Abstract

This article presents a literature review to identify the current knowledge of supply chains 4.0 from the sustainability perspective. Reviewed papers were classified in terms of objectives, results, and sustainability approaches. Additionally, a critical discussion with the main results and recommendations for further research was carried out. Manufacturing supply chains have been contemplated but agri-food supply chains and chains related to diversified cropping systems have been also considered. In this way, 54 articles were identified and revised, and were classified according to the three main aspects of sustainability: economic, social, and environmental. The classification of articles indicated that more attention has been paid to the environmental aspect in the industry 4.0 (I4.0) context in the literature, while the social aspect has been paid less attention. Finally, reference frameworks were identified, along with the I4.0 models, algorithms, heuristics, metaheuristics, and technologies, which have enabled sustainability in supply chains.

1. Introduction

The fourth industrial revolution is expected to cause a tremendous industrialization growth and may disturb the sustainability of current industrial systems [,]. In addition, further impacts in terms of higher resources consumption, global warming, and climate change issues [] are expected. In this sense, adopting management practices for production and supply chain systems that considers all the sustainability—economic, social, and environmental—aspects and exploits the digital transformation characteristics that industry 4.0 (I4.0) represents is a relevant theme that requires research and needs to be applied in manufacturing supply chains. The importance of incorporating sustainability in supply chains has been the focus of attention by researchers [,], however, few practical efforts were made within the context of a sustainable supply chain and I4.0 []. Regarding this, Duarte and Cruz-Machado [] proposed a conceptual model that integrates I4.0 concepts into green and lean supply chains. In this context, many efforts have been made focusing on I4.0-related technologies and not I4.0 as a whole approach. Here, we address supply chain 4.0 as an extension of the I4.0 definition, incorporating value chain creation processes that comprise of vendors, producers, wholesalers, retailers, and end clients, that intends to synchronize demand and supply []. According to Luthra et al. [], the majority of studies on I4.0 have considered the manufacturing sector context and ignored supply chain systems. To bridge this gap, this article presents a literature review on the sustainable supply chain 4.0 using the three afore-cited perspectives: social, environmental, and economic. In order to determine what has been done to date and who has worked on this research subject, a literature review was done and includes an analysis of 54 articles selected according to their novelty criteria, number of times cited, if they dealt with I4.0 on the whole, and the aspects that sustainability represents. Thus, the main contributions of this paper are to: (1) provide a literature review on sustainable supply chains and I4.0; (2) organize the main insights in order to support and facilitate exchanges of the main supply chain 4.0 objectives, results, and sustainability approaches; and (3) examine the main contributions and limitations of the reviewed papers in order to identify recommendations for sustainable supply chain 4.0 future research works. This literature review can be useful for researchers and decision makers to clarify the state of the art of the addressed topic and define future research paths.

The rest of the article is set out as follows. Section 2 presents the structure of the methodology followed to conduct this article. Section 3 presents the literature review, which identifies the works related to sustainable supply chains and I4.0; the social, economic, and environmental aspects in the I4.0 context; the most relevant works that have dealt with sustainability; and I4.0 in general. Finally, Section 4 offers conclusions and future lines of work.

2. Review Methodology

The methodology proposed for this literature review started by selecting the databases: i.e., Science Direct, IEEE Explore, Scopus, Google Scholar, and Web of Science. The search criteria included filtering documents and articles by title and containing the following keywords always combined with the term Industry 4.0: sustain, sustainability, sustainable, agri, agro, econo, economic, social, human, operator, cost, environment, energy, waste, water, eco. Table 1 illustrates the data collection methodology.

Table 1.

Data collection methodology.

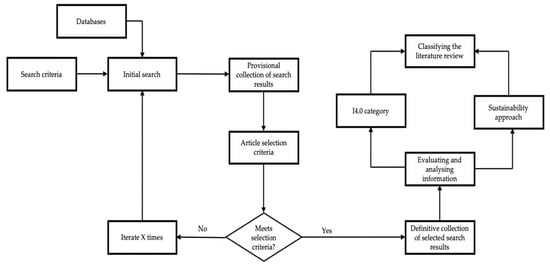

Consequently, an initial search was conducted and collected provisional search results. Next, with this provisional information collected, it was filtered considering the following selection criteria: novelty, times cited, publication date, journal impact, abstract briefly reviewed, and sustainability approach. In case the provisional collection did not meet the selection criteria, the initial search was continued, iterating as long as every article in the literature was filtered. Otherwise, if an article was selected, it formed part of a definitive collection of search results and proceeded for deep evaluation and analysis. Next, each article was categorized by I4.0 category and sustainability approach. Figure 1 illustrates the described review methodology followed.

Figure 1.

Structure of the methodology followed for the literature review.

Table 2 summarizes the sources of the articles selected for the literature review of the supply chain 4.0 and sustainability.

Table 2.

Sources of the selected articles.

3. Literature Review

3.1. Taxonomy

The selected papers have been reviewed and classified by sustainability approach (EC: economic, ENV: environmental, and S: social), its main objectives, supply chain and Industry 4.0 approach (SC4.0), and results of each work (Table 3).

Table 3.

Selected articles classification by approach and results of each work.

Regarding the I4.0 and the sustainable supply chain, Lin et al. [] compared innovation policies of the sustainable I4.0 transformation-related projects called China Manufacturing 2025 and Taiwan Productivity 4.0. However, this work was limited to national and industrial level of I4.0, future works should focus on firm level. Man and Strandhagen [] discussed different scenarios with the incorporation of I4.0 and sustainability included in business processes. They recommended that in order to measure the effect of sustainability strategies, the impact on the environmental aspect of sustainability can be measured through life cycle assessments (LCA). Thus, the following research lines were proposed: study how markets will shift to sustainable products in the context of I4.0 and how this could support sustainable supply chains, the creation of sustainable awareness of customers through I4.0 horizontal integration, achieving customer loyalty and satisfaction for sustainable I4.0 products, overcoming psychological of products obsolescence through I4.0, cost–benefit analysis of I4.0 solutions that support a sustainable supply chain, and research into the potential revenue models for I4.0 supported sustainable products.

Kiel et al. [] presented a classification of the challenges and benefits of the Internet of Things (IoT) that focused on the sustainability of creating value. Waibel et al. [] discussed the effects of smart production systems in a sustainable setting, in which they evaluated each sustainability aspect (economic, social, environmental, and technical) in terms of efficiency of resources. Manavalan and Jayakrishna [] reviewed the I4.0 requirements of a sustainable supply chain and analyzed different IoT aspects, supply chain management, and which software can be used to plan material resources in companies (ERP). These authors proposed a reference framework to evaluate the level of the supply chain’s readiness in companies that pursue transformation towards I4.0. This reference framework comprises five supply chain management perspectives: businesses, technology, sustainable development, collaboration, and strategic management. The conceptual model addressed the criteria belonging to each sustainability enabler, the technology was only shown as a tool to reach the enablers (IoT, CPS, augmented reality, and big data). Additionally, the basic characteristic of a sustainable supply chain 4.0 is that organizations should realize closed loop life cycles for products.

Ghadimi et al. [] proposed a model based on multiagent systems to automatically evaluate and select suppliers in the sustainability context and I4.0 supply chains, which consists of a three-layer system architecture: i.e., interface layer, technical layer, and data resources layer. These authors described how the developed model can act as a tool for I4.0 supply chains and described its advantages according to four I4.0 design principles []: (1) interconnection, which allows I4.0 supply chains to dynamically adapt to environments of the market and businesses; (2) transparent information, where several agents will be able to send and receive information in real time by different protocols; (3) decentralization, in which agents will have the capacity to communicate and make decisions themselves; (4) technical assistance, e.g., automating suppliers’ selection process in a sustainable I4.0 supply chain.

Luthra and Mangla [] presented a literature review that identified 18 I4.0 challenges, which they grouped as organizational, strategical, legal, and ethical challenges. These authors then validated challenges by an AHP (analytical hierarchy process) in the manufacturing sector in India. Within the context of sustainable supply chain 4.0 and from the organizational point of view, the authors addressed that technology and process innovation are fundamental in value chains.

Ding [] offered a literature review to identify the barriers faced when including sustainability in the pharmaceutical supply chain: high costs and long usage times, little experience and training, reinforcing regulations, coordinating supply chains, and ineffective collaboration. Moreover, via the sustainable supply chains called Pharma 4.0, they identified how I4.0 can be applied to these supply chains to solve problems when including sustainability, which the authors divided into four aspects: increasing supply chains’ flexibility, enhancing the effectiveness of coordination/communication of all the parties involved in a supply chain, reducing waste and pollution in different stages, and setting up an autonomous decision-making process.

Bag et al. [] revised the literature in the sustainable and I4.0 supply chains context. They proposed a reference framework with which they identified 13 enablers that influenced sustainability in a supply chain. These enablers of a sustainable supply chain 4.0 are as follows: government support, third party audits, corporate governance, vertical integration, horizontal integration, change management, focus on human capital, information transparency, standardization and reference architecture, management commitment, improved IT security and standards, law and policy regarding employment, and support of research institutes and universities.

Ivanov [] revised sustainability, I.40, and self-adaptation as drivers for the structural dynamics of supply chains and resilience. This author considered that resilience in supply chains contains intersections with sustainable supply chains and analysed the factors affecting the structural design of resilient supply chains to eliminate the ripple effect and to enhance sustainability. Therefore, in supply chains’ structural dynamics, I4.0 plays a key role as it facilitates flexible customized production at the expense of mass production. Yazdi et al. [] conducted empirical research about OEE (overall effective equipment) and a sustainable manufacturing system in which they proposed an algorithm as a control architecture. Braccini and Margherita [] investigated the supports that help to adopt I4.0 in a case study about a company that manufactures ceramics by dealing with sustainability on the whole. Moghaddam et al. [] devised different reference architectures of sustainable smart I4.0 factories and dealt with manufacturing sustainable products. Paravizo et al. [] proposed a conceptual framework to develop gamified applications in the I4.0 field that focus on sustainable manufacturing. Müller et al. [] put forward a search model with which to identify the opportunities and challenges of hypothetically implementing I4.0, which they applied to a sample of 746 German manufacturing companies and to five different industrial sectors. Kamble et al. [] revised the I4.0 literature and built a reference framework of sustainability in the I4.0 context by taking 85 selected and classified articles as a basis. Hidayatno et al. [] proposed a conceptual model to determine the impact of developing and implementing I4.0 technology with sustainable energy with the project “Making Indonesia 4.0”. They conceptualized the model by causal diagrams and using system dynamics to represent the variables that support I4.0 technologies. They developed this model within three sustainability components: environmental, social, and economic. The authors concluded that the model could be validated and presented quantitative and qualitative results using the sustainable energy data that were collected. Phuong and Guidat [] presented a methodology to apply sustainable value stream mapping and a conceptual model to acquire and extract data using RFID technology. Kumar and Lamba [] proposed a metaheuristic for a sustainable robust stochastic cellular facility layout problem. Wiśniewska-Sałek [] assessed the opportunities that I4.0 provides when developing sustainability and presented a furniture industry case study. Müller and Voigt [] compared the implementation of projects in Germany entitled “Industrie 4.0” and the project in China known as “Made in China 2025” in the sustainability context. This study was done using studies conducted in several SMEs in Germany and China. The results of this study revealed that the German SMEs perceived that I4.0 has a low impact, which benefits large companies more. The Chinese SMEs perceived social benefits. These authors contemplated that the energy efficiency potential obtained through the digitalization and interconnection of I4.0 must be considered by SMEs, which cannot be achieved as an individual organization, but as part of a supply chain as a whole. Tsai and Lu [] proposed a framework to plan production and control with a carbon tax in the I4.0 setting. Bibaud-Alves et al. [] provided a link among the development process concepts of new products, digital transformation, and sustainable development using an I4.0 approach. Birkel et al. [] put forward a reference framework of the risks involved in implementing I4.0 into SMEs with a sustainability approach, i.e., environmental, social, and economic risks, as well as technical risks, risks with information technologies and legal/political risks. Roda-Sánchez et al. [] proposed two power-aware algorithms with a flexibility approach to face the sustainability challenge in I4.0 (efficiency and working conditions). Ardanza et al. [] presented a human–machine interface with efficient sustainable hardware/software for I4.0. In the context of agri-food supply chains and crop diversification, Zambon et al. [] set out a framework of a system to manage agriculture 4.0 by the virtualization of an agro-food chain. Here, precision agriculture and IoT applied in the farming sector led to agriculture 4.0, which improved sustainability of crops and yields, increasing quality of working conditions, production, and processing.

Belaud et al. [] proposed an approach to integrate I4.0 into a supply chain with the aim to improve sustainability management for valorization of agricultural 4.0 waste with the use of big data. Trivelli et al. [] mapped precision agriculture technologies linked to I4.0 and developed a dictionary of terms that could be used as a basis of digitalized agri-food value chain. Miranda et al. [] considered sensing, smart, and sustainable technologies as key characteristics of future sustainable products.

With respect to the social approach in the I4.0 environment, Stock et al. [] offered a literature review based on creating value by an approach based on the social and environmental dimensions in the I4.0 context. These authors used “intelligent cube production”, made up of a smart product with RFID technology located in China (the Sino-German Research Institute) to assess and analyze the outcomes of the I4.0 potential in social and ecological domains. The environmental and social study assessment revealed that individual I4.0 technologies have a positive impact on resource management, such as RFID and 3d printing technologies. RFID can be used to store data of products life cycle and 3d printing leads to reduction of resources consumption. A lack of quantitative research on social and environmental impacts of I4.0 and sustainable development contributions was identified.

Chaim et al. [] discussed the possibility of incorporating key performance indicators (KPIs) to evaluate sustainability in a virtual learning environment in the I4.0 context. Indicators were based on the classification offered in the work of [], which consisted of classifying sustainability indicators in environmental stewardship (emissions, pollution, and resource consumption) and social well-being (employee, customer, and community).

In the environmental approach in sustainability and I4.0, the works by [] stand out, which deal with how the IoT will improve the energy efficiency of smart factories and will determine the process by means of which this practice will be adopted in four phases: (i) implementing production processes and evaluation of today’s energy management practices; (ii) monitoring and analyzing real-time uses by IoT technology; (iii) integrating data into energy management tools by energy decision support systems, simulation tools, etc.; (iv) defining sustainability strategies and production management practices to improve energy efficiency. Bonilla et al. [] evaluated challenges and impacts when incorporating I4.0 using different I4.0 development scenarios, long-term sustainable development challenges, and operations with an environmental sustainability approach. Stock et al. [] resorted to an environmental approach and I4.0. De Sousa Jabbour et al. [] proposed a reference framework to set up the synergy between I4.0 and environmentally sustainable manufacturing. Meng et al. [] revised the literature by considering sustainability and energy efficiency in smart factories to determine how they interact and benefit one another, and to also deal with any problems arising between both. Kamble et al. [] analyzed the energy barriers that emerge when adopting I4.0 into production in India. Huh and Lee [] set up a testbed and simulation for a lower-power digital “excitement” system for I4.0. Fritzsche et al. [] revised the literature to identify gaps in intergovernmental organizations that study climate change and I4.0. Campo et al. [] presented a solution by using the IoT for optimizing energy in an I4.0 domain and discussed applying it to real life. Axelsson et al. [] pursued increasing efficiency and reducing waste when building roads using a lean approach and I4.0 with a “system of systems”. Hernández-Luna et al. [] presented a statistical analysis of correlations for energy management in an I4.0 environment. Medojevic et al. [] revised the energy management literature in an I4.0 ecosystem and dealt with integrating both energy management and I4.0 and their related challenges. Wang and Wang [] put forward and set up a system based on the digital version of a system, or “a digital twin”, of I4.0 to recycle electrical waste and electronic devices. Tsai [] proposed a mathematical model that considers environmental problems, ABC (activity-based costing) and TOC (theory of constraints) for the green planning and control of the textile industry. Sherazi et al. [] presented a methodology to collect energy with a LoRaWAN (long-range wide area network) and analyzed its related costs for I4.0. Tsai et al. [] suggested an optimization model for green production planning with the ABC classification and I4.0. It is worth mentioning that for the environmental aspect, searches to improve energy efficiency by means of the IoT technology in I4.0 were stressed, where sensors will enable energy use to be monitored in real time, and this information can be analyzed and shared through all the supply chain I4.0 links. Monteleone et al. [] proposed a conceptual model for water management in the agriculture 4.0 context.

With the economic approach of sustainability and I4.0, Bechtsis et al. [] dealt with materials manipulation processes with the help of AGV (automated guided vehicles) technology. Franciosi et al. [] revised the literature about maintenance in sustainable I4.0 manufacturing and enabling technologies called maintenance 4.0. De las Heras García de Vinuesa et al. [,] proposed a reference framework to evaluate the sustainability of products by focusing on circular economy in the I4.0 context. Ma [] suggested a reference framework to manage the resources of a management system for warehouses based on I4.0 enablers. Nascimento et al. [] put forward a business model with circular economy to recycle waste according to an I4.0 approach.

3.2. Discussion

I4.0 could cause a growth in industrialization and disrupt the sustainability of existing manufacturing supply chains in terms of higher resource consumption, global warming, and climate change issues. Therefore, it is relevant to the research of the sustainable supply chain 4.0, i.e., to adopt management practices for manufacturing supply chains that contemplate sustainability and address the digital transformation toward I4.0. Sustainability should be addressed in an integrated manner from its three perspectives: social, environmental, and economic. In this sense, the distribution of the 54 selected articles by approach is as follows: 50 (93%) of the reviewed papers have contemplated the sustainability from the environmental view, 48 (89%) from the economic view, and 34 (62%) from the social view. Also, it is important to highlight that only 10 (19%) papers have also addressed the concept of SC4.0 (Table 3).

We have identified that supply chains’ sustainable practice drives towards: using sustainable energy and that the benefits of I4.0 in these chains involve companies being completely connected digitally, reducing the carbon footprint, and supporting decision makers in dynamic decision-making in real time []. Additionally, supply chains will have the characteristics to be flexible, sensitive, cost-effective and robust to be competitive in the long-term, sustainable, and resilient [].

Concerning which characteristics are needed to enable a supply chain 4.0, I4.0 should allow the connection between the customer and supply chain digitally by providing information about smart products use and its status at different stages of the supply chain. Such characteristics enable visualization of the energy efficiency of the product they are using, preventive maintenance, and end-of-life monitoring, which allows recycling planning []. In this sense, it is recommended that the knowledge of challenges for the design, operation, control, and optimization for enabling sustainable business models by adopting accurate I4.0 technologies. Thus, the incorporation of characteristics such as sustainable products/operations, lean practices, and IT is required to achieve sustainability in industrial supply chains. The importance of the implication of I4.0 in a sustainable supply chain was identified through the adoption of continuous production processes and 3D printing technology, CPS, IoT, big data, and process analytical technologies. They improve productivity and flexibility of the manufacturing processes, enabling product mass customization and reducing waste of materials across product life cycles, consequently, making them more environmentally and energy efficient manufacturing [,].

Regarding the barriers for developing manufacturing sustainable supply chains 4.0, organizational challenges are the most critical ones, followed by legal/ethical issues, strategic challenges, and finally, technological challenges []. In this context, a supply chain 4.0 should become adaptive, self-organizational, and self-learning through the following drivers []: adaptation, coordination, agility, and sustainability. Thus, the impact of the I4.0 technological revolution, particularly of education and the standards required of the human factor, and the demand for highly skilled workers will change in many areas of companies []. Here, it is important to highlight the limitation of I4.0 as the inevitable investment on technology and efforts should be made on finding solutions regarding IT security, workforce with required skills, and information sharing in collaborative business models [].

With respect to crop and value diversification, it is important to highlight the technologies oriented to the agri-food 4.0/agriculture 4.0 in the agri-food supply chains, i.e., virtualization, big data, map precision, and sensing smart, among others.

Finally, the importance of I4.0 design principles to create new reference models that will act as a basis to include each sustainability aspect has been detected. It has been determined that an intrinsic relationship exists between the reviewed works on the economic and environmental aspects of sustainability, while the social aspect appears to be the least addressed approach. Here, it is necessary to highlight the difficulty in designing sustainability indicators because of the unconstrained nature of the social factor, which transcends to companies towards suppliers, customers, and manufacturers []. Social issues can rely on indicators such as emissions, working conditions, and publicity/social acceptance. It is important to highlight the benefits in the social aspect, which is expected for a better integration and inclusion of employees. Challenges in this matter are related to the impacts on substitution of jobs by technological systems. One key aspect, namely I4.0 technologies, can help to improve these aspects.

4. Conclusions

This article has analyzed the different sustainability aspects in supply chains in the digital transformation context that I4.0 represents and identified the challenges and advantages of adopting I4.0. We have identified different reference frameworks and conceptual models on supply chains 4.0 and sustainability. Only a few works that deal with the social approach of sustainability and I4.0 on the whole have been identified, given that most tend to focus mainly on enabling technologies to reduce costs and for monitoring. Contrarily, more works have been published with an approach related to economic and environmental aspects and I4.0. Therefore, there is a need for a reference sustainable and standardized I4.0 framework. This work has identified different projects that have adopted sustainability as part of their objectives: “Industrie 4.0”, “agri-food 4.0/agriculture 4.0”, “Making Indonesia 4.0”, “Taiwan Productivity 4.0”, “Made in China 2025”, “China Manufacturing 2025”, “Horizon 2020”, and “Thailand Sustainable Smart Industry, MSIE4.0”, among others. It has verified the sustainable manufacturing and sustainable supply chain 4.0 concepts, as well as models, algorithms, heuristics, and metaheuristics to deal with the sustainability and I4.0.

Future research lines should center on validating the different proposed conceptual models, reference sustainable frameworks and I4.0, mathematical models, and solution approaches to evaluate the impact of I4.0 enablers in a sustainable supply chain from the three perspectives—economic, environmental, and social—in an integrated manner. Thus, more applied research and real-world applications on the incorporation I4.0 into supply chains and manufacturing systems are recommended. Also, future research could focus on proposing solutions for challenges/barriers caused by agriculture 4.0/industry 4.0 adoption in the SMEs background. Appling novelty models on self-optimizing agricultural supply chain structures [,] in terms of cost of distribution and improving demand management, both contemplated within variable lead times scenarios (which may affect product obsolescence), could be a relevant research field. In this sense, a proposal and validation in a real world agri-food supply chain (where disruptions that most affect perishable products) related to crop diversification is a forthcoming work.

Author Contributions

The work was shared as follows: H.C. contributed with article conceptualization, methodology, data curation, formal analysis, investigation, visualization, writing original draft; J.M. and F.C.-B. contributed as well with conceptualization, supervision, resources, visualization, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the European Commission Horizon 2020 project entitled ‘Crop diversification and low-input farming cross Europe: From practitioners’ engagement and ecosystems services to increased revenues and value chain organisation’ (Diverfarming), grant agreement 728003; and the Spanish Ministry of Science, Innovation, and Universities project entitled ‘Optimisation of zero-defects production technologies enabling supply chains 4.0 (CADS4.0)’ (RTI2018-101344-B-I00).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. Available online: https://ieeexplore.ieee.org/document/7427673 (accessed on 24 September 2020).

- Liao, Y.X.; Deschamps, F.; Loures, E.D.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 8, 1–21. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Zhu, Q.; Sarkis, J.; Chiu, A. Responsible consumption and production (RCP) in corporate decision-making models using soft computation. Ind. Manag. Data Syst. 2018, 118, 322–329. [Google Scholar] [CrossRef]

- Ghadimi, P.; Wang, C.; Lim, M.K.; Heavey, C. Intelligent sustainable supplier selection using multi-agent technology: Theory and application for Industry 4.0 supply chains. Comput. Ind. Eng. 2019, 127, 588–600. [Google Scholar] [CrossRef]

- Wang, C.; Ghadimi, P.; Lim, M.K.; Tseng, M.-L. A literature review of sustainable consumption and production: A comparative analysis in developed and developing economies. J. Clean. Prod. 2019, 206, 741–754. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz-Machado, V. Exploring Linkages between Lean and Green Supply Chain and the Industry 4.0. Available online: https://link.springer.com/chapter/10.1007/978-3-319-59280-0_103 (accessed on 24 September 2020).

- Stefanou, C. Supply chain management (SCM) and organizational key factors for successful implementation of enterprise resource planning (ERP) systems. AMCIS 1999 Proc. 1999, 276, 800–802. [Google Scholar]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process. Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Lin, K.C.; Shyu, J.Z.; Ding, K. A Cross-Strait Comparison of Innovation Policy under Industry 4.0 and Sustainability Development Transition. Sustainability 2017, 9, 786. [Google Scholar] [CrossRef]

- De Man, J.C.; Strandhagen, J.O. An Industry 4.0 Research Agenda for Sustainable Business Models. Procedia CIRP 2017, 63, 721–726. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Waibel, M.; Steenkamp, L.; Moloko, N.; Oosthuizen, G. Investigating the Effects of Smart Production Systems on Sustainability Elements. Procedia Manuf. 2017, 8, 731–737. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Ding, B. Pharma Industry 4.0: Literature review and research opportunities in sustainable pharmaceutical supply chains. Process. Saf. Environ. Prot. 2018, 119, 115–130. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2018. [Google Scholar] [CrossRef]

- Ivanov, D. Structural Dynamics and Resilience in Supply Chain Risk Management; International Series in Operations Research & Management Science; Springer International Publishing: Cham, Switzerland, 2018; Volume 265, ISBN 978-3-319-69304-0. [Google Scholar]

- Yazdi, P.G.; Azizi, A.; Hashemipour, M. An Empirical Investigation of the Relationship between Overall Equipment Efficiency (OEE) and Manufacturing Sustainability in Industry 4.0 with Time Study Approach. Sustainability 2018, 10, 3031. [Google Scholar] [CrossRef]

- Braccini, A.M.; Margherita, E.G. Exploring Organizational Sustainability of Industry 4.0 under the Triple Bottom Line: The Case of a Manufacturing Company. Sustainability 2018, 11, 36. [Google Scholar] [CrossRef]

- Moghaddam, M.; Cadavid, M.N.; Kenley, B.; Deshmukh, A.V. Reference architectures for smart manufacturing: A critical review. J. Manuf. Syst. 2018, 49, 215–225. [Google Scholar] [CrossRef]

- Paravizo, E.; Chaim, O.C.; Braatz, D.; Muschard, B.; Rozenfeld, H. Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 2018, 21, 438–445. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process. Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Hidayatno, A.; Destyanto, A.R.; Hulu, C.A. Industry 4.0 Technology Implementation Impact to Industrial Sustainable Energy in Indonesia: A Model Conceptualization. Energy Procedia 2019, 156, 227–233. [Google Scholar] [CrossRef]

- Phuong, N.A.; Guidat, T. Sustainable Value Stream Mapping and Technologies of Industry 4.0 in Manufacturing Process Reconfiguration: A Case Study in an Apparel Company. Available online: https://ieeexplore.ieee.org/document/8476750 (accessed on 24 September 2020).

- Kumar, R.; Singh, S.P.; Lamba, K. Sustainable robust layout using Big Data approach: A key towards industry 4.0. J. Clean. Prod. 2018, 204, 643–659. [Google Scholar] [CrossRef]

- Wiśniewska-Sałek, A. Sustainable Development in Accordance With the Concept of Industry 4.0 on the Example of the Furniture Industry. MATEC Web Conf. 2018, 183, 04005. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.-I. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Tsai, W.-H.; Lu, Y.-H. A Framework of Production Planning and Control with Carbon Tax under Industry 4.0. Sustainability 2018, 10, 3221. [Google Scholar] [CrossRef]

- Bibaud-Alves, J.; El-Haouzi, H.B.; Thomas, P.; Boucinha, V. Toward a Sustainable New Product Development Approach Based on Industry 4.0 Assets. In Service Orientation in Holonic and Multi-Agent Manufacturing; Borangiu, T., Trentesaux, D., Thomas, A., Cavalieri, S., Eds.; Studies in Computational Intelligence; Springer International Publishing: Cham, Switzerland, 2019; Volume 803, pp. 156–167. ISBN 978-3-030-03002-5. [Google Scholar]

- Birkel, H.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- Roda-Sanchez, L.; Garrido-Hidalgo, C.; Hortelano, D.; Olivares, T.; Ruiz, M.C. OperaBLE: An IoT-Based Wearable to Improve Efficiency and Smart Worker Care Services in Industry 4.0. J. Sens. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Ardanza, A.; Moreno, A.; Segura, Á.; De La Cruz, M.; Aguinaga, D. Sustainable and flexible industrial human machine interfaces to support adaptable applications in the Industry 4.0 paradigm. Int. J. Prod. Res. 2019, 57, 4045–4059. [Google Scholar] [CrossRef]

- Zambon, I.; Cecchini, M.; Egidi, G.; Saporito, M.G.; Colantoni, A. Revolution 4.0: Industry vs. Agriculture in a Future Development for SMEs. Processes 2019, 7, 36. [Google Scholar] [CrossRef]

- Belaud, J.-P.; Prioux, N.; Vialle, C.; Sablayrolles, C. Big data for agri-food 4.0: Application to sustainability management for by-products supply chain. Comput. Ind. 2019, 111, 41–50. [Google Scholar] [CrossRef]

- Trivelli, L.; Apicella, A.; Chiarello, F.; Rana, R.; Fantoni, G.; Tarabella, A. From precision agriculture to Industry 4.0: Unveiling technological connections in the agrifood sector. Br. Food J. 2019, BFJ-11-2018-0747. [Google Scholar] [CrossRef]

- Miranda, J.; Ponce, P.; Molina, A.; Wright, P. Sensing, smart and sustainable technologies for Agri-Food 4.0. Comput. Ind. 2019, 108, 21–36. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process. Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Chaim, O.; Muschard, B.; Cazarini, E.; Rozenfeld, H. Insertion of sustainability performance indicators in an industry 4.0 virtual learning environment. Procedia Manuf. 2018, 21, 446–453. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart Factories in Industry 4.0: A Review of the Concept and of Energy Management Approached in Production Based on the Internet of Things Paradigm. Available online: https://ieeexplore.ieee.org/document/7058728 (accessed on 24 September 2020).

- Bonilla, S.H.; Silva, H.R.O.; Da Silva, M.T.; Gonçalves, R.F.; Sacomano, J.B. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.D.S.; Jabbour, C.J.C.; Foropon, C.; Filho, M.G. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, Y.; Chung, H.; Lee, P.-H.; Shao, C. Enhancing Sustainability and Energy Efficiency in Smart Factories: A Review. Sustainability 2018, 10, 4779. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput. Ind. 2018, 101, 107–119. [Google Scholar] [CrossRef]

- Huh, J.-H.; Lee, H.-G. Simulation and Test Bed of a Low-Power Digital Excitation System for Industry 4.0. Processes 2018, 6, 145. [Google Scholar] [CrossRef]

- Fritzsche, K.; Niehoff, S.; Beier, G. Industry 4.0 and Climate Change—Exploring the Science-Policy Gap. Sustainability 2018, 10, 4511. [Google Scholar] [CrossRef]

- Del Campo, G.; Calatrava, S.; Canada, G.; Olloqui, J.; Martinez, R.; Santamaria, A. IoT Solution for Energy Optimization in Industry 4.0: Issues of a Real-life Implementation. Available online: https://ieeexplore.ieee.org/document/8534537 (accessed on 24 September 2020).

- Axelsson, J.; Froberg, J.; Eriksson, P. Towards a System-of-Systems for Improved Road Construction Efficiency Using Lean and Industry 4.0. Available online: https://ieeexplore.ieee.org/document/8428698 (accessed on 24 September 2020).

- Hernandez-Luna, M.; Robledo-Fava, R.; Fernández de Córdoba, P.; Paredes, A.; Michinel Álvarez, H.; Zaragoza Fernández, S. Uso de la correlación estadística para la gestión energética en locales de oficina empleando técnicas de la Industria 4.0. DYNA Ing. Ind. 2018, 93, 602–607. [Google Scholar] [CrossRef]

- Medojevic, M.; Diaz Villar, P.; Cosic, I.; Rikalovic, A.; Sremcev, N.; Lazarevic, M. Energy Management in Industry 4.0 Ecosystem: A Review on Possibilities and Concerns. Available online: https://www.daaam.info/Downloads/Pdfs/proceedings/proceedings_2018/097.pdf (accessed on 24 September 2020).

- Wang, X.V.; Wang, L. Digital twin-based WEEE recycling, recovery and remanufacturing in the background of Industry 4.0. Int. J. Prod. Res. 2018, 57, 3892–3902. [Google Scholar] [CrossRef]

- Tsai, W.-H. Green Production Planning and Control for the Textile Industry by Using Mathematical Programming and Industry 4.0 Techniques. Energies 2018, 11, 2072. [Google Scholar] [CrossRef]

- Sherazi, H.H.R.; Imran, M.; Boggia, G.; Grieco, L.A. Energy Harvesting in LoRaWAN: A Cost Analysis for the Industry 4.0. IEEE Commun. Lett. 2018, 22, 2358–2361. [Google Scholar] [CrossRef]

- Tsai, W.-H.; Chu, P.-Y.; Lee, H.-L. Green Activity-Based Costing Production Planning and Scenario Analysis for the Aluminum-Alloy Wheel Industry under Industry 4.0. Sustainability 2019, 11, 756. [Google Scholar] [CrossRef]

- Monteleone, S.; de Moraes, E.A.; Maia, R.F. Analysis of the Variables That Affect the Intention to Adopt Precision Agriculture for Smart Water Management in Agriculture 4.0 Context. Available online: https://ieeexplore.ieee.org/document/8766384 (accessed on 24 September 2020).

- Bechtsis, D.; Tsolakis, N.; Vouzas, M.; Vlachos, D. Industry 4.0: Sustainable material handling processes in industrial environments. In Computer Aided Molecular Design: Theory and Practice; Elsevier BV: Amsterdam, The Netherlands, 2017; Volume 40, pp. 2281–2286. [Google Scholar]

- Franciosi, C.; Iung, B.; Miranda, S.; Riemma, S. Maintenance for Sustainability in the Industry 4.0 context: A Scoping Literature Review. IFAC-PapersOnLine 2018, 51, 903–908. [Google Scholar] [CrossRef]

- Vinuela, A.D.L.H.G.; Gonzalez, F.A.; Roldan, A.C. Propuesta de marco de trabajo para la evaluación de la sostenibilidad de productos desde el paradigma de la economía circular basada en industria 4.0 (parte 1). DYNA 2018, 93, 360–364. [Google Scholar] [CrossRef]

- Vinuela, A.D.L.H.G.; Gonzalez, F.A.; Roldan, A.C. Propuesta de marco de trabajo para la evaluación de la sostenibilidad de los productos desde el paradigma de la economía circular basada en industria 4.0 (Parte 2). DYNA 2018, 93, 488–496. [Google Scholar] [CrossRef]

- Ma, H. An Industry 4.0 Technologies-Driven Warehouse Resource Management System. In Advanced Manufacturing and Automation VIII; Wang, K., Wang, Y., Strandhagen, J.O., Yu, T., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2019; Volume 484, pp. 27–33. ISBN 9789811323744. [Google Scholar]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Campuzano-Bolarín, F.; García, F.M.; Nicolas, J.A.M. Bogataj Supply Chain Risk of Obsolescence at Simultaneous Robust Perturbations. Sustainability 2019, 11, 5484. [Google Scholar] [CrossRef]

- Campuzano-Bolarín, F.; Mula, J.; Díaz-Madroñero, M.; Legaz-Aparicio, Á.-G. A rolling horizon simulation approach for managing demand with lead time variability. Int. J. Prod. Res. 2020, 58, 3800–3820. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).