Abstract

The increased demand for food and the challenge for space for agriculture production in urban centers have made the vertical growth system an interesting trend. Agriculture is no longer only the horizontal, traditional, and soil grown method. Urban agriculture has created ways for inner city growers to be able to farm in a restricted space. Vertical farming is the practice of growing crops, especially leafy vegetables such as lettuce, in vertically stacked layers, as this results in significantly higher plant population per unit area. Two research trials were conducted in the fall of 2018 and the spring of 2019 to determine the effect of substrate properties and fertilizers on lettuce yield to optimize the urban production of lettuce. Three substrates (P3 + CF7 = Perlite 30%: Coco fiber 70%, PB7 + C3 = Pine Bark 70%: Compost 30%, and PB9 + C1 = Pine Bark 90%: Compost 10%) along with full and half rates of a fertilizer blend (VertiGro Organics fermented molasses, Ohrstrom’s Maxicrop liquid seaweed, and organic mineral blend) were evaluated on fresh and dried weight yield of lettuce. Substrate physical properties (air space, water holding capacity, total porosity, and bulk density) and substrate volumetric water content were also determined. ‘Nevada’ and ‘Optima’ lettuce varieties showed similar yield responses (fresh and dried weight) to substrate and fertilizer rates in both trials. In the fall 2018 trial, the highest fresh weight was observed in substrate PB7 + C3 with half fertilizer rate, with a mean plant weight of 41.13 g and 49.75 g for ‘Optima’ and ‘Nevada’, respectively. The least mean fresh weight was observed in half fertilizer rate of substrate P3 + CF7. For the spring 2019 trial, PB7 + C3 in half fertilizer strength gave the highest fresh weight for ‘Optima’ and ‘Nevada’ (45.64 g and 41.13 g, respectively). These values were statistically comparable to all other treatments except for substrate P3 + CF7 in full and half fertilizer which gave the least mean fresh weight. Volumetric water content in substrates P3 + CF7 recorded the highest average, while PB7 + C3 gave the least. Higher water holding capacity, total porosity, and lower airspace were observed in substrate P3 + CF7. Higher airspace was observed in PB9 + C1 but was comparable to PB7 + C3. PB7 + C3 gave the highest bulk density in both trials.

1. Introduction

Urban agriculture is causing an energetic movement that is influencing the economy, landscape, and environment of the inner cities. Urban agriculture can play an essential role for consumers wanting to support local farms and food systems. There is a huge need for an expansion of locally grown, healthy foods inside city limits [1]. There has been a significant change in the present society and food production systems, even when compared to just a few decades ago. The most mentioned benefit of urban agriculture is its ability to increase access to nutritious and healthy food. Effective urban agriculture practices can also reduce the disparity between low income and wealthier communities, reduce preventable health issues, such as obesity (especially in low income communities), by reducing the amounts of processed and fatty foods bought and consumed from convenience and fast food stores [2]. Many studies have shown that urban agriculture does not only improve food production, but also improves socio-economic and environmental conditions which ultimately impact a person’s overall health [2]. Despite the many advantages of urban agriculture, a fundamental challenge is the lack of space available for crop production. The United States Census Bureau reports that although urban areas account for 3% of the nation’s land area, it contains about 80% (over 250 million people and rising) of the population [1]. Due to the constraints of space, some urban agriculture techniques encourage the cultivation of crops in pots filled with soilless mix and arranged in vertical stands instead of the conventional horizontal setup. Soilless plant culture provides support for plant growth without the use of soil as a rooting medium. Soilless medium [3] provides plant roots with functions similar to those provided by soil, which includes providing aeration and water, allowing for maximum root growth and physically supporting the plant [4,5]. Materials commonly used for soilless medium include organic materials such as peat moss, compost, tree bark, coconut coir, poultry feathers, or inorganic materials such as clay, perlite, vermiculite, and mineral wool [6,7]. This method is associated with many advantages, such as enabling good root growth, improved germination rates, and better management of irrigation and fertilizer applied. The yield of crop depends on the substrates properties, such as absorption capability and making water and nutrients (fertilizer) available at the plant root region for uptake and utilization by the plant.

Vertical farming is the cutting edge of agriculture. Offering the ability to grow more crops, in a controlled environment, inside major distributions hubs (i.e., cities), it takes advantage of economies of scale in a way no other farming operation can. Even if there is adequate spacing for traditional farming, it is not guaranteed that the soil is farmable. Vertical farming holds the promise of addressing these issues by enabling more food to be produced with less resources use [8]. There are other substantial benefits, such as: year-round crop production, limited environmental crop failures (drought, hail, and floods), reduced pest infestations, diminished pesticide use, proficient weed management, and no polluted ground water [9].

Another straightforward advantage is the ease of harvest. Traditional farming could require difficult labor to harvest crops, such as bending over numerous hours. In a vertical system, crops are much easier to harvest, given that they are grown at an elevated height, normally starting around the knees to a higher level. There are limitations to certain crops that cannot be grown in a vertical system such as tree nuts, tree fruits, and much taller crops due to height restrictions. However, many other vegetable crops can be grown. The most common products now produced in vertical farms are lettuce, leafy greens, herbs, strawberries, and cucumbers [10]. For example, a research project in 2016 associating lettuce yield per unit area compared to conventional horizontal hydroponic growing clearly demonstrated an increase in yield with the vertical growing system [11]. Lettuce is cultivated worldwide and is one of the most consumed green, leafy vegetables due to its utilization in the food world for the preparation of salads, soups, sandwiches, and vegetable curries. Not only is lettuce heavily used for the taste, but also for its exceptional medicinal elements, as it is considered highly rich in phytonutrients such as vitamins (A, C, E, K), minerals, beta carotene, lutein, and fibers. Lettuce is categorized into two types: head (iceberg) and leaf, which includes romaine, butterhead, and leaf types. Lettuce is a cool-season crop and is not a good crop selection to grow in temperate or high temperatures. There are many diverse varieties of lettuce, but this project focuses on two types: Bibb and Summer Crisp. Bibb lettuce, also known as Butterhead, has thicker and darker green colored leaves compared to iceberg lettuce. Butterheads develop a light yellow, buttery appearance and are very attractive in salads. It can be grown indoors for an even longer season. Bibb lettuce will develop bitterness readily if temperatures get too high [12]. Summer Crisp lettuce is one of the few very good types that can thrive in early summer heat and possesses large, lively leaves. One characteristic that makes Summer Crisp an excellent summer variety is the resistance against bolting. In addition, it is used in the food industry for its heavy heads and thick, crispy leaves. This study seeks to evaluate the yield response of lettuce to substrate composition and fertilizer rate in a vertical growth system.

2. Materials and Methods

Two research trials were conducted in the fall of 2018 and in the spring of 2019 in a hoop house at the Organic Farm of Tennessee State University, Nashville, TN. Organic seeds of Bibb and Summer Crisp (varieties ‘Optima’ and ‘Nevada’ respectfully) were obtained from High Mowing Seed Company, Vermont, USA. The seeds were sown in 72 cell seed trays filled with potting mix (Harvest Organics, Lowes, Nashville, TN, USA). Seed trays were kept moist and in optimum conditions for seed germination. The substrates were prepared 2 days before transplanting using coco fiber (CF), pine bark (PB; 1.6 cm screened; Morton’s Horticultural Products, McMinnville, TN, USA), perlite (P), and/or compost (C) in the ratio 3 perlite: 7 coco fiber (P3 + CF7), 7 pine bark: 3 compost (PB7 + C3), and 9 pine bark: 1 compost (PB9 + C1). Two fertilizer rates (full and half) were prepared in separate 170-L containers (Brute, Lowes, Nashville, TN, USA) labeled for full and half strength fertilizer, respectively. Container 1 with 600 mL VertiGro Organics fermented molasses, 600 mL Ohrstrom’s Maxicrop liquid seaweed, and 300 mL organic mineral blend in 170 L of water. Container 2 had the same ingredients as container 1, but half the quantity in the same 170 L of water. Fertigation timers were set to turn on four times within a 24-h interval for 5 min each period (5 min was the necessary time required to saturate all pots in all four tiers of setup). The vertical system was purchased from Verti-Gro Inc., Florida and included a metal vertical system support framework, irrigation system, Styrofoam pots, and fertilization/irrigation resources (comprising of 2 digital timers, drip irrigation, two 170 L drums) to operate the entire system. Seedlings were transplanted to the vertical growth system 4 weeks after sowing and closely monitored. Plants were harvested at 65 days after planting and data on shoot fresh weight was collected. Additionally, shoot dry weight was collected by placing in paper sample bags and drying in the oven at 80 °C for 72 h. Substrate samples were collected prior to planting and physical properties (air space, water holding capacity, total porosity, and bulk density) were determined using porometer analysis (n = 3) [13]. Substrate volumetric water content (VWC; m3·m−3) was measured every 15 min over the period of one week for each study using Decagon EC−5 sensors and EM50 data loggers (Decagon Devices Inc., Pullman, WA, USA). The experiment was laid in a randomized complete block design with 4 replicates and 4 plants per replicate. Statistical analysis was done with SAS statistical software, version 9.4.

3. Results

3.1. ‘Nevada’ and ‘Optima’ Lettuce Results on Fresh and Dry Weight in Fall 2018

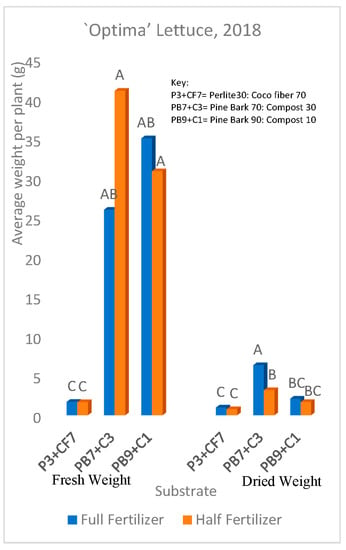

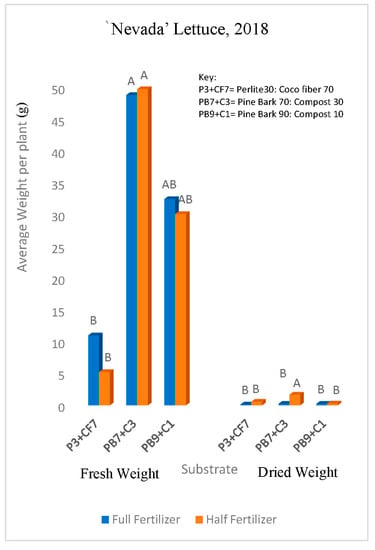

‘Nevada’ and ‘Optima’ lettuce varieties showed similar yield (fresh and dried weight) responses to substrate and fertilizer rates in the fall of 2018. In the fall 2018 trial, the highest fresh weight was observed in PB7 + C3 with half fertilizer rate, with a mean plant weight of 41.13 g and 49.75 g for both ‘Optima’ and ‘Nevada’. These findings were statistically similar to the full fertilizer rate of the same substrate and both full and half fertilizer rates of PB9 + C1. The least mean fresh weight was observed in half fertilizer rate of P3 + CF7. Substrate PB7 + C3 with full fertilizer had the highest dried weight in ‘Optima’ (6.35 g), whereas the half fertilizer rate of same substrate gave the highest dried weight in ‘Nevada’ and was significantly higher than all other treatments (Figure 1 and Figure 2).

Figure 1.

Effect of substrates and fertilizer on fresh and dried weight of ‘Optima’ lettuce, Fall 2018.

Figure 2.

Effect of substrates and fertilizer on fresh and dry weight of ‘Nevada’ lettuce, Fall 2018.

3.2. ‘Nevada’ and ‘Optima’ Lettuce Results on Fresh and Dry Weight in Spring 2019

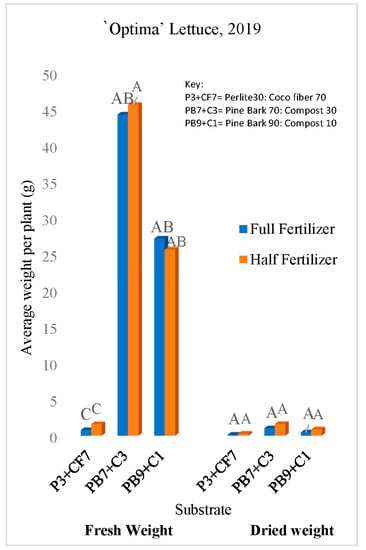

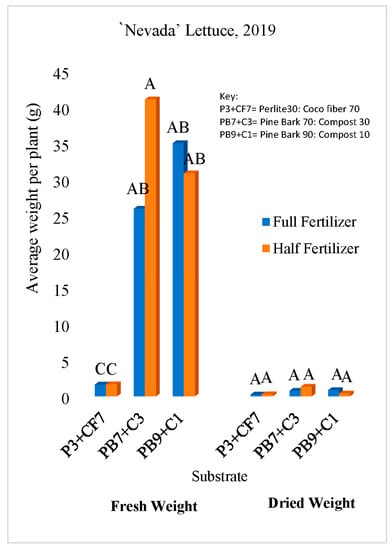

For the 2019 trial, PB7 + C3 in half fertilizer strength gave the highest fresh weight for ‘Optima’ and ‘Nevada’ (45.64 and 41.13 g, respectively). These values were statistically comparable to all other treatments, except for P3 + CF7 in full and half fertilizer, which gave the least mean fresh weight (Figure 3 and Figure 4). There were no significant differences in dried weight for ‘Nevada’ and ‘Optima’ varieties across all treatments.

Figure 3.

Effect of substrates and fertilizer on fresh and dry weight of ‘Optima’ lettuce, Spring 2019.

Figure 4.

Effect of substrates and fertilizer on fresh and dry weight of ‘Nevada’ lettuce, Spring 2019.

3.3. ‘Nevada’ and ‘Optima’ Lettuce Results on Volumetric Water Content

Substrate composition influenced volumetric water content. Volumetric water content in substrates was higher in the fall 2018 trial. However, for both fall 2018 and spring 2019 trials, P3 + CF7 gave the highest average volumetric water content. It was statistically comparable to PB7 + C3, but different from PB9 + C1, which gave the least value. Tier also influenced volumetric water content as upper tiers had higher volumetric moisture content than lower tiers (Table 1 and Table 2).

Table 1.

Volumetric water content of three substrates in a vertical tower measured at the upper and lower tiers of the tower in the fall of 2018.

Table 2.

Volumetric water content of three substrates in a vertical tower measured at the upper and lower tiers of the tower in the spring of 2019.

Table 3 shows that a similar trend was observed in the physical properties (airspace, water holding capacity, total porosity, and bulk density) in both trials. Highest water holding capacity, highest total porosity, lowest airspace, and lowest bulk density were observed in substrate P3 + CF7. Highest airspace was observed in PB9 + C1, but was comparable to PB7 + C3 in 2018, but different in 2019. PB7 + C3 gave the highest bulk density in both trials and were significantly different from P3 + CF7 and PB9 + C1, respectively.

Table 3.

Physical properties of three substrates used in a vertical tower growing system in the fall of 2018 and the spring of 2019.

4. Discussion

The vertical growth system has a significant space utilization efficiency to grow agricultural produce, especially in urban centers. The setup for this experiment consisted of 18 towers arranged in two rows with a spacing of 1 m within rows and 0.5 m between rows. Each tower contained 4 Styrofoam pots (stacked vertically), and each Styrofoam pots contained 4 plants each. Therefore, with this technique, a total of 288 stands of lettuce were produced within 9 square meters. The same number of lettuce plants would have required at least 22 square meters to grow on the flat. By using the vertical growth system, more crops can be produced within a limited space/area. Moreover, the vertical growth system gives the farmer the flexibility of choice in choosing appropriate or preferred substrates in contrast to growing on the flat where the farmer is limited to only growing on soil. Furthermore, weeding, fertilizer application, irrigation, and harvesting operation were less tedious compared to planting on the flat. An ideal soilless plant growth media should provide basic plant requirements, such as anchorage, good drainage, aeration, biological and chemical stability, and water. It should also possess good nutrient retention capabilities [14]. The final attributes of the potting mix are dependent on the individual constituents. This study evaluated natural substrates such as perlite, and organic substrates such as coco fiber, compost, and pine bark at different ratios. Substrates varied in physical characteristics and their ability to support plant growth. Although the substrate air space was within the recommended range (10–30%; [15]) for all substrates, it was significantly lower in P3 + CF7. For substrate water holding capacity, P3 + CF7 was above the recommended range (45–65%; [16]) in 2018 and was significantly greater compared to the other substrates in 2019. Overall, the yield was lowest in P3 + CF7 and greatest in PB7 + C3. Plants did not grow as well in P3 + CF7 due to the low substrate air space and high-water holding capacity. Although volumetric water content was similar for P3 + CF7 and PB7 + C3, low substrate aeration resulted in poor drainage and subsequent poor plant growth.

A similar trend was noticed by Al-Far et al. (2019) who reported varied properties (water holding capacity, pH, EC, porosity, etc.) of soilless media (tuff, tuff +perlite, tuff + perlite + sawdust and tuff + sawdust) and different growth, yield, and fruit quality responses of cucumber. Fascella and Zizzo (2005) also reported that substrates affected yield and quality of Rose flowers.

Two fertilizer rates (full and half) were also evaluated in this study. The findings showed that the yield of lettuce varieties was not entirely dependent on the fertilizer rate, but on the interaction between the substrate and fertilizer. This is most likely due to the ability of the substrate to balance the level of humidity in the organic mixture and nutrients in the fertilizer, in addition to a sufficient degree of aeration and other environmental conditions in the root zone favorable for plant growth [17].

5. Conclusions

The plant growth support properties such as air space, water holding capacity, total porosity, and bulk density are dependent on the individual constituents of the substrates. Highest fresh and dried weight for ‘Optima’ and ‘Nevada’ lettuce varieties were obtained in substrate made of 70% pine bark plus 30% compost at half fertilizer strength. For the most part, the half fertilizer rate gave better or comparable fresh and dried weight to the full rate. Therefore, it may make more economical sense to apply the half rate fertilizer for lettuce. This will not only produce substantial results, but will also be more efficient for the grower that is looking to save money while growing their own lettuce.

Author Contributions

Conceptualization, D.N. and A.W.; methodology, D.N. and A.W.; formal analysis, All; investigation, All; resources, D.N.; data curation, Z.W., O.A. and A.W.; writing—original draft preparation, Z.W., O.A.; writing—review and editing, All; supervision, D.N.; project administration, D.N.; funding acquisition, D.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding for this study.

Acknowledgments

Authors sincerely thank Saidullah Chowdhary in field assistance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Carr, R. Vertical Gardening. In Vertical Gardening in an Urban Environment; Carr, R., Ed.; Rodale Institute: Kutztown, PA, USA, 2017; pp. 7–12. Available online: https://issuu.com/igrownews/docs/vertical-gardening-booklet-draft-3- (accessed on 27 February 2020).

- Hagey, A.; Solana, R.; Flournoy, R. Growing Urban Agriculture: Equitable Strategies and Policies for Improving Access to Healthy Food and Revitalizing Communities. PolicyLink 2012, 1–52. Available online: http//www.policylink (accessed on 28 February 2020).

- Olle, M.; Ngouajio, M.; Siomos, A. Vegetable quality and productivity as influenced by growing medium: A review. Zemdirbyste 2012, 99, 399–408. [Google Scholar]

- Bilderback, T.E.; Warren, S.L.; Owen, J.S.; Albano, J.P. Healthy Substrates Need Physicals Too! Horttechnology 2005, 15, 747–751. [Google Scholar] [CrossRef]

- Barrett, G.E.; Alexander, P.D.; Robinson, J.S.; Bragg, N.C. Achieving environmentally sustainable growing media for soilless plant cultivation systems–A review. Sci. Hortic. 2016, 212, 220–234. [Google Scholar] [CrossRef]

- Grunert, O.; Perneel, M.; Vandaele, S. Peat-based organic growbags as a solution to the mineral wool waste problem. Mires Peat 2008, 3, 6. [Google Scholar]

- Vaughn, S.F.; Deppe, N.A.; Palmquist, D.E.; Berhow, M.A. Extracted sweet corn tassels as a renewable alternative to peat in greenhouse substrates. Ind. Crops Prod. 2011, 33, 514–517. [Google Scholar] [CrossRef]

- Banerjee, C.; Adenaeuer, L. Up, Up and Away! The Economics of Vertical Farming. J. Agric. Stud. 2014, 2, 40. [Google Scholar] [CrossRef]

- Zeidler, C.; Schubert, D. From Bioregenerative Life Support Systems for Space to Vertical Farming on Earth—The 100% Spin-off. 2014, p. 9. Available online: https://www.researchgate.net/publication/263747164_From_Bioregenerative_Life_Support_Systems_for_Space_to_Vertical_Farming_on_Earth_-_The_100_Spin-off/citation/download (accessed on 14 July 2020).

- Kalantari, F.; Tahir, O.M.; Lahijani, A.M.; Kalantari, S. A Review of Vertical Farming Technology: A Guide for Implementation of Building Integrated Agriculture in Cities. Adv. Eng. Forum. 2017, 24, 76–91. [Google Scholar] [CrossRef]

- Touliatos, D.; Dodd, I.C.; McAinsh, M. Vertical farming increases lettuce yield per unit area compared to conventional horizontal hydroponics. Food Energy Secur. 2016, 5, 184–191. [Google Scholar] [CrossRef] [PubMed]

- University of California, Agriculture and Natural Resources. Contra Costa County Vegetable Planting Guide for Interior Regions; ANR: Concord, CA, USA, 2020; pp. 1–7. Available online: http://ccmg.ucdavis.edu/files/131284.pdf (accessed on 8 March 2020).

- Fonteno, W.C.; Harden, C.T. Procedures for Determining Physical Properties of Horticultural Substrates Using the NCSU Porometer; North Carolina State University: Raleigh, NC, USA, 2003. [Google Scholar]

- Langenhoven, P. Characteristics of Soilless Substrates. 2017. Available online: https://api.ag.purdue.edu/hla/fruitveg/Presentations/Langenhoven_Characteristics_Soilless_IHC2017.pdf (accessed on 12 March 2020).

- Bilderback, T.E.; Boyer, C.; Chappell, M.; Fain, G.; Fare, D.; Gilliam, C.; Jackson, B.E.; Lea-Cox, J.; LeBude, A.V.; Niemiera, A.; et al. Best Management Practices: Guide for Producing Nursery Crops, 3rd ed.; Southern Nursery Association: Acworth, GA, USA, 2013. [Google Scholar]

- Al-Far, A.M.; Tadros, M.J.; Makhadmeh, I.M. Evaluation of different soilless media on growth, quality, and yield of cucumber (Cucumis sativus L.) grown under greenhouse conditions. Aust. J. Crop Sci. 2019, 13, 1388–1400. [Google Scholar] [CrossRef]

- Fascella, G.; Zizzo, G.V. Effect of growing media on yield and quality of soilless cultivated rose. Acta Hortic. 2005, 697, 133–138. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).