Setbacks to IoT Implementation in the Function of FMCG Supply Chain Sustainability during COVID-19 Pandemic

Abstract

1. Introduction

2. Theoretical Background

2.1. Subject, Goals, and Contributions of the Paper

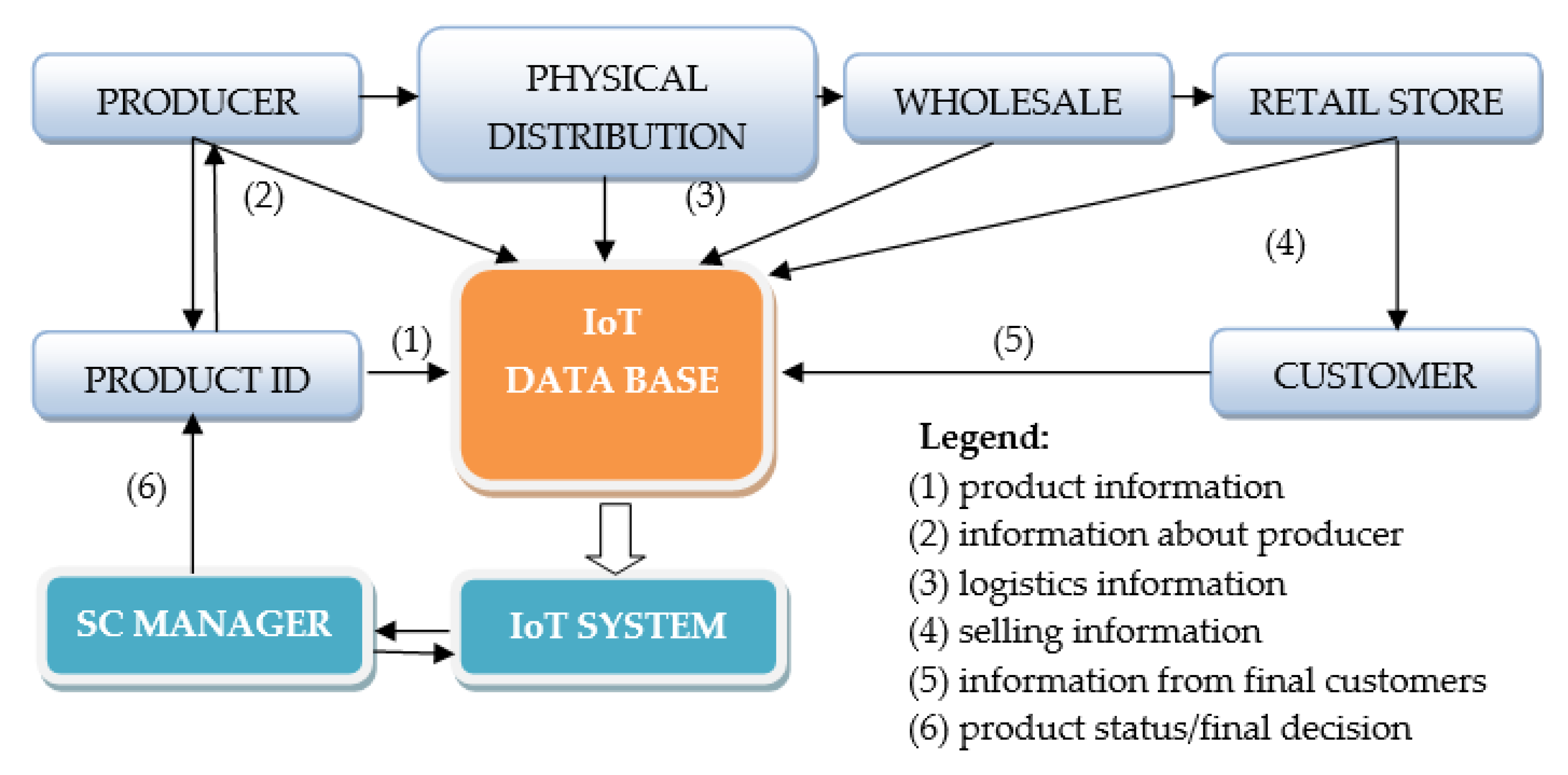

2.2. Theoretical Basis of Formation and Structuring of the IoT implementation in the FMCG Supply Chain

2.3. The Setbacks to IoT Implementation in the FMCG Supply Chain

3. Methodology

3.1. Aim and Hypotheses

3.2. Research Variables

3.3. Research Sample

3.4. Research Procedure and Data Analysis

4. Results

5. Discussion

5.1. Defining a Model for Predicting the Significance of Setbacks to Delaying IoT Implementation

- Financial incentives—Imply taking a whole set of measures to financially empower the supply chain participants for the implementation of IoT. These would be specialized credit lines for the introduction of advanced technology (e.g., low-interest rates, long repayment period), tax relief and exemptions from VAT on devices and equipment for the implementation and application of IoT, deferral of payment for primary energy sources (electricity, water, gas), programs for co-financing the development of modern information infrastructure (e.g., co-financing by National Funds, commercial banks).

- Incentives for employment—Are related to measures aimed at empowering human resources and training them for the application of advanced technology. These measures imply subsidies for new employment for participants who are accessing digitalization. They also include reduction of taxes and contributions for existing workers, organization of specialized courses and training programs for the use of advanced technologies, education of employees on safety, hygiene, and health measures during the COVID-19 pandemic, knowledge transfer, etc.

- Security measures—Are all those measures that guarantee the security and privacy protection of users. They include clearly defined privacy policy rules for all IoT users, the introduction of security measures when transferring data (e.g., application of SSL—Secure Socket Layer encryption), strictly defined rules when passing data to third parties, the introduction of security measures to protect networking processes within a chain from malware and external attacks (e.g., installation of firewalls, high-security codes), the assistance of experts and institutions in process standardization, etc. In addition to these measures, state institutions, as well as the participants in the supply chain in the WB region, should raise awareness among producers, distributors, wholesalers, and retailers, as well as consumers, about the need for digitalization and its advantages over traditional supply chains, especially during severe market disruptions and long-term shocks caused by the COVID-19 pandemic.

5.2. Comments on the Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, L.; Wells, P. Automobilities after SARS-CoV-2: A Socio-Technical Perspective. Sustainability 2020, 12, 5978. [Google Scholar] [CrossRef]

- Obrenović, B.; Du, J.; Godinic, D.; Tsoy, D.; Shafique Khan, M.A.; Jakhongirov, I. Sustaining Enterprise Operations and Productivity during the COVID-19 Pandemic: Enterprise Effectiveness and Sustainability Model. Sustainability 2020, 12, 5981. [Google Scholar] [CrossRef]

- Agbehadji, I.E.; Awuzie, B.O.; Ngowi, A.B.; Millham, R.C. Review of Big Data, Artificial Intelligence and Nature-Inspired Computing Models for Performance Improvement towards Detection of COVID-19 Pandemic Case and Contact Tracing. Int. J. Environ. Res. Public Health 2020, 17, 5330. [Google Scholar] [CrossRef] [PubMed]

- Hirata, A.; Kodera, S.; Gomez-Tames, J.; Rashed, E.A. Influence of Absolute Humidity and Population Density on COVID-19 Spread and Decay Durations: Multi-prefecture Study in Japan. Int. J. Environ. Res. Public Health 2020, 17, 5354. [Google Scholar] [CrossRef]

- Worldometer. Reported Corrona Cases and Deaths by Country, Territory, or Conveyance. Available online: https://www.worldometers.info/coronavirus/ (accessed on 25 July 2020).

- Nientied, P.; Shutina, D. Tourism in Transition, the post Covid-19 Aftermath in the Western Balkan. Co-PLAN Resil. Ser. 2020, 2, 1–20. [Google Scholar] [CrossRef]

- Ivanov, D. Viable supply chain model: Integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Ann. Oper. Res. 2020, 1, 1–21. [Google Scholar] [CrossRef]

- Hobbs, J.E. Food supply chains during the COVID-19 pandemic. Can. J. Agric. Econ. Rev. Canadienne D’agroeconomie 2020, 68, 171–176. [Google Scholar] [CrossRef]

- Zhu, G.; Chou, M.C.; Tsai, C.W. Lessons Learned from the COVID-19 Pandemic Exposing the Shortcomings of Current Supply Chain Operations: A Long-Term Prescriptive Offering. Sustainability 2020, 12, 5858. [Google Scholar] [CrossRef]

- Ivanov, D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922. [Google Scholar] [CrossRef]

- Rizou, M.; Galanakis, I.M.; Aldawoud, T.M.; Galanakis, C.M. Safety of foods, food supply chain and environment within the COVID-19 pandemic. Trends Food Sci. Technol. 2020, 102, 293–299. [Google Scholar] [CrossRef]

- Shahzad, A.; Zhang, K.; Gherbi, A. Intuitive Development to Examine Collaborative IoT Supply Chain System Underlying Privacy and Security Levels and Perspective Powering through Proactive Blockchain. Sensors 2020, 20, 3760. [Google Scholar] [CrossRef]

- Silva, B.N.; Khan, M.; Han, K. Futuristic Sustainable Energy Management in Smart Environments: A Review of Peak Load Shaving and Demand Response Strategies, Challenges, and Opportunities. Sustainability 2020, 12, 5561. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Tata Consultancy Services—TCS. Annual Report 2015–2016. Available online: https://www.tcs.com/content/dam/tcs/investor-relations/financial-statements/2015-16/ar/TCS%20Annual%20Report%202015-2016.pdf (accessed on 26 July 2020).

- Khan, M.A.; Salah, K. IoT security: Review, blockchain solutions, and open challenges. Future Gener. Comput. Syst. 2018, 82, 395–411. [Google Scholar] [CrossRef]

- Končar, J.; Vučenović, S.; Marić, R. Green Supply Chain Management in Retailing Based on Internet of Things. In Integration of Information Flow for Greening Supply Chain Management; Springer: Cham, Switzerland, 2020; pp. 181–202. [Google Scholar]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Kukard, W.; Wood, L. Consumers’ perceptions of item-level RFID Use in FMCG: A balanced perspective of benefits and risks. J. Glob. Inf. Manag. (JGIM) 2017, 25, 21–42. [Google Scholar] [CrossRef]

- Read, J.; Martino, L.; Luengo, D. Efficient Monte Carlo methods for multi-dimensional learning with classifier chains. Pattern Recognit. 2014, 47, 1535–1546. [Google Scholar] [CrossRef]

- Jia, B.B.; Zhang, M.L. Multi-dimensional classification via knn feature augmentation. Pattern Recognit. 2020, 106, 107423. [Google Scholar] [CrossRef]

- Camps-Valls, G.; Martino, L.; Svendsen, D.H.; Campos-Taberner, M.; Muñoz-Marí, J.; Laparra, V.; García-Haro, F.J. Physics-aware Gaussian processes in remote sensing. App. Soft Comput. 2018, 68, 69–82. [Google Scholar] [CrossRef]

- Dreiseitl, S.; Ohno-Machado, L. Logistic regression and artificial neural network classification models: A methodology review. J. Biomed. Inform. 2002, 35, 352–359. [Google Scholar] [CrossRef]

- Sharma, A.; Adhikary, A.; Borah, S.B. Covid-19’s Impact on Supply Chain Decisions: Strategic Insights for NASDAQ 100 Firms using Twitter Data. J. Bus. Res. 2020, 117, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, N. Economic Effects of Coronavirus Outbreak (COVID-19) on the World Economy; IESE Business School: Barcelona, Spain, 2020; pp. 1–29. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3557504 (accessed on 27 July 2020).

- Ivanov, D.; Das, A. Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: A research note. Int. J. Integr. Supply Manag. 2020, 13, 90–102. [Google Scholar] [CrossRef]

- Mattinson, A. Coronavirus Demand Surge Supercharges Grocery Industry Growth. 2020. Available online: https://www.thegrocer.co.uk/finance/coronavirus-demand-surge-supercharges-grocery-industry-growth/603530.article (accessed on 27 July 2020).

- Redman, R. Grocery a Bright Spot in Record March Retail Sales Decline. 2020. Available online: https://www.supermarketnews.com/consumer-trends/grocery-bright-spot-record-march-retail-sales-decline (accessed on 27 July 2020).

- Chang, H.H.; Meyerhoefer, C. COVID-19 and the Demand for Online Food Shopping Services: Empirical Evidence from Taiwan; National Bureau of Economic Research: Cambridge, MA, USA, 2020; pp. 1–31. [Google Scholar] [CrossRef]

- Kilpatrick, J. COVID-19: Managing Supply Chain Risk and Disruption. Available online: https://www2.deloitte.com/ca/en/pages/finance/articles/covid-19-managing-supply-chain-risk-and-disruption (accessed on 27 July 2020).

- Singh, R.; Dwivedi, A.D.; Srivastava, G. Internet of Things Based Blockchain for Temperature Monitoring and Counterfeit Pharmaceutical Prevention. Sensors 2020, 20, 3951. [Google Scholar] [CrossRef]

- Din, M.S.; Rehman, M.A.U.; Ullah, R.; Park, C.-W.; Kim, B.S. Towards Network Lifetime Enhancement of Resource Constrained IoT Devices in Heterogeneous Wireless Sensor Networks. Sensors 2020, 20, 4156. [Google Scholar] [CrossRef] [PubMed]

- Pešterac, A.; Tomić, N. Loss of privacy in electronic payment systems. Ann. Fac. Econ. Subot. 2020, 56, 135–149. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Manogaran, G.; Mohamed, M.; Gunasekaran, M. Internet of Things (IoT) and its impact onsupply chain: A framework for building smart, secure and efficient systems. Future Gener. Comput. Syst. 2018, 86, 614–628. [Google Scholar] [CrossRef]

- Majeed, A.A.; Rupasinghe, T.D. Internet of things (IoT) embedded future supply chains for industry 4.0: An assessment from an ERP-based fashion apparel and footwear industry. Int. J. Supply Chain Manag. 2017, 6, 25–40. [Google Scholar]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Wang, P.; Chaudhry, S.; Li, L.; Li, S.; Tryfonas, T.; Li, H. The Internet of Things: A security point of view. Internet Res. 2016, 26, 337–359. [Google Scholar] [CrossRef]

- Granjal, J.; Monteiro, E.; Sá Silva, J. Security for the internet of things: A survey of existing protocols and open research issues. IEEE Commun. Surv. Tutor. 2015, 17, 1294–1312. [Google Scholar] [CrossRef]

- Bedekar, A. Opportunities & Challenges for IoT in India. Available online: http://www.startupcity.com/leaders-talk/-opportunitieschallenges-for-iot-in-india-nid-3444.html (accessed on 30 July 2020).

- Hameed, S.; Khan, F.I.; Hameed, B. Understanding security requirements and challenges in Internet of Things (IoT): A review. J. Comput. Netw. Commun. 2019, 1–14. [Google Scholar] [CrossRef]

- Whitmore, A.; Agarwal, A.; Da Xu, L. The Internet of Things—A Survey of Topics and Trends. Inf. Syst. Front. 2015, 17, 261–274. Available online: https://link.springer.com/content/pdf/10.1007/s10796-014-9489-2.pdf (accessed on 30 July 2020). [CrossRef]

- Botta, A.; De Donato, W.; Persico, V.; Pescapé, A. Integration of cloud computing and internet of things: A survey. Future Gener. Comput. Syst. 2016, 56, 684–700. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Mangla, S.K.; Berwal, Y.P.S. Analyzing challenges to Internet of Things (IoT) adoption and diffusion: An Indian context. Procedia Comput. Sci. 2018, 125, 733–739. [Google Scholar] [CrossRef]

- Al-Fuqaha, A.; Guizani, M.; Mohammadi, M.; Aledhari, M.; Ayyash, M. Internet of things: A survey on enabling technologies, protocols, and applications. IEEE Commun. Surv. Tutor. 2015, 17, 2347–2376. [Google Scholar] [CrossRef]

- Anđelković, A.; Radosavljević, M. The length of the distribution channel as a factor of its efficiency. Strateg. Manag. 2020, 25, 9–17. [Google Scholar] [CrossRef]

- Eurostat. Real GDP Growth Rate—Volume 2020Q1. Available online: https://ec.europa.eu/eurostat/databrowser/view/tec00115/default/table?lang=en (accessed on 31 July 2020).

- Bjelotomic, S. Brussels: Serbian GDP at −4.1%, Balkan Region at −9.1%. Available online: https://www.serbianmonitor.com/en/brussels-serbian-gdp-at-4-1-balkan-region-at-9-1/ (accessed on 31 July 2020).

- Szüdi, J. Fostering the Danube Region for Shared Prosperity. Der Donauraum 2019, 59, 177–188. [Google Scholar] [CrossRef]

- Vojvodic, K. Brick-and-Mortar Retailers: Becoming Smarter with Innovative Technologies. Strateg. Manag. 2019, 24, 3–11. [Google Scholar] [CrossRef]

- Petković, G.; Užar, D. Marketing channels in value creation and delivery of cheese in the Republic of Serbia. Ann. Fac. Econ. Subot. 2020, 56, 101–115. [Google Scholar] [CrossRef]

| No | Setback/ Indicator | Description | Sources |

|---|---|---|---|

| 1 | Data analysis and comprehension | Analysis of streaming data generated by digital sensors requires advanced computing devices, knowledge of mathematical models, as well as highly qualified and trained analysts | Lee and Lee [36] |

| 2 | User safety | User vulnerabilities due to lack of secure web interfaces, inadequate software protection, and insufficient authorization | Wang et al. [37] Gubbi et al. [18] Lee et al. [36] |

| 3 | Lack of financial resources | The implementation of IoT platforms requires substantial initial investments and enormous initial system maintenance cost | Končar et al. [17] Granjal et al. [38] |

| 4 | Lack of skilled workers | Insufficient training of all participants in the supply chain to apply advanced technologies and lack of skilled labor | Bedekar [39] |

| 5 | Privacy protection | Inability of IoT application users to protect their data related to their movement, consumption, needs, habits, and interactions | Hameed et al. [40] |

| 6 | Changing the business model | The implementation of IoT requires changes in the organization of the chain itself, for which participants are often not ready | Whitmore et al. [41] |

| 7 | Underdeveloped infrastructure | Infrastructure that is not able to effectively support and successfully manage interconnected products, equipment, and devices | Botta et al. [42] Luthra et al. [43] |

| 8 | Standardization | Problems with the introduction of new standards, certificates and permits for the implementation of IoT | Al-Fugaha et al. [44] |

| 9 | Lack of internet connection | Lack of internet connection, frequent signal interruptions, low use of WiFi connection, etc. | Luthra et al. [43] Bedekar [39] |

| 10 | Lack of awareness | Existence of an unclear need to digitalize IoT-based supply chain business operations. | Končar et al. [17] Anđelković and Radosavljević [45] |

| Gender | n | Structure (%) | Age | n | Structure (%) |

|---|---|---|---|---|---|

| Male | 121 | 57.9% | up to 30 | 34 | 16.3% |

| Female | 88 | 42.1% | 30–40 | 51 | 24.4% |

| 40–50 | 78 | 37.3% | |||

| over 50 | 46 | 22.0% | |||

| WB Countries | n | Structure (%) | FMCG Supply Chain Sector | n | Structure (%) |

| Crotia | 42 | 20.1% | Production | 49 | 23.4% |

| Serbia | 44 | 21.1% | Physical Distribution | 52 | 24.9% |

| Bosnia and Hercegovina | 40 | 19.1% | Wholesale | 51 | 24.4% |

| North Macedonia | 42 | 20.1% | Retail | 57 | 27.3% |

| Montenegro | 41 | 19.6% |

| Indicators | Cronbach’s Alpha | Skewness | Kurtosis |

|---|---|---|---|

| Data analysis and comprehension | 0.911 | −0.069 | −1.040 |

| User safety | 0.728 | −0.108 | −1.017 |

| Lack of financial resources | 0.839 | 0.341 | −0.885 |

| Lack of skilled workers | 0.701 | −0.327 | −1.273 |

| Privacy protection | 0.672 | −0.212 | −1.248 |

| Changing the business model | 0.755 | 0.057 | −1.538 |

| Underdeveloped infrastructure | 0.932 | −0.319 | −0.545 |

| Standardization | 0.811 | 0.273 | −1.143 |

| Lack of internet connection | 0.683 | 0.322 | −1.300 |

| Lack of awareness | 0.847 | 0.224 | −1.655 |

| Ord. No. | Indicators (Setbacks) | Production | Physical Distribution | Wholesale | Retail | Mean (M) |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1 | Data analysis and comprehension | 4.11 | 2.83 | 3.72 | 4.21 | 3.72 |

| 2 | User safety | 3.87 | 3.14 | 3.21 | 3.12 | 3.34 |

| 3 | Lack of financial resources | 4.41 | 4.13 | 4.25 | 4.05 | 4.21 |

| 4 | Lack of skilled workers | 3.96 | 3.35 | 4.11 | 3.70 | 3.78 |

| 5 | Privacy protection | 3.15 | 4.23 | 3.77 | 3.41 | 3.64 |

| 6 | Changing the business model | 4.01 | 3.27 | 2.88 | 2.96 | 3.28 |

| 7 | Underdeveloped infrastructure | 3.91 | 3.52 | 4.09 | 3.83 | 3.84 |

| 8 | Standardization | 3.86 | 3.28 | 2.62 | 3.40 | 3.29 |

| 9 | Lack of internet connection | 2.74 | 2.67 | 2.11 | 2.89 | 2.60 |

| 10 | Lack of awareness | 3.14 | 2.62 | 3.04 | 3.73 | 3.13 |

| Ord. No. | Indicators (Setbacks) | Min | Max. | Mean (M) | Standard Error (SE) | Standard Deviation (SD) |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1 | Data analysis and comprehension | 2.00 | 5.00 | 3.72 | 0.0603 | 0.8715 |

| 2 | User safety | 1.00 | 4.00 | 3.34 | 0.0649 | 0.9381 |

| 3 | Lack of financial resources | 2.00 | 5.00 | 4.21 | 0.0583 | 0.8425 |

| 4 | Lack of skilled workers | 1.00 | 5.00 | 3.78 | 0.0694 | 1.0027 |

| 5 | Privacy protection | 1.00 | 5.00 | 3.64 | 0.0811 | 1.1724 |

| 6 | Changing the business model | 1.00 | 5.00 | 3.28 | 0.0851 | 1.2308 |

| 7 | Underdeveloped infrastructure | 2.00 | 5.00 | 3.84 | 0.0448 | 0.6481 |

| 8 | Standardization | 1.00 | 5.00 | 3.29 | 0.0880 | 1.2728 |

| 9 | Lack of internet connection | 1.00 | 4.00 | 2.60 | 0.0600 | 0.8675 |

| 10 | Lack of awareness | 1.00 | 4.00 | 3.13 | 0.0638 | 0.9224 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Data analysis and comprehension | 1 | |||||||||

| 2 | User safety | 0.84 ** | 1 | ||||||||

| 3 | Lack of financial resources | 0.89 | 0.73 | 1 | |||||||

| 4 | Lack of skilled workers | 0.60 * | 0.36 | 0.77 ** | 1 | ||||||

| 5 | Privacy protection | 0.59 * | 0.75 ** | 0.49 | 0.59 | 1 | |||||

| 6 | Changing the business model | 0.73 | 0.83 | 0.35 | 0.47 | 0.53 | 1 | ||||

| 7 | Underdeveloped infrastructure | 0.78 ** | −0.87 | 0.91 ** | 0.86 ** | −0.25 | 0.61 * | 1 | |||

| 8 | Standardization | 0.34 | 0.51 | 0.64 | 0.66 * | 0.54 | 0.52 | 0.72 * | 1 | ||

| 9 | Lack of internet connection | 0.48 | 0.61 | 0.57 | 0.63 | −0.67 | 0.75 * | 0.58 | 0.46 | 1 | |

| 10 | Lack of awareness | 0.54 | 0.56 | 0.44 | 0.49 | −0.55 | 0.54 * | 0.60 | 0.56 | 0.62 | 1 |

| Stand. Coefficient | t | Sig. | ||

|---|---|---|---|---|

| Beta | St. Error | |||

| (const.) | 0.69 | 1.163 | 3.577 | 0.000 |

| Data analysis and comprehension | 0.462 ** | 0.362 | 0.528 | 0.045 |

| User safety | 0.865 | 0.476 | 0.813 | 0.183 |

| Lack of financial resources | 0.776 ** | 0.403 | 0.620 | 0.000 |

| Lack of skilled workers | 0.683 ** | 0.612 | 1.032 | 0.004 |

| Privacy protection | 0.492 * | 0,781 | 0.297 | 0.016 |

| Changing the business model | 0.518 * | 0.576 | 1.251 | 0.047 |

| Underdeveloped infrastructure | 0.559 ** | 0.391 | 0.405 | 0.004 |

| Standardization | 0.491 | 0.584 | 0.624 | 0.063 |

| Lack of internet connection | 0.517 | 0.374 | 0.416 | 0.084 |

| Lack of awareness | 0.255 | 0.572 | 0.734 | 0.191 |

| Production (p) | Physichal Distribution (phd) | Wholesale (w) | Retail (r) | |||||

|---|---|---|---|---|---|---|---|---|

| Beta | Sig. | Beta | Sig. | Beta | Sig. | Beta | Sig. | |

| (const.) | 0.81 | 0.017 | 0.74 | 0.003 | 0.62 | 0.000 | 0.74 | 0.001 |

| Data analysis and comprehension | 0.573 ** | 0.000 | 0.512 | 0.073 | 0.662 * | 0.033 | 0.795 ** | 0.002 |

| User safety | −0.608 | 0.055 | 0.929 * | 0.012 | 0.737 | −0.081 | 0.623 | 0.557 |

| Lack of financial resources | 0.490 ** | 0.001 | 0.627 ** | 0.000 | 0.914 ** | 0.000 | 0.769 * | 0.041 |

| Lack of skilled workers | 0.223 * | 0.042 | 0.036 | 0.790 | 0.228 ** | 0.003 | 0.095 ** | 0.003 |

| Privacy protection | 0.582 | 0.184 | 0.703 ** | 0.002 | - 0.653 | 0,694 | 0.704 ** | 0.008 |

| Changing the business model | 0.747 ** | 0.006 | 0.626 | 0.088 | 0.854 | 0.142 | 0.791 | 0.100 |

| Underdeveloped infrastructure | 0.711 * | 0.024 | 0.559 ** | 0.001 | 0.605 ** | 0.007 | 0.622 * | 0.013 |

| Standardization | −0.891 | 0.057 | 0.782 | −0.247 | 0.527 * | 0.046 | 0.303 | 0.114 |

| Lack of internet connection | −0.522 | 0.315 | −0.358 | 0.681 | 0.694 | 0.067 | 0.433 | 0.323 |

| Lack of awareness | 0.671 | 0.066 | 0.581 | 0.054 | 0.481 | 0.112 | 0.191 | 0.074 |

| Implementation of IoT | Analysis and Data Comprehension | User Safety | Lack of Financial Resources | Lack of Skilled Workers | Privacy Protection | Change of the Business Model | Underdeveloped Infrastructure | Standardization | Lack of Internet Connection | Lack of Awareness |

|---|---|---|---|---|---|---|---|---|---|---|

| Croatia | ||||||||||

| Correlation coefficient (r) | 0.722 ** | 0.306 | 0.689 ** | 0.397 ** | 0.687 * | 0.514 * | 0.784 * | 0.475 | 0.655 | 0.475 |

| Significance | 0.000 | 0.214 | 0.000 | 0.008 | 0.025 | 0.047 | 0.001 | 0.142 | 0.055 | 0.100 |

| Number | 42 | 42 | 42 | 42 | 42 | 42 | 42 | 42 | 42 | 42 |

| Serbia | ||||||||||

| Correlation coefficient (r) | 0.641 ** | 0.156 | 0.763 ** | 0.624 ** | 0.867 ** | 0.792 * | 0.386 ** | 0.861 | 0.660 | 0.704 |

| Significance | 0.008 | 0.074 | 0.000 | 0.001 | 0.003 | 0.035 | 0.004 | 0.110 | 0.081 | 0.817 |

| Number | 44 | 44 | 44 | 44 | 44 | 44 | 44 | 44 | 44 | 44 |

| Bosnia and Herzegovina | ||||||||||

| Correlation coefficient(r) | 0.662 ** | 0.381 | 0.782 ** | 0.838 ** | 0.630 * | 0.872 * | 0.746 ** | 0.482 | 0.516 | 0.441 |

| Significance | 0.000 | 0.071 | 0.003 | 0.000 | 0.021 | 0.000 | 0.001 | 0.066 | 0.141 | 0.091 |

| Number | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Montenegro | ||||||||||

| Correlation coefficient (r) | 0.487 ** | 0.142 | 0.597 ** | 0.609 * | 0.490 * | 0.717 * | 0.496 ** | 0.215 | 0.,234 | 0.500 |

| Significance | 0.001 | 0.100 | 0.003 | 0.014 | 0.044 | 0.000 | 0.000 | 0.107 | 0.059 | 0.084 |

| Number | 42 | 42 | 42 | 42 | 42 | 42 | 42 | 42 | 42 | 42 |

| Northern Macedonia | ||||||||||

| Correlation coefficient (r) | 0.765 * | 0.236 | 0.650 ** | 0.788 ** | 0.582 * | 0.560 * | 0.833 ** | 0.406 | 0.610 | 0.320 |

| Significance | 0.031 | 0.426 | 0.001 | 0.000 | 0.040 | 0.033 | 0.001 | 0.202 | 0.069 | 0.110 |

| Number | 41 | 41 | 41 | 41 | 41 | 41 | 41 | 41 | 41 | 41 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Končar, J.; Grubor, A.; Marić, R.; Vučenović, S.; Vukmirović, G. Setbacks to IoT Implementation in the Function of FMCG Supply Chain Sustainability during COVID-19 Pandemic. Sustainability 2020, 12, 7391. https://doi.org/10.3390/su12187391

Končar J, Grubor A, Marić R, Vučenović S, Vukmirović G. Setbacks to IoT Implementation in the Function of FMCG Supply Chain Sustainability during COVID-19 Pandemic. Sustainability. 2020; 12(18):7391. https://doi.org/10.3390/su12187391

Chicago/Turabian StyleKončar, Jelena, Aleksandar Grubor, Radenko Marić, Sonja Vučenović, and Goran Vukmirović. 2020. "Setbacks to IoT Implementation in the Function of FMCG Supply Chain Sustainability during COVID-19 Pandemic" Sustainability 12, no. 18: 7391. https://doi.org/10.3390/su12187391

APA StyleKončar, J., Grubor, A., Marić, R., Vučenović, S., & Vukmirović, G. (2020). Setbacks to IoT Implementation in the Function of FMCG Supply Chain Sustainability during COVID-19 Pandemic. Sustainability, 12(18), 7391. https://doi.org/10.3390/su12187391