Abstract

The energy refurbishment of the existing building heritage is one of the pillars of Italian energy policy. Aiming for energy efficiency and energy saving in end uses, there are wide and diversified improvement strategies, which include interventions on the building envelope and Heating, Ventilation, and Air Conditioning (HVAC) systems, with the introduction of renewable energy sources. The research aims at evaluating the building energy consumptions and Indoor Environmental Quality (IEQ), varying the airflow rates handled by the HVAC system. A Case Study (the Aula Magna of a university building) is analysed; an in-situ monitoring campaign was carried out to evaluate the trend of some environmental parameters that are considered to be significant when varying the external airflow rates handled by the HVAC system. Additionally, dynamic simulations were carried out, with the aim of evaluating the energy savings coming from the airflow rates reduction. The results of this case study highlight the opportunity to achieve significant energy savings, with only slight variations in IEQ; a 50% reduction in airflow rate would decrease energy consumption by up to 45.2%, while increasing the carbon dioxide concentration from 545 ppm to 655 ppm, while the Particulate Matter and Total Volatile Organic Compounds increase is insignificant.

1. Introduction

The debate on climate change and the exhaustion of traditional fossil fuels has now clarified the need for a sustainable and more efficient energy system to decrease the energy consumption and pollutants in the building sector [1]. At the same time, achieving a good IEQ in existing buildings is an extremely current topic, which is related to the strong demand for retrofit of buildings in Europe [2].

Nowadays, people spend a large part of their time (60–90%) inside buildings [3]; for this reason, the quality of confined spaces is a major concern for healthy indoor environments in Europe [4] and it has a decisive impact on wellbeing of occupants [5] and their productivity [6].

The EE-TC-IAQ (Energy Efficiency-Thermal Comfort-Indoor Air Quality) dilemma represents a significant issue for building design and management [7,8,9]. In the past, issues that are to IEQ have been separately addressed from those concerning energy efficiency in buildings [10]. Therefore, scientific literature reports many case studies that only analyse one of the aspects. Nevertheless, examples of an integrated approach are present, such as [11,12,13], in which attention was simultaneously paid to the reduction of energy consumptions in school buildings and ensuring satisfactory internal environmental conditions; in [14,15], where IAQ issues have been considered together with architecture preservation and sustainability concerns when retrofitting a prestigious building.

Most of the existing building stock has been constructed before the promulgation of energy efficiency directive. Thus, such buildings offer interesting possibilities for improvement. Furthermore, in Italy, public buildings have been given a particular attention and they must be refurbished in the next future [16]. The refurbishment measures include windows replacement, roofs, and external walls insulation, as well as energy efficiency measures for the energy systems and the introduction of renewable energy sources [17]. Nevertheless, the building energy consumption due to air treatments will not benefit from those measures, since those are mostly dependent on the external climatic condition and the air exchange rates, whose national regulations determine the minimum values. Thus, the energy consumption of HVAC systems will gain an ever-increasing importance, especially for highly crowded buildings.

Indeed, this research paper will focus on energy efficiency measures applied to the HVAC system. Particularly, the proposed solutions will be studied and applied on a public university building. Such buildings have been demonstrated to have a significant energy savings potential [18,19]. University and scholastic buildings have, in fact, large energy consumptions and broad occupancy schedules (e.g., offices, libraries, classrooms, conference rooms, and laboratories), thus offering several opportunities for efficient refurbishment [20]. Furthermore, universities and school buildings represent an interesting case study because of the high IAQ standard requirement. Several studies about retrofitted school buildings with the implementation of measures in line with the Energy Performance of Buildings Directive have been conducted in Mediterranean countries, with the application of cost-optimal methods for designing strategies to achieve nearly zero-energy educational buildings [21]. Other authors focused on the link between energy retrofitting interventions and IAQ in school buildings [22,23]. Another study that was conducted on a school building [24] identified an IEQ index to be used as an indicator of comfort, health, and building management costs. Particularly, the study highlights a close link between IEQ, comfort and satisfaction, study/work performance, and energy consumptions. Research activities on non-retrofitted school buildings in Portugal [25] generally revealed insufficient comfort and inadequate IAQ, mainly due to low indoor air temperatures, along with low ventilation rates. Another study on school and offices buildings showed high energy saving potential [26], by introducing Demand Control Ventilation (DCV). Additionally, the implementation of Building Automation and Control (BACs) systems [27,28] can allow for HVAC operation with reduced airflow rates during the period with low occupancy and can therefore lead to relevant energy savings; in addition, BACs can also allow for combining the positive effects on energy consumption [29,30] of different ventilation systems with different control strategies. Indeed, one of the most usual solutions to reduce HVAC system energy consumption is currently to adopt smart control systems that might control airflow rate, supply air temperature and air humidity, and several other parameters.

Another interesting aspect is represented by the selection of parameters to be monitored. Indeed, selecting the pollutants is more complex while techniques for measurement of air temperature and relative humidity are generally shared. The variety of pollutants that are potentially present in a confined environment actually makes it very difficult to identify a synthetic air pollution parameter acting as a representative IEQ indicator [31,32]. In [33], an interesting review of the air quality indicators used in different green buildings certification schemes is presented. The review shows the pollutants that are most commonly found in indoor air (i.e., VOC, in 84% of cases; CO2, 65%; asbestos, 45%; PM10 or PM2.5, 16%) and that most of the schemes that propose the measurement of indoor air identify and evaluate only three of those pollutants. In [34], a measurement system for monitoring the buildings performance is presented, which focuses on IEQ; the system includes sensors for measuring air temperature, relative humidity, illuminance, and occupancy, while air quality is evaluated through the measurement of Carbon Dioxide (CO2); Particulate Matter 10 µm or less in diameter (PM10); and, Total Volatile Organic Compounds (TVOCs). In [35], a study evaluating the IAQ in residential buildings is presented, the measurement of environmental parameters (Temperature, T; Relative Humidity, RH) and the concentration of significant pollutants (i.e., volatile organic compounds, PM2.5 and PM10) is carried out.

The aim of this research is to assess the link between energy consumptions and IEQ through the variation of the airflow rate that is handled by the HVAC system by means of an integrated and holistic approach that covers energy consumption, temperature, relative humidity, and IAQ. Particularly, the research wants to demonstrate the possibility of strongly reducing the energy consumption without heavily affecting the IEQ by adopting a performance-based approach instead of the traditional prescriptive one.

The results of this study can be used to define ventilation strategies, which are aimed at minimizing energy consumptions while providing the required IEQ level. The proposed methodology could be replicated to evaluate similar situations in other university buildings and more generally in buildings that are equipped with HVAC systems.

2. Materials and Methods

2.1. Methodological Approach

The target of this work is the evaluation of building energy consumptions and IEQ, varying the outdoor airflow rates that are handled by the HVAC system.

The study was carried out integrating two different methodological approaches, namely: (i) a dynamic simulation has been carried out for the building energy performance assessment, while (ii) an in-situ measurement campaign has been developed to evaluate the IEQ. Furthermore, the results of the in-situ measurement campaign, in terms of indoor temperature, relative humidity, and electric load, have been used as reference for the dynamic model calibration and validation. Dynamic simulation has been used to evaluate the energy consumption as well as the indoor temperature and relative humidity in different scenarios. The in-situ measurement campaign aimed at evaluating the IAQ through the measurement of temperature, relative humidity, and different pollutants.

Regarding the dynamic simulation model, the in-house developed code explained in detail in [36] has been adopted (which has been validated by comparison with the EnergyPlus software [37,38]). Aiming at creating a simple, yet accurate, model, the code allows for performing single-zone hourly dynamic simulations fully responding to the specific simulation needs of the case study consisting of a single large space.

Regarding the IEQ assessment, a detailed analysis of data was performed that had been gathered by means of in-situ experimental campaigns, during which indoor air temperature, relative humidity, and the concentration of some significant pollutants have been monitored, namely: CO2; PM10; and, TVOCs.

The measured concentrations of indoor air pollutants have been compared to threshold values; the ranges of thresholds concentration may vary, depending on exposure times. In this study, the intervals that are shown in Table 1 [39,40] were used, associating them with a synthetic qualitative classification.

Table 1.

Measured pollutants: threshold values and classes.

Measurement strategies are not mentioned in detail in most researches; in general, the number and position of the sampling points depend on the size of the building and they must cover areas and spaces that are normally occupied. In this work, the measurement equipment were positioned at the average height of the first human respiratory tract (1.0 m, for people sitting) [41,42]. The indoor measurement was carried out in a central position of the Aula Magna, in the part of the corridor between the four sitting areas; outside the Aula Magna, the measurements were made on the roof of the building where the external air intakes of the HVAC system are located. Figure 1 shows the measurement equipment, while Table 2 presents the specifics of the measurement equipment.

Figure 1.

Measurement equipment (a) Temperature, RH and CO2; (b) Particulate Matter 10 µm or less in diameter (PM10); and, (c) Total Volatile Organic Compounds (TVOC).

Table 2.

Measurement equipment details.

Regarding dynamic simulations, four different operating conditions of the HVAC system were simulated, as shown in Table 3, namely: normal operating situation (Scenario #0), and three other scenarios characterized by a reduction in the airflow rate handled by the Air Handling Units (AHUs) of 15% (Scen. #1), 30% (Scen. #2), and 50% (Scen. #3). Table 3 summarizes scenarios details.

Table 3.

Summary of the analysed scenario.

Regarding the measurement campaign, only two scenarios have been tested (Table 3); this is due to the current possibilities offered by the HVAC system that is composed by two AHUs. Thus, the measurements were carried out in two different operating conditions: (i) with the two AHUs operating at the same time (relative airflow rate 100%; Scen. #0); aand, (ii) only one operating AHU (relative airflow rate 50%; Scen. #3; having simply turned off one of the AHUs).

2.2. Case Study Description

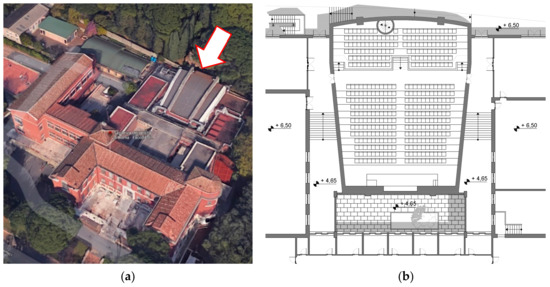

The analysed Case Study is the Aula Magna of Valle Giulia, headquarters of the Faculty of Architecture of the Sapienza University of Rome. It can be considered to be a relevant example for other highly crowded educational buildings, particularly for those buildings of outdated design in which HVAC or mechanical ventilation systems were inserted in a later stage.

The building hosting the Aula Magna is located in the Municipality of Rome, within the so-called Valle delle Accademie (Figure 2a). The Aula Magna has a useful floor area of approximately 370 m2 and a net volume of 2500 m3. It has a stepped floor with 400 seats auditorium (Figure 2b). The surrounding walls are opaque, except for the two emergency exit doors. The windows in the upper part of the side-walls had been closed to allow for the placement of the HVAC system ducts and air supply inlets during the building renovation in 2005.

Figure 2.

Aula Magna. (a) Top view (Google Maps) (b) Plant.

All the data regarding the building envelope and HVAC system were collected in order to characterise the building energy performance. An abacus of the existing vertical dispersing surfaces was created through non-destructive testing. The direct wall thicknesses survey allowed for determining the typology of the wall structures; historical resources analysis allowed for deducing the absence of thermal insulation that became mandatory only after the construction of the building.

The back perimetral walls are adjacent with the external environment. The lower part of the side walls is adjacent to indoor environments, while the higher part of surrounding walls is exterior. The roof is exposed externally, while the floor is partially adjacent to the soil and to a basement level below the upper part of the Aula Magna.

The front walls are made of reinforced concrete masonry and have a thickness of 130 cm and thermal transmittance (U) of 1.16 W/m2K. The side walls are made of solid tuff masonry blocks, they are only 48 cm thick, with a U of 1.73 W/m2K. The external roof consists of a mixed slab; it has a thickness of 32 cm and a U of 1.66 W/m2K. The floor towards the ground has a thickness of 40 cm and it consists of a concrete screed positioned above pebbles and crushed stones; its U value is equal to 1.1 W/m2K.

Regarding the dynamic simulation, the following thermal loads were considered: (i) loads due to the presence of occupants (full room occupation: 50 W/m2 [43]); and, (ii) loads due to the lighting system (LED lighting: 20 W/m2, evaluated considering the actual lighting systems as fully radiative); loads due to electrical equipment (14 W/m2: evaluated considering the presence of 1 projector, 500 W, and 50 laptop 90 W each one).

In order to evaluate the seasons and yearly energy consumption, the weekly occupancy schedule was set while considering:

- two days with morning lessons (occupancy 9 ÷ 12 a.m., HVAC system operation 8 ÷ 12 a.m.);

- two days with afternoon lessons (occupancy 14 ÷ 17 p.m., HVAC system start-up 13 ÷ 17 p.m.); and,

- one conference day (occupancy 9 a.m. ÷ 17 p.m., HVAC system start-up 8 a.m.÷ 17 p.m.).

The Aula Magna indoor temperature was set to remain within the standard comfort limits (winter 20 °C, 50 % RH, summer 26 °C, 50% RH).

The Aula Magna is equipped with an external HVAC system, which processes airflow rate of 14,000 m3/h with two AHUs of 7000 m3/h each. The AHUs are in the classic configuration (pre-heating coil, adiabatic humidifier, cooling coil, and post-heating coil) and they are equipped with a sensible heat recovery unit on the exhaust air.

The system relies on a Heat Pump (HP) unit (absorbed power 66.4 kW, nominal heat output 236.0 kW, nominal cooling capacity 209.0 kW) exclusively used for the two AHUs. Pre-heating coil, cooling coil, and post-heating coil are controlled by means of three-way valves, being controlled by a Programmable Logic Controller (PLC) system (Figure 3).

Figure 3.

Top view of Aula Magna. (a) Left side; (b) Right side. (1) Heat Pump; (2) Pumps and storage tanks; (3) Duct protection carter; (4) and (5) Air Handling Units.

The air is supplied to the Aula Magna by means of high induction diffusers positioned in the upper part of the side walls (Figure 4); air is extracted through vents that are incorporated into the furnishings of the short sides of the classroom.

Figure 4.

Top view of Aula Magna (a) High induction diffusers; and, (b) Air extraction vents.

3. Results and Discussion

3.1. Dynamic Simulation for Energy Savings

The first simulation phase concerned the modelling of the building in its current configuration, followed by the model calibration. Precisely, the initial calibration of the model was carried out by comparing the results of scenario #0 with the data that were collected from the general electric meter of the HPs by means of a watt-meter and a PLC for data-logging. Currently, there is no direct measurement of the energy consumption of the HP and, therefore, it was necessary to carry out targeted comparisons that aimed at assessing electricity consumptions related to measurements with and without the HVAC system. This feature explains the quite high percentage error in terms of power consumption. Nevertheless, the error is considered to be acceptable to define the energy performance of the proposed solutions. In Table 4 and Table 5, the validation of the model against the measured values of temperature, RH, and electric power consumption (Pel) is shown for the cooling and heating mode, respectively.

Table 4.

Dynamic model validation against the measured values of electric power consumption, indoor temperature and RH in cooling mode. Scen. #0—cooling mode.

Table 5.

Dynamic model validation against the measured values of electric power consumption, indoor temperature and RH in heating mode. Scen.0#—heating mode.

Given the low percentage error values, the model has been considered to be reliable to simulate the real condition and energy performance of the HVAC system in the Aula Magna.

As already mentioned, scenarios with different airflow rates have been simulated, namely: (i) Scen. #0 (100% airflow rate: 14,000 m3/h); (ii) Scen. #1 (85% airflow rate: 11,900 m3/h); (iii) Scen. #2 (70% airflow rate: 9800 m3/h); and, (iv) Scen. #3 (50% airflow rate: 7000 m3/h).

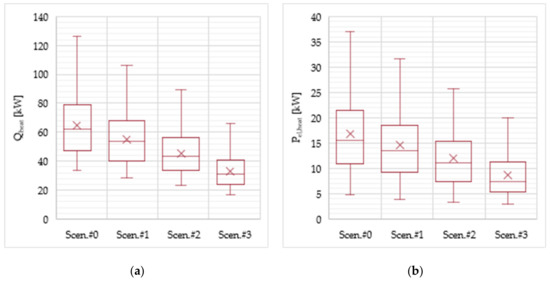

Figure 5 and Figure 6 show the result of the simulations, namely the average hourly thermal power (Qheat) supplied by the AHU to the Aula Magna and the average hourly electric power (Pel,heat) consumed by the HP, both relating to the winter season and the summer season (thermal power supplied, Qcool; electric power consumed, Pel,cool).

Figure 5.

Heating (a) and electrical (b) power for heating purpose.

Figure 6.

Heating (a) and electrical (b) power for cooling purpose.

Table 6 and Table 7 summarize the results of the simulations carried out, respectively, for winter and summer operation, for each of the four simulated scenarios. In particular, the tables show the average values (Qheat,average; Qcool,average) and maximum values (Qheat,max; Qcool,max) of the thermal or cooling power supplied by the AHU to the environment and the corresponding values of the electric power consumed by the HP to supply the AHUs (Pel,average; Pel,max). These Tables highlight the total heating and cooling energy (Eheat,TOT, Ecool,TOT) that are supplied to the environment and the total electric consumptions minus the one in Scen. #0 (ΔEel,TOT) as a percentage of the baseline electric consumption. Additionally, the energy consumption due to the circulation of heat transfer fluids is considered.

Table 6.

Power and energy in winter operation for simulated scenarios.

Table 7.

Power and energy in summer operation for simulated scenarios.

A comparison between the different scenarios shows a general reduction in energy consumptions, being higher during winter and lower during summer. Reducing airflow rate by 50% (scenario #3), during the winter season, energy savings of 58.6% were achieved, while lower savings (28.3%) were achieved during the summer. On an annual basis, the savings reached 45.2% in scenario #3, 14.4% in scenario #1, and 27.8% in scenario #2.

3.2. Measurement Campaign—Summer Operation

The Aula Magna of the Architecture Faculty is not used every day; therefore, the measures were carried out in conjunction with events taking place in the Aula Magna, which provided relevant occupancy values throughout the day. Parallel to the thermo-hygrometric measurements, air quality measurements were carried out by detecting the concentrations of the selected pollutants (CO2, PM10, TVOC); Table 8 shows the results of the measurements. As previously mentioned, the measurements were carried out in two different operating conditions, with the two AHUs operating at the same time (Scen. #0) and with only one functioning AHU (Scen. #3).

Table 8.

Measurement campaign results—summer operation.

The full occupancy of the Aula Magna, which has a capacity of 400 seats, during the measurement days never occurred.

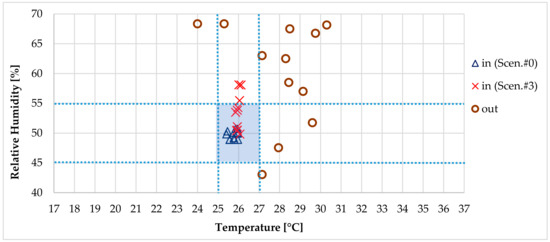

Figure 7 shows the results of temperature and relative humidity measurements; it can be seen how the HVAC system, operating at nominal flow (Scen. #0), is able to maintain the environmental parameters within the comfort range (T = 26 ± 1 °C; RH = 50 ± 5%). Otherwise, when it operates with a halved flow rate (Scen. #3), the temperature control is maintained while problems arise in the relative humidity control, which tends to assume higher values exiting, in some cases, the comfort range.

Figure 7.

Relative humidity vs air temperature.

The reason for this behaviour must be found in the relationship between the handled airflow rate and the sensible and latent loads (for summer season), according to the balances that are described by Equations (1) and (2).

where:

- Qsens and Qlat are the sensible and latent loads [W];

- G is the external airflow rate handled by the AHU [kg/s];

- cp is the specific heat at constant pressure, it can be considered constant and equal to 1005 J/(kgK);

- r is the heat of vaporization, it can be considered constant and equal to 2501 kJ/kg;

- TA and TS are the temperatures of the extracted air and the supply air, respectively [K]; and,

- xA and xS are the humidity ratio in the extracted air and in the supply air, respectively [g/kg].

Indeed, when the flow rate is halved, going from 14,000 m3/h to 7000 m3/h, the plant is able to guarantee the thermal power balance, as described by Equation (1), since it does not need to compensate for the maximum sensible load during the tests, due to milder external climatic conditions when compared to the design condition and to a not complete occupation of the Aula Magna. Nevertheless, when the flow rate was halved, going from 14,000 m3/h to 7000 m3/h, the plant was not always able to guarantee the needed balance of the latent heat described by Equation (2); even in this case, the maximum latent load condition was never recorded; however, the registered occupancy has always been higher than half of the design value.

As mentioned, the full employment of the Aula Magna never occurred during the days in which the measures were carried out. Thus, simulation was used in order to check the maximum load condition (sensible and latent). The simulations confirmed the above-mentioned observations, namely: the plant is always able to maintain temperature control, while, as the flow rate decreases, difficulties in controlling relative humidity become evident (as shown in Table 4).

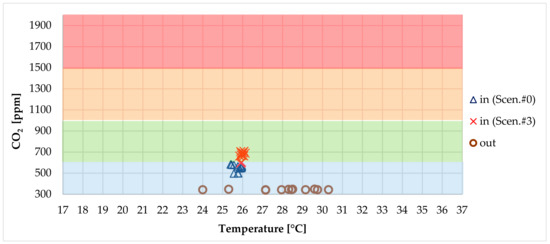

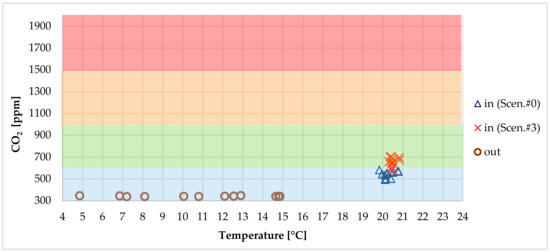

Figure 8, Figure 9 and Figure 10 show the results of the in-situ measurements in the two different operating conditions (Scen. #0; Scen. #3), for each of the selected pollutants. In addition, the graphs background has been coloured while using the corresponding pollutants concentration levels, as previously shown in Table 1 in order to immediately grasp the changes in the air quality level.

Figure 8.

Carbon dioxide concentration.

Figure 9.

PM10 concentration.

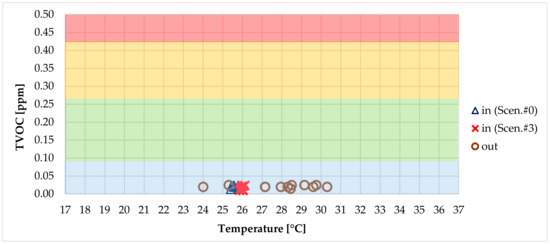

Figure 10.

TVOC concentration.

With regard to the concentration of carbon dioxide (Figure 10), there are substantial differences between the two monitored conditions. The value of the average concentration changes from 548 ppm (Scen. #0) to 663 ppm (Scen. #3), corresponding to a worsening of CO2 index level, which passes from the “good” to the “moderate” value.

Regarding PM10 concentration (Figure 11), there are minimal differences between the two monitored conditions. In fact, the value of the average concentration passes from 23 μg/m3 to 21 μg/m3, with an improvement that does not significantly affect the index level relative to PM10, which remains in both situations “good”. In relative terms, taking the outdoor air as reference, characterized by an average PM10 concentration (27 μg/m3), the decrease due to the action of the filters is slightly higher in the ex-post situation, a direct consequence of flow rate decrease.

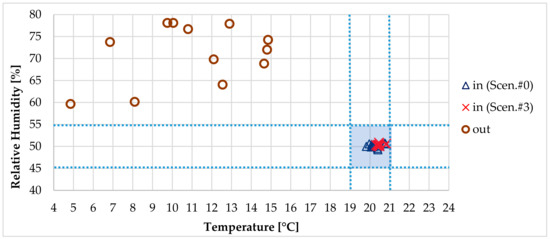

Figure 11.

Relative humidity vs air temperature.

Regarding the TVOC concentration (Figure 12), there are minimal differences between the two monitored conditions, and both cases remain well within a “good” value. It can be observed the very slight differences between the two conditions characterized by an average concentration of 0.018 ppm (Scen. #0) and by an average concentration of 0.016 ppm (Scen. #3); in both cases the average concentration of external air remains higher, being equal to 0.021 ppm.

Figure 12.

CO2 concentration.

However, it is noteworthy that, for the examined case study, the concentration of TVOC detected in the internal environment is strongly affected by the cleaning operations that were carried out in the morning, before the room was occupied. Indeed, as the Aula Magna is not continuously occupied, it can happen that it remains inactive for few days, during which normal cleaning operations are carried out and while natural ventilation is almost zero. In this situation, the TVOC concentration is always higher when the plant is started up and it progressively decreases.

3.3. Measurement Campaign—Winter Operation

The measurements related to winter operation, as shown in Table 9, were carried out with the same conditions as the ones used for summer operation in terms of operating conditions (full flow rate and half flow rate) and relative to the positioning of the measuring instruments. Moreover, the full occupation of the Aula Magna (400 seats) has never occurred in this case.

Table 9.

Measurement campaign results—winter operation.

Figure 11 shows the results of measurements of temperature and relative humidity; it can be seen how the HVAC system, operating at nominal flow (Scen. #3), is able to maintain the environmental parameters within the comfort range (T = 20 ± 1 °C; RH= 50 ± 5 %), which confirms what has already been seen for the summer season. However, there is an interesting difference with respect to the summer season; indeed, the HVAC system is able to maintain the environmental parameters within the comfort range, even in half-capacity operation during winter season.

Additionally, in this case, the reason must be found in the relationship between the handled airflow rate and the sensible and latent loads (for winter season), according to the balances that are described by previously Equations (1) and (2).

In winter season, the air changes include adiabatic air humidification. In winter operation at a reduced flow rate, it is sufficient to humidify the air less to maintain the relative humidity value in the comfort range.

Additionally, during winter, the Aula Magna was never fully occupied. Therefore, it was necessary to check the maximum load condition (sensible and latent) by using simulations. The simulation results confirmed that the plant is always able to maintain control of temperature and relative humidity (Table 5).

Figure 12, Figure 13 and Figure 14 show the results of the measurements that were carried out in the two different operating conditions (Scen. #0; Scen. #3), for each of the selected pollutants.

Figure 13.

PM10 concentration.

Figure 14.

TVOC concentration.

With regard to the CO2 concentration (Figure 12), the results confirm what has already been seen for summer operation. The value of the average concentration goes from 539 ppm (Scen. #0) to 647 ppm (Scen.# 3), with a deterioration that affects the level of the carbon dioxide index, which passes from the “good” value to the “moderate” one.

Regarding PM10 concentration (Figure 13), there are minimal differences between the two monitored conditions, similarly to what has already been observed for the summer season. The average concentration value goes from 23.5 μg/m3 (Scen. #0) to 20.6 μg/m3 (Scen. #3), with a slight improvement in the level of the PM10 index, which remains, on average, in both situations at a “good” value.

Regarding TVOC concentration (Figure 14), there are minimal differences between the two monitored conditions, both of which remain within the “good” value. In fact, it passes from an average concentration of 0.019 ppm (Scen. #0) to an average concentration of 0.015 ppm (Scen. #3), thus it remains lower than the average concentration of external air that is equal to 0.020 ppm.

3.4. Discussion

As expected, simulations proved that reducing the airflow rate the energy consumption would also decrease; by reducing the airflow rate by 50% the energy consumption might be reduced by 28.3% in summer operation and by 58.6% in winter operation. On the other hand, the measurement campaign showed the following results:

- the HVAC system is able to control the indoor temperature, even with half of the flow rate;

- in summer operation, the relative humidity was increased, due to the lesser ability of the system to dilute the water vapour linked to the decreased airflow rate, but was still acceptable (i.e., 53%);

- in winter operation, the HVAC system was able to maintain the relative humidity within the design range by humidifying the halved external airflow rate to a lesser extent;

- CO2 concentration with 50% of the nominal airflow rate resulted to be higher but it is still within the moderate class, namely: it shifts from 539 ppm (good) to 663 ppm (moderate) in summer and from 539 ppm (good) to 647 ppm (moderate) in winter; and,

- concentration of other pollutants decreases proportionally with the airflow rate.

Hence, it is clear that a decrease in the airflow rate causes a decrease in IEQ; thus, it is required to set a threshold on IEQ level, so as to control the minimum airflow rate accordingly. Precisely, the approach should focus on setting the pollutants concentration instead of setting the airflow rate in order to ensure acceptable energy performance as well as IEQ level [44]. By doing this, the airflow rate should then be evaluated based on the actual occupancy rate in the indoor environment [45,46,47].

A building automation control system that is able to control the HVAC system by means of real-time measures and the evaluation of an omni-comprehensive Indoor Air Quality Index (IAQI) is required to maximise such an approach [39].

4. Conclusions

The aim of this work is the evaluation of building energy consumptions and IEQ, varying the air ventilation rates. The analysis has been developed by means of (i) dynamic simulations and (ii) an in-situ measurement campaign analysing a relevant case study, such as the Aula Magna of the Faculty of Architecture of Sapienza University of Rome. The case study can be considered to be significant for many highly crowded, ancient school buildings, whose HVAC system was installed in a later stage.

The obtained results show that the energy consumptions may be strongly reduced (i.e., up to 45%) by decreasing the airflow rate by 50% with slight variations in the IEQ. Indeed, PM10 and TVOC variations are insignificant, while the CO2 concentration is increased by up to 100 ppm and RH is increased for a maximum of 3% during summer.

Hence, measures that aim at increasing the energy efficiency of HVAC systems can be very efficient in highly crowded university building, even if the occupancy level is not very high. Furthermore, it is also evident that a prescriptive approach, which is based on supplying the prescribed airflow rate despite the actual occupancy and pollutants concentrations, is not as effective as approaches that are based on performance able to adjust depending on real-time monitoring and current pollutants concentrations.

Even if the results are strictly linked to the peculiar case study, which presents high but irregular occupancy, and even more important that has a HVAC system designated to supply one single environment (i.e., the Aula Magna), they can be considered to be relevant for many similar buildings.

Nevertheless, future researches will analyse different case studies with diverse end uses and occupancy schedules, so as to test the proposed solution and validate the obtained results in several boundary conditions.

Author Contributions

F.M., D.G. and F.N. contributes to this paper by the conceptualization, building dynamic simulation and validation; F.R. has carried out the monitoring campaign; C.R. and F.M. are the project scientific coordinators, conceived the study and were in charge of overall direction and planning taking care of funding acquisition and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

This work is a part of a wider research activity dealing with: “Misure di qualità dell’aria esterna ed interna in un edificio ad elevate prestazioni di proprietà della PA per la ottimizzazione delle portate di aria di ricambio finalizzate all’efficienza energetica”. The project has been carried out in cooperation with ENEA-DUEE (Italian National Agency for Technologies, Energy and Sustainable Economic Development-Energy Efficiency Department) and DPDTA (Sapienza University of Rome-Department of Planning, Design, and Technology of Architecture). The aforementioned institutions are gratefully acknowledged by the authors for their support and funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Soares, N.; Bastos, J.; Pereira, L.D.; Soares, A.; Amaral, A.R.; Asadi, E.; Rodrigues, E.; Lamas, F.B.; Monteiro, H.; Lopes, M.A.R.; et al. A review on current advances in the energy and environmental performance of buildings towards a more sustainable built environment. Renew. Sustain. Energy Rev. 2017, 77, 845–860. [Google Scholar] [CrossRef]

- Anderson, J.E.; Wulfhorst, G.; Lang, W. Energy analysis of the built environment—A review and outlook. Renew. Sustain. Energy Rev. 2015, 44, 149–158. [Google Scholar] [CrossRef]

- Frontczak, M.; Wargocki, P. Literature survey on how different factors influence human comfort in indoor environments. Build. Environ. 2011, 46, 922–937. [Google Scholar] [CrossRef]

- Al horr, Y.; Arif, M.; Katafygiotou, M.; Mazroei, A.; Kaushik, A.; Elsarrag, E. Impact of indoor environmental quality on occupant well-being and comfort: A review of the literature. Int. J. Sustain. Built Environ. 2016, 5, 1–11. [Google Scholar] [CrossRef]

- Wolkoff, P. Indoor air humidity, air quality, and health—An overview. Int. J. Hyg. Environ. Health 2018, 221, 376–390. [Google Scholar] [CrossRef]

- Kang, S.; Ou, D.; Mak, C.M. The impact of indoor environmental quality on work productivity in university open-plan research offices. Build. Environ. 2017, 124, 78–89. [Google Scholar] [CrossRef]

- Becker, R.; Goldberger, I.; Paciuk, M. Improving energy performance of school buildings while ensuring indoor air quality ventilation. Build. Environ. 2007, 42, 3261–3276. [Google Scholar] [CrossRef]

- De Santoli, L.; Garcia, D.A.; Groppi, D.; Bellia, L.; Palella, B.I.; Riccio, G.; Cuccurullo, G.; d’Ambrosio, F.R.; Stabile, L.; Dell’Isola, M.; et al. A General Approach for Retrofit of Existing Buildings Towards NZEB: The Windows Retrofit Effects on Indoor Air Quality and the Use of Low Temperature District Heating. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar]

- Manfren, M.; Nastasi, B.; Piana, E.; Tronchin, L. On the link between energy performance of building and thermal comfort: An example. In Proceedings of the AIP Conference Proceedings (TMREES19), Beirut, Lebanon, 10–12 April 2019; AIP Publishing LLC: Melville, NY, USA, 2019; Volume 2123, p. 020066. [Google Scholar]

- Šujanová, P.; Rychtáriková, M.; Sotto Mayor, T.; Hyder, A. A Healthy, Energy-Efficient and Comfortable Indoor Environment, a Review. Energies 2019, 12, 1414. [Google Scholar] [CrossRef]

- Allab, Y.; Pellegrino, M.; Guo, X.; Nefzaoui, E.; Kindinis, A. Energy and comfort assessment in educational building: Case study in a French university campus. Energy Build. 2017, 143, 202–219. [Google Scholar] [CrossRef]

- Dias Pereira, L.; Neto, L.; Bernardo, H.; Gameiro da Silva, M. An integrated approach on energy consumption and indoor environmental quality performance in six Portuguese secondary schools. Energy Res. Soc. Sci. 2017, 32, 23–43. [Google Scholar] [CrossRef]

- Zuhaib, S.; Manton, R.; Griffin, C.; Hajdukiewicz, M.; Keane, M.M.; Goggins, J. An Indoor Environmental Quality (IEQ) assessment of a partially-retrofitted university building. Build. Environ. 2018, 139, 69–85. [Google Scholar] [CrossRef]

- Balocco, C.; Colaianni, A. Assessment of energy sustainable operations on a historical building. The Dante Alighieri high school in Florence. Sustainability 2018, 10, 2054. [Google Scholar] [CrossRef]

- De Santoli, L.; Mancini, F.; Rossetti, S.; Nastasi, B. Energy and system renovation plan for Galleria Borghese, Rome. Energy Build. 2016, 129, 549–562. [Google Scholar] [CrossRef]

- Legislative Decree no. 102/2014. Implementation of Directive 2012/27/EU. 2010, pp. 1–39. Available online: https://www.gazzettaufficiale.it/atto/vediMenuHTML;jsessionid=A+nWnzbPN4bZ5rVKTNAPXQ__.ntc-as2-guri2b?atto.dataPubblicazioneGazzetta=2014-07-18&atto.codiceRedazionale=14G00113&tipoSerie=serie_generale&tipoVigenza=originario (accessed on 1 December 2019).

- Mikučionienė, R.; Martinaitis, V.; Keras, E. Evaluation of energy efficiency measures sustainability by decision tree method. Energy Build. 2014, 76, 64–71. [Google Scholar] [CrossRef]

- Chung, M.H.; Rhee, E.K. Potential opportunities for energy conservation in existing buildings on university campus: A field survey in Korea. Energy Build. 2014, 78, 176–182. [Google Scholar] [CrossRef]

- Han, Y.; Zhou, X.; Luo, R. Analysis on Campus Energy Consumption and Energy Saving Measures in Cold Region of China. Procedia Eng. 2015, 121, 801–808. [Google Scholar] [CrossRef]

- Amber, K.P.; Aslam, M.W.; Mahmood, A.; Kousar, A.; Younis, M.Y.; Akbar, B.; Chaudhary, G.Q.; Hussain, S.K. Energy Consumption Forecasting for University Sector Buildings. Energies 2017, 10, 1579. [Google Scholar] [CrossRef]

- Congedo, P.; D’Agostino, D.; Baglivo, C.; Tornese, G.; Zacà, I. Efficient Solutions and Cost-Optimal Analysis for Existing School Buildings. Energies 2016, 9, 851. [Google Scholar] [CrossRef]

- Daisey, J.M.; Angell, W.J.; Apte, M.G. Indoor air quality, ventilation and health symptoms in schools: An analysis of existing information. Indoor Air 2003, 13, 53–64. [Google Scholar] [CrossRef]

- Zhong, L.; Yuan, J.; Fleck, B. Indoor Environmental Quality Evaluation of Lecture Classrooms in an Institutional Building in a Cold Climate. Sustainability 2019, 11, 6591. [Google Scholar] [CrossRef]

- Mihai, T.; Iordache, V. Determining the Indoor Environment Quality for an Educational Building. Energy Procedia 2016, 85, 566–574. [Google Scholar] [CrossRef]

- Almeida, R.M.S.F.; de Freitas, V.P. Indoor environmental quality of classrooms in Southern European climate. Energy Build. 2014, 81, 127–140. [Google Scholar] [CrossRef]

- Merema, B.; Delwati, M.; Sourbron, M.; Breesch, H. Demand controlled ventilation (DCV) in school and office buildings: Lessons learnt from case studies. Energy Build. 2018, 172, 349–360. [Google Scholar] [CrossRef]

- Aste, N.; Manfren, M.; Marenzi, G. Building Automation and Control Systems and performance optimization: A framework for analysis. Renew. Sustain. Energy Rev. 2017, 75, 313–330. [Google Scholar] [CrossRef]

- Mancini, F.; Lo Basso, G.; de Santoli, L. Energy Use in Residential Buildings: Impact of Building Automation Control Systems on Energy Performance and Flexibility. Energies 2019, 12, 2896. [Google Scholar] [CrossRef]

- Chenari, B.; Dias Carrilho, J.; Gameiro da Silva, M. Towards sustainable, energy-efficient and healthy ventilation strategies in buildings: A review. Renew. Sustain. Energy Rev. 2016, 59, 1426–1447. [Google Scholar] [CrossRef]

- Ben-David, T.; Waring, M.S. Impact of natural versus mechanical ventilation on simulated indoor air quality and energy consumption in offices in fourteen U.S. cities. Build. Environ. 2016, 104, 320–336. [Google Scholar] [CrossRef]

- Mui, K.W.; Wong, L.T.; Hui, P.S. Indoor Environmental Quality Benchmarks for Air-conditioned Offices in the Subtropics. Indoor Built Environ. 2009, 18, 123–129. [Google Scholar] [CrossRef]

- Wong, L.; Mui, K.; Tsang, T. Evaluation of Indoor Air Quality Screening Strategies: A Step-Wise Approach for IAQ Screening. Int. J. Environ. Res. Public Health 2016, 13, 1240. [Google Scholar] [CrossRef]

- Gabriel Rojas Rainer Pfluger, W.F. Ventilation concepts for energy efficient housing in Central European climate—A simulation study comparing indoor air quality, mould risk and ventilation losses. In Proceedings of the Indoor Air 2016, Ghent, Belgium, 3–8 July 2016. [Google Scholar]

- Karami, M.; McMorrow, G.V.; Wang, L. Continuous monitoring of indoor environmental quality using an Arduino-based data acquisition system. J. Build. Eng. 2018, 19, 412–419. [Google Scholar] [CrossRef]

- Vilčeková, S.; Apostoloski, I.; Mečiarová, Ľ.; Burdová, E.; Kiseľák, J. Investigation of Indoor Air Quality in Houses of Macedonia. Int. J. Environ. Res. Public Health 2017, 14, 37. [Google Scholar] [CrossRef] [PubMed]

- Bianco, V.; De Rosa, M.; Scarpa, F.; Tagliafico, L.A. Analysis of energy demand in residential buildings for different climates by means of dynamic simulation. Int. J. Ambient Energy 2016, 37, 108–120. [Google Scholar] [CrossRef]

- Mancini, F.; Cecconi, M.; De Sanctis, F.; Beltotto, A. Energy Retrofit of a Historic Building Using Simplified Dynamic Energy Modeling. Energy Procedia 2016, 101, 1119–1126. [Google Scholar] [CrossRef]

- De Santoli, L.; Mancini, F.; Clemente, C.; Lucci, S. Energy and technological refurbishment of the School of Architecture Valle Giulia, Rome. Energy Procedia 2017, 133, 382–391. [Google Scholar] [CrossRef]

- Chiesa, G.; Cesari, S.; Garcia, M.; Issa, M.; Li, S. Multisensor IoT Platform for Optimising IAQ Levels in Buildings through a Smart Ventilation System. Sustainability 2019, 11, 5777. [Google Scholar] [CrossRef]

- Kang, J.; Hwang, K.-I. A Comprehensive Real-Time Indoor Air-Quality Level Indicator. Sustainability 2016, 8, 881. [Google Scholar] [CrossRef]

- Hnat, T.W.; Srinivasan, V.; Lu, J.; Sookoor, T.I.; Dawson, R.; Stankovic, J.; Whitehouse, K. The hitchhiker’s guide to successful residential sensing deployments. In Proceedings of the SenSys 2011—9th ACM Conference on Embedded Networked Sensor Systems, Seattle, WA, USA, 1–4 November 2011; pp. 232–245. [Google Scholar]

- Pereira, P.F.; Ramos, N.M.M. The influence of sensor placement in the study of occupant behavior in a residential building. In Proceedings of the 2018 International Conference on Smart Energy Systems and Technologies (SEST), Sevilla, Spain, 10–12 September 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018. [Google Scholar]

- UNI Ente Italiano di Normazione Italian technical standard UNI/TS 11300-1:2014—Energy Performance of Buildings—Evaluation of Energy Need for Space Heating and Cooling. Available online: http://store.uni.com/catalogo/index.php/uni-ts-11300-1-2014.html (accessed on 18 September 2019).

- Han, K.; Zhang, J.S.; Guo, B. A novel approach of integrating ventilation and air cleaning for sustainable and healthy office environments. Energy Build. 2014, 76, 32–42. [Google Scholar] [CrossRef]

- Noris, F.; Delp, W.W.; Vermeer, K.; Adamkiewicz, G.; Singer, B.C.; Fisk, W.J. Protocol for maximizing energy savings and indoor environmental quality improvements when retrofitting apartments. Energy Build. 2013, 61, 378–386. [Google Scholar] [CrossRef]

- Turner, W.J.N.; Logue, J.M.; Wray, C.P. A combined energy and IAQ assessment of the potential value of commissioning residential mechanical ventilation systems. Build. Environ. 2013, 60, 194–201. [Google Scholar] [CrossRef]

- Leivo, V.; Turunen, M.; Aaltonen, A.; Kiviste, M.; Du, L.; Haverinen-Shaughnessy, U. Impacts of Energy Retrofits on Ventilation Rates, CO2-levels and Occupants’ Satisfaction with Indoor Air Quality. Energy Procedia 2016, 96, 260–265. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).