Classifications of Sustainable Manufacturing Practices in ASEAN Region: A Systematic Review and Bibliometric Analysis of the Past Decade of Research

Abstract

1. Introduction

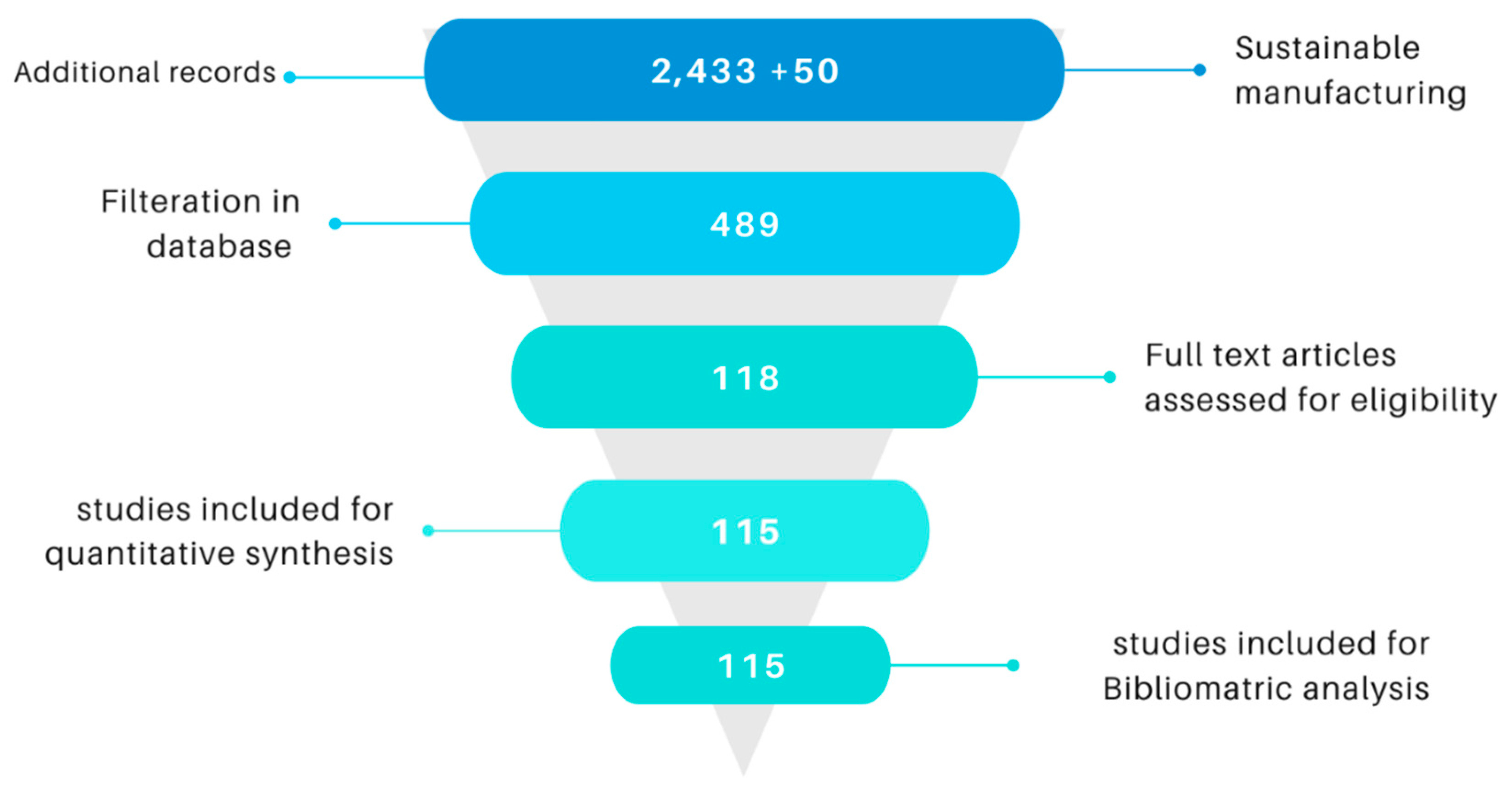

2. Review Methodology

2.1. Quality Evaluation

2.2. Eligibility and Inclusion

2.3. Studies Included in Qualitative Synthesis

3. Results

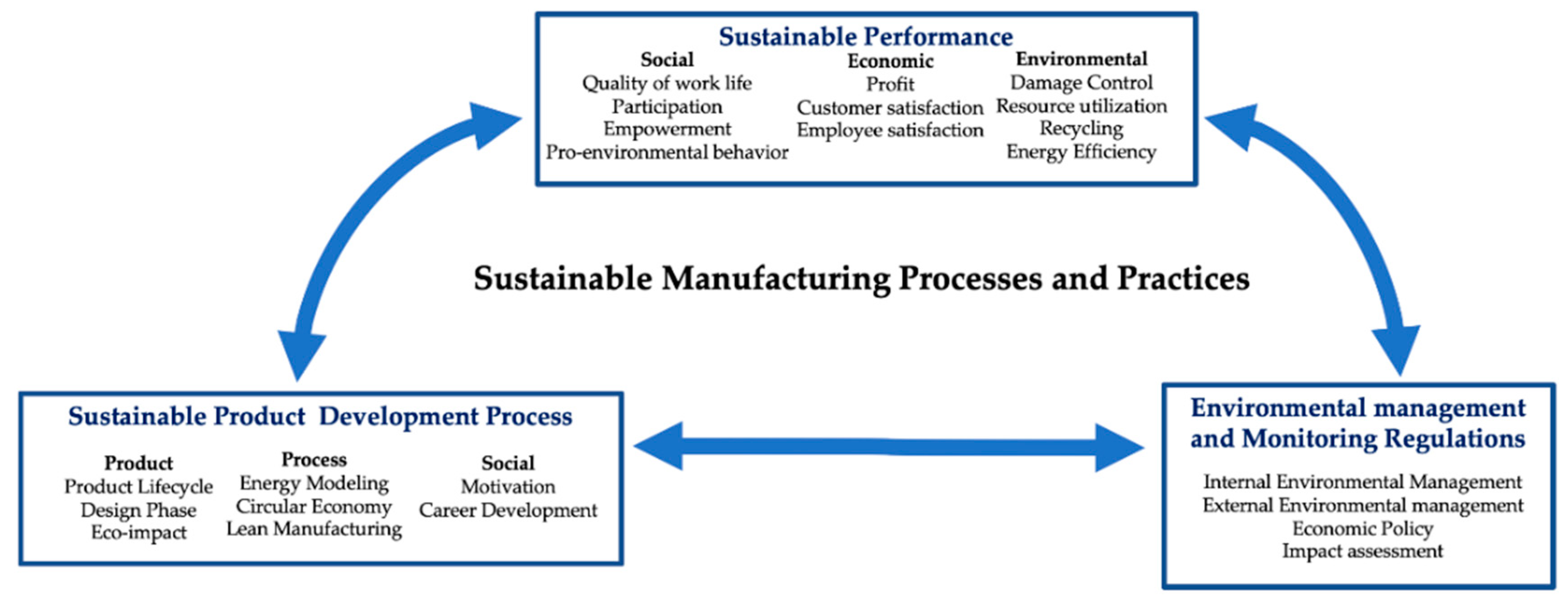

4. Classifications of Literature on Sustainable Manufacturing Practices

4.1. Sustainable Product Development Process

4.2. Environmental Management and Monitoring Regulations

4.3. Sustainable Performance

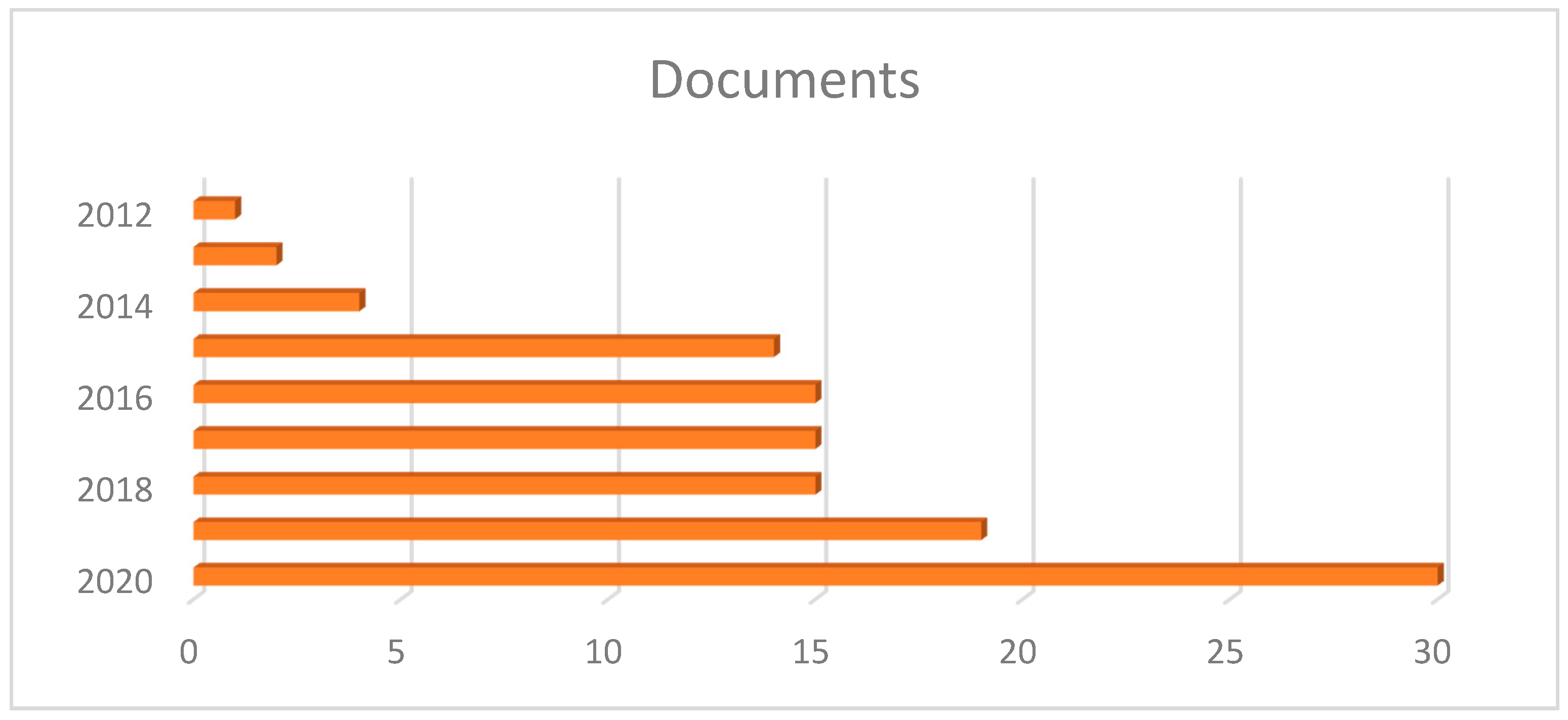

5. Bibliometric Analysis of Collaborative Research and Development in the ASEAN Region

6. Conclusions

Literature Gaps and Future Agenda

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Köhler, J.; Geels, F.W.; Kern, F.; Markard, J.; Onsongo, E.; Wieczorek, A.; Alkemade, F.; Avelino, F.; Bergek, A.; Boons, F.; et al. An agenda for sustainability transitions research: State of the art and future directions. Environ. Innov. Soc. Transit. 2019, 31, 1–32. [Google Scholar] [CrossRef]

- Brundtland, G.H. Report of the World Commission on Environment and Development:“Our Common Future”. United Nations. Available online: https://sustainabledevelopment.un.org/content/documents/5987our-common-future.pdf (accessed on 15 September 2020).

- Roxas, B.; Chadee, D. Environmental sustainability orientation and financial resources of small manufacturing firms in the Philippines. Soc. Responsib. J. 2012, 8, 208–226. [Google Scholar] [CrossRef]

- Faulkner, W.; Badurdeen, F. Sustainable Value Stream Mapping (Sus-VSM): Methodology to visualize and assess manufacturing sustainability performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- Donoghue, M.J.; Maddison, D.R.; Weston, P.H.; Scotland, R.W.; Williams, D.M.; Swofford, D.L.; Maddison, W.P. Two-Dimensional Photonic Band-Gap Defect Mode Laser. Science 1999, 284, 1819–1822. [Google Scholar]

- Yang, X.; Li, L. miRDeep-P: A computational tool for analyzing the microRNA transcriptome in plants. Bioinformatics 2011, 27, 2614–2615. [Google Scholar] [CrossRef] [PubMed]

- Linke, B.S.; Corman, G.J.; Dornfeld, D.A.; Tönissen, S. Sustainability indicators for discrete manufacturing processes applied to grinding technology. J. Manuf. Syst. 2013, 32, 556–563. [Google Scholar] [CrossRef]

- Qureshi, M.I.; Al Rasiah, R.; Al-Ghazali, B.M.; Haider, M.; Jambari, H.; Iswan; Sasmoko. Modeling work practices under socio-technical systems for sustainable manufacturing performance. Sustainability 2019, 11, 4294. [Google Scholar] [CrossRef]

- Allen, D.; Bauer, D.; Bras, B.; Gutowski, T.; Murphy, C.; Piwonka, T.; Sheng, P.; Sutherland, J.; Thurston, D.; Wolff, E. Environmentally Benign Manufacturing: Trends in Europe, Japan, and the USA. J. Manuf. Sci. Eng. 2002, 124, 908. [Google Scholar] [CrossRef]

- Abdul-Rashid, S.H.; Sakundarini, N.; Raja Ghazilla, R.A.; Thurasamy, R. The impact of sustainable manufacturing practices on sustainability performance: Empirical evidence from Malaysia. Int. J. Oper. Prod. Manag. 2017, 37, 182–204. [Google Scholar] [CrossRef]

- Daily, B.F.; Huang, S.C. Achieving sustainability through attention to human resource factors in environmental management. Int. J. Oper. Prod. Manag. 2001, 21, 1539–1552. [Google Scholar] [CrossRef]

- Barrera-Roldán, A.; Saldívar-Valdés, A. Proposal and application of a Sustainable Development Index. Ecol. Indic. 2002, 2, 251–256. [Google Scholar] [CrossRef]

- Jerneck, A.; Olsson, L.; Ness, B.; Anderberg, S.; Baier, M.; Clark, E.; Hickler, T.; Hornborg, A.; Kronsell, A.; Lövbrand, E.; et al. Structuring sustainability science. Sustain. Sci. 2011, 6, 69–82. [Google Scholar] [CrossRef]

- Diesendorf, M. Sustainability and Sustainable Development by Mark Diesendorf. Corp. Chall. 21st Century 1999, 2, 19–37. [Google Scholar]

- Bakshi, B.R.; Fiksel, J. The quest for sustainability: Challenges for process systems engineering. AICHE J. 2003, 49, 1350–1358. [Google Scholar] [CrossRef]

- Jawahir, I.; Badurdeen, F.; Rouch, K. Innovation in Sustainable Manufacturing Education; University press of the TU Berlin: Berlin, Germany, 2013; ISBN 9783798326095. [Google Scholar]

- Ng, R.; Low, J.S.; Song, B. Integrating and implementing Lean and Green practices based on proposition of Carbon-Value Efficiency metric. J. Clean. Prod. 2015, 95, 242–255. [Google Scholar] [CrossRef]

- Upton, N.; Teal, E.J.; Felan, J.T. Strategic and business planning practices of fast growth family firms. J. Small Bus. Manag. 2001, 39, 60–72. [Google Scholar] [CrossRef]

- Beck, M.E.; Bergeron, H.; Balla, I.; Sangwan, V.K.; Lee, H.-S.; Chen, K.-S.; Hersam, M.C. Multi-terminal memtransistors from polycrystalline monolayer molybdenum disulfide. Nature 2018, 554, 500–504. [Google Scholar]

- May, N.; Günther, E.; Haller, P. The sustainable use of wood as a regional resource—An ecological assessment of common and new processing technologies for wood poles. Sustain. Manag. Forum Nachhalt. 2019, 27, 177–201. [Google Scholar] [CrossRef]

- Keathley-Herring, H.; Van Aken, E.; Gonzalez-Aleu, F.; Deschamps, F.; Letens, G.; Orlandini, P.C. Assessing the maturity of a research area: Bibliometric review and proposed framework. Scientometrics 2016, 109, 927–951. [Google Scholar] [CrossRef]

- Shu, F.; Julien, C.A.; Zhang, L.; Qiu, J.; Zhang, J.; Larivière, V. Comparing journal and paper level classifications of science. J. Informetrics. 2019, 13, 202–225. [Google Scholar] [CrossRef]

- Ghadimi, P.; Azadnia, A.H.; Mohd Yusof, N.; Mat Saman, M.Z. A weighted fuzzy approach for product sustainability assessment: A case study in automotive industry. J. Clean. Prod. 2012, 33, 10–21. [Google Scholar] [CrossRef]

- Jegatheesan, V.; Liow, J.L.; Shu, L.; Kim, S.H.; Visvanathan, C. The need for global coordination in sustainable development. J. Clean. Prod. 2009, 17, 637–643. [Google Scholar] [CrossRef]

- Tao, F.; Bi, L.N.; Zuo, Y.; Nee, A.Y.C. A hybrid group leader algorithm for green material selection with energy consideration in product design. CIRP Ann.-Manuf. Technol. 2016, 65, 9–12. [Google Scholar] [CrossRef]

- Singh, S.; Olugu, E.U.; Fallahpour, A. Fuzzy-based sustainable manufacturing assessment model for SMEs. Clean Technol. Environ. Policy 2014, 16, 847–860. [Google Scholar] [CrossRef]

- Singh, S.; Olugu, E.U.; Musa, S.N.; Mahat, A.B.; Wong, K.Y. Strategy selection for sustainable manufacturing with integrated AHP-VIKOR method under interval-valued fuzzy environment. Int. J. Adv. Manuf. Technol. 2016, 84, 547–563. [Google Scholar] [CrossRef]

- Vijayaraghavan, V.; Garg, A.; Gao, L.; Vijayaraghavan, R.; Lu, G. A finite element based data analytics approach for modeling turning process of Inconel 718 alloys. J. Clean. Prod. 2016, 137, 1619–1627. [Google Scholar] [CrossRef]

- Beng, L.G.; Omar, B. Integrating axiomatic design principles into sustainable product development. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 107–117. [Google Scholar] [CrossRef]

- Raja Ghazilla, R.A.; Sakundarini, N.; Taha, Z.; Abdul-Rashid, S.H.; Yusoff, S. Design for environment and design for disassembly practices in Malaysia: A practitioner’s perspectives. J. Clean. Prod. 2015, 108, 331–342. [Google Scholar] [CrossRef]

- Lis, A.; Sudolska, A.; Tomanek, M. Mapping research on sustainable supply-chain management. Sustainability 2020, 12, 3987. [Google Scholar] [CrossRef]

- Nugroho, Y.K.; Zhu, L. Platforms planning and process optimization for biofuels supply chain. Renew. Energy 2019, 140, 563–579. [Google Scholar] [CrossRef]

- Ying, A.; Reimann, J.; Boccaccini, L.; Enoeda, M.; Kamlah, M.; Knitter, R.; Gan, Y.; Van Der Laan, J.G.; Magielsen, L.; Maio, P.A.D.; et al. Status of ceramic breeder pebble bed thermo-mechanics R&D and impact on breeder material mechanical strength. Fusion Eng. Des. 2012, 87, 1130–1137. [Google Scholar]

- Dell’Orco, P.; Jiménez-González, C.; Teik, K. A unique collaboration to promote sustainability for pharmaceuticals and fine chemicals: The GSK-Singapore Partnership for Green and Sustainable Manufacturing. Green Process. Synth. 2012, 1, 5–9. [Google Scholar] [CrossRef]

- Ingarao, G.; Priarone, P.C.; Di Lorenzo, R.; Settineri, L. Guidelines to compare additive and subtractive manufacturing approaches under the energy demand perspective. Int. J. Sustain. Manuf. 2020, 4, 266–280. [Google Scholar] [CrossRef]

- Abedini, A.; Li, W.; Badurdeen, F.; Jawahir, I.S. A metric-based framework for sustainable production scheduling. J. Manuf. Syst. 2020, 54, 174–185. [Google Scholar] [CrossRef]

- Nicoletti Junior, A.; de Oliveira, M.C.; Helleno, A.L. Sustainability evaluation model for manufacturing systems based on the correlation between triple bottom line dimensions and balanced scorecard perspectives. J. Clean. Prod. 2018, 190, 84–93. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Rajoo, S. Sustainability indicators for manufacturing sectors: A literature survey and maturity analysis from the triple-bottom line perspective. J. Manuf. Technol. Manag. 2019, 30, 312–334. [Google Scholar] [CrossRef]

- Ahmad, A.; Lajis, M.A.; Yusuf, N.K.; Shamsudin, S.; Zhong, Z.W. Parametric optimisation of heat treated recycling aluminium (AA6061) by response surface methodology. In Proceedings of the AIP Conference Proceedings, Aonang Krabi, Thailand, 29–30 April 2017; American Institute of Physics Inc.: Singapore, 2017; Volume 1885, p. 020046. [Google Scholar]

- Qureshi, M.I.; Rasli, A.M.; Awan, U.; Ma, J.; Ali, G.; Faridullah; Alam, A.; Sajjad, F.; Zaman, K. Environment and air pollution: Health services bequeath to grotesque menace. Environ. Sci. Pollut. Res. 2015, 22, 3467–3476. [Google Scholar] [CrossRef] [PubMed]

- Ocampo, L.A. Fuzzy analytic network process (FANP) approach in formulating infrastructural decisions of sustainable manufacturing strategy. J. Manag. Anal. 2016, 3, 266–284. [Google Scholar] [CrossRef]

- Ghani, J.A.; Rizal, M.; Che Haron, C.H. Performance of green machining: A comparative study of turning ductile cast iron FCD700. J. Clean. Prod. 2014, 85, 289–292. [Google Scholar] [CrossRef]

- Iesa, W.; Alferjani, M.; Ali, N.; Abdul Samad, A. Study on shear strengthening of RC continuous beams with different CFRP wrapping schemes. Int. J. Integr. Eng. 2010, 2, 1–10. [Google Scholar]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A Big Data-driven Framework for Sustainable and Smart Additive Manufacturing. Robot. Comput. Integr. Manuf. 2020, 67, 102026. [Google Scholar] [CrossRef]

- Jain, T.; Hazra, J.; Cheng, T.C.E. IT Outsourcing and Vendor Cost Improvement Strategies under Asymmetric Information. Decis. Sci. 2020, in press. [Google Scholar] [CrossRef]

- Ordoñez Duran, J.F.; Chimenos, J.M.; Segarra, M.; de Antonio Boada, P.A.; Ferreira, J.C.E. Analysis of embodied energy and product lifespan: The potential embodied power sustainability indicator. Clean Technol. Environ. Policy 2020, 22, 1055–1068. [Google Scholar] [CrossRef]

- He, B.; Cao, X.; Production, Z.G.-J. Undefined Kinematics of Underactuated Robotics for Product Carbon Footprint; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Zheng, J.; Zhou, X.; Yu, Y.; Wu, J.; Ling, W.; Ma, H. Low carbon, high efficiency and sustainable production of traditional manufacturing methods through process design strategy: Improvement process for sand casting defects. J. Clean. Prod. 2020, 253, 119917. [Google Scholar] [CrossRef]

- Gunna, V.R. Adaptive Multi-Objective Operating Room Planning With Stochastic Demand And Case Times. Theses and Dissertations—Mechanical Engineering. Available online: https://uknowledge.uky.edu/cgi/viewcontent.cgi?article=1113&context=me_etds (accessed on 15 September 2020).

- Kamalakkannan, S.; Kulatunga, A.K.; Kassel, N.C. Environmental and social sustainability of the tea industry in the wake of global market challenges: A case study in Sri Lanka. Int. J. Sustain. Manuf. 2020, 4, 379–395. [Google Scholar] [CrossRef]

- Jegede, D.O.; Shokunbi, O.S.; Ogunnowo, A.A.; Adewumi, A.; Ayofe, N.A.; Oladoye, P.O. Toxic Metals Assessment in the Tissues and Organs of Three Commonly Consumed Fishes in Igbona Market, Osogbo, Nigeria. J. Chem. Pharm. Res. 2018, 10, 192–199. [Google Scholar]

- Bevilacqua, M.; Ciarapica, F.E.; D’Orazio, A.; Forcellese, A.; Simoncini, M. Sustainability Analysis of Friction Stir Welding of AA5754 Sheets. In Proceedings of the Procedia CIRP, Ischia, Italy, 20–22 July 2016; Volume 62, pp. 529–534. [Google Scholar]

- Üstündağ Okur, N.; Hökenek, N.; Okur, M.E.; Ayla, Ş.; Yoltaş, A.; Siafaka, P.I.; Cevher, E. An alternative approach to wound healing field; new composite films from natural polymers for mupirocin dermal delivery. Saudi Pharm. J. 2019, 27, 738–752. [Google Scholar] [CrossRef] [PubMed]

- Laverne, F.; Marquardt, R.; Segonds, F.; Koutiri, I.; Perry, N. Improving resources consumption of additive manufacturing use during early design stages: A case study. Int. J. Sustain. Eng. 2019, 12, 365–375. [Google Scholar] [CrossRef]

- Ansari, A.; Modarress, B. Challenges of outsourcing logistics to third-party providers. Int. J. Logist. Syst. Manag. 2010, 7, 198–218. [Google Scholar] [CrossRef]

- Zhu, L.; Nugroho, Y.K.; Shakeel, S.R.; Li, Z.; Martinkauppi, B.; Hiltunen, E. Using microalgae to produce liquid transportation biodiesel: What is next? Renew. Sustain. Energy Rev. 2017, 78, 391–400. [Google Scholar] [CrossRef]

- Raoufi, K.; Wisthoff, A.K.; DuPont, B.L.; Haapala, K.R. A questionnaire-based methodology to assist non-experts in selecting sustainable engineering analysis methods and software tools. J. Clean. Prod. 2019, 229, 528–541. [Google Scholar] [CrossRef]

- Balakrishnan, V.; Unnikrishnan, A.G.; Thomas, V.; Choudhuri, G.; Veeraraju, P.; Singh, S.P.; Garg, P.; Pai, C.G.; Devi, R.N.S.; Bhasin, D.; et al. Chronic pancreatitis. A prospective nationwide study of 1,086 subjects from India. J. Pancreas 2008, 9, 593–600. [Google Scholar]

- Miranda, J.; Pérez-Rodríguez, R.; Borja, V.; Wright, P.K.; Molina, A. Integrated Product, Process and Manufacturing System Development Reference Model to develop Cyber-Physical Production Systems—The Sensing, Smart and Sustainable Microfactory Case Study. IFAC-PapersOnLine 2017, 50, 13065–13071. [Google Scholar] [CrossRef]

- Yu, J.; Wang, J.; Lin, W.; Li, S.; Li, H.; Zhou, J.; Ni, P.; Dong, W.; Hu, S.; Zeng, C.; et al. The genomes of Oryza sativa: A history of duplications. PLoS Biol. 2005, 3, 0266–0281. [Google Scholar] [CrossRef] [PubMed]

- Qiu, T.; Chen, N.; Li, K.; Atiquzzaman, M.; Zhao, W. How can heterogeneous internet of things build our future: A survey. IEEE Commun. Surv. Tutor. 2018, 20, 2011–2027. [Google Scholar] [CrossRef]

- Zuo, Y.; Tao, F.; Nee, A.Y.C. An Internet of things and cloud-based approach for energy consumption evaluation and analysis for a product. Int. J. Comput. Integr. Manuf. 2018, 31, 337–348. [Google Scholar] [CrossRef]

- Vijayaraghavan, V.; Castagne, S. Sustainable manufacturing models for mass finishing process. Int. J. Adv. Manuf. Technol. 2016, 86, 49–57. [Google Scholar] [CrossRef]

- Balogun, V.A.; Mativenga, P.T. Modelling of direct energy requirements in mechanical machining processes. J. Clean. Prod. 2013, 41, 179–186. [Google Scholar] [CrossRef]

- Yang, S.; Raghavendra, M.R.A.; Kaminski, J.; Pepin, H. Opportunities for industry 4.0 to support remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to sustainable production–Part I: Application on machining technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- Jain, T.; Hazra, J. Optimal regulation and sustainable product design under uncertainties. Int. J. Prod. Econ. 2020, 225, 107574. [Google Scholar] [CrossRef]

- Nujoom, R.; Mohammed, A.; Wang, Q. A sustainable manufacturing system design: A fuzzy multi-objective optimization model. Environ. Sci. Pollut. Res. 2018, 25, 24535–24547. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020. [Google Scholar] [CrossRef]

- Muñoz-Villamizar, A.; Santos, J.; Viles, E.; Ormazábal, M. Manufacturing and environmental practices in the Spanish context. J.Clean. Prod. 2018, 178, 268–275. [Google Scholar] [CrossRef]

- Lu, J.; Ren, L.; Zhang, C.; Rong, D.; Ahmed, R.R.; Streimikis, J. Modified Carroll’s pyramid of corporate social responsibility to enhance organizational performance of SMEs industry. J. Clean. Prod. 2020, 271, 122456. [Google Scholar] [CrossRef]

- Geda, A.; Ghosh, V.; Karamemis, G.; Vakharia, A. Coordination strategies and analysis of waste management supply chain. J. Clean. Prod. 2020, 256, 120298. [Google Scholar] [CrossRef]

- Khan, A.M.; Jamil, M.; Mia, M.; He, N.; Zhao, W.; Gong, L. Sustainability-based performance evaluation of hybrid nanofluid assisted machining: Sustainability assessment of hybrid nanofluid assisted machining. J. Clean. Prod. 2020, 257, 120541. [Google Scholar] [CrossRef]

- Meng, K.; Qian, X.; Lou, P.; Zhang, J. Smart recovery decision-making of used industrial equipment for sustainable manufacturing: Belt lifter case study. J. Intell. Manuf. 2020, 31, 183–197. [Google Scholar] [CrossRef]

- Sivaiah, P.; Chakradhar, D. Modeling and optimization of sustainable manufacturing process in machining of 17-4 PH stainless steel. Meas. J. Int. Meas. Confed. 2019, 134, 142–152. [Google Scholar] [CrossRef]

- Gao, J.; Xiao, Z.; Wei, H.; Zhou, G. Active or passive? Sustainable manufacturing in the direct-channel green supply chain: A perspective of two types of green product designs. Transp. Res. Part D Transp. Environ. 2018, 65, 332–354. [Google Scholar] [CrossRef]

- Choi, S.S.; Lee, J.Y. Development of a framework for the integration and management of sustainability for small- and medium-sized enterprises. Int. J. Comput. Integr. Manuf. 2017, 30, 1190–1202. [Google Scholar] [CrossRef]

- Alayón, C.; Säfsten, K.; Johansson, G. Conceptual sustainable production principles in practice: Do they reflect what companies do? J. Clean. Prod. 2017, 141, 693–701. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Vaish, A. Suppliers’ green performance evaluation using fuzzy extended ELECTRE approach. Clean Technol. Environ. Policy 2017, 19, 809–821. [Google Scholar] [CrossRef]

- Qureshi, M.I.; Hassan, M.A.; Hishan, S.S.; Rasli, A.M.; Zaman, K. Dynamic linkages between sustainable tourism, energy, health and wealth: Evidence from top 80 international tourist destination cities in 37 countries. J. Clean. Prod. 2017, 158, 143–155. [Google Scholar] [CrossRef]

- Adebambo, H.; Ashari, H.; Nordin, N. Moderating role of perceived benefit between sustainable environmental manufacturing practices and firm performance. J. Teknol. 2015, 77, 91–96. [Google Scholar] [CrossRef]

- Pipatprapa, A.; Huang, H.H.; Huang, C.H. Enhancing the effectiveness of AHP for environmental performance assessment of Thailand and Taiwan’s food industry. Environ. Monit. Assess. 2018, 190, 748. [Google Scholar] [CrossRef] [PubMed]

- Rezai, G.; Sumin, V.; Mohamed, Z.; Shamsudin, M.N.; Sharifuddin, J. Implementing Green Practices as Sustainable Innovation Among Herbal-Based SME Entrepreneurs. J. Food Prod. Mark. 2016, 22, 1–18. [Google Scholar] [CrossRef]

- Dawal, S.Z.M.; Tahriri, F.; Jen, Y.H.; Case, K.; Tho, N.H.; Zuhdi, A.; Mousavi, M.; Amindoust, A.; Sakundarini, N. Empirical evidence of AMT practices and sustainable environmental initiatives in malaysian automotive SMEs. Int. J. Precis. Eng. Manuf. 2015, 16, 1195–1203. [Google Scholar] [CrossRef]

- Yasir, M.; Rasli, A.; Qureshi, M.I. Investigation of the factors that affect and gets affected by organizational ethical climate. Adv. Sci. Lett. 2017, 23, 9351–9355. [Google Scholar] [CrossRef]

- Hassan, M.G.; Nordin, N.; Ashari, H. Sustainable manufacturing practices implementation in Malaysia industries. J. Teknol. 2015, 77, 49–56. [Google Scholar] [CrossRef]

- Hami, N.; Yamin, F.M.; Shafie, S.M.; Muhamad, M.R.; Ebrahim, Z. Sustainable manufacturing practices among smes in Malaysia. Int. J. Technol. 2018, 9, 1658–1667. [Google Scholar] [CrossRef]

- Hami, N.; Ibrahim, Y.M.; Yamin, F.M.; Shafie, S.M.; Abdulameer, S.S. The moderating role of sustainable maintenance on the relationship between sustainable manufacturing practices and social sustainability: A conceptual framework. Int. J. Eng. Adv. Technol. 2019, 8, 222–228. [Google Scholar]

- Iqbal, A.; Al-Ghamdi, K.A. Energy-efficient cellular manufacturing system: Eco-friendly revamping of machine shop configuration. Energy 2018, 163, 863–872. [Google Scholar] [CrossRef]

- Abdul-Rashid, S.H.; Sakundarini, N.; Ariffin, R.; Ramayah, T. Drivers for the adoption of sustainable manufacturing practices: A Malaysia perspective. Int. J. Precis. Eng. Manuf. 2017, 18, 1619–1631. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Gupta, M.K. Towards zero waste manufacturing: A multidisciplinary review. J. Clean. Prod. 2017, 168, 1230–1243. [Google Scholar] [CrossRef]

- Rodrigues, V.P.; Pigosso, D.C.A.; McAloone, T.C. Process-related key performance indicators for measuring sustainability performance of ecodesign implementation into product development. J. Clean. Prod. 2016, 139, 416–428. [Google Scholar] [CrossRef]

- Durden, J.M.; Lallier, L.E.; Murphy, K.; Jaeckel, A.; Gjerde, K.; Jones, D.O.B. Environmental Impact Assessment process for deep-sea mining in ‘the Area’. Mar. Policy 2018, 87, 194–202. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

| Web of Science Categories | Records | Percentage |

|---|---|---|

| Engineering, Manufacturing | 15 | 13% |

| Green & Sustainable Science & Technology | 14 | 12% |

| Environmental Sciences | 12 | 10% |

| Engineering, Mechanical | 10 | 9% |

| Engineering, Environmental | 9 | 8% |

| Engineering, Multidisciplinary | 9 | 8% |

| Materials Science, Multidisciplinary | 8 | 7% |

| Management | 9 | 8% |

| Chemistry, Multidisciplinary | 3 | 3% |

| Engineering, Chemical | 3 | 3% |

| Engineering, Industrial | 3 | 3% |

| Automation Control Systems | 2 | 2% |

| Computer Science, Artificial Intelligence | 2 | 2% |

| Environmental Studies | 2 | 2% |

| Multidisciplinary Sciences | 2 | 2% |

| Operations Research & Management Science | 2 | 2% |

| Thermodynamics | 2 | 2% |

| Biotechnology & Applied Microbiology | 1 | 1% |

| Business | 1 | 1% |

| Computer Science, Interdisciplinary Applications | 1 | 1% |

| Energy & Fuels | 1 | 1% |

| Humanities, Multidisciplinary | 1 | 1% |

| Materials Science, Biomaterials | 1 | 1% |

| Materials Science, Composites | 1 | 1% |

| Metallurgy & Metallurgical Engineering | 1 | 1% |

| Total | 115 | 100% |

| Title | Authors | Source Title | Total Citations | Average per Year |

|---|---|---|---|---|

| A weighted fuzzy approach for product sustainability assessment: a case study in the automotive industry | Ghadimi et al. [23] | Journal of Cleaner Production | 62 | 7.75 |

| The need for global coordination in sustainable development | Jegatheesan et al. [24] | Journal of Cleaner Production | 49 | 4.45 |

| Fuzzy-based sustainable manufacturing assessment model for SMEs | Singh et al. [26] | Clean Technologies and Environmental Policies | 31 | 5.17 |

| A hybrid group leader algorithm for green material selection with energy consideration in product design | Ta et al. [25] | CIRP Annals – Manufacturing Technology | 27 | 6.75 |

| The impact of sustainable manufacturing practices on sustainability performance: Empirical evidence from Malaysia | Abdul-Rashid et al. [10] | International Journal of Operations & Production Management | 24 | 8 |

| Strategy selection for sustainable manufacturing with integrated AHP-VIKOR method under interval-valued fuzzy environment | Singh et al. [27] | International Journal of Advanced Manufacturing Technology | 21 | 5.25 |

| A finite element based data analytics approach for modelling turning process of Inconel 718 alloys | Vijayaraghavan et al. [28] | Journal of Cleaner Production | 13 | 3.25 |

| Integrating Axiomatic Design Principles into Sustainable Product Development | Beng et al. [29] | International Journal of Precision Engineering and Manufacturing – Green Technology | 13 | 2.17 |

| Design for environment and design for disassembly practices in Malaysia: a practitioner’s perspectives | Ghazilla et al. [30] | Journal of Cleaner Production | 11 | 2.2 |

| Authors | Classification | Settings | Procedures |

|---|---|---|---|

| Majeed et al. [44] | Smart manufacturing | Sustainable manufacturing | Product life cycle |

| Jain et al. [45] | Environmental regulations | Auto manufacturers | Design phase |

| Ordoñez Duran et al. [46] | Product design | Environmental impact | Sustainability indicators |

| He et al. [47] | Product design | Natural dynamic control systems | Robotic ankle |

| Zheng et al. [48] | Defective products | Design phase | Emission reduction |

| Ingarao et al. [35] | Product life cycle | Production | Environmental impact |

| Gunna R V. [49] | Product life cycle | Triple bottom line (TBL) | Production schedules |

| Kamalakkannan et al. [50] | Product life cycle | Environmental sustainability | Tea industry |

| Jegede et al. [51] | Energy consumption | Eco-impact | Stainless steel |

| Bevilacqua et al. [52] | Assessment | Environmental impact | Welding speeds |

| Üstündağ Okur et al. [53] | Design | Product demand | Solar energy |

| Laverne et al. [54] | Design | Environmental impact | Electrical energy |

| Ansari and Modarress [55] | Design | Environmental impact | Motor vehicles |

| Zhu et al. [56] | Development | Design of biofuel supply chain networks | Biofuel |

| Raoufi et al. [57] | Development | Design | Software tools |

| Balakrishnan et al. [58] | Eco-friendly product | Environmentally responsible | Global warming |

| Miranda et al. [59] | Development | New-generation products | Marketplace |

| Ahmad et al. [39] | Design | Environmental impacts | Aluminum |

| Ahmad et al. [38] | Assessment | Triple bottom line (TBL) | Environment, economy, and society |

| Yu et al. [60] | Green products | Environmental policies | Supply chain |

| Yu et al. [60] | Design | Multi-criteria decision making | Eco-efficiency |

| Authors | Classification | Settings | Procedures |

|---|---|---|---|

| Lu et al. [71] | Corporate social responsibility (CSR) | Small- and medium-sized enterprises (SMEs) | Policies |

| Geda et al. [72] | Environmental regulations | Vehicle | Greenhouse gas emissions |

| Ordoñez Duran et al. [46] | Regulations | Environmental Performance Index (EPI) | Energy consumption |

| Han et al. [73] | Producer’s responsibility | Environmentally friendly recovery | Recovery decision support system |

| Meng et al. [74] | Environmental regulations | Metal-cutting industries | Eco-friendly techniques |

| Sivaiah and Chakradhar [75] | Government interventions | Social welfare | Green products and non-green products |

| Gao et al. [76] | Rules and regulations | Manufacturing industries | Energy saving and minimizing the production of carbon dioxide |

| Kamalakkannan et al. [50] | Government environmental regulations | Small- and medium-sized enterprises (SMEs) | Environmental effects |

| Gao et al. [76] | Production principles | Sustainable manufacturing practices | Energy and material conservation |

| Choi and Lee [77] | Environmental rules | Globalized market | Green performance measures |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qureshi, M.I.; Khan, N.; Qayyum, S.; Malik, S.; Hishan, S.S.; Ramayah, T. Classifications of Sustainable Manufacturing Practices in ASEAN Region: A Systematic Review and Bibliometric Analysis of the Past Decade of Research. Sustainability 2020, 12, 8950. https://doi.org/10.3390/su12218950

Qureshi MI, Khan N, Qayyum S, Malik S, Hishan SS, Ramayah T. Classifications of Sustainable Manufacturing Practices in ASEAN Region: A Systematic Review and Bibliometric Analysis of the Past Decade of Research. Sustainability. 2020; 12(21):8950. https://doi.org/10.3390/su12218950

Chicago/Turabian StyleQureshi, Muhammad Imran, Nohman Khan, Shazia Qayyum, Subha Malik, Sanil S Hishan, and Thurasamy Ramayah. 2020. "Classifications of Sustainable Manufacturing Practices in ASEAN Region: A Systematic Review and Bibliometric Analysis of the Past Decade of Research" Sustainability 12, no. 21: 8950. https://doi.org/10.3390/su12218950

APA StyleQureshi, M. I., Khan, N., Qayyum, S., Malik, S., Hishan, S. S., & Ramayah, T. (2020). Classifications of Sustainable Manufacturing Practices in ASEAN Region: A Systematic Review and Bibliometric Analysis of the Past Decade of Research. Sustainability, 12(21), 8950. https://doi.org/10.3390/su12218950