1. Introduction

Recent decades of environmental degradation have gradually increased the pressure to change production and consumption behavior, especially in the business sector. A circular economy (CE) involves three main concerns: the environment, resources, and economic benefits [

1]. In an evolving circular economy, both firms and customers should strive to conserve the use of resources in production as much as possible while deriving the maximum value, and finally regenerating and retaking materials and components at the end of a product or service’s life. These are the 3R principles of a circular economy—reduce, reuse, and recycle materials [

2,

3].

In most developed and developing countries, many studies have addressed the issues of sustainable development and growth. However, what is required is a new approach in which each country aims for new types of development. Resource conservation and enhancements that are linked to the provision of an adequate livelihood base and equitable access to resources are required for a circular economy. When it comes to the environment, all countries are linked and interdependent. Suppose one country pursues an energy policy intending to reduce its air pollution. It might be able to improve its pollution levels, but its economic growth rate might be lower than before, without a new circular business model. Similarly, if a country strengthens its agricultural development, this can also be linked with a worsened environment due to the degradation of land, water, and forests. For these reasons, a new business model is needed to embrace the principles of a circular economy.

A few decades ago, many developed countries realized that they needed to find an alternative development strategy to replace their current behavior that burdened future generations because of a misplaced belief that there was a choice between the economy and the environment. Sustainable development is defined as a guiding principle in addressing the present generation’s needs without undermining future generations’ capacity to meet their own primary needs. Circular economy business models can help get a greater competitive edge in the future because, consistent with their objectives, they produce more value from each unit of resources than the conventional linear production and consumption models do. Further, a firm’s growth also depends on innovations. Innovations and economics are developing and becoming closely inter-related to the environment.

However, most of the existing studies on innovations pay little attention to the relationship between innovations and the environment. In comparison, a circular economy is an industrial ecology that is regenerative or restorative by design and intention. Businesses are threatened by resource shortages, population growth, migration, climate change, and urbanization, even though some regulations are addressing issues ranging from hazardous chemicals to initiatives related to zero-waste and recycling. All these put pressure on businesses to switch from their existing industrialized open loop make-use-dispose linear economic models to a more closed loop circular reduce-reuse-recycle approach.

In general, concerns about the natural environment have driven consumers to mitigate the damages inflicted on the natural environment and producers to take advantage of the cost savings and new business opportunities that a circular economy provides. Several factors affect consumers’ willingness to purchase reused, remanufactured, and recycled products. Warranty, discount, and money-back guarantee (return acceptance) are among such factors. Many studies indicate that recycled products are evaluated favorably by consumers if reliability, product quality, and service availability are guaranteed, and recycled products are price competitive.

Reproduced and reused products that can substitute for new products are generally claimed to not only provide material saving but can also save energy. These arguments are taken from studies that look at the differences in material extraction and production and manufacturing products. If the remanufactured product can be considered a substitute for a new product, then credit is usually claimed for the avoided resource use and emissions generated in association with the production of new products. Recycling of materials, their collection, transport, and the remanufacturing of used products is energy-intensive. In this case, the consumption of energy is considered to be less than the amount used to manufacture virgin products. It is worth mentioning that, in addition to energy, material saving is the main advantage of recycling, reusing, and, remanufacturing products.

Product disassembly is formally known as the systematic separation of components. It can be divided into several types, namely, destructive or non-destructive and partial (selective) or complete (full) component disassembly. Generally, the greatest savings come from the avoided new material extraction and production, but the gap between new manufacturing and remanufacturing may also be significant. Strategic issues that concern disassembly include lot sizing, process layout and material transfer, and levels of scheduling.

CE replaces the concept of the end-of-life of a product or service with renewable and restoration of energy, and stops the utilization of poisonous chemicals that impede effluent reuse and a return to the ecosystem. A circular economy’s aim is eliminating waste using improved designs for systems, products, materials, and circular business models.

This paper discusses CE research and evaluates the information thus collected to help implement the goals of a sustainable business. It also assesses the outcomes concerning a comprehensive scope for CE, which covers its environmental impact, the current resource scarcity, and the economic benefits of using a CE model. This paper’s goal is to provide theoretical and methodical foundations for a sustainable business model, which is in line with CE’s aims. We seek a new conceptual framework for business models that emerge in CE. The paper also focuses on product servitization in the market as a pass-loop model.

Servitization refers to industries using their products to sell services. As part of servitization, companies offer additional services associated with reuse and recycling materials and components, such as maintenance to supplement their traditional products. It is a practical and necessary step in implementing the key principles of a circular economy.

Over time, business models have changed [

4,

5,

6]. CE perhaps emerged because of the concept of sharing economic, environmental, and sustainable technologies [

7]. The relationship between industry and the environment is equally important for a business’s performance and growth. Due to limited natural resources, ceaseless and exponential economic growth can have serious side effects on human health and the environment [

8].

This paper offers a business model with five components: the green-loop, the pass-loop, the having-loop, the being-loop, and the hybrid-loop. We illustrate this innovative circular business model through product servitization at the Hyundai Automotive Enterprise in Korea as an example of the model’s pass-loop component.

The rest of this paper is structured as follows:

Section 2 presents the methodology used and discusses the latest research findings on CE.

Section 3 discusses the research on business model innovations. The business model’s typology in CE is provided in

Section 4.

Section 5 gives the conclusion and implications.

2. Literature Review and Research Methodology

2.1. Methodology

For implementing our research goal, we used two methodologies: conceptual and case analysis. This paper is a conceptual discussion based on an analysis of literature [

9,

10]. Qualitative studies have flexibility in applications that are more reactive to the dynamics of social phenomena such as business activities as compared to quantitative techniques, which provide direct observable indicators [

9]. For studying current academic insights regarding the concept of a circular economy, this paper considered published articles, including those in general journals and academic books and reports. In particular, it used Scopus, Google, and Web of Science, including books, magazines, and periodical journals; ‘articles’, ‘editorials’, and ‘review’ types of documents were also used.

After classifying the abstracts, the articles relevant to the research topic were scanned. After reviewing the studies, the areas were limited to industrial ecology dealing with energy and material flow trends within and outside industrial systems. The paper also considered products in servitization as one of the business components in a circular economy due to the advent of the internet of things (IoT) and network technologies. IoT is a network of interconnected activities that collect and exchange data, making them responsive. It includes technological dynamics, studies of the environmental impact of economic activities, and an evaluation of their effects on the environment by managing waste and emissions sourced from the business. The latter contains research on economic theories and an assessment of the issues related to logical managerial decisions.

A case study is a beneficial way of verifying or expanding conventional theories or challenging a specified theory [

11]. Our study discusses the business model structure based on a circular economy through a single case. The Blue Members model of Hyundai Automotive in Korea (BMH) was selected as a product servitization case in a circular economy because it is a product-as-service model. We interviewed developers and two other researchers (in October and November, 2019) for collecting the data. In confidential cases, we collected the data via email. In addition to the web data, other objective data was also collected through a literature review and by reviewing periodicals from Hyundai Automotive.

2.2. Circular Economy

The environment and business circumstances are closely associated. However, many business studies pay little attention to the environment. Environmental deterioration is a global challenge regardless of the country and its level of development. The main challenge of the 21st century is facilitating and strengthening democratic collaborations within and between countries on sustainability at the national and global levels for improving the environment and human health and welfare. The European Council has been encouraging member states since 2001 to develop their strategies for sustainable development with the objective that this can lead to the production and implementation of a sustainable development strategy worldwide in collaboration with the UN system.

The word ‘circular’ means a closed-loop instead of an open-loop system. When considering production resources as important factors in an economy, we can understand that CE is a closed loop economic system based on limited resources. Rapid environmental degradation across the world has contributed to introducing policies for reducing harmful impacts on the environment because of consumption and production. Many countries have made serious efforts to bring in acts and laws to create a circular economy’s recycling concept. CE combines many previous concepts, which give it a broad scope. In this part of the paper, we define CE based on studies and give an overview of various scholars’ perspectives. The concept of CE was first used by Stahel and Reday-Mulvery [

3].

Following this concept, discarded resources such as water and nutrients could be used as resources. This concept led to the thinking that labor could substitute energy since energy prices and unemployment had increased in the mid-1970s. At that time, architects and decision makers felt that it took more labor and fewer resources to refurbish buildings than to erect new ones.

Hence, economic prosperity should be measured not only by industrial production, but also by the environment and earth’s resource stocks, including human beings. Stahel’s [

12] priority concerns were the extension of product life cycles to minimize energy and material flows. The environment, resources, and the economy are closely related to manufacturing products and services. In this context, a study of the circular economy can be divided into three areas: resource oriented, economic oriented, and environment oriented.

A study of what a circular economy is based on needs a resource-oriented perspective for the looped system because of resource scarcity. Heshmati [

2,

13] asserts that CE with its 3R principles of reusing, reducing, and recycling has strong linkages with resources. Pearce and Turner [

14] were the first to use the concept of a ‘circular economy’ in their book

Economics of Natural Resources and the Environment. These authors illustrated how ignoring the environment meant ignoring the economy because it was an open-ended loop or a linear system without an integrated system for reusing material and recycling waste. Some researchers recommend using the material balance model. In other words, they often define resource supply and waste assimilation and utility as being functions of the economy of resource use as well. CE is a development strategy that is aimed at maximizing resource use efficiency and minimizing waste production [

15]. CE’s concept highlights the benefits of recycling and reusing residual waste materials including water, energy, other by-products, and knowledge [

16,

17,

18,

19,

20].

Preston [

21] defines CE as an approach that transforms the function of resources in an economy. He also emphasizes that waste from factories becomes a precious input for other processes through recycling. Furthermore, products can be reused, repaired, or upgraded rather than being disposed.

In line with the resource perspective, diminishing waste and coping with resource scarcity are essential for social and green entrepreneurship [

22]. Hence, new business models (which are discussed later) are developed with the primary motivation of finding scientific solutions to environmental problems. According to Vermander [

23], the circular economy wants to reduce the huge resource demand and supply constraints concerning population and industrial structures. The economic boom and high growth rate of heavy and energy intensive industries led to a doubling of energy consumption during the last decade [

24]. The energy used mainly came from non-renewable and polluting sources [

25]. Heshmati [

26] suggests that one way to reduce electricity consumption is by using demand response for real time pricing.

Using gravity as an example, shifting from an economy that is based on scarcity to an economy that is based on resource abundance may depend on innovators. According to the Ellen MacArthur Foundation [

27], a circular economy goes beyond pursuing waste prevention and waste reduction and encourages organizational, technological, and social innovations in the value chain. These are intended to ‘design-out’ waste from the outset rather than relying solely on end-of-chain recycling. The Ellen MacArthur Foundation [

28] stresses the material flow aspect of resources.

An analysis of circular economy literature concerning both its economic and environmental aspects provides an opportunity to understand the derived business model for a circular economy (BMCE). Originally, an economic system was seen as part of a large system that is planet earth. Both economic and environmental systems are dependent on each other. Hence, studies should prioritize a joint economy-environment system perspective that considers principles of thermodynamics and natural sciences.

On a practical level, if human beings can live without environmental degradation, the available renewable resources thus made available may provide an answer to all environmental problems. Generally, since every country’s economic goal is value creation, linkages among the actors (supply, demand, customers, and manufacturers) form a critical perspective. According to Van den Berg and Bakker (2015), CE is an industrial and economic system based on the reuse of raw materials and the absorptive capacity of renewable natural resources as it tries to minimize the value of destruction in the overall system and maximizes value creation in each system’s links. According to the European Commission [

29], CE is ‘a development strategy that allows economic growth while maximizing resource use, fundamentally changes supply chains and patterns of use, and redesigns industrial systems.’ Instead of the depletion of resources, in a circular economy, waste is ‘built-out’ and the consumed material is used as nutrients in the associated usage cycle. Ironically, resource shortages allow new business models to be developed [

30,

31].

The process’ effluents act as raw material for another process or industry, and the industrial ecosystem is supposed to behave as a biological ecosystem’s analogue. Industrial ecology promotes a systemic, detailed, and interconnected view of all the biosphere-related components of the industrial economy. Industrial ecology is research on material and energy flows. A circular economy encompasses the industrial ecosystem. Waste and by-products should be addressed for a better ecology through: (i) an eco-industrial network as waste becomes a resource for others, (ii) designing new services and products for reducing dispersion or at least eliminating its dangerous side effects, (iii) following the objective of minimizing total matter (and energy) flows, and (iv) not using fossil fuels, which are a source of many environmental problems [

32].

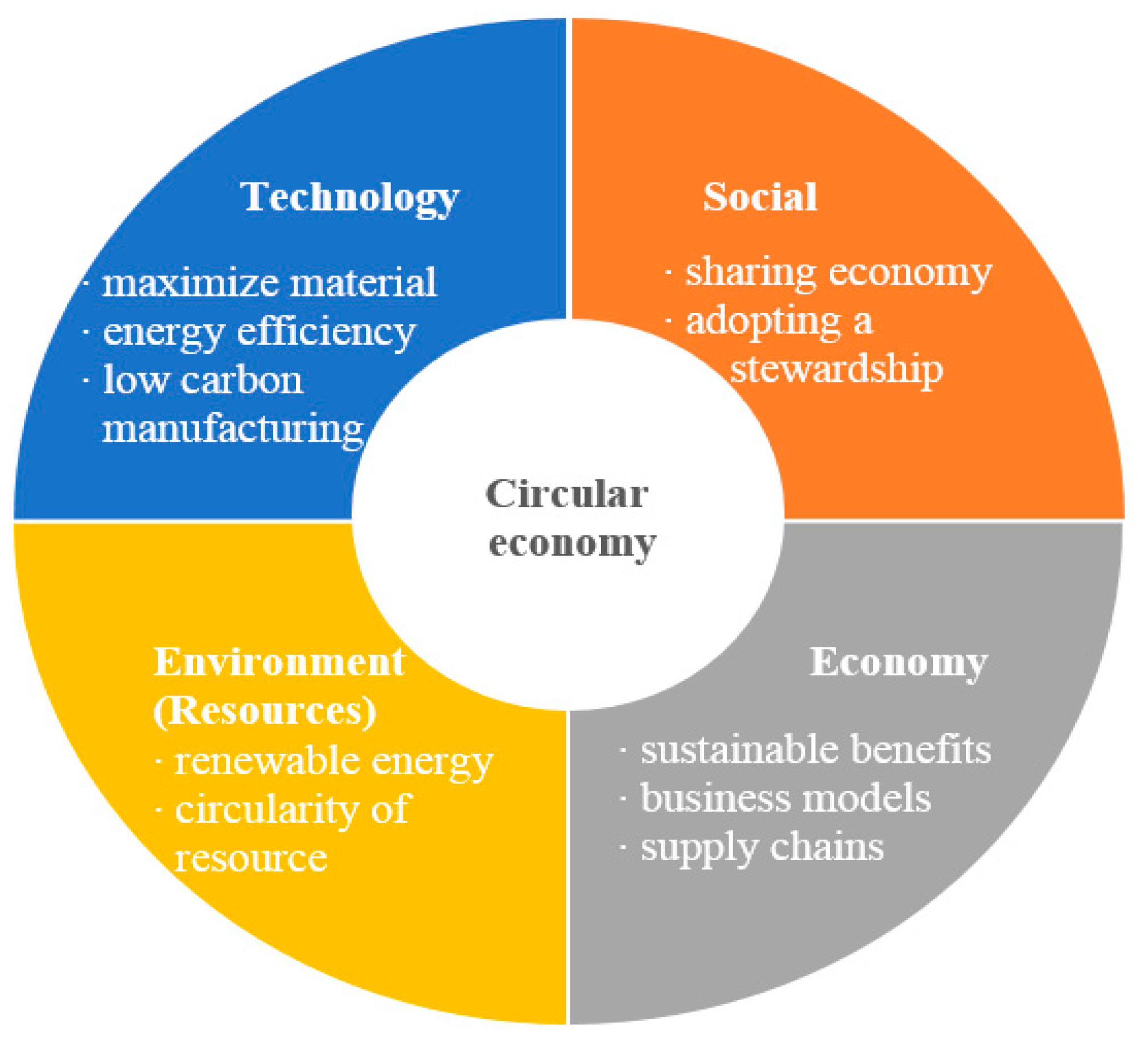

Based on the literature, CE is a system that relates to resources, the environment, and the economy to optimize the total material cycle from original materials to finalized materials, components, products, obsolete products, and ultimately to disposal. Based on the literature review, one can derive a conceptualization of a comprehensive circular economy framework, as explained in

Figure 1.

A circular economy is like a reservoir holding critical topics. Perhaps another word would be more appropriate, and a system such as a business model is the agent for its successful implementation. Thus, the ultimate goal of a circular economy is maximizing the value added by products and eliminating waste.

3. Business Models in a Circular Economy System

Users or manufacturers regularly make decisions on how to raise and spend capital. These decisions are influenced by numerous factors in a changing world. Currently, a circular economy is seen as a critical idea underlining fundamental changes in the business models of today [

33].

Enterprises need to solve emerging problems and redefine their business models for adopting a circular economy.

Through cost and convenience focused incentives, generating consumer demand will help introduce and expand the circular economy to the market. According to a GreenBiz [

34] study, critical challenges in the introduction of an efficient global circular economy are insufficient business opportunities (38 percent), logistics costs for reclaiming recycled goods (36 percent), and lack of awareness and knowledge among consumers (36 percent). These are accompanied by other prioritized business objectives (30 percent). In the survey, numerous participating enterprises considered diminishing business models also as the biggest risk to circular economy.

Before making any changes, it is essential to understand what a business model is. Business models have to adjust to changes in markets, innovations, and legal frameworks [

5,

35]. As technologies and market conditions change over time, newer and better business models that satisfy both customers and firms are needed. With the advent of the internet, scholars [

36,

37,

38] have paid particular attention to business models. While there is no widely accepted definition of a ‘business model’ yet, each corporation has its own unique business model. When it comes to business models, some researchers have devoted their attention to business model innovations [

4,

5,

6,

37,

39]. A business model can play a role in converting the value delivered to customers to value captured by an enterprise [

40]. Business models have also been analyzed from an evolutionary perspective for which Han and Cho [

41] suggest the preparation, spread, evolution (PSE) curve, consisting of three phases: (i) the preparation phase establishing the target group platform; (ii) the spread phase in which content is provided in the early stages of platforms such as KakaoGame, a low-pricing strategy, and strengthening the rules of the platform; and (iii) finally the evolution phase in which the platform continues to grow.

A business model is considered a way of building a business and adding value for its customers [

5]. The model can be described as a way an enterprise generates and provides value to its customers, and then turns the payments received into profits [

35,

37,

38,

42,

43]. Business models are described according to firms’ economic models [

44]. Therefore, a business model in general revolves around the logic of how a firm produces profits. Steward and Zhao (2000) argue that a business model illustrates how a firm can make profits and retain its profit streams over time.

It is also possible to describe this business model as an architectural structure for a firm’s survival. Slywotzky [

45] states that a business model is the totality of how a company chooses its clients, defines and differentiates the services it provides, defines the tasks it will perform itself and those it will outsource, and configures its resources, goes to the market, creates utility for its customers, and makes profits. A business model is linked to a variety of other managerial principles and, as such, it captures the key components of a business plan. The components of a business model are product, price, distribution, organization, and market strategy [

46,

47,

48,

49].

A business model needs to be tested against the current market environment and against how it could develop in such an environment [

50]. No matter the industry to which a firm belongs, there are requirements that allow one to decide whether a successful business model has been built or not. Business models produce value propositions that are convincing for their customers. They attain benefits regarding the cost-risk structure and allow a business to capture a significant value [

41]. This paper considers recent related studies describing the business model as a condensed representation of its business logic. The business model is defined in the ways in which a firm survives while creating and capturing its values.

A recent area of research in business models is the sustainability of the economy. In an overview of business models as embedded in their socio-technical context, Bolton and Hannon [

51] propose a system-based approach that can provide new insights into the complexities and governance of business sustainability transformations. Business models can induce value flows and share profits between two strategic partners and producers and retailers for optimizing profits for a person and the reverse supply chain at the same time [

52].

As the literature review shows, a business model can benefit a firm in terms of growth and profits but, at the same time, it also encourages over-consumption and waste, which generates significant negative environmental and social externalities. However, in a circular economy, it is necessary to have new business models that can reduce consumption and waste as they will bring fruitful gains for firms and users. According to Sempels [

53] and Wicki [

54], business models are systems of inter-related concepts. So, if one component changes, other components often have to change as well. For example, creating a new value needs new inputs and new production processes.

Before the concept of a circular economy was used, studies dealt with different definitions of a business model. For implementing a circular economy, firms often require a new business model. Closing resource (material) loops can produce new goods or services, new customers, new production processes, and different profit-making methods. This includes values other than financial profits.

Stahel and Reday-Mulvey [

3] note that a business model can enhance a product’s life through reuse, remanufacturing, and maintenance. They emphasize changes from ownership to stewardship, where consumers become the users and creators as, according to them, remanufacturing and repairing old goods creates skilled jobs. Stahel [

55] emphasizes recycling at the material level in a circular economy from selling products to selling services. This model could become an ultimate business model for closing the loop. These authors assert that, in a circular economy, recycling and reusing materials on a molecular level becomes an important business model.

3.1. Business Models for a Circular Economy

The University of Cambridge, Institute for Leadership (2016) states that broadening the level of a business’ engagement through multi-stakeholder partnerships can help the business gain by building more efficient supply chains and reducing costs by sharing the implementation of solutions with other firms.

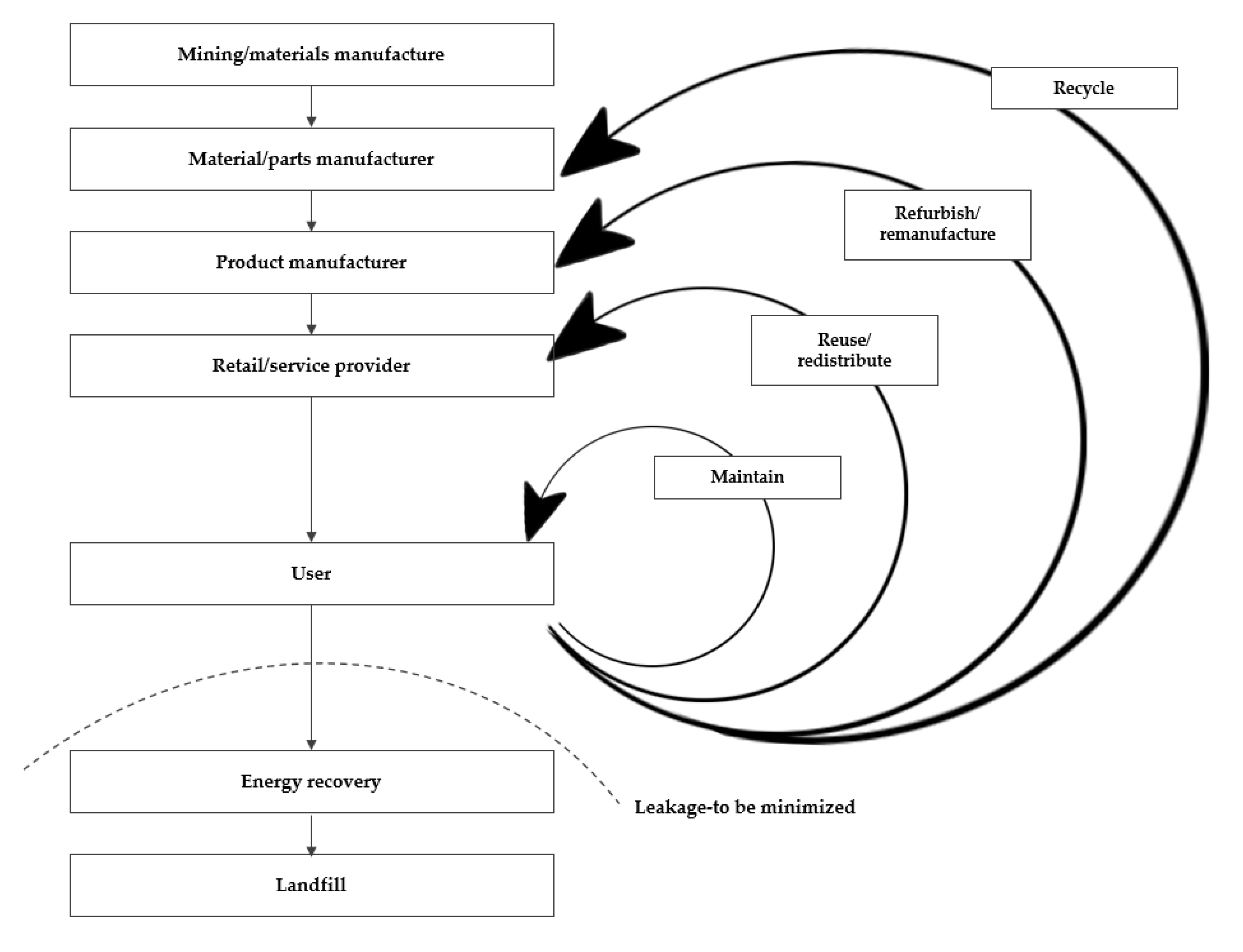

This study gives an overview of business models, including: (i) product as a service; (ii) design, manufacture, and distribution; (iii) usage; (iv) reuse and redistribution; and (v) refurbish, remanufacture, and product recycling. Mentink [

56] gives a productive concept for understanding what a business model for a circular economy (BMCE) is. Nguyen et al. [

57] suggest a remaking of the industrial economy (see

Figure 2).

BMCE can be looked at as a sub-category of a business model that fits in an economic system of restorative or closed material loops [

56]. According to Mentink [

56], BMCE is not a closed material loop by itself; rather, it is a part of a business model that, together, close a material loop to be called circular. As an illustration, from

Figure 1, a Blue Material cycle can be regarded as a BMCE. BMCEs keep materials and enable other firms to do so as well. Business models 1, 2, 3, and 4 in

Figure 1 close the Blue Material loop. Business models 6 and 7 are considered non-circular. Business model 5 cannot be regarded as a BMCE because, if a firm makes goods out of recycled material so that it is very difficult to recycle the material again, the firm violates a closed material loop.

According to Mentink [

56] a circular business model is the reason behind the way a company generates, produces, and collects value inside closed loop materials. BMCE can be conceptualized as: (i) maintenance, (ii) repair, (iii) redistribution (reuse without treatment), (iv) upgrading, (v) remanufacturing, (vi) recycling, (vii) energy recovery, and (viii) disposal. Lacy and Rutqvist [

8] and Lacy [

58] propose five business models for a circular economy:

The circular supply chain model: This is a fully reusable, recyclable, or biodegradable material that can be used in consecutive life cycles for minimizing costs and improving profitability when businesses require access to scarce or environmentally harmful material.

Recovery and recycling model: For instance, using flax, hemp, or other fabrics, a company can produce sustainable and environmentally friendly biomass resources that allow textile companies to manufacture textiles without growing cotton. This model can reduce environmental risks. The recovery and recycling model generates production and consumption by considering everything treated as waste which is recycled for other uses.

The product life extension model: Even users discard products when they are no longer valued, but many of the products still have circular value. The product life extension model seeks to recapture this potential circular value of a product. Firms can economically recapture value by improving products through upgrading, repairs, or remaking. This business model enables a firm to generate value by merely selling products for keeping them alive and relevant.

The sharing platform model: Sharing means sharing things when they are not being used using the internet and other digital technologies. This model can connect the products to those who want to use them. For instance, many things that are stored in a home that are infrequently used can be shared through a platform. Fewer resources go into making goods that are never used, and customers have a new way of supplying goods and producing income. This business model is seen frequently because new entrepreneurs, such as Airbnb (home sharing), Uber, and Lyft (car sharing, ride-sharing), are starting businesses using this business model

The product as a service model: This model can be called a lease model. It is attractive when manufacturers or retailers spend a lot of money and time to keep the products and services in the market. In other words, when the total cost of ownership and maintenance is high, and the products are less frequently used, firms try to come up with cost reduction strategies through alternative ways of using the products such as leasing.

3.2. Key Principles for Business Models in a Circular Economy

The types of business models listed earlier help adjust firms’ behavior by focusing on the reliability, longevity, and reusability of products. Customers can benefit from leasing or paying for products by use in a product-as-service model. Firms have an opportunity to create new relationships with customers. Bakker et al. [

30] suggest some alternative BMCE models such as the classic long-life model, the hybrid model (combining durable goods with short-lived consumables), the gap exploiter model (components of goods that last longer than the rest), the access model (customers pay for access to products), and performance model (customers pay for performance instead of the products). A classic long-life model focuses on having a long product life and a design that promotes extended durability and possibilities of its repair.

To make a product have a long life, firms should take care of its designs for repairs, refurbishment, and remanufacturing. A hybrid model focuses on durable products that have short life cycles. Hence, a hybrid model is a mixture of a durable product and a short-lived consumable. Such products are manufactured by using disposable materials. In this way, the obsolescence of the products is delayed.

A gap exploiter model gives value. This model is targeted at exploiting a product’s residual value. In an ideal case, businesses refurbish or remanufacture the same goods by being aligned with this model.

In the access and performance model, firms provide the service or capacity to meet customers’ needs without owning the physical products. From a circular economy’s perspective, manufacturers or service providers retain the ownership of the products and are therefore incentivized to make the products last as long as possible. Mouazan [

59] explains the value of customer interactions (collaborations) in transitioning from a linear model to a BMCE. Generally, a traditional business model is firm-driven in a linear form. However, circular business models are associated with relationships at the value network level.

One of the critical barriers to a transition to BMCEs is related to final consumers. To overcome this barrier, Mouazan [

59] proposes a sector-level strategy by targeting particular ‘customer segments’ of the market to decide how to perceive personal, cultural, social, and psychological variables for creating effective circular marketing strategies. Collaborations will help a company transform and reshape its business model [

60,

61]. By reviewing the literature on business models for a circular economy, certain widely agreed upon structural factors constituting BMCEs can be obtained.

According to existing research, the key principles of a BMCE are: First, circular business models should have eco-friendly regulations based on the reuse of products and resources and the use of the restorative capacity of scarce natural resources. Second, the models can operate to minimize waste in the production process and system design by using adequate materials (for example, fewer composite materials); designing for facilitating recycling; and striving for easy solutions. Third, the business model can operate to maximize the value proposition through its design. This should create not only intrinsic value but also added value by applying the product design for easy repairs to add to a product’s life cycle and to strive towards recycling. Fourth, the model can minimize and reduce energy use through technology innovations to maximize energy efficiency for producing products and services. Fifth, manufacturers and customers should consider the ‘total ecosystem’ of a business and ensure that this is reflected in the business model for keeping the circular loop closed. Finally, the model allows businesses to collaborate for operating a business model. Collaborative relations usually increase the degree of cooperation between the groups and their members [

62]. Collaboration between manufacturers and customers includes knowledge exchange [

61] and coordination of activities.

As stated earlier, the current economies (that is, production and consumption) follow a linear approach to resource use (take-make-use-dispose). It will not be easy and sufficiently profitable for these economies to switch from these existing linear ways of doing business to a circular economy approach. A 100 percent linear business model or a completely circular business model does not exist in the real world as there are many drawbacks in production stages and the use of products such as energy leakage at the implementation level or emissions. Unlike the linear models of today, a circular economy provides a development strategy that allows a business to achieve economic growth by capturing value in using resources efficiently through circular business models. A circular economy can generate added value as long as possible in goods and services and eliminate waste at the same time. The transition from a linear process to a circular one involves changes in the use of materials. Additionally, it involves changes in the structures of ownership, business models, and producers’ and consumers’ responsibilities. BMCEs strengthened with standards, legislation, enforcement, and incentive programs offer instruments for converting goods designed for reuse into compelling value propositions.

A circular business model’s innovations should focus on product life extension. A product’s value can be maintained in terms of remanufacturing (for example, by designing for endurance), repairing, upgrading, or remarketing. It should focus on resource efficiency and resource recovery and products as services (for example, sharing platforms and renting). Enticing customers by offering value needs a different business logic for reaching out to customers. Firms’ behavior needs to adapt to select production technologies and design features to be implemented in the products for determining benefits to customers for using the products, confirming revenue streams, identifying market segments, and designing mechanisms for capturing the products’ value. Choosing a business model is like choosing a business architecture. Shafer et al. [

63] describe a business model as a firm implementing its core logic and strategic choices for creating and extracting new values from within a network of values.

4. Hyundai Automotive Enterprise as a Product and Service Model

For illustrating the application of a circular economy in an implementable field such as in the automotive industry and investigating how the circular economy’s processes operate and are linked to the current linear supply chain, it is important to configure a new network. If service-based models are to be linked together, then products in a circular economy will certainly lead to new value creation.

One business model in a circular economy is the product as a service model. The circular economy is co-evolving with the internet of things (IoT) technology. This has resulted in internet-enabled communication between objects that gather and produce data from their use, context, and interactions with other objects and individuals [

64]. IoT enables continuous monitoring of individual products as they are linked to and separated from networks of other goods and players. It is possible to make even fairly cheap products ‘smart’, collecting and analyzing data, and improving necessary technologies and capacity so that more granularity can be interpreted as an interaction between multiple products [

24]. Further, IoT plays an important role in facilitating the qualification and other institutional frameworks and processes needed to ensure that the circular economy is realized.

Services are categorized as product-related or not product-related [

65]. Services are also classified as ‘product-oriented’ and ‘end-user’s-process-oriented’, which are new business approaches for reducing raw materials and resource inputs. Servitization products encompass the creation of new capabilities [

65]. Porter and Heppelmann [

14] call them ‘smart, connected products’. IoT enables the production of related products going down to specific parts and components that can be used in several ways. A connected product can open up new business opportunities such as maintenance (for example, management of spare part inventories). This is already known in servitization to some extent [

24].

Hyundai Automotive Enterprise is a representative manufacturer in Korea. Hyundai has developed a circular economy approach for various aspects of its business by establishing remanufacturing and service stations where more than 500 people are employed for offering services, tests, and recovering mechanical sub-assemblies. These remanufactured parts are sold at prices below their original prices. The relatively low reuse costs make car repairs economical and attractive for customers. This kind of remanufacturing was made possible by changing the designs of the goods, keeping reuse and remanufacturing in mind at the outset. These techniques involve making reuse simpler, using recycled material as much as possible so that the recycled materials are kept rather than downgraded. Hyundai’s supply network has been reconfigured and repurposed. Reuse of sub-assemblies for remanufacturing and repair has been integrated into the return of delivery vehicles that are used for delivering replacement parts to retailers in the market.

To expect the business model for a circular (BMCE) economy to function, and in the absence of empirical evidence, a number of assumptions are required. These include, among others, the implement ability of the business model, its profitability, and various standard regulations and support mechanism provided by the government for implementation of BMCE. The key mechanism is financial support from the local municipality and state to promote start-ups and their hiring. Effective and sufficient infrastructure for the collection of components and distribution of repaired components must be developed and accessible to the consumers. Service stations need to be established with the capacity to provide the same service to different automaker producers and retail distributors in competition.

The BMCE can have substantial implications for the extractive and material production sectors as well as circular economy sector job creation. The gain can be larger when considering the import of materials. South Korea has several large automakers who produce and export a large number of cars annually. The car production and density is very high. The models implementation gains from economies of scale and the green growth strategy and environmental and sustainability policy of the country. It helps to cope with the increasing waste generation and management and air pollution and environmental degradation. The uncertainty from a business perspective can be reduced through standards, regulation, financial and infrastructure supports, and facilitating cooperation between different actors in the market.

The customers who have Hyundai Motor’s blue membership are aware that they will benefit significantly from the continuous use of components through the replacement of Hyundai Motor’s parts. Hyundai Motor Company’s blue membership system is currently the most highly preferred and reliable parts exchange system. The practical significance of our research throughout the Hyundai Motor Company’s blue membership system is to lower the negative thoughts (image) of using the reused and remanufactured parts, and it is practically sufficient in terms of performance and usability. In the near future, given the depletion of earth resources, environmental pollution is becoming our biggest problem; as a solution, we are emphasizing that the circular economy is the cornerstone of the global shared value that all countries in the world want to prosper together. Our case has some uncertainties in terms of its use only for blue membership. It is an incentive system to promote using reused and remanufactured parts through the membership.

Hyundai Motor Company’s Blue Members are fully informed about reuse and they are reusing the products. In cases where customers use the remanufactured parts, Hyundai Motor Company’s Blue Members are given some benefits by the company. While reproducing products, when it comes to a product’s lifespan, its use is permitted only when there is no difference between the regenerated product and the new product concerning operational safety.

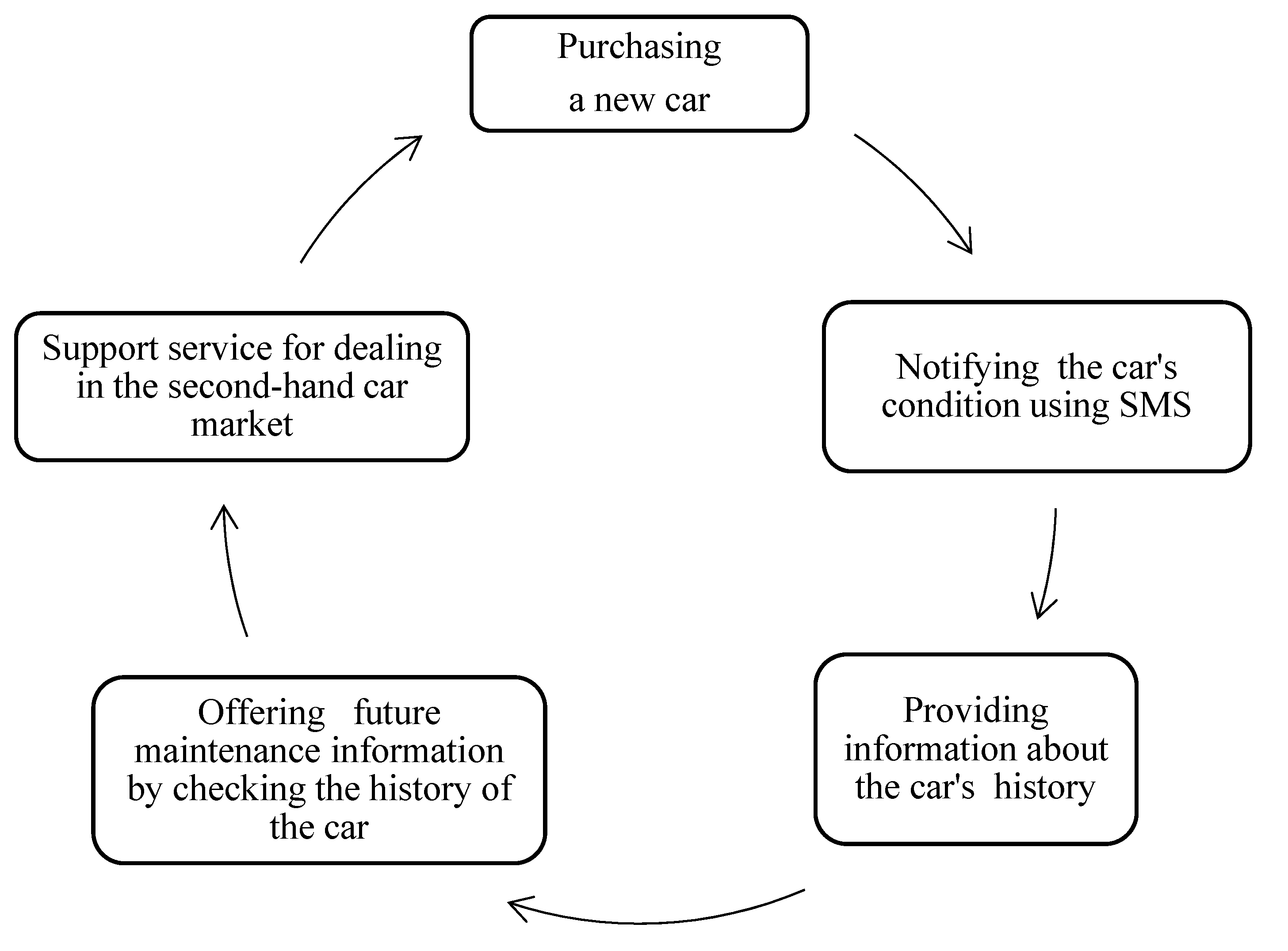

To maximize product life extension and to extend its material use, Hyundai (see

Figure 3) uses a new service model called the ‘Blue Members’ model by adopting IoT. The Blue Members service has been operating in the process of purchasing a car from the second-hand car market through to destroying a car. When purchasing a new car, an owner automatically gets membership of Blue. Over time, an owner receives information about the car’s current engine condition, when to change the oil, and its tire condition. Hyundai Automotive Enterprise also provides customized leisure related information such as information about a restaurant that the owner visits frequently. If the car owners are fans of a certain baseball team, they can match dates and information about promotions and events that the company is holding.

Figure 3 illustrates the circular model of product services at Hyundai. When a customer buys a new car, she/he is signed up for Blue membership if she/he wants it. The Hyundai Motor Company provides customers who have enrolled as Blue Members all the information about the vehicles that they have bought. From the perspective of an organizational system, Hyundai Motor Group has been pursuing structural changes in its service provisions since 2012. Customers can obtain information, including information about unexpected services for cars depending on their condition. In particular, the Hyundai Motor Company offers a service package by using advanced information technology. It informs customers when to replace parts and removes the inconvenience of identifying a service provider, a service needs evaluation, and replacement time. By using a smartphone, customers can signal the problematic parts of their cars and they are guided to a nearby service center in real-time. Additionally, subsidiaries can enhance customer services by notifying customers when to replace automotive consumable parts. This is a significant shift from traditional business models.

The model increases the life expectancy of the cars in use and provides reliable and complete information to both buyers and sellers. Thus, safety on the roads also improves. If owners sell the cars in a second-hand car market, all the information is transformed to the new owners.

Korea is an information society producing and exporting cars on a large scale. The country has a high density of population and cars. Advanced information technology and full connectivity will ease the development and operations of the market and its efficiency and profitability.

By using the product as a service model, Hyundai has been providing information including when to replace consumables such as oil, tires, and belts as well as the degree of fatigue of the car’s parts. For example, the firm tells customers that if they continue using their cars the way they are they will have major problems with the oil caps after four months. Thus, car owners get to know when to visit the car repair center. Some important aspects that need to be considered in the product as a service model in a circular economy for prolonging a car’s life include the firm providing information about certification of second-hand cars based on their maintenance history. A car could be successfully used as a second-hand model. In particular, un-manipulated information about a car is critical for the growth of the used car market. In the long run, product life cycles feed into other products and create new value through reuse and redistribution.

The product-service business model can be opened up as a consequence of IoT as well as telematics technology called the ‘smart connected product’ [

14]. Smart and connected products increase knowledge and strategic choices about how value is generated and retrieved, how the prodigious amount of new (and sensitive) data they produce is used and managed, how relationships with conventional business partners such as communication/interaction channels are redefined, and what role businesses can play in expanding the industry’s boundaries [

14]. The Blue Members model is an example of the servitization of products, because smart components improve a car’s utilization capabilities and its value. Smart, connected products allow the tracking of comprehensive conditions, functions, and the external environment of a product through sensors and external data sources. A product may use data to inform users or others about changes in performance or circumstances. What we can understand from Hyundai is that, in the circular economy, using IoT and smart connected products can help solve some critical issues for prolonging a car’s life. Additionally, product hardware (including embedded processors, sensors, and connectivity parts) and product software (an embedded operating system), onboard software applications, and product control components enable connectivity.

Software, processors, embedded sensors, and networking in products are linked to the cloud in which product data is stored and evaluated. This leads to dramatic changes in the product’s performance and functionality. According to Mentink [

56], in a circular economy, the environment, repair, reuse, and redistribution comprise new value creation.

5. Conclusions and Implications

The circular economy is a challenging conceptual and empirical context in which examining the potential implications of the product as service model is released from the constraints of the traditional servitization framing. This paper’s aim was to study and find a business model of innovation in the framework of a circular economy. To meet this goal, we searched for case studies and reviewed existing relevant literature. A circular economy provides a solution to the conventional linear economy (take-make-use-dispose) in which resources are used for as long as possible, optimizing value creation during the usage process, and where fully useable goods and materials are obtained at the end of a service’s life. We summarize our findings as follows:

First, we need to re-think the repair, reuse, and redistribution (3R) principles of a circular economy business model. The 3R principles are generally understood as part of the range of product-related services in an available form for servitization. By using the 3R approach, services are supposed to incentivize manufacturers to plan better maintenance of their products with a view to reducing their costs. This type of business model innovation encompasses the widespread creation of new values. Hence, a product’s life cycle can be extended in a circular economy. Second, the product-servitized business model uses smart connected products, thus increasing the usability of products in various industries. IoT enables almost continuous monitoring of individual goods as they are linked to and separated from other product and actor networks. Further, IoT and 5G network technology will play a significant role in facilitating the other institutional frameworks and processes needed for the circular economy to become a reality.

The insights from an analysis of the Hyundai Automotive Enterprise case have the potential to impact business models oriented to a circular economy. In particular, products can become services, leading to the establishment of new businesses and the creation of circular supply chain jobs. For maximizing a product’s life cycle, ‘3R’ and ‘servitization’ are needed to bring both the product as a service model and the circular supply chain model in line with the notions of a circular economy.

This study contributes to servitization literature in various ways. First, it shows that servitization can be used for maximizing a product’s life cycle in a circular economy, or that the servitization of a product can extend its life. Second, according to the principles of a circular economy, products’ history should be seen as a combination of trajectories rather than a linear path from design to the manufacture, consumption, and disposal phases. The suggested business model enables goods to get repaired, refurbished, and upgraded. This paper shows how the loops of the circular economy are employed by studying the Hyundai Automotive Enterprise. From a circular economy’s viewpoint, this paper argues that IoT’s ‘smart connected products’ have a significant role in the path to multiple circular economy oriented service transitions.

However, this paper also has some limitations that are attributed to data access. The current research emphasizes the consumer perspective. Ideally, it should be extended to a producer perspective, including even material extraction and production stages. It uses the results of a single case analysis even though a circular economy has a wider dimension. Thus, using a circular economy perspective, ‘3R’ and ‘servitization’ can be used for studying innovations in a green business model. Further, this paper does not provide enough information for defining a general strategy for success in different industries in terms of the components of a circular economy’s business model. Better access to data and future research will help overcome these limitations.