Evaluation of the Resilient Modulus of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste

Abstract

1. Introduction

2. Aim and Scope Definition

3. Materials and Methods

3.1. Materials

3.1.1. Natural Aggregates

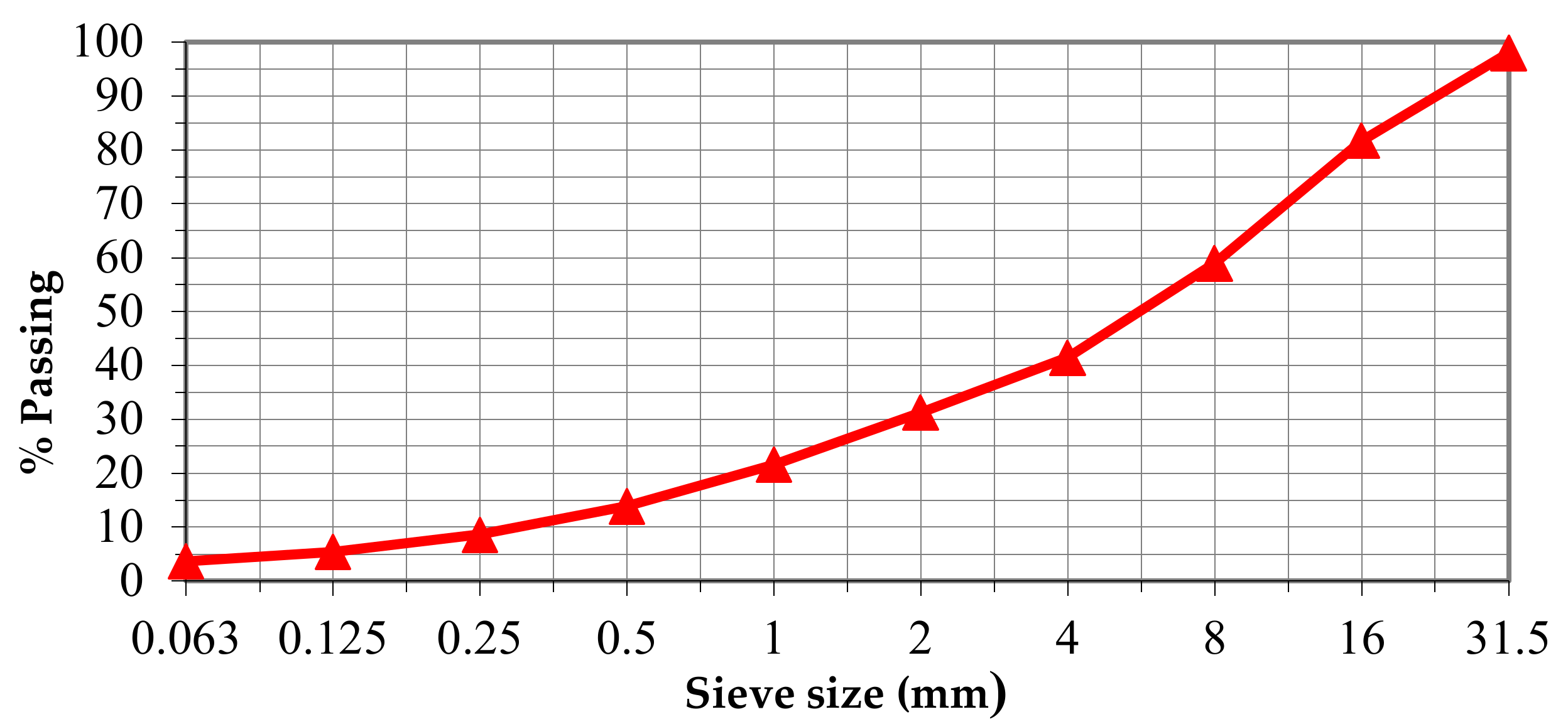

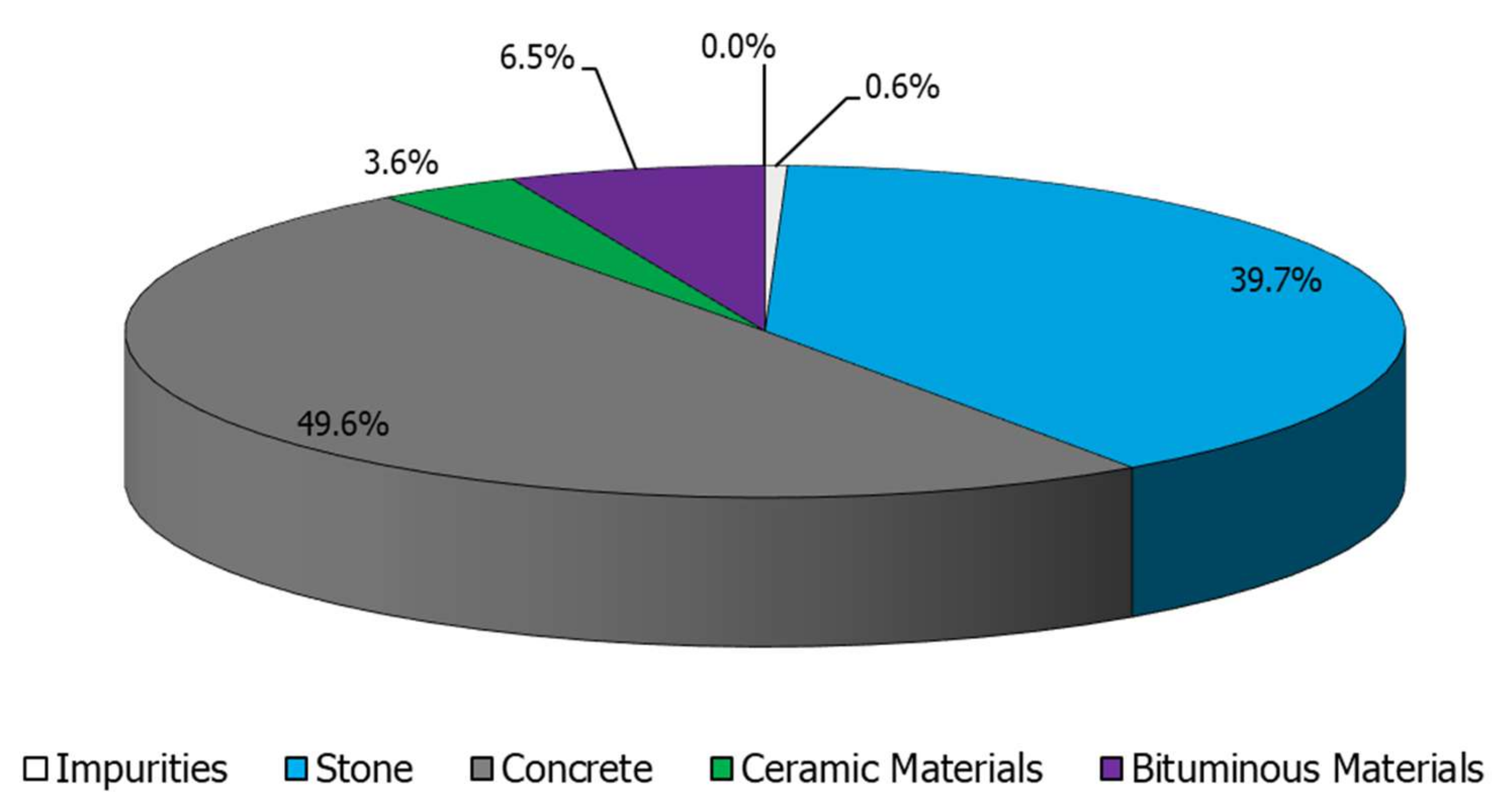

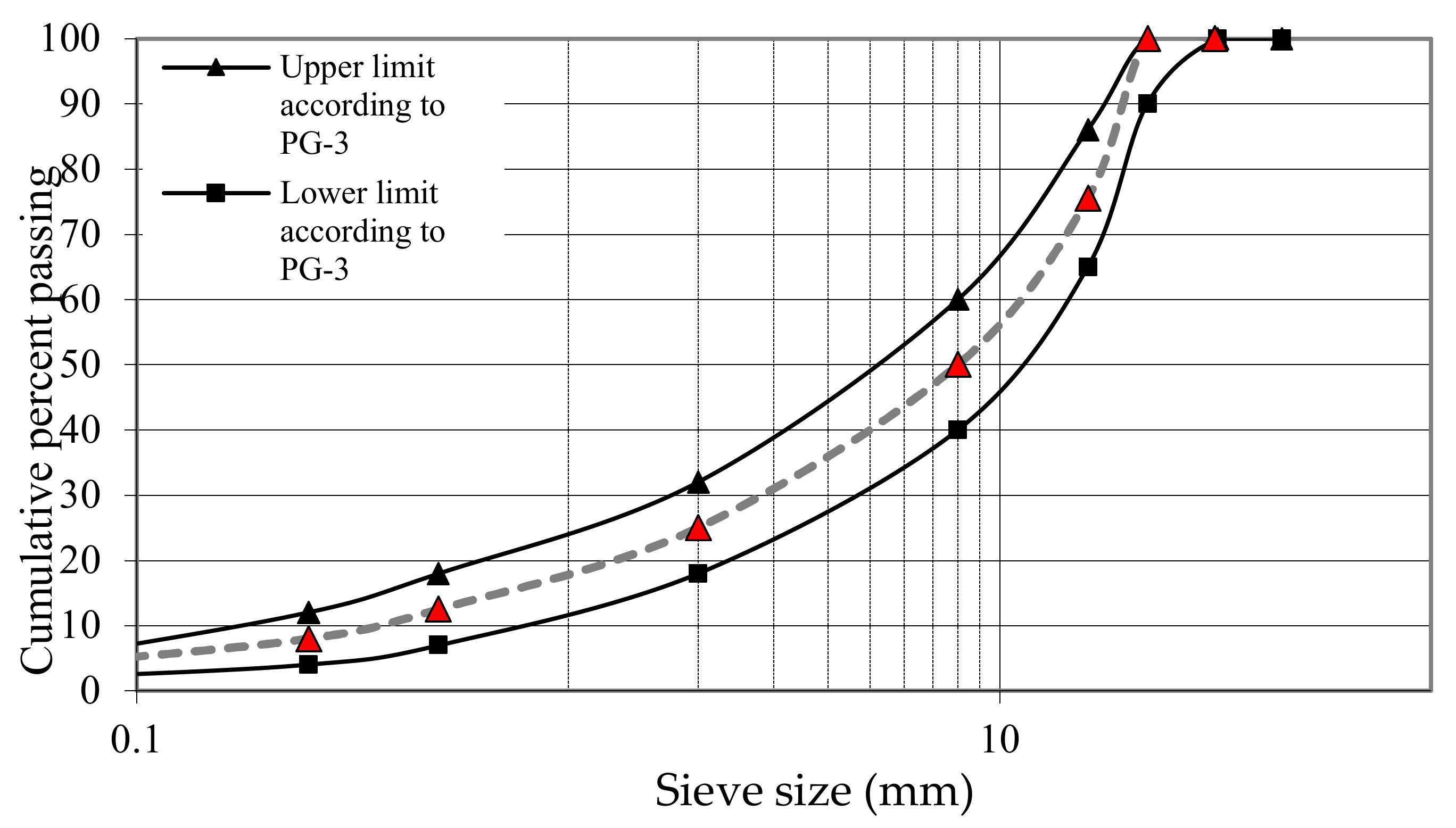

3.1.2. Recycled Aggregates (RCA)

3.1.3. Filler

3.1.4. Asphalt Binder

3.2. Methods

3.2.1. Manufacturing of the Samples

3.2.2. Stiffness

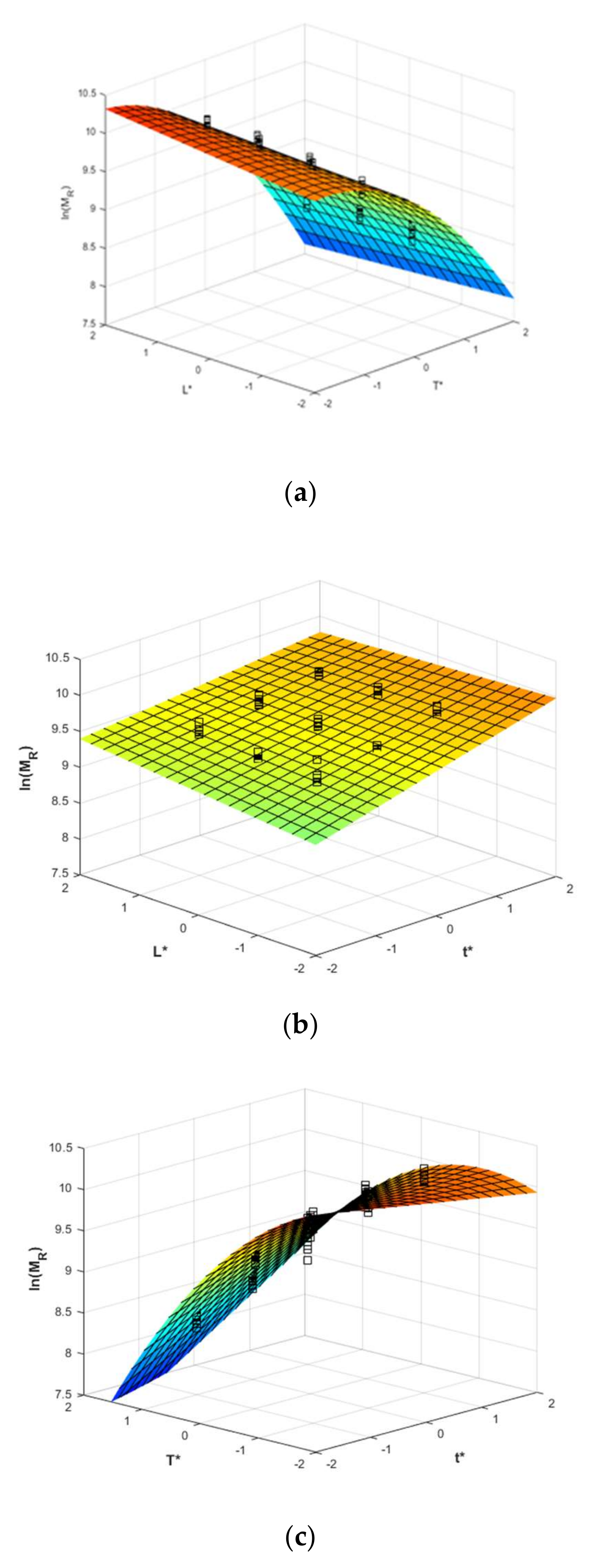

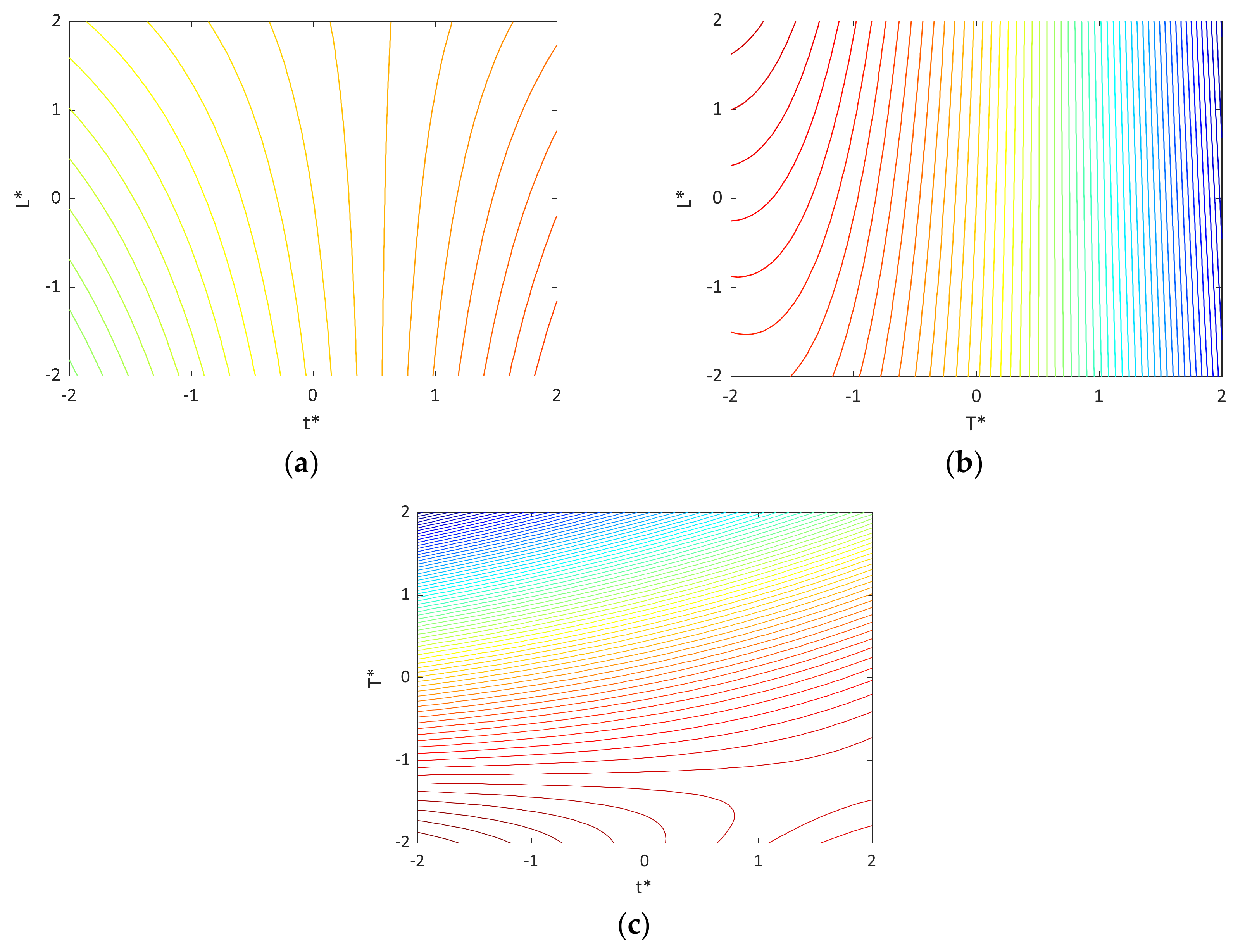

3.2.3. Response Surface Methodology

4. Results and Discuss

Resilient Modulus (MR)

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy. COM (2015) 614 Final. 2015. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 13 October 2020).

- Pereira, P.A.; Oliveira, J.; Santos, L.P. Mechanical Characterisation of Hot Mix Recycled Materials. Int. J. Pavement Eng. 2004, 5, 211–220. [Google Scholar] [CrossRef]

- Pérez, I.P.; Pasandin, A.R.; Gallego, J. Stripping in hot mix asphalt produced by aggregates from construction and demolition waste. Waste Manag. Res. 2012, 30, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Environmental impacts of construction and demolition waste management alternatives. Chem. Eng. Trans. 2018, 63, 343–348. [Google Scholar]

- Chappat, M.; Bilal, J. Energy “Consumption and Greenhouse Gas Emissions”. Sustainable Developmentethe Environmental Road of the Future; Colas Group: Paris, France, 2003. [Google Scholar]

- Lee, N.; Chou, C.-P.; Chen, K.-Y. Benefits in energy savings and CO2 reduction by using reclaimed asphalt pavement. In Proceedings of the Transportation Research Board 91st Annual Meeting, Washington, DC, USA, 22–26 January 2012. [Google Scholar]

- Aurangzeb, Q.; Al-Qadi, I.; Hasan, M.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Nguyen, B.T.; Setunge, S. Estimating the resilient modulus of crushed recycled pavement materials containing crumb rubber using the Clegg impact value. Resour. Conserv. Recycl. 2019, 141, 301–307. [Google Scholar] [CrossRef]

- Aljassar, A.H.; Al-Fadala, K.B.; Ali, M.A. Recycling building demolition waste in hot-mix asphalt concrete: A case study in Kuwait. J. Mater. Cycles Waste Manag. 2005, 7, 112–115. [Google Scholar] [CrossRef]

- Paranavithana, S.; Mohajerani, A. Effects of recycled concrete aggregates on properties of asphalt concrete. Resour. Conserv. Recycl. 2006, 48, 1–12. [Google Scholar] [CrossRef]

- Pérez, I.P.; Pasandin, A.R.; Medina, L. Hot mix asphalt using C&D waste as coarse aggregates. Mater. Des. 2012, 36, 840–846. [Google Scholar] [CrossRef]

- Mamlouk, M.; Sarofim, R.T. Modulus of asphalt mixtures-an unresolved dilemma. Transp. Res. Rec. 1988, 1171, 193–198. [Google Scholar]

- AENOR. Asociación Española de Normalización y Certificación. UNE-EN 12697-23 “Bituminous Mixtures; Test Methods for Hot Mix Asphalt; Stiffness: Madrid, Spain, 2006. [Google Scholar]

- Galan, J.J.; Silva, L.M.S.; Pérez, I.P.; Pasandin, A.R. Mechanical Behavior of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste: A Design of Experiments Approach. Sustainability 2019, 11, 3730. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Tang, Y. Comparison of Semi-Circular Bending and Indirect Tensile Strength Tests for HMA Mixtures. Soil Dyn. Symp. Profr. Richard D. Woods 2005, 1–12. [Google Scholar] [CrossRef]

- Haghshenas, H.; Khodaii, A.; Khedmati, M.; Tapkın, S. A mathematical model for predicting stripping potential of Hot Mix Asphalt. Constr. Build. Mater. 2015, 75, 488–495. [Google Scholar] [CrossRef]

- Chávez-Valencia, L.; Manzano-Ramírez, A.; Luna-Bárcenas, G.; Alonso-Guzmán, E. Modelling of the performance of asphalt pavement using response surface methodology. Build. Environ. 2005, 40, 1140–1149. [Google Scholar] [CrossRef]

- Nassar, A.I.; Thom, N.; Parry, T. Optimizing the mix design of cold bitumen emulsion mixtures using response surface methodology. Constr. Build. Mater. 2016, 104, 216–229. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Teh, S.Y.; Golchin, B.; Voskuilen, J. Use of imaging technique and direct tensile test to evaluate moisture damage properties of warm mix asphalt using response surface method. Constr. Build. Mater. 2017, 132, 323–334. [Google Scholar] [CrossRef]

- Dirección General de Carreteras. Pliego de Prescripciones Técnicas Generales Para Obras de Carreteras y Puentes PG-3; Ediciones Liteam: Madrid, Spain, 2002. [Google Scholar]

- Montgomery, D. Design and Analysis of Experiments, 8th ed.; Joh Wiley and Sons: London, UK, 2013; pp. 478–496. [Google Scholar]

- Available online: https://www.zicla.com/en/project/concrete-recycled-aggregates/ (accessed on 1 September 2020).

| Fraction | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test | Standard | PG-3 | 0/2 | 2/4 | 4/6.3 | 5/6.3 | 4/8 | 6.3/12.5 | 10/16 | 16/31.5 |

| LA (%) | EN-1097-2 | <25 | - | - | - | - | - | - | - | 14.2 |

| WA (%) | EN-1097-6 | - | 0.79 | 1.67 | 1.25 | - | 1.08 | 0.92 | 0.60 | 0.62 |

| FP (%) | EN-933-5 | 100 | 100 | 100 | 100 | - | 100 | 100 | 100 | 100 |

| ρ(g/cm3) | EN-1097-6 | - | 2.74 | 2.78 | 2.78 | 2.79 | 2.79 | 2.77 | 2.79 | |

| SE (%) | EN-933-8 | >50 | 61 | - | - | - | - | - | - | - |

| FI (%) | EN-933-3 | <35 | - | - | - | 24 | - | - | - | - |

| RCA Fraction | |||

|---|---|---|---|

| Test | Standard | PG-3 | 0/40 |

| LA (%) | EN-1097-2 | <25 | 34 |

| WA (%) | EN-1097-6 | - | 6.1 |

| FP (%) | EN-933-5 | 100 | 100 |

| ρ (g/cm3) | EN-1097-6 | - | 2.63 |

| SE (%) | EN-933-8 | >50 | 67 |

| Flakiness index (%) | EN-933-3 | <35 | 34 |

| Factor | xi | Original Value | Code Level |

|---|---|---|---|

| t | x1 | 0 h | −1 |

| 2 h | 0 | ||

| 4 h | +1 | ||

| T | x2 | 0 °C | −1 |

| 10 °C | 0 | ||

| 20 °C | +1 | ||

| RCA | x3 | 0% | −13/15 |

| 5% | −8/15 | ||

| 10% | −3/15 | ||

| 20% | +7/15 | ||

| 30% | +17/15 | ||

| L | x4 | 3.5% | −1 |

| 4% | 0 | ||

| 4.5% | +1 |

| Temperature | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 °C | 10 °C | 20 °C | ||||||||

| Binder | ||||||||||

| 3.5% | 4% | 4.5% | 3.5% | 4% | 4.5% | 3.5% | 4% | 4.5% | ||

| t(h) | Resilient Modulus (MPa) | |||||||||

| RCA 0% (Control) | ||||||||||

| 0 | sample 1 | 24,394.0 | 23,616.0 | 23,213.0 | 15,932.0 | 13,259.0 | 12,938.0 | 5214.0 | 5281.0 | 4879.0 |

| sample 2 | 20,144.0 | 22,515.0 | 22,120.0 | 12,761.0 | 10,607.2 | 12,665.0 | 4634.0 | 5338.0 | 4828.0 | |

| 2 | sample 1 | 20,564.0 | 24,496.0 | 24,107.0 | 13,913.0 | 13,491.0 | 16,979.0 | 7252.0 | 6436.0 | 7412.0 |

| sample 2 | 22,443.0 | 23,852.0 | 26,186.0 | 12,913.0 | 13,809.0 | 16,668.0 | 5802.0 | 6034.0 | 7569.0 | |

| 4 | sample 1 | 21,574.0 | 20,097.0 | 24,526.0 | 16,472.0 | 18,186.0 | 16,611.0 | 9515.0 | 10,694.0 | 8747.0 |

| sample 2 | 19,122.0 | 19,922.0 | 24,393.0 | 13,787.0 | 14,548.8 | 16,379.0 | 7612.0 | 9596.0 | 6997.6 | |

| RCA 5% | ||||||||||

| 0 | sample 1 | 20,021.0 | 21,268.0 | 22,417.0 | 10,302.0 | 12,224.0 | 12,902.0 | 3926.0 | 4673.0 | 4780.0 |

| sample 2 | 19,896.0 | 20,654.0 | 22,754.0 | 10,975.0 | 11,874.0 | 12,816.0 | 3647.0 | 4297.0 | 4719.0 | |

| 2 | sample 1 | 22,131.0 | 23,579.0 | 21,669.0 | 12,756.0 | 14,500.0 | 11,617.0 | 6402.0 | 6394.0 | 5157.0 |

| sample 2 | 23,145.0 | 22,817.0 | 20,556.0 | 13,370.0 | 14,427.0 | 11,921.0 | 6394.0 | 6593.0 | 5642.0 | |

| 4 | sample 1 | 26,774.0 | 25,614.0 | 23,808.0 | 19,155.0 | 18,946.0 | 14,679.0 | 11,692.0 | 10,182.0 | 8195.0 |

| sample 2 | 21,609.0 | 27,637.0 | 23,646.0 | 19,124.0 | 17,017.0 | 14,064.0 | 11,564.0 | 8473.6 | 7660.0 | |

| RCA 10% | ||||||||||

| 0 | sample 1 | 19,995.0 | 21,540.0 | 22,661.0 | 10,550.0 | 11,570.0 | 15,358.0 | 4308.0 | 4694.0 | 5495.0 |

| sample 2 | 19,177.0 | 21,116.0 | 20,702.0 | 10,248.0 | 11,561.0 | 12,951.0 | 4027.0 | 4603.0 | 5285.0 | |

| 2 | sample 1 | 22,345.0 | 25,288.0 | 22,395.0 | 14,593.0 | 15,417.0 | 14,722.0 | 6416.0 | 6872.0 | 6583.0 |

| sample 2 | 20,060.0 | 22,082.0 | 22,847.0 | 12,174.0 | 14,660.0 | 13,704.0 | 6021.0 | 6899.0 | 6192.0 | |

| 4 | sample 1 | 23,416.0 | 25,694.0 | 22,981.0 | 16,128.0 | 16,879.0 | 17,863.0 | 10,014.0 | 8052.0 | 9603.0 |

| sample 2 | 21,351.0 | 24,291.0 | 24,378.0 | 16,478.0 | 16,615.0 | 17,516.0 | 9874.0 | 6441.6 | 9514.0 | |

| Temperature | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 °C | 10 °C | 20 °C | ||||||||

| Binder | ||||||||||

| 3.5% | 4% | 4.5% | 3.5% | 4% | 4.5% | 3.5% | 4% | 4.5% | ||

| t(h) | Resilient Modulus (MPa) | |||||||||

| RCA 20% | ||||||||||

| 0 | sample 1 | 20,398.0 | 21,603.0 | 20,706.0 | 12,176.0 | 11,972.0 | 11,961.0 | 5722.0 | 5164.0 | 4719.0 |

| sample 2 | 20,432.0 | 21,655.0 | 21,663.0 | 11,601.0 | 11,749.0 | 12,379.0 | 5537.0 | 4717.0 | 4916.0 | |

| 2 | sample 1 | 23,229.0 | 20,612.0 | 25,917.0 | 12,625.0 | 13,425.0 | 14,925.0 | 5727.0 | 5477.0 | 6762.0 |

| sample 2 | 19,042.0 | 20,745.0 | 25,708.0 | 12,130.0 | 12,056.0 | 15,402.0 | 5167.0 | 5664.0 | 6878.0 | |

| 4 | sample 1 | 20,964.0 | 21,830.0 | 25,537.0 | 15,793.0 | 16,584.0 | 16,863.0 | 10,015.0 | 7660.0 | 9277.0 |

| sample 2 | 20,659.0 | 21,498.0 | 25,949.0 | 16,083.0 | 17,992.0 | 16,487.0 | 9703.0 | 7317.0 | 8765.0 | |

| RCA 30% | ||||||||||

| 0 | sample 1 | 21,039.0 | 22,633.0 | 22,110.0 | 11,232.0 | 11,352.0 | 13,745.0 | 6006.0 | 4497.0 | 5036.0 |

| sample 2 | 19,588.0 | 19,132.0 | 22,588.0 | 11,182.0 | 10,384.0 | 13,324.0 | 5320.0 | 4037.0 | 5137.0 | |

| 2 | sample 1 | 20,604.0 | 19,502.0 | 24,873.0 | 13,294.0 | 15,891.0 | 15,523.0 | 7044.0 | 6390.0 | 7368.0 |

| sample 2 | 19,600.0 | 20,557.0 | 23,415.0 | 13,781.0 | 15,155.0 | 15,891.0 | 7182.0 | 6140.0 | 7368.0 | |

| 4 | sample 1 | 23,312.0 | 21,594.0 | 21,525.0 | 17,048.0 | 15,378.0 | 14,201.0 | 12,941.0 | 9239.0 | 7622.0 |

| sample 2 | 21,746.0 | 21,151.0 | 21,157.0 | 16,648.0 | 14,841.0 | 13,428.0 | 10,453.0 | 8836.0 | 7793.0 | |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F0 | p-Value |

|---|---|---|---|---|---|

| Regression | 1.14 × 1010 | 14 | 8.16 × 108 | 4.16 × 102 | <0.0001 |

| Residual | 5.00 × 108 | 255 | 1.96 × 106 | ||

| Lack of fit | 3.85 × 108 | 120 | 3.21 × 106 | 3.77 | <0.0001 |

| Pure error | 1.15 × 108 | 135 | 8.50 × 105 | ||

| Total | 1.19 × 1010 | 269 | 4.43 × 107 |

| xi | βj | Standard Error | t-Test | p-Value | H0 |

|---|---|---|---|---|---|

| independent | 9.52 | 0.02 | 525.4 | 0.0000 | No |

| x1 | 1.66 × 10−1 | 7.54 × 10−3 | 21.98 | <0.0001 | No |

| x2 | −6.11 × 10−1 | 7.54 × 10−3 | −81.06 | <0.0001 | No |

| x3 | −1.32 × 10−2 | 9.67 × 10−3 | −1.37 | 0.1726 | Yes |

| x4 | 1.82 × 10−2 | 7.54 × 10−3 | 2.42 | 0.0163 | No |

| x1x2 | 1.40 × 10−1 | 9.24 × 10−3 | 15.17 | <0.0001 | No |

| x1.x3 | −4.63 × 10−3 | 1.05 × 10−2 | −0.44 | 0.6596 | Yes |

| x1x4 | −3.46 × 10−2 | 9.24 × 10−3 | −3.75 | 0.0002 | No |

| x2x3 | 2.30 × 10−2 | 1.05 × 10−2 | 2.19 | 0.0296 | No |

| x2.x4 | −3.07 × 10−2 | 9.24 × 10−3 | −3.33 | 0.0010 | No |

| x3x4 | −5.72 × 10−3 | 1.05 × 10−2 | −0.54 | 0.5866 | Yes |

| x12 | 5.97 × 10−3 | 1.31 × 10−2 | 0.46 | 0.6479 | Yes |

| x22 | −1.53 × 10−1 | 1.31 × 10−2 | −11.71 | <0.0001 | No |

| x32 | 1.97 × 10−2 | 1.54 × 10−2 | 1.28 | 0.2023 | Yes |

| x42 | 1.55 × 10−2 | 1.31 × 10−2 | 1.19 | 0.2368 | Yes |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F0 | p-Value |

|---|---|---|---|---|---|

| Regression | 76.3 | 7 | 10.9 | 1.06 × 103 | <0.0001 |

| Residual | 2.71 | 262 | 0.01 | ||

| Lack of fit | 0.30 | 19 | 0.016 | 1.60 | 0.0569 |

| Pure error | 2.41 | 243 | 0.010 | ||

| Total | 79.01 | 269 | 0.294 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galan, J.J.; Silva, L.M.; Pasandín, A.R.; Pérez, I. Evaluation of the Resilient Modulus of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste. Sustainability 2020, 12, 8551. https://doi.org/10.3390/su12208551

Galan JJ, Silva LM, Pasandín AR, Pérez I. Evaluation of the Resilient Modulus of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste. Sustainability. 2020; 12(20):8551. https://doi.org/10.3390/su12208551

Chicago/Turabian StyleGalan, Juan J., Luís M. Silva, Ana R. Pasandín, and Ignacio Pérez. 2020. "Evaluation of the Resilient Modulus of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste" Sustainability 12, no. 20: 8551. https://doi.org/10.3390/su12208551

APA StyleGalan, J. J., Silva, L. M., Pasandín, A. R., & Pérez, I. (2020). Evaluation of the Resilient Modulus of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste. Sustainability, 12(20), 8551. https://doi.org/10.3390/su12208551