Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete

Abstract

1. Introduction

2. Experimental Program

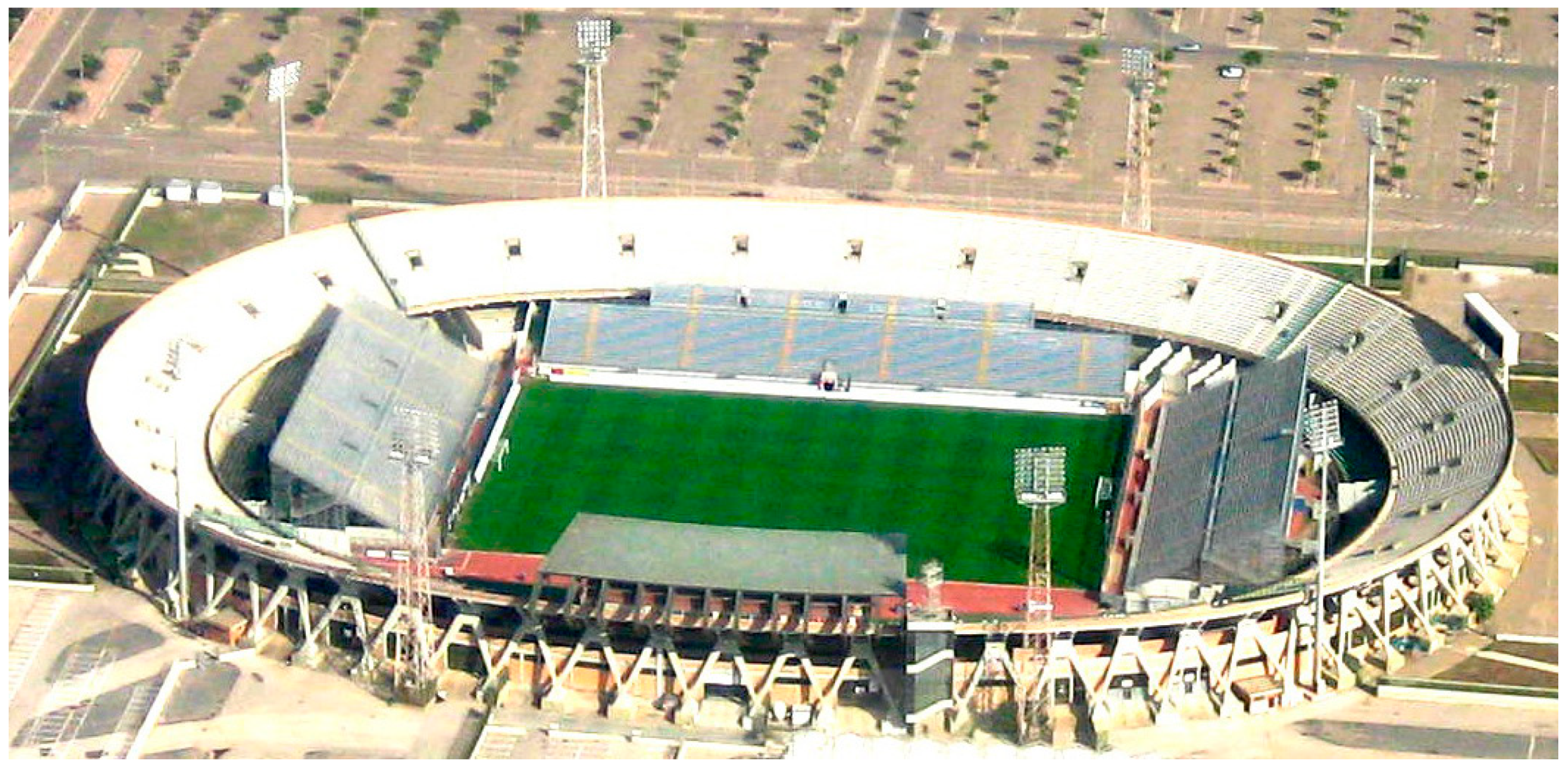

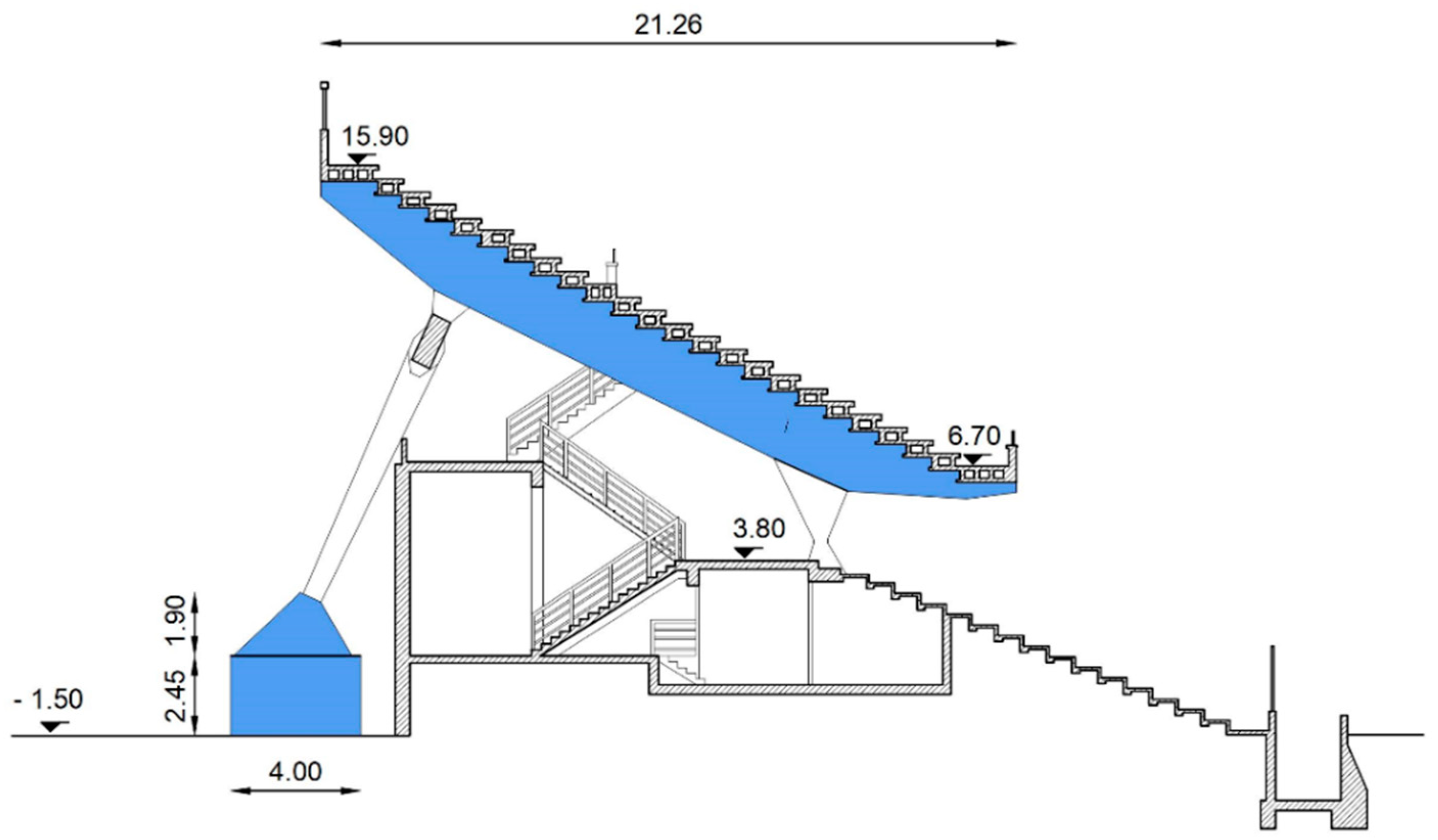

Parent Concrete Quality

3. Recycled Aggregates

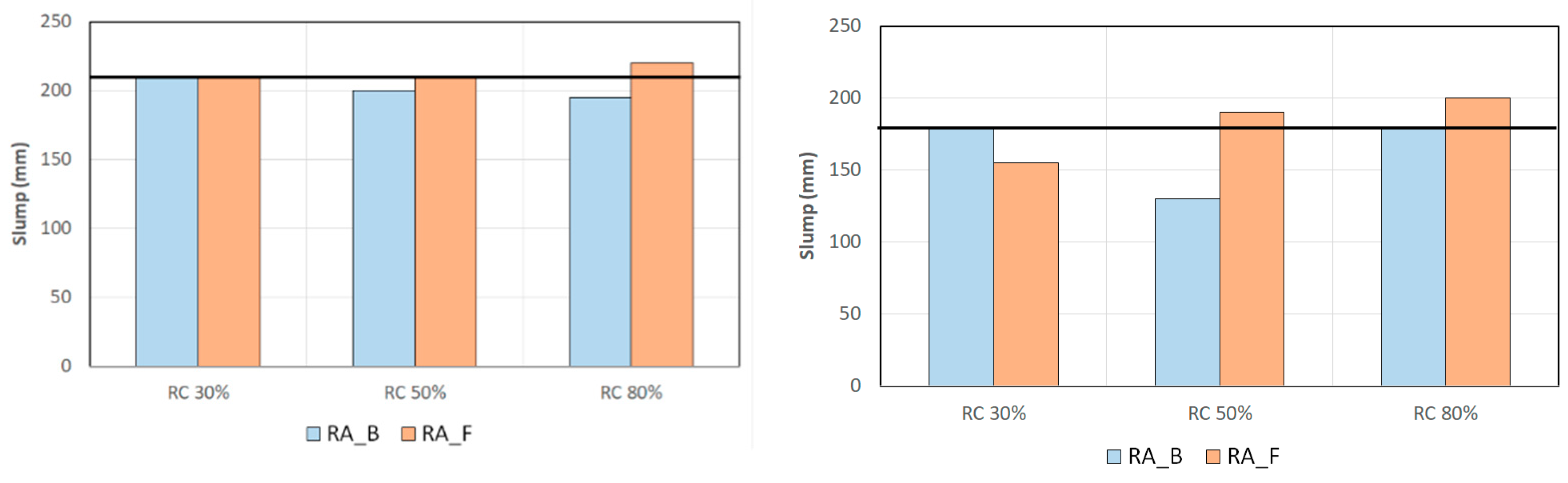

4. Concrete

4.1. Concrete Mechanical Properties

4.2. Concrete Durability Properties

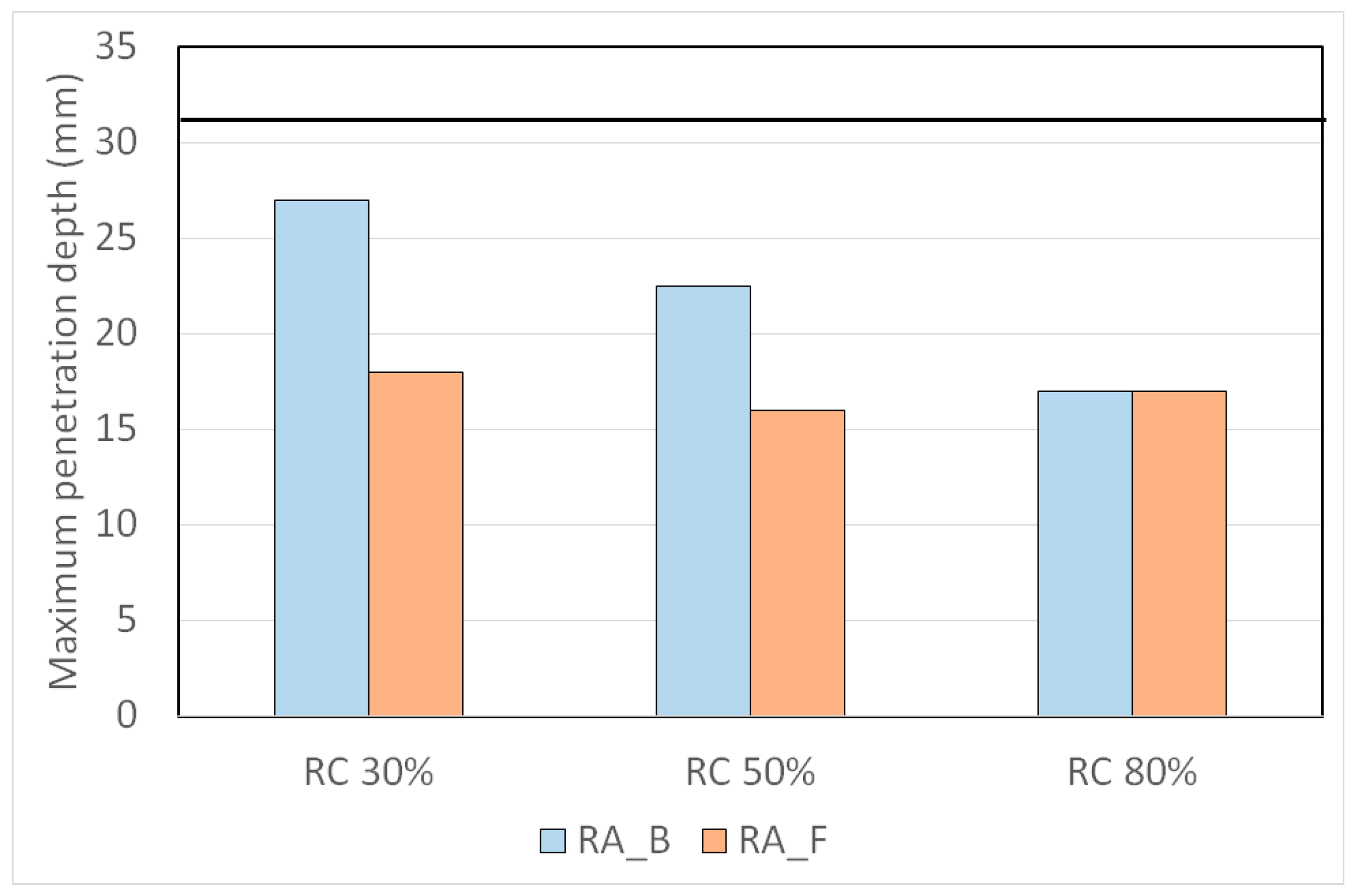

4.2.1. Permeability of Concretes

4.2.2. Resistance to Chloride Penetration

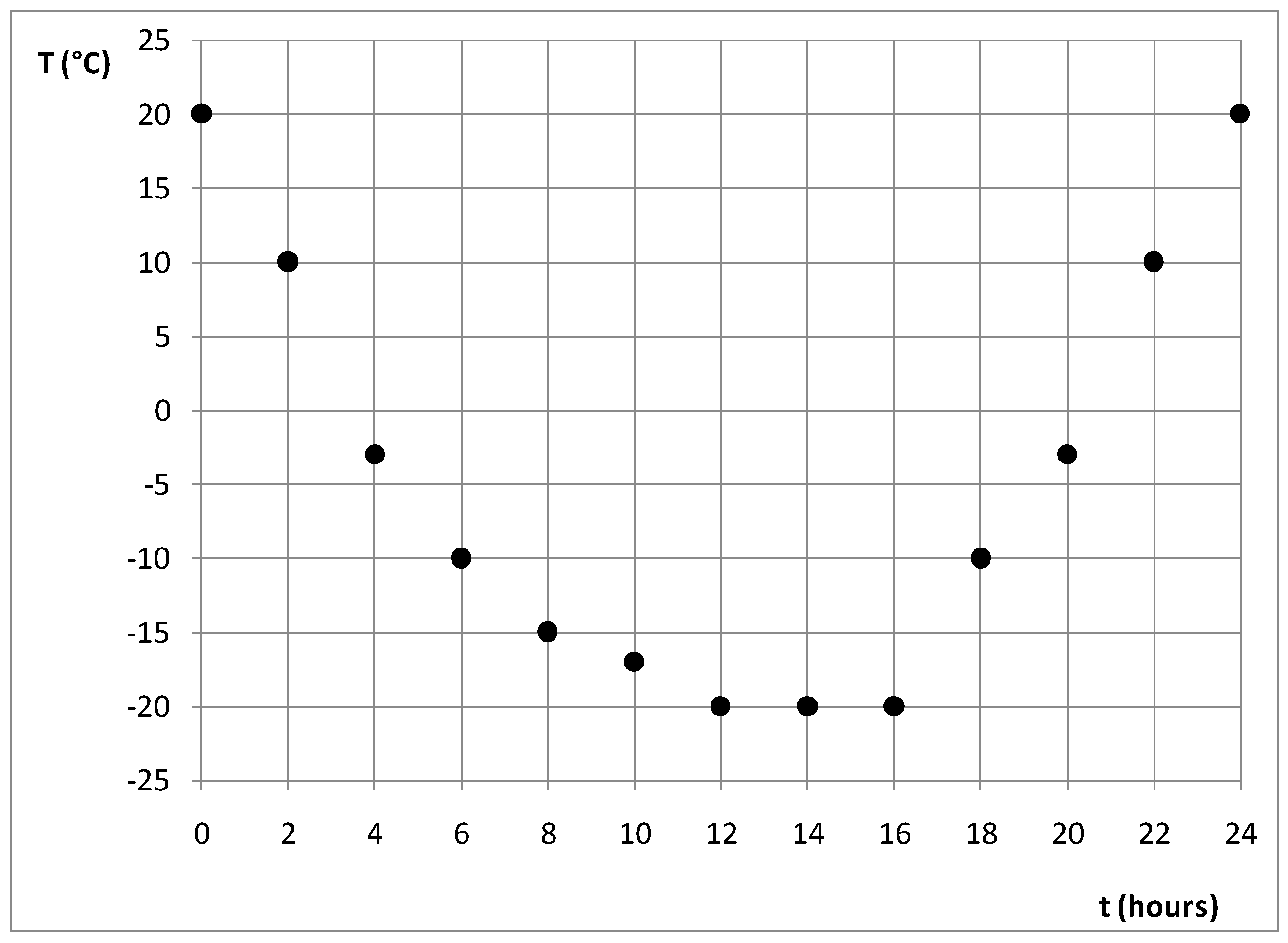

4.2.3. Freeze–Thaw Resistance of Concrete

5. Discussion and Conclusions

- -

- Recycled concrete produced with coarse recycled aggregates has shown similar mechanical performances to normal concrete produced with natural aggregate, even when the natural aggregates replacement percentage reaches 80%.

- -

- The mechanical performance of recycled concrete is not related to the parent concrete mechanical characteristics.

- -

- Concerning the durability, experimental results show that:

- -

- The resistance to pressured water penetration is not reduced by the presence of recycled aggregates.

- -

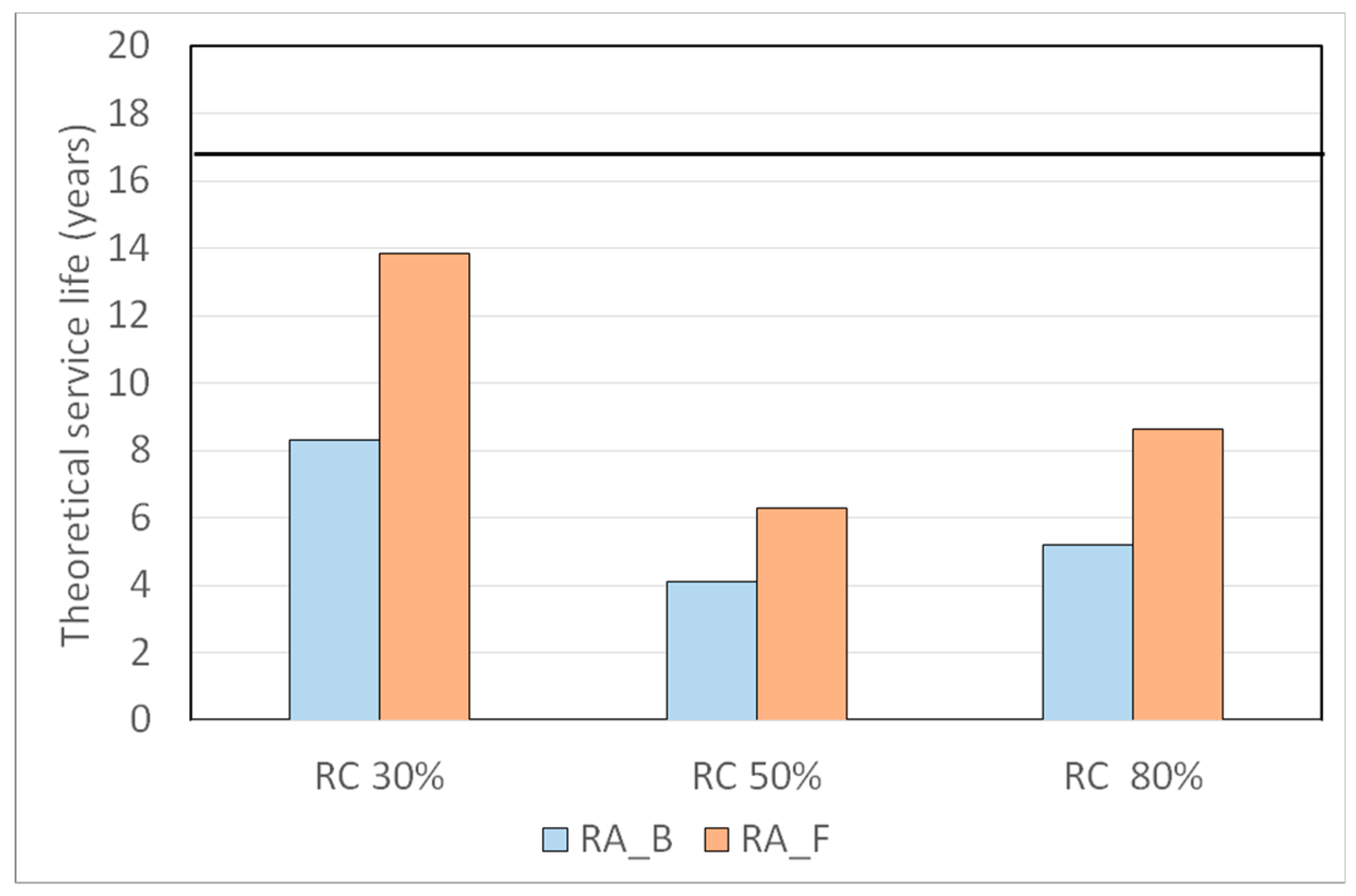

- The chloride penetration resistance of concrete with RA is lower than that of normal concrete (NC). In addition, it appears to be influenced by the parent concrete. Indeed, the theoretical service life of RC_F is 40% higher than that of RC_B, regardless of the percentage of recycled aggregate replacement.

- -

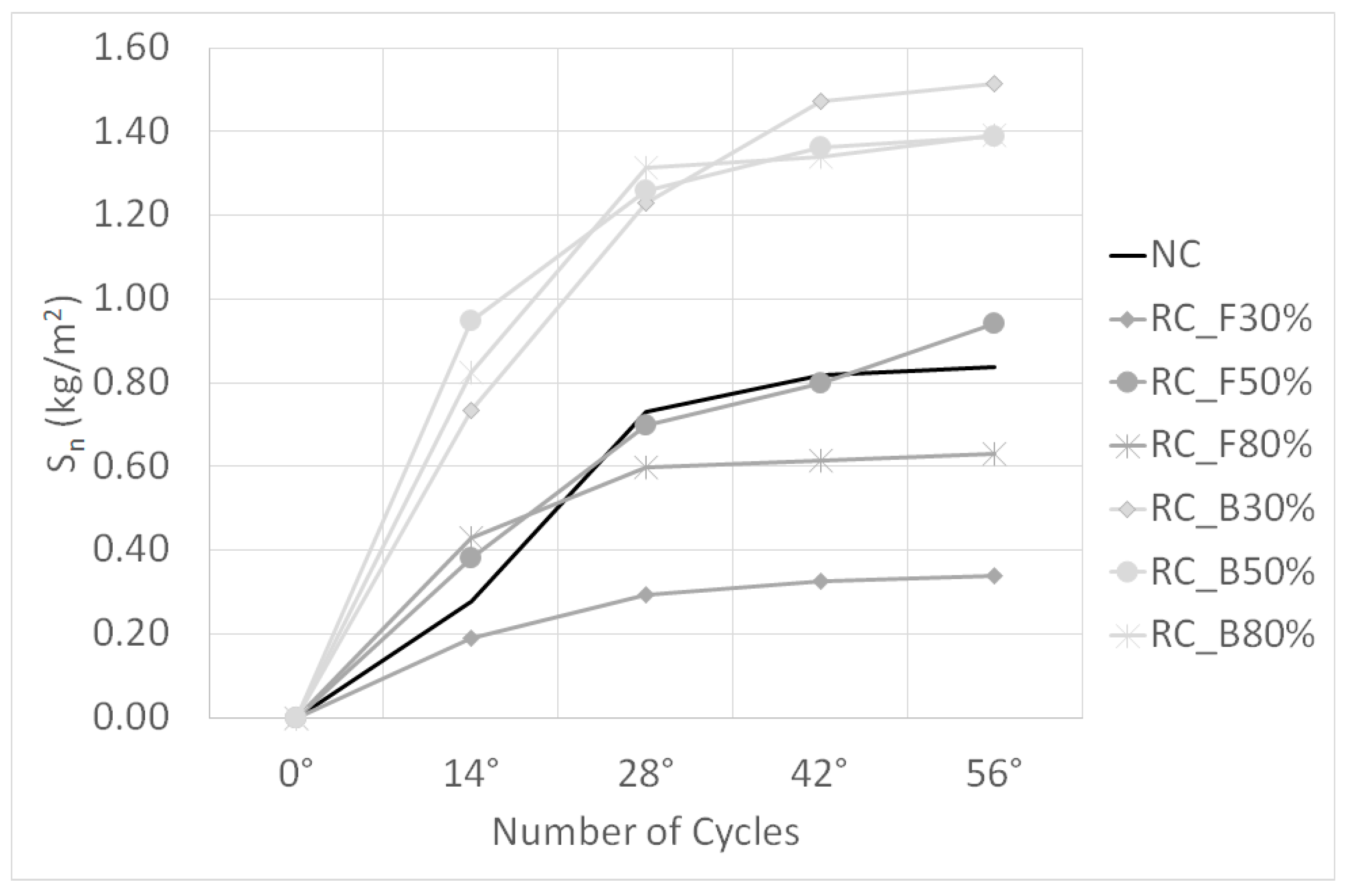

- The resistance to the frost–thawing cycle is higher in concrete with RA_B. Instead the Sn value of the concrete with RA_F is lower or approximately equal to the value of the normal concrete NC. The results obtained do not show a relationship between the replacement percentage of recycled aggregates and the resistance to frost and thaw.

Author Contributions

Funding

Conflicts of Interest

References

- Etxeberria, M.; Mari, A.R.; Vazquez, E. Recycled aggregate concrete as structural material. Mater. Struct. 2007, 40, 529–541. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Li, W.; Long, C.; Tam, V.W.Y.; Poon, C.-S.; Duan, W.H. Effects of nano-particles on failure process and microstructural properties of recycled aggregate concrete. Constr. Build. Mater. 2017, 142, 42–50. [Google Scholar] [CrossRef]

- Li, W.; Luo, Z.; Sun, Z.; Hu, Y.; Duan, W.H. Numerical modelling of plastic–damage response and crack propagation in RAC under uniaxial loading. Mag. Concr. Res. 2018, 70, 459–472. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. The influence of the use of recycled aggregates on the compressive strength of concrete: A review. Eur. J. Environ. Civ. Eng. 2015, 19, 825–849. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Establishing a relationship between modulus of elasticity and compressive strength of recycled aggregate concrete. J. Clean. Prod. 2016, 112, 2171–2186. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Tensile strength behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Francesconi, L.; Pani, L.; Stochino, F. Punching shear strength of reinforced recycled concrete slabs. Constr. Build. Mater. 2016, 127, 248–263. [Google Scholar] [CrossRef]

- Rahman, M.M.; Beecham, S.; Iqbal, A.; Karim, M.R.; Rabbi, A.T.Z. Sustainability assessment of using recycled aggregates in concrete block pavements. Sustainability 2020, 12, 4313. [Google Scholar] [CrossRef]

- Shi, X.; Grasley, Z.; Mukhopadhyay, A.; Zollinger, D. Use of recycled aggregates in concrete pavement: Pavement design and life cycle assessment. In Proceedings of the International Symposium on Pavement. Roadway, and Bridge Life Cycle Assessment 2020 (LCA 2020), Sacramento, CA, USA, 3–6 June 2020; CRC Press: Boca Raton, FL, USA, 2020; p. 324. [Google Scholar]

- Silva, R.V.; de Brito, J. Reinforced recycled aggregate concrete slabs: Structural design based on Eurocode 2. Eng. Struct. 2020, 204, 110047. [Google Scholar] [CrossRef]

- Cantero, B.; Bravo, M.; de Brito, J.; del Bosque, I.S.; Medina, C. Mechanical behaviour of structural concrete with ground recycled concrete cement and mixed recycled aggregate. J. Clean. Prod. 2020, 275, 122913. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. Use of recycled concrete aggregate in high-strength concrete. Mater. Struct. 2000, 33, 574–580. [Google Scholar] [CrossRef]

- Ardalan, R.B.; Emamzadeh, Z.N.; Rasekh, H.; Joshaghani, A.; Samali, B. Physical and mechanical properties of polymer modified self-compacting concrete (SCC) using natural and recycled aggregates. J. Sustain. Cem. Based Mater. 2020, 9, 1–16. [Google Scholar] [CrossRef]

- Singh, A.; Duan, Z.; Xiao, J.; Liu, Q. Incorporating recycled aggregates in self-compacting concrete: A review. J. Sustain. Cem. Based Mater. 2020, 9, 165–189. [Google Scholar] [CrossRef]

- ACI Committee 555. Removal and Reuse of Hardened Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2001. [Google Scholar]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Prediction of chloride ion penetration of recycled aggregate concrete. Mater. Res. 2015, 18, 427–440. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; de Brito, J. The effect of superplasticizers on the mechanical performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2012, 34, 1044–1052. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Dhinakaran, G. Durability characteristics of recycled aggregate concrete. Struct. Eng. Mech. 2013, 47, 701–711. [Google Scholar] [CrossRef]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Medina, C.; de Rojas, M.I.S.; Frías, M. Freeze-thaw durability of recycled concrete containing ceramic aggregate. J. Clean. Prod. 2013, 40, 151–160. [Google Scholar] [CrossRef]

- Olorunsogo, F.; Padayachee, N. Performance of recycled aggregate concrete monitored by durability indexes. Cem. Concr. Res. 2002, 32, 179–185. [Google Scholar] [CrossRef]

- Wang, H.; Sun, X.; Wang, J.; Monteiro, P.J.M. Permeability of concrete with recycled concrete aggregate and pozzolanic materials under stress. Materials 2016, 9, 252. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Otsuki, N.; Miyazato, S.S.; Yodsudjai, W. Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. J. Mater. Civil. Eng. 2003, 15, 443–551. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J.; Chastre, C.; Evangelista, L. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 201, 110–120. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Effect of the quality of parent concrete on the properties of high performance recycled aggregate concrete. Constr. Build. Mater. 2015, 77, 501–508. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem. Concr. Compos. 2002, 24, 269–279. [Google Scholar] [CrossRef]

- Rahal, K.N. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- González-Fonteboa, B.; Martínez-Abella, F. Concretes with aggregates from demolition waste and silica fume. Materials and mechanical properties. Build. Environ. 2008, 43, 429–437. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Naitza, S.; Balletto, G.; Mei, G. Recycled aggregates, mechanical properties and environmental sustainability. In Planning, Nature and Ecosystem Services, INPUT aCAdemy; FedOAPress—Federico II Open ACCESS University Press: Cagliari, Italy, 2019; pp. 431–442. [Google Scholar]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Aggregates for Concrete; UNI EN 12620: 2008; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2008.

- Aggregates for Concrete. Additional Provisions for the Application of EN 12620 Part 1: Designation and Conformity Criteria; UNI 8520-1: 2015; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2015.

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Omary, S.; Ghorbel, E.; Wardeh, G.; Nguyen, M.D. Mix design and recycled aggregates effects on the concrete’s properties. J. Civ. Eng. 2018, 16, 973–992. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Concu, G. Influence of replacement percentage of recycled aggregates on recycled aggregate concrete properties. In Proceedings of the 2011 FIB Symposium: Concrete Engineering for Excellence and Efficiency, Prague, Czech Republic, 8–10 June 2011. [Google Scholar]

- Pani, L.; Francesconi, L.; Concu, G. Relation between static and dynamic moduli of elasticity for recycled aggregate concrete. In Proceedings of the First International Conference on Concrete Sustainability, Tokyo, Japan, 27–29 May 2013; pp. 676–681. [Google Scholar]

- Pani, L.; Balletto, G.; Naitza, S.; Francesconi, L.; Trulli, N.; Mei, G.; Furcas, C. Evaluation of mechanical, physical and chemical properties of recycled aggregates for structural concrete. In Proceedings of the Sardinia 2013, Fourteenth International Waste Management and Landfill Symposium, Cagliari, Italy, 30 September–4 October 2013. [Google Scholar]

- Tavakoli, M.; Soroushian, P. Strength of recycled aggregate concrete made using field-demolished concrete as aggregate. ACI Mat. J. 1996, 93, 182–190. [Google Scholar]

- Salem, R.M.; Burdette, E.G. Role of chemical and mineral admixtures on physical properties and frost-resistance of recycled aggregate concrete. ACI Mat. J. 1998, 95, 558–563. [Google Scholar]

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournier, B.; Foo, S. Proposed method for determining the residual mortar content of recycled concrete aggregates. J. ASTM Intern. 2007, 5, 1–12. [Google Scholar]

- Testing Fresh Concrete—Part 2: Slump Test; UNI EN 12350-2:2019; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2019.

- Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; UNI EN 12390-3: 2019; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2019.

- Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression; UNI EN 12390-13: 2013; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2013.

- Testing Hardened Concrete—Part 6: Tensile Splitting Strength of the Specimens; UNI EN 12390-6: 2010; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2010.

- Stochino, F.; Pani, L.; Francesconi, L.; Mistretta, F. Cracking of reinforced recycled concrete slabs. Int. J. Struct. Glass Adv. Mater. Res. 2017, 1, 3–9. [Google Scholar] [CrossRef]

- Pepe, M.; Filho, R.D.T.; Koenders, E.A.; Martinelli, E. A novel mix design methodology for recycled aggregate concrete. Constr. Build. Mater. 2016, 122, 362–372. [Google Scholar] [CrossRef]

- Testing Hardened Concrete. Part. 8 Depth of Penetration of Water Under Pressure; UNI EN 12390-8: 2009; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2009.

- Testing Hardened Concrete. Part. 11: Determination of the Chloride Resistance of Concrete, Unidirectional Diffusion; UNI EN 12390-11: 2015; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2015.

- Hanjari, K.Z.; Utgenannt, P.; Lundgren, K. Experimental study of the material and bond properties of frost-damaged concrete. Cem. Concr. Res. 2011, 41, 244–254. [Google Scholar] [CrossRef]

- Harrison, T.A.; Dewar, J.D.; Brown, B.V. Freeze-Thaw Resisting Concrete: Its Achievement in the UK; CIRIA: London, UK, 2001. [Google Scholar]

- Testing Hardened Concrete. Part 9. Freeze-Thaw Resistance with Deicing Salts. Scaling; UNI CEN/TS 12390-9: 2017; Ente Nazionale Italiano di Unificazione (UNI): Milan, Italy, 2017.

- Stochino, F.; Fadda, M.L.; Mistretta, F. Assessment of RC Bridges integrity by means of low-cost investigations. Frat. Integrita Strutt. 2018, 46, 216–225. [Google Scholar] [CrossRef]

- Stochino, F.; Fadda, M.L.; Mistretta, F. Low cost condition assessment method for existing RC bridges. Eng. Fail. Anal. 2018, 86, 56–71. [Google Scholar] [CrossRef]

- Sassu, M.; Stochino, F.; Mistretta, F. Assessment method for combined structural and energy retrofitting in masonry buildings. Buildings 2017, 7, 71. [Google Scholar] [CrossRef]

- Mistretta, F.; Stochino, F.; Sassu, M. Structural and thermal retrofitting of masonry walls: An integrated cost-analysis approach for the Italian context. Build. Environ. 2019, 155, 127–136. [Google Scholar] [CrossRef]

- Sassu, M.; Giresini, L.; Bonannini, E.; Puppio, M.L. On the use of vibro-compressed units with bio-natural aggregate. Buildings 2016, 6, 40. [Google Scholar] [CrossRef]

- Sassu, M.; de Falco, A.; Giresini, L.; Puppio, M.L. Structural solutions for low-cost bamboo frames: Experimental tests and constructive assessments. Materials 2016, 9, 346. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.J.; Chen, Z.P.; Zhao, X.Y.; Demartino, C.; Ozbakkaloglu, T.; Xue, J.Y. Seismic performance of circular recycled aggregate concrete-filled steel tubular columns: FEM modelling and sensitivity analysis. Thin Walled Struct. 2019, 141, 509–525. [Google Scholar] [CrossRef]

- Xu, J.J.; Chen, Z.P.; Ozbakkaloglu, T.; Zhao, X.-Y.; Demartino, C. A critical assessment of the compressive behavior of reinforced recycled aggregate concrete columns. Eng. Struct. 2018, 161, 161–175. [Google Scholar] [CrossRef]

- Xu, J.J.; Chen, Z.P.; Xiao, Y.; Demartino, C.; Wang, J.H. Recycled aggregate concrete in FRP-confined columns: A review of experimental results. Comp. Struct. 2017, 174, 277–291. [Google Scholar] [CrossRef]

- Deresa, S.T.; Xu, J.; Demartino, C.; Heo, Y.; Li, Z.; Xiao, Y. A review of experimental results on structural performance of reinforced recycled aggregate concrete beams and columns. Adv. Struct. Eng. 2020, 23, 3351–3369. [Google Scholar] [CrossRef]

| Identification | Carbonatation Depth (mm) | Density (kg/m3) | Compressive Strength (MPa) | Elasticity Modulus (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| C. Found. 1 | 30 | 2299 | 26.8 | 24,470 | - |

| C. Found. 2 | 30 | 2334 | 32.2 | 27,751 | - |

| C. Found. 3 | 0 | 2283 | 24.7 | 23,785 | - |

| C. Found. 4 | 0 | 2345 | - | - | 2.04 |

| C. Found. 5 | 0 | 2298 | - | - | 1.83 |

| C. Found. 6 | 0 | 2327 | - | - | 2.28 |

| C. Found. Average | 10 | 2314 | 27.9 | 25,335 | 2.05 |

| C. Beam 1 | 50 | 2271 | 22.2 | 19,744 | - |

| C. Beam 2 | 0 | 2315 | 22.1 | 18,537 | - |

| C. Beam 3 | 60 | 2233 | 18.7 | 15,845 | - |

| C. Beam 4 | 0 | 2295 | - | - | 1.50 |

| C. Beam 5 | 40 | 2248 | - | - | 1.58 |

| C. Beam 6 | 40 | 2259 | - | - | 1.40 |

| C. Beam: Average | 32 | 2270 | 21.0 | 18,042 | 1.49 |

| Property | RA_F | RA_B |

|---|---|---|

| Size designation | 4/16 | 4/16 |

| Category grading | GC 90/15, GT 17.5 | GC 90/15, GT 17.5 |

| Flakiness Index | 4 | 4 |

| Shape Index | 59 | 34 |

| Saturated surface-dried particle density | 2.39 Mg/m3 | 2.38 Mg/m3 |

| Loose bulk density and voids | ρb = 1.23 Mg/m3 v% = 45 | ρb = 1.14 Mg/m3 v% = 49 |

| Percentage of fines | 0.15% | 0.59% |

| Percentage of shells | absent | absent |

| Resistance to fragmentation | 39 | 39 |

| Constituents of coarse RA | X = 0; Rc = 74%; Ru = 27%; Rb = 0; Ra = 0; Rg = 0 | X = 0; Rc = 78%; Ru = 22%; Rb = 0; Ra = 0; Rg = 0 |

| Content of water-soluble chloride salts | 0.005% | 0.005% |

| Content of acid-soluble chloride salts | 0.325% | 0.325% |

| Content of acid-soluble sulphate | 0.43% | 0.26% |

| Content of total sulfur | S < 0.1% | S < 0.1% |

| Content of water-soluble sulphates | SS = 0.148% | SS = 0.068% |

| Lightweight contaminator | absent | absent |

| Water absorption | WA24 = 7.0% | WA24 = 6.7% |

| Resistance to freezing and thawing | 41% | 42% |

| Resistance to magnesium sulphate | 2.56% | 0% |

| Presence of humus | absent | absent |

| Residual Mortar Content (%) | RA_F | RA_B |

|---|---|---|

| Sieve Retained 4 mm | 55.81% | 49.67% |

| Sieve Retained 10 mm | 45.82% | 45.65% |

| Notation | w/c Ratio | Cement (kg/m3) | Water (l/m3) | Fine NA (kg/m3) | Coarse NA (kg/m3) | Coarse RA_F (kg/m3) | Coarse RA_B (kg/m3) | Additive (kg/m3) | Density (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| NC | 0.463 | 400 | 185 | 847.49 | 880.06 | - | - | 2.91 | 2322 |

| RC_B 30% | 0.463 | 400 | 185 | 821.8 | 616.04 | - | 263.69 | 3.31 | 2293 |

| RC_F 30% | 0.463 | 400 | 185 | 821.8 | 616.04 | 263.69 | - | 3.31 | 2287 |

| RC_B 50% | 0.463 | 400 | 185 | 802.97 | 440.03 | - | 440.27 | 3.31 | 2298 |

| RC_F 50% | 0.463 | 400 | 185 | 802.97 | 440.03 | 440.27 | - | 4.00 | 2283 |

| RC_B 80% | 0.463 | 400 | 185 | 778.15 | 176.01 | - | 703.96 | 4.00 | 2268 |

| RC_F 80% | 0.463 | 400 | 185 | 778.15 | 176.01 | 703.96 | - | 4.00 | 2229 |

| Notation | N. | Rc,14d (MPa) | Rc,28d (MPa) | fct (MPa) | Ec (MPa) |

|---|---|---|---|---|---|

| NC | 1 | 37.4 | 41.7 | 3.53 | 26,601 |

| 2 | 41.1 | 41.4 | 3.71 | 25,473 | |

| 3 | 40.3 | 45.2 | 3.75 | 26,037 | |

| Average Value | 39.6 | 42.8 | 3.66 | 26,037 | |

| RC_B 30% | 1 | 44.4 | 45.5 | 3.46 | 24,138 |

| 2 | 41.7 | 47.3 | 3.83 | 23,553 | |

| 3 | 41.5 | 44.8 | 4.06 | 22,846 | |

| Average Value | 42.5 | 45.9 | 3.78 | 23,512 | |

| RC_F 30% | 1 | 43.1 | 44.2 | 3.87 | 25,081 |

| 2 | 38.5 | 46.3 | 3.95 | 25,081 | |

| 3 | 42.0 | 43.1 | 3.87 | 24,543 | |

| Average Value | 41.2 | 44.5 | 3.89 | 24,902 | |

| RC_B 50% | 1 | 45.5 | 43.9 | 3.70 | 23,383 |

| 2 | 44.9 | 41.8 | 4.04 | 22,976 | |

| 3 | 43.9 | 47.5 | 3.95 | 22,675 | |

| Average Value | 44.8 | 44.4 | 3.90 | 23,011 | |

| RC_F 50% | 1 | 45.5 | 48.6 | 3.19 | 25,796 |

| 2 | 45.3 | 46.3 | 3.26 | 23,842 | |

| 3 | 44.0 | 48.9 | 4.60 | 26,889 | |

| Average Value | 44.9 | 47.9 | 3.68 | 25,509 | |

| RC_B 80% | 1 | 43.4 | 45.6 | 4.10 | 25,314 |

| 2 | 42.8 | 47.9 | 3.59 | 22,602 | |

| 3 | 43.1 | 48.1 | 3.87 | 22,541 | |

| Average Value | 43.1 | 47.2 | 3.85 | 23,486 | |

| RC_F 80% | 1 | 39.4 | 42.6 | 3.77 | 25,398 |

| 2 | 41.0 | 43.5 | 3.47 | 23,415 | |

| 3 | 40.6 | 47.3 | 3.84 | 23,315 | |

| Average Value | 40.3 | 44.5 | 3.69 | 24,043 |

| Concrete | NC | RC_F30% | RC_F50% | RC_F80% | RC_B30% | RC_B50% | RC_B80% | |

|---|---|---|---|---|---|---|---|---|

| Ci (%) | 0.007 | 0.016 | 0.012 | 0.010 | 0.011 | 0.006 | 0.007 | |

| Layer 1 | x (mm) | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Cx (%) | 0.176 | 0.074 | 0.274 | 0.157 | 0.272 | 0.130 | 0.108 | |

| Layer 2 | x (mm) | 2.310 | 2.690 | 2.950 | 2.520 | 3.000 | 2.800 | 2.810 |

| Cx (%) | 0.060 | 0.061 | 0.075 | 0.070 | 0.070 | 0.083 | 0.099 | |

| Layer 3 | x (mm) | 4.190 | 4.950 | 4.930 | 4.740 | 5.000 | 4.450 | 4.940 |

| Cx (%) | 0.055 | 0.052 | 0.063 | 0.057 | 0.058 | 0.077 | 0.080 | |

| Layer 4 | x (mm) | 7.270 | 7.060 | 6.720 | 6.950 | 7.500 | 6.600 | 7.200 |

| Cx (%) | 0.040 | 0.044 | 0.055 | 0.050 | 0.048 | 0.060 | 0.060 | |

| Layer 5 | x (mm) | 9.930 | 9.180 | 10.97 | 10.90 | 10.46 | 10.11 | 9.960 |

| Cx (%) | 0.038 | 0.040 | 0.038 | 0.038 | 0.032 | 0.054 | 0.050 | |

| Layer 6 | x (mm) | 13.35 | 13.50 | 14.10 | 14.83 | 14.17 | 13.87 | 14.39 |

| Cx (%) | 0.020 | 0.021 | 0.030 | 0.026 | 0.028 | 0.038 | 0.015 | |

| Layer 7 | x (mm) | 16.63 | 17.23 | 17.80 | 17.67 | 17.17 | 17.78 | 17.67 |

| Cx (%) | 0.013 | 0.007 | 0.009 | 0.020 | 0.020 | 0.017 | 0.013 | |

| Layer 8 | x (mm) | 20.06 | 21.14 | 20.40 | 21.75 | 20.73 | 21.88 | 21.95 |

| Cx (%) | 0.011 | 0.006 | 0.006 | 0.009 | 0.009 | 0.012 | 0.007 | |

| Cs (%) | 0.071 | 0.075 | 0.090 | 0.083 | 0.085 | 0.099 | 0.128 | |

| Dnss (mm2/days) | 0.787 | 0.516 | 0.731 | 0.711 | 0.649 | 1.019 | 0.496 | |

| R2 | 0.953 | 0.961 | 0.998 | 0.993 | 0.980 | 0.970 | 0.970 |

| Concrete | Sample | Sn (kg/m2) | Sn, average (kg/m2) |

|---|---|---|---|

| RC_B30% | 1 | 1.39 | 1.52 |

| 2 | 0.76 | ||

| 3 | 1.71 | ||

| 4 | 2.20 | ||

| RC_B50% | 1 | 1.97 | 1.39 |

| 2 | 1.00 | ||

| 3 | 0.66 | ||

| 4 | 1.93 | ||

| RC_B80% | 1 | 1.03 | 1.39 |

| 2 | 2.60 | ||

| 3 | 0.79 | ||

| 4 | 1.16 | ||

| NC | 1 | 1.12 | 0.88 |

| 2 | 0.21 | ||

| 3 | 1.17 | ||

| 4 | 1.00 | ||

| RC_F30% | 1 | 0.20 | 0.34 |

| 2 | 0.21 | ||

| 3 | 0.63 | ||

| 4 | 0.31 | ||

| RC_F50% | 1 | 0.97 | 0.94 |

| 2 | 0.94 | ||

| 3 | 1.27 | ||

| 4 | 0.57 | ||

| RC_F80% | 1 | 0.36 | 0.63 |

| 2 | 0.70 | ||

| 3 | 0.86 | ||

| 4 | 0.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pani, L.; Francesconi, L.; Rombi, J.; Mistretta, F.; Sassu, M.; Stochino, F. Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete. Sustainability 2020, 12, 9399. https://doi.org/10.3390/su12229399

Pani L, Francesconi L, Rombi J, Mistretta F, Sassu M, Stochino F. Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete. Sustainability. 2020; 12(22):9399. https://doi.org/10.3390/su12229399

Chicago/Turabian StylePani, Luisa, Lorena Francesconi, James Rombi, Fausto Mistretta, Mauro Sassu, and Flavio Stochino. 2020. "Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete" Sustainability 12, no. 22: 9399. https://doi.org/10.3390/su12229399

APA StylePani, L., Francesconi, L., Rombi, J., Mistretta, F., Sassu, M., & Stochino, F. (2020). Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete. Sustainability, 12(22), 9399. https://doi.org/10.3390/su12229399