Potential of Sustainable Concept for Handling Organic Waste in Tunisia

Abstract

1. Introduction

2. Background Information

2.1. Study Area: Coastline of Tunisia

2.2. Biowaste Sources: Land-Use Planning per Sector of Activity

2.2.1. Urban Sector

2.2.2. Touristic Sector

2.2.3. Agricultural Sector

2.2.4. Industrial Sector

2.3. Current Waste Management System in Tunisia

2.4. Alternatives for Biowaste Recovery in Tunisia: Compost or Biogas?

3. Materials and Methods

3.1. Data Collection

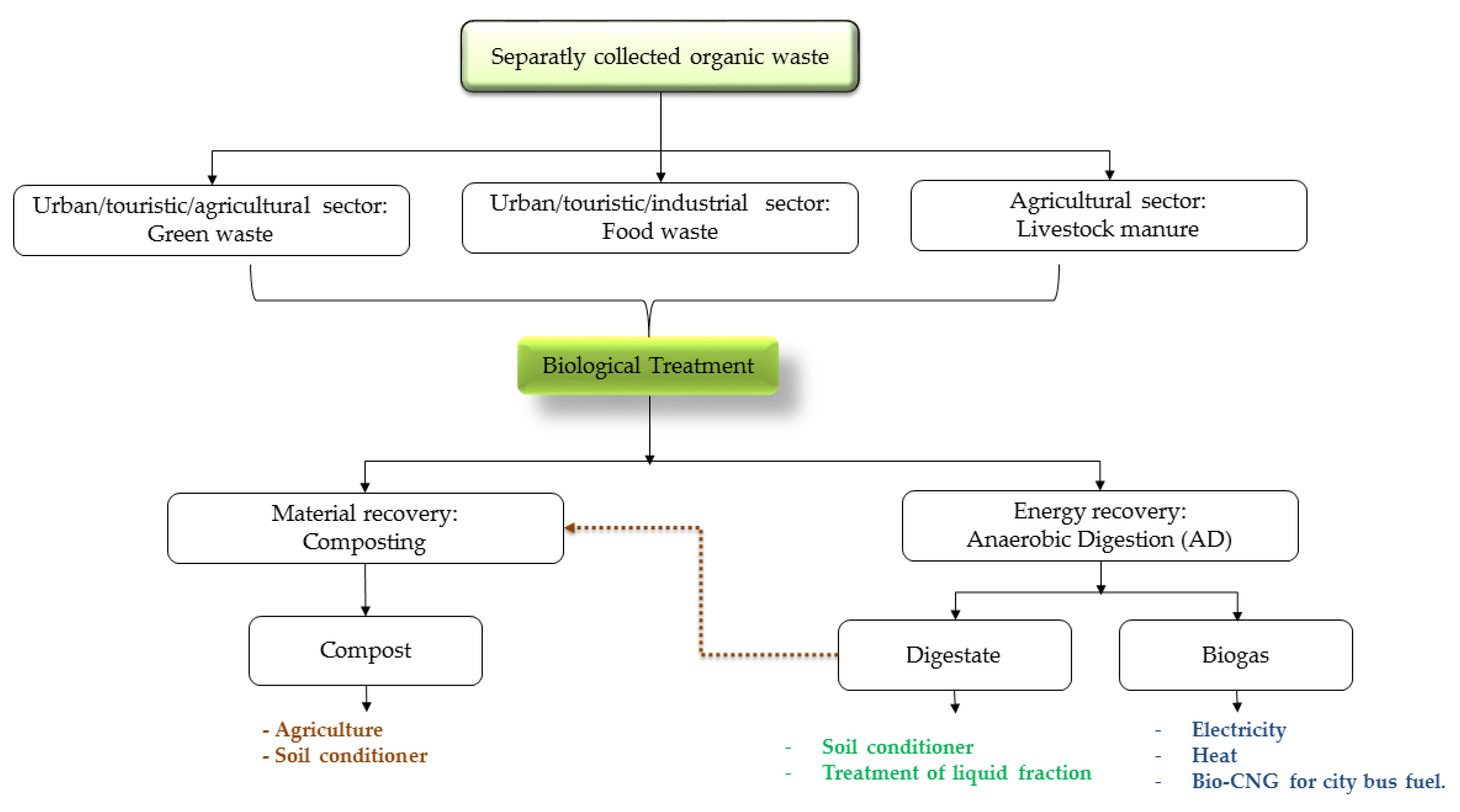

3.2. General Description of the Methodology: ECO-Concept for Biowaste Recovery in Tunisia

3.3. Upcycling of Biowaste Generated from Different Sectors of Activity

3.3.1. Selection and Characterization of Biowaste

3.3.2. Food and Green Waste Co-Composting Process

- P0: 100% GW

- P1: FW:GW = 25:75

- P2: FW:GW = 50:50

- P3: FW:GW = 75:25

3.3.3. Food Waste and Livestock Manure Anaerobic Co-Digestion Process

3.4. Economical Evaluation of ECO-Concept

- is the annual distribution of the capital cost;

- ri is the interest rate [%];

- tdebt is the annual debt [year]; and

- CAPEX is the capital expenditure.

- LEC is the levelized cost of electricity;

- is the annual distribution of the operational cost;

- rd is the discount rate [%]; and

- E_(el-y) is the annual power production [MWe/year].

- f is the inflation rate [%];

- Il is the income for the first year [US $];

- Dt is the level of production [kWh/tons per day]; and

- AWMP is the average market price [US $].

4. Results and Discussion

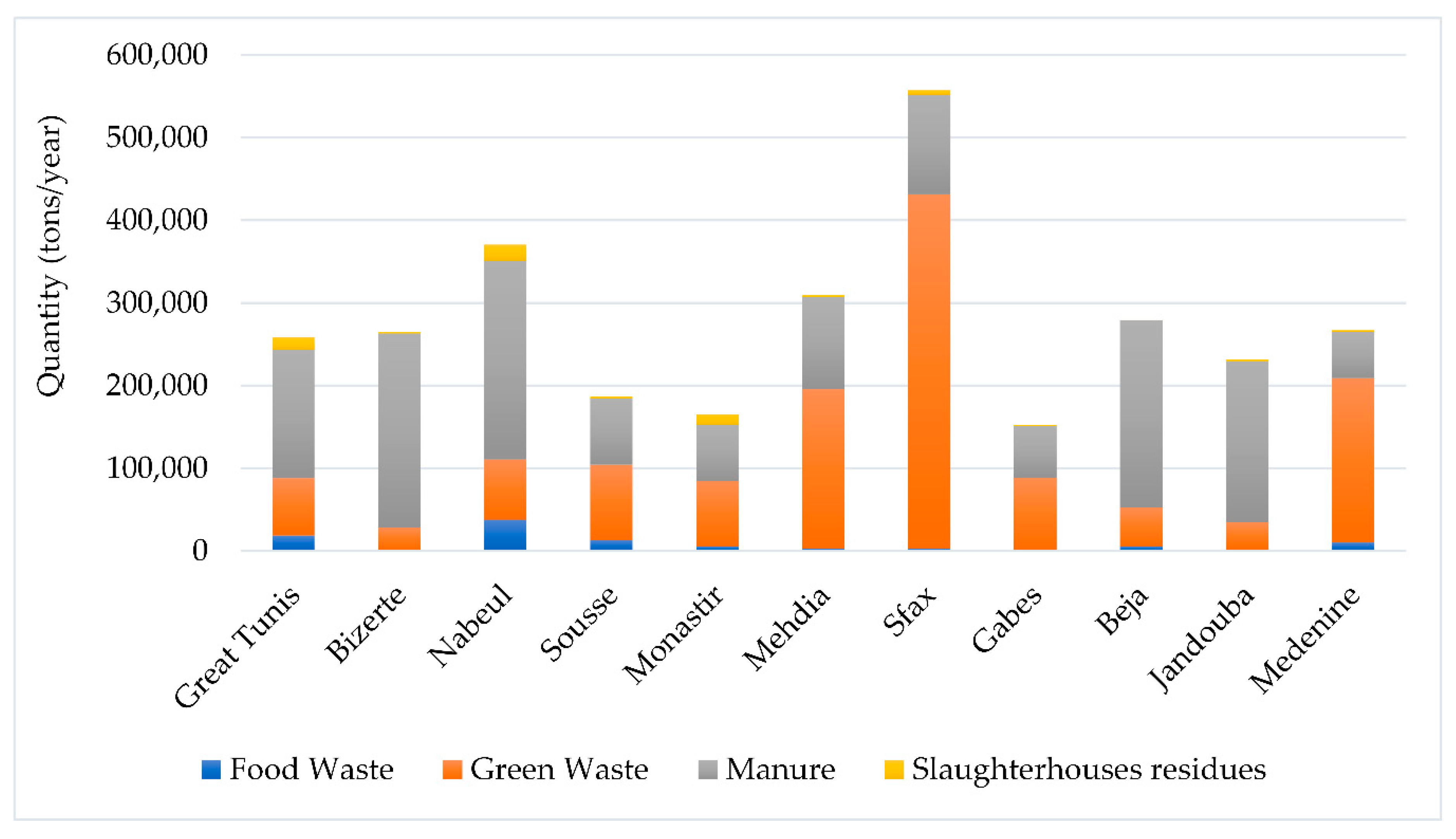

4.1. Potential of Biowaste in Tunisia: Quantification of Biowaste per Sector of Activity

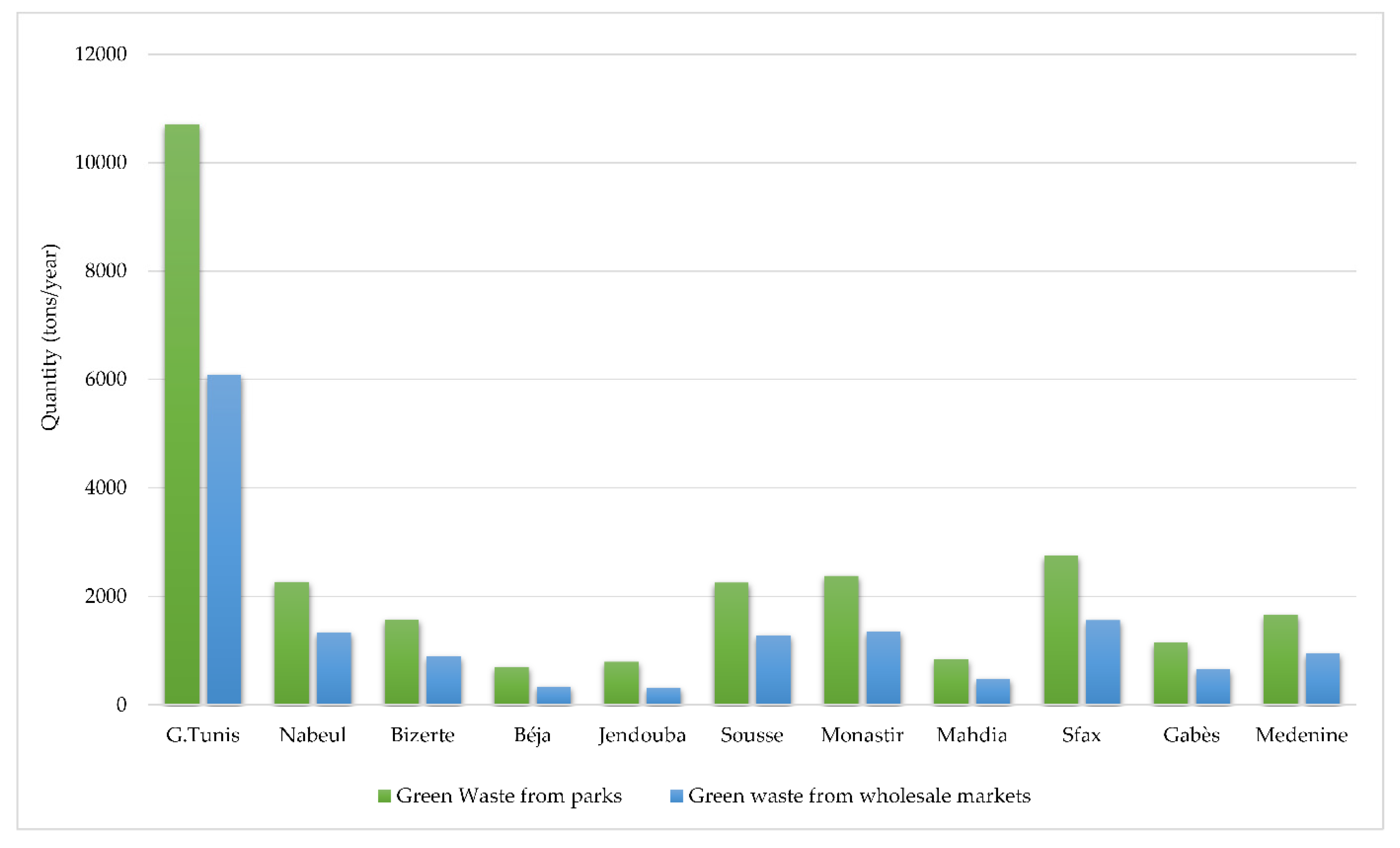

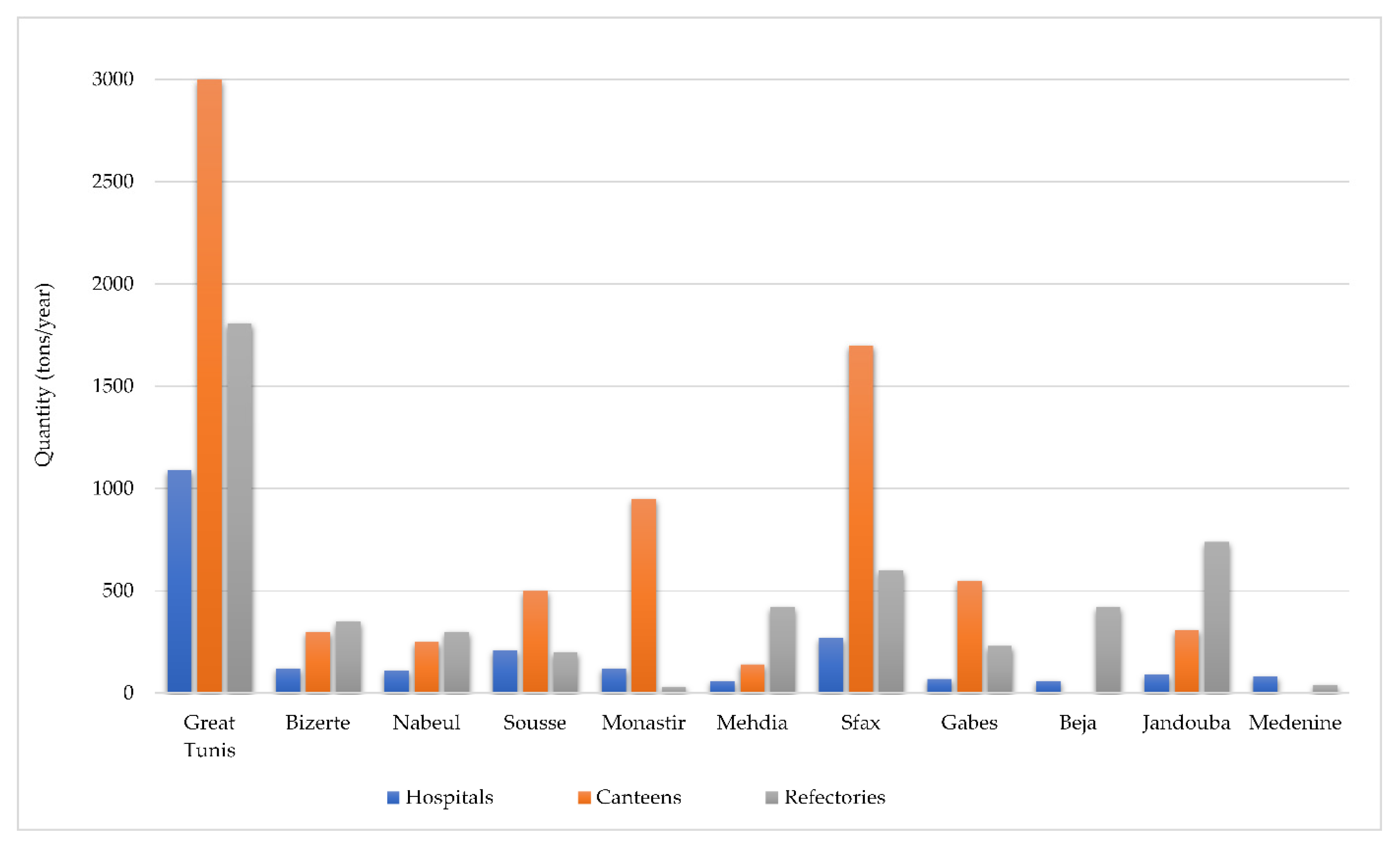

4.1.1. Biowaste Generated by the Urban Sector

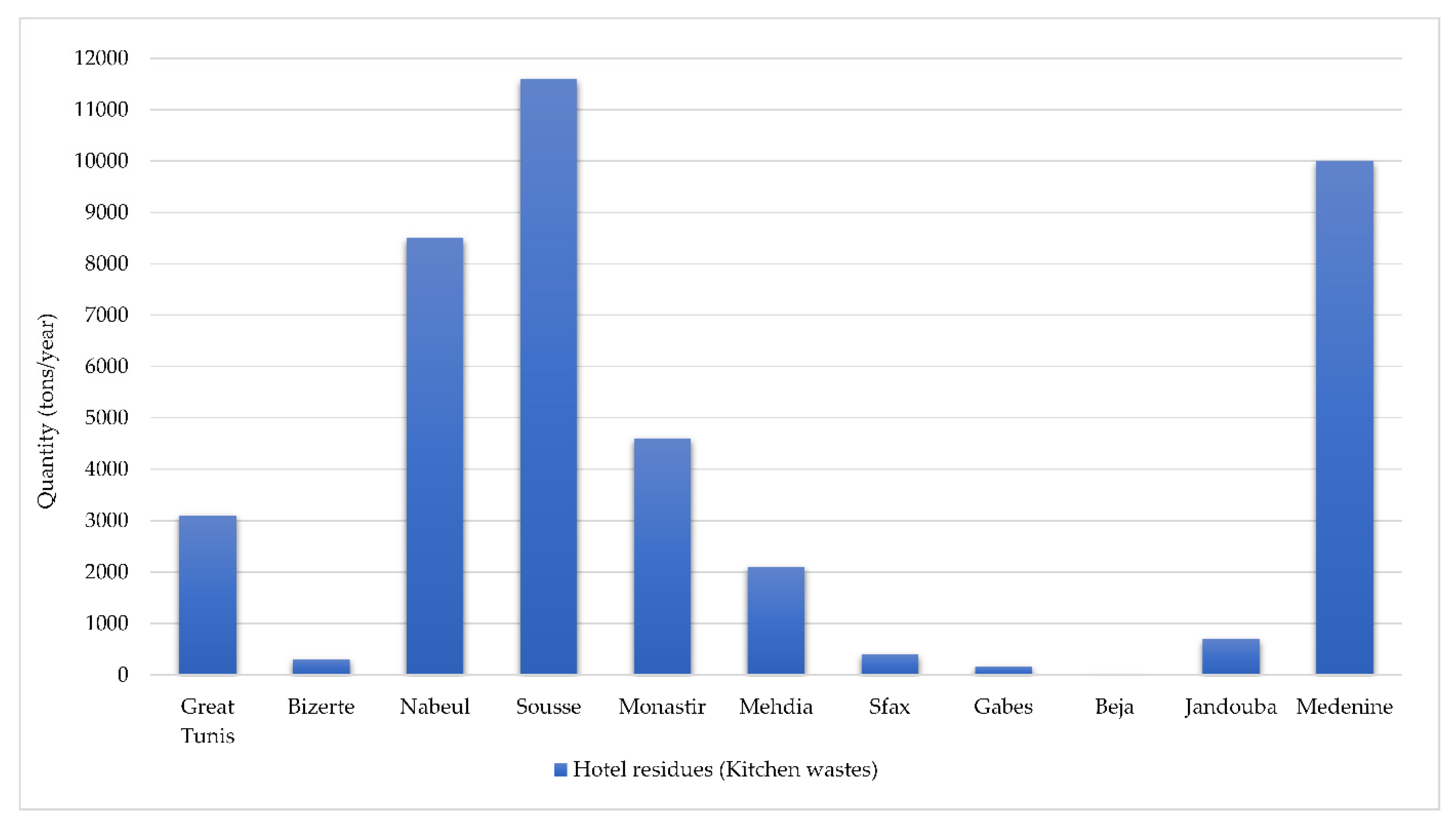

4.1.2. Biowaste Generated by the Tourism Sector

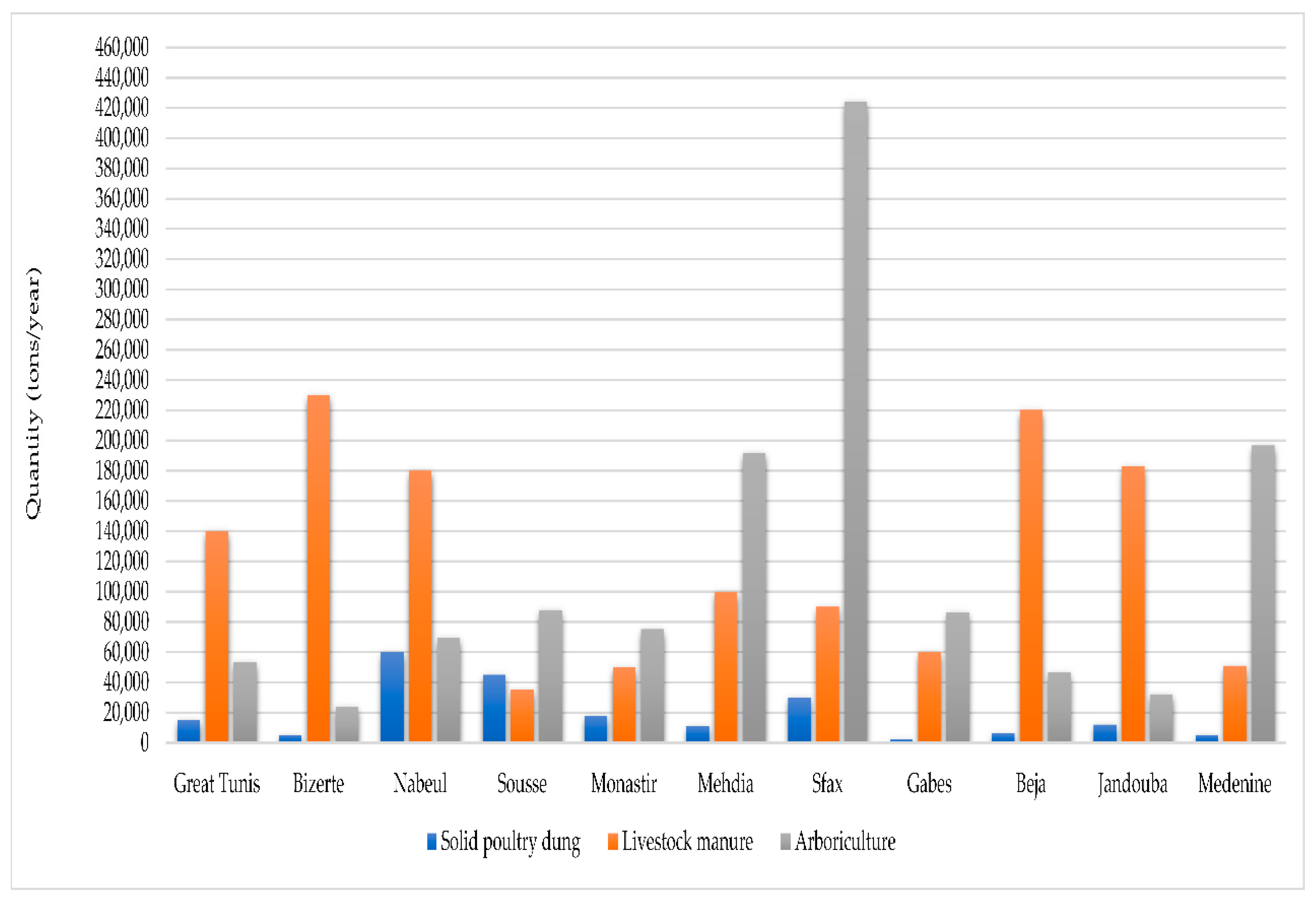

4.1.3. Biowaste Generated by the Agricultural Sector

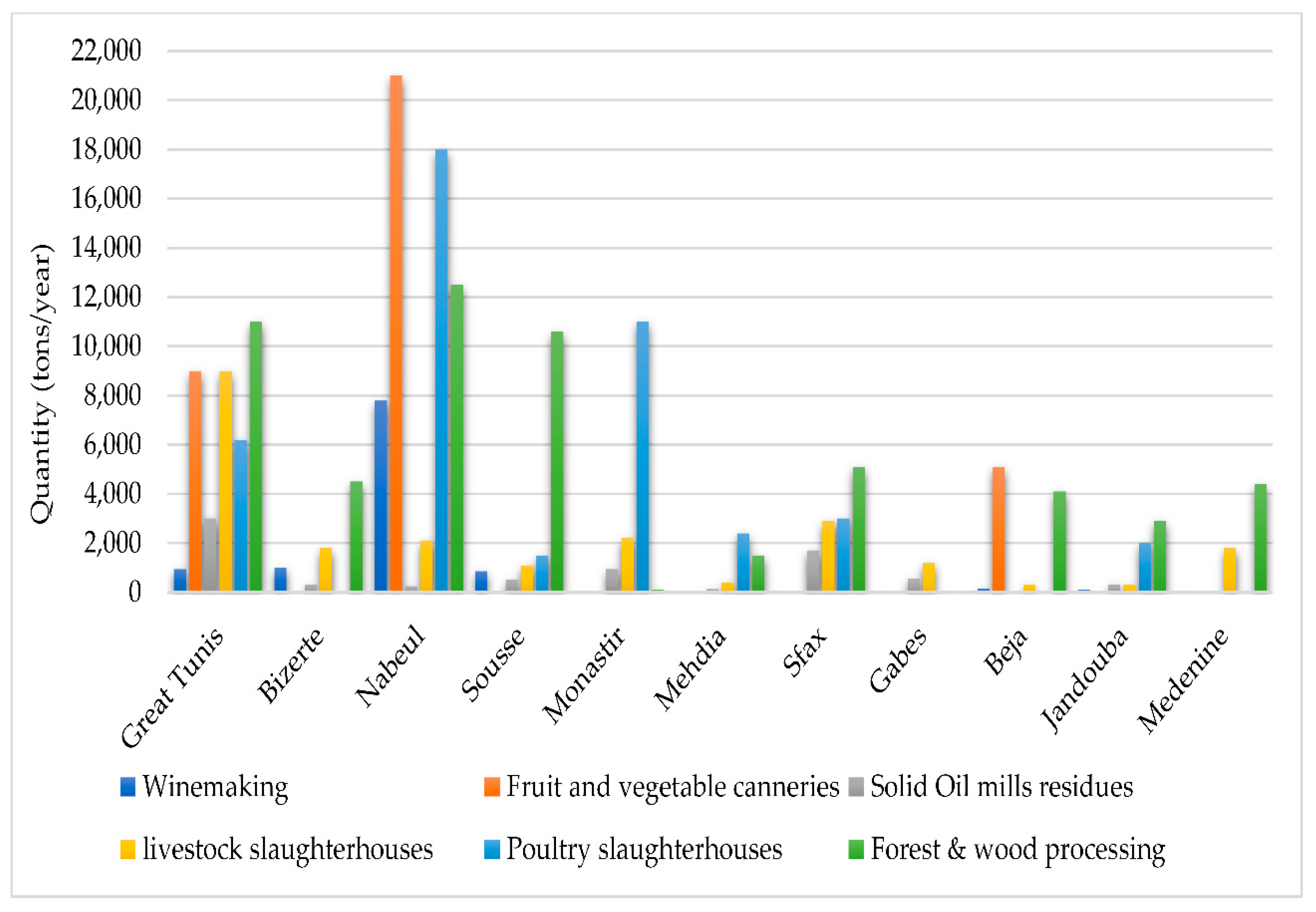

4.1.4. Biowaste Generated by the Industrial Sector

4.2. Lab-Scale Biological Process Performance

4.2.1. Characterization of the Selected Biowaste

4.2.2. Evaluation of Food and Green Waste Co-Composting Performance

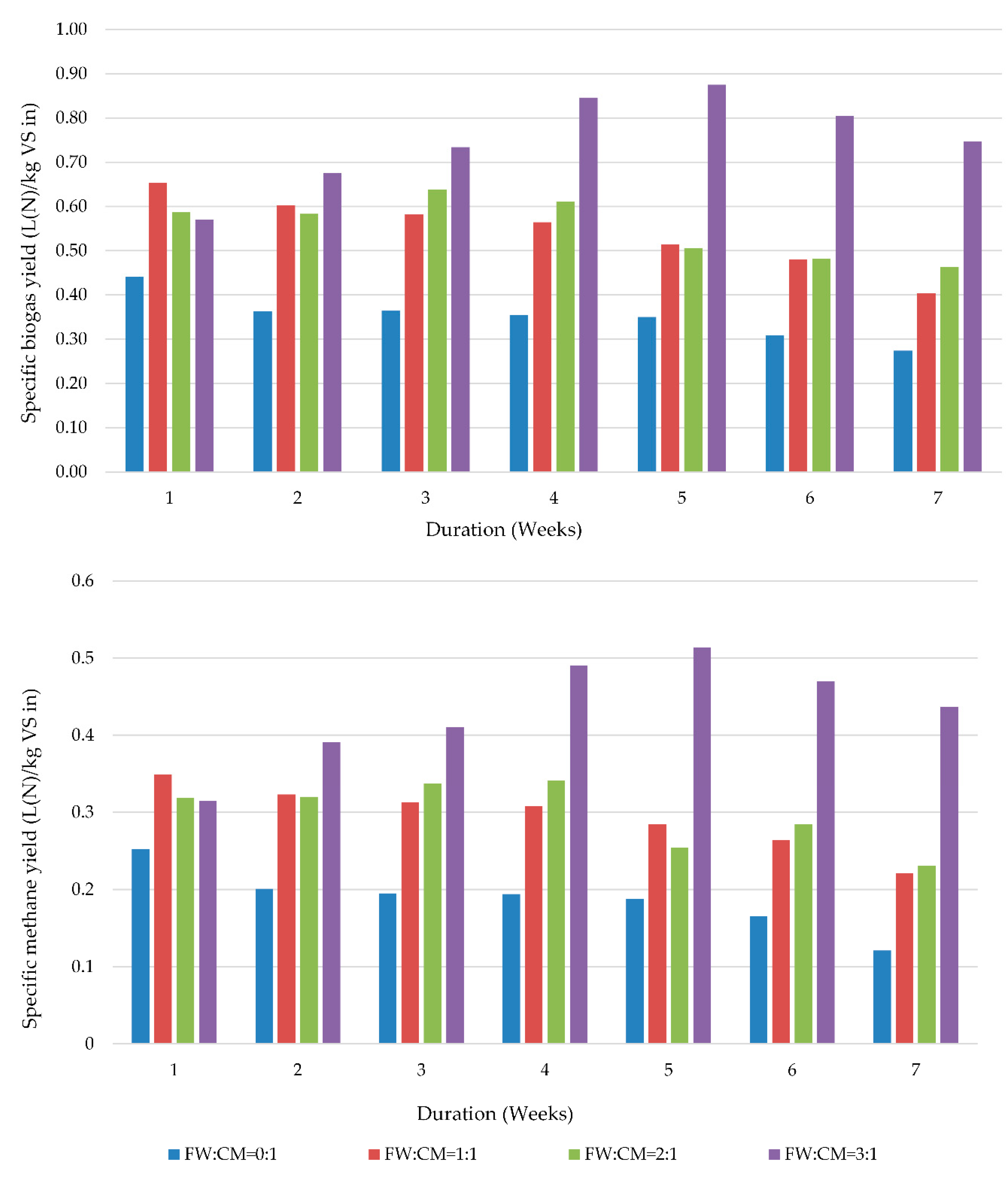

4.2.3. Evaluation of Food Waste and Cattle Manure Anaerobic Co-Digestion Performance

4.3. Technical and Economic Feasibility Analysis of Aerobic Treatment in Tunisia

4.3.1. Design of a Composting Plant

4.3.2. Cost–Benefit of Establishing a Composting Plant in Tunisia

- Scenario 1: Designing a triangular windrow section from green residues only (100% GW)

- Volume of material available to be composted = 317 m3/d.

- Assume dimensions of windrow: length = 10 m, height = 2.0 m, and width = 3.5 m.

- Volume of windrow: triangular section V = 1⁄2 × (3.5 × 2.0) × 10 m = 35 m3.

- Number of windrow/days = total volume of material/volume of windrow 317/35 ≈ 9.

- Volume of finished compost = 317 × 0.7 (reduction volume 30%) = 222 m3 d−1 = 66,600 m3 y−1;

- Weight of finished compost ≈ 6926 tons y−1; and

- Profit from compost sale = 6926-ton y−1 X 30 €/ton = 207.792 €/y.

- Scenario 2: Designing a triangular windrow section from FW and GW (1:1)

- Volume of material available to be composted: 50% FW + 50% GW = 55 m3 d−1 + 159 m3 d−1 = 214 m3/d;

- Number of windrows/days = total volume of material/volume of windrow 214/35 ≈ 6;

- Volume of finished compost = 214 × 0.7 (reduction volume 30%) =150 m3 d−1= 45,000 m3 y−1; and

- Mixture density = 200 kg m−3.

- So, the weight of finished compost ≈ 9000 tons y−1.

- Profit from compost sale = 9000 ton/y × 30 €/ton =270,000 €/y.

- Scenario 3: Designing a triangular windrow section from FW and GW (1:3)

- Volume of material available to be composted: 25% FW + 75% GW = 28 m3 d−1 + 238 m3 d−1 = 266 m3/d;

- Number of windrows/days = total volume of material/volume of windrow 214/35 ≈ 8;

- Volume of finished compost = 266 × 0.7(reduction volume 30%) =186 m3 d−1= 55,860 m3 y−1; and

- Mixture density= 153 kg m−3.

- So, the weight of finished compost ≈ 8550 tons y−1.

- Profit from compost sale = 8550 ton/y × 30 €/ton =256,500 €/y.

4.4. Technical and Economic Feasibility Analysis of Anaerobic Treatment in Tunisia

4.4.1. Design of a Biogas Plant

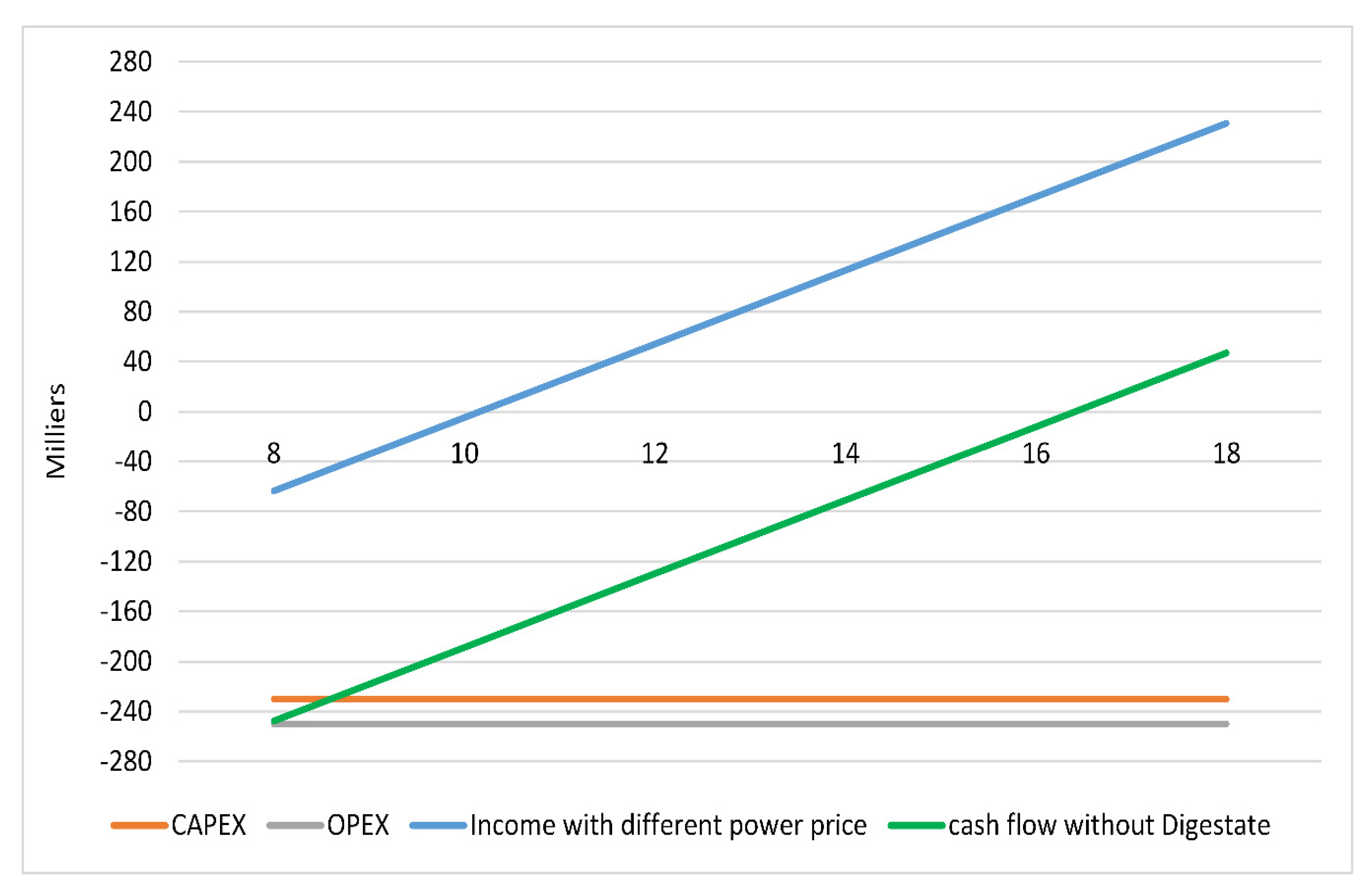

4.4.2. Cost–Benefit of Establishing a Composting Plant in Tunisia

- At a selling price of 8 cent/kwh, it is not worth building such a plant.

- The digestate should be included in the income streams to increase the affordability of the plant and to determine the economic life of the project.

- The optimum price for determining a matching level among all the cash streams is 18 cent/kwh as a power price. Furthermore, the payback percentage must be increased to around 25–30% of the income to cover the cost of loans or any other commitment.

4.5. Mapping of Biowaste and Appropriate Biological Treatment in the Coastal Region of Tunisia

- Infrastructure: location (sufficient space), equipment, water, and energy supplies;

- Raw materials: continuous availability of clean feedstock; and

- Marketing: stable market demand for the output (biogas, digestate/compost).

- The mapping of biowaste generated from different zones (Figure 6);

- Meeting the above-cited challenges;

- Assuming a biogas plant capacity of around 30,000–40,000 tons/year; and

- Assuming a composting plant capacity of around 5000–10,000 tons/year.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, Y.-C. Effects of urbanization on municipal solid waste composition. Waste Manag. 2018, 79, 828–836. [Google Scholar] [CrossRef] [PubMed]

- Brancoli, P.; Bolton, K.; Eriksson, M. Environmental impacts of waste management and valorisation pathways for surplus bread in Sweden. Waste Manag. 2020, 117, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.-J.; Zhao, Y.; Zhang, X.-L.; Bai, Z.-B. Leachate leakage investigation, assessment and engineering countermeasures for tunneling underneath a MSW landfill. Eng. Geol. 2020, 265, 105447. [Google Scholar] [CrossRef]

- What a Waste: An Updated Look into the Future of Solid Waste Management. Available online: https://www.worldbank.org/en/news/immersive-story/2018/09/20/what-a-waste-an-updated-look-into-the-future-of-solid-waste-management (accessed on 26 June 2020).

- Mahjoub, O.; Jemai, A.; Haddaoui, I. Waste Management in Tunisia—What Could the Past Bring to the Future? In The Economics of Water; Springer International Publishing: Cham, Switzerland, 2019; pp. 35–69. [Google Scholar]

- Ammar, S.B. Les Enjeux de la Caractérisation des Déchets Ménagers Pour le Choix des Traitements Adaptés Dans les Pays en Développement: Résultats de la Caractérisation Dans le Grand Tunis Mise au Point d’un Méthode Adaptée. Ph.D. Thesis, Lorraine Polytechnical Institute, National Higher School of Geology of Nancy, Vandœuvre-lès-Nancy, France, 2006; p. 328. [Google Scholar]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Negm, A.M.; Shareef, N. Introduction to the Waste Management in MENA Regions. In Waste Management in MENA Regions; Negm, A.M., Shareef, N., Eds.; Springer Water; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–11. ISBN 978-3-030-18350-9. [Google Scholar]

- Bhatia, S.K.; Joo, H.-S.; Yang, Y.-H. Biowaste-to-bioenergy using biological methods—A mini-review. Energy Convers. Manag. 2018, 177, 640–660. [Google Scholar] [CrossRef]

- Agapiou, A.; Andreas, V.; Marinos, S.; Katerina, M.; Zorpas, A.A. Waste aroma profile in the framework of food waste management through household composting. J. Clean. Prod. 2020, 257, 120340. [Google Scholar] [CrossRef]

- European Economy 2008—European Commission. Available online: https://ec.europa.eu/economy_finance/publications/european_economy/2008/index_en.htm (accessed on 23 September 2020).

- NDE GermanyBMUB Environmental Technologies Export Initiative. Available online: https://www.nde-germany.de/en/profiles/ (accessed on 1 July 2020).

- Hannisdal, R.; Nøstbakken, O.J.; Hove, H.; Madsen, L.; Horsberg, T.E.; Lunestad, B.T. Anti-sea lice agents in Norwegian aquaculture; surveillance, treatment trends and possible implications for food safety. Aquaculture 2020, 521, 735044. [Google Scholar] [CrossRef]

- ANGED. 2014. Available online: http://www.anged.nat.tn/index.php?option=com_content&view=article&id=146 (accessed on 8 July 2019).

- Bank, T.W. Tunisia—Sustainable Municipal Solid Waste Management Project; The World Bank: Tunis, Tunisia, 2015; pp. 1–9. [Google Scholar]

- Chaher, N.E.H.; Chakchouk, M.; Nassour, A.; Nelles, M.; Hamdi, M. Potential of windrow food and green waste composting in Tunisia. Environ. Sci. Pollut. Res. 2020, 1–13. [Google Scholar] [CrossRef]

- Ardolino, F.; Colaleo, G.; Arena, U. The cleaner option for energy production from a municipal solid biowaste. J. Clean. Prod. 2020, 266, 121908. [Google Scholar] [CrossRef]

- Dennehy, C.; Lawlor, P.G.; McCabe, M.; Cormican, P.; Sheahan, J.; Jiang, Y.; Zhan, X.; Gardiner, G. Anaerobic co-digestion of pig manure and food waste; effects on digestate biosafety, dewaterability, and microbial community dynamics. Waste Manag. 2018, 71, 532–541. [Google Scholar] [CrossRef]

- Beggio, G.; Schievano, A.; Bonato, T.; Hennebert, P.; Pivato, A. Statistical analysis for the quality assessment of digestates from separately collected organic fraction of municipal solid waste (OFMSW) and agro-industrial feedstock. Should input feedstock to anaerobic digestion determine the legal status of digestate? Waste Manag. 2019, 87, 546–558. [Google Scholar] [CrossRef]

- Cesàro, A.; Russo, L.; Belgiorno, V. Combined anaerobic/aerobic treatment of OFMSW: Performance evaluation using mass balances. Chem. Eng. J. 2015, 267, 16–24. [Google Scholar] [CrossRef]

- Carabassa, V.; Domene, X.; Alcañiz, J.M. Soil restoration using compost-like-outputs and digestates from non-source-separated urban waste as organic amendments: Limitations and opportunities. J. Environ. Manag. 2020, 255, 109909. [Google Scholar] [CrossRef] [PubMed]

- Abdulrahman, A. Solid Waste Management in Tunisia, EcoMENA, Africa, Recycling. 2 June 2018. Available online: https://www.ecomena.org/solid-waste-management-tunisia/ (accessed on 26 June 2020).

- Ardhaoui, K.; Bellali, F.; Moussa, M. Composting and lixiviation, case study in Médenine-Tunisia. J. Res. Environ. Earth Sci. 2019, 7, 161–167. [Google Scholar]

- Population de la Tunisie 2014–2024. Available online: https://fr.statista.com/statistiques/687752/population-totale-tunisie/ (accessed on 3 February 2020).

- Zhou, J.; Shen, L.; Song, X.; Zhang, X. Selection and modeling sustainable urbanization indicators: A responsibility-based method. Ecol. Indic. 2015, 56, 87–95. [Google Scholar] [CrossRef]

- Chouari, W.; Belarem, M. Enjeux de la Tunisie orientale: Un territoire développé et un environnement à protéger. Confins 2017. [Google Scholar] [CrossRef]

- Tunisie: Rapport de Suivi de la Situation Économique. Available online: https://www.banquemondiale.org/fr/country/tunisia/publication/economic-update-april-2020 (accessed on 23 July 2020).

- Statista—Le Portail de Statistiques. Available online: https://fr.statista.com/map/afrique/tunisie/ (accessed on 18 September 2020).

- Chaabane, W.; Nassour, A.; Nelles, M. Solid Waste Management Key Indicator Development for Hotels: A Tunisian Case Study Analysis. Recycle 2018, 3, 56. [Google Scholar] [CrossRef]

- Pellera, F.-M.; Gidarakos, E. Anaerobic digestion of solid agroindustrial waste in semi-continuous mode: Evaluation of mono-digestion and co-digestion systems. Waste Manag. 2017, 68, 103–119. [Google Scholar] [CrossRef]

- Elnaas, A. Actual situation and Approach for Municipal Solid Waste Treatment in the Arab Region. Ph.D. Thesis, The Academic Board of Rostock University, Rostock, Germany, 2015; p. 152. [Google Scholar]

- Ministère de l’Industrie, de l’Energie et des Mines. Available online: http://www.tunisieindustrie.gov.tn/ (accessed on 18 September 2020).

- Millati, R.; Cahyono, R.B.; Ariyanto, T.; Azzahrani, I.N.; Putri, R.U.; Taherzadeh, M.J. Chapter 1—Agricultural, Industrial, Municipal, and Forest Wastes: An Overview. In Sustainable Resource Recovery and Zero Waste Approaches; Taherzadeh, M.J., Bolton, K., Wong, J., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–22. ISBN 978-0-444-64200-4. [Google Scholar]

- Marzougui, A.; Ben Mammou, A. Impacts of the dumping site on the environment: Case of the Henchir El Yahoudia Site, Tunis, Tunisia. Comptes Rendus Geosci. 2006, 338, 1176–1183. [Google Scholar] [CrossRef]

- DevelopmentAid. Available online: https://www.developmentaid.org/ (accessed on 18 September 2020).

- Law No. 96-41 of 10 June 1996 on Wastes and the Control of their Management and Disposal | InforMEA. Available online: https://www.informea.org/en/law-no-96-41-10-june-1996-wastes-and-control-their-management-and-disposal (accessed on 18 September 2020).

- Abu Hajar, H.A.; Tweissi, A.; Abu Hajar, Y.A.; Al-Weshah, R.; Shatanawi, K.M.; Imam, R.; Murad, Y.Z.; Abu Hajer, M.A. Assessment of the municipal solid waste management sector development in Jordan towards green growth by sustainability window analysis. J. Clean. Prod. 2020, 258, 120539. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.; Kuthiala, S.; Angelidaki, I. Co-digestion and model simulations of source separated municipal organic waste with cattle manure under batch and continuously stirred tank reactors. Energy Convers. Manag. 2018, 159, 1–6. [Google Scholar] [CrossRef]

- Pandyaswargo, A.H.; Gamaralalage, P.J.D.; Liu, C.; Knaus, M.; Onoda, H.; Mahichi, F.; Guo, Y.; Gamaralalage, J.D.; Liu, G. Challenges and An Implementation Framework for Sustainable Municipal Organic Waste Management Using Biogas Technology in Emerging Asian Countries. Sustainability 2019, 11, 6331. [Google Scholar] [CrossRef]

- SWEEP-Net Report. Report on the Solid Waste Management in Tunisia, Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ). 2014. Available online: http://www.retech-germany.net/fileadmin/retech/05_mediathek/laenderinformationen/Tunesien_laenderprofile_sweep_net.pdf (accessed on 25 August 2018).

- Wang, H.; Wang, D.; Zhou, X. Analysis on the Trend of Water Quality in Haihe River Basin from 2005 to 2017. J. Geosci. Environ. Prot. 2018, 6, 1–7. [Google Scholar] [CrossRef]

- Thabit, Q.; Nassour, A.; Nelles, M. Potentiality of Waste-to-Energy Sector Coupling in the MENA Region: Jordan as a Case Study. Energies 2020, 13, 2786. [Google Scholar] [CrossRef]

- Huiru, Z.; Yan, Y.; Liberti, F.; Bartocci, P.; Fantozzi, F. Technical and economic feasibility analysis of an anaerobic digestion plant fed with canteen food waste. Energy Convers. Manag. 2019, 180, 938–948. [Google Scholar] [CrossRef]

- Diebels, J. Feasibility Study of Biological Treatment of Organic Waste in Tsumeb Municipality, Namibia. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2014. [Google Scholar]

- Garcia, A.P. Techno-Economic Feasibility Study of a Small-Scale Biogas Plant for Treating Market Waste in the City of El Alto. 2014. Available online: http://kth.diva-portal.org/smash/get/diva2:741758/FULLTEXT01.pdf (accessed on 25 July 2019).

- Dhinesh, N.; Annamary, J.M.; Iswarya, K.; Murugan, K.V.; Kirubakaran, V. A Comprehensive Study of Food Waste to Biogas Plant: Paths to Improve the Performance—A Case Study. In Bioresource Utilization and Bioprocess; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–12. [Google Scholar]

- Liu, J.; Li, Q.; Gu, W.; Wang, C. The Impact of Consumption Patterns on the Generation of Municipal Solid Waste in China: Evidences from Provincial Data. Int. J. Environ. Res. Public Health 2019, 16, 1717. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Smith, S.R.; Fowler, G.; Velis, C.; Arya, S.; Rena Kumar, R.; Cheeseman, C.; Kumar, S.J. Challenges and opportunities associated with waste management in India. R. Soc. Open Sci. 2017, 4, 160764. [Google Scholar] [CrossRef] [PubMed]

- Directive (EU) 2018/of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. 32. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0851&from=EN (accessed on 19 September 2020).

- Boschini, M.; Falasconi, L.; Claudia, G.; Alboni, F. Food waste in school canteens: A reference methodology for large-scale studies. J. Clean. Prod. 2018, 182, 1024–1032. [Google Scholar] [CrossRef]

- Wafi, T.; Ben Othman, A.; Besbes, M. Qualitative and quantitative characterization of municipal solid waste and the unexploited potential of green energy in Tunisia. Bioresour. Bioprocess. 2019, 6, 1–16. [Google Scholar] [CrossRef]

- Burke, E.; Napawan, N.C. Between Kitchen Sink and City Sewer: A Socio-Ecological Approach to Food Waste in Environmental Design. In Food Waste Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 169–191. [Google Scholar]

- Dias-Ferreira, C.; Santos, T.; Oliveira, V. Hospital food waste and environmental and economic indicators—A Portuguese case study. Waste Manag. 2015, 46, 146–154. [Google Scholar] [CrossRef]

- Pirani, S.I.; Arafat, H.A. Solid waste management in the hospitality industry: A review. J. Environ. Manag. 2014, 146, 320–336. [Google Scholar] [CrossRef]

- Filimonau, V.; De Coteau, D.A. Food waste management in hospitality operations: A critical review. Tour. Manag. 2019, 71, 234–245. [Google Scholar] [CrossRef]

- Dileep, M.R. Tourism and Waste Management: A Review of Implementation of Zero Waste at Kovalam. Asia Pac. J. Tour. Res. 2007, 12, 377–392. [Google Scholar] [CrossRef]

- Malefors, C.; Callewaert, P.; Hansson, P.-A.; Hartikainen, H.; Pietiläinen, O.; Strid, I.; Strotmann, C.; Eriksson, M. Towards a Baseline for Food-Waste Quantification in the Hospitality Sector—Quantities and Data Processing Criteria. Sustainability 2019, 11, 3541. [Google Scholar] [CrossRef]

- Obi, F.; Ugwuishiwu, B.; Nwakaire, J. Agricultural Waste Concept, Generation, Utilization and Management. Niger. J. Technol. 2016, 35, 957. [Google Scholar] [CrossRef]

- Demichelis, F.; Piovano, F.; Fiore, S. Biowaste Management in Italy: Challenges and Perspectives. Sustainability 2019, 11, 4213. [Google Scholar] [CrossRef]

- Oviedo-Ocaña, E.R.; Dominguez, I.; Komilis, D.; Sánchez, A. Co-composting of Green Waste Mixed with Unprocessed and Processed Food Waste: Influence on the Composting Process and Product Quality. Waste Biomass-Valorizat. 2017, 10, 63–74. [Google Scholar] [CrossRef]

- Akturk, A.S.; Demirer, G.N. Improved Food Waste Stabilization and Valorization by Anaerobic Digestion through Supplementation of Conductive Materials and Trace Elements. Sustainability 2020, 12, 5222. [Google Scholar] [CrossRef]

- Chaher, N.E.H.; Chakchouk, M.; Engler, N.; Nassour, A.; Nelles, M.; Hamdi, M. Optimization of Food Waste and Biochar In-Vessel Co-Composting. Sustainability 2020, 12, 1356. [Google Scholar] [CrossRef]

- Tibu, C.; Annang, T.; Solomon, N.; Yirenya-Tawiah, D. Effect of the composting process on physicochemical properties and concentration of heavy metals in market waste with additive materials in the Ga West Municipality, Ghana. Int. J. Recycl. Org. Waste Agric. 2019, 8, 393–403. [Google Scholar] [CrossRef]

- Ramachandra, T.V.; Bharath, H.; Kulkarni, G.; Han, S.S. Municipal solid waste: Generation, composition and GHG emissions in Bangalore, India. Renew. Sustain. Energy Rev. 2018, 82, 1122–1136. [Google Scholar] [CrossRef]

- Km, K.; Reinhart, D.R.; Hawkins, C.V.; Motlagh, A.; Wright, J.D. Food waste and the food-energy-water nexus: A review of food waste management alternatives. Waste Manag. 2018, 74, 52–62. [Google Scholar] [CrossRef]

- Bong, C.P.C.; Lim, L.Y.; Lee, C.T.; Klemeš, J.J.; Ho, C.S.; Ho, W.S. The characterisation and treatment of food waste for improvement of biogas production during anaerobic digestion—A review. J. Clean. Prod. 2018, 172, 1545–1558. [Google Scholar] [CrossRef]

- Zarkadas, I.S.; Sofikiti, A.S.; Voudrias, E.A.; Pilidis, G.A. Thermophilic anaerobic digestion of pasteurised food wastes and dairy cattle manure in batch and large volume laboratory digesters: Focussing on mixing ratios. Renew. Energy 2015, 80, 432–440. [Google Scholar] [CrossRef]

- Li, R.; Chen, S.; Li, X. Anaerobic Co-digestion of Kitchen Waste and Cattle Manure for Methane Production. Energy Sources Part A Recover. Util. Environ. Eff. 2009, 31, 1848–1856. [Google Scholar] [CrossRef]

- Serrano, A.; Siles, J.A.; Chica, A.F.; Martín, M.A. Agri-food waste valorization through anaerobic co-digestion: Fish and strawberry residues. J. Clean. Prod. 2013, 54, 125–132. [Google Scholar] [CrossRef]

- Wan, S.; Sun, L.; Douieb, Y.; Sun, J.; Luo, W. Anaerobic digestion of municipal solid waste composed of food waste, wastepaper, and plastic in a single-stage system: Performance and microbial community structure characterization. Bioresour. Technol. 2013, 146, 619–627. [Google Scholar] [CrossRef]

- Fisgativa, H.; Tremier, A.; Dabert, P. Characterizing the variability of food waste quality: A need for efficient valorisation through anaerobic digestion. Waste Manag. 2016, 50, 264–274. [Google Scholar] [CrossRef]

- Bedoić, R.; Čuček, L.; Ćosić, B.; Krajnc, D.; Smoljanić, G.; Kravanja, Z.; Ljubas, D.; Pukšec, T.; Duić, N. Green biomass to biogas—A study on anaerobic digestion of residue grass. J. Clean. Prod. 2019, 213, 700–709. [Google Scholar] [CrossRef]

- Lytras, G.; Koutroumanou, E.; Lyberatos, G. Anaerobic co-digestion of condensate produced from drying of Household Food Waste and Waste Activated Sludge. J. Environ. Chem. Eng. 2020, 8, 103947. [Google Scholar] [CrossRef]

- Umweltbundesamt | Für Mensch und Umwelt. Available online: https://www.umweltbundesamt.de/en (accessed on 29 September 2020).

| Sector of Activity | Composting | Anaerobic Digestion | |

|---|---|---|---|

| Source of Organic Waste | |||

| Urban area | Green waste from municipal and wholesale markets | √ | |

| Green waste from urban green spaces | √ | ||

| Food waste from catering services | √ | √ | |

| Touristic sector | Food leftovers, kitchen waste | √ | √ |

| Green waste from gardening activity | √ | ||

| Industrial and food-processing | Winemaking residues | √ | √ |

| Livestock slaughterhouses waste | √ | ||

| Poultry slaughterhouses waste | √ | ||

| Fruits and vegetables waste from canneries | √ | √ | |

| Wood manufacturing waste | √ | ||

| Solid waste from olive-oil mills (stones, leaves…) | √ | ||

| Agricultural sector | Livestock manure | √ | √ |

| Poultry manure | √ | √ | |

| Arboricultural residue (Palm leaves, olive leaves…) | √ |

| Parameters | Units | Method of Analysis | Reference |

|---|---|---|---|

| pH | - | (1:10 w/v sample: water extract) | ISO 10390 (1994) |

| Moisture content (MC) | % of FM 1 | Using electronic oven by drying at 105oC for 24h | NF ISO 11465 (1994) |

| Total solids (TS) | % of FM 1 | ||

| Total Carbon (TC) | % of FM 1 | TOC (%) = ((100 − Ash%) ÷ 1/8) | [42] |

| Total Nitrogen (TN) | % of FM 1 | Titrimetric methods | NF ISO 11265 (1995) |

| Phosphorus (P) | % of TS 2 | Atomic absorption spectrometric methods | ISO 11885 (2007) |

| Potassium (K) | % of TS 2 | ||

| Magnesium (Mg) | % of TS 2 | Spectrometer, Thermo-Elemental ICP MS-X Series | ISO 11885 (2007) |

| Lead (Pb) | mg/kg TS | ||

| Copper (Cu) | mg/kg TS | ||

| Zinc (Zn) | mg/kg TS | ||

| Nickel (Ni) | mg/kg TS | ||

| Cadmium (Cd) | mg/kg TS | ||

| Arsenic (As) | mg/kg TS |

| Parameter | Unit | Symbol | Value | Reference of Values |

|---|---|---|---|---|

| Inflation rate | % | F | 1 | Assumed |

| Interest rate | % | ri | 8 | Assumed |

| Discount rate | % | rd | 5 | Assumed |

| Cost of power sale | US$ | - | 0.08 | Assumed |

| Cost of digestate sale | US$ | - | 1.2 | [44] |

| Lifetime of the power plant | Years | N | 15 | [45] |

| Operational hours of the Power plant | h/year | H | 8000 | [46] |

| Plant capacity | Ton/year | - | 30.000 | [47] |

| Power production | MWe | P | 0.4 | Assumed |

| Selected Organic Waste | Units | Urban & Touristic Areas | Agricultural Area | ||

|---|---|---|---|---|---|

| Parameters | Green Waste | Food Waste | Cattle Manure | ||

| pH | - | 6.51 | 4.22 | 5.23 | |

| Moisture content (MC) | % of FM 1 | 41.12 | 77.40 | 88.50 | |

| Total solids (TS) | % of FM | 58.88 | 22.60 | 11.50 | |

| Volatile solids (VS) | % of TS 2 | - | 94.60 | 8.90 | |

| Total Carbon (TC) | % of FM | 48.81 | 47.70 | 42.61 | |

| Total Nitrogen (TN) | % of FM | 1.12 | 2.60 | 1.70 | |

| C:N ratio | 43.58 | 18.34 | 25.06 | ||

| Phosphorus (P) | % of TS | 0.23 | 0.48 | 0.60 | |

| Potassium (K) | % of TS | 2.01 | 0.91 | 2.95 | |

| Magnesium (Mg) | % of TS | - | 0.09 | 2.82 | |

| Lead (Pb) | mg/kg TS | 0.12 | 0.91 | 0.85 | |

| Copper (Cu) | mg/kg TS | 17.83 | 6.82 | 18.20 | |

| Zinc (Zn) | mg/kg TS | 25.81 | 16.33 | 131.00 | |

| Nickel (Ni) | mg/kg TS | 9.63 | 0.95 | 6.91 | |

| Cadmium (Cd) | mg/kg TS | 0.09 | 0.07 | 0.91 | |

| Arsenic (As) | mg/kg TS | - | 0.57 | 0.28 | |

| Trial | Thermophilic Phase (days) | Tmax (°C) | pH | Nitrification Index | C:N Ratio | AT4 (mg O2/g TS) | Classification vs. “German Standards” |

|---|---|---|---|---|---|---|---|

| P0 | 16 days | 60 °C | 7.34 | 2.2 | 17.5 | 4.2 | Finished compost: Class V |

| P1 | 17 days | 63 °C | 7.41 | 2.6 | 15.2 | 4.9 | Finished compost: Class V |

| P2 | 23 days | 66 °C | 7.53 | 3.3 | 11.5 | 5.3 | Finished compost: Class V |

| P3 | 11 days | 61 °C | 8.03 | 4.1 | 9.2 | 5.2 | Finished compost: Class V |

| Metal (mg/kg TS) | Actual Experiments | Compost Quality | |||||||

|---|---|---|---|---|---|---|---|---|---|

| P0 | P1 | P2 | P3 | UK | Tunisia | Canada | Germany | ||

| Class A | Class B | ||||||||

| Lead (Pb) | 2.63 | 3.47 | 9.03 | 9.87 | 200 | 180 | 150 | 150 | 100 |

| Copper (Cu) | 13.54 | 23.61 | 37.12 | 42.31 | 200 | 300 | 400 | 100 | 70 |

| Zinc (Zn) | 37.89 | 50.19 | 61.04 | 61.25 | 400 | 600 | 700 | 400 | 300 |

| Nickel (Ni) | 12.31 | 15.47 | 11.12 | 13.44 | 50 | 60 | 62 | 50 | 35 |

| Cadmium (Cd) | 0.09 | 0.23 | 0.60 | 0.84 | 1.5 | 3 | 3 | 1.5 | 1 |

| Chrome (Cr) | 8.13 | 10.94 | 33.90 | 37.17 | 100 | 120 | 210 | 100 | 70 |

| Mercury (Hg) | <0.01 | <0.01 | <0.01 | 0.01 | - | - | - | 1 | 0.7 |

| Calculated Parameters | Unit | Amount | |

|---|---|---|---|

| Composting plant of size | tons year−1 | 10,000 | |

| Average density of green waste | Kg m−3 | 104 | |

| Average density of food waste | Kg m−3 | 300 | |

| Working collection days | days/year−1 | 300 | |

| Composting period for each pile | Week | 13–15 | |

| Dimensions of windrow piles | Length (l) | M | 10 |

| Height (h) | M | 2 | |

| Width (w) | M | 3.5 | |

| Volume of windrow: triangular section | ½ × (l × h × w) | m3 | 35 |

| Volume reduction in windrow piles | % | 30 | |

| Volume of finished compost | Volume of inputs × 0.7 | m3 | Depending on the feedstock mixtures |

| Number of windrows per day | Volume of inputs/volume of windrow pile | m3 | |

| Estimated Civil Engineering * Investment Cost (Part 1) | Investment Costs on Material and Equipment (Part 2) ** | Investment Cost Management | Yearly Costs for Operation and Maintenance *** | Yearly Costs for Capital, Consumption, & Operation | Yearly Profit from the Sales of Compost at 30 €/ton | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engineering a | 3% | 70,000 | Turner machine | 12% | 250,000 | State grants | 30% | 622,500 | Personal cost | 60,000 | Capital related cost | 43,575 | Compost sales | 210,000 |

| Preparation of land and layout (10 donums) | 24% | 500,000 | Front loader | 6% | 120,000 | Own contribution | 0% | 0.00 | Fuel & energy consumption | 45,000 | Operation and maintenance related cost | 158,500 | Production cost | 202,075 |

| Outdoor facility | 34% | 700,000 | Rotary drum screen) | 10% | 200,000 | Additional investment required | 70% | 1,452,500 | Water consumption | 3500 | Total yearly cost (€/year) | 202,075 | Net profit | 7925 |

| Sum of Part1 | 61% | 1,270,000 | Shredder | 10% | 200,000 | ** Machines and equipment needed:

| Equipment’s and others | 10,000 | *** Personnel:

| |||||

* Site preparation and design including:

| Workshop equipment’s | 1% | 25,000 | Building maintenance | 5000 | |||||||||

| Office equipment | 0.5% | 10,000 | Machine maintenance | 30,000 | ||||||||||

| Sum of Part 2 | 39% | 805,000 | Insurance | 5000 | ||||||||||

| Total setup costs | 100% | 2,075,000 | Total operation & maintenance cost/a | 158,500 | ||||||||||

| Capital Investment Costs (CAPEX) * | Operation Costs (OPEX) | ||||

|---|---|---|---|---|---|

| Capital Cost Component ** | Percentage of the Cost (%) *** | Operation Components | Unit | Number | Operation Cost |

| Construction and land arrangement | 3.78% | Maintenance cost | €/kWh | - | 0.015 |

| Loading hall | 9.28% | Maintenance cost for pumps and compressors | % | - | 1.5 |

| CHP facility | 2.32% | Staff salaries **** | €/Mann | 12 | 1000 |

| Drilling cost | 0.93% | Personal logistic | €/Mann | 12 | 500 |

| Mixing chamber | 1.39% | Facility insurance | % | - | 7 |

| Sanitization | 4.64% | Power consumption | % | - | 10 |

| Fermenter | 2.32% | Load management | % | - | 5 |

| Storage | 6.49% | ||||

| Control system | 5.57% | ||||

| Social room | 3.71% | ||||

| Gas track (pipes) | 1.67% | ||||

| Emergency factors | 1.39% | ||||

| Pumps & compressors | 1.39% | ||||

| Heat exchangers | 0.93% | ||||

| Pipes connections | 4.64% | ||||

| Biofilter | 7.42% | ||||

| Electrical installation | 4.64% | ||||

| Planning and design steps | 1.5% | ||||

| Networks | 4.64% | ||||

| Others | 2.13% | ||||

| Total setup costs | 100% | ||||

| Power Price (cent/kWh) | Without Digestate Sale | With Digestate Sale | ||||

|---|---|---|---|---|---|---|

| Cash Flow without Digestate | Payback without Digestate | Evaluation | Cash flow with Digestate | Payback with Digestate | Evaluation | |

| 8 | −247,480 | 20,480.00 | Deficient | −63,480.00 | 36,480.00 | Deficient |

| 10 | −188,600.00 | 25,600.00 | Deficient | −4600.00 | 41,600.00 | Deficient |

| 12 | −129,720.00 | 30,720.00 | Deficient | 54,280.00 | 46,720.00 | Efficient |

| 14 | −70,840.00 | 35,840.00 | Deficient | 113,160.00 | 51,840.00 | Efficient |

| 16 | −11,960.00 | 40,960.00 | Deficient | 172,040.00 | 56,960.00 | Efficient |

| 18 | 46,920.00 | 46,080.00 | Efficient | 230,920.00 | 62,080.00 | Efficient |

| Zone | Great Tunis | Bizerte | Nebeul | Sousse | Monastir | Mehdia | Sfax | Gabes | Beja | Jendouba | Medenine | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Process | ||||||||||||

| Composting | P0, P1 | P0 | P0, P1, P2 | P0, P1 | P0, P1 | P0 | P0 | P0 | P0, P1 | P0 | P0, P1 | |

| Anaerobic digestion | R2 | R1 | R1, R2, R3 | R1, R2 | R1 | R1 | R1 | R1 | R1 | R1 | R1, R2 | |

| Number of composting plants suggested | 9 | 3 | 8 | 9 | 8 | 18 | 38 | 8 | 6 | 4 | 19 | |

| No. of biogas plants suggested | 3 | 6 | 7 | 2 | 2 | 3 | 3 | 1 | 5 | 4 | 1 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaher, N.E.H.; Hemidat, S.; Thabit, Q.; Chakchouk, M.; Nassour, A.; Hamdi, M.; Nelles, M. Potential of Sustainable Concept for Handling Organic Waste in Tunisia. Sustainability 2020, 12, 8167. https://doi.org/10.3390/su12198167

Chaher NEH, Hemidat S, Thabit Q, Chakchouk M, Nassour A, Hamdi M, Nelles M. Potential of Sustainable Concept for Handling Organic Waste in Tunisia. Sustainability. 2020; 12(19):8167. https://doi.org/10.3390/su12198167

Chicago/Turabian StyleChaher, Nour El Houda, Safwat Hemidat, Qahtan Thabit, Mehrez Chakchouk, Abdallah Nassour, Moktar Hamdi, and Michael Nelles. 2020. "Potential of Sustainable Concept for Handling Organic Waste in Tunisia" Sustainability 12, no. 19: 8167. https://doi.org/10.3390/su12198167

APA StyleChaher, N. E. H., Hemidat, S., Thabit, Q., Chakchouk, M., Nassour, A., Hamdi, M., & Nelles, M. (2020). Potential of Sustainable Concept for Handling Organic Waste in Tunisia. Sustainability, 12(19), 8167. https://doi.org/10.3390/su12198167