1. Introduction

In the current scenario of the house building industry, there is a fierce market competition in different countries, primarily concerned with costs, demanding strategies to increase productivity [

1,

2] and, at the same time, to consider customers heterogeneous demands [

3]. Understanding customers’ needs and preferences is a challenge due to their changing lifestyles and different family structures [

4,

5,

6]. Therefore, customer requirements must be appropriately understood and communicated to decision-makers, such as investors, developers and designers; otherwise, value generation may be compromised [

4]. The progressively increasing diversity of customer requirements has created business opportunities related to product customisation in several different sectors [

7,

8], including house building [

9]. According to Wang et al. [

10] this shifting focus from company to customer demand is a driving force in industrial innovation.

Mass customisation (MC) is a strategy that aims to fulfil customer requirements [

11,

12,

13], and, at the same time, achieve high efficiency and competitive advantage [

2,

11], through flexible processes and supply chain integration [

1,

14]. Therefore, companies combine elements of mass and craft production to improve value generation for specific market segments [

15,

16,

17]. In the house building industry, besides contributing to competitive advantage, the adoption of MC can provide benefits related to environmental and social sustainability, by avoiding waste caused by product changes made after occupancy by users, as well as by increasing their perceived value and sense of ownership [

5,

18].

Several successful applications of MC in the manufacturing industry have been reported in the literature [

7,

19,

20]. However, its body of knowledge is dispersed and is still growing [

7]. According to Piller [

21] and Suzic et al. [

20], there is a lack of in-depth understanding of the strategies for implementation. Other authors [

22,

23] argue that the further expansion of the field depends on the development of models and tools to support companies in new product development (NPD). A major challenge in MC is customer integration, i.e., how to improve value generation by understanding and considering requirements from different customers, as well as defining their degree of involvement in NPD [

22,

24]. Most studies on this topic tend to be technology-focused [

19], being often limited to methods and digital tools to generate and display product alternatives, such as configurators and choice menus [

22].

In the house building industry, the implementation of MC is still latent [

1,

25], sparse and more focused on operations [

1]. A critical challenge for the adoption of MC in housing is capturing customers’ requirements [

3,

14,

25,

26,

27], and establishing a balance between offering variety and achieving efficiency and, consequently, housing affordability [

1,

9,

25,

27]. Several research opportunities on this topic have been pointed out in the literature, such as the definition of solution spaces, and the support to customers’ decision-making during the configuration process [

1,

2,

3,

22,

25]. However, Khalili-Araghi and Kolarevic [

3] suggest that new methods for customer integration are needed to reduce the trade-offs between customers perceived value and the complexity that results from customisation. Kotha [

17] argues that technologies and tools alone are insufficient to achieve MC goals, as the adoption of this strategy requires an organisational context that fosters continuous improvement, learning and knowledge creation.

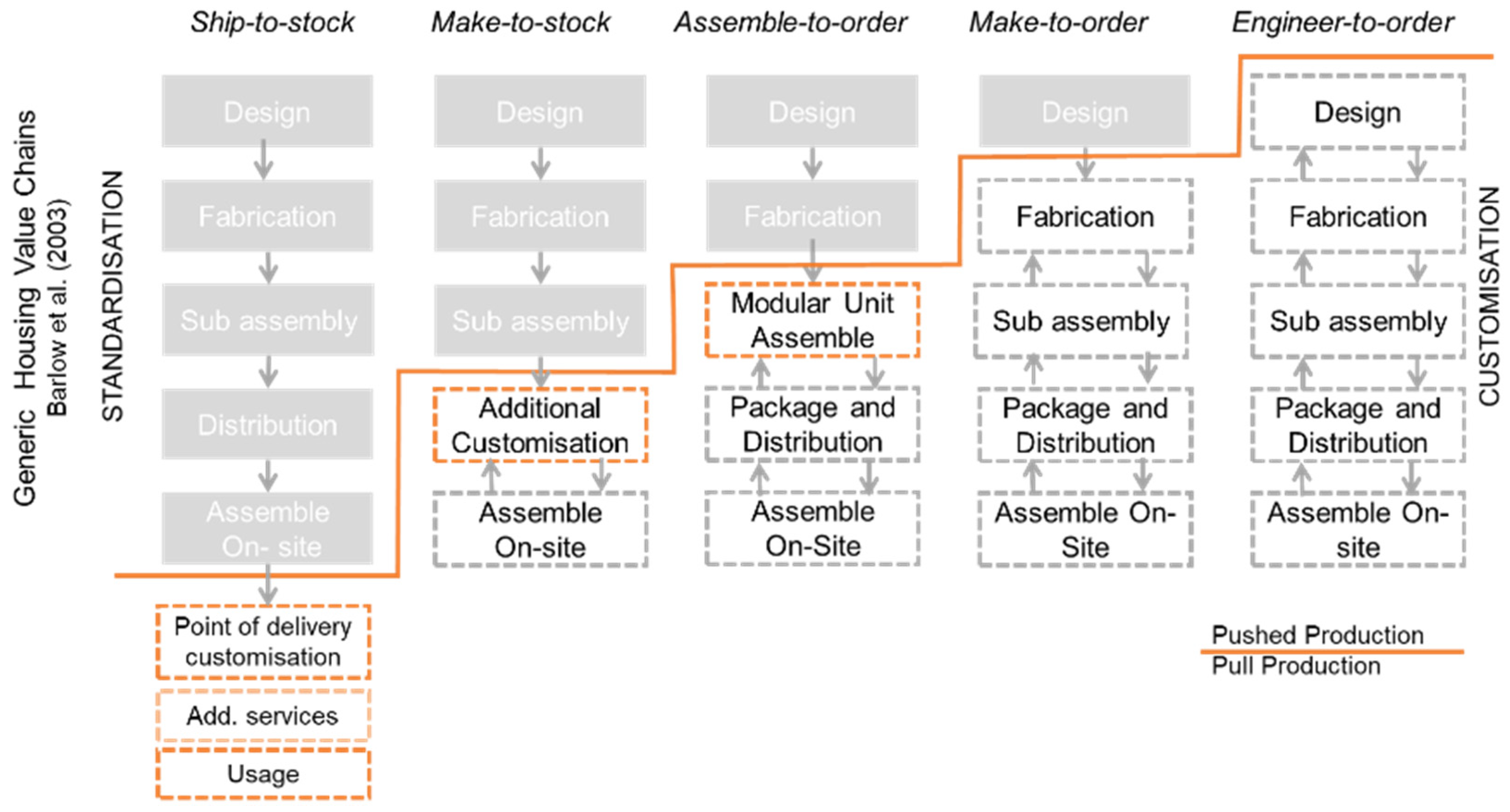

Some studies have associated the use of MC strategies with prefabricated or industrialised construction methods (e.g., [

1,

28,

29]). However, this strategy has also been explored by companies that adopt traditional construction methods (e.g., [

6,

9,

25,

26]). In fact, some of the potential improvements related to MC are not directly related to the type of technology used, such as understanding customer requirements, customer interaction, and visualisation approaches [

2,

6,

25,

30]. Rocha [

30] suggests that the definition of an MC strategy can be divided into decision categories, and should start by making some core decisions related to the scope of MC, and then move to other areas, including customer integration. Wikner [

31] defines decision categories as ways to classify decisions and support the segmentation of complex decision problems into a structured and relatively independent way to facilitate decision-making.

A possible starting point to understand key decision categories is to analyse practices implemented in the industry [

20,

32,

33]. Those practices can be regarded as methods, tools or techniques that have been successfully used in real-life situations for improving performance or solving problems [

32]. By understanding the underlying ideas of those practices, they can be adapted to other companies facing similar challenges [

33]. This research seeks to further understand practices as an expression of tacit knowledge that can be applied for learning, working, innovating and organising [

34].

Therefore, this research study aims to answer the question: How can customer integration in the NPD of mass-customised house building projects be managed? The main outcome of this investigation is a framework of decision categories for customer integration and for devising the scope of customisation to support the definition of MC strategies. It is based on practices identified in the literature and also on an empirical study carried out in a house building company. The framework is meant to be used by companies to support the definition of MC strategies. A secondary contribution of this investigation is a set of constructs that have been used to describe the decision categories and their relationships.

This paper is structured into six sections, including the introduction. In the theoretical background section, MC is discussed, emphasising its core concepts, especially the ones related to customer integration. In the third section, the research method is presented, including the methodological approach and research design. Then, the results of the empirical study are presented in the fourth section. In section five, the framework for customer integration is presented and evaluated. Finally, in section six, the main conclusions and opportunities for future research are presented.

3. Research Method

Design science research (DSR) was the methodological approach adopted in this investigation. This approach typically involves the development of innovative solution concepts, named artefacts, to solve classes of practical problems, and at the same time contribute to the development of mid-range theories, i.e., theoretical models that apply to a limited range of situations [

52,

53]. The main reason for choosing DSR is the prescriptive, rather than descriptive character of this investigation. The practical problem addressed by this research work is how house building companies can use customer integration concepts to support the definition of MC strategies and improve value generation for customers.

There are different types of outcomes in DSR, such as models, methods, constructs, instantiations [

54] and technological rules [

55]. The artefact proposed in this research is a conceptual framework which prescribes a set of core and customer integration decision categories that can be used to support the definition of MC strategies in house building companies. This research work also proposes new constructs and adapts existing ones, which are useful for describing those decisions categories.

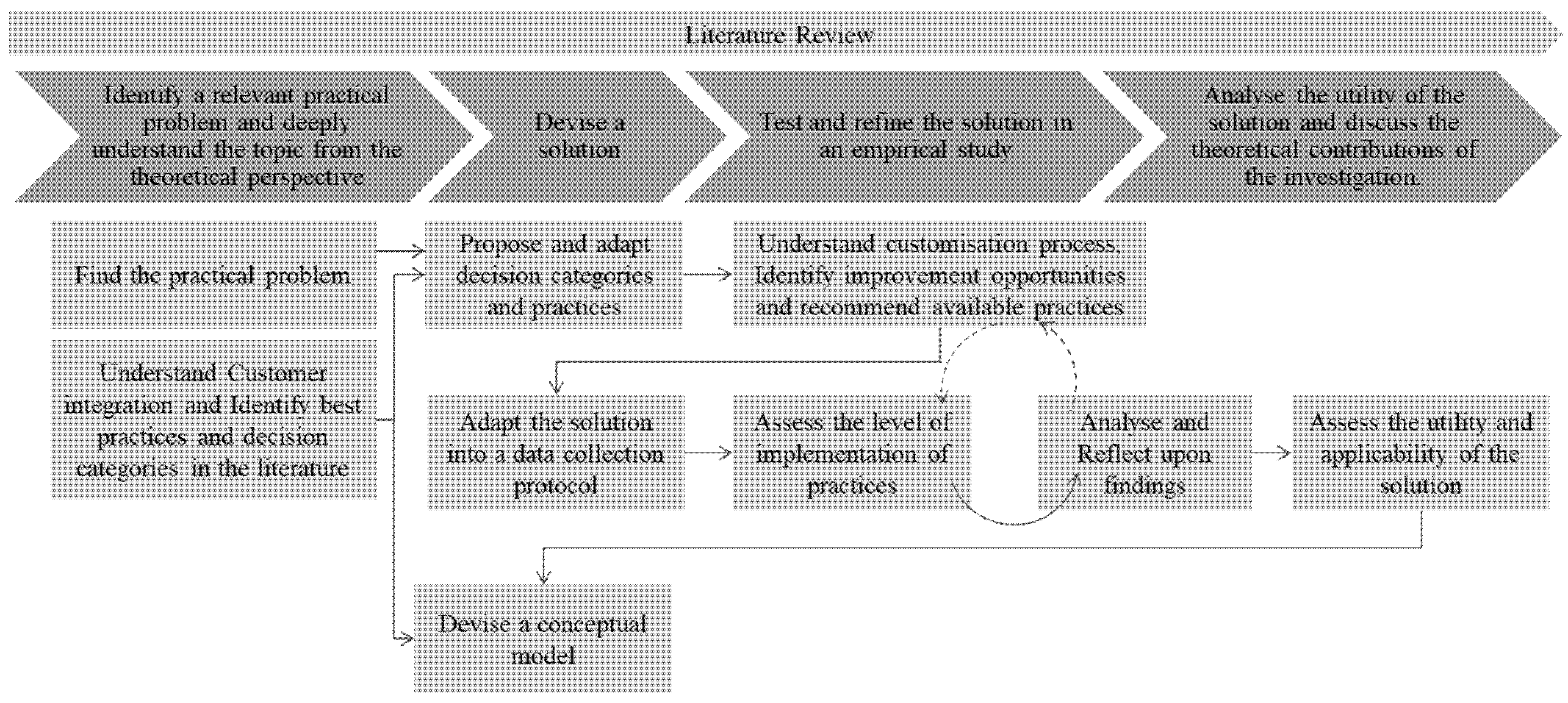

Figure 2 provides an overview of the research design, in which the activities are organised similarly to the DSR steps proposed by Lukka [

53]: (i) identify a practical problem and understand it from a theoretical perspective; (ii) devise the solution; (iii) test and refine the solution in an empirical study; (iv) analyse the utility of the solution and discuss the theoretical contributions of the investigation.

A literature review on customer integration and MC practices was carried out in order to obtain a deep understanding of the topic, in the first step of the research (

Figure 2). The aim was also to find descriptions of practices that were successfully used for customer integration, by using the snowballing technique, complemented by an advanced search in the Scopus repository. The search was undertaken in journal and conference papers, from 1998 to 2018 and its results were limited to areas relevant for house building such as engineering, management, and environmental science, from which 24 papers were selected. As a result, two sets of practices were identified, one related to the MC core decision categories and the other to customer integration. Information about those practices was stored and further categorised in a database, according to authors, and country of adoption.

In the second step of the research, the selected practices were associated with decision categories (

Figure 2). Some of the decision categories considered were identified in the literature review (see

Section 2), such as solution space, visualisation approaches, and configuration sequence. Furthermore, the processes of classifying practices into decision categories available in the literature brought to light some gaps, which resulted in the proposition of some additional decision categories.

The third step of the research consisted of the development of an empirical study in a house building company, named Company P, in which the implementation of MC practices and decision categories was assessed (

Figure 2). The aim of this study was to understand further the underlying ideas of practices and to test the utility of the proposed decision categories. It was part of a broader research project, in which the MC strategy of the company was assessed, and some improvements were implemented by the company, which took approximately two years.

Company P was founded in the 1970s as a family company, being currently one of the largest construction companies of the South Brasil, with 252.312 m2 built so far. They have over 20 years of experience in delivering customised residential building projects for upper-middle and middle-class customers. Their products are made from a combination of traditional methods of construction with industrialised components, such as internal drywall partitions and precast façades. This company was chosen because its business strategy was strongly based on the customisation of products to obtain market differentiation. Moreover, the company was willing to take part in this project and had a department entirely dedicated to customising residential projects. The customisation team (CT) had six architects, including a coordinator.

The focus of the empirical study was on a relatively new market segment explored by the company in which a limited solution space was offered to customers. Within this context, the productivity–flexibility trade-off had to be managed carefully in order to increase the perceived value for customers without substantially increasing costs and lead time.

The empirical study started by assessing and analysing the customisation process adopted by Company P, based on multiple sources of evidence (see

Table 2). Several semi-structured interviews were carried out with representatives of different departments of the company. These interviews were divided into three sections: (i) company’s general information (e.g., business model, customers, competitors, history); (ii) description of NPD and customisation practices; (iii) description of products and customisation options. Additionally, one open-ended interview was carried out with the customers and customisation manager about the role of the customisation department and the MC strategy. Based on the interviews and documents analysis, a customisation process map was devised by researchers and discussed with the CT. Simultaneously, the existing customer integration practices were compared to a preliminary list of practices extracted from the literature, and a gap analysis was then carried out, resulting in the identification of some improvement opportunities. Those improvements were discussed with Company P’s representatives in two meetings. Then, the company decided to implement some of the suggested improvements.

Approximately one year later, after the implementation of some improvements by the company, a data collection protocol was used to assess Company P’s MC strategy regarding core and customer integration categories. This data collection protocol was based on the final set of decision categories and on the full list of practices, being used as a reference to discuss the adoption of practices with the CT (

Table 3). This assessment was based on a 5 point scale. Besides, data about the perspective of customers were captured qualitatively during three open days in construction sites, bringing another perspective to the discussions.

Analysis and reflection of the research findings were carried out in the fourth step of the research study. The utility of the research outcomes, i.e., decision categories and MC practices, was assessed based on the following criteria: (i) provide underpinnings to the assessment and monitoring of core and customer integration decision categories; (ii) provide support to understand MC related concepts and its underlying ideas; (iii) support decision-making for defining the MC strategy, particularly in terms of integrating customers in customisation processes. The assessment of utility was carried out in six meetings with representatives of the customisation department, as shown in

Table 2 and

Table 3. Finally, the conceptual framework of decision categories for customer integration was devised.

4. Results

4.1. Identification of Practices from the Literature

Table 4 presents the 44 MC practices that were identified in the literature review concerned with core and customer integration areas, organised according to decision categories. It is noteworthy that 35 of those practices were discussed in up to three different papers out of the twenty four reviewed. The maximum number was seven papers per practice. Therefore, this investigation provides a much broader view of customer integration practices than previous studies. Furthermore, these practices do not overlap with each other, so they can be combined to formulate strategies. Some of the practices provide support to decision making regarding the definition of strategies, while some other practices support the operationalisation of the strategic decisions undertaken.

The descriptions of the decision categories proposed in this investigation are presented in

Table 5. Some of them were subdivided into sub-categories or decision domains that characterise sets of processes that depend on similar preconditions [

31].

Four core decision categories for MC in house building were defined in this investigation (

Table 5). In relation to the previous literature, a new core decision category related to knowledge management was proposed, which is concerned with how to establish a knowledge-creating system to support MC. This decision category was based on contributions from several authors [

17,

22,

24,

35,

36]. Three decision domains were proposed within the knowledge management category: customer-based knowledge, organisational knowledge, and communication of customisation information.

Three customer integration decision categories were defined, including “visualisation approaches” and “configuration sequence”, based on Rocha [

30]. The “customer interaction and relationship category” was proposed to address decisions regarding how companies interact with customers, when and for which purpose, and establish a trustworthy relationship, during NPD. By contrast, the decision categories proposed by Rocha [

30] were focused on defining the customer–company interface, by broadly specifying who visualises what during the customisation process, and the sequence of decisions to be made by customers when configuring a product. The adapted version of visualisation approaches decision category includes the decision on whether to use visualisation tools for displaying the solution space. Additionally, there seems to be a gap in the literature regarding configuration sequences, since no practices for the house building industry have been found.

4.2. Empirical Study in Company P

4.2.1. Understanding the Customisation Process and Identifying Improvement Opportunities

Company P offers six different product types; each one of them focused on a different market segment with different customisation levels (

Table 6). Most of the company’s previous experience on customisation is related to A and B product types, which can be classified as tailored customisation. In those market segments, customers may hire their own architects to develop the interior design of their units. However, the focus of this investigation is on the D, E and F product types, in which customers can customise only a limited set of elements, mostly related to the finishings and fixtures of the residential unit. Product types D and E could be classified as a “segmented standardisation” level of customisation and F as a “point of delivery customisation”.

The customisation department is in charge of defining the solution space for each project within the boundaries established for each product type by the NPD department. During the conceptual stage, representatives of both departments discuss which customisation units regarding layout and finishings will be offered to customers. At the end of that stage, two customer decision-making deadlines for the layout and finishings are established at the project launch meeting, which involves several departments of the company. These deadlines are included in a brief that is delivered to the project designers. After the project launch into the market, the CT defines different alternatives to be offered as finishings.

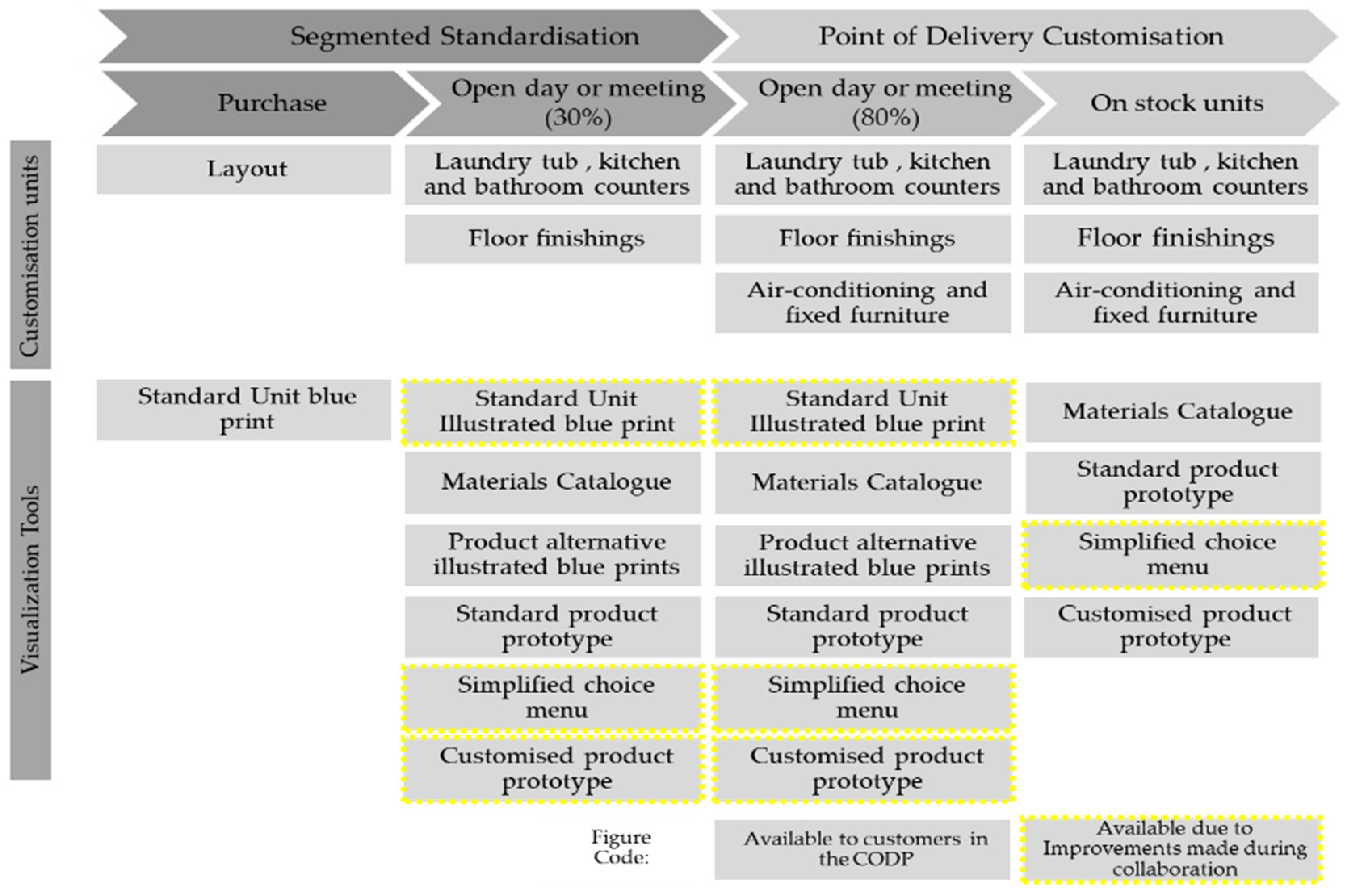

The customisation offered involves four main touchpoints with customers, in which different customisation units are available and portrayed by different visualisation tools (

Figure 3). At each of these points, the customisation department is in charge of: (i) establishing a dialogue with customers; (ii) collecting and processing customer orders; (iii) making design changes; and (iv) delivering that information to the construction site. The CRM department promotes open days for visits to construction sites by the clients. In those open days, the CT is available at the housing unit prototype to offer customisation services. The CT guides customers through the solution space by using different visualisation tools, such as illustrated blueprints and finishing material catalogues, and informs prices of product alternatives by using simulations based on a simplified choice menu. The visualisation tools highlighted in yellow were, in

Figure 3, improvements carried out during the empirical study.

The display of product prototypes in the construction site open days was identified as a key element for the customisation strategy of Company P. These enabled the CT to guide customers to make decisions within the solution space offered, and provided an opportunity for creating a relationship with clients. The CT may also arrange individual meetings in case open days cannot be undertaken or if customers show an interest in product customisation after those events. If the customer opts for a customised unit, an additional contract is signed. During construction, the CT carries out routine visits to the site to check whether customers’ orders have been fulfilled in the construction site.

In Company P, customers initiate their journey with the company when they purchase a housing unit, being registered at the CRM department. That department has three communication channels with customers: (i) an area in the company’s web site, (ii) an APP, and (iii) a call-centre that connects customers to different departments. Besides being in charge of promoting construction site visits and events with customers, the CRM department is responsible for carrying out customer satisfaction surveys in different moments: (i) in construction site open days; (ii) post-occupancy evaluation undertaken one-year after project delivery; (iii) after the response of the company to complaints after project delivery; and (iv) when completing five years, considering the possibility of providing references of the company to friends or family.

Table 7 summarises the identified improvement opportunities as well as the improvements implemented by Company P during this research study. Those opportunities were classified according to decision categories and practices. For instance, regarding the “knowledge management”, the company carries out a POE, yet, it is mostly concerned with the overall customer satisfaction with the product, but no questions are asked about customised items. Another example is facilitating, standardising and digitalising customer order collection, which was carried out by the CT, who used to handwrite customers’ requests during open days, before processing these back at the office and e-mailing them to be confirmed by customers. This opportunity, for instance, inspired the development of a simplified choice menu, which enabled the use of a digital tool for registering customers’ orders and simulating the product alternative costs in real-time.

A critical barrier for improvements, identified in interviews and participant observations, was the lack of communication between departments, which occasionally confused customers. For instance, the sales department offered the “point of delivery customisation” of residential units that have not been sold yet, while the customisation department offered other options at different touchpoints. Moreover, different customisation units are offered in each touchpoint, so by making the early announcement of the “point of delivery customisation”, the sales department has confused customers regarding the available customisation units, the timing and to whom report their decision.

Lastly, the use of traditional construction methods and the outsourcing of product design created barriers for Company P in the adoption of modularity-related practices. As discussed by Fettermann et al. [

25], the customisation of buildings that use traditional construction methods usually has little support from modularity, limiting the advantages of scale.

4.2.2. Assessing the Level of Implementation of Practices

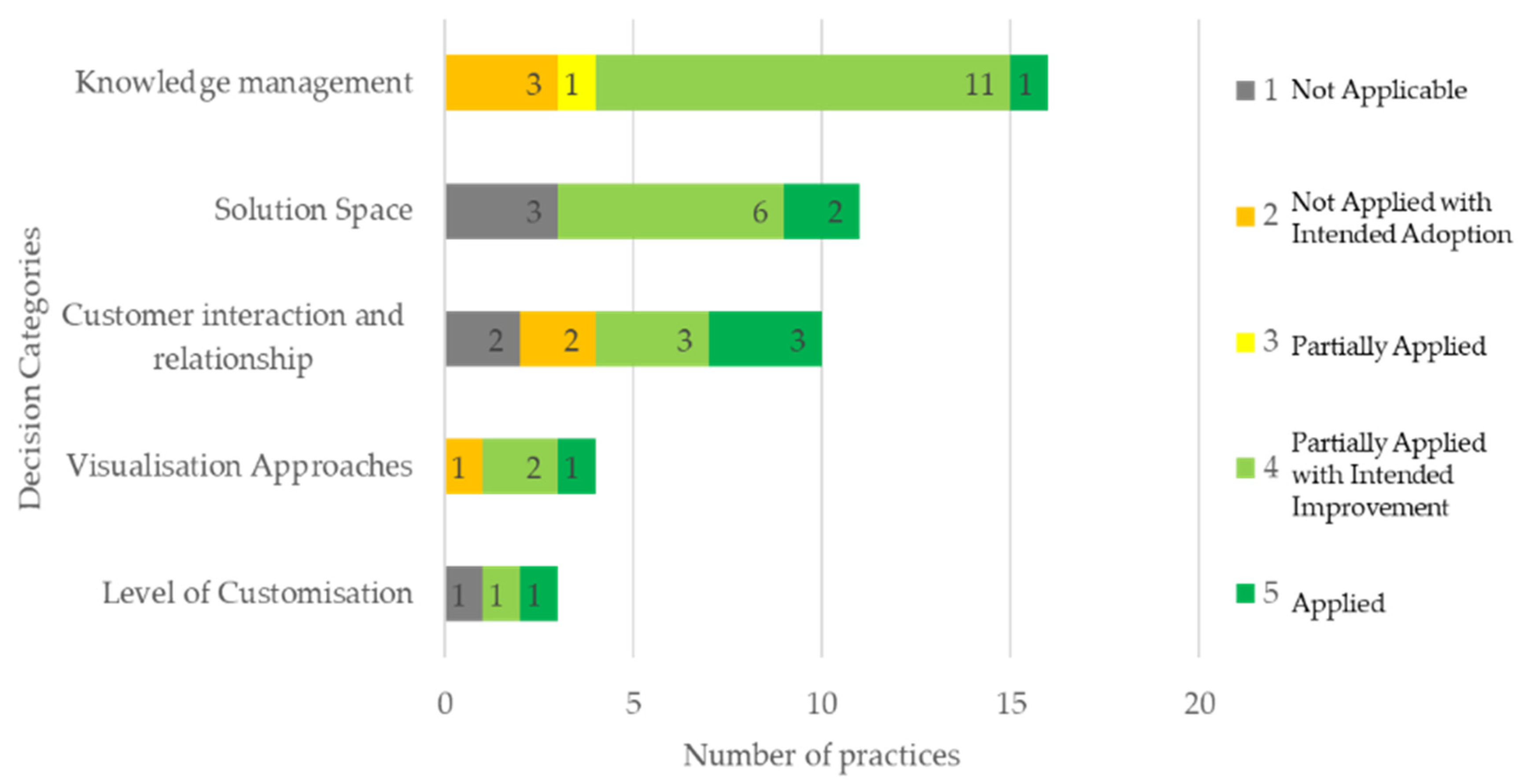

The level of implementation of practices was assessed by the CT considering a five-point scale: not applicable (1), not applied with intended adoption (2), partially applied (3), partially applied with intended improvement (4), applied (5). This assessment is presented in

Figure 4. It is noteworthy that the adoption of practices depends on the context of each organisation. Therefore, practices that are “not applicable” are the ones that were not considered to be useful to Company P, while the practices that are “not adopted with intended adoption” are the ones that the company recognises the need to implement shortly. Some practices were assessed as “partially applied with intended improvement”, meaning the company has adopted it, but there is still room and motivation to improve.

The number of fully applied practices is noticeably low. However, there was evidence that the company is motivated to continue improving, considering that many of the recommended practices changed to partially applied within the time frame of this research project. Further details on each decision category assessment are discussed in subsequent sections.

During the assessment of the level of implementation of MC practices, other improvement opportunities were identified (

Table 8). Although many improvement opportunities remained from the previous research stage, the CT seemed motivated to improve. For example, the use of three-dimensional models to display product alternatives as a visualisation tool for meetings with customers was suggested during the discussions and shortly adopted two weeks later.

The CT mentioned some barriers that they face in the adoption of MC practices such as financial and human resources, and tools to develop and implement new solutions. Moreover, a challenge for the customisation department is to be perceived as an innovation and customer-oriented sector as the development of new product ideas is often assigned to them. Thus, the CT must embrace activities that were not always related to their scope of expertise, such as customising non-residential projects. Moreover, the uncertainty of the new product types and attempts to improve the existing ones can be overwhelming, since their scope is continuously increasing.

4.2.3. Analysis of Decision Categories

Knowledge Management

Knowledge management was one of the decision categories which had the largest number of improvements during the empirical study and the highest number of “partially applied with intended improvement”. One of the most significant improvements implemented was to share customisation information among departments, by using a customised units database. Initially, data regarding the customisation of housing units were held on by the CT and operations only. After that change, the CT compiles that information and shares it in the company intranet, making it available to sales and other departments. Additionally, any changes in customers’ orders are also registered in that database. These improvements resulted in a high level of implementation of practices related to the “communication of customisation information” decision domain (see

Table 4 practices one to seven), yet with room for improvement.

Even though the CT considered that many of the partially adopted practices of the “customer based knowledge” decision domain (see

Table 4 practices eight to 13) had to be improved, there was much concern with how to operationalise the proposed practices, due to limited resources, and fear of exhausting customers with too many questions.

When discussing practice eight, “POE to understand customers’ needs, capture new requirements and feedback the NDP”, the CT stated that it would be beneficial to know customers’ desires and preferences by including questions related to the scope of customisation on the existing POE. This improvement would avoid the initial concern to overload CT with an additional task and overwhelm customers with too many questionnaires.

Practices 14, 15 and 16 are related to the “organisational knowledge” decision domain, and for the last two of them, the company has plenty of data. However, the data have not been processed to create knowledge. For instance, practice 16, “share information regarding customisation performance …”, is at its early adoption stage. Another example is practice 15, related to the creation of metrics: the CT argued that they have a large amount of data, but have not been able to establish any metrics yet. The reflections regarding strengths and shortcomings of the company strategy also inspired the proposition of a new practice, named “use methods and discussions to learn from practices adopted in other departments and levels of customisation”, fostering the creation of a knowledge creation system and continuous improvement.

Level of Customisation

Practices 17 to 19 (see

Table 4) are related to the definition of the level of customisation. The CT reported that they offer options for the attributes defined by the company, according to market segments and CODPs, yet the variation of the solution space offered in different projects is small. Nevertheless, the CT argued that they intend to offer more variety (e.g., painting services), as this would probably contribute to increasing customer satisfaction. However, the decision about the solution space should be carefully defined, as this would also affect operations. Furthermore, the decisions regarding the level of customisation are more strategic, once it might affect different departments, being out of the scope of the CT to be undertaken.

Solution Space

The solution space was identified as a critical area for improvement in the gap analysis. The CT’s partially apply six practices that could still be improved. Regarding the assessment of practice 28, “define the customisation units based on the balance between the potential value-adding to customers and its feasibility and operations costs”, the CT defines the solution space based on their previous experience with customers, considering general definitions made by the company for the segment and the return of investment. However, Company P has no systematic way to assess the value-adding potential of customisation units, neither discuss its feasibility and operations costs with all stakeholders. This criticism corroborates the findings of Fettermann et al. [

25].

Practice 29, “IT tools and choice menu to enable customers to choose, configure and be integrated into the NPD”, was assessed as partially applied with improvements to be done. Its application has evolved significantly during this research study, by the development of a simplified choice menu. However, some additional improvements opportunities were identified, regarding the visualisation of the product alternatives.

Some of the identified practices provided insights on how to overcome improvement opportunities. For instance, “Promote multidisciplinary discussions, among different departments and stakeholders” (practice 26), should be used to overcome the poor communication among stakeholders regarding customisation issues. The CT suggested some inter-department seminars to increase awareness about their work. As discussed by Kotha (1995), the information exchange between coworkers and cross-training can support the conversion of tacit into explicit knowledge and foster the adoption of practices and organisational learning. Another practice that was poorly adopted by Company P was “refine solution space according to previous experience in other projects” (practice27), meaning that lessons from previous projects were only learned informally.

Customer Interaction and Relationship

The practices related to customer interaction and relationship have significantly evolved over the empirical study. In fact, this decision category was concerned with an important role played by the customisation department, as the CT had the mission of establishing a good relationship with customers, as well as dealing with some reported problems related to customisation during NPD.

A strength of Company P’s customer integration strategy was to “establish a dialogue between customers and the company’s representatives for configuring the product…” (practice 37), which was mentioned by customers in the interviews and by the CT during the meetings. Customers mentioned that having a dialogue with the CT and engineers was an important source of information, which made it easier to choose customisation units and created trust. Additionally, several customers seemed to like the customisation service because of its convenience, reducing the time to move in and the need to deal with further construction works. At the end of the empirical study, this dialogue was aided by the combination of different visualisation approaches, such as the product prototype (practice 42), finishing material samples and the choice menu (practice 41).

The CT pointed out that practice 35, “have meetings with customers for product configuration”, was implemented for product types D and E during the collaboration period. During those meetings, the architects explained the solution space and established a dialogue for configuring the unit, but without having the chance to show the prototype for customers.

Three improvement opportunities related to three practices that were considered as “not applied but intended”: “advertise the possibility of customisation…” (practices 31), “use product catalogues for advertising and informing customers about the product and customisation process” (practice 40), and “clearly define interactions with customers and display them in a customer journey” (practice 33). In fact, the possibility of customisation was timidly mentioned in project information at the company website, and it was not always announced in the open day invitations. Interviews and observations in open days confirmed this fact, as several customers had only been informed of the possibility of customising their housing unit during that day, being surprised and confused.

Therefore, the company could improve communication regarding the possibility of customising residential units, to avoid confusion and increase transparency and trust in the relationship with customers. These shortcomings are also related to the lack of clarity about customers’ involvement in the customisation process.

Visualisation Approaches

Several improvements have been made to embrace practices related to the visualisation approaches decision category. Currently, the CT offers more precise information regarding the customised units through the customised product prototype (practice 42), and the use of the simplified choice menu to simulate product alternative additional costs (practice 41). During the discussions, the CT architects revealed that they were trying to adapt the choice menu to product type B, in which the range of options is broader than in other product types, highlighting the opportunity of tailoring practices for different market segments.

An intended adoption by the CT can be seen in regard to practice 44 “Virtual prototyping, e.g., building information management (BIM) models, to show product alternatives to customers and ease choice”. The initial step was developing three-dimensional models to illustrate product alternatives to be used in meetings with customers.

According to customers, some additional visualisation tools supported decision making during the open days such as standard housing unit prototype, finishing materials catalogue, and, in the third open day, the comparison between the standard and customised housing unit prototypes.

4.2.4. Analysis and Reflection

A low level of implementation of MC practices was identified in Company P, similarly to the results carried out by Fettermann et al. [

25] on the MC practices of three Brazilian house building companies. The main improvement opportunities identified in this investigation were also similar to that study, being concerned with the solution space and visualisation decision categories, and customer-based knowledge decision domain. Jensen et al. [

2] argue that by understanding customer’s needs and preferences and making product recommendations based on the available solution space, companies can save much time in the configuration process, and also increase quality and reduce rework. Additionally, the implementation of MC practices enabled Company P to provide a better service for customers and to improve efficiency in some internal processes.

The CT has pointed out in the discussion meetings that some practices could be adapted for other product types that had a higher degree of customisation. However, this would require the analysis of a different context, in which the complexity of interactions with stakeholders would be much higher. These considerations reinforce the need for devising context-specific practices and implementation guidelines, as suggested by Suzic et al. [

20].

The lack of communication, according to Andújar-Montoya [

9], can be attributed to the fact that the NPD in housing is often divided into stages, which are not properly integrated. Beyond that, Schoenwitz et al. [

60] suggest that this disconnection reflects different degrees of awareness regarding the customisation strategy, similar to what was observed in Company P. For example, the sales department was willing to extend the list of options with the aim of signing a contract, in opposition to the production management team. This often occurs due to different mindsets, concerns and nature of the job [

60]. According to CT members’, this reflects the lack of a common understanding in Company P of the role and impacts of customisation in house building projects. Thus, by encouraging better communication between departments, companies should be able to build up relationships based on trust, mutual commitment and understanding of others expectations, which might avoid extra costs and delays [

9].

According to Gherardi [

34], a shared understanding is needed to apply MC practices, i.e., a minimum agreement is necessary for the practice to be adopted and continue to be used. Therefore, there must be opportunities for increasing the awareness of different stakeholders regarding MC, as well as for negotiation when deciding to adopt MC practices as a way to promote innovation.

4.3. Assessment of the Utility of the Solution

The utility of the proposed decision categories and the list of practices was tested in two different stages of the empirical study, both in terms of identifying improvement opportunities and assessing the evolution of the MC strategy. The decision categories were also used to increase the CT awareness and understanding regarding key concepts, enabling them to provide numerous examples and opinions during the discussions. In fact, the CT stated that through the discussions they were able to perceive underlying ideas that they overpass in daily routine, and that this can also be useful as arguments when discussing with other departments, which contributes to improve collaboration.

The discussions regarding practices and decision categories were also useful to understand the scope of the MC strategy of Company P, and, more specifically, to identify gaps and limits for implementation. For instance, some of the solution space practices were immediately rejected by the CT, due to limitations of MC scope that were defined by existing capabilities, and focus on specific market segments. Moreover, the customer and customisation manager highlighted that the practices identified in this investigation could be useful to support decision making, such as, for refining the solution space based on the choice of users from previously delivered residential projects. Furthermore, the participants pointed out the need to improve the identification of customers’ needs and to provide feedback to NPD as two major gaps in the MC strategy of the company, highlighting the importance of the customer based knowledge decision domain.

Several improvement opportunities provided further evidences of the utility of the customer integration and core decision categories. After the first presentation of research findings, many improvements were undertaken, regarding the communications with other departments, customer interaction and relationship, and visualisation approaches. Furthermore, the refinement of the strategy was also influenced by lessons learned from other segments, projects and experiences. An example is the simplified choice menu that was adopted for some market segments, in which the team had more experience. That successful solution inspired the customisation department to adapt it to A and B product types. This example reinforces the need for creating a knowledge system that enables continuous improvement and organisational learning.

The discussions with the CT also brought to light many relevant customer integration aspects. The CT coordinator highlighted the utility of customer integration decision categories in terms of making explicit what the company offers, and how the customer is involved, which makes the decision-making process as straightforward as possible. In fact, some practices related to product visualisation approaches that were implemented by the company along the study, such as the choice menu, the customised product prototype, and 3D models had a positive impact in terms of explaining the solution space to customers.

5. Discussion

The aim of this research was to devise a framework to support the definition of MC strategies by house building companies regarding customer integration. The framework was initially based on a set of practices obtained from the literature review and on some existing MC conceptual frameworks (e.g., [

24,

28,

30,

36]). Furthermore, new MC decision categories and some adaptations on the existing ones have been proposed, for the context of house building projects. This research work has two main contributions in terms of new decision categories, namely “knowledge management” and “customer interaction and relationship”. The first one sheds light on the relevance of creating knowledge and disseminating it within the company as a core element of an MC strategy. The second decision category expands the vision of previous research, concerned with defining an interface, to establish a long-lasting relationship with customers, by planning interactions and building trust. Tommaso [

50] states that comprehensive knowledge about customers is essential to create relationships and manage customers experience, by anticipating behaviour and needs. This statement brings up the inherent connection between those two decision categories.

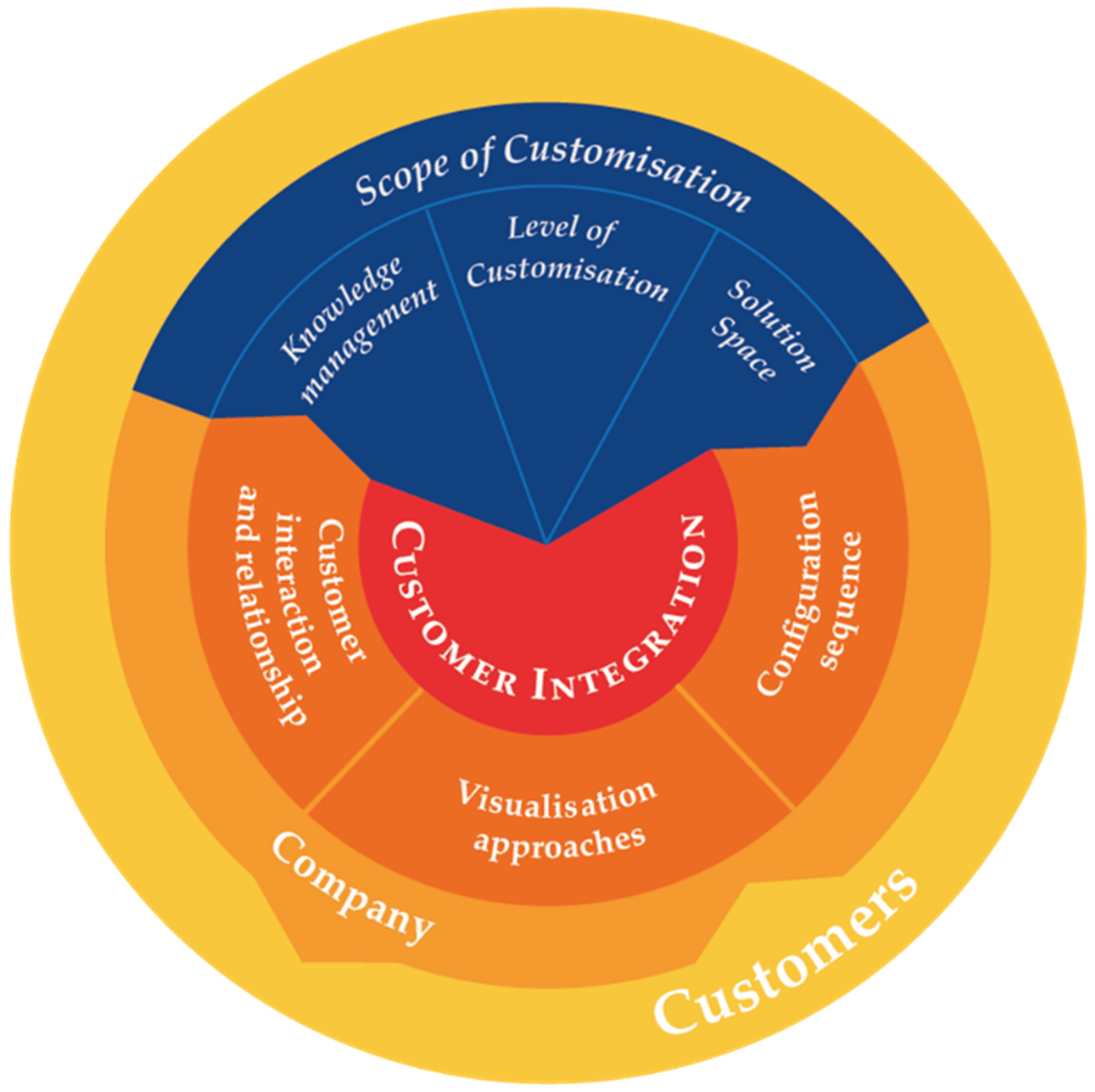

The resulting set of decision categories and practices, as well as their relationships, are the building blocks for the proposed framework on customer integration.

Figure 5 provides an overview of the framework. It is noteworthy that the framework also includes a set of core decision categories at a higher abstraction level, as customer integration and core decision categories are connected by decision making refinement cycles.

Firstly, decisions regarding customer based knowledge must be undertaken (

Figure 5). Moreover, the definition of the level of customisation and of the solution space must be made, based on understanding the demand for customisation [

21,

28]. In this research, the level of customisation was assumed to be a strategic decision, being part of a broad definition of product types.

In the construction industry, there are often multiple CODPs, and the level of customisation and the customisation units must be defined for each of them. Therefore, the definition of the solution space follows the level of customisation by specifying the customisation units to be offered in each CODP. The solution space is outstandingly a core element of the MC strategy, as it influences the decisions regarding customer integration. Moreover, both visualisation approaches and configuration sequence decision categories are related to operationalising the solution space offer and supporting customers decision-making regarding the customisation units and product configuration. The customisation level and solution space definition provide directions on how should customer and company interact and establish a relationship.

The development of the framework can also be regarded as a contribution in terms of understanding of MC concepts, decision categories and domains, and their relationships in more detail, as shown in

Table 9.

Finally, as pointed out by some previous studies, customer integration needs to be aligned with operations and product design areas [

22,

28,

30]. Although these areas are not represented in the framework, it is recognised that interactions between decision categories from different areas must be considered when defining strategies. This connection between areas becomes explicit when considering practices, such as, for example, the application of practices 28 and 36 requires information and actions from both customer integration and operations management teams. It means that communication and close collaboration between areas are essential for the successful implementation of practices.

6. Conclusions

The main outcome of this investigation is a framework of decision categories related to customer integration and the definition of the scope of customisation, considering the context of house building projects. These decision categories emerged from a list of MC practices that were identified in the literature and refined in an in-depth empirical study carried out in a Brazilian company that adopted some MC ideas as part of its business strategy. Some of the decision categories have been proposed in previous studies, and refined in this investigation, while two of them, knowledge management, and customer interaction and relationship, have been originally proposed in this research study.

The main theoretical contributions are concerned with exploring the underlying ideas of those practices, which have been used to explain the decision categories and their relationships. Additionally, the list of practices can be used to assess the degree of implementation of core and customer integration practices in house building companies in order to identify gaps in the existing strategy.

This exploration portrays the fruitful context of MC in construction. There are plenty of opportunities to improve value generation, not only for companies that use industrialised construction methods but also in the case of traditional ones. Customer integration seems to be a key area of improvement in house building companies, demanding efforts from different areas, which are not limited to the development of configurators or digital tools.

A major limitation of this investigation is that it was based on a single empirical study. More insights about customer integration could be obtained if other in-depth empirical studies were carried out in companies from other market segments or countries, providing opportunities for refining the framework and the assessment method.

Some opportunities for further research emerged from the discussions of the framework, such as the need to explore the interfaces between functional areas (customer integration, operations management and product design) and also between decision categories. Those interfaces need to be considered as it is expected that effective MC should have a holistic character. Other opportunities include the development of specific frameworks for product design and operations management for mass customised housing.

Another theme to be explored is how the customisation level contributes to different challenges and issues on the adoption of different sets of practices for customer integration. The higher the level of customisation and the degree of integration, the higher the complexity that needs to be dealt with due to the increasing number of stakeholders and product customisable items. Therefore, different types of MC strategies should be explored by considering the need for using different sets of practices or adapting some of them to specific contexts.

Finally, some other future research opportunities were identified regarding specific decision categories. For instance, not much has been explored regarding the configuration sequence decision category and the interdependences between customisation units that need to be considered in the design of choice menus. Another opportunity is the relationship between the solution space and the level of customisation, which has been superficially explored in the literature. Regarding the customer based knowledge decision domain, there are still many opportunities to explore approaches based on information-driven decision making and recommendation systems. Finally, the customer interaction and relationship decision category represents a fertile ground for the further exploration of experience design in mass customised housing.