Generalized Framework for the Design of Eco-Industrial Parks: Case Study of End-of-Life Vehicles

Abstract

1. Introduction

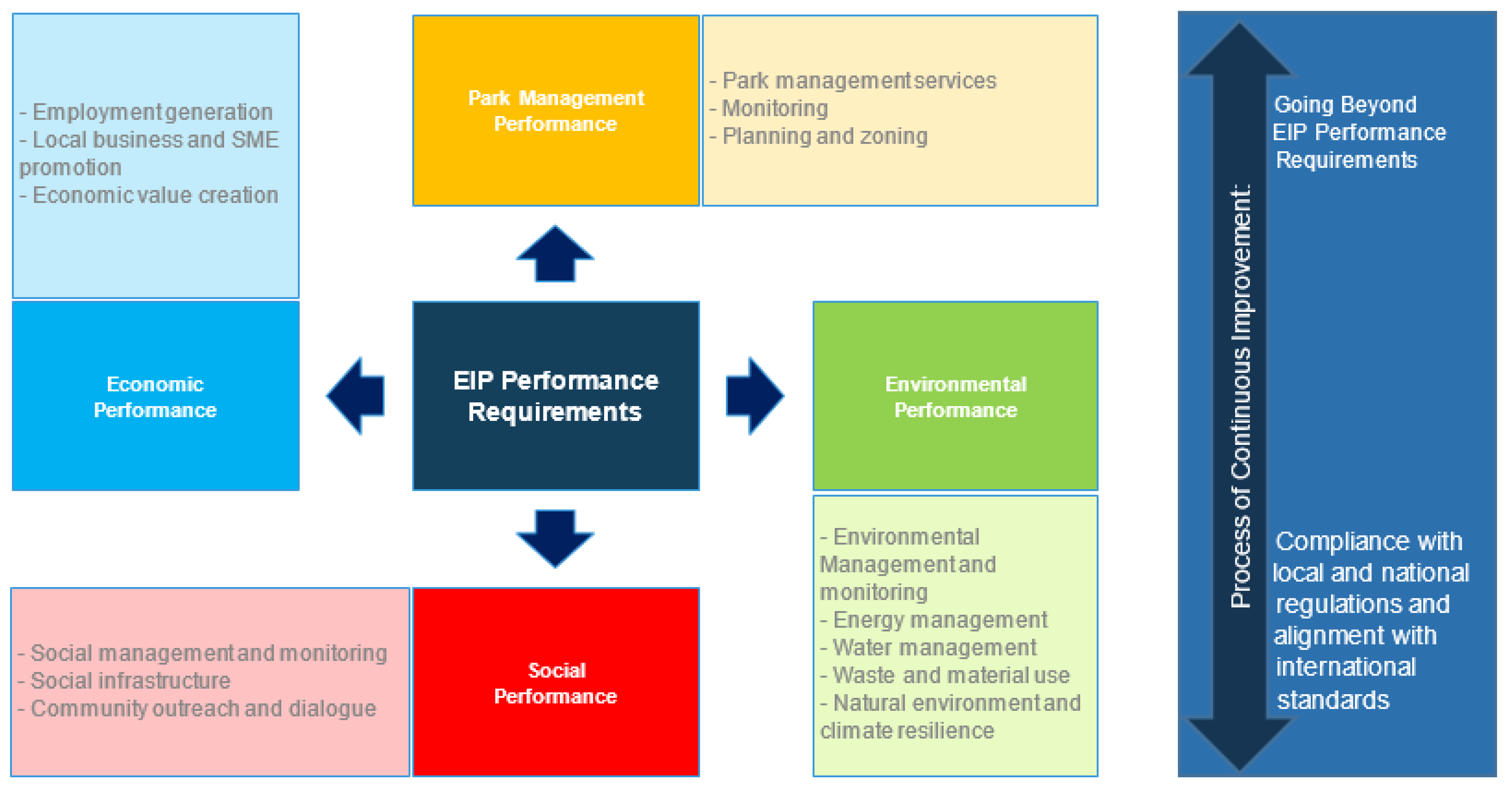

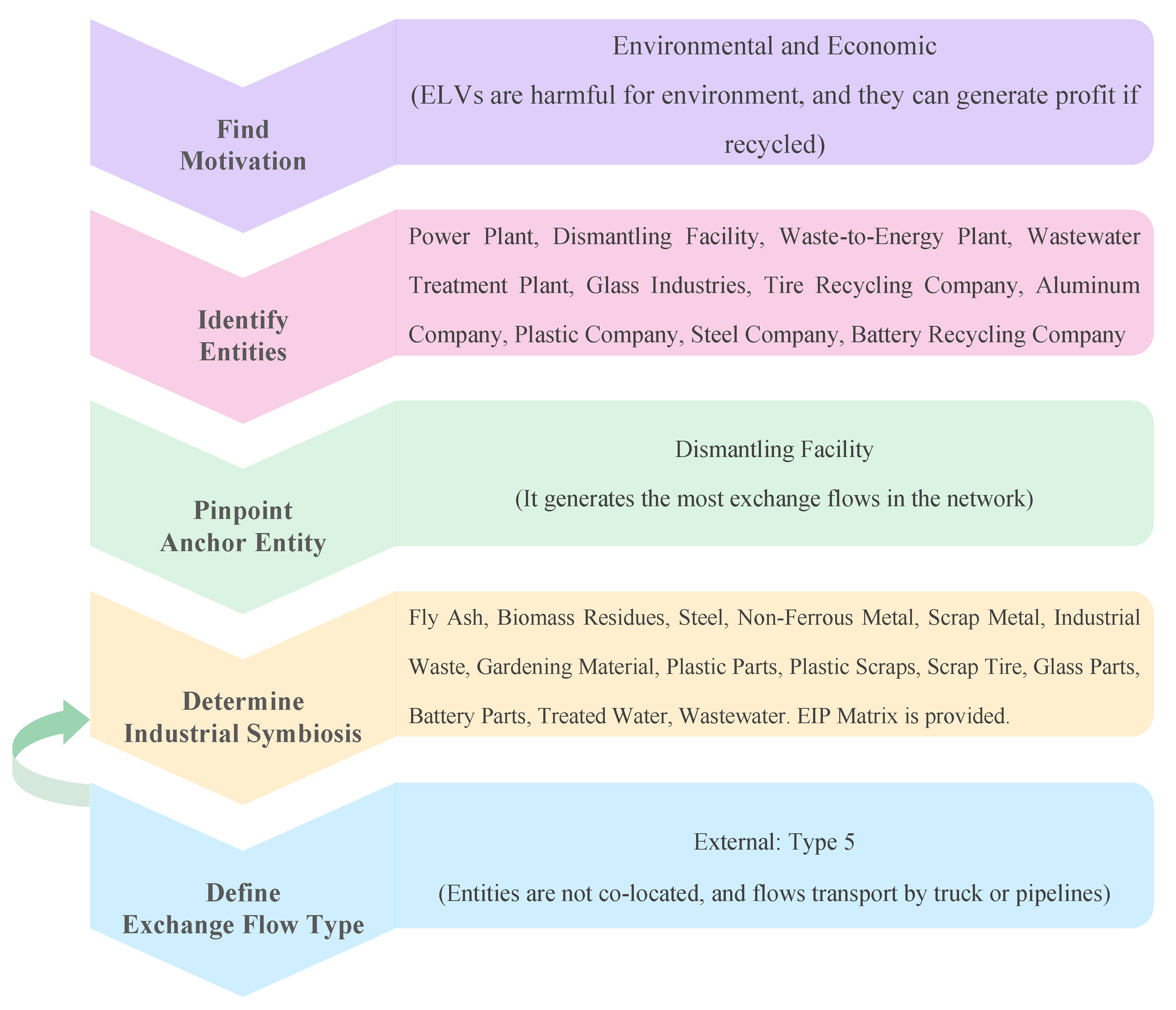

2. Generalized Framework for Eco-Industrial Park Design

2.1. Find Motivation

2.2. Identify Entities

2.3. Pinpoint Anchor Entity

2.4. Determining Industrial Symbiosis

2.5. Define Exchange-Flow Types

3. Framework Application

3.1. ELV Overview

3.2. Eco-Industrial Park for End-of-Life Vehicles

3.3. EIP-4-ELV Simulation

3.3.1. Model Assumptions

3.3.2. Model Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. Sci. Am. 1989, 261, 144–153. [Google Scholar] [CrossRef]

- Frosch, R.A. Industrial Ecology: Minimizing the Impact of Industrial Waste. Phys. Today 1994, 47, 63–68. [Google Scholar] [CrossRef]

- Gu, C.; Leveneur, S.; Estel, L.; Yassine, A. Modeling and optimization of material/energy flow exchanges in an eco-industrial park. Energy Procedia 2013, 36, 243–252. [Google Scholar] [CrossRef]

- Chertow, M.R. Uncovering’ Industrial Symbiosis. J. Ind. Ecol. 2007, 11, 20. [Google Scholar]

- Ehrenfeld, J.; Gertler, N. Industrial Ecology in Practice; The Evolution of Interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. [Google Scholar] [CrossRef]

- Piaszczyk, C. Model Based Systems Engineering with Department of Defense Architectural Framework. Syst. Eng. 2011, 14, 305–326. [Google Scholar] [CrossRef]

- Behera, S.K.; Kim, J.-H.; Lee, S.-Y.; Suh, S.; Park, H.-S. Evolution of ‘designed’ industrial symbiosis networks in the Ulsan Eco-industrial Park: ‘Research and development into business’ as the enabling framework. J. Clean. Prod. 2012, 29–30, 103–112. [Google Scholar] [CrossRef]

- Tessitore, S.; Daddi, T.; Iraldo, F. Eco-industrial parks development and integrated management challenges: Findings from Italy. Sustainability 2015, 7, 10036–10051. [Google Scholar] [CrossRef]

- Mat, N.; Cerceau, J.; Shi, L.; Park, H.S.; Junqua, G.; Lopez-Ferber, M. Socio-ecological transitions toward low-carbon port cities: Trends, changes and adaptation processes in Asia and Europe. J. Clean. Prod. 2016, 114, 362–375. [Google Scholar] [CrossRef]

- Aid, G.; Eklund, M.; Anderberg, S.; Baas, L. Expanding roles for the Swedish waste management sector in inter-organizational resource management. Resour. Conserv. Recycl. 2017, 124, 85–97. [Google Scholar] [CrossRef]

- Susur, E.; Hidalgo, A.; Chiaroni, D. A strategic niche management perspective on transitions to eco-industrial park development: A systematic review of case studies. Resour. Conserv. Recycl. 2019, 140, 338–359. [Google Scholar] [CrossRef]

- Boix, M.; Montastruc, L.; Azzaro-Pantel, C.; Domenech, S. Optimization methods applied to the design of eco-industrial parks: A literature review. J. Clean. Prod. 2015, 87, 303–317. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, S.; Li, J.; Shao, S.; Wang, W.; Zhang, S. Life cycle assessment of industrial symbiosis in Songmudao chemical industrial park, Dalian, China. J. Clean. Prod. 2017, 158, 192–199. [Google Scholar] [CrossRef]

- Jiao, W.; Boons, F. Toward a research agenda for policy intervention and facilitation to enhance industrial symbiosis based on a comprehensive literature review. J. Clean. Prod. 2014, 67, 14–25. [Google Scholar] [CrossRef]

- Song, X.; Geng, Y.; Dong, H.; Chen, W. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. J. Clean. Prod. 2018, 193, 414–423. [Google Scholar] [CrossRef]

- UNIDO; GIZ; WBG. An International Framework for Eco-Industrial Parks; UNIDO: Danver, MA, USA, 2017. [Google Scholar]

- Haskins, C. A systems engineering framework for eco-industrial park formation. Syst. Eng. 2007, 10, 83–97. [Google Scholar] [CrossRef]

- Sopha, B.M.; Fet, A.M.; Keitsch, M.M.; Haskins, C. Using Systems Engineering to Create a Framework for Evaluating Industrial Symbiosis Options. Syst. Eng. 2009, 13, 149–160. [Google Scholar]

- Boons, F.; Spekkink, W.; Mouzakitis, Y. The dynamics of industrial symbiosis: A proposal for a conceptual framework based upon a comprehensive literature review. J. Clean. Prod. 2011, 19, 905–911. [Google Scholar] [CrossRef]

- Dumoulin, F.; Wassenaar, T.; Avadi, A.; Paillat, J. A Framework for Accurately Informing Facilitated Regional Industrial Symbioses on Environmental Consequences. J. Ind. Ecol. 2016, 21, 1049–1067. [Google Scholar] [CrossRef]

- Konstantinova, Y.; Johannes, E.; Vejrum, B. Dare to make investments in industrial symbiosis? A conceptual framework and research agenda for developing trust. J. Clean. Prod. 2019, 223, 989–997. [Google Scholar]

- Andiappan, V.; Tan, R.R.; Ng, D.K.S. An optimization-based negotiation framework for energy systems in an eco-industrial park. J. Clean. Prod. 2016, 129, 496–507. [Google Scholar] [CrossRef]

- Yedla, S.; Park, H. Eco-Industrial Networking for Sustainable Development: Review of Issues and Development Strategies. Clean Technol. Environ. Policy 2017, 19, 391–402. [Google Scholar] [CrossRef]

- Romero, E.; Ruiz, M.C. Framework for applying a complex adaptive system approach to model the operation of eco-industrial parks. J. Ind. Ecol. 2013, 17, 731–741. [Google Scholar] [CrossRef]

- Tao, Y.; Evans, S.; Wen, Z.; Ma, M. The influence of policy on industrial symbiosis from the Firm’s perspective: A framework. J. Clean. Prod. 2019, 213, 1172–1187. [Google Scholar] [CrossRef]

- Liu, C.; Côté, R. A framework for integrating ecosystem services into China’s circular economy: The case of eco-industrial parks. Sustainability 2017, 9, 1510. [Google Scholar] [CrossRef]

- Gopinath, A.; Bahurudeen, A.; Appari, S.; Nanthagopalan, P. A circular framework for the valorisation of sugar industry wastes: Review on the industrial symbiosis between sugar, construction and energy industries. J. Clean. Prod. 2018, 203, 89–108. [Google Scholar] [CrossRef]

- Kuznetsova, E.; Zio, E.; Farel, R. A methodological framework for Eco-Industrial Park design and optimization. J. Clean. Prod. 2016, 126, 308–324. [Google Scholar] [CrossRef]

- Villalba, G.; Segarra, M.; Chimenos, J.M.; Espiell, F. Using the recyclability index of materials as a tool for design for disassembly. Ecol. Econ. 2004, 50, 195–200. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Eilering, J.A.M.; Vermeulen, W.J.V. Eco-industrial parks: Toward industrial symbiosis and utility sharing in practice. Prog. Ind. Ecol. Int. J. 2004, 1, 245. [Google Scholar] [CrossRef]

- Felicio, M.; Amaral, D.; Esposto, K.; Durany, X.G. Industrial symbiosis indicators to manage eco-industrial parks as dynamic systems. J. Clean. Prod. 2016, 118, 54–64. [Google Scholar] [CrossRef]

- Heeres, R.R.; Vermeulen, W.J.V.; de Walle, F.B. Eco-industrial park initiatives in the USA and the Netherlands: First lessons. J. Clean. Prod. 2004, 12, 985–995. [Google Scholar] [CrossRef]

- Tian, J.; Liu, W.; Lai, B.; Li, X.; Chen, L. Study of the performance of eco-industrial park development in China. J. Clean. Prod. 2014, 64, 486–494. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 2000/53/EC on End-of-Life Vehicles; Official Journal of the European Communities European Parliament and Council: Brussels, Belgium, 2000; L269; pp. 34–42. [Google Scholar]

- Garcia, J.; Millet, D.; Tonnelier, P. A tool to evaluate the impacts of an innovation on a product’s recyclability rate by adopting a modular approach: Automotive sector application. Int. J. Veh. Des. 2015, 67, 178–204. [Google Scholar] [CrossRef]

- Watson, B.; Radcliffe, D. Structuring Design for X Tool Use for Improved Utilization. J. Eng. Des. 2010, 9, 211–223. [Google Scholar] [CrossRef]

- Meerkamm, H. Design for X—A Core Area of Design Methodology. J. Eng. Des. 2007, 5, 165–181. [Google Scholar] [CrossRef]

- Tonnelier, P.; Millet, D.; Richir, S.; Lecoq, M. Is it possible to evaluate the recovery potential earlier in the design process? Proposal of a qualitative evaluation tool. J. Eng. Des. 2007, 16, 297–309. [Google Scholar] [CrossRef]

- Curlee, T.R.; Das, S.; Rizy, C.G.; Schexnayder, S.M. Recent Trends in Automobile Recycling: An Energy and Economic Assessment; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1994. [Google Scholar]

- Reuter, M.A.; Hudson, C.; van Schaik, A.; Heiskanen, K.; Meskers, C.; Hagelüken, C. Metal Recycling: Opportunities, Limits, Infrastructure, a Report of the Working Group on the Global Metal Flows to the International Resource Panel; UNEP: Paris, France, 2013. [Google Scholar]

- Vezzoli, C.; Ceschin, F.; Osanjo, L.; M’Rithaa, M.K.; Moalosi, R.; Nakazibwe, V.; Diehl, J.C. Designing Sustainable Energy for All. Sustainable Product-Service System Design Applied to Distributed Renewable Energy; Springer: Cham, Switzerland, 2018; p. 230. [Google Scholar]

- Andersson, M. Innovating Recycling of End-of-Life Cars; Chalmers University of Technology: Göteborg, Sweden, 2016. [Google Scholar]

- ARA. Automotive Recycling Industry: Environmentally Friendly, Market Driven, and Sustainable; ARA: Manassas, VA, USA, 2012. [Google Scholar]

- Graedel, T.E.; Allwood, J.; Birat, J.-P.; Reck, B.K.; Sibley, S.F.; Sonnemann, G.; Buchert, M.; Hagelüken, C. Recycling Rates of Metals—A Status Report, a Report of the Working Group on the Global Metal Flows to the International Resource Panel; UNEP: Paris, France, 2011. [Google Scholar]

- Simic, V. End-of-life vehicle recycling—A review of the state-of-the-art. Recikliranje vozila na Kraj. životnog ciklusa—Pregl. Najsuvremnijih Znan. Rad. 2013, 20, 371–380. [Google Scholar]

- Karagoz, S.; Aydin, N.; Simic, V. End-of-life vehicle management: A comprehensive review. J. Mater. Cycles Waste Manag. 2019, 22, 416–442. [Google Scholar] [CrossRef]

- Maudet, C.; Yannou-Le Bris, G.; Froelich, D. Integrating plastic recycling industries into the automotive supply chain. HAL 2012, 13, 71–89. [Google Scholar]

- Edwards, C.; Bhamra, T.; Rahimifard, S. A Design Framework for End-of-Life Vehicle Recovery. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; pp. 365–370. [Google Scholar]

- Choi, J.K.; Stuart, J.A.; Ramani, K. Modeling of automotive recycling planning in the United States. Int. J. Automot. Technol. 2005, 6, 413–419. [Google Scholar]

- Paul, R. End-of-life management of waste automotive materials and efforts to improve sustainability in North America. WIT Trans. Ecol. Environ. 2009, 120, 853–861. [Google Scholar]

- Baker, B.A.; Brookside, N.J.; Woodruff, K.L.; Morrisville, P.; Naporano, J.F.; Fells, N.J.E. Automobile Shredder Residue (ASR) Separation and Recycling System. U.S. Patent WO1995026826A1, 12 October 1995. [Google Scholar]

- van Schaik, A.; Reuter, M.A. The optimization of end-of-life vehicle recycling in the European Union. JOM 2004, 56, 39–43. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Rosa, P. Recycling of end-of-life vehicles: Assessing trends and performances in Europe. Technol. Forecast. Soc. Chang. 2020, 152, 119887. [Google Scholar] [CrossRef]

- de Almeida, S.T.; Borsato, M. Assessing the efficiency of End of Life technology in waste treatment—A bibliometric literature review. Resour. Conserv. Recycl. 2019, 140, 189–208. [Google Scholar] [CrossRef]

- Che, J.; Yu, J.; Kevin, R.S. End-of-life vehicle recycling and international cooperation between Japan, China and Korea: Present and future scenario analysis. J. Environ. Sci. 2011, 23, S162–S166. [Google Scholar] [CrossRef]

- Yu, J.; Wang, S.; Toshiki, K.; Serrona, K.R.B.; Fan, G.; Erdenedalai, B. Latest Trends and New Challenges in End-of-life Vehicle Recycling. In Environmental Impacts of Road Vehicles: Past, Present and Future; The Royal Society of Chemistry: London, UK, 2017; Volume 44, pp. 174–213. [Google Scholar]

- Kahane, C.J. Vehicle Weight, Fatality Risk and Crash Compatibility of Model Year 1991–99 Passenger Cars and Light Trucks; National Highway Traffic Safety Administration: Springfield, VA, USA, 2003. [Google Scholar]

- Joines, J.A.; Roberts, S. Simulation Modeling with SIMIO: A Workbook, 4th ed.; SIMIO LLC: Sewickley, PA, USA, 2015. [Google Scholar]

| Entity 1 | Entity 2 | Entity n | |

|---|---|---|---|

| Entity 1 | Internal exchange | Exchange flow(s) from 1 to 2 | Exchange flow(s) from 1 to n |

| Entity 2 | Exchange flow(s) from 2 to 1 | Internal exchange | Exchange flow(s) from 2 to n |

| Entity n | Exchange flow (s) from n to 1 | Exchange flow(s) from n to 2 | Internal exchange |

| PP | DF | WEP | WTP | GI | TRC | ACo | PCo | SCo | BCo | |

|---|---|---|---|---|---|---|---|---|---|---|

| PP | - | Power-to-grid | Power-to-grid | Power-to-grid | Power-to-grid | Power-to-grid | Power-to-grid | Power-to-grid | Power-to-grid | Power-to-grid |

| DF | - | - | Industrial waste | Waste water | Glass parts | Scrap tire | Nonferrous metal | Plastic parts | Steel parts | Battery parts |

| WEP | Fly ash | - | - | Wastewater | - | - | - | - | - | - |

| WTP | Treated water | Treated water | Treated water | - | Treated water | Treated water | Treated water | Treated water | Treated water | Treated water |

| GI | - | - | Industrial waste | Waste water | - | - | - | - | - | - |

| TRC | - | - | - | Waste water | - | - | - | - | Metal parts | - |

| ACo | - | - | - | Waste water | - | - | - | Plastic scraps | Scrap metal | - |

| PCo | - | - | - | Waste water | - | - | - | - | - | - |

| SCo | - | - | - | Waste water | - | - | - | - | - | - |

| BCo | - | - | - | Waste water | - | - | - | Plastic scraps | Metal parts | - |

| Total Weight (kg) | Iron and Steel | Aluminum | Glass | Plastic | Tires | Battery | Fluids | Other | |

|---|---|---|---|---|---|---|---|---|---|

| Petrol | 1240 | 742 | 68 | 40 | 114 | 31 | 14 | 50 | 86 |

| Diesel | 1463 | 959 | 72 | 40 | 114 | 31 | 14 | 50 | 86 |

| Average weight (Petrol and Diesel cars) | 1352 | 851 | 70 | 40 | 114 | 31 | 14 | 50 | 86 |

| Percentage of material in average passenger car: | 63% | 5% | 3% | 8% | 2% | 1% | 4% | 6% | |

| Total ELVs Processed form 28 Working Days: 1820 | Unit: Thousands kg | |||||||

| Iron and Steel | Aluminum | Glass | Plastic | Tires | Battery | Fluids | Other | |

| 1548 | 127 | 73 | 207 | 56 | 25 | 91 | 157 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Quradaghi, S.; Zheng, Q.P.; Elkamel, A. Generalized Framework for the Design of Eco-Industrial Parks: Case Study of End-of-Life Vehicles. Sustainability 2020, 12, 6612. https://doi.org/10.3390/su12166612

Al-Quradaghi S, Zheng QP, Elkamel A. Generalized Framework for the Design of Eco-Industrial Parks: Case Study of End-of-Life Vehicles. Sustainability. 2020; 12(16):6612. https://doi.org/10.3390/su12166612

Chicago/Turabian StyleAl-Quradaghi, Shimaa, Qipeng P. Zheng, and Ali Elkamel. 2020. "Generalized Framework for the Design of Eco-Industrial Parks: Case Study of End-of-Life Vehicles" Sustainability 12, no. 16: 6612. https://doi.org/10.3390/su12166612

APA StyleAl-Quradaghi, S., Zheng, Q. P., & Elkamel, A. (2020). Generalized Framework for the Design of Eco-Industrial Parks: Case Study of End-of-Life Vehicles. Sustainability, 12(16), 6612. https://doi.org/10.3390/su12166612