Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs

Abstract

1. Introduction

2. Experimental Program; A Brief Description

3. Half-shaped Slab Configuration, Preparing, Casting Process and Production

3.1. Preparing, and Casting Process and Production

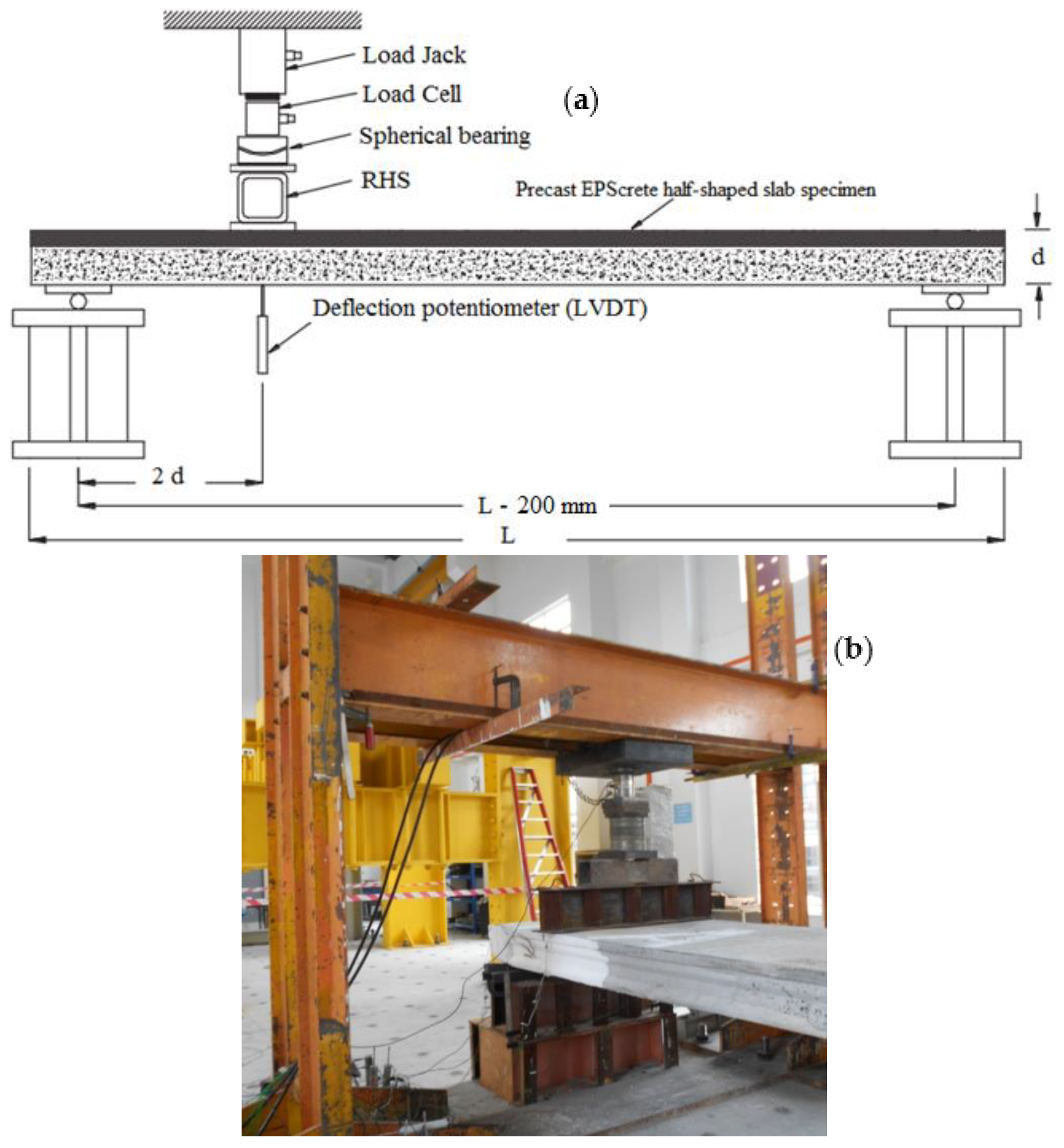

3.2. Arrangement, Instrumenting and Setup of Shear Test

4. Results and Discussions

4.1. Properties of EPS-foam Concrete

4.2. Precast EPS-foam Concrete Half-Shaped Slabs

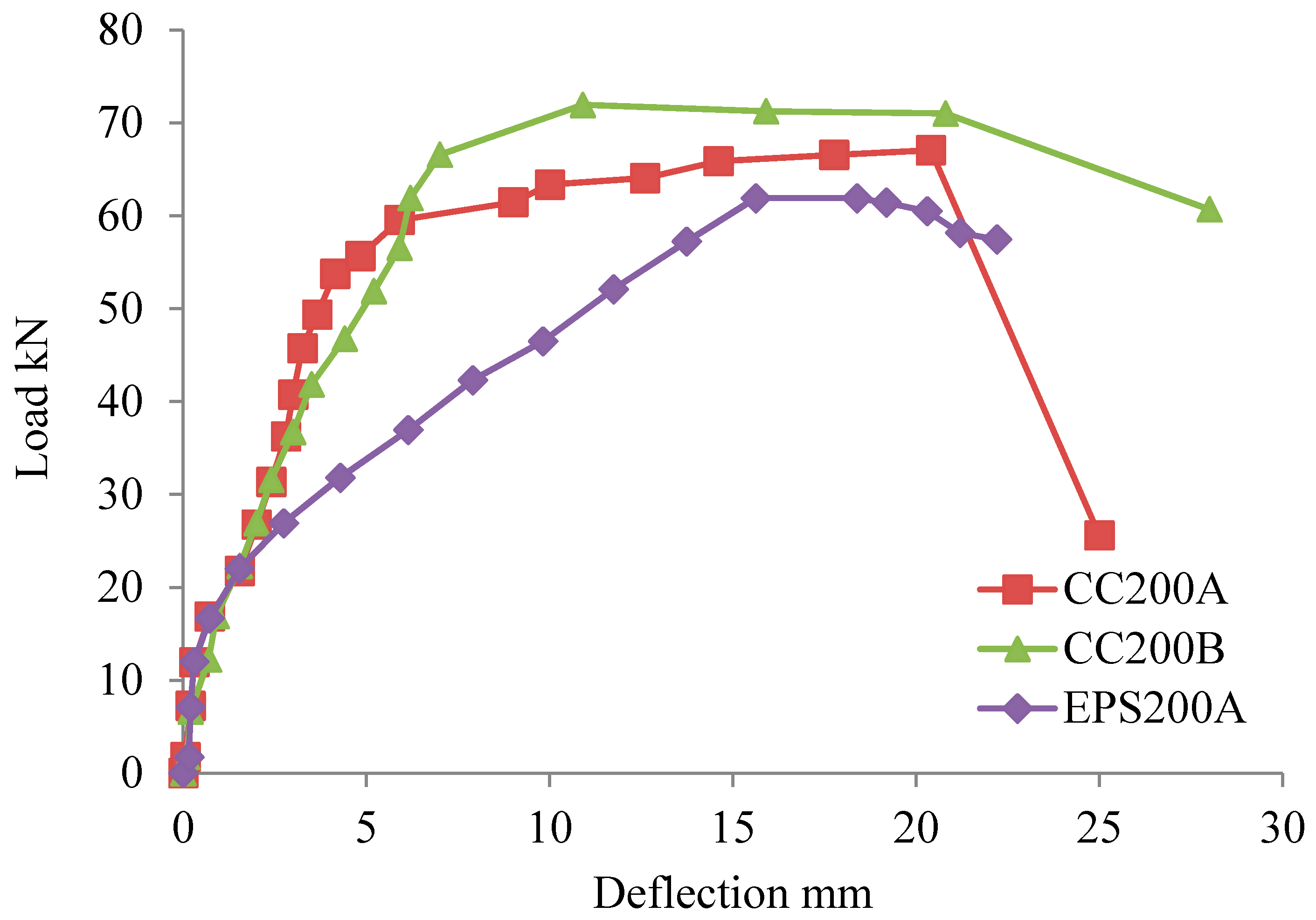

4.2.1. Load-Deflection Profiles

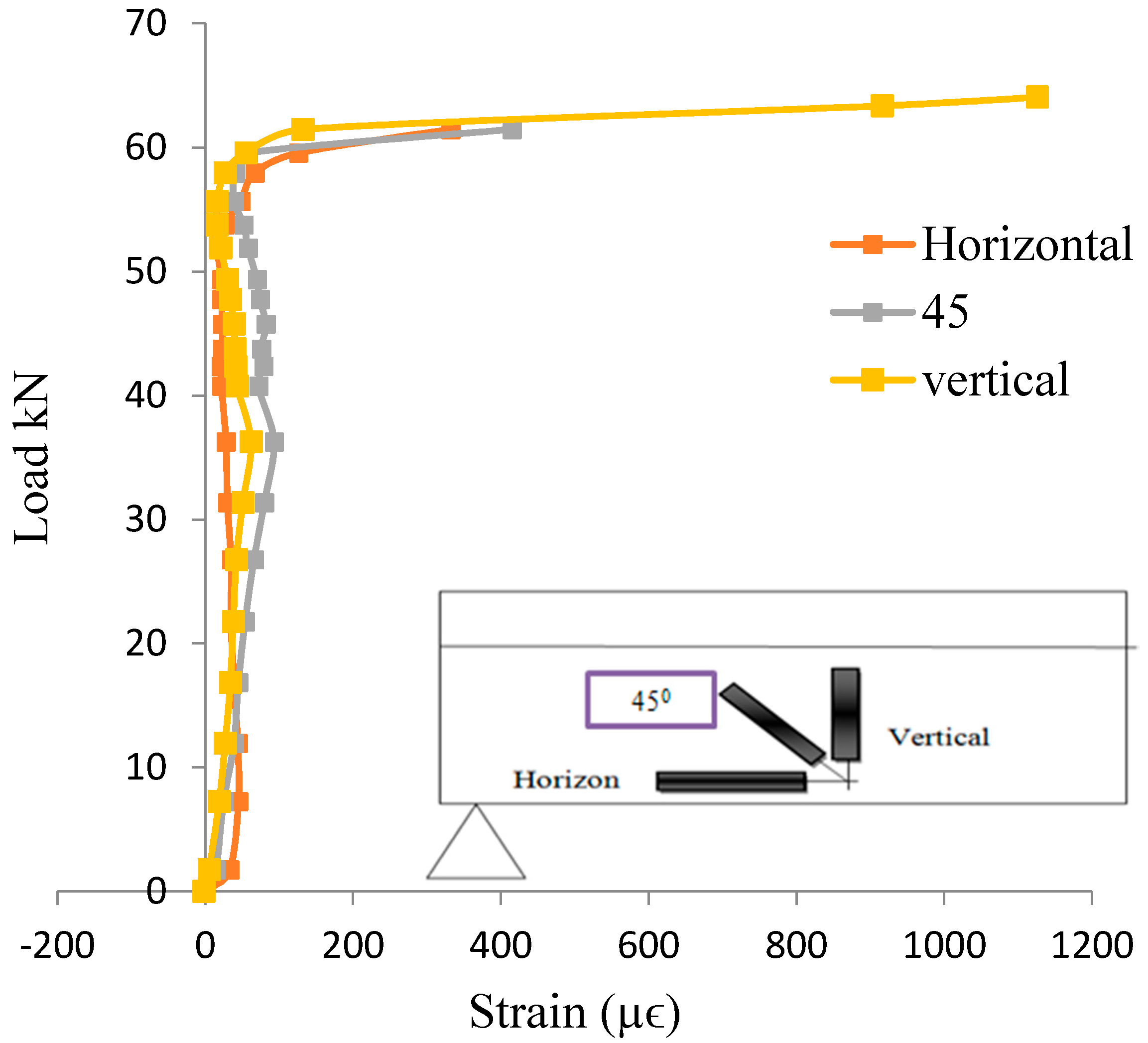

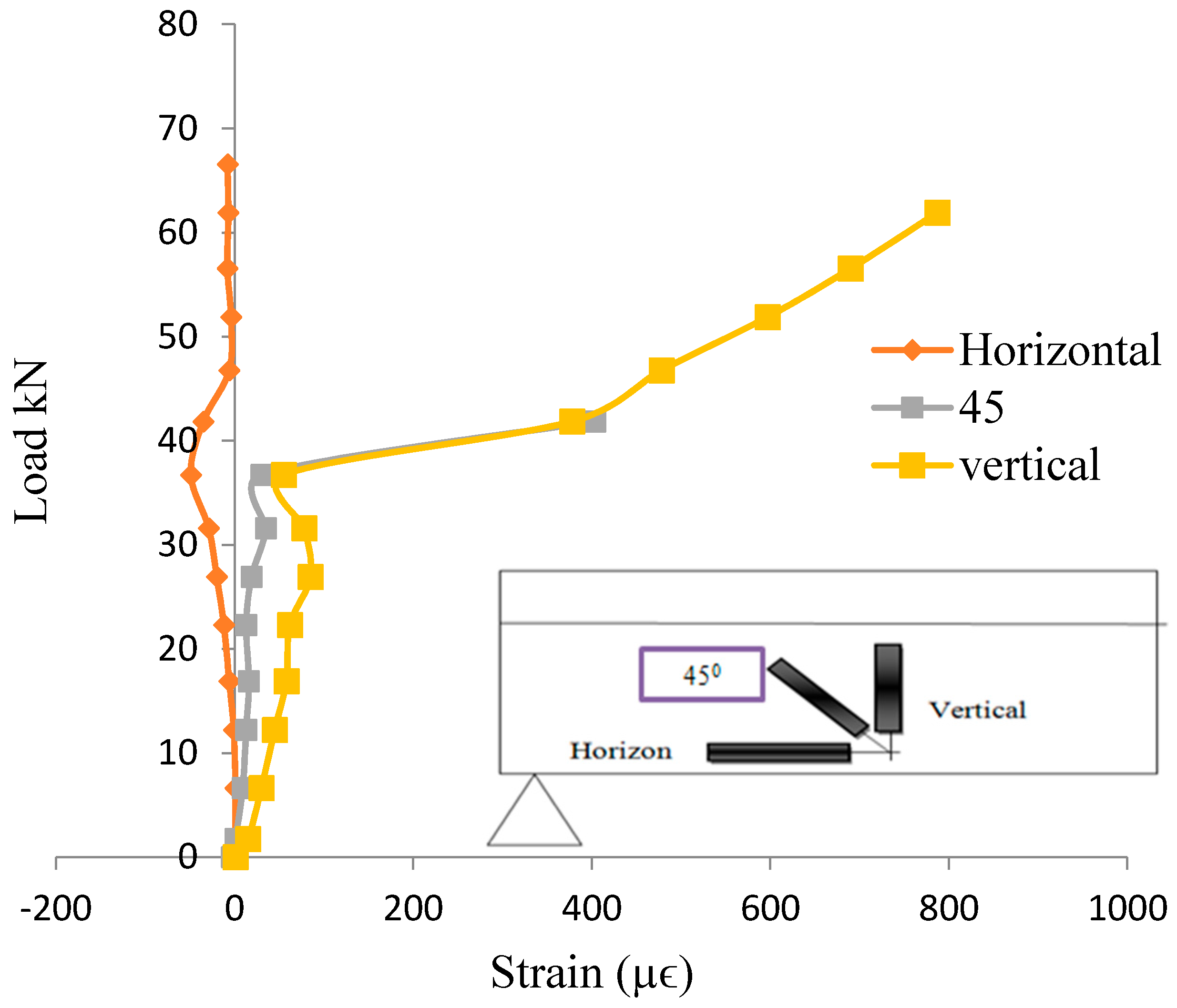

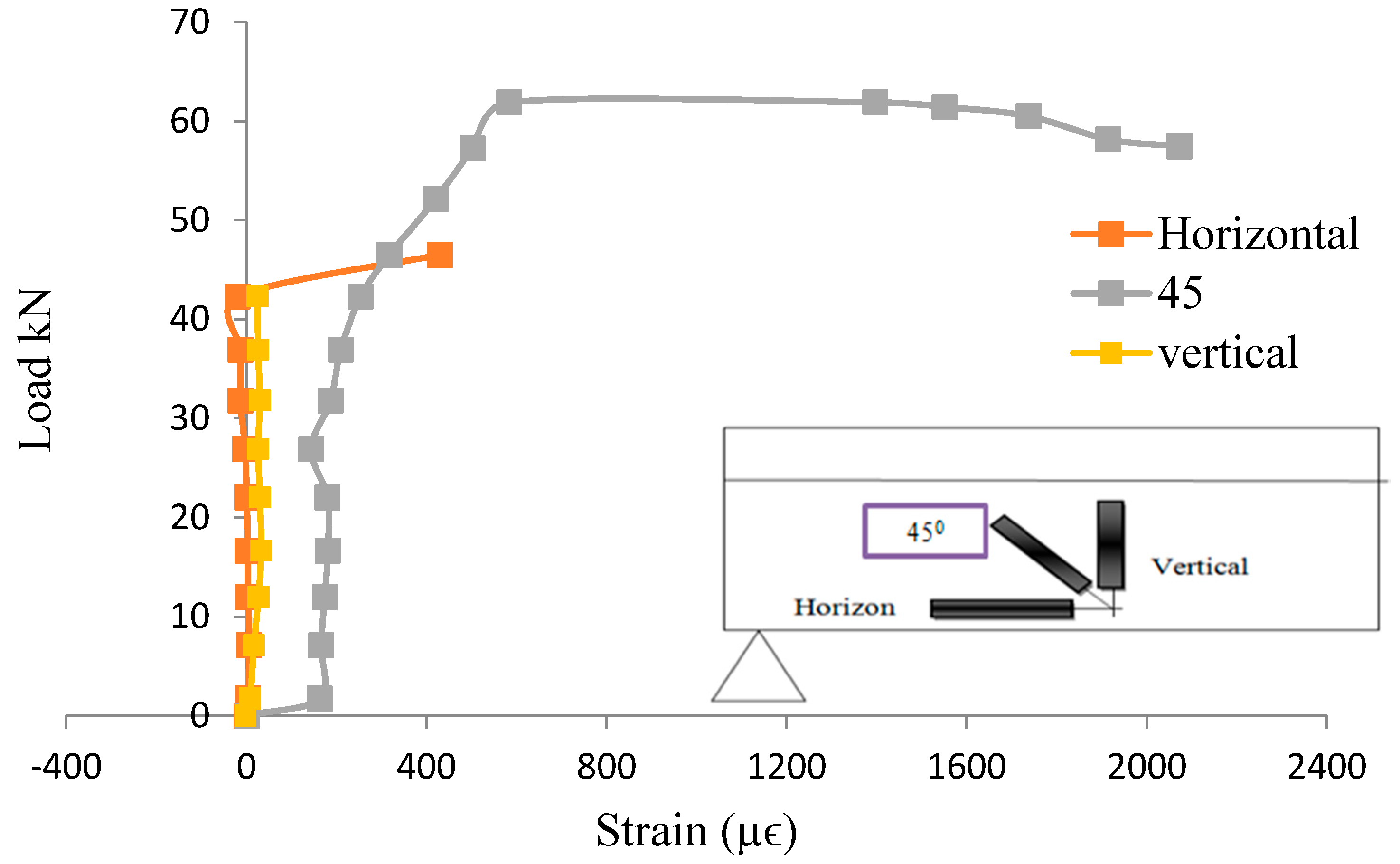

4.2.2. Concrete Strain Curves

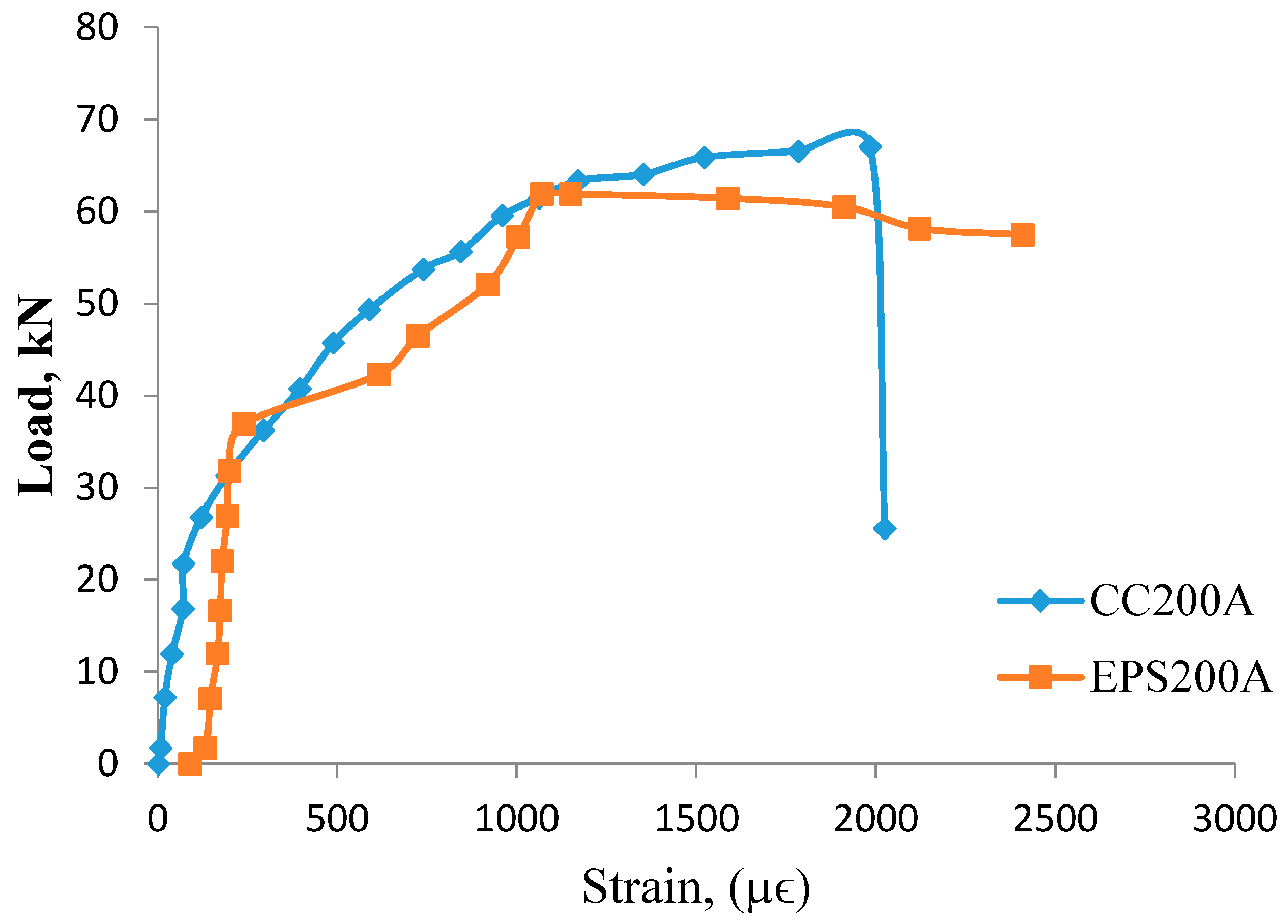

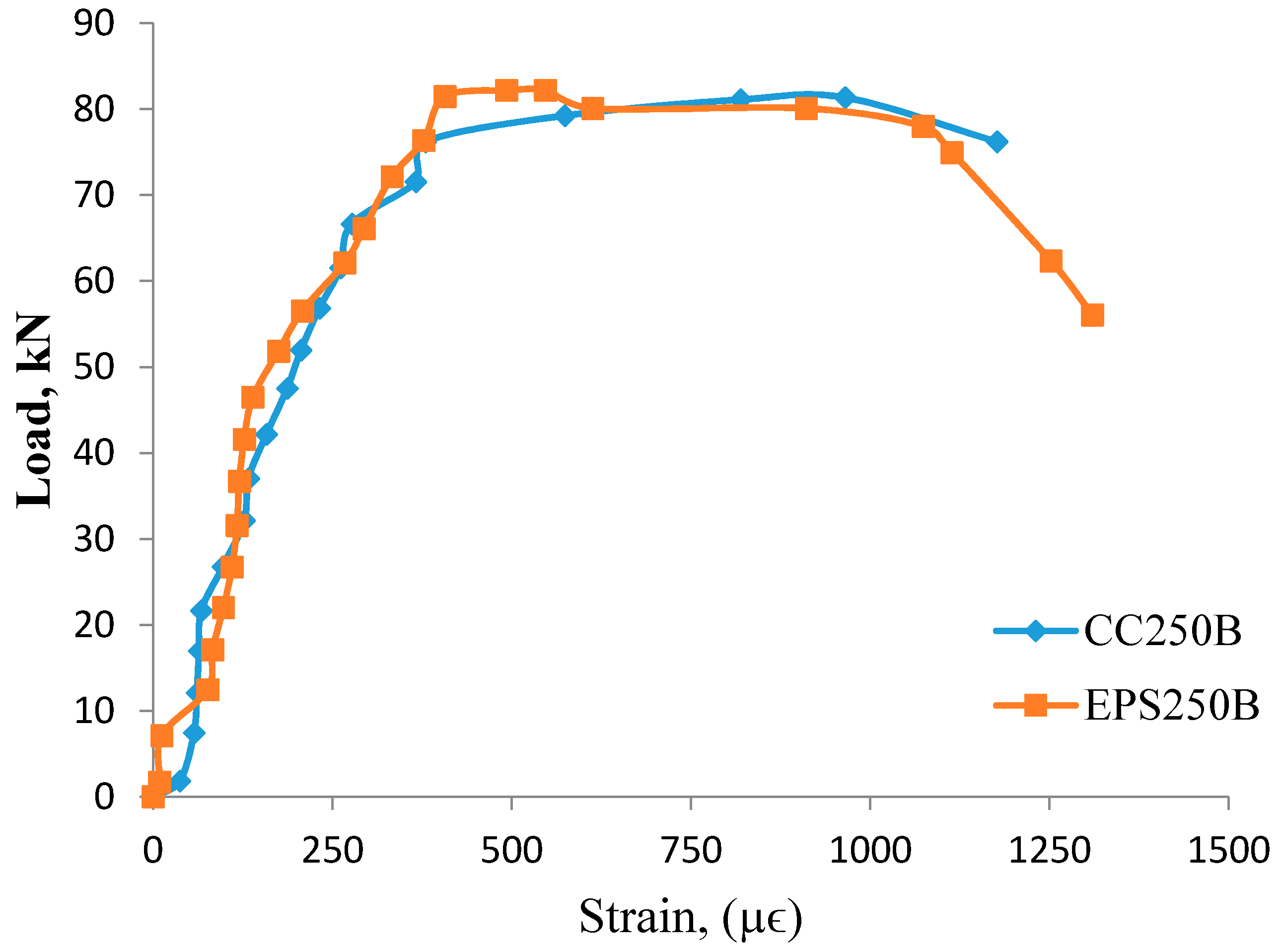

4.2.3. Steel Bar Strain Curves

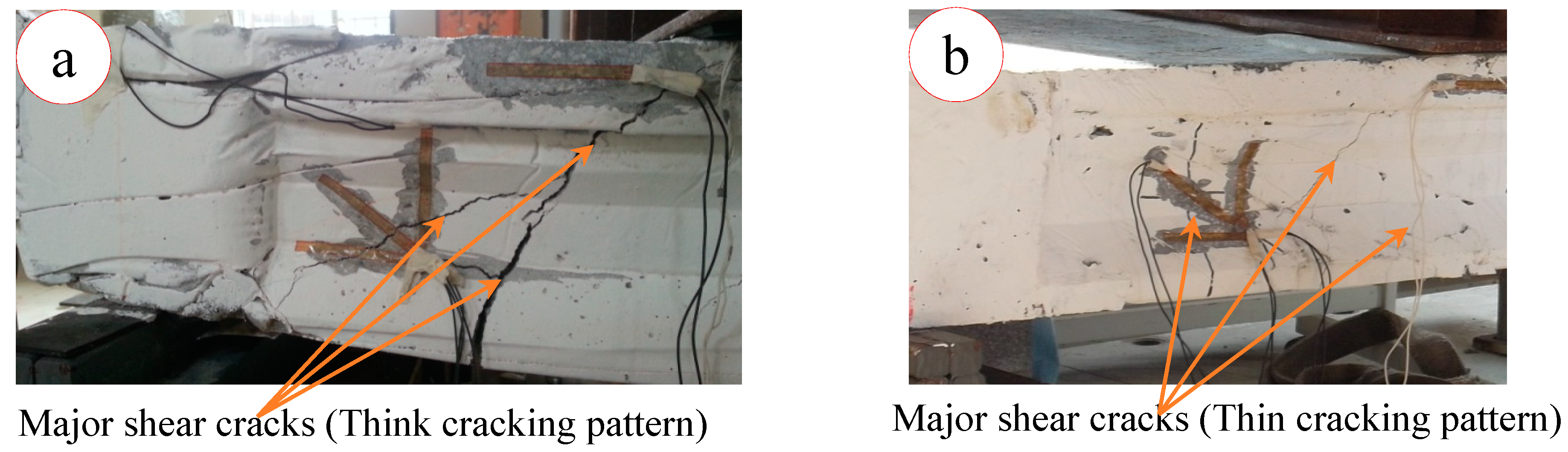

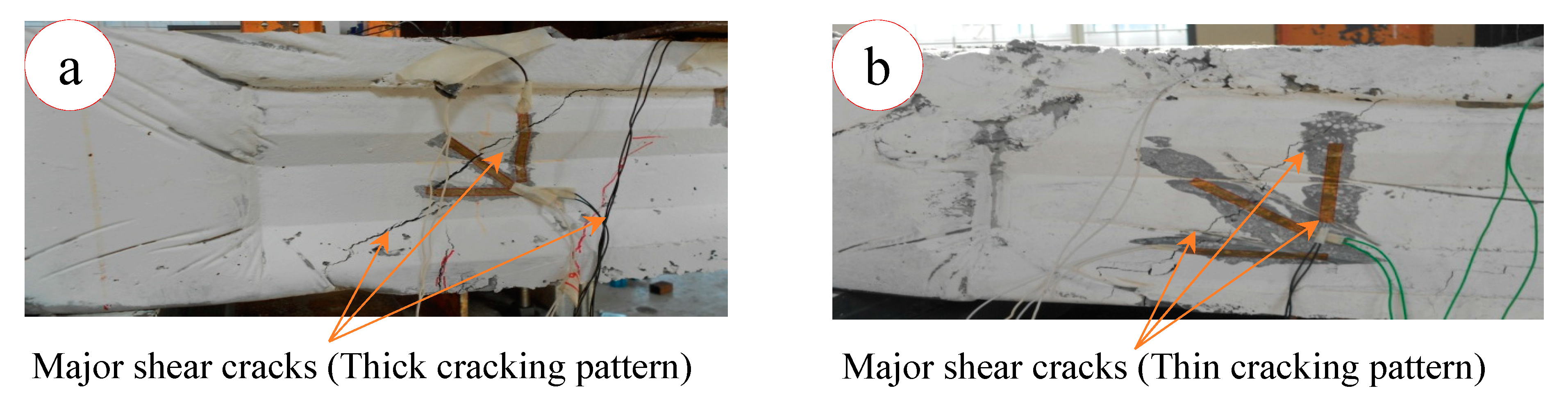

4.3. Crack Patterns

5. Conclusions

- to concentrate on enhancing the structural behavior of EPS-foam concrete half-shaped slabs, (e.g., addressing the stiffness and allowable deflections of the design system in order to satisfy the serviceability limit state);

- to further predict the feasibility of the developed precast EPS-foam concrete half-shaped slab via numerical simulations; and

- to enhance the connection efficiency between precast EPS-foam concrete half-shaped slab elements.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ju, H.; Han, S.-J.; Choi, I.; Choi, S.; Park, M.-K.; Kim, K. Experimental Study on an Optimized-Section Precast Slab with Structural Aesthetics. Appl. Sci. 2018, 8, 1234. [Google Scholar] [CrossRef]

- Elliott, K.S.; Jolly, C.K. Multi-Storey Precast Concrete Framed Structures; Elliott, K.S., Jolly, C.K., Eds.; John Wiley & Sons, Ltd.: Oxford, UK, 2013; ISBN 9781118587379. [Google Scholar]

- Lee, D.H.; Park, M.K.; Oh, J.Y.; Kim, K.S.; Im, J.H.; Seo, S.Y. Web-shear capacity of prestressed hollow-core slab unit with consideration on the minimum shear reinforcement requirement. Comput. Concr. 2014, 14, 211–231. [Google Scholar] [CrossRef]

- Newell, S.; Goggins, J. Real-time monitoring of concrete–lattice-girder slabs during construction. Proc. Inst. Civ. Eng. Struct. Build. 2017, 170, 885–900. [Google Scholar] [CrossRef]

- Hou, H.; Liu, X.; Qu, B.; Ma, T.; Liu, H.; Feng, M.; Zhang, B. Experimental evaluation of flexural behavior of composite beams with cast-in-place concrete slabs on precast prestressed concrete decks. Eng. Struct. 2016, 126, 405–416. [Google Scholar] [CrossRef]

- Yang, L. Design of Prestressed Hollow Core Slabs with Reference to Web Shear Failure. J. Struct. Eng. 1994, 120, 2675–2696. [Google Scholar] [CrossRef]

- Palmer, K.D.; Schultz, A.E. Factors affecting web-shear capacity of deep hollow-core units. PCI J. 2010, 55, 123–146. [Google Scholar] [CrossRef]

- Palmer, K.D.; Schultz, A.E. Experimental investigation of the web-shear strength of deep hollow-core units. PCI J. 2011, 56, 83–104. [Google Scholar] [CrossRef]

- Pisanty, A. The shear strength of extruded hollow-core slabs. Mater. Struct. 1992, 25, 224–230. [Google Scholar] [CrossRef]

- Fiset, M.; Bastien, J.; Mitchell, D. Methods for Shear Strengthening of Thick Concrete Slabs. J. Perform. Constr. Facil. 2017, 31, 04016103. [Google Scholar] [CrossRef]

- Ju, H.; Han, S.-J.; Joo, H.-E.; Cho, H.-C.; Kim, K.; Oh, Y.-H. Shear Performance of Optimized-Section Precast Slab with Tapered Cross Section. Sustainability 2018, 11, 163. [Google Scholar] [CrossRef]

- Naito, C.; Cao, L.; Peter, W. Precast concrete double-tee connections, part 1: Tension behavior. PCI J. 2009, 54, 49–66. [Google Scholar] [CrossRef]

- Cao, L.; Naito, C. Precast concrete double-tee connectors, part 2: Shear behavior. PCI J. 2009, 54, 97–115. [Google Scholar] [CrossRef]

- Shaw, C.S.J.; Woodland, A.B.; Hopp, J.; Trenholm, N.D. Structure and evolution of the Rockeskyllerkopf Volcanic Complex, West Eifel Volcanic Field, Germany. Bull. Volcanol. 2010, 72, 971–990. [Google Scholar] [CrossRef]

- Jong, L.Y.; Teo, D.C.L. Concrete Containing Palm Oil Fuel Ash (POFA) and Oil Palm Shell (OPS) Subjected to Elevated Temperatures. J. Civ. Eng. Sci. Technol. 2014, 5, 13–17. [Google Scholar] [CrossRef]

- Hiong, N.C.; Kameswara Rao, N.S.V.; Mannan, M.A. Precast c-channel floor for rural and estate housings. Malays. Constr. Res. J. 2011, 9, 63–72. [Google Scholar]

- Babu, D.S.; Ganesh Babu, K.; Wee, T.H. Properties of lightweight expanded polystyrene aggregate concretes containing fly ash. Cem. Concr. Res. 2005, 35, 1218–1223. [Google Scholar] [CrossRef]

- Topçu, I.B.; Uygunoǧlu, T. Properties of autoclaved lightweight aggregate concrete. Build. Environ. 2007, 42, 4108–4116. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z. Properties of Green Lightweight Aggregate Concrete. Int. Work. Sustain. Dev. Concr. Technol. 2002, 81, 113–118. [Google Scholar]

- Koksal, F.; Gencel, O.; Kaya, M. Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr. Build. Mater. 2015, 88, 175–187. [Google Scholar] [CrossRef]

- Johnson Alengaram, U.; Al Muhit, B.A.; bin Jumaat, M.Z.; Jing, M.L.Y. A comparison of the thermal conductivity of oil palm shell foamed concrete with conventional materials. Mater. Des. 2013, 51, 522–529. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; Gluth, G.J.G.; Pistol, K. In-situ thermo-mechanical testing of fly ash geopolymer concretes made with quartz and expanded clay aggregates. Cem. Concr. Res. 2016, 80, 33–43. [Google Scholar] [CrossRef]

- Mazaheripour, H.; Ghanbarpour, S.; Mirmoradi, S.H.; Hosseinpour, I. The effect of polypropylene fibers on the properties of fresh and hardened lightweight self-compacting concrete. Constr. Build. Mater. 2011, 25, 351–358. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z. Oil-palm by-products as lightweight aggregate in concrete mixture: A review. J. Clean. Prod. 2016, 126, 56–73. [Google Scholar] [CrossRef]

- Amudhavalli, N.K.; Mathew, J. Effect of Silica Fume on Strength and Durability Parameters of Concrete. Int. J. Eng. Sci. Emerg. Technol. 2012, 3, 2231–6604. [Google Scholar]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cem. Concr. Compos. 2013, 37, 108–118. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Ukpata, J.O.; Ephraim, M.E. Flexural and tensile strength properties of concrete using lateritic sand and quarry dust as fine aggregate. ARPN J. Eng. Appl. Sci. 2012, 7, 324–331. [Google Scholar]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012, 35, 211–219. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Rashid, R.S.M.; Hejazi, F.; Abang Ali, A.A.; Safiee, N.A.; Bida, S.M. Structural Performance of Precast Foamed Concrete Sandwich Panel Subjected to Axial Load. KSCE J. Civ. Eng. 2018, 22, 1179–1192. [Google Scholar] [CrossRef]

- Thanoon, W.A.; Yardim, Y.; Jaafar, M.S.; Noorzaei, J. Development of interlocking mechanism for shear transfer in composite floor. Constr. Build. Mater. 2010, 24, 2604–2611. [Google Scholar] [CrossRef]

- Yip, C.C.; Marsono, A.K.; Wong, J.Y.; Amran, M.Y.H. Flexural strength of special reinforced lightweight concrete beam for Industrialised Building System (IBS). J. Teknol. 2015, 77, 187–196. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Idriss, I.M.; Mathur, J.M.; Bolton Seed, H. Earth Dam-foundation interaction during earthquakes. Earthq. Eng. Struct. Dyn. 1973, 2, 313–323. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Abang Ali, A.A.; Rashid, R.S.M.; Hejazi, F.; Safiee, N.A. Structural behavior of axially loaded precast foamed concrete sandwich panels. Constr. Build. Mater. 2016, 107, 307–320. [Google Scholar] [CrossRef]

- Mohamad, N.; Omar, W.; Abdullah, R. Structural Behaviour of Precast Lightweight Foamed Concrete Sandwich Panel as a Load Bearing Wall. OIDA Int. J. Sustain. Dev. 2012, 5, 49–58. [Google Scholar]

- Saheed, S.; Amran, Y.H.M.; El-Zeadani, M.; Aziz, F.N.A.; Fediuk, R.; Alyousef, R.; Alabduljabbar, H. Structural behavior of out-of-plane loaded precast lightweight EPS-foam concrete C-shaped slabs. J. Build. Eng. 2021, 33, 101597. [Google Scholar] [CrossRef]

- BSI. BS 1881-116, BS-1881-Part 102: 1983 Method for Determination of Slump; BSI: London, UK, 1983. [Google Scholar]

- BSI. BS-1881: Part-110, Method for Making Test Cylinders from Fresh Concrete; BSI: London, UK, 1983. [Google Scholar]

- ASTM International. ASTM C597, Standard Test Method for Pulse Velocity Through Concrete; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- PCI. P.C.I.B.D. Manual; Precast/Prestressed Concrete Institute: Chicago, IL, USA, 2003. [Google Scholar]

- Wilden, H. PCI Design Handbook: Precast and Prestressed Concrete; Precast/Prestressed Concrete Institute: Wakefield, MA, USA, 2010. [Google Scholar]

- Ibrahim, I.S.; Bakar, M.B.C.; Nabilah, N. Shear Capacity of Composite Slab Reinforced With Steel Fibre Concrete Topping. Malays. J. Civ. Eng. 2011, 23, 1–23. [Google Scholar]

- Sarbini, N.N.; Ibrahim, I.S.; Saim, A.A.; Abdul Rahman, A.B.; Harun, N.F.; Hasbullah, N.N. Shear capacity of composite slab reinforced with steel fibre to that of fabric reinforcement in concrete topping. Mater. Res. Innov. 2014, 18, S6-236–S6-240. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Rashid, R.S.M.; Hejazi, F.; Safiee, N.A.; Ali, A.A.A. Response of precast foamed concrete sandwich panels to flexural loading. J. Build. Eng. 2016, 7, 143–158. [Google Scholar] [CrossRef]

- Benayoune, A.; Samad, A.A.A.; Trikha, D.N.; Ali, A.A.A.; Ellinna, S.H.M. Flexural behaviour of pre-cast concrete sandwich composite panel—Experimental and theoretical investigations. Constr. Build. Mater. 2008, 22, 580–592. [Google Scholar] [CrossRef]

- BSI. BS 8110-2, Structural Use of Cocnrete. Part 2: Code of Practice for Special Circumstances; BSI: London, UK, 1985. [Google Scholar]

- Girhammar, U.A.; Pajari, M. Tests and analysis on shear strength of composite slabs of hollow core units and concrete topping. Constr. Build. Mater. 2008, 22, 1708–1722. [Google Scholar] [CrossRef]

| Specimen | Fu, kN | Mode of Failure |

|---|---|---|

| CC200B | 71.9 | Shear-compression |

| CC200A | 65.8 | |

| CC250B | 81.1 | |

| CC250A | 93.7 | |

| EPS250A | 82.2 | Shear-compression |

| EPS200A | 61.8 | Shear-compression and de-bonding |

| Name of Sample | (a/d) Ratio | Ultimate Shear Force, V (kN) | Capacity Ratios = | |

|---|---|---|---|---|

| Experimental | Theoretical | |||

| CC200A | 2.0 | 65.8 | 49 | 1.3 |

| CC200B | 2.0 | 71.9 | 49 | 1.4 |

| CC250A | 2.0 | 93.7 | 62 | 1.5 |

| CC250B | 2.0 | 81.1 | 62 | 1.3 |

| EPS200A | 2.0 | 61.8 | 49 | 1.2 |

| EPS250A | 2.0 | 82.2 | 62 | 1.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saheed, S.; Aziz, F.N.A.A.; Amran, M.; Vatin, N.; Fediuk, R.; Ozbakkaloglu, T.; Murali, G.; Mosaberpanah, M.A. Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs. Sustainability 2020, 12, 9679. https://doi.org/10.3390/su12229679

Saheed S, Aziz FNAA, Amran M, Vatin N, Fediuk R, Ozbakkaloglu T, Murali G, Mosaberpanah MA. Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs. Sustainability. 2020; 12(22):9679. https://doi.org/10.3390/su12229679

Chicago/Turabian StyleSaheed, Sanusi, Farah N. A. Abd. Aziz, Mugahed Amran, Nikolai Vatin, Roman Fediuk, Togay Ozbakkaloglu, Gunasekaran Murali, and Mohammad Ali Mosaberpanah. 2020. "Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs" Sustainability 12, no. 22: 9679. https://doi.org/10.3390/su12229679

APA StyleSaheed, S., Aziz, F. N. A. A., Amran, M., Vatin, N., Fediuk, R., Ozbakkaloglu, T., Murali, G., & Mosaberpanah, M. A. (2020). Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs. Sustainability, 12(22), 9679. https://doi.org/10.3390/su12229679