Traceability of Ready-to-Wear Clothing through Blockchain Technology

Abstract

1. Introduction

- Tracing the goods transported by ship worldwide as part of international logistics processes, to avoid unnecessary paperwork associated to each container (as an example, sending refrigerated goods from a country in East Africa to another one in Europe requires several stamps and approvals from more than twenty workers and officials).

- Managing fishing industries where the quality control and quality assurance is a challenging task.

- Enabling a record with details about the provenance for each aircraft component.

- Helping to improve integrity and traceability in the global supply chains.

- Transparency and visibility in all the information shared among the different supply chain actors have become essential characteristics for a sustainable supply chain.

- The textile product maintenance affects the durability and recyclability of the product. The maintenance takes place especially during processes such as washing, dyeing and drying. Product maintenance aspects must be shared with retailers, suppliers and consumers.

- Reverse logistics processes must include waste management and the collection of used products. An efficient inverse logistic system should make use of traceability mechanisms.

- Market surveillance ensures that the products meet the proper standards and applicable laws, using data about the origin, history, raw material composition, etc.

- Sales forecasting and production data management use records of real-time product data, enabling more effective and precise sales forecasts, production management, and also control.

- Confidentiality and prevention of data leakages are some of the key concerns of the textile and clothes supply chain in terms of information security. In this respect, cryptographic protocols are one of the advantages of blockchain technology, as they guarantee the protection of data and avoid unauthorized changes.

- Marketing activities are changing and consumers need more information about products. The capability to trace the history of garments helps to promote a positive brand image and increases sales.

2. Blockchain Technology

2.1. Introduction

2.2. Hash Functions

2.3. Digital Signatures

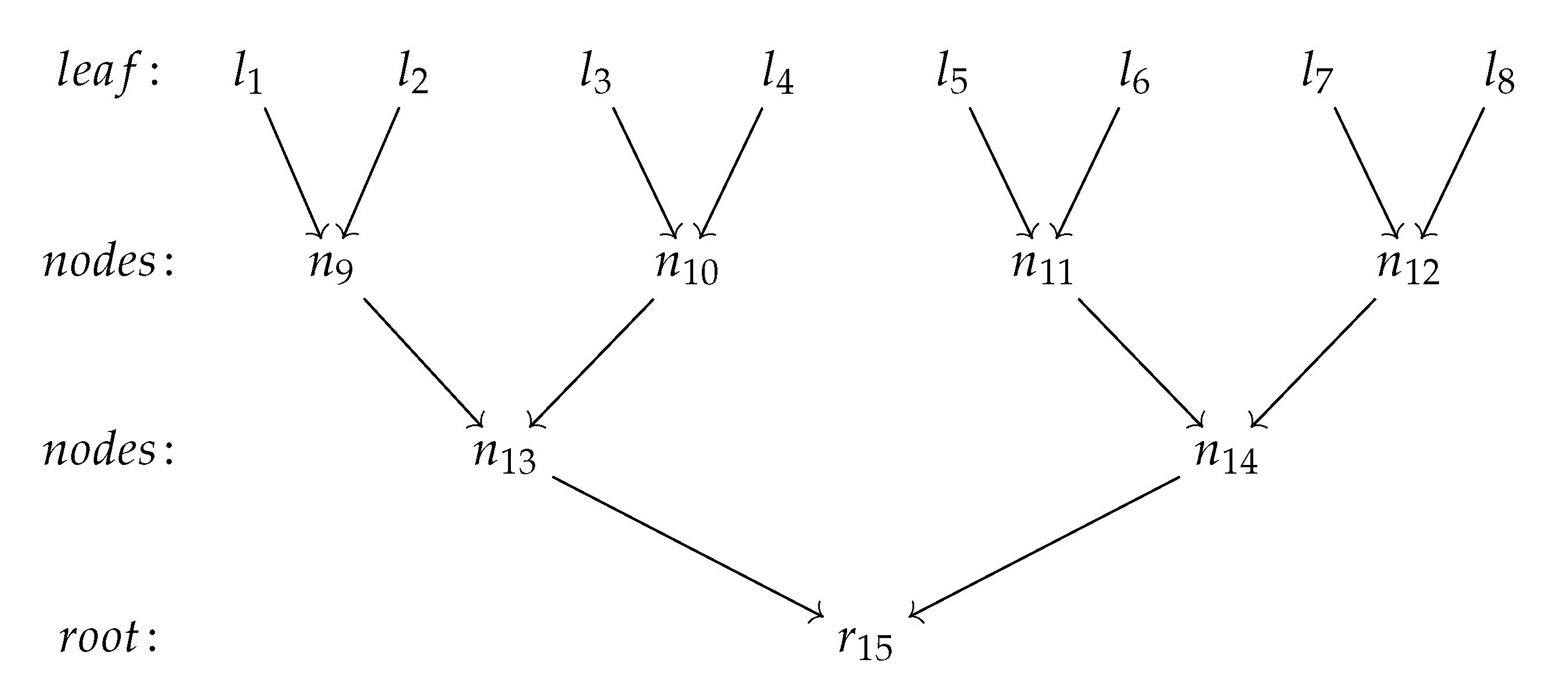

2.4. Merkle Trees

2.5. Blockchain Distributed System for Tracking the Supply Chain

3. Traceability of the Apparel Industry

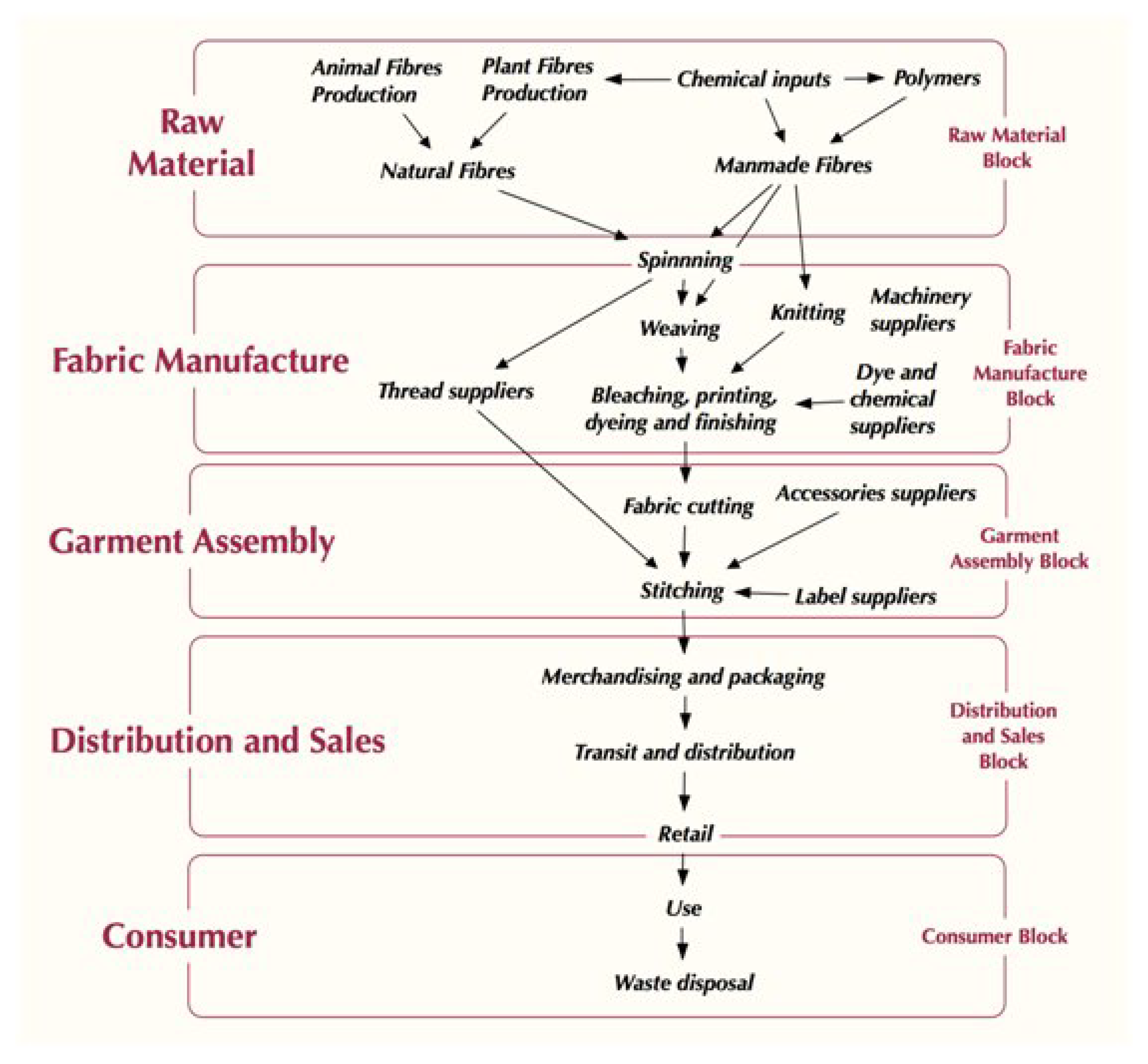

3.1. Textile Supply Chain

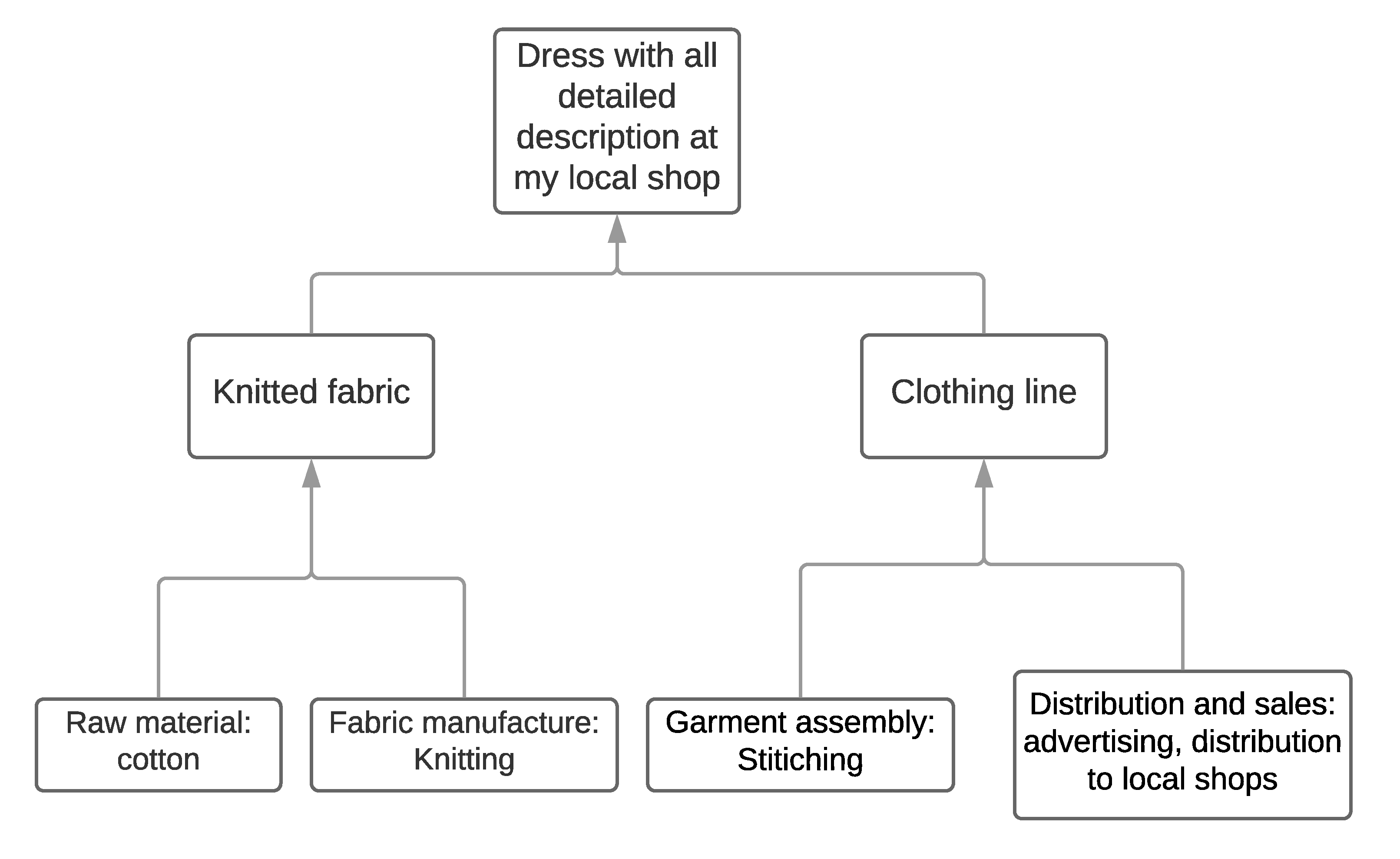

- Suppliers from the raw material network. This information also contains the origin of the material, and some physical properties such as the composition, fineness, fibre length, color, or color fastness.

- Yarns that are woven or knitted into fabrics. The thickness, strength and elongation, colour, colour fastness and humidity level are also included in the spinning phase. In addition to the spinning process, the fabric manufacture also returns information on the weight or the pilling. Machinery suppliers act in the whole fabric manufacture because they are responsible for machinery certification and products validation. These companies certify the history or origin of garments manufacture through their networks for machines and software always connected.

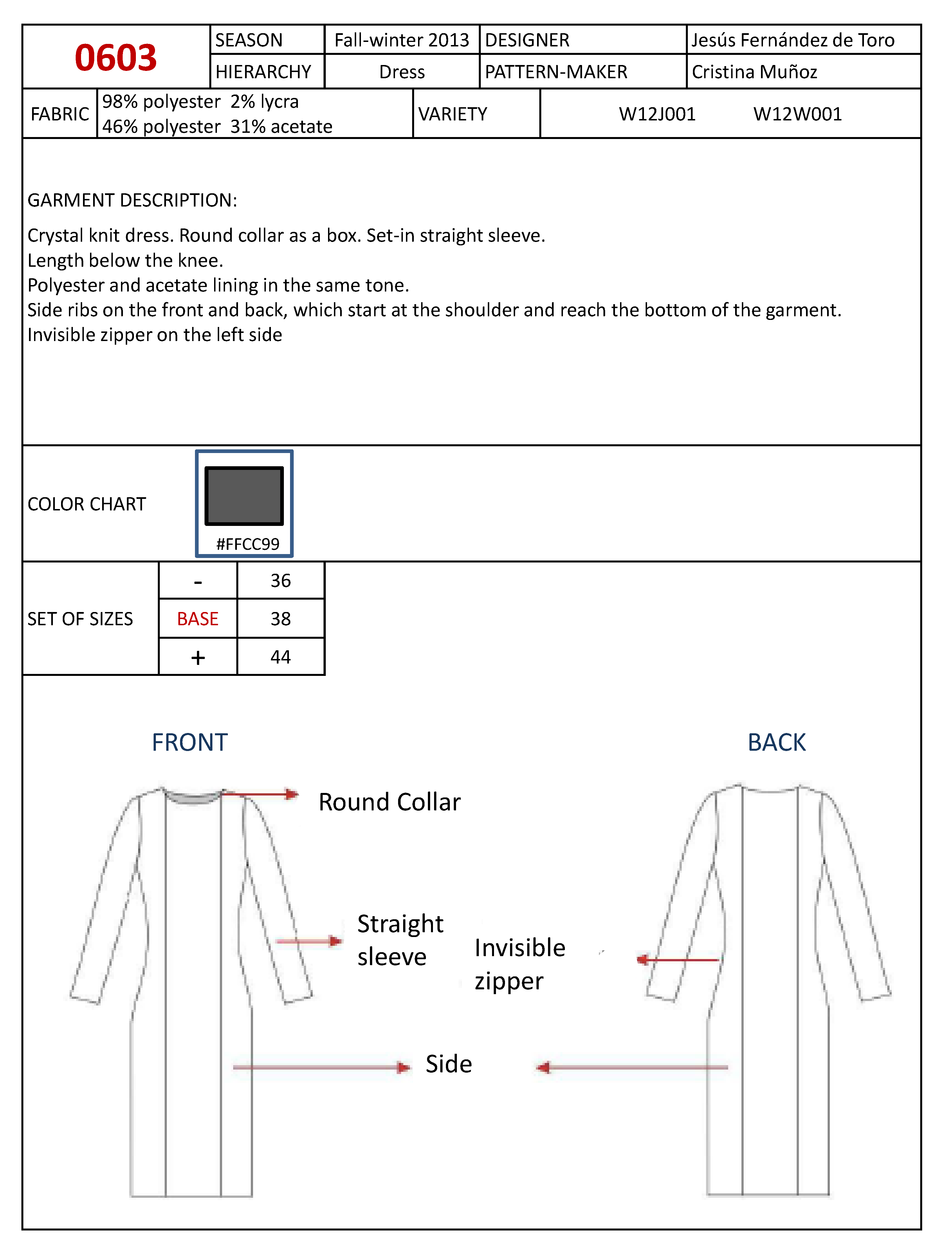

- Information about the production network with the corresponding steps through the garments. The garment assembly is very important when working with prêt à porter clothing, as it includes the design, the data sheet, the basic pattern, data about the scaled clothing, and the industry’s operations for the final assembly.

- Buying offices, agents, domestic apparel companies, and distribution centres or speciality stores as part of the marketing network.

- The retailer or customer that gets the product with some specific characteristics.

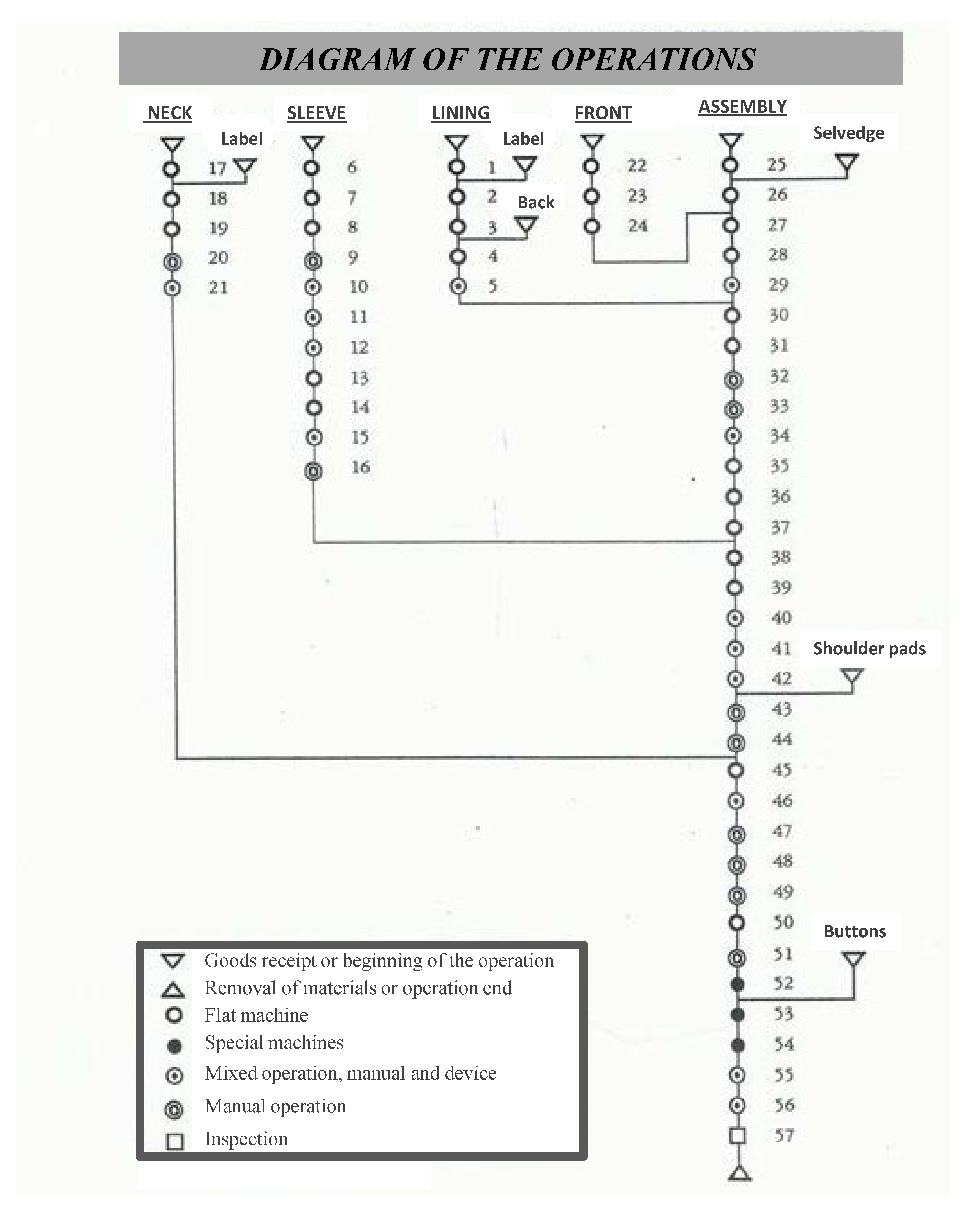

- The operations diagram, which is simple, contains less information and specifies the parts, the assembly order and the type of machines to be used. Figure 3 shows one of these operations diagram that were used during our developments.

- The list of phases that specifies the activity to be carried out in the packaging, as well as the frequency, the machine, the type of code of stitch in reference to the activity carried out, and the space for the necessary observations that have been made in the office and that will be passed on to the clothing workshop. It could also include the time per unit (TMU).

3.2. Traceability of Ready-to-Wear Clothing Manufacturing Industry

- The composition and origin of the product, including organic and non-organic compounds, and raw materials that were employed in the elaboration of the final products.

- Detailed information about all the companies and all the suppliers that contribute to the lifecycle of the product.

- Inbound and outbound specific information about material that is provided by suppliers.

- Cost of the final product, calculated as sum of costs of raw material and all intermediate products.

- Lot numbers to facilitate traceability.

- Real-time sales data in different retail channels.

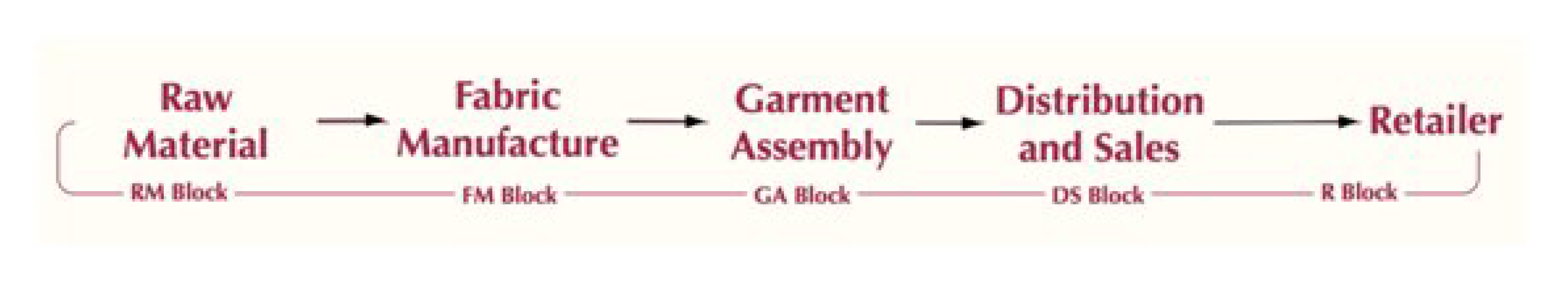

- Raw material and fibre manufacture: it is common to monitor plant growth parameters like temperature, blend, moisture and fertility. Furthermore, raw material and fibre manufacture are also responsible for the processes or period of getting the crops. Chain records should contain, at the very least, location, types of fibres, origin, treatments, and performance characteristics of fibres durability, strength, elasticity, and flexibility.

- Fabric manufacture is the set of operations that allow to derive fabric from fibres. In order to ensure traceability, records of the processes and raw materials employed to create the fabric should be kept on the chain. This should include the suppliers’ detailed information, the date provided, a description of the received products, types of fibres, records of internal procedures (e.g., carding and spinning), chemical composition (including additives), distribution records, etc. At this step, the fabric may be sent to a distributor or a clothing manufacturer.

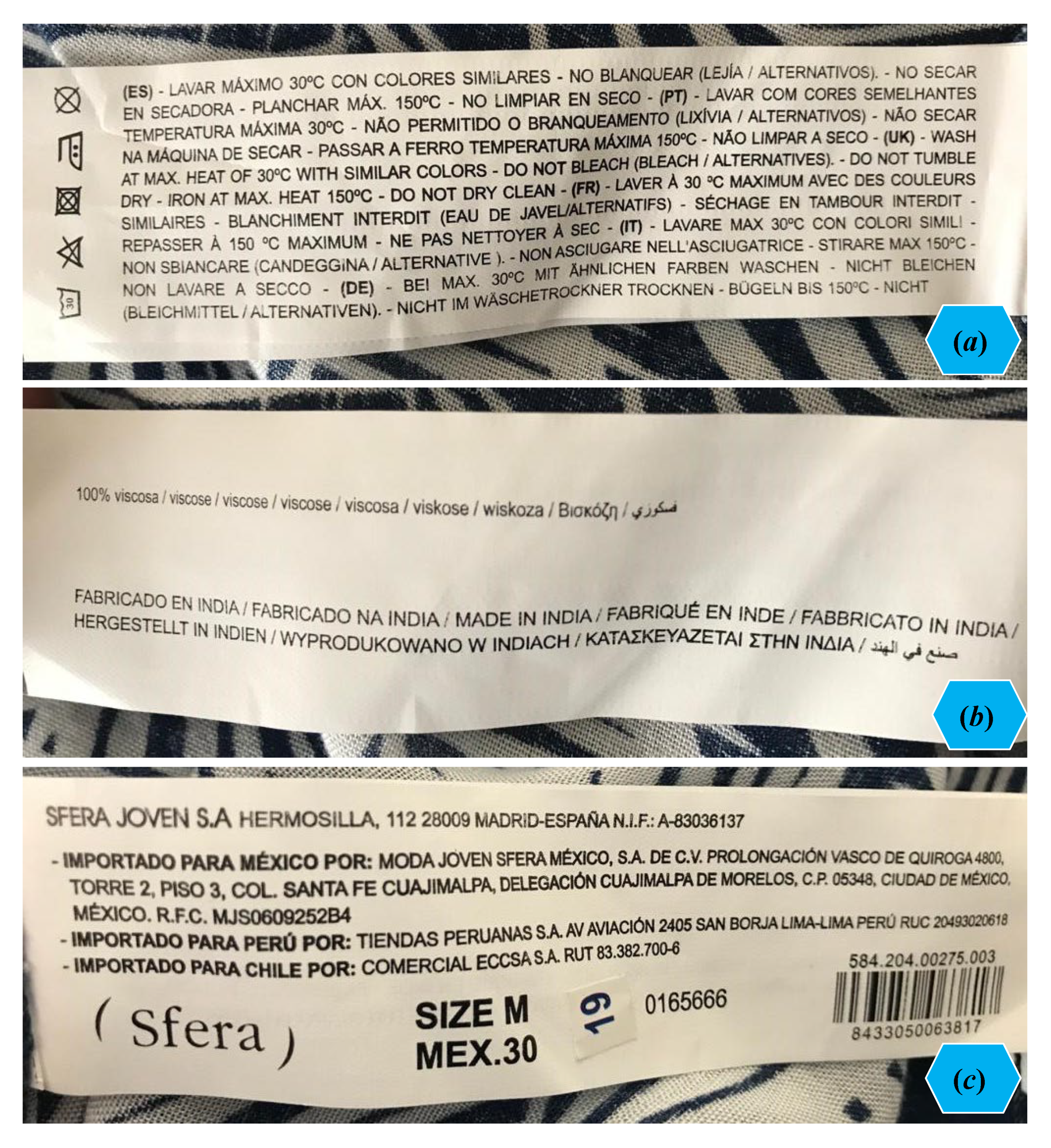

- Garment assembly: the clothing manufacturer is responsible for receiving fabrics from the producers or distributor and producing the garment. From the design of a garment to the packing of a finished product, several data elements are required. The information that should be recorded at this stage includes grading, pattern making, nesting, marking, cutting, sewing, quality inspection, pressing and packaging. Given that the identification and labelling of each garment is performed at this stage, it is important to ensure consistency of the information that appears on the label and the records stored on the blockchain.

- Distribution and sales includes:

- Finished goods distributor: the load received by the goods distributor are dispatched to wholesalers or retailers. The responsibilities of goods distributor include receiving, storing, dispatching, and managing the inventory of finished goods. At this step of the process, if any re-packing or re-labelling is needed, the new details must be inserted into the blockchain.

- Wholesalers, which receive the finished goods from distributors, dispatch them to retail stores. Wholesalers are responsible for the logistic process, with the reception of garments, storage in the corresponding warehouse, and finally, the dispatch of the goods. For that reason, they also need to maintain consistency of the information stored in the blockchain.

- Retailers, which receive finished goods from wholesalers or the goods distributors, sell them to end customers. When a garment is sold, the information must be accordingly recorded in the blockchain. Retailers are responsible for managing the details of the items they have received and stored. After storing the information on the blockchain, consumers will be able to see the provenance of the purchased garment by entering the identification number on the website.

- Other entities: In addition to the above mentioned entities, there are other participants in the supply chain that are not directly related to the production or processing of garments. Some of these stakeholders are machinery (thread suppliers, dye and chemical, and label suppliers), freight operators responsible for transporting goods, and importers that are responsible for buying goods from the original manufacturer and delivering them to the destination country.

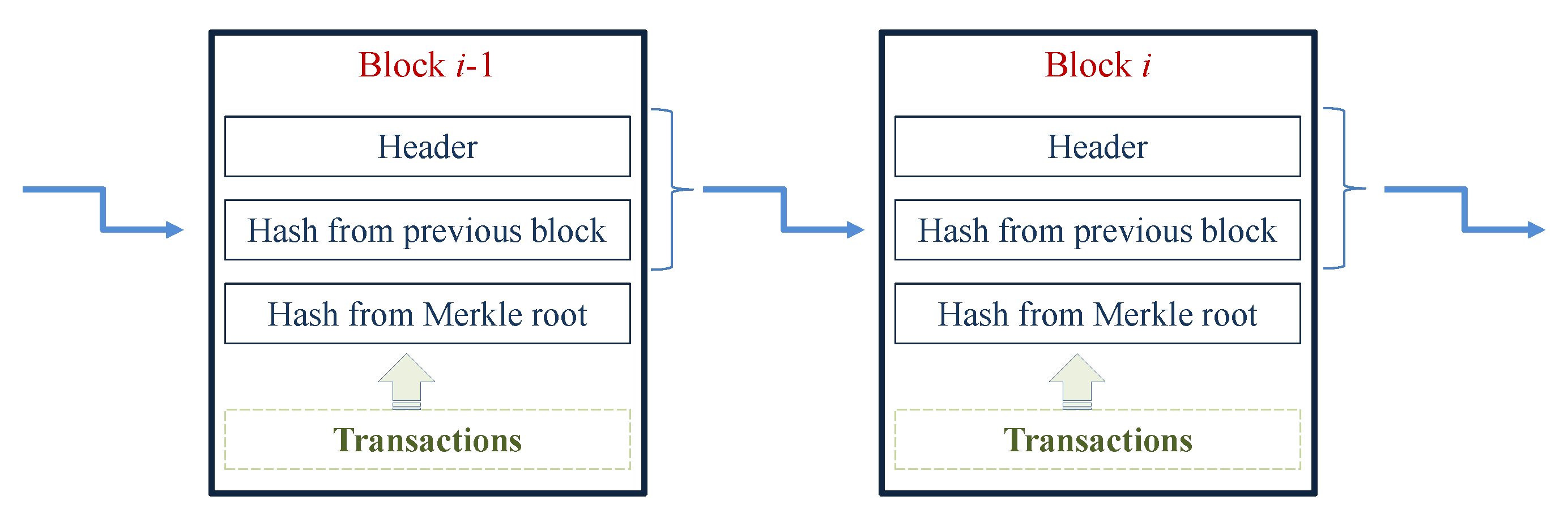

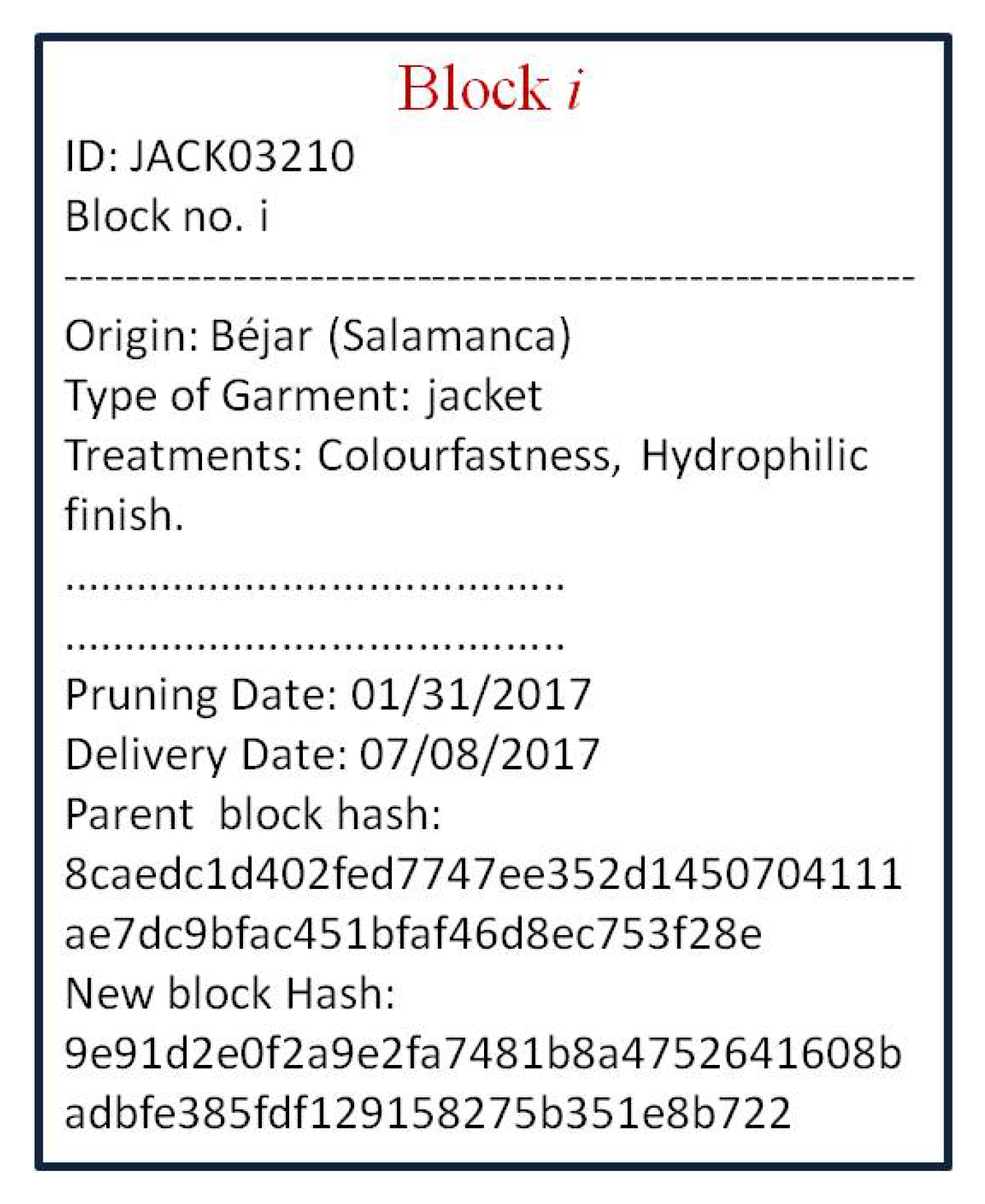

- The block version indicating the set of rules to be followed.

- The Merkle tree root and the hash value obtained from all the transactions in the block.

- A timestamp with the current time (typically measured in seconds passed since 1 January 1970).

- The limit of a valid block hash.

- A nonce consisting in a 4-byte value.

- The parent block hash pointing to the previous block (typically computed with the SHA-256 function).

- The new block hash with a SHA-256 hash value pointing to the next block.

- Additional information as block description.

4. Garment Traceability: A Case Study

| Algorithm 1: How to trace a garment |

|

- Unique identification code for textile agents and their role within the production chain, marketing, distribution, and sale of the textile unit to be registered.

- Location of the establishment where the textile unit is located at the time of registration.

- Unique code and batch number of the textile unit.

- All the intervening agents must corroborate the identity of their buyers and their suppliers, providing their unique identification code for textile agents, as well as certify the delivery or reception of the textile units to them.

- Information on the following activities may be incorporated: Shipping and reception of the product in a state of return, deteriorated or destroyed code, stolen or lost product.

- String: Material: 100% viscose. Extracted from plant-based products. Made from wood pulp. Chemical treatment with ammonia, acetone, and sulphuric acid. From China. Durability: 7 years.#70:00b5ed758dfc28ff6fd56b7a1b6d2ccb279c82121695e337b528ae460eee126a#293:00034157ad04991ca0a2e7a54f3ac4bce74b87a0ab708b06446d5af3573e3e00#129697:000069b2ee4512a3178cb56343ff30d24c089d47c34209a51de17f97e12734dc#1206386:00000a1d995b03a0f248f076e255b0cd11f4392a5d96f7ba4b6bfb8eab54cfa2#11094201:000000db8d2f7b35ba38bf5c17e090aa54fd466a8486ac114820ce28ae035c99

- String: Wet spinning process in which H2SO4 reacs to Na2SO4, which is recycled to H2SO4 in an additional process.#185:00c603ca0b14f99ff32c44efb7d7997e19c33970faeaefeeced46b08fcd84d95#945:0006d1d709ff63fb48825a711fa908bbe4ce1af483b89deaba2d7fec70ff21a6#2115:00002d8285f59b2904759f831ddfa778f35c83c649beee816d64e4ccb5627048#281320:000005089e0b762c0e123b03c372e79a270a02683b1f61ac22e991bd418ae505#26585528:0000003c20fdd23e189aae6ee3a043348cb6b090609a0eb8de81f1a7f3d0e512

- String: Patterns make by a Spanish designer company. Specific software is used for this. Quality inspection passed each 2 years.#229:00c5afbbf8819443302e32e56bb241fae320c561c5aa63cc5f78d9d13c0d74ad#3851:0001835e911982a3f000c76bc2675f568634e50688f208222078a9b5a4ab63e1#49592:0000f7b48c117c8696e1a090c90441011594626a157d5290ef39ea63491c17af#2240215:000005c93ea7674006f463065ffb4ba6cf57a2f66c26bc1571e619cef30e5e8b#15075051:000000d11b1baffbe98fc631f103bc6f751a0e30b69b6b7dc921755aabe780c2

- String: Recibido en España por El Corte Inglés central logistics platform (Calle Carpetanos, 85, 28320 Pinto, Madrid). Distribuido por El Corte Inglés de Salamanca (María Auxiliadora 71-85, 37004 - Salamanca). Local de venta: Sfera: C/ Toro 40, 37002 - Salamanca.#729:00c591befee611245b6945015e59c9b25f5b4be02298396a2ed23452c0d0585f#5798:000b3052094c977db55da14b8f03a5538c23107d89cc813ade074ff71c3fa4a1#63038:0000739ffe583f37667a93d95313c04d9470c045a598685706f9d207b18decb9#767278:00000404b6ead67fca498533f6c1ec785ac91a99d50cae83b3400688fd5e676d#10094157:0000003a01f51e59dce09b6242683ff54f1aac9caf9ede5a2b48b3eca49a4890

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| DLT | Distributed Ledger Technology |

| ECDSA | Elliptic Curve Discrete Logarithm Algorithm |

| EdDSA | Edwards-curve Digital Signature Algorithm |

| IoT | Internet of Things |

| NIST | National Institute of Standards and Technology |

| RSA | Rivest–Shamir–Adleman |

| SHA | Secure Hash Algorithm |

| TOWF | Trapdoor One-Way Functions |

References

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How virtualization, decentralization and network building change the manufacturing landscape: An industry 4.0 perspective. Int. J. Mech. Ind. Sci. Eng. 2014, 8, 37–44. [Google Scholar]

- Onufrey, K.; Bergek, A. Second wind for exploitation: Pursuing high degrees of product and process innovativeness in mature industries. Technovation 2020, 89, 102068. [Google Scholar] [CrossRef]

- Chan, P.; Barnett, J.; Lee, J. Systems and Methods for Monitoring Construction Projects. U.S. Patent App. 15/235,090, 16 February 2017. [Google Scholar]

- Andoni, M.; Robu, V.; Flynn, D.; Abram, S.; Geach, D.; Jenkins, D.; McCallum, P.; Peacock, A. Blockchain technology in the energy sector: A systematic review of challenges and opportunities. Renew. Sustain. Energy Rev. 2019, 100, 143–174. [Google Scholar] [CrossRef]

- Lu, H.; Huang, K.; Azimi, M.; Guo, L. Blockchain technology in the oil and gas industry: A review of applications, opportunities, challenges, and risks. IEEE Access 2019, 7, 41426–41444. [Google Scholar] [CrossRef]

- Miravete, D.; Guzmán, D. Sistema y Método de Monitorización del Daño en Estructuras. WO Patent App. PCT/ES2009/000,280, 26 November 2009. [Google Scholar]

- Rojas, O.; León, J.; Crespo, F.; Gross, N.; Sánchez, M. Sistema Para la Monitorización y Análisis de Señales Cardiorrespiratorias y del Ronquido. WO Patent App. PCT/ES2007/000,254, 25 March 2008. [Google Scholar]

- Stivoric, J.; Andre, D.; Kasabach, C.; Hanlon, J.; Vishnubhatla, S.; Pacione, C.; Boehmke, S.; Teller, E.; Gasbarro, J.; Farringdon, J. Non-Invasive Temperature Monitoring Device. U.S. Patent 8,663,106, 4 March 2014. [Google Scholar]

- Biswas, K.; Muthukkumarasamy, V.; Tan, W.L. Blockchain Based Wine Supply Chain Traceability System. In Proceedings of the Future Technologies Conference, Vancouver, BC, Canada, 29–30 November 2017. [Google Scholar]

- Agrawal, T.K.; Koehl, L.; Campagne, C. A secured tag for implementation of traceability in textile and clothing supply chain. Int. J. Adv. Manuf. Technol. 2018, 99, 2563–2577. [Google Scholar] [CrossRef]

- Pigini, D.; Conti, M. NFC-Based Traceability in the Food Chain. Sustainability 2017, 9, 1910. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- Pigni, F.; Crave, S.; Aurelio, R. Traceability in the textile and clothing industry: Issues and implications for RFId adoption. In Proceedings of the 2nd Mediterranean Conference on Information Systems, MCIS 2007, Venice, Italy, 4–8 October 2007. [Google Scholar]

- Tse, D.; Zhang, B.; Yang, Y.; Cheng, C.; Mu, H. Blockchain application in food supply information security. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 1357–1361. [Google Scholar]

- Kshetri, N. 1 Blockchain’s roles in meeting key supply chain management objectives. Int. J. Inf. Manag. 2018, 39, 80–89. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

- Keung Kwok, S.; Wu, K.K. RFID-based intra-supply chain in textile industry. Ind. Manag. Data Syst. 2009, 109, 1166–1178. [Google Scholar] [CrossRef]

- Shen, B. Sustainable fashion supply chain: Lessons from H&M. Sustainability 2014, 6, 6236–6249. [Google Scholar]

- Remy, N.; Speelman, E.; Swartz, S. Style That’s Sustainable: A New Fast-Fashion Formula; McKinsey & Company: New York, NY, USA, 2016; pp. 1–6. [Google Scholar]

- Kamath, N. Handbook of Research on Strategic Supply Chain Management in the Retail Industry; IGI Global: Hershey, PA, USA, 2016. [Google Scholar]

- Weller, F.; Wilson, M. Changemakers: Embracing Hope, Taking Action, and Transforming the World; New Society Publishers: Gabriola, BC, Canada, 2018. [Google Scholar]

- Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Sources; IUCN Gland: Gland, Switzerland, 2017. [Google Scholar]

- Kumar, V.; Agrawal, T.K.; Wang, L.; Chen, Y. Contribution of traceability towards attaining sustainability in the textile sector. Text. Cloth. Sustain. 2017, 3, 5. [Google Scholar] [CrossRef]

- Bruce, M.; Daly, L.; Towers, N. Lean or agile: A solution for supply chain management in the textiles and clothing industry? Int. J. Oper. Prod. Manag. 2004, 24, 151–170. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Sharma, A.; Kumar, V. Blockchain-based secured traceability system for textile and clothing supply chain. In Artificial Intelligence for Fashion Industry in the Big Data Era; Springer: Berlin/Heidelberg, Germany, 2018; pp. 197–208. [Google Scholar]

- Corbellini, S.; Ferraris, F.; Parvis, M. A cryptographic system for brand authentication and material traceability in the textile industry. In Proceedings of the 2006 Instrumentation and Measurement Technology Conference, Sorrento, Italy, 24–27 April 2006; pp. 1331–1335. [Google Scholar]

- Egels-Zandén, N.; Hulthén, K.; Wulff, G. Trade-offs in supply chain transparency: The case of Nudie Jeans Co. J. Clean. Prod. 2015, 107, 95–104. [Google Scholar] [CrossRef]

- Kumar, V. Exploring Fully Integrated Textile Tags and Information Systems for Implementing Traceability in Textile Supply Chains. Ph.D. Thesis, University Lille 1 in Collaboration with Högskolan i Boras (Sweden) and Soochow University (Suzhou), Boras, Sweden, 2017. [Google Scholar]

- Agrawal, T.K.; Pal, R. Traceability in textile and clothing supply chains: Classifying implementation factors and information sets via Delphi study. Sustainability 2019, 11, 1698. [Google Scholar] [CrossRef]

- Swan, M. Blockchain: Blueprint for a New Economy; O’Reilly Media, Inc.: New York, NY, USA, 2015. [Google Scholar]

- Reyna, A.; Martín, C.; Chen, J.; Soler, E.; Díaz, M. On blockchain and its integration with IoT. Challenges and opportunities. Future Gener. Comput. Syst. 2018, 88, 173–190. [Google Scholar] [CrossRef]

- Stein, T. Supply Chain with Blockchain–Showcase RFID. 2017. Available online: https://faizod.com/wp-content/downloads/Supply-Chain-with-Blockchain—Showcase-RFID-en.pdf (accessed on 21 February 2018).

- Menezes, A.J.; Katz, J.; Van Oorschot, P.C.; Vanstone, S.A. Handbook of Applied Cryptography; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Balmat, N. RFC 1321: The MD5 Message-Digest Algorithm. 1992. Available online: https://tools.ietf.org/html/rfc1321. (accessed on 15 March 2018).

- NIST. Secure Hash Standard (SHS). Federal Information Processing Standard Publication, FIPS 180-4. 2015. Available online: https://nvlpubs.nist.gov/nistpubs/FIPS/NIST.FIPS.180-4.pdf (accessed on 15 March 2018).

- NIST. Digital Signature Standard (DSS). 2013. Available online: https://nvlpubs.nist.gov/nistpubs/FIPS/NIST.FIPS.186-4.pdf (accessed on 30 August 2020).

- Josefsson, S.; Liusvaara, I. Edwards-Curve Digital Signature Algorithm (EdDSA). 2017. Available online: https://tools.ietf.org/html/rfc8032 (accessed on 30 August 2020).

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. 2008. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 9 September 2020).

- Gayoso Martínez, V.; Hernández-Álvarez, L.; Hernández Encinas, L. Analysis of the Cryptographic Tools for Blockchain and Bitcoin. Mathematics 2020, 8, 131. [Google Scholar] [CrossRef]

- Johnson, D.; Menezes, A.; Vanstone, S. The elliptic curve digital signature algorithm (ECDSA). Int. J. Inf. Sec. 2001, 1, 36–63. [Google Scholar] [CrossRef]

- Merkle, R.C. Protocols for public key cryptosystems. In Proceedings of the 1980 IEEE Symposium on Security and Privacy, Oakland, CA, USA, 14–16 April 1980; p. 122. [Google Scholar]

- Nan, Y.; Nan, Y.; Liu, Y.; Liu, Y.; Shen, J.; Shen, J.; Chai, Y.; Chai, Y. A study on MCIN model in intelligent clothing industry. Int. J. Crowd Sci. 2017, 1, 133–145. [Google Scholar] [CrossRef]

- Zheng, Z.; Xie, S.; Dai, H.N.; Wang, H. Blockchain challenges and opportunities: A survey. J. Web Grid Serv. 2018, 14, 352–375. [Google Scholar] [CrossRef]

- ElMessiry, M.; ElMessiry, A. Blockchain framework for textile supply chain management. In Proceedings of the International Conference on Blockchain, Seattle, WA, USA, 25–30 June 2018; pp. 213–227. [Google Scholar]

- Bullón Pérez, J.J.; Arrieta, G.A.; Encinas, A.H.; Queiruga-Dios, A. Manufacturing processes in the textile industry. Expert Systems for fabrics production. Adcaij-Adv. Distrib. Comput. Artif. Intell. J. 2017, 6, 15–23. [Google Scholar] [CrossRef][Green Version]

- Ali, A.; Haseeb, M. Radio frequency identification (RFID) technology as a strategic tool towards higher performance of supply chain operations in textile and apparel industry of Malaysia. Uncertain Supply Chain Manag. 2019, 7, 215–226. [Google Scholar] [CrossRef]

- Obser, S. Facing the Challenge of Supply Chain Traceability; Niederrhein University of Applied Sciences in Mönchengladbach: Mönchengladbach, Germany, 2015. [Google Scholar]

- Zhelyazkov, G. Agile Supply Chain: Zara’s case study analysis. Des. Manuf. Eng. Manag. 2011, 1, 2–11. [Google Scholar]

- Lam, O.W.A.; Zhibin, L. Textile and Apparel Supply Chain with Distributed Ledger Technology (DLT). In Proceedings of the 2019 20th IEEE International Conference on Mobile Data Management (MDM), Hong Kong, China, 10–13 June 2019; pp. 447–451. [Google Scholar]

- Kumar, V.; Hallqvist, C.; Ekwall, D. Developing a framework for traceability implementation in the textile supply chain. Systems 2017, 5, 33. [Google Scholar] [CrossRef]

- Strähle, J.; Merz, L. Case Study: Total transparency at Honestby. com. In Green Fashion Retail; Springer: Berlin/Heidelberg, Germany, 2017; pp. 269–291. [Google Scholar]

- Phau, I.; Teah, M.; Chuah, J. Consumer attitudes towards luxury fashion apparel made in sweatshops. J. Fash. Mark. Manag. 2015. [Google Scholar] [CrossRef]

- Petersen, O.; Jansson, F. Blockchain Technology in Supply Chain Traceability Systems. Master’s Thesis, Lund University, Lund, Sweden, 2017. [Google Scholar]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An overview of blockchain technology: Architecture, consensus, and future trends. In Proceedings of the 2017 IEEE International Congress on Big Data (BigData Congress), Honolulu, HI, USA, 25–30 June 2017; pp. 557–564. [Google Scholar]

- Shahbandeh, M. Cotton Production by Country Worldwide in 2018/2019. 2019. Available online: http://https://www.statista.com/statistics/263055/cotton-production-worldwide-by-top-countries/ (accessed on 5 August 2020).

- Tobler-Rohr, M.I. Handbook of Sustainable Textile Production; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Gatteschi, V.; Lamberti, F.; Demartini, C.; Pranteda, C.; Santamaria, V. To blockchain or not to blockchain: That is the question. IT Prof. 2018, 20, 62–74. [Google Scholar] [CrossRef]

- Pathak, S. How Blockchain Can Be Used in Fashion. 2016. Available online: http://campfire-capital.com/retail-tech/blockchain-and-fashion/ (accessed on 15 February 2018).

- Balmat, N. Blockchain | How tech Can Provide Transparency to Fashion Supply Chains. 2014. Available online: https://futur404.com/blockchain/ (accessed on 15 February 2018).

- Singla, A. Blockchain Visualisation using the Wolfram Language. 2017. Available online: http://community.wolfram.com/groups/-/m/t/1139834 (accessed on 15 February 2018).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bullón Pérez, J.J.; Queiruga-Dios, A.; Gayoso Martínez, V.; Martín del Rey, Á. Traceability of Ready-to-Wear Clothing through Blockchain Technology. Sustainability 2020, 12, 7491. https://doi.org/10.3390/su12187491

Bullón Pérez JJ, Queiruga-Dios A, Gayoso Martínez V, Martín del Rey Á. Traceability of Ready-to-Wear Clothing through Blockchain Technology. Sustainability. 2020; 12(18):7491. https://doi.org/10.3390/su12187491

Chicago/Turabian StyleBullón Pérez, Juan José, Araceli Queiruga-Dios, Víctor Gayoso Martínez, and Ángel Martín del Rey. 2020. "Traceability of Ready-to-Wear Clothing through Blockchain Technology" Sustainability 12, no. 18: 7491. https://doi.org/10.3390/su12187491

APA StyleBullón Pérez, J. J., Queiruga-Dios, A., Gayoso Martínez, V., & Martín del Rey, Á. (2020). Traceability of Ready-to-Wear Clothing through Blockchain Technology. Sustainability, 12(18), 7491. https://doi.org/10.3390/su12187491