Bangladesh is a small country on the world map; located in south Asia having a land area of 148,460 square kilometers. Apart from the hilly areas, most of the land consists of plains with a strong network of rivers throughout the country. Bangladesh is a small country with a large population, where more than 1085 persons live per square kilometer. Besides industrialization and other commercial infrastructures, agriculture plays the most vital role in the country’s economy. Agriculture and livestock not only boost the Gross Domestic Product (GDP), they also ensure food security and help to reduce poverty and unemployment in rural areas. The contribution made by livestock to the GDP for the Fiscal Year 2017–2018 was 1.53% at a constant price, which was 13.6% of the total agricultural sector contribution to GDP [

1]. Despite achieving improvement in many aspects of food security, the people of Bangladesh still lack dietary diversification, which leads to nutritional imbalance [

2]. There is a great discrepancy between demand and production in the case of protein intake. Milk production for the year 2018–2019 was 99.23 lakh Metric Ton against a demand of 152.02 lakh Metric Ton (one lakh is equivalent to 100,000) [

3]. On the other hand, many people in rural areas cannot afford to maintain a balanced diet daily. Sustainable and well-distributed livestock farms in different regions of the country not only improve nutrition but are also preferred assets of investment [

4]. Cattle farming has a good economic impact in generating income and food security in rural areas which employ about 20% of the rural labor force [

5]. The United Nations Food and Agriculture Organization (FAO) reported that per capita meat consumption in Bangladesh is low (about four kilograms) compared to other neighboring countries such as Pakistan. However, according to the data from the Department of Livestock Services (DLS) Bangladesh, the country’s total demand for meat stands at 72.97 lakh tonnes with the requirement of 120 g of meat per head, almost 55% of which comes from cows and goats. Besides the regular beef intake, there is a huge need for cows during one of the biggest festivals (Eid-Ul-Adha) of the Muslim calendar. In the past 20 years, Bangladesh has attempted to become fully dependent on domestic production to meet the extra demand for cattle during the Eid-Ul-Adha celebrations due to a drastic reduction in cattle imports from a neighboring country. Twenty years ago, Bangladesh entered a new era introducing professional micro-scale cattle farms to meet the demand of the local market for milk and meat. According to the report published as in Reference [

6], 80 to 90% of the country’s cattle production comes from rural farmers with either small- or medium-sized farms. Many people are also currently interested in modern agriculture, including cultivation of fruits, vegetables, fish and cattle as e-commerce has opened a promising platform for the young entrepreneur. Nevertheless, the housing shortage in Bangladesh is a major issue with the result being that many cultivable lands, as well as fields formerly used for open grazing, are nowadays utilized to build new houses and apartments which are reducing the open land areas at an alarming rate in Bangladesh. This is the reason Bangladesh cannot consider an open field cattle farm as found in Australia, New Zealand, or large European countries. Most of the cattle farms (small and medium scale) in Bangladesh either in rural or semi-town areas have very limited land size. Though there are many modern and scientifically advanced tools and equipment widely used in agriculture nowadays in Bangladesh, only a negligible number of farms are to be found using the energy engineering approach to become self-sufficient and sustainable and whilst mitigating the energy costs against the production costs. For the cattle farm, the most challenging part is the meat collection, milk collection, storage and marketing, for which each farm needs high-quality electrical equipment including electric blade, vacuum pump milking parlor systems, and high-performance refrigeration systems. Besides all other costs, such kinds of facilities require a massive budget for energy consumption to regulate as well as maintain adequate temperature, relative humidity, and ventilation. In recent years, energy cost efficiency becomes a key factor for sustainable food and crop storage facilities worldwide, which has stimulated many scientists’ enthusiasm to introduce more off-grid, self-sustainable energy-harvesting and saving facilities [

7,

8,

9,

10,

11]. Hybrid (PV, Wind, Diesel and Battery) power generation systems have recently become very promising for 100% electrification for the rural or remote island areas. A significant number of research works have been conducted worldwide by researchers and scientists in the field of renewable energy (RE) to design and optimize various types of hybrid power generation systems [

12,

13,

14,

15,

16,

17]. In addition, these types of hybrid power systems can be attractive alternatives for cost-effective power generation in Bangladesh. It is very hard for the government to provide on-going subsidies in power production. Bangladesh has set the goal of becoming a country with zero power supply issues such as daily power cuts, to provide electricity for everyone within the very near future. In support of the country’s goal these types of hybrid power systems, together with nano-coated building materials with power-saving features, if used in different infrastructures, can help to reach to the goal of 100% electrification of the country. Renewable power generation and savings based multi-component hybrid systems can also lower carbon emissions to an acceptable level. The exploration of possible and economically viable renewable energy sources is one of the prime interests of the country’s policymakers and research scientists to mitigate the energy demand of the country. However, there are several factors involved in the successful development of new renewable-type energy production systems [

18,

19,

20,

21]. M. E. Karim et al. has conducted a comprehensive study on the government involvements, legal issues, regulatory measures and the policy aspects related to the renewable energy in Bangladesh [

22]. They have reported on the significance having of comprehensive policy initiatives, including active and enhancing government participation on developing RE systems, ensuring localization and easily accessible of RE technology, evaluation of relevant legal policy initiatives and others that can shape the country’s sustainable development.

At present, the novel coronavirus (COVID-19) outbreak (first spread in Wuhan, China in late 2019) has resulted in a worldwide severe pandemic that has already disrupted human life and civilization. This coronavirus has already caused a huge number of deaths and becomes a major threat for mostly older people who are suffering from diabetes, cardiovascular disease, cancer, and chronic respiratory syndrome [

23]. The world’s leading scientists, chemists, microbiologists, engineers, doctors, and other health professionals are working very hard to find proper solutions for this new virus by understanding the nature of COVID-19. There are many predictions available online nowadays about the microstructural properties and weather- and region-dependent nature of COVID-19; however, getting an active vaccine against this virus requires a significant amount of research effort together with on-going worldwide clinical trials. The world is seeking new hope while currently relying on the precautions that have been recommended by the World Health Organization (WHO), including social and physical distancing to control the rapid spread of this virus [

24]. The outbreak of COVID-19 has overturned not only human life but also the global economy by seriously affecting all kinds of industries including food, agriculture, readymade garments, leather, building and infrastructure materials, energy and power sectors, science and technology and others all over the world [

25,

26,

27,

28,

29,

30]. Many industries and businesses were forced to take actions like job cuts, even in some cases shut down completely. As a result, millions previously in the workforce have become jobless, and severely affecting—directly and indirectly—developing countries like Bangladesh. As COVID-19 can transfer easily from one affected person to others (i.e., community transmission), it becomes a great concern how, as well as how long is needed, to get back to normal life. According to the proposal jointly made by WHO and FAO for food safety including multi-agency co-operation, proper inspections in different stages of production can mitigate significantly the spread of this corona-virus but to achieve this is a very much challenging task [

31,

32]. In these circumstances, the risk of contamination can be minimized and kept under control only if the local demand for foods and protein supply can be met by the local growers and suppliers. In Bangladesh, the well-being of the economic cycle as well as of a large number of the population is mainly dependent on good agricultural and industrial prospects. All agricultural and industrial sectors including garment, leather and industries requiring construction materials are major candidates where continuous electricity supply is needed for maintaining a non-disruptive production cycle for the well-being of the economy. However, currently, these sectors are facing severe problems during the COVID-19 crisis and maintaining a continuous electricity supply will continue to be a major issue for many smallholder farmers in the rural farming and cultivation areas in post-COVID-19 Bangladesh [

33,

34,

35,

36,

37,

38,

39,

40,

41,

42]. Besides, the national grid electricity supply, solar photovoltaics (PVs)-assisted power generation can help all industries and factories to maintain their continuous production cycle. Therefore, designing new and modification of existing infrastructures that can generate and save energy will be the most effective approach for the well-being of post-COVID-19 Bangladesh and will assist in returning the country to a normal lifestyle. In addition, this energy engineering can be a model for future modern farming in any country of the world and, in the near future, potentially can help to diminish the current rise in unemployment due to the COVID-19 pandemic by making all the farms and food industries active and fully productive again.

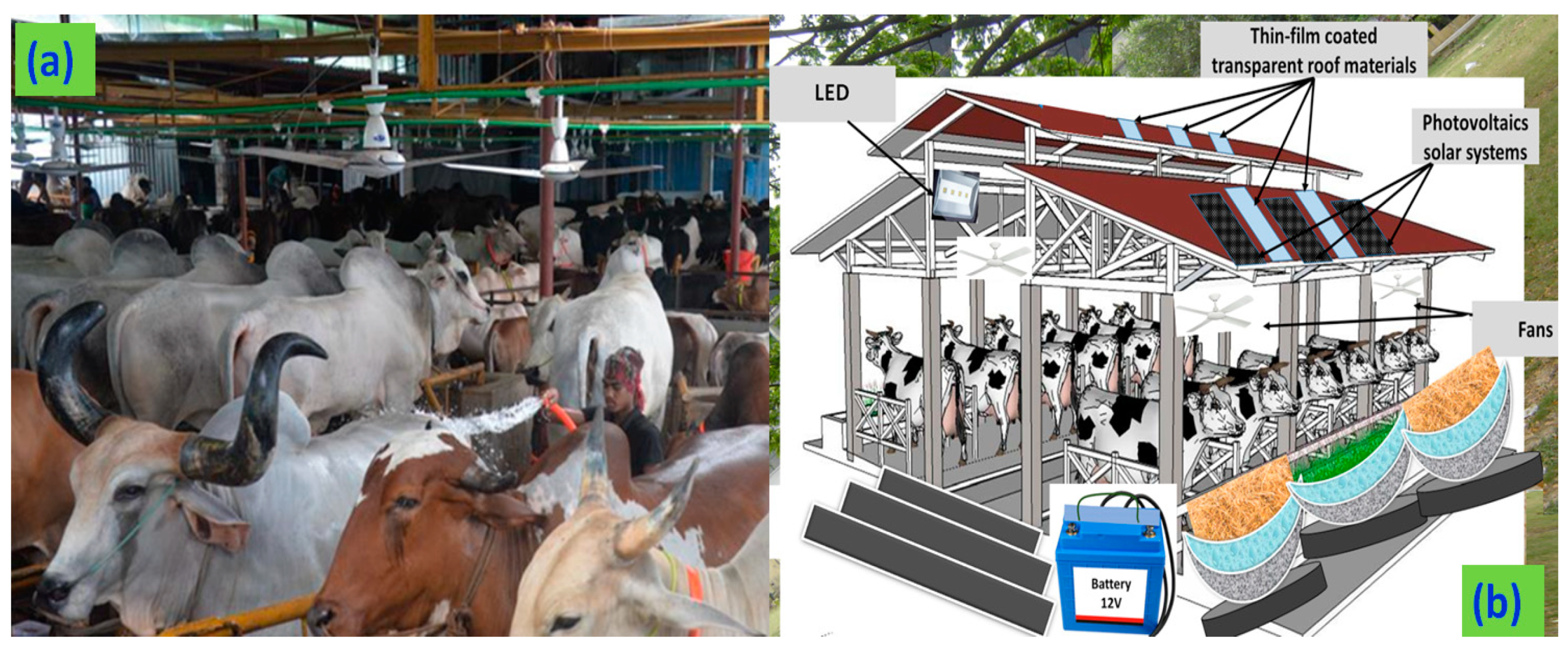

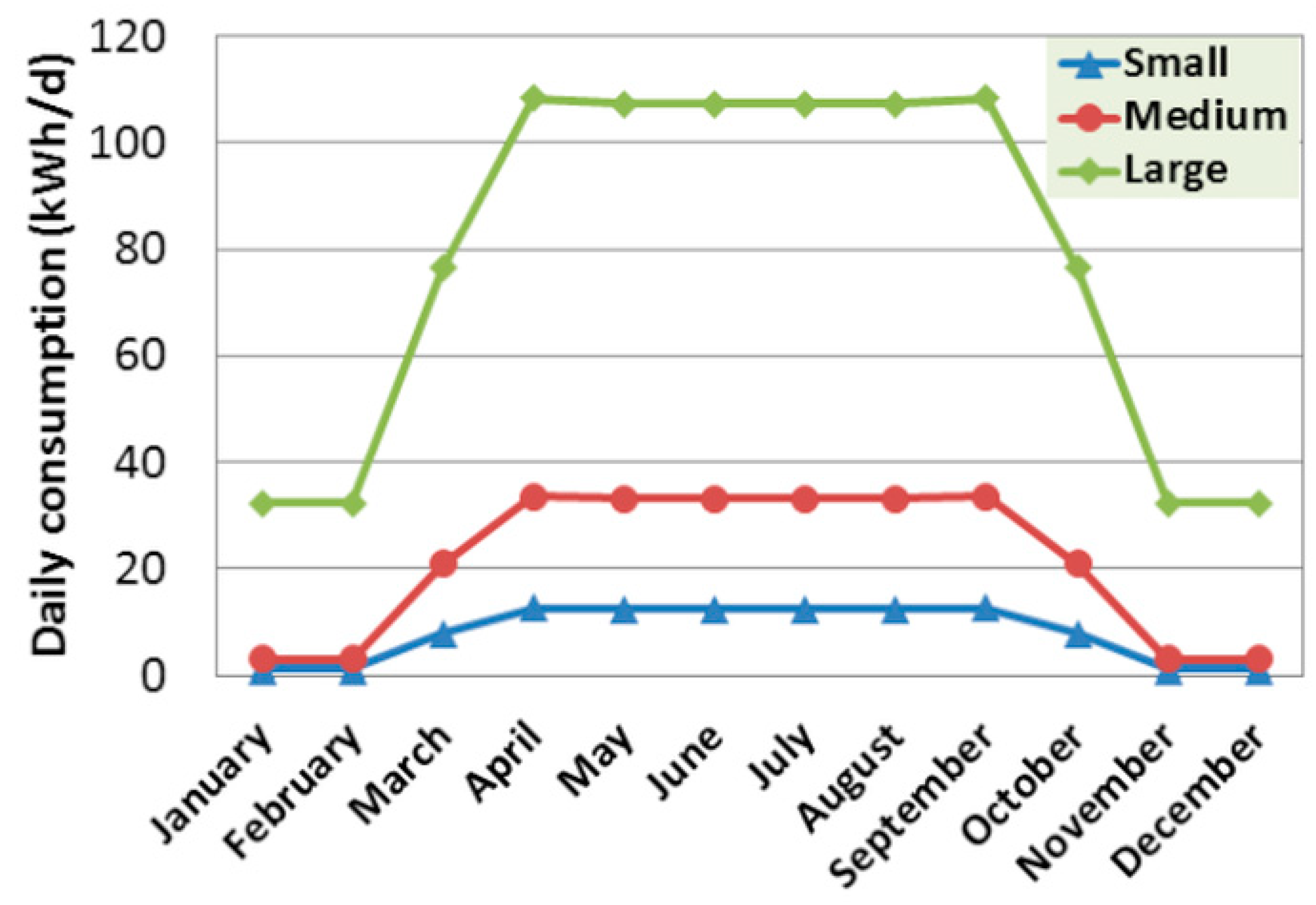

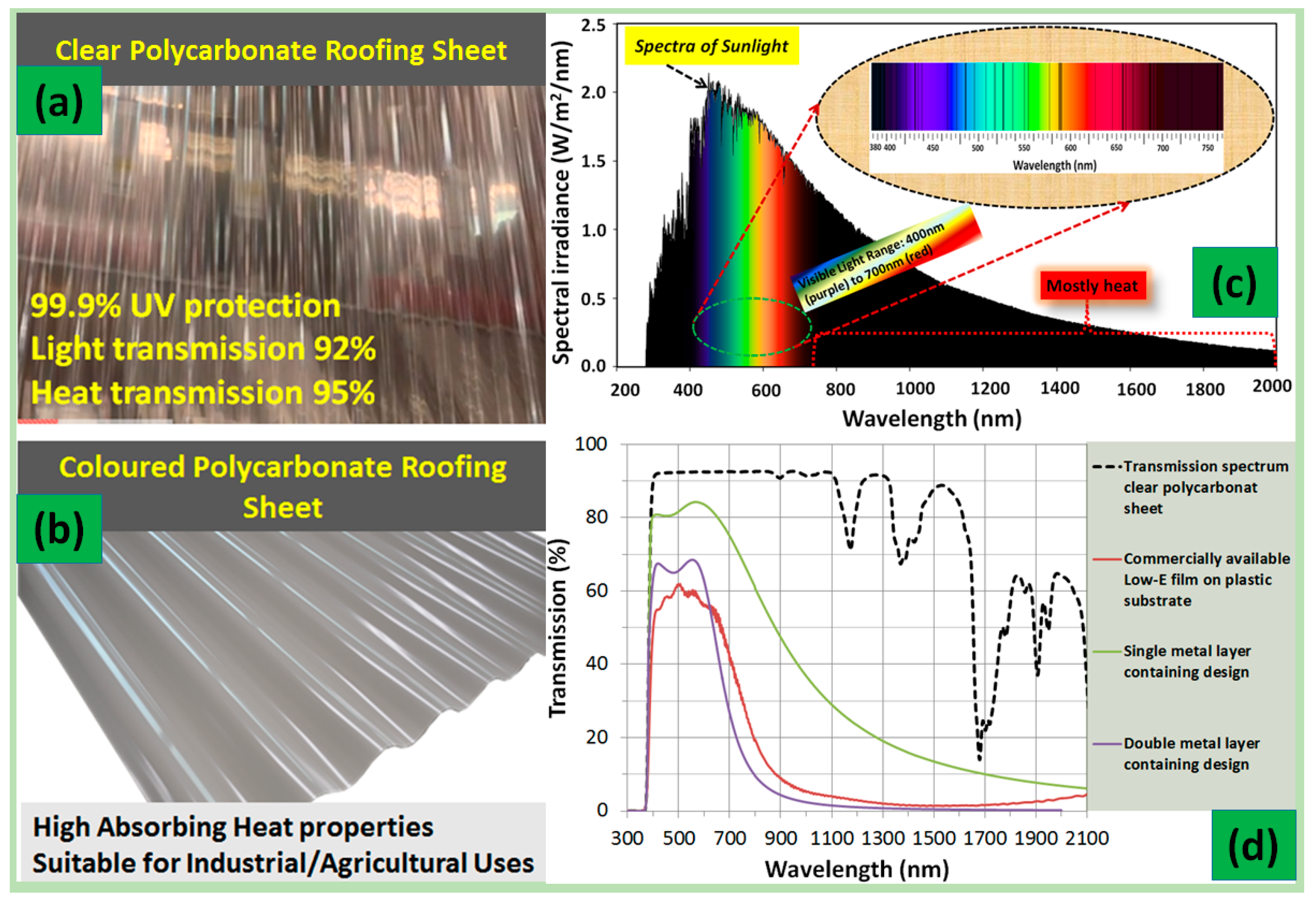

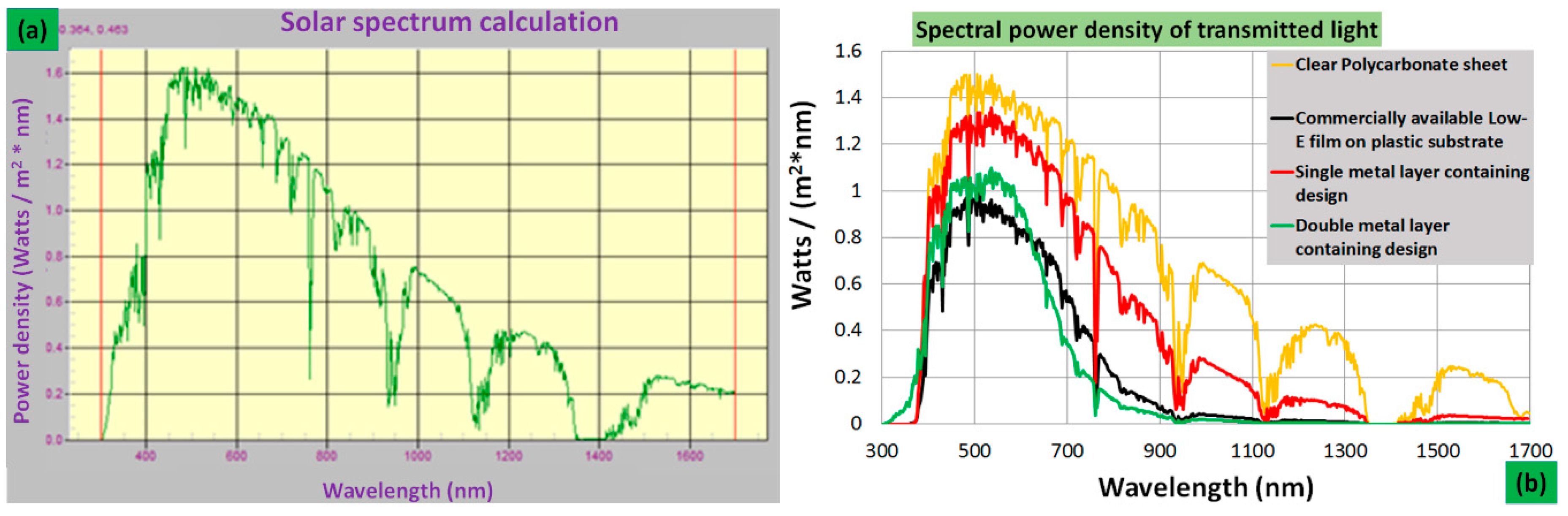

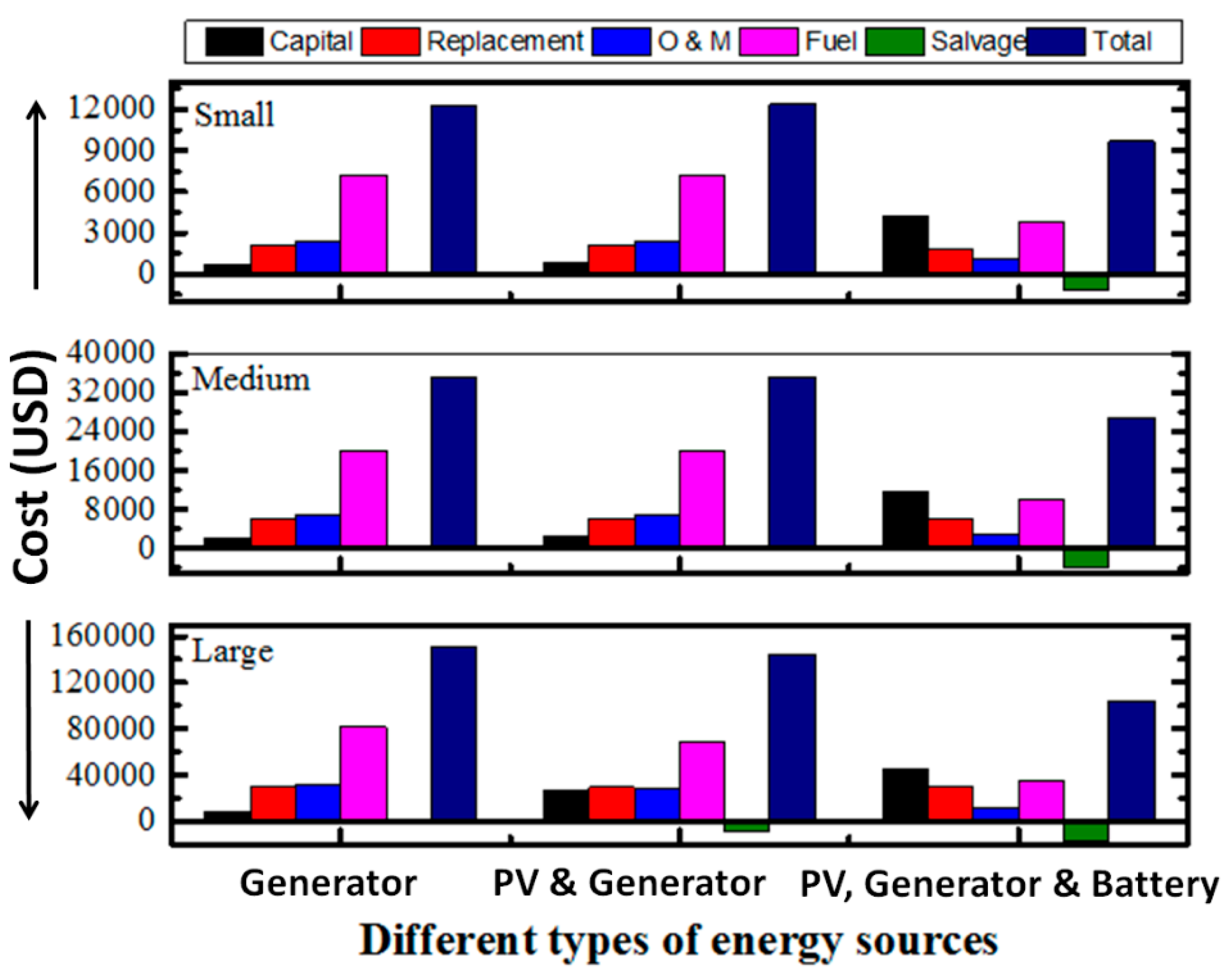

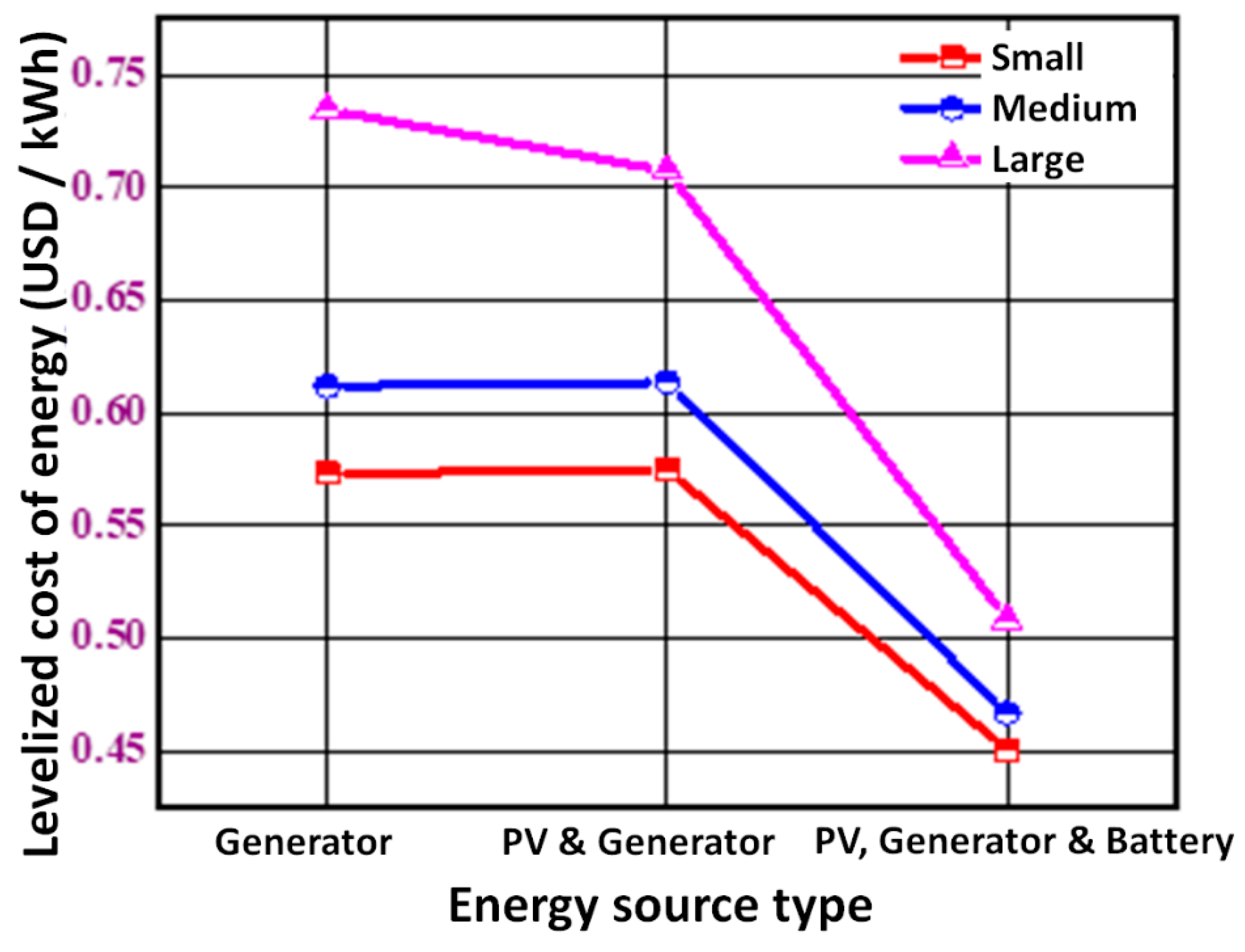

In this article, we design and optimize a hybrid power generation system that can be applied together with thin-film, low-emissivity (Low-E) coating-assisted, energy-saving features for self-sustainable off-grid or semi-off-grid infrastructure for cattle farmers in rural areas. In Bangladesh, grid connection is not available throughout the country, and there is no alternative of a micro-grid to ensure the power availability to any new or existing infrastructures for farming and food storage. However, the implementation of modern scientific processes can increase the production levels by up to 50%, whereas if the conventional power sources are used, the fuel cost will have a negative impact on profit margins. The organization of this paper is as follows:

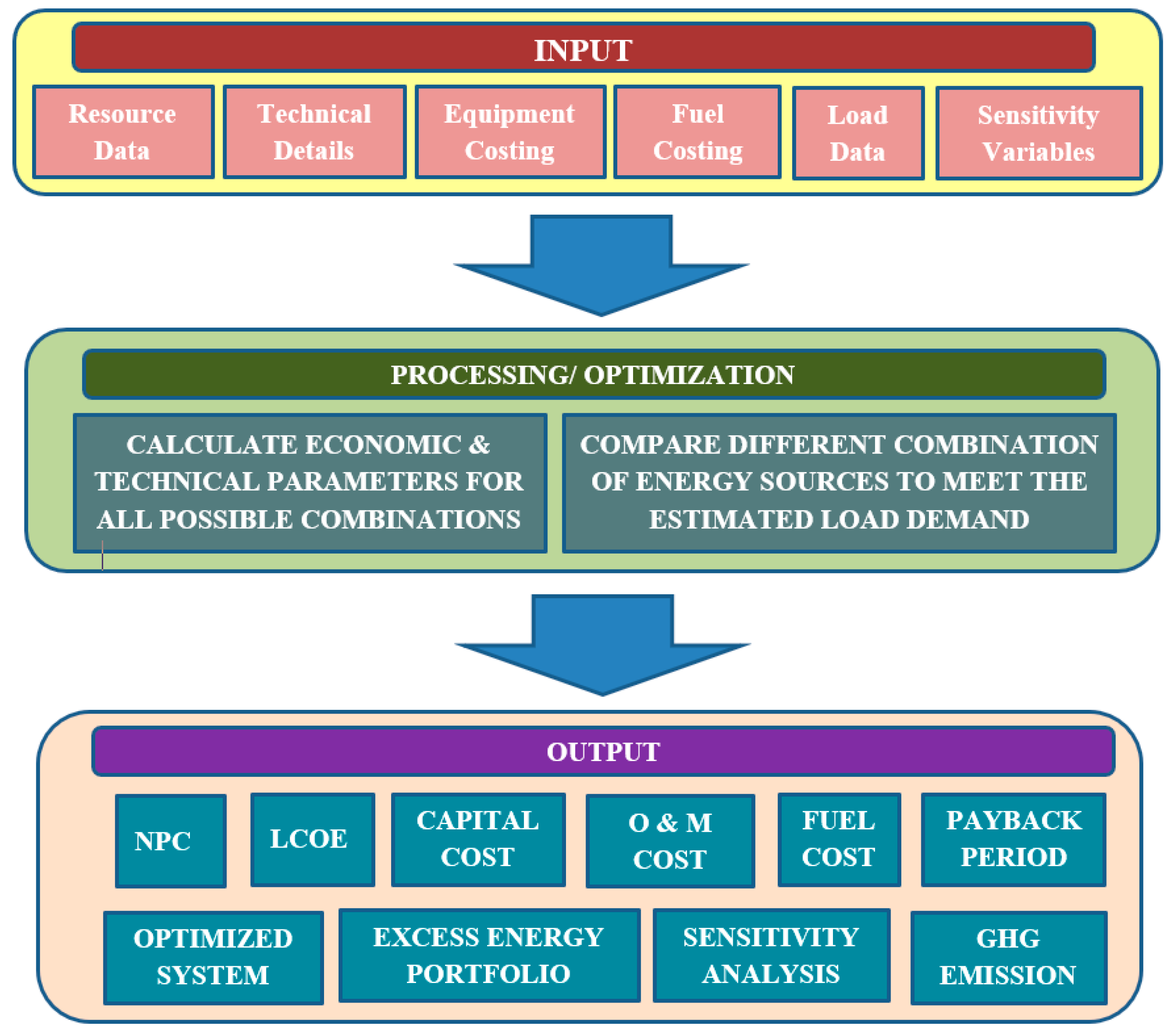

Section 2 briefly describes the materials and methods, where we describe the types of farms targeted and ways of power optimization.

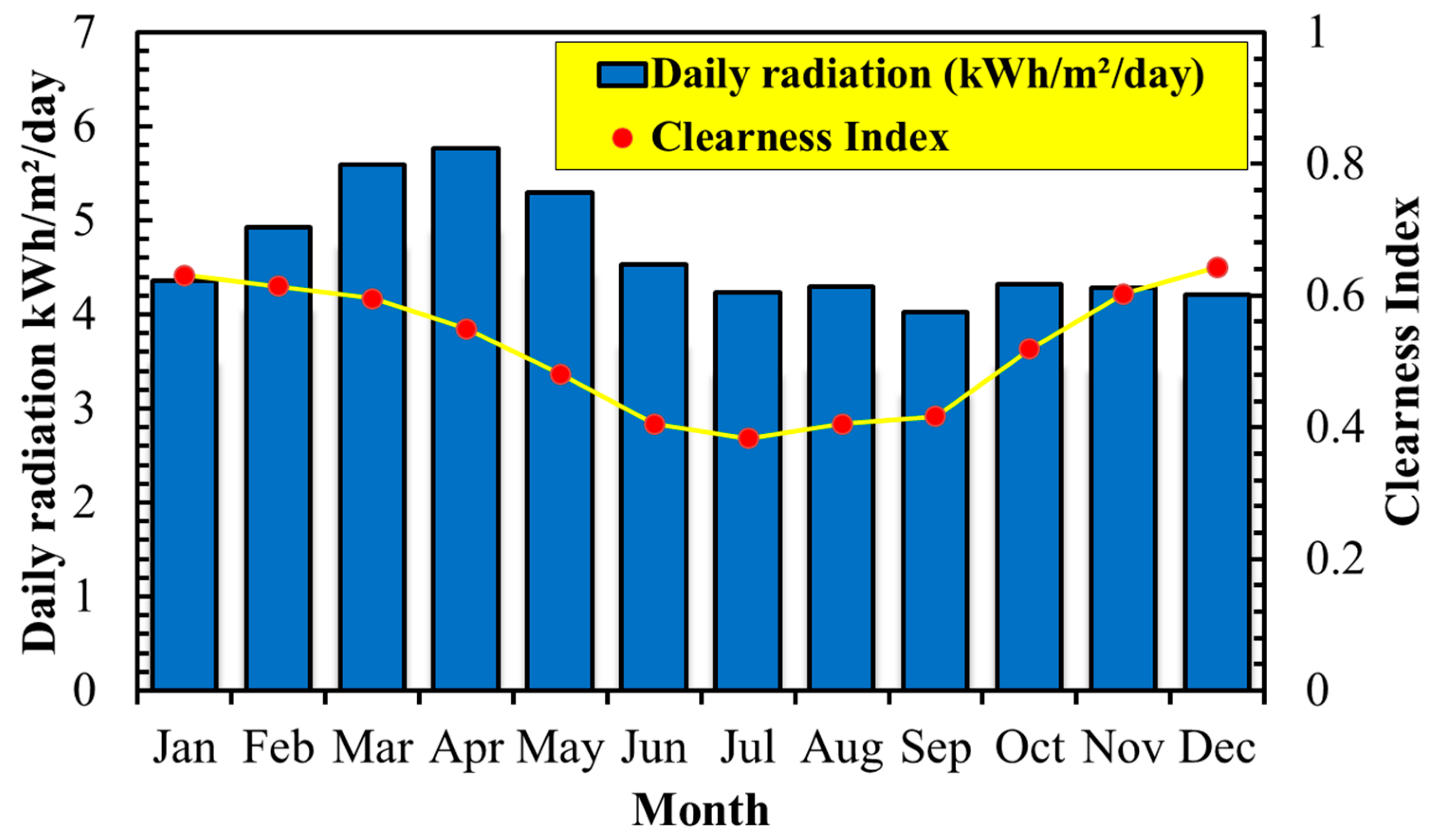

Section 3 describes in detail the means of engineering of energy generation and savings including the components that are considered in this work.

Section 4 presents the optimized simulation results, and

Section 5 includes a short discussion based on the outcome of the hybrid energy engineering optimization, followed by a conclusion in

Section 6.