Abstract

Compared with the conventional cast-in-situ method, prefabricated construction (PC) is a sustainable construction method. In China, the sustainable performance qualities of PC—such as its improved quality, lower cost and shorter turnaround—have barely been achieved. This is likely attributable to the weak sustainable construction capability of construction enterprises in undertaking PC projects. This study observed that there is relatively scant research on critical influencing factors relating to this capability, after investigating the most recent literature about PC development obstacles. Without a clear understanding of this knowledge, construction enterprises are unlikely to formulate effective measures to enhance their sustainable construction capability to tackle efficiency, cost, risk, and broader performance issues in PC. Therefore, this study identified 27 factors from the literature and interviews, ranked these factors using the Entropy method and the fuzzy analytic hierarchy process (FAHP), examined the top five critical factors, and discussed the problem-solving measures. This study drew the conclusion that construction enterprises should focus on PC business scope expansion, project delivery quality improvement, and technology investment and innovation, as well as the return on investments in technology. It is also suggested that incentivised strategies be formulated by the Chinese government in order to improve industry practitioners’ capability of implementing sustainable PC projects. This will eventually expedite the industry’s transformation towards leaner, more efficient and sustainable practice.

1. Introduction

Prefabricated construction (PC) is a sustainable and productive construction mode, which allows cast-in-situ processes to take place in a controlled environment such as a factory [1,2]. Compared with traditional cast-in-situ construction, PC has some potential advantages for sustainable performance, such as faster construction, the improved quality of architecture and workforce safety, reduced construction waste and greenhouse gas (GHG) emissions, and so on [3,4,5,6]. Nowadays, while it has become widespread in many developed countries, such as the United Kingdom (U.K.), Singapore and Japan, PC is also gradually being applied by some developing countries, such as China and Malaysia, as a sustainable alternative to conventional cast-in-situ construction [7,8].

Thanks to the new-type urbanisation strategy, the Chinese PC market share has gradually increased over the last decade [9]. Such an increase is also owing to the extensive policies and measures that have been formulated by governments at different levels to promote the application of PC [10]. For instance, the proportion of prefabricated buildings to new buildings has to increase to 30% in large cities until 2025 [11]; in addition to that, certain cities, such as Tianjin, are expected to deliver public buildings completely using PC workmanship.

Despite the tremendous development opportunity of PC in China, the use of PC techniques is still limited due to various barriers, such as its high initial cost, its poor quality, the lack of skilled labor, and technology standards. Extensive research has been conducted to address these challenges from the perspectives of project management, technical innovation, business modelling and performance evaluation [1]. However, the stakeholders’ sustainable construction capability of implementing PC, a key factor affecting the successful delivery of PC projects, has been overlooked frequently [12]. The sustainable construction capability oriented to PC is the capacity of stakeholders to sustainably utilise, extend or adjust their resources (including technology, investment, and management), and to obtain the improved sustainable performance of PC projects [13,14]. It is necessary for stakeholders to have a clear understanding about the factors influencing their sustainable construction capability in PC projects [12]. It is critical for stakeholders to get to know how to stipulate and undertake effective measures for the improvement of their capability. Therefore, these factors should be identified.

PC stakeholders include, but are not limited to, designers, developers, general contractors, manufacturers, suppliers, governments, and the public [15,16]. In this study, general contractors, also known as construction enterprises, are one of the main stakeholder types, given their responsibility for project performance in areas such as quality, cost and duration [17]. In China, construction enterprises’ sustainable construction capability is more influential to the sustainable performance and successful delivery of PC projects due to their low level of capability in developing PC technologies. Furthermore, compared with traditional construction, the improvement of construction enterprises’ sustainable capability is more challenging due to the complexity of PC processes. In order to improve such a capability, construction enterprises should take into account many factors, such as technology innovation, workforce upskilling, workmanship and management adjustment, lifecycle sustainability, equipment and utilities. Thus, this study aims to develop construction enterprises’ understanding and help them better leverage the positive aspects of these influencing factors when implementing PC projects. This study also aims to recommend effective strategies to boost the uptake of PC across the entire construction industry.

2. Literature Review

PC has overwhelming advantages over traditional construction, such as its shortened delivery time, and its improved project quality, safety and overall sustainability [8,18,19]. However, the challenges and constraints of implementing PC, including its high initial cost, lack of skilled workers, and inadequate technical and managerial experience, should not be overlooked in practice [20,21,22,23]. Researchers have made significant effort to solve these issues from different angles. As stated in Table 1, these articles can be organised into six major research themes and twenty-four research areas. It is recommended that stakeholders should make use of these findings in order to improve their PC performance in terms of PC quality, efficiency, economy, and sustainability [1,24].

Table 1.

Previous research focusing on PC.

According to the literature review, the process of identifying the critical factors affecting PC can be mainly divided into two steps; namely, identifying a list of factors and ranking the factors based on their importance level. Each step includes different methods as well (Table 2). First, the primary factors were identified through the literature review (LR) and interview (IR) methods [61]. Second, the critical factors were further determined based on the questionnaire survey and mean value techniques [61]. Thanks to its simplicity in application, the mean value technique, in combination with questionnaires, tends to be the most widely used method [61,62]. Meanwhile, in order to improve the effectiveness, more innovative ranking approaches have been developed as an alternative to the mean score method. For instance, social network analysis (SNA) was applied to identify and analyse critical factors for schedule risk from the perspective of stakeholders, based on the initial factors determined by the literature review and interview [63].

Table 2.

Methods of identifying the factors affecting PC.

However, these ranking approaches are mostly based on the factors’ subjective values derived from the survey, which may overlook the objectivity of the factors. The objective value is a direct reflection of the factors’ importance relating to the sustainable construction capability oriented to PC for construction enterprises, especially during the initial development phase. For instance, the market scale of the construction enterprise was generally small during the initial development stage of the Chinese PC industry, which can be important to the reflection of their sustainable capability.

In fact, methods for the importance evaluation that integrate the objective and subjective weights have been developed. These methods include, but are not limited to, analytic hierarchy process integrated with Entropy (AHP-Entropy) [68], fuzzy AHP-Entropy (FAHP-Entropy), and so on [69]. For example, the AHP-Entropy method was adopted in order to evaluate the capability of the construction industrialisation of construction firms [70]. The FAHP-Entropy approach was used to construct an evaluation index system of energy-saving building design, and to identify the critical indexes to optimise the design [69]. On this basis, an integrated quantitative FAHP-Entropy approach that takes into account both the subjective and objective values was used to identify the critical factors of this study. The objective value of factors was further evaluated by different categories of values in this study in order to assure the accuracy and comprehensiveness of the values. The categories include numeric values (NV), interval values (IV) (such as [1,4] and [5,10]), and linguistic values (LV) (such as good and poor) [71].

3. Research Method

In this study, the research process involves two stages; namely, the identification of the primary factors using the literature review and the in-depth interview, and the identification of the critical factors using the Entropy-AHP approach.

3.1. Preliminary Factors

This study further conducted a literature review and interviews in order to identify the factors relating to the sustainable construction capability of construction enterprises that implement PC. A systematic literature review was first undertaken in order to identify a list of preliminary factors. This study searched journal articles in Scopus through the keywords of prefabricated construction, off-site construction, precast construction, and the like. Then, in-depth interviews with ten experts were conducted in order to validate the initial factors’ rationality and comprehensiveness.

These experts included one government official, two developers, five contractors and two consultants. They all had more than five years of PC experience. They were presented with the aforementioned preliminary factors, and were asked to formulate a number of valid factors at the end of the day. They also determined each factor’s objective (O) or subjective type. The objective type could be represented with a precise NV (PNV) or an IV. The subjective type can be represented with an intuitive fuzzy number (IFN) or an LV.

As illustrated in Table 3, twenty-seven factors were identified as the preliminary factors relating to the sustainable construction capability. They were grouped into seven categories, and were coded with Ci (i = 1, 2, …, 27) and Bc (c = 1, 2, …, 7).

Table 3.

Identified preliminary factors for PC.

3.2. The Ranking Model of Preliminary Factors

This study further ranked the twenty-seven preliminary factors using the FAHP-Entropy method, in order to identify the critical factors. This method determined each factor’s importance degree through the calculation of its integrated weight, which combined the subjective and objective weights [93]. FAHP was used to calculate the subjective weight, based on experts’ opinions on the factors’ relative importance [60]. Entropy was used to calculate the objective weight, based on the factors’ practical value [94].

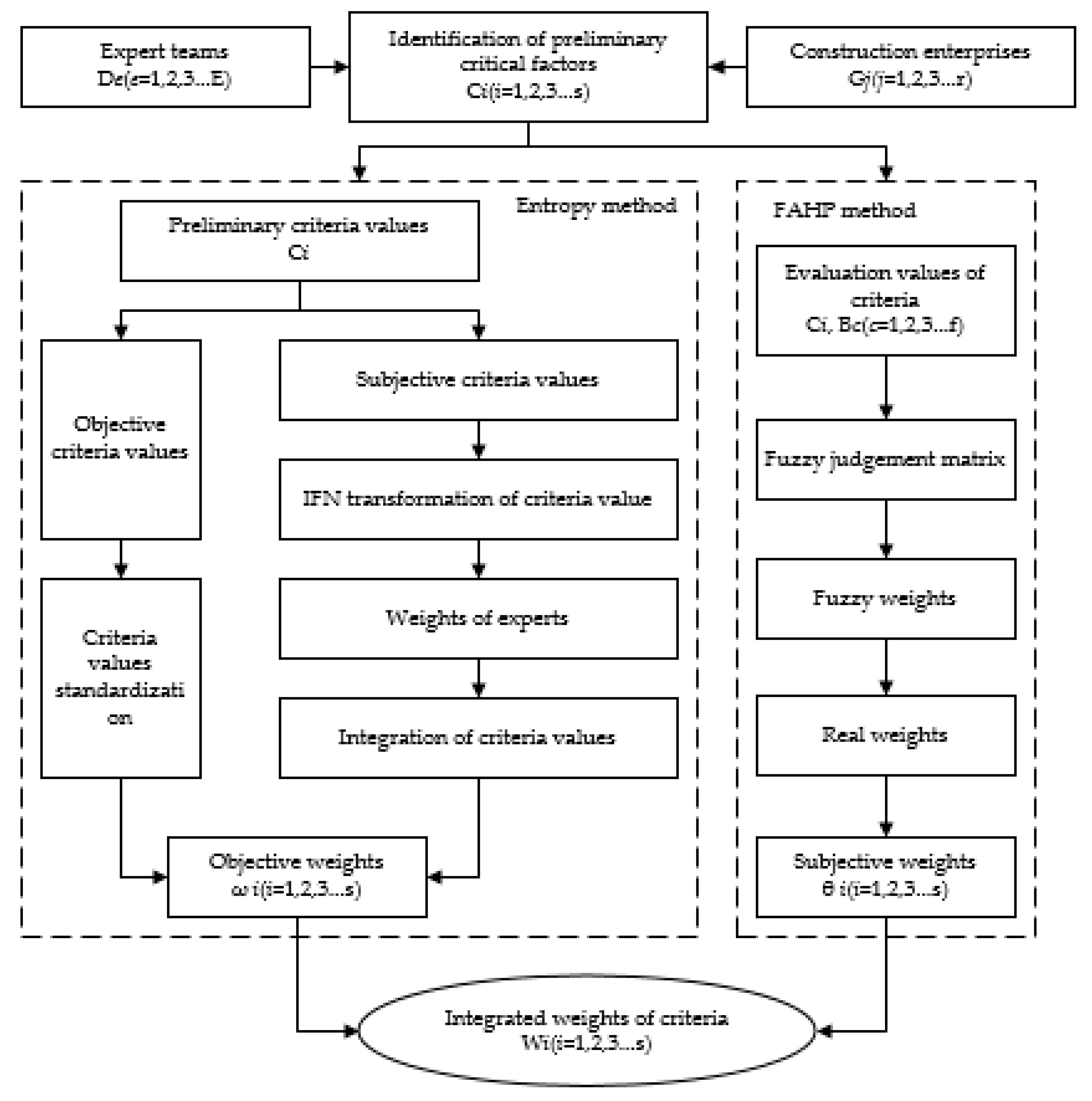

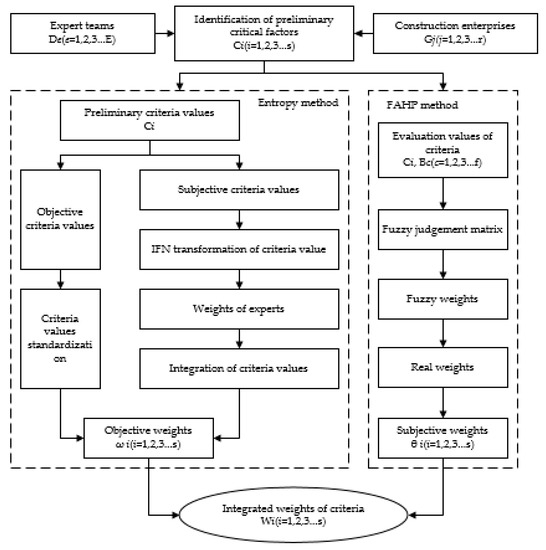

As illustrated in Figure 1, the data collection and calculation processes consisted of four steps: data collection from the experts (coded by De) and construction enterprises (coded by Gj); the calculation of the subjective weights (coded by θi), based on FAHP; the calculation of the objective weights (coded by ωi), based on Entropy; and the calculation of the integrated weights (coded by Wi), before the preliminary factors were ranked down.

Figure 1.

Integrated weights calculation process.

- Step 1:

- Data collection.

In order to rank the twenty-seven preliminary factors using FAHP-Entropy, this study first needed to select some construction enterprises as the study cases. Then, the data for the calculation of the subjective and objective factors’ weights using FAHP and Entropy were respectively collected.

Four Chinese construction enterprises undertaking PC projects were selected as the study cases. They were four main contractors, namely, ZJ (denoted as G1), YD (denoted as G2), BY (denoted as G3), and YZ (denoted as G4). The criteria for the selection of these enterprises mainly included the PC market scale and the start time. The four construction enterprises covered four different cases, including the big market scale with the early start time (ZJ), the big market scale with the late start time (YD), the small market scale with the early start time (BY), and the small market scale with the late start time (YZ). All four cases were considered in this study in order to achieve a balanced view and measure the importance of difference factors.

When calculating the subjective weights, an important process was to construct a fuzzy pairwise comparison matrix based on the relative importance scores among the factors collected from the aforementioned ten experts.

The relative importance involved the comparisons not only between the factors under one aspect, but also between aspects under the project goal (the sustainable construction capability oriented to PC for construction enterprise). In order to simplify the calculation, these experts were further organised into four stakeholder types, which are the government (coded by D1), the developer (coded by D2), the contractor (coded by D3), and the consultant (coded by D4).

The four expert teams, respectively, presented the relative importance scores using the trianglular fuzzy number (TFN) [75]. TFN was represented by (l, m, u) in this study, where l, m and u denote the smallest, most and bigger possible values, respectively. Generally, the expert teams determined the m value using a 1 to 9 scale [60,95]. They further evaluated the fuzzy degree of the determination of m, including not fuzzy, fuzzy and very fuzzy, which were used to calculate the l and u values [96]. The relative importance scores for the aspects (B→B) were taken as an example to illustrate the processes (see Appendix A).

This study used the questionnaire technique to collect the expert evaluation of the fuzzy degree. The questionnaire covered all of the factors and aspects, which were delivered to the four expert teams via email. Then, the relative importance was aggregated through the geometric mean method (GMM); thus, the final fuzzy pairwise comparison matrices were calculated [75].

In the calculation of the objective weights using Entropy, the values of the factors were collected for the four construction enterprises. As illustrated in Table 3, the types of factors relating to the sustainable construction capability oriented to PC for construction enterprises included objective and subjective factors. The values of the objective factors were determined from the construction enterprise practical data. This study utilised the survey of construction enterprise and a website-based search to collect these data. In terms of subjective factors, their values came from the aforementioned expert team evaluation. This study conducted a questionnaire to collect these values. Each team, respectively, evaluated the IFN or LV. The linguistic value included nine aspects—namely, extremely poor (EP), very poor (VP), poor (P), a little poor (LP), common (C), a little good (LG), good (G), very good (VG), and extremely good (EG)—and should be further converted into IFN using the Entropy calculation process [97,98]. Appendix B shows the value of the subjective factors collected from the four expert teams. Therefore, the collected data provided the basis for the calculation of the subjective and objective weights of all of the preliminary factors.

- Step 2:

- The calculation of the objective weight using the Entropy method.

The Entropy method is commonly used to calculate objective weights relying on practical factors’ values, as illustrated in step 1. Entropy is the reflection that the more various values of a factor for different construction enterprises, the larger the weight of the factor [68]. The calculation processes and equations using Entropy are described as follows.

is the factors’ objective weight. Specially, is the objective weight of the i-th criterion, and , .

represents the i-th factor value of the j-th enterprise. The mean value of can be calculated using the following equation:

M1 is the set of precise values, which are the normalised values of the raw precise data. M2 is the set of interval values, which are the normalised values of the raw interval data. M3 is the set of IFNs, including the converted IFNs from the LVs [99]. Due to the fact that the subjective factors’ values for the evaluation object are evaluated by different expert teams, the values need to be integrated into one comprehensive value based on the weighting of the experts. The Entropy value of the i-th factor can be calculated using the following equation:

Here, d is the distance between xij and , which can be calculated by referring to [99]. Ultimately, the can be calculated using the following equation:

- Step 3:

- The calculation of the subjective weight using FAHP.

FAHP is used widely to calculate subjective weights based on experts’ opinions [100]. The calculation processes of FAHP is mainly comprised of four steps [75]: (1) the construction of pairwise comparison matrices through the integration of p experts’ evaluation of each factor using the GMM method; (2) the determination of the fuzzy weights; (3) the conversion of the fuzzy weights into real weights with defuzzification; (4) the determination of the final weights through normalization.

The specific calculation processes of FAHP are generally illustrated as follows, with the example of one factor. The value f represents the number of holistic aspects (Bc). n is the number of factors (Ci) corresponding to a certain aspect, where n = 1, 2, 3, …, s.

First, the fuzzy judgment matrix can be constructed as follows:

In this matrix, is the mean value of the Ci factor’s relative importance scores corresponding to the c aspect from all of the experts, where i, j = 1, 2, 3,…,n and c = 1, 2, 3,…, f. The is the score for the Ci factor corresponding to the c aspect from t-th experts, where t = 1, 2, 3, … P. Moreover, can be calculated using the following equation:

The original fuzzy weight ( of the i-th factor corresponding to the c-th aspect can then be calculated:

Based on this, the fuzzy weights (Cc) of all of the factors corresponding to the aspect can be calculated. Moreover, the fuzzy weights (S) of all of the aspects corresponding to the goal (the sustainable construction capability) can be calculated.

Then, Cc and S should undergo defuzzification, following [75]. Cc is thus transformed into the actual weights d(Ci), and S is transformed to d(Si). Furthermore, d(Ci) and d(Si) should be normalized through the min–max equation [75], which can be defined in terms of D(Ci) and D(Si). Finally, the actual weights of all of the factors corresponding to the goal can be calculated as follows:

- Step 4:

- The calculation of the integrated weights.

The integrated weights can be calculated by combining objective and subjective weights. The equation used to calculate the integrated weights is [99]:

In this equation, was the risk preference factor, which indicates risk neutrality in the experts’ evaluation. Generally, was taken to be 0.5.

4. Factors’ Weights and Ranking Analysis

4.1. Factors’ Weight Results Using the FAHP-Entropy Method

The factors’ integrated weights can be further calculated based on the aforementioned processes. The specific results are illustrated below.

- Step 1:

- Data preprocessing.

The factors’ precise and interval values should be normalised in order to eliminate their dimensional impact, and this could be done using the extremum method [99]. The factors’ LVs should be transformed into IFNs.

- Step 2:

- The calculation of the factors’ objective weights using the Entropy approach.

In calculating factors’ objective weight processes using Entropy, two key parameters including and were first calculated using Equations (1) and (2). and represented the factors’ comprehensive value and Entropy value, respectively. Based on the and values, the factors’ objective weight was determined using the Equation (3). The calculation results of , and were specifically illustrated in Table 4.

Table 4.

, and values.

- Step 3:

- The calculation of the factors’ subjective weights using the FAHP method.

In calculating the factors’ subjective weight processes using FAHP, the seven aspects’ fuzzy weights S and factors’ weights were respectively calculated based on Equations (4)—(6). Then, the fuzzy weights of S and C were respectively converted into real weights coded by D(S) and D(C) through the undertaking of defuzzification and normalisation. For example, S for each aspect can be represented by S1 = (0.125, 0.190, 0.297), S2 = (0.092, 0.147, 0.231), S3 = (0.067, 0.104, 0.166), S4 = (0.087, 0.133, 0.204), S5 = (0.118, 0.175, 0.258), S6 = (0.083, 0.128, 0.197) and S7 = (0.083, 0.121, 0.177), which were further converted into D(S) = (0.210, 0.210,0.068, 0.122,0.188, 0.113, 0.090).

Based on D(S) and D(C), the final weights were calculated using Equation (7). More specifically, the D(S), D(C) and values are illustrated in Table 5.

Table 5.

D(S), D(C), and values.

- Step 4:

- The calculation of the factors’ integrated weights.

The factors’ integrated weight W was calculated based on the objective weights ω and subjective weights using Equation (8). The W result was shown as follows:

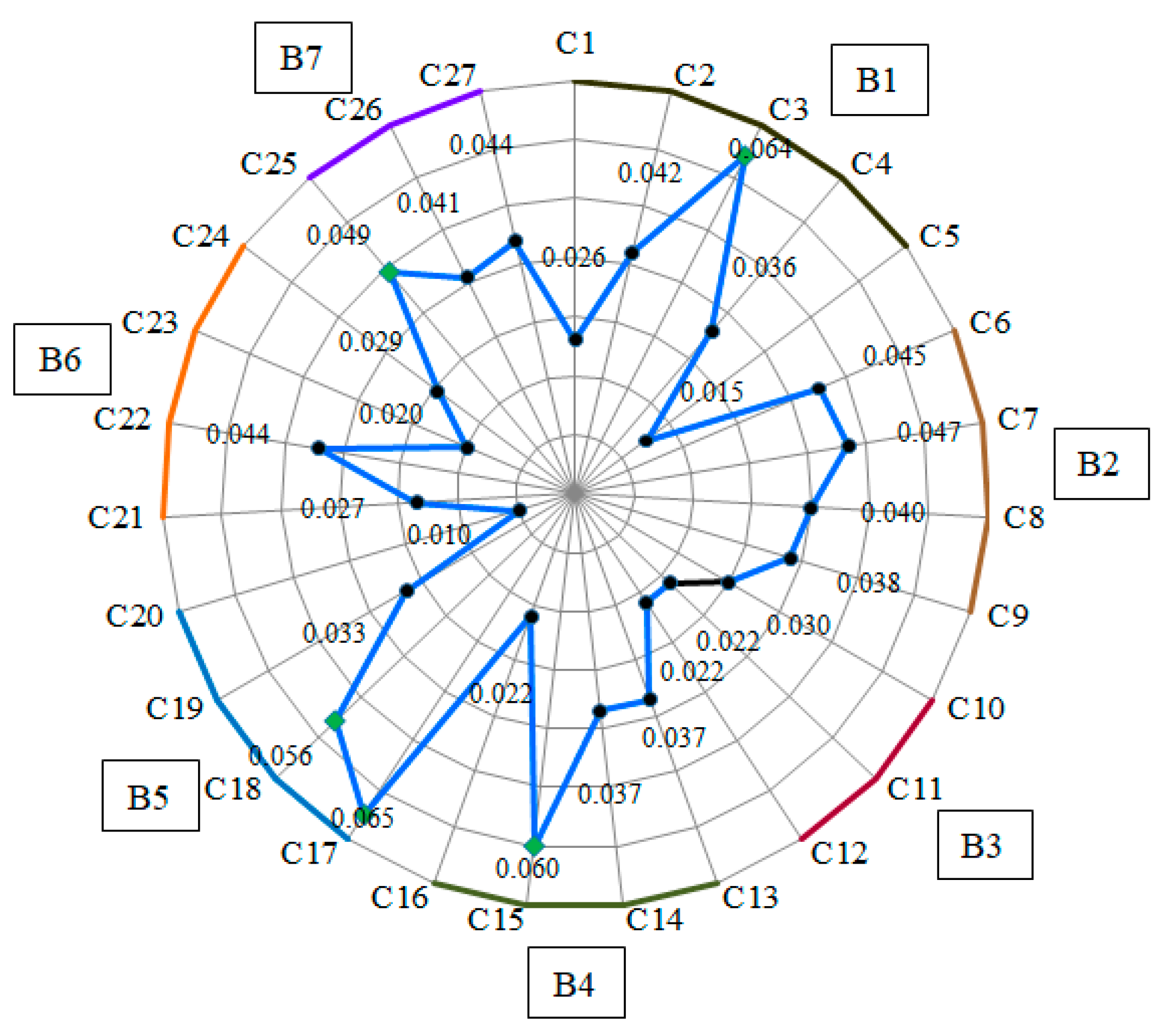

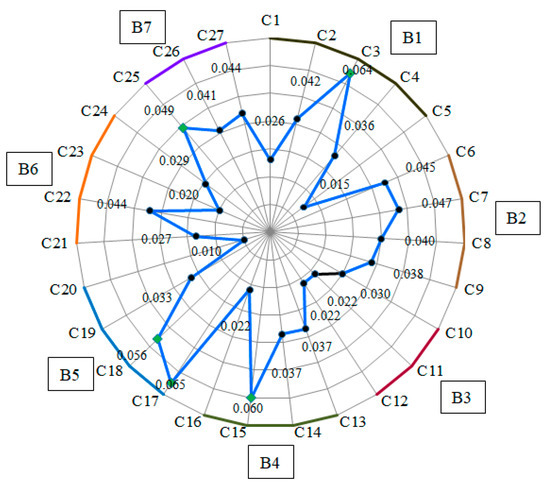

W = (W1, W2, W3,…,W27) = (0.026, 0.042, 0.064, 0.036, 0.015, 0.045, 0.047, 0.040, 0.038, 0.030, 0.022, 0.022, 0.037, 0.037, 0.060, 0.022, 0.065, 0.056, 0.033, 0.010, 0.027, 0.044, 0.020, 0.029, 0.049, 0.041, 0.044).

4.2. Ranking Analysis Results

As a result, the twenty-seven preliminary factors were ranked by the integrated weights W, as depicted in Table 6. The five critical factors are C17, C3, C15, C18 and C25. C17, the number of prefabricated construction areas per year, is ranked the first, with the highest integrated weight of 0.065. Hence, C17 is considered to be the most important factor impacting the sustainable construction capability oriented to PC for construction enterprises.

Table 6.

Factor ranking results.

C3, the applicability of the quality control technology, obtained the integrated weight of 0.064, which is just lower than C17′s weight. The third-, fourth- and fifth-ranked factors are C15, C18 and C25, which represent the number of standard and system innovations, the number of prefabricated projects per year, and the annual output value of the prefabricated projects, respectively.

Moreover, these five critical factors, e.g., C17, C3, C15, C18 and C25, are distributed in different aspects involving B1, B4, B5 and B7. The five critical factors are indicated with the green square, which is distinguished with other factors indicated with black dots, as illustrated in Figure 2. Figure 2 also demonstrates the correlation between B1 to B7 and C1 to C27. For example, C17 and C18 belong to B5, which represents market-related aspects.

Figure 2.

Radar chart of the weightings.

5. Discussion

The above five factors are the most important factors influencing the construction enterprises’ sustainable construction capability. These five factors can be further divided into four clusters through aggregation with their corresponding aspects. These four clusters are market scale, quality control technology, standard and system innovation, and economic output value. Their important impacts are further analysed as follows.

- (1)

- Market scale.

C17 (the number of prefabricated construction areas per year) and C18 (the number of prefabricated projects per year) belong to B5 [21,22]. The market scale aspect has been perceived as the most direct influencing aspect of the sustainable construction capability oriented to PC for construction enterprises [4]. Especially in the Chinese original PC development phase, the market scale is the main indicator reflecting the sustainable construction capability for construction enterprises. This is probably because construction enterprises need to depend on higher sustainable construction capability in order to help expand their PC market scale. In fact, the Chinese PC sector is less mature, with the proportion of PC market scale to the new construction market being only about 3%–5% [21,24], which is far lower than some developed countries such as Sweden (80%) and Japan (70%).

Moreover, PC projects cost more than traditional construction projects, and this is considered to be one of the main barriers for the developer for the expansion of the holistic PC market scale [21]. In this way, construction enterprises with higher sustainable construction capability can reduce PC costs and expand their PC market scale [77]. Thus, the PC market is always dominated by a few construction enterprises with higher capability.

The increment of the holistic PC market scale is critical in reaching the scale economy, which is likely to promote construction enterprises to expand the PC market. In fact, the Chinese policy-maker has issued a set of policies and incentive measures to expand the holistic PC market scale [11,101]. For example, the Ministry of Housing and Urban–Rural Development of the People’s Republic of China (MOHURD) has stated that the proportion will reach 15% throughout China, and 20% in major areas—such as Beijing, Tianjin and Shanghai—by 2020 [102]; an incentivised measure issued by the Beijing government was to provide financial and building area incentives for non-nation-owned PC projects. This may provide a good opportunity for more and more construction enterprises to enter the PC market and boost the share.

- (2)

- Quality control technology.

C3, the quality control technology, is a critical factor relating to the sustainable construction capability oriented to PC for construction enterprises. In fact, it is essential for construction enterprises to place quality in the primary position, and to take quality control very seriously. Assuring PC projects’ higher quality is key to PC enterprises, which should rely on their sustainable construction capability.

The PC quality level is another key factor influencing PC development [64]. Excellent quality performance plays a vital role in obtaining significant progress in PC in some countries, e.g., Japan, Sweden, Singapore [64]. In fact, its high quality is considered to be one of the advantages of PC, which should attract the stakeholders’ and policymakers’ attention [77]. Furthermore, quality is also the main concern for the public to accept prefabricated buildings [103]. Therefore, policymakers should always emphasise quality assurance and control when promoting PC. For example, high quality has also been identified as the most critical requirement in the 2011–2015 Malaysian roadmap for PC.

In addition, quality control is always more difficult in PC projects than traditional projects. This is largely attributed to the more complicated construction processes in PC projects, such as production, transportation and assembly. Thus, this is a big challenge that construction enterprises have to face and resolve [64]. There have been frequent quality issues in some of the PC projects in China; for example, there have been connection problems of prefabricated components and main structures [103].

The Chinese policymaker emphasises PC quality, and has issued many laws, policies and mandatory standards, especially since 2016. For example, there is a government policy issued by MOHURD relating to the guidelines for the enhancement of construction quality by improving the system of quality control [104]. In addition, policymakers have also encouraged academic institutions such as universities and technical colleges to develop training courses about PC in order to cultivate more PC-oriented skilled workers. Nowadays, some universities have set up PC majors which offer enterprise-oriented professional education and upskilling. For example, Nanjing University built a PC industry training base in 2018 which provides classroom and laboratory subjects, in order to develop hands-on PC knowledge and hands-on skills. In line with government requirements and incentives, construction enterprises should continuously enhance their sustainable construction capability in order to improve quality control and reduce the quality risks in PC projects.

- (3)

- Standard and system innovation.

C15, the number of standard and system innovations, is a critical indicator of the R&D capability for construction enterprises. From the holistic perspective, PC standards and systems are more complex, due to the complicated construction processes in PC projects. Thus, it is difficult for construction enterprises to carry out innovations on PC standards and systems. Construction enterprises are generally weak in PC innovation capability [21,87]. Especially in the primary PC stage in China, construction enterprises are also confronted with the lack of national standards and limited R&D resources, resulting in more challenges for construction enterprise PC innovation. Thus, innovation capability can better reflect the sustainable construction capability oriented to PC for a construction enterprise. With the limited innovation capability for construction enterprises, the existing PC standard and system are often unmatured, which has resulted in some issues, further impeding the Chinese PC development.

The issues are mainly due to three reasons. Firstly, the quality of PC products—such as stairs, walls and pillars—is not reliable [103]. For example, the connection between walls and floors with grounding sleeve technology is not always effective, therefore resulting in weak structural strength. Secondly, the PC application is mostly used in highly standardised, low-to-medium level buildings for public institutions, e.g., schools, hospitals and enterprises. However, PC applications in high-rise buildings and private commercial real estate are limited [34]. Thirdly, for the PC modular level aspect, the levels can be categorised into four levels, namely component subassembly, non-volumetric preassembly, volumetric preassembly, and modular construction. The modular degree in China remains at the component subassembly level [20]. In contrast, some developed countries—such as North America, Australia and Japan—have widely adopted modular construction in their PC projects.

In fact, Chinese policymakers have considered PC innovation as one of the critical factors for the development of PC, and have made a great effort to develop PC standards and innovative PC systems [87]. Although the proportion of R&D investment in the building sector to the total GDP of the Chinese construction industry is only 0.4%–0.6% [21], the investment in innovative PC applications has increased a lot in recent years. Part of this investment has been used to support scientific research. For example, the guidance on PC technological systems for residential buildings was issued, which provided a technical system and reference for construction enterprises to extend the PC application range [105]. In addition, different schemes—such as financial subsidy, tax reduction and subject support—have been developed in order to incentivise construction enterprises to innovate PC workmanship. For example, the Tianjin government would reduce the tax for enterprises exploring innovative PC applications [66,76].

- (4)

- Economic output value.

C25, the annual output value of prefabricated projects, is an economic aspect, which is also one of the major indicators of the construction enterprise’s competitiveness and sustainable construction capability [23,44]. The output value directly impacts the investment in PC R&D, and the work extension. However, the output value of Chinese construction enterprises is generally low, thus not only limiting their sustainable construction capability increase but also reducing their motivation in developing the PC project [21].

The reason for the low output value is probably attributable to the high cost of implementing PC. The incremental cost in PC projects would be one to two times higher than traditional construction projects. In the initial stage of transforming from traditional construction to PC, construction enterprises need to invest in PC facilities, thus increasing the initial cost of a PC project. For example, a construction enterprise, YZ, invested approximately USD 14 million in building a PC factory, which covered the cost of the land, equipment, and buildings.

In addition, most construction enterprises lack PC experience, skilled workers, and resource management capability [106]. These issues would increase the cost of implementing PC. For example, the weak capability for construction enterprises in PC operation and supply chain management can result in more design changes and quality deficiency, bringing about resource waste and cost blowouts. Therefore, the sustainable construction capability oriented to PC can affect the output value positively. Construction enterprises should pay more attention to their internal improvement, in order to enhance their sustainable capability. The improvement plan may involve the development of lean construction, information management and automated construction methods [1].

6. Conclusions

Although PC has been regarded as a sustainable method to address various issues related to the construction sector—such as resource waste, environment pollution and quality deficiency—it is still in its infancy in China. To some extent, this is due to the limited sustainable performance in PC projects, and the solution relies on the improvement of the sustainable construction capability oriented to PC for construction enterprise.

This study explored the factors affecting the sustainable construction capability oriented to PC for construction enterprises, contributing to the existing literature around the improvement of the PC development. Twenty-seven factors relating to sustainable construction capability were identified and examined using qualitative methods including a literature review and in-depth interviews. These factors were further ranked through the FAHP-Entropy method. Five critical factors were selected to analyse the ways in which these factors affect construction enterprises’ sustainable construction capability, and what measures construction enterprise can take to improve these factors’ performance and the overall sustainable construction level.

The results of this study indicate that the sustainable construction capability for Chinese construction enterprise is weak. Construction enterprises should pay more attention to the development of the sustainable construction capability related to market scale, quality control technology, standard and system innovation and economic output value. Furthermore, construction enterprises are encouraged to extend their production scale, increase investments on innovation, and adopt lean construction and digital technologies in order to improve their sustainable construction capability. The results provide a reference for Chinese governments at different levels to formulate appropriate policies.

Although this study contributes to the identification of the critical influencing factors relating to the sustainable construction capability using the comprehensive quantitative approach of FAHP-Entropy, it also has some limitations. One is that, since this study is based on the current PC development state in China, the critical influencing factors may vary from country to country. The other limitation refers to the lack of concrete measures to tackle the critical influencing factors, due to the limited number of construction enterprises and experts that were examined in our study.

In view of this, our future study will revolve around conducting more case studies to explore the impact of the critical factors on the sustainable construction capability, the formulation of concrete measures for more and more construction enterprises to improve their sustainable construction capability, the evaluation of more construction enterprises’ sustainable construction capability maturity, and the determination of their capability levels.

Author Contributions

Conceptualization, P.D. and Z.N.; methodology, P.D. and G.Z.; validation, Z.N.; formal analysis, P.D.; investigation, P.D. and Z.N.; writing—original draft preparation, P.D.; writing—review and editing, G.Z., S.G. and L.H.; visualization, S.G.; supervision, G.Z. All authors have read and agreed to the published version of the manuscript.

Funding

P.D. finished the original manuscript of this article during the period of being a visiting student at RMIT university under the supervision of G.Z. The visiting was funded by the International Academic Exchange Fund from Tianjin University.

Acknowledgments

The authors would also like to thank the four Chinese construction enterprises considered as study cases, and all the survey interviewees providing a large amount of data.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Table of importance scores, taking aspects as an example in FAHP.

Table A1.

Table of importance scores, taking aspects as an example in FAHP.

| B→B | Expert Teams | Making Score Items | B1 | B2 | B3 | B4 | B5 | B6 | B7 |

|---|---|---|---|---|---|---|---|---|---|

| B1 | D1 | m | (1,1,1) | 1/4 | 1/3 | 1 | 3 | 3 | 1 |

| Fuzzy degree | Not fuzzy | Fuzzy | Fuzzy | Not fuzzy | Fuzzy | Fuzzy | |||

| D2 | m | 3 | 3 | 1 | 4 | 3 | 3 | ||

| Fuzzy degree | Not fuzzy | Fuzzy | Not fuzzy | Fuzzy | Fuzzy | Fuzzy | |||

| D3 | m | 5 | 2 | 2 | 1/3 | 4 | 1/3 | ||

| Fuzzy degree | Not fuzzy | Not fuzzy | Fuzzy | Not fuzzy | Fuzzy | Not fuzzy | |||

| D4 | m | 3 | 4 | 5 | 1 | 4 | 4 | ||

| Fuzzy degree | Not fuzzy | Fuzzy | Not fuzzy | Not fuzzy | Fuzzy | Not fuzzy | |||

| B2 | D1 | m | 1/B1→B2 | (1,1,1) | 3 | 2 | 4 | 3 | 4 |

| Fuzzy degree | Not fuzzy | Fuzzy | Not fuzzy | Fuzzy | Fuzzy | ||||

| D2 | m | 1/4 | 1/4 | 3 | 3 | 2 | |||

| Fuzzy degree | Not fuzzy | Fuzzy | Fuzzy | Fuzzy | Not fuzzy | ||||

| D3 | m | 2 | 1/5 | 1/4 | 1/2 | 1/4 | |||

| Fuzzy degree | Fuzzy | Fuzzy | Not fuzzy | Fuzzy | Not fuzzy | ||||

| D4 | m | 4 | 4 | 1/5 | 2 | 3 | |||

| Fuzzy degree | Fuzzy | Not fuzzy | Fuzzy | Fuzzy | Fuzzy | ||||

| B3 | D1 | m | 1/B1→B3 | 1/B2→B3 | (1,1,1) | 2 | 3 | 2 | 3 |

| Fuzzy degree | Very fuzzy | Not fuzzy | Fuzzy | Not fuzzy | |||||

| D2 | m | 1/3 | 1/4 | 4 | 2 | ||||

| Fuzzy degree | Not fuzzy | Fuzzy | Fuzzy | Fuzzy | |||||

| D3 | m | 1/5 | 1/4 | 1 | 1/5 | ||||

| Fuzzy degree | Fuzzy | Not fuzzy | Fuzzy | Not fuzzy | |||||

| D4 | m | 1/3 | 1/5 | 1/3 | 3 | ||||

| Fuzzy degree | Not fuzzy | Fuzzy | Fuzzy | Not fuzzy | |||||

| B4 | D1 | m | 1/B1→B4 | 1/B2→B4 | 1/B3→B4 | (1,1,1) | 2 | 1/4 | 3 |

| Fuzzy degree | Not fuzzy | Fuzzy | Not fuzzy | ||||||

| D2 | m | 3 | 1/4 | 3 | |||||

| Fuzzy degree | Fuzzy | Not fuzzy | Fuzzy | ||||||

| D3 | m | 1/2 | 4 | 1/3 | |||||

| Fuzzy degree | Fuzzy | Not fuzzy | Fuzzy | ||||||

| D4 | m | 1/5 | 1/4 | 1/4 | |||||

| Fuzzy degree | Not fuzzy | Fuzzy | Not fuzzy | ||||||

| B5 | D1 | m | 1/B1→B5 | 1/B2→B5 | 1/B3→B5 | 1/B4→B5 | (1,1,1) | 1/5 | 3 |

| Fuzzy degree | Not fuzzy | Not fuzzy | |||||||

| D2 | m | 1/3 | 1/5 | ||||||

| Fuzzy degree | Fuzzy | Not fuzzy | |||||||

| D3 | m | 5 | 3 | ||||||

| Fuzzy degree | Fuzzy | Not fuzzy | |||||||

| D4 | m | 4 | 4 | ||||||

| Fuzzy degree | Not fuzzy | Fuzzy | |||||||

| B6 | D1 | m | 1/B1→B6 | 1/B2→B6 | 1/B3→B6 | 1/B4→B6 | 1/B5→B6 | (1,1,1) | 4 |

| Fuzzy degree | Fuzzy | ||||||||

| D2 | m | 1/3 | |||||||

| Fuzzy degree | Not fuzzy | ||||||||

| D3 | m | 1/4 | |||||||

| Fuzzy degree | Fuzzy | ||||||||

| D4 | m | 5 | |||||||

| Fuzzy degree | Not fuzzy | ||||||||

| B7 | D1 | m | 1/B1→B7 | 1/B2→B7 | 1/B3→B7 | 1/B4→B7 | 1/B5→B7 | 1/B6→B7 | (1,1,1) |

| Fuzzy degree | |||||||||

| D2 | m | ||||||||

| Fuzzy degree | |||||||||

| D3 | m | ||||||||

| Fuzzy degree | |||||||||

| D4 | m | ||||||||

| Fuzzy degree |

Appendix B

Table A2.

The collected data of the subjective factors in Entropy.

Table A2.

The collected data of the subjective factors in Entropy.

| Enterprises | Factors | Value Type | Minimum Value | Maximum Value | Expert Teams’ Evaluated Value | |||

|---|---|---|---|---|---|---|---|---|

| D1 | D2 | D3 | D4 | |||||

| G1 | C1 | IFN | (0.01, 0.99) | (0.99, 0.01) | (0.45, 0.40) | (0.50, 0.45) | (0.55, 0.40) | (0.45, 0.40) |

| C2 | LV | EP | EG | P | LG | C | C | |

| C3 | LV | EP | EG | C | C | LG | G | |

| C4 | LV | EP | EG | LP | LP | C | C | |

| C6 | LV | EP | EG | P | LP | C | LP | |

| C7 | LV | EP | EG | LP | C | LP | P | |

| C8 | LV | EP | EG | P | LP | C | C | |

| C9 | IFN | (0.01,0.99) | (0.99,0.01) | (0.35,0.6) | (0.40,05) | (0.40,0.50) | (0.45,0.50) | |

| C11 | LV | EP | EG | C | LG | LG | LG | |

| C16 | LV | EP | EG | LP | C | C | LP | |

| C22 | LV | EP | EG | LP | C | C | LP | |

| C23 | IFN | (0.01,0.99) | (0.99,0.01) | (050, 0.30) | (0.50, 0.40) | (0.55,0.35) | (0.50, 0.25) | |

| C24 | LV | EP | EG | LG | G | LG | G | |

| G2 | C1 | IFN | (0.01,0.99) | (0.99,0.01) | (0.55, 0,40) | (0.60,0.25) | (0.65,0.30) | (0.60,0.30) |

| C2 | LV | EP | EG | LP | C | G | C | |

| C3 | LV | EP | EG | C | LG | G | LG | |

| C4 | LV | EP | EG | LP | C | C | LP | |

| C6 | LV | EP | EG | P | C | LG | LP | |

| C7 | LV | EP | EG | VP | P | C | C | |

| C8 | LV | EP | EG | P | C | LG | LP | |

| C9 | IFN | (0.01, 0.99) | (0.99, 0.01) | (0.30, 0,65) | (0.45, 0.50) | (0.50, 0.45) | (0.55, 0.40) | |

| C11 | LV | EP | EG | LP | C | G | LG | |

| C16 | LV | EP | EG | LP | LG | G | LG | |

| C22 | LV | EP | EG | P | LP | C | C | |

| C23 | IFN | (0.01, 0.99) | (0.99, 0.01) | (0.3, 0.45) | (0.45, 0.45) | (0.50, 0.40) | (0.45, 0.35) | |

| C24 | LV | EP | EG | G | G | G | LG | |

| G3 | C1 | IFN | (0.01, 0.99) | (0.99, 0.01) | (0.60, 0.30) | (0.65, 0.20) | (0.65, 0.30) | (0.55, 0.40) |

| C2 | LV | EP | EG | C | C | LG | LG | |

| C3 | LV | EP | EG | LG | C | LG | LG | |

| C4 | LV | EP | EG | C | C | LG | C | |

| C6 | LV | EP | EG | LP | LP | C | C | |

| C7 | LV | EP | EG | P | P | C | LG | |

| C8 | LV | EP | EG | LP | C | C | LG | |

| C9 | IFN | (0.01, 0.99) | (0.99, 0.01) | (0.25, 0.60) | (0.55, 0.30) | (0.60, 0.30) | (0.50, 0.45) | |

| C11 | LV | EP | EG | C | G | C | LG | |

| C16 | LV | EP | EG | C | G | LG | LG | |

| C22 | LV | EP | EG | C | C | LG | C | |

| C23 | IFN | (0.01,0.99) | (0.99,0.01) | (0.40, 0.40) | (0.45, 0.40) | (0.50, 0.35) | (0.55, 0.30) | |

| C24 | LV | EP | EG | G | G | VG | G | |

| G4 | C1 | IFN | (0.01,0.99) | (0.99, 0.01) | (0.10, 0.85) | (0.10, 0.80) | (0.15, 0.75) | (0.05, 0.80) |

| C2 | LV | EP | EG | VP | P | C | LP | |

| C3 | LV | EP | EG | C | LP | C | C | |

| C4 | LV | EP | EG | P | LP | P | P | |

| C6 | LV | EP | EG | VP | P | LP | P | |

| C7 | LV | EP | EG | VP | VP | LP | P | |

| C8 | LV | EP | EG | VP | LP | P | P | |

| C9 | IFN | (0.01,0.99) | (0.99,0.01) | (0.15, 0.70) | (0.25, 0.60) | (0.30, 0.55) | (0.10, 0.85) | |

| C11 | LV | EP | EG | P | LP | LP | P | |

| C16 | LV | EP | EG | VP | VP | P | VP | |

| C22 | LV | EP | EG | P | LP | LP | LP | |

| C23 | IFN | (0.01, 0.99) | (0.99, 0.01) | (0.25, 0.70) | (0.40, 0.35) | (0.35, 0.40) | (0.45, 0.25) | |

| C24 | LV | EP | EG | C | G | G | G | |

References

- Jin, R.Y.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.X.; Luo, L.Z. SWOT analysis and Internet of Things-enabled platform for prefabrication housing production in Hong Kong. Habitat. Int. 2016, 57, 74–87. [Google Scholar] [CrossRef]

- Mao, C.; Xie, F.Y.; Hou, L.; Wu, P.; Wang, J.; Wang, X.Y. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat. Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manage. (Oxford) 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Arashpour, M.; Wakefield, R.; Blismas, N.; Minas, J. Optimization of process integration and multi-skilled resource utilization in off-site construction. Autom. Constr. 2015, 50, 72–80. [Google Scholar] [CrossRef]

- Lu, W.S.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.K.; Tan, J.J. A SWOT analysis for promoting off-site construction under the backdrop of China’s new urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Zhang, X.L.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat. Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Guidelines on the Vigorous Development of Prefabricated Buildings (In Chinese). Available online: http://www.gov.cn/zhengce/content/2016-09/30/content_5114118.htm (accessed on 30 September 2016).

- Hou, L.; Tan, Y.; Luo, W.; Xu, S.; Mao, C.; Moon, S. Towards a more extensive application of off-site construction: A technological review. Int. J. Constr. Manag. 2020, 20, 1–12. [Google Scholar] [CrossRef]

- Tan, Y.; Shen, L.; Yao, H. Sustainable construction practice and contractors’ competitiveness: A preliminary study. Habitat Int. 2011, 35, 225–230. [Google Scholar] [CrossRef]

- Tan, Y.; Shuai, C.; Shen, L.; Hou, L.; Zhang, G. A study of sustainable practices in the sustainability leadership of international contractors. Sustain. Dev. 2019, 28, 697–710. [Google Scholar] [CrossRef]

- Teng, Y.; Mao, C.; Liu, G.W.; Wang, X.Y. Analysis of stakeholder relationships in the industry chain of industrialized building in China. J. Clean. Prod. 2017, 152, 387–398. [Google Scholar] [CrossRef]

- Gan, X.L.; Chang, R.D.; Wen, T. Overcoming barriers to off-site construction through engaging stakeholders: A two-mode social network analysis. J. Clean. Prod. 2018, 201, 735–747. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.J.; Su, Y.K.; Wu, Z.Z.; Yang, R.J. Effect of stakeholder collaborative management on off-site construction cost performance. J. Clean. Prod. 2018, 184, 490–502. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, R.Y.; Li, Z.; Huang, G. Production lead-time hedging and coordination in prefabricated construction supply chain management. Int. J. Prod. Res. 2017, 55, 3984–4002. [Google Scholar] [CrossRef]

- Zhai, Y.; Fu, Y.L.; Xu, G.Y.; Huang, G. Multi-period hedging and coordination in a prefabricated construction supply chain. Int. J. Prod. Res. 2019, 57, 1949–1971. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.P.; Pan, W.; Ye, K.H. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Hong, J.K.; Shen, G.Q.P.; Li, Z.D.; Zhang, B.Y.; Zhang, W.Q. Barriers to promoting prefabricated construction in China: A cost-benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Li, L.; Gao, Y. Constraints on the Promotion of Prefabricated Construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef]

- Zakaria, S.A.S.; Gajendran, T.; Rose, T.; Brewer, G. Contextual, structural and behavioural factors influencing the adoption of industrialised building systems: A review. Archit. Eng. Des. Manag. 2018, 14, 3–26. [Google Scholar]

- Ji, Y.B.; Li, K.J.; Liu, G.W.; Shrestha, A.; Jing, J.X. Comparing greenhouse gas emissions of precast in-situ and conventional construction methods. J. Clean. Prod. 2018, 173, 124–134. [Google Scholar] [CrossRef]

- Wong, P.S.P.; Zwar, C.; Gharaie, E. Examining the Drivers and States of Organizational Change for Greater Use of Prefabrication in Construction Projects. J. Constr. Eng. Manag. 2017, 143, 04017020. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, D. A hybrid model of external environmental benefits compensation to practitioners for the application of prefabricated construction. Environ. Impact Assess. Rev. 2020, 81, 106358. [Google Scholar] [CrossRef]

- Cavaco, E.; Pacheco, I.; Camara, J. Detailing of concrete-to-concrete interfaces for improved ductility. Eng. Struct. 2018, 156, 210–223. [Google Scholar] [CrossRef]

- Kale, S.; Arditi, D. Diffusion of ISO 9000 certification in the precast concrete industry. Constr. Manag. Econ. 2006, 24, 485–495. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Perspectives of UK housebuilders on the use of offsite modern methods of construction. Constr. Manag. Econ. 2007, 25, 183–194. [Google Scholar] [CrossRef]

- Jeong, Y.S.; Eastman, C.M.; Sacks, R.; Kaner, I. Benchmark tests for BIM data exchanges of precast concrete. Autom. Constr. 2009, 18, 469–484. [Google Scholar] [CrossRef]

- Luo, L.Z.; Shen, G.Q.; Xu, G.Y.; Liu, Y.L.; Wang, Y.J. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Fung, I.W.H.; Sing, M.C.P.; Ogunlana, S.O. Best practice of prefabrication implementation in the Hong Kong public and private sectors. J. Clean. Prod. 2015, 109, 216–231. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Isaac, S.; Bock, T.; Stoliar, Y. A methodology for the optimal modularization of building design. Autom. Constr. 2016, 65, 116–124. [Google Scholar] [CrossRef]

- Park, J.; Choi, J.; Jang, Y.; Park, S.K.; Hong, S. An Experimental and Analytical Study on the Deflection Behavior of Precast Concrete Beams with Joints. Appl. Sci. 2017, 7, 1198. [Google Scholar] [CrossRef]

- Shea, A.; Wall, K.; Walker, P. Evaluation of the thermal performance of an innovative prefabricated natural plant fibre building system. Build. Serv. Eng. Res. Technol. 2013, 34, 369–380. [Google Scholar] [CrossRef]

- Lee, D.; Lim, C.; Kim, S. CO2 emission reduction effects of an innovative composite precast concrete structure applied to heavy loaded and long span buildings. Energy Build. 2016, 126, 36–43. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Maranan, G.B.; Muttashar, M.; Yan, Z.G.; Vijay, P.V.; Pettigrew, J. Effectiveness of a novel composite jacket in repairing damaged reinforced concrete structures subject to flexural loads. Compos. Struct. 2020, 233, 111634. [Google Scholar] [CrossRef]

- Tullini, N.; Minghini, F. Grouted sleeve connections used in precast reinforced concrete construction-Experimental investigation of a column-to-column joint. Eng. Struct. 2016, 127, 784–803. [Google Scholar] [CrossRef]

- Vaghei, R.; Hejazi, F.; Taheri, H.; Jaafar, M.S.; Aziz, F.N.A.A. Development of a new connection for precast concrete walls subjected to cyclic loading. Earthq. Eng. Eng. Vib. 2017, 16, 97–117. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. J. Clean. Prod. 2017, 142, 3592–3606. [Google Scholar] [CrossRef]

- Xue, H.; Zhang, S.J.; Su, Y.K.; Wu, Z.Z. Factors Affecting the Capital Cost of Prefabrication-A Case Study of China. Sustainability 2017, 9, 1512. [Google Scholar] [CrossRef]

- Liu, J.K.; Gong, E.Q.; Wang, D.; Teng, Y. Cloud Model-Based Safety Performance Evaluation of Prefabricated Building Project in China. Wirel. Pers. Commun. 2018, 102, 3021–3039. [Google Scholar] [CrossRef]

- Shahtaheri, Y.; Rausch, C.; West, J.; Haas, C.; Nahangi, M. Managing risk in modular construction using dimensional and geometric tolerance strategies. Autom. Constr. 2017, 83, 303–315. [Google Scholar] [CrossRef]

- Choi, J.O.; O’Connor, J.T.; Kim, T.W. Recipes for Cost and Schedule Successes in Industrial Modular Projects: Qualitative Comparative Analysis. J. Constr. Eng. Manag. 2016, 142, 04016055. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, R.Y.; Huang, G.Q. Buffer space hedging and coordination in prefabricated construction supply chain management. Int. J. Prod. Econ. 2018, 200, 192–206. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Abbasi, B.; Lee, E.W.M.; Minas, J. Off-site construction optimization: Sequencing multiple job classes with time constraints. Autom. Constr. 2016, 71, 262–270. [Google Scholar] [CrossRef]

- Yang, Z.T.; Ma, Z.L.; Wu, S. Optimized flowshop scheduling of multiple production lines for precast production. Autom. Constr. 2016, 72, 321–329. [Google Scholar] [CrossRef]

- Li, X.; Shen, G.Q.; Wu, P.; Fan, H.Q.; Wu, H.Q.; Teng, Y. RBL-PHP: Simulation of Lean Construction and Information Technologies for Prefabrication Housing Production. J. Manag. Eng. 2018, 34, 04017053. [Google Scholar] [CrossRef]

- Ramaji, I.J.; Memari, A.M.; Messner, J.I. Product-Oriented Information Delivery Framework for Multistory Modular Building Projects. J. Comput. Civ. Eng. 2017, 31, 04017001. [Google Scholar] [CrossRef]

- Sutrisna, M.; Goulding, J. Managing information flow and design processes to reduce design risks in offsite construction projects. Eng. Constr. Archit. Manag. 2019, 26, 267–284. [Google Scholar] [CrossRef]

- Gibb, A.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2010, 31, 146–160. [Google Scholar] [CrossRef]

- Benjaoran, V.; Dawood, N. Intelligence approach to production planning system for bespoke precast concrete products. Autom. Constr. 2006, 15, 737–745. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Strategies for Integrating the Use of Off-Site Production Technologies in House Building. J. Constr. Eng. Manag. ASCE 2012, 138, 1331–1340. [Google Scholar] [CrossRef]

- Kasperzyk, C.; Kim, M.K.; Brilakis, I. Automated re-prefabrication system for buildings using robotics. Autom. Constr. 2017, 83, 184–195. [Google Scholar] [CrossRef]

- Taghaddos, H.; Hermann, U.; Abbasi, A. Automated Crane Planning and Optimization for modular construction. Autom. Constr. 2018, 95, 219–232. [Google Scholar] [CrossRef]

- Mostafa, S.; Chileshe, N.; Abdelhamid, T. Lean and agile integration within offsite construction using discrete event simulation A systematic literature review. Constr. Innov. Engl. 2016, 16, 483–525. [Google Scholar] [CrossRef]

- Bansal, S.; Biswas, S.; Singh, S.K. Fuzzy decision approach for selection of most suitable construction method of Green Buildings. Int. J. Sustain. Built Environ. 2017, 6, 122–132. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2019, 5, 763–784. [Google Scholar] [CrossRef]

- Martin, E.W. Critical Success Factors of Chief MIS/DP Executives. Mis Q. 1982, 6, 1–9. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.K.; Xue, F.; Shen, G.Q.; Xu, X.X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef]

- Gan, Y.; Shen, L.; Chen, J.; Tam, V.; Tan, Y.; Illankoon, I. Critical Factors Affecting the Quality of Industrialized Building System Projects in China. Sustainability 2017, 9, 216. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Wu, G.; Li, X. Critical Success Factors for Project Planning and Control in Prefabrication Housing Production: A China Study. Sustainability 2018, 10, 836. [Google Scholar] [CrossRef]

- O’Connor, J.T.; O’Brien, W.J.; Choi, J.O. Critical Success Factors and Enablers for Optimum and Maximum Industrial Modularization. J. Constr. Eng. Manag. 2014, 140, 04014012. [Google Scholar] [CrossRef]

- Ji, Y.; Qi, L.; Liu, Y.; Liu, X.; Li, H.; Li, Y. Assessing and Prioritising Delay Factors of Prefabricated Concrete Building Projects in China. Appl. Sci. 2018, 8, 2324. [Google Scholar] [CrossRef]

- Bai, L.B.; Wang, H.L.; Huang, N.; Du, Q.; Huang, Y.D. An Environmental Management Maturity Model of Construction Programs Using the AHP-Entropy Approach. Int. J. Environ. Res. Public Health 2018, 15, 1317. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.B.; Shen, L.J.; Gu, P. Study of the integrated evaluation index system of the design of energy-saving building and the optimization of these designs based on FAHP- entropy weight. Appl. Mech. Mater. 2013, 357–360, 2859–2864. [Google Scholar] [CrossRef]

- Dou, Y.; Xue, X. Evaluation of Industrialized Construction Capability of Construction Enterprises based on AHP-Entropy Method. In ICCREM; American Society of Civil Engineers (ASCE): Guangzhou, China, 2017. [Google Scholar]

- Afshari, A.R.; Yusuff, R.M.; Derayatifar, A.R. Linguistic Extension of Fuzzy Integral for Group Personnel Selection Problem. Arab. J. Sci. Eng. 2013, 38, 2901–2910. [Google Scholar] [CrossRef]

- Li, C.Z.D.; Zhong, R.Y.; Xue, F.; Xu, G.Y.; Chen, K.; Huang, G.G.Q.; Shen, G.Q.P. Integrating RFID and BIM technologies for mitigating risks and improving schedule performance of prefabricated house construction. J. Clean. Prod. 2017, 165, 1048–1062. [Google Scholar] [CrossRef]

- Tan, T.; Chen, K.; Xue, F.; Lu, W.S. Barriers to Building Information Modeling (BIM) implementation in China’s prefabricated construction: An interpretive structural modeling (ISM) approach. J. Clean. Prod. 2019, 219, 949–959. [Google Scholar] [CrossRef]

- Khalili, A.; Chua, D.K. Integrated Prefabrication Configuration and Component Grouping for Resource Optimization of Precast Production. J. Constr. Eng. Manag. 2014, 140, 04013052. [Google Scholar] [CrossRef]

- Liang, H.; Zhang, S.; Su, Y. Evaluating the Efficiency of Industrialization Process in Prefabricated Residential Buildings Using a Fuzzy Multicriteria Decision-Making Method. Math. Probl. Eng. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Mao, C.; Liu, G.; Shen, L.; Wang, X.; Wang, J. Structural Equation Modeling to Analyze the Critical Driving Factors and Paths for Off-site Construction in China. KSCE J. Civ. Eng. 2018, 22, 2678–2690. [Google Scholar] [CrossRef]

- Chiang, Y.H.; Chan, E.H.W.; Lok, L.K.L. Prefabrication and barriers to entry-a case study of public housing and institutional buildings in Hong Kong. Habitat. Int. 2006, 30, 482–499. [Google Scholar] [CrossRef]

- Said, H. Modeling and Likelihood Prediction of Prefabrication Feasibility for Electrical Construction Firms. J. Constr. Eng. Manag. 2016, 142, 04015071. [Google Scholar] [CrossRef]

- Meng, X.; Sun, M.; Jones, M. Maturity Model for Supply Chain Relationships in Construction. J. Manag. Eng. 2011, 27, 97–105. [Google Scholar] [CrossRef]

- Broft, R.; Badi, S.; Pryke, S. Towards supply chain maturity in construction. Built Environ. Proj. Asset Manag. 2016, 6, 187–204. [Google Scholar] [CrossRef]

- Han, Y.; Skibniewski, M.; Wang, L. A Market Equilibrium Supply Chain Model for Supporting Self-Manufacturing or Outsourcing Decisions in Prefabricated Construction. Sustainability 2017, 9, 2069. [Google Scholar] [CrossRef]

- Low, S.P.; Gao, S.; Tiong, K.L. Applying lean production principles to facilities design of ramp-up factories. Facilities 2015, 33, 280–301. [Google Scholar] [CrossRef]

- Pheng, L.S.; Gao, S.; Lin, J.L. Converging early contractor involvement (ECI) and lean construction practices for productivity enhancement: Some preliminary findings from Singapore. Int. J. Product. Perform. Manag. 2015, 64, 831–852. [Google Scholar] [CrossRef]

- Kong, L.; Li, H.; Luo, H.; Ding, L.; Luo, X.; Skitmore, M. Optimal single-machine batch scheduling for the manufacture, transportation and JIT assembly of precast construction with changeover costs within due dates. Autom. Constr. 2017, 81, 34–43. [Google Scholar] [CrossRef]

- Chan, W.T.; Hu, H. Constraint programming approach to-precast production scheduling. J. Constr. Eng. Manag. 2002, 128, 513–521. [Google Scholar] [CrossRef]

- Li, Z.D.; Shen, G.Q.; Xue, X.L. Critical review of the research on the management of prefabricated construction. Habitat. Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Wu, G.B.; Yang, R.; Li, L.; Bi, X.; Liu, B.S.; Li, S.Y.; Zhou, S.X. Factors influencing the application of prefabricated construction in China: From perspectives of technology promotion and cleaner production. J. Clean. Prod. 2019, 219, 753–762. [Google Scholar] [CrossRef]

- Li, C.Z.; Xu, X.; Shen, G.Q.; Fan, C.; Li, X.; Hong, J. A model for simulating schedule risks in prefabrication housing production: A case study of six-day cycle assembly activities in Hong Kong. J. Clean. Prod. 2018, 185, 366–381. [Google Scholar] [CrossRef]

- Yuan, Z.M.; Sun, C.S.; Wang, Y.W. Design for Manufacture and Assembly-oriented parametric design of prefabricated buildings. Autom. Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Chang, Y.; Li, X.D.; Masanet, E.; Zhang, L.X.; Huang, Z.Y.; Ries, R. Unlocking the green opportunity for prefabricated buildings and construction in China. Resour. Conserv. Recycl. 2018, 139, 259–261. [Google Scholar] [CrossRef]

- Shen, K.; Cheng, C.; Li, X.; Zhang, Z. Environmental Cost-Benefit Analysis of Prefabricated Public Housing in Beijing. Sustainability 2019, 11, 207. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Zhang, H.; Gu, C.L.; Gu, L.W.; Zhang, Y. The evaluation of tourism destination competitiveness by TOPSIS & information entropy-A case in the Yangtze River Delta of China. Tour. Manag. 2011, 32, 443–451. [Google Scholar]

- Shemshadi, A.; Shirazi, H.; Toreihi, M.; Tarokh, M.J. A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Syst. Appl. 2011, 38, 12160–12167. [Google Scholar] [CrossRef]

- Zhang, G.; Zou, P.X.W. Fuzzy Analytical Hierarchy Process Risk Assessment Approach for Joint Venture Construction Projects in China. J. Constr. Eng. Manag. 2007, 133, 771–779. [Google Scholar] [CrossRef]

- Yun, C. Research on Evaluation Index System of Low-carbon Building Based on Triangular Fuzzy AHP in Chongqing in Chongqing University; Chongqing University: Chongqing, China, 2014. (In Chinese) [Google Scholar]

- Ye, J. Fuzzy cross entropy of interval-valued intuitionistic fuzzy sets and its optimal decision-making method based on the weights of alternatives. Expert Syst. Appl. 2011, 38, 6179–6183. [Google Scholar] [CrossRef]

- Ye, J. Multicriteria fuzzy decision-making method using entropy weights-based correlation coefficients of interval-valued intuitionistic fuzzy sets. Appl. Math. Model. 2010, 34, 3864–3870. [Google Scholar] [CrossRef]

- Yuan, Y.; Guan, T.; Yan, X.B.; Li, Y.J. Based on hybrid VIKOR method decision making model for supplier selection. Control Decis. 2014, 29, 551–560. (In Chinese) [Google Scholar]

- Buckley, J.J. Fuzzy Hierarchical Analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Zhou, Y.; Hou, L.; Yang, Y.; Chong, H.; Moon, S. A comparative review and framework development on public participation for decision-making in Chinese public projects. Environ. Impact Assess. Rev. 2019, 75, 79–87. [Google Scholar] [CrossRef]

- The Thirteenth Five-Year Plan for Prefabricated Building (In Chinese). Available online: http://www.mohurd.gov.cn/wjfb/201703/t20170327_231283.html (accessed on 23 March 2017).

- Luo, L.Z.; Mao, C.; Shen, L.Y.; Li, Z.D. Risk factors affecting practitioners’ attitudes toward the implementation of an industrialized building system A case study from China. Eng. Constr. Archit. Manag. 2015, 22, 622–643. [Google Scholar] [CrossRef]

- Guidance on Improving Quality Assurance System to Improve the Quality of Construction Projects (In Chinese). Available online: http://www.mohurd.gov.cn/wjfb/201909/t20190925_241956.html (accessed on 15 September 2019).

- Guide to the Development of Prefabricated Concrete construction Technology System (Residential Building) (In Chinese). Available online: http://www.mohurd.gov.cn/wjfb/201911/t20191104_242548.html (accessed on 4 July 2019).

- Li, H.X.; Al-Hussein, M.; Lei, Z.; Ajweh, Z. Risk identification and assessment of modular construction utilizing fuzzy analytic hierarchy process (AHP) and simulation. Can. J. Civ. Eng. 2013, 40, 1184–1195. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).