The Influence of Reclaimed Asphalt Pavement on the Mechanical Performance of Bituminous Mixtures. An Analysis at the Mortar Scale

Abstract

1. Introduction

2. Materials and Methods

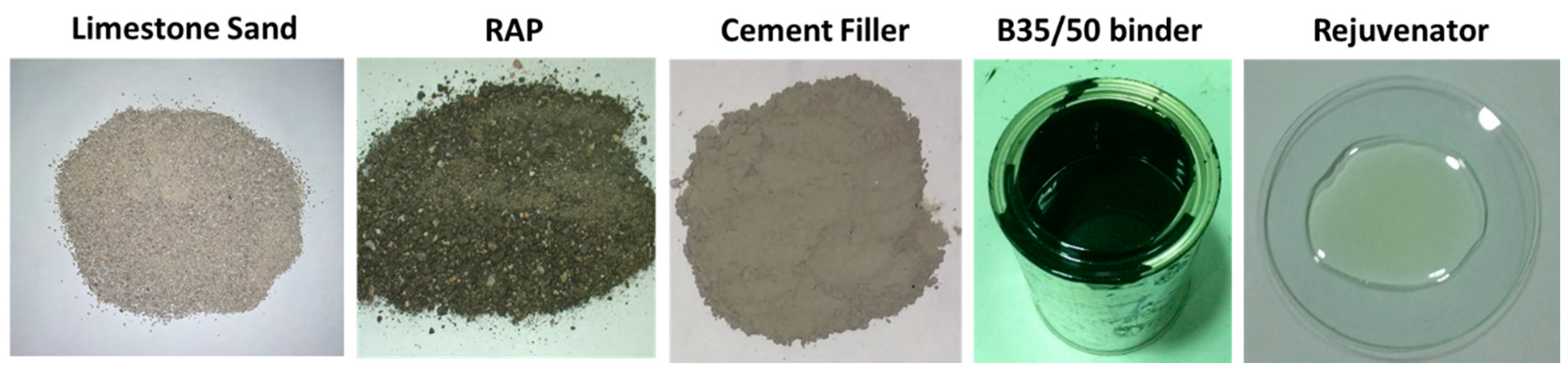

2.1. Materials

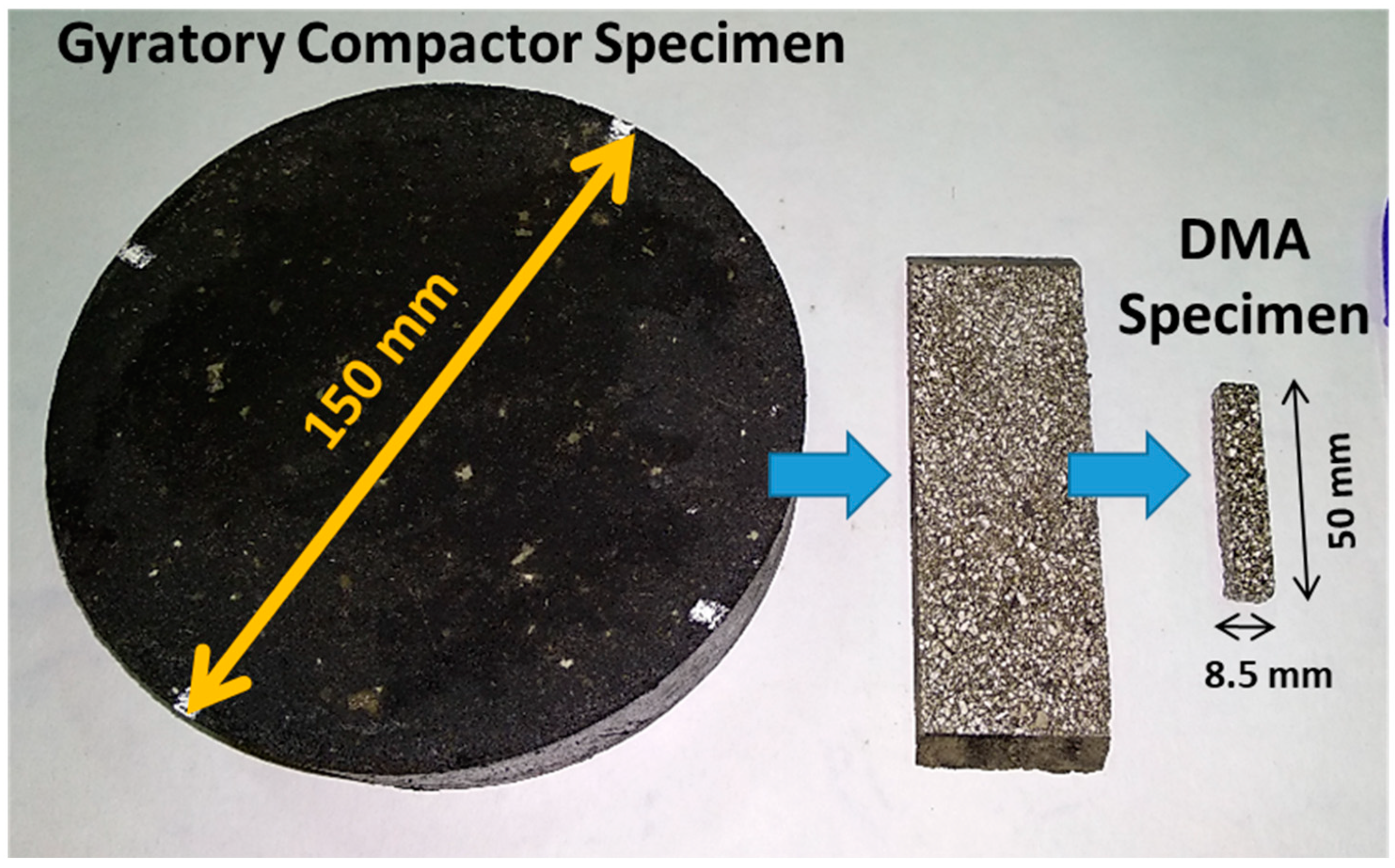

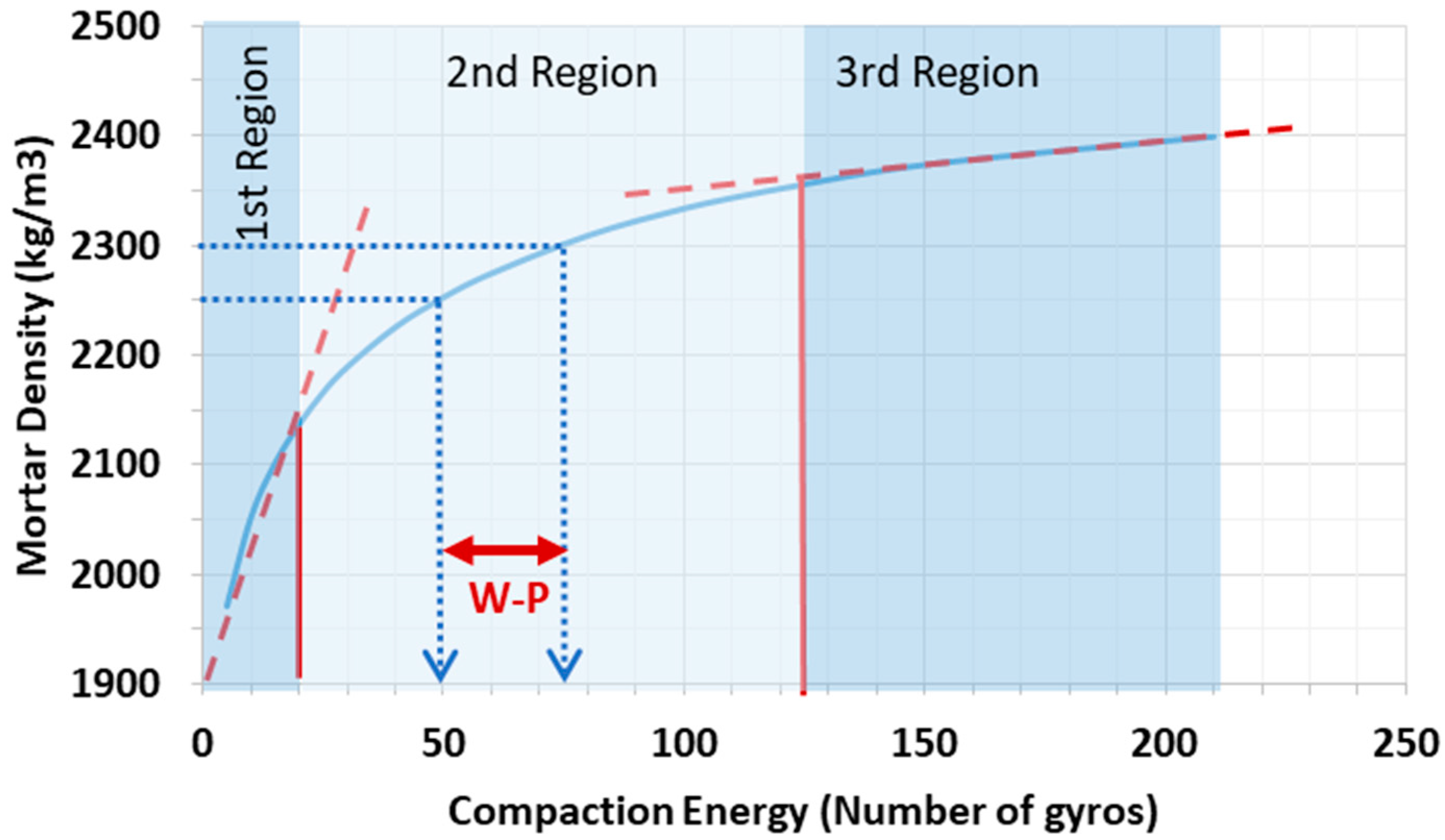

2.2. Methods

- -

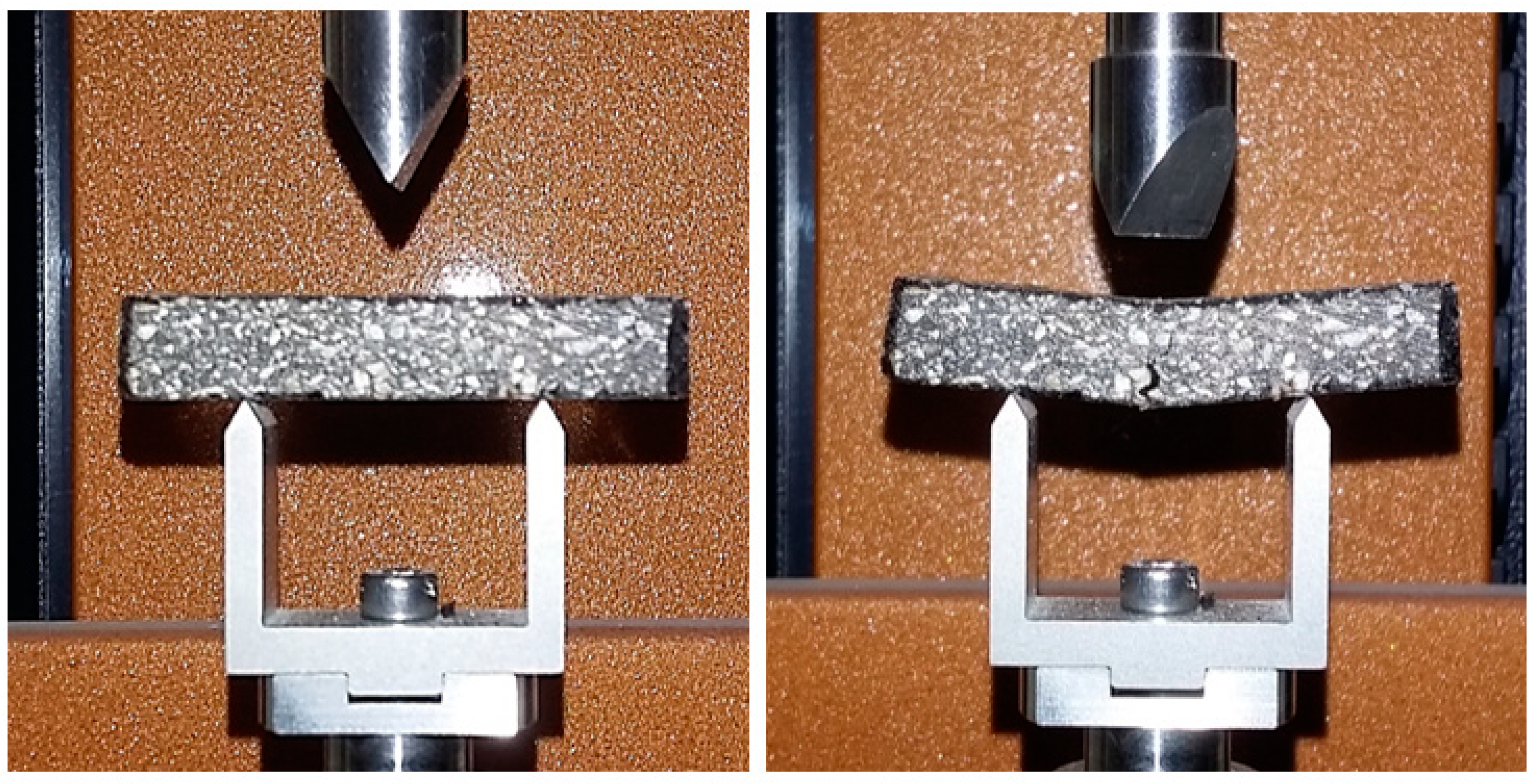

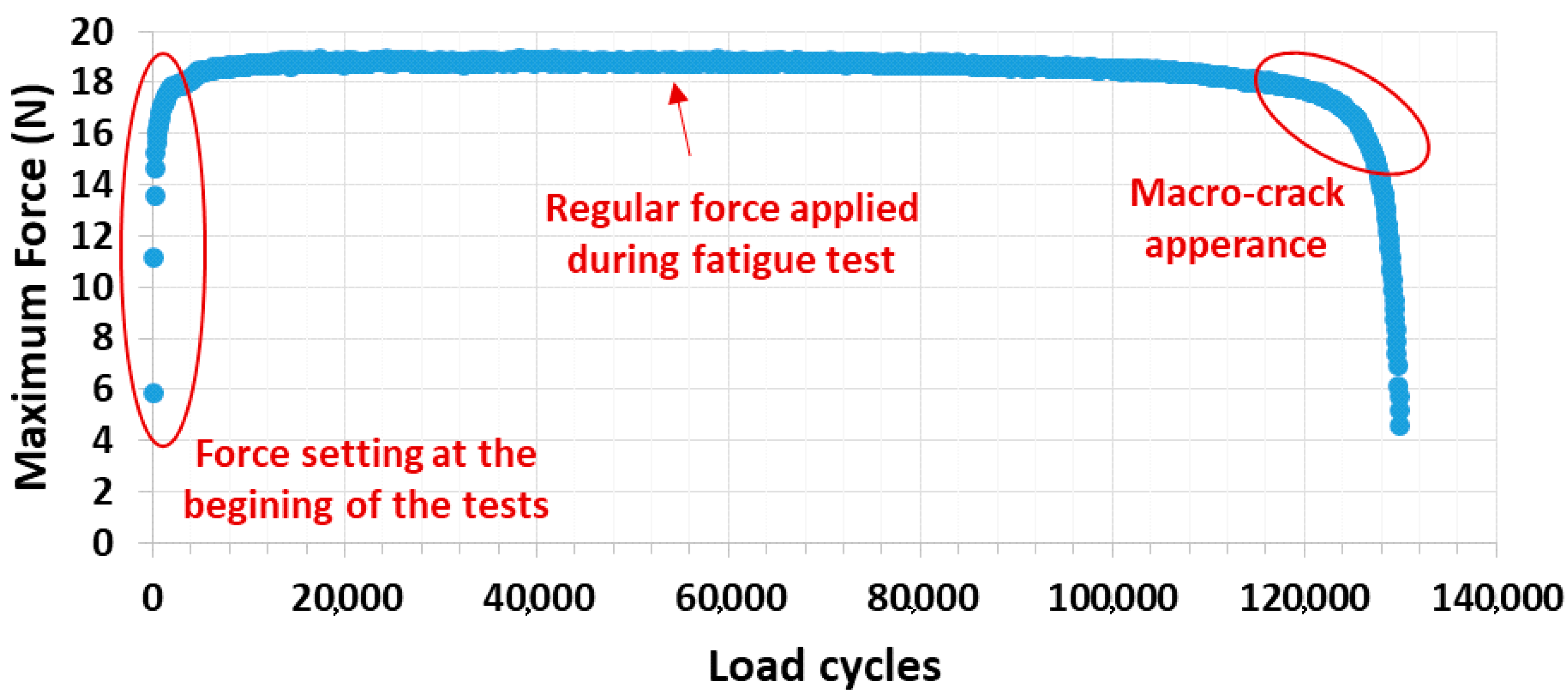

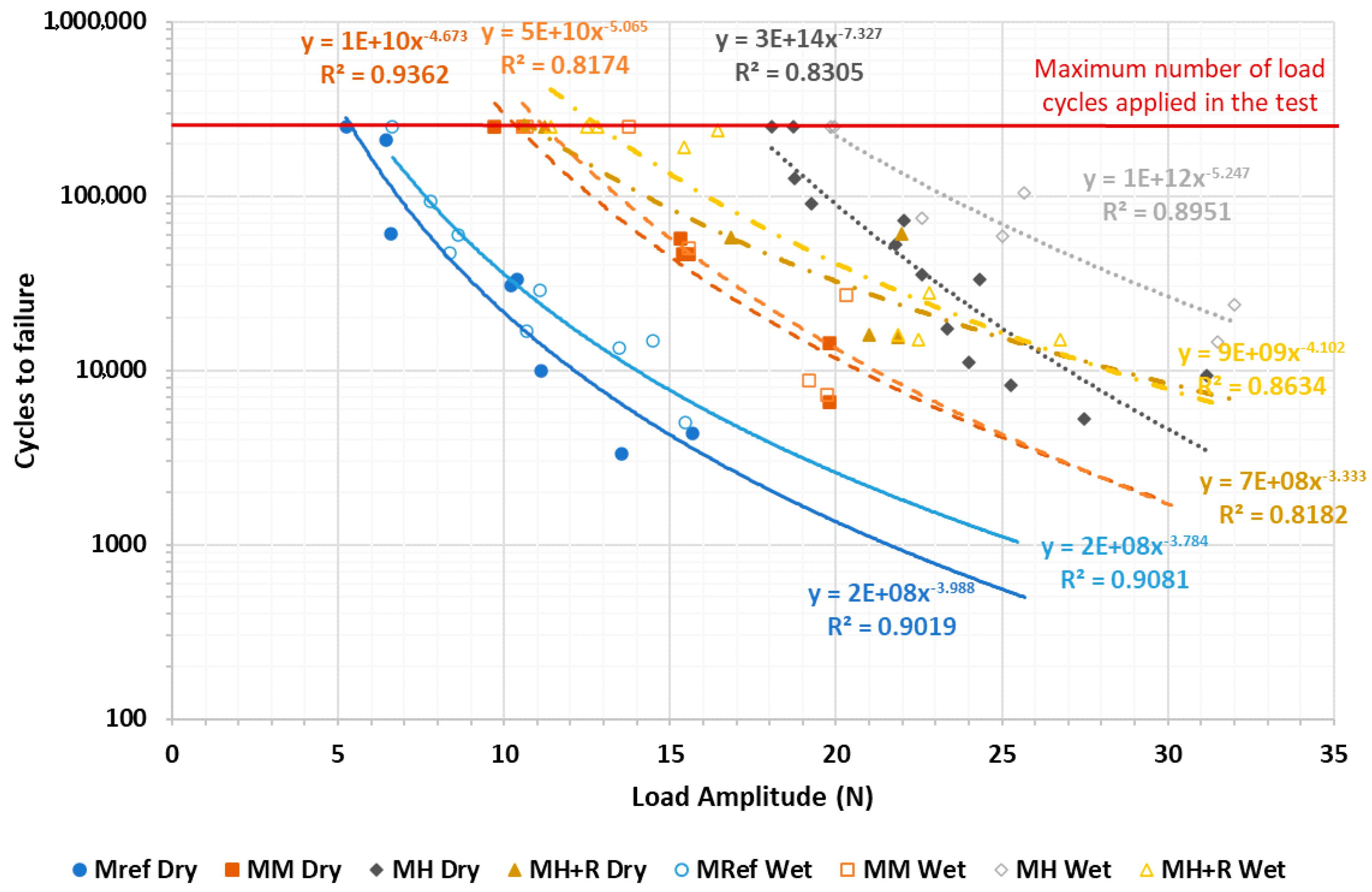

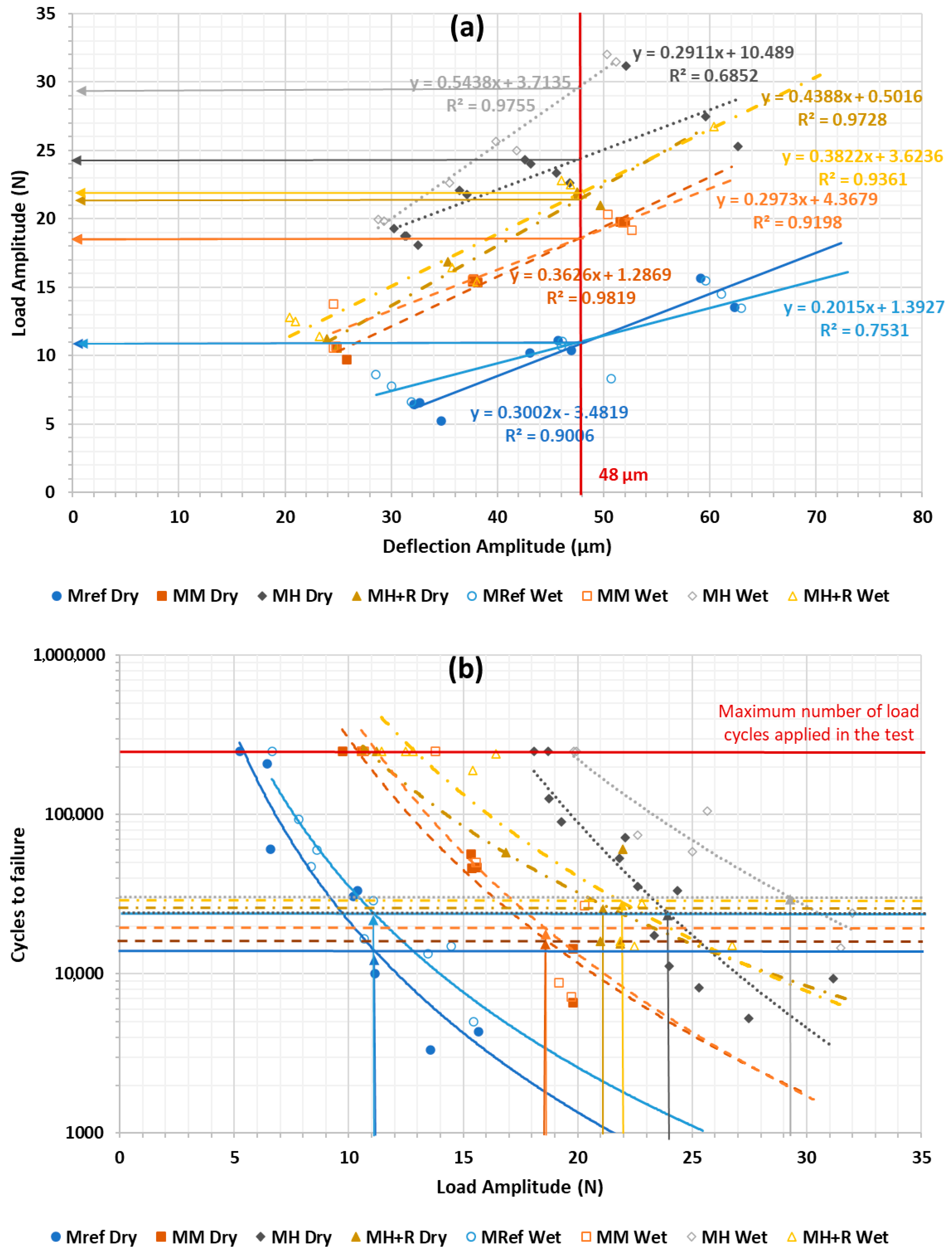

- Cycles to failure (Nf). Number of load cycles applied to the specimen until the appearance of a macro-crack. This parameter is set to 250,000. If a macro-crack did not appear in the specimens after 250,000 load cycles, a direct measurement of the mechanical resistance of the mortars was taken (the higher the parameter, the more resistant the mortars);

- -

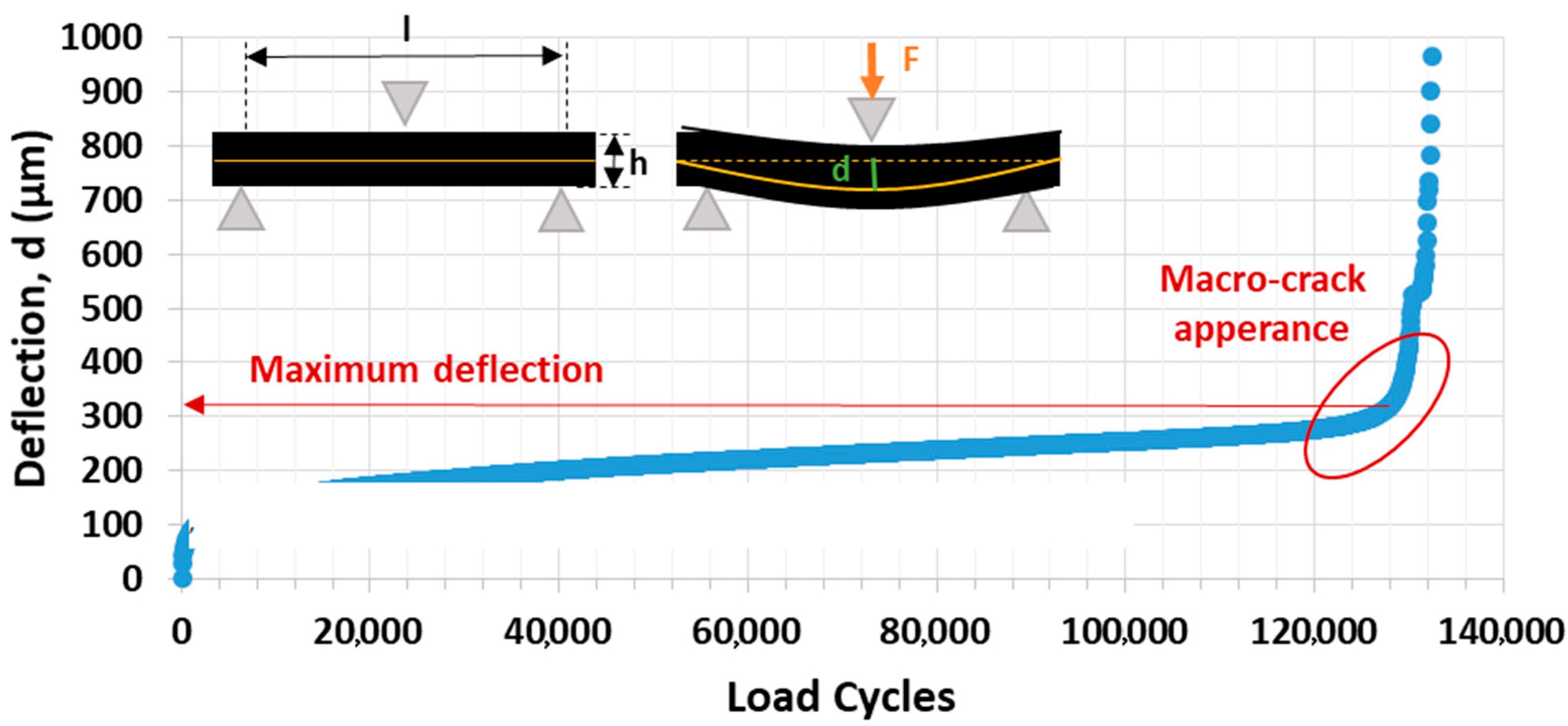

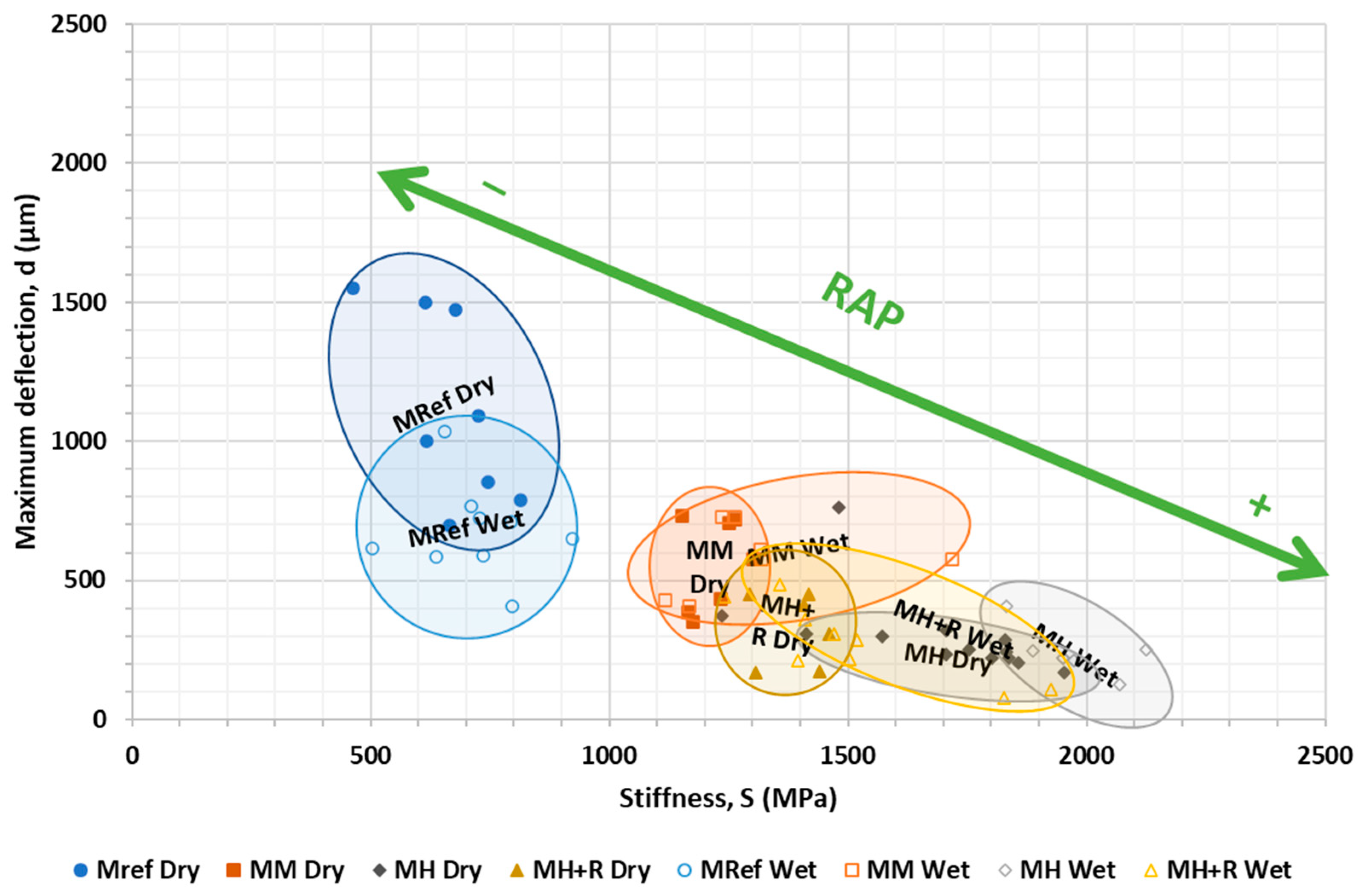

- Stiffness (S). Relationship between the force applied and the deflection produced in the mortar specimen after 1000 load cycles (Figure 7). This stiffness is calculated based on Young’s modulus (Equation (1) [23]), which measures the viscoelastic response of the mortar (as it increases, the mortar behaves more elastically), as all the tests has been conducted under the same loading conditions (amplitude and frequency) and temperature;where F is the maximum force applied at the 1000th load cycle (where the specimen is considered undamaged); l is the length between the supports; d is the deflection displacement measured at the 1000th cycle; b is the width of the specimen; and h is the height of the specimen;

- -

- Maximum deflection (dmax). Measured as the accumulated deflection in the specimen before the crack appears (Figure 7), this parameter measures the ductility (ability to deform before cracking) of the mortar studied. As the maximum deflection increases, the ductility of the mortar increases.

3. Results

4. Conclusions

- -

- As the amount of RAP increases, the workability of the asphalt mortars was reduced. However, the use of rejuvenators would facilitate the paving and compaction of materials with high RAP quantities;

- -

- When using an active filler (e.g., Portland cement), the use of high RAP quantities does not affect the water sensitivity of asphalt mortars;

- -

- As RAP content is increased, asphalt mortars offer a more elastic response, and therefore, they are more resistant to fatigue loads;

- -

- In spite of the presence of RAP reducing the ductility of the asphalt mortars, for a given deformation level, the long-term mechanical resistance (fatigue) seems to be unaffected due to its contribution in their elastic response.

Author Contributions

Funding

Conflicts of Interest

References

- Corriere, F.; Rizzo, A. Sustainability in road design: A methodological proposal for the drafting of guideline. Procedia Soc. Behav. Sci. 2012, 53, 39–48. [Google Scholar] [CrossRef]

- Rubio, M.C.; Moreno, F.; Belmonte, A.; Menéndez, A. Reuse of waste material from decorative quartz solid surfacing in the manufacture of hot bituminous mixes. Constr. Build. Mater. 2010, 24, 610–618. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Neves, J. A review on the effect of RAP recycling on bituminous mixtures properties and the viability of multi-recycling. Constr. Build. Mater. 2019, 211, 453–469. [Google Scholar] [CrossRef]

- Picado Santos, L.; Baptista, A.M.; Dias Capitao, S. Assessment of the Use of Hot Mix Recycled Asphalt Concrete in Plant. J. Transp. Eng. 2010, 136, 1159–1164. [Google Scholar] [CrossRef]

- Arámbula-Mercado, E.; Kaseer, F.; Epps Martin, A.; Yin, F.; Garcia Cucalon, L. Evaluation of recycling agent dosage selection and incorporation methods for asphalt mixtures with high RAP and RAS contents. Constr. Build. Mater. 2018, 158, 432–442. [Google Scholar] [CrossRef]

- Miguel Baptista, A.; Picado-Santos, L.G.; Capitão, S.D. Design of hot-mix recycled asphalt concrete produced in plant without preheating the reclaimed material. Int. J. Pavement Eng. 2013, 14, 95–102. [Google Scholar] [CrossRef]

- Saleh, M.; Nguyen, N.H. Effect of rejuvenator and mixing methods on behaviour of warm mix asphalt containing high RAP content. Constr. Build. Mater. 2019, 197, 792–802. [Google Scholar]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Huang, S.C.; Qin, Q.; Grimes, W.R.; Pauli, A.T.; Glaser, R. Influence of rejuvenators on the physical properties of RAP binders. J. Test. Eval. 2015, 43, 594–603. [Google Scholar] [CrossRef]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. The Effect of the Nature of Rejuvenators on the Rheological Properties of Aged Asphalt Binders. In RILEM 252-CMB-Symposium on Chemo Mechanical Characterization of Bituminous Materials; Springer: Braunschweig, Germany, 2018; pp. 220–225. [Google Scholar]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. The effect of polymer modified binders on the long-term performance of bituminous mixtures: The influence of temperature. Mater. Des. 2015, 78, 5–11. [Google Scholar] [CrossRef]

- Presti, D.L.; del Barco Carrión, A.J.; Airey, G.; Hajj, E. Towards 100% recycling of reclaimed asphalt in road surface courses: Binder design methodology and case studies. J. Clean. Prod. 2016, 131, 43–51. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Jimenez del Barco, A.; Rubio-Gámez, M.C. Analysis of the influence of binder properties on the mechanical response of bituminous mixtures. Int. J. Pavement Eng. 2017, 18, 73–82. [Google Scholar] [CrossRef]

- EN 13108-2. Bituminous Mixtures—Material Specifications—Part 2: Asphalt Concrete for very Thin Layers. Available online: https://standards.iteh.ai/catalog/standards/cen/40901d76-cd7a-464a-916c-9e1cf277ac2f/en-13108-2-2016 (accessed on 8 October 2020).

- Bituminous Mixtures—Material Specifications—Part 5: Stone Mastic Asphalt. Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030278718 (accessed on 8 October 2020).

- EN 13108-7. Bituminous Mixtures—Material Specifications—Part 7: Porous Asphalt. Available online: https://infostore.saiglobal.com/preview/256741893600.pdf?sku=872309_SAIG_NSAI_NSAI_2074070 (accessed on 8 October 2020).

- EN 1426. Bitumen and Bituminous Binders–Determination of Needle Penetration. Available online: https://infostore.saiglobal.com/en-us/Standards/EN-1426-2015-345393_SAIG_CEN_CEN_790099/ (accessed on 8 October 2020).

- EN 1427. Bitumen and Bituminous Binders–Determination of the Softening Point–Ring and Ball Method. Available online: https://infostore.saiglobal.com/preview/is/en/2015/i.s.en1427-2015.pdf?sku=1814087 (accessed on 8 October 2020).

- Cavalcanti De Sousa, P. Automated Protocol for the Analysis of Dynamic Mechanical Analyzer Date from Fine Aggregate Asphalt Mixes. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2010. [Google Scholar]

- EN 12697-31. Bituminous Mixtures. Test Methods for Hot Mix Asphalt-Part 31: Specimen Preparation by Gyratory Compactor. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030154393 (accessed on 8 October 2020).

- EN 12697-6. Bituminous Mixtures. Test Methods for Hot Mix Asphalt-Part 6: Determination of Bulk Density of Bituminous Specimens. Available online: https://standards.iteh.ai/catalog/standards/cen/25d7a9c5-15fd-4242-be8c-1856a7a3a049/en-12697-6-2012 (accessed on 8 October 2020).

- Canet, J.M. Resistencia de Materiales y Estructuras; Centro Internacional de Métodos Numéricos en Ingeniería: Barcelona, Spain, 2012. [Google Scholar]

- Farooq, M.A.; Mir, M.S.; Sharma, A. Laboratory study on use of RAP in WMA pavements using rejuvenator. Constr. Build. Mater. 2018, 168, 61–72. [Google Scholar] [CrossRef]

- Silva, H.M.; Oliveira, J.R.; Jesus, C.M. Are totally recycled hot mix asphalts a sustainable alternative for road paving? Resour. Conserv. Recycl. 2012, 60, 38–48. [Google Scholar] [CrossRef]

| Components | Mortar without RAP (MRef) | Mortar with Medium RAP Rate (MM) | Mortar with High RAP Rate (MH) | Mortar with High RAP Rate + Rejuvenator (MH+R) |

|---|---|---|---|---|

| Asphalt binder B35/50 (% over the total weight of the mortar) | 8.0 | 5.5 | 3.0 | 3.0 |

| Limestone Sand (% over the total weight of the mortar) | 64.4 | 35 | 0.0 | 0.0 |

| Cement Filler (% over the total weight of the mortar) | 27.6 | 22.5 | 15.0 | 15.0 |

| RAP (% over the total weight of the mortar) | 0.0 | 37.0 | 82.0 | 82.0 |

| Rejuvenating agent (% over the total weight of the binder contained in the RAP) | 0.0 | 0.0 | 0.0 | 0.15 |

| Parameter | Sieve (mm) | Percentage of Material Passing (%) |

|---|---|---|

| Granulometry (EN 933-1) | 2 | 100 |

| 0.5 | 18 | |

| 0.063 | 0 | |

| Sand equivalent (EN 933-8) | 77.0 | |

| Density (Mg/m3) (EN 1097-6) | 2.77 | |

| Water absorption (%) (EN 1097-6) | 0.88 | |

| Parameter | Sieve (mm) | Percentage of Material Passing (%) |

|---|---|---|

| Granulometry (EN 933-1) | 2 | 100 |

| 0.5 | 54 | |

| 0.063 | 14.7 | |

| Percentage of asphalt bitumen extracted from RAP (%) | 5.8 | |

| Penetration at 25 °C of the asphalt bitumen extracted from RAP (dmm, EN 1426 [18]) | 16 | |

| Softening point of the asphalt bitumen extracted from RAP (°C, EN 1427 [19]) | 71 | |

| Parameter | Sieve (mm) | Percentage of Material Passing (%) |

|---|---|---|

| Granulometry (EN 933-1) | 2 | 100 |

| 0.5 | 100 | |

| 0.125 | 100 | |

| 0.063 | 96.0 | |

| Density (Mg/m3) (EN 1097-3, annex A) | 3.12 | |

| Mortar | Mortar without RAP (MRef) | Mortar with Medium RAP Rate (MM) | Mortar with High RAP Rate (MH) | Mortar with High RAP Rate + Rejuvenator (MH+R) |

|---|---|---|---|---|

| Apparent Density (kg/m3) EN-12697-6 [22] | 2399 | 2406 | 2261 | 2247 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hidalgo, A.E.; Moreno-Navarro, F.; Tauste, R.; Rubio-Gámez, M.C. The Influence of Reclaimed Asphalt Pavement on the Mechanical Performance of Bituminous Mixtures. An Analysis at the Mortar Scale. Sustainability 2020, 12, 8343. https://doi.org/10.3390/su12208343

Hidalgo AE, Moreno-Navarro F, Tauste R, Rubio-Gámez MC. The Influence of Reclaimed Asphalt Pavement on the Mechanical Performance of Bituminous Mixtures. An Analysis at the Mortar Scale. Sustainability. 2020; 12(20):8343. https://doi.org/10.3390/su12208343

Chicago/Turabian StyleHidalgo, Ana E., Fernando Moreno-Navarro, Raúl Tauste, and M. Carmen Rubio-Gámez. 2020. "The Influence of Reclaimed Asphalt Pavement on the Mechanical Performance of Bituminous Mixtures. An Analysis at the Mortar Scale" Sustainability 12, no. 20: 8343. https://doi.org/10.3390/su12208343

APA StyleHidalgo, A. E., Moreno-Navarro, F., Tauste, R., & Rubio-Gámez, M. C. (2020). The Influence of Reclaimed Asphalt Pavement on the Mechanical Performance of Bituminous Mixtures. An Analysis at the Mortar Scale. Sustainability, 12(20), 8343. https://doi.org/10.3390/su12208343