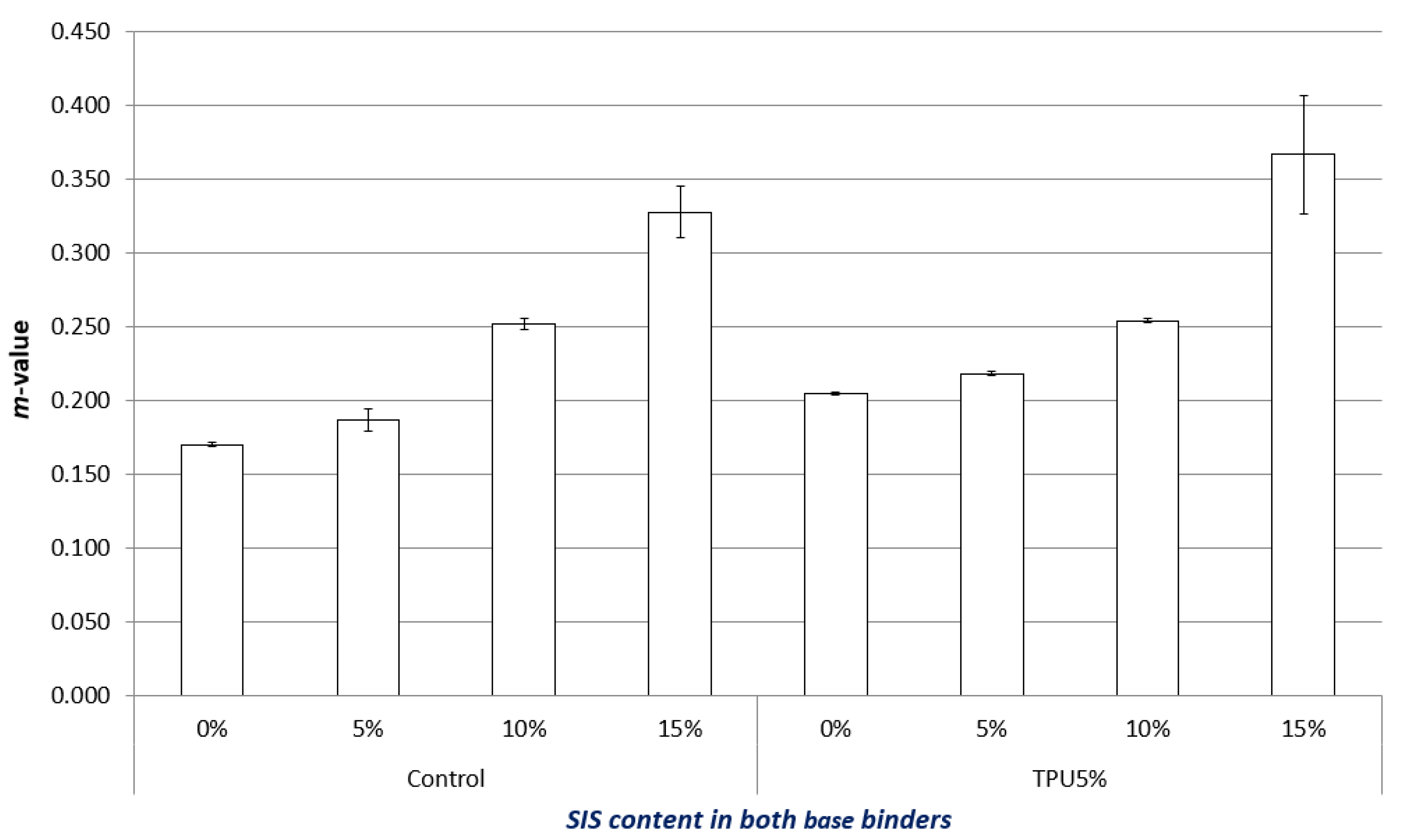

The fatigue cracking results showed that both polymer materials of TPU and SIS are effective in improving crack resistance at intermediate temperature.

According to the results of the BBR test measured at −18 °C, the stiffness value was found to decrease with 5% TPU and the higher percentage of SIS. It indicated that both additives have a positive effect on low temperature cracking property.

Through the overall results, both additives were found to upgrade the performance of the base binder. It is considered that the blending of the two polymer modifiers increased the elongation and tensile strength of the binder.

TPU is a polyester-based material with excellent wear resistance, low-temperature properties, and high hardness as an elastomer with perfect thermoplastic properties; on the other hand, SIS (styrene-b-isoprene-b-styrene) has isoprene as a rubbery midblock. The SIS molecule chain is composed of isoprene. It increases the complex modulus at high temperatures, and due to its branch methyl in the isoprene group, it has better tenacity and compatibility with other materials. Due to that, it can be observed that the addition of 5% TPU improved the rutting and cracking properties when added with SIS, without increasing the viscosity. The use of polymer modifiers results in the increase in binder and mixture viscosity properties, which leads to a decrease in workability during production and paving operations. TPU can be a good material to overcome this challenge.