Pervious Pavement Blocks Made from Recycled Polyethylene Terephthalate (PET): Fabrication and Engineering Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of RPA Blocks

2.3. Material Testing

2.3.1. Flexural Strength Test

2.3.2. In Situ Permeability Test

2.3.3. Sand-Clogged Permeability Test

2.3.4. Freeze–Thaw Durability Test

3. Engineering Properties of RPA Blocks

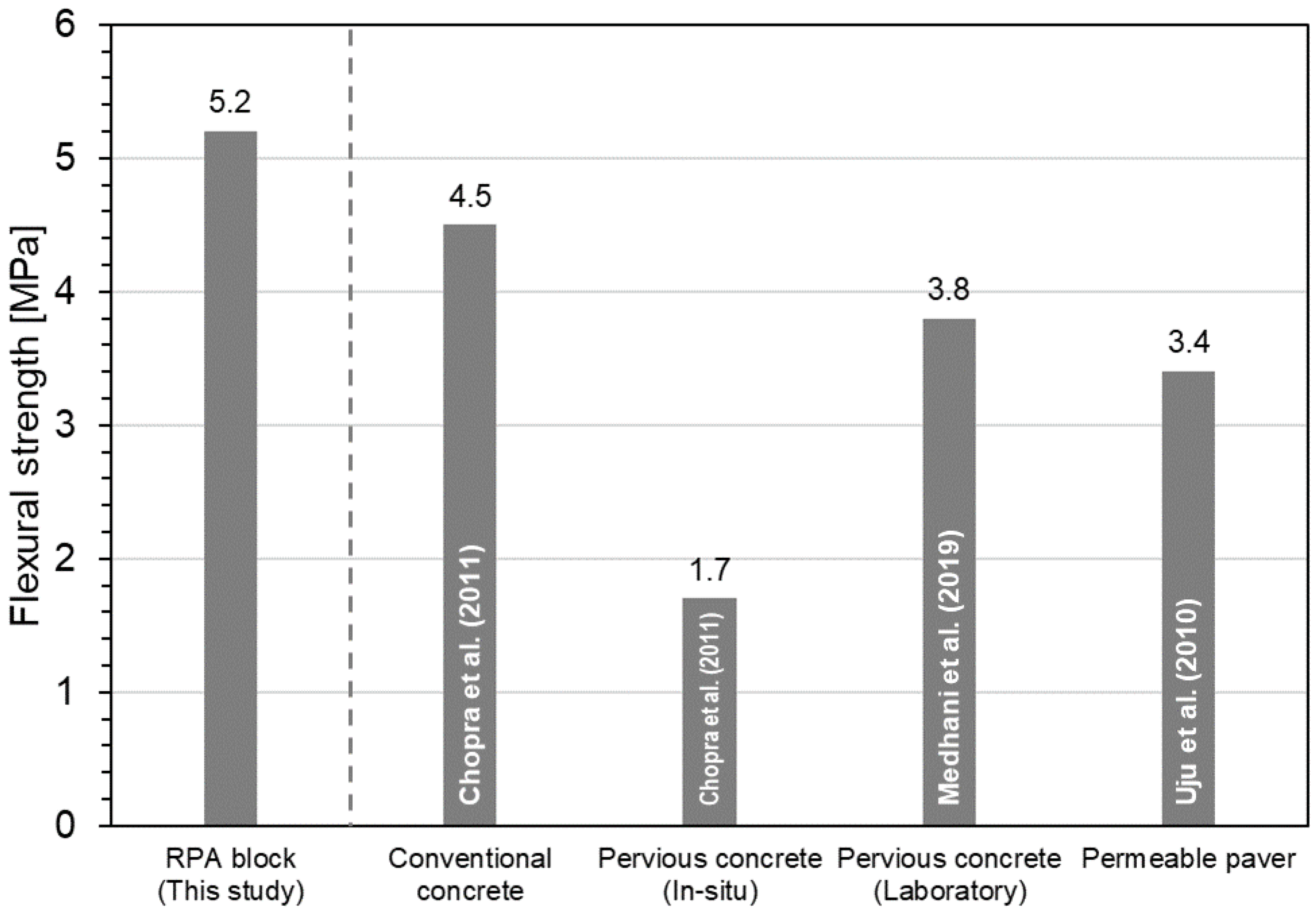

3.1. Flexural Strength

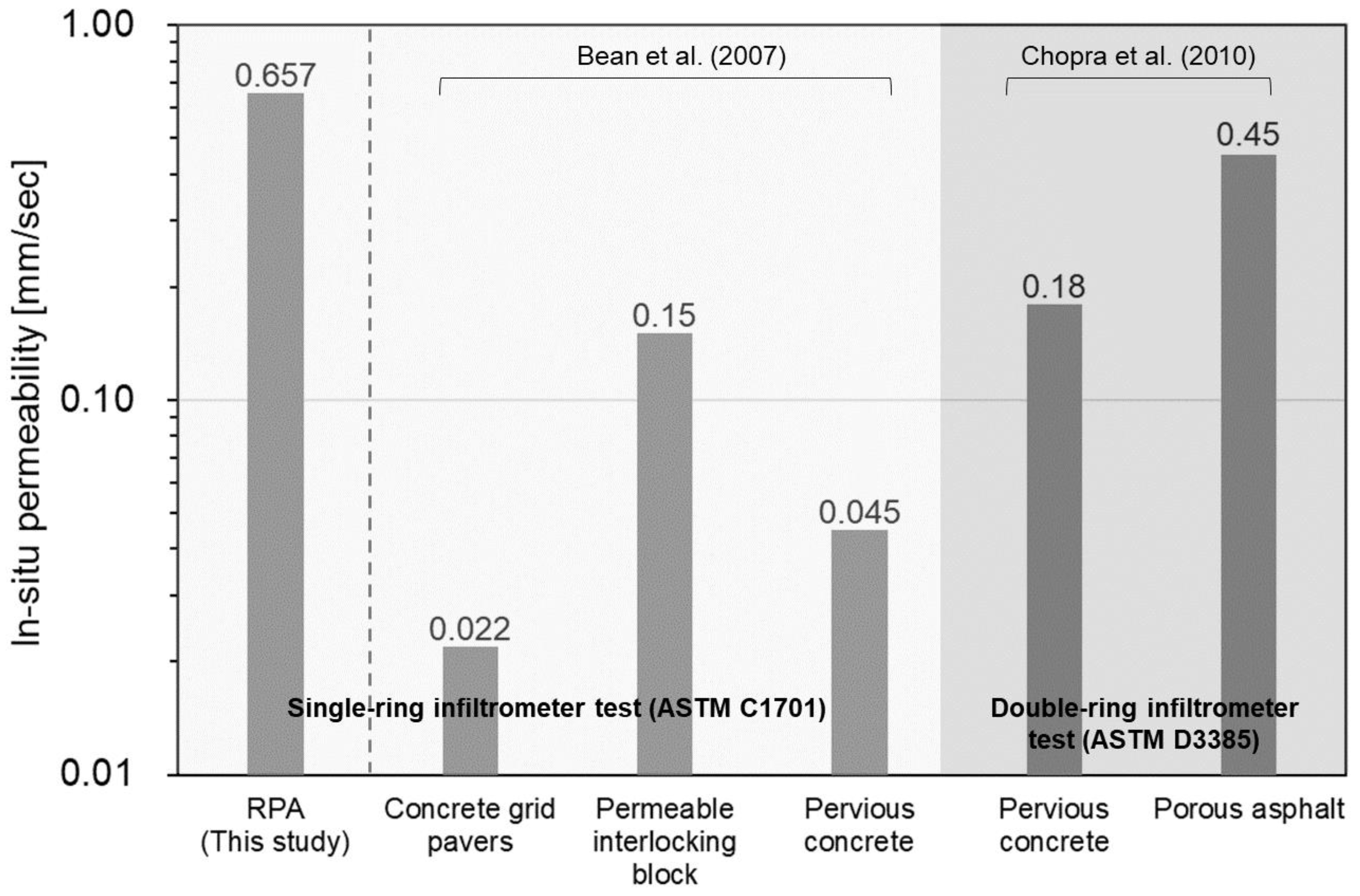

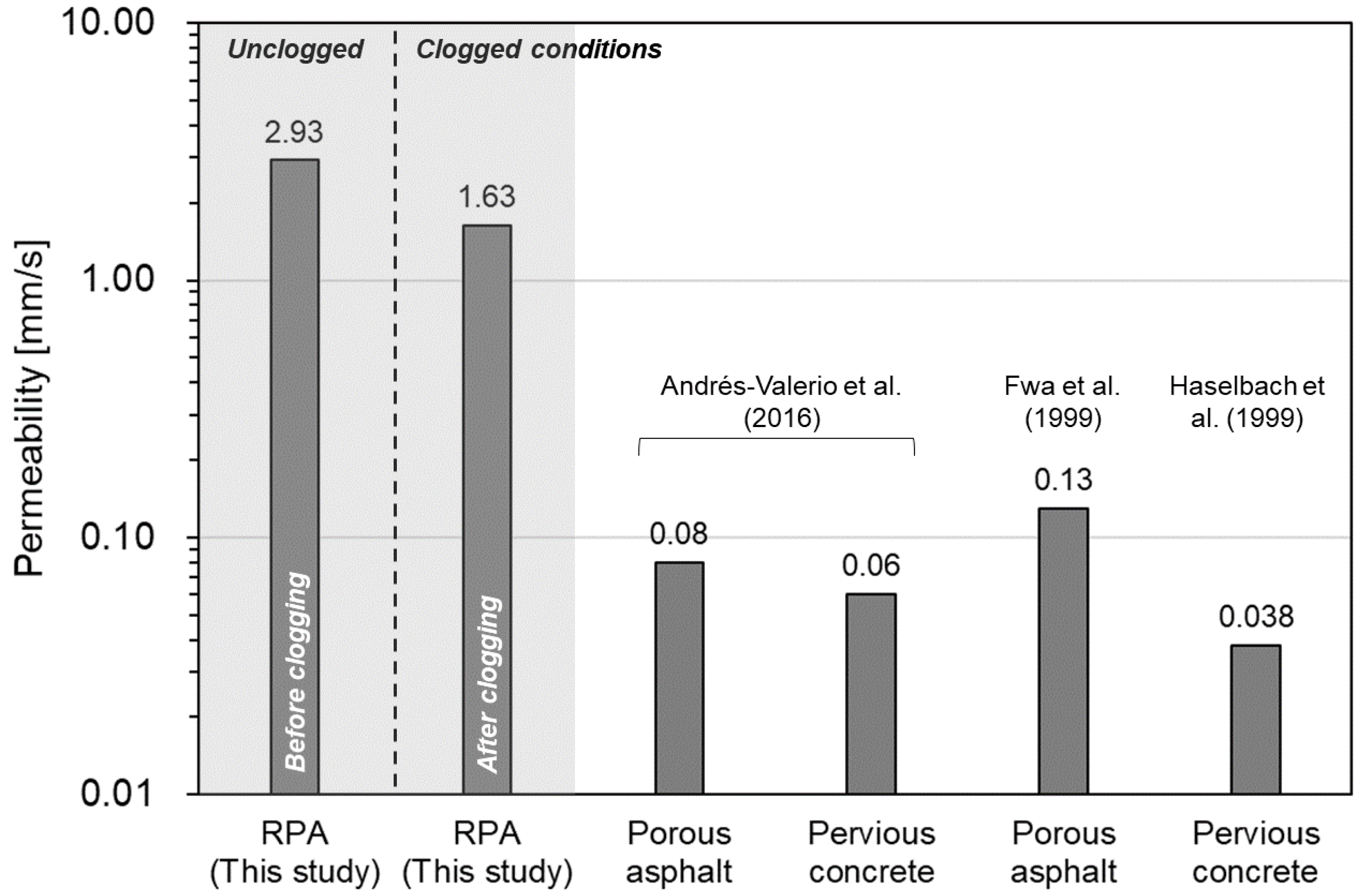

3.2. In Situ Permeability and Sand-Clogged Permeability

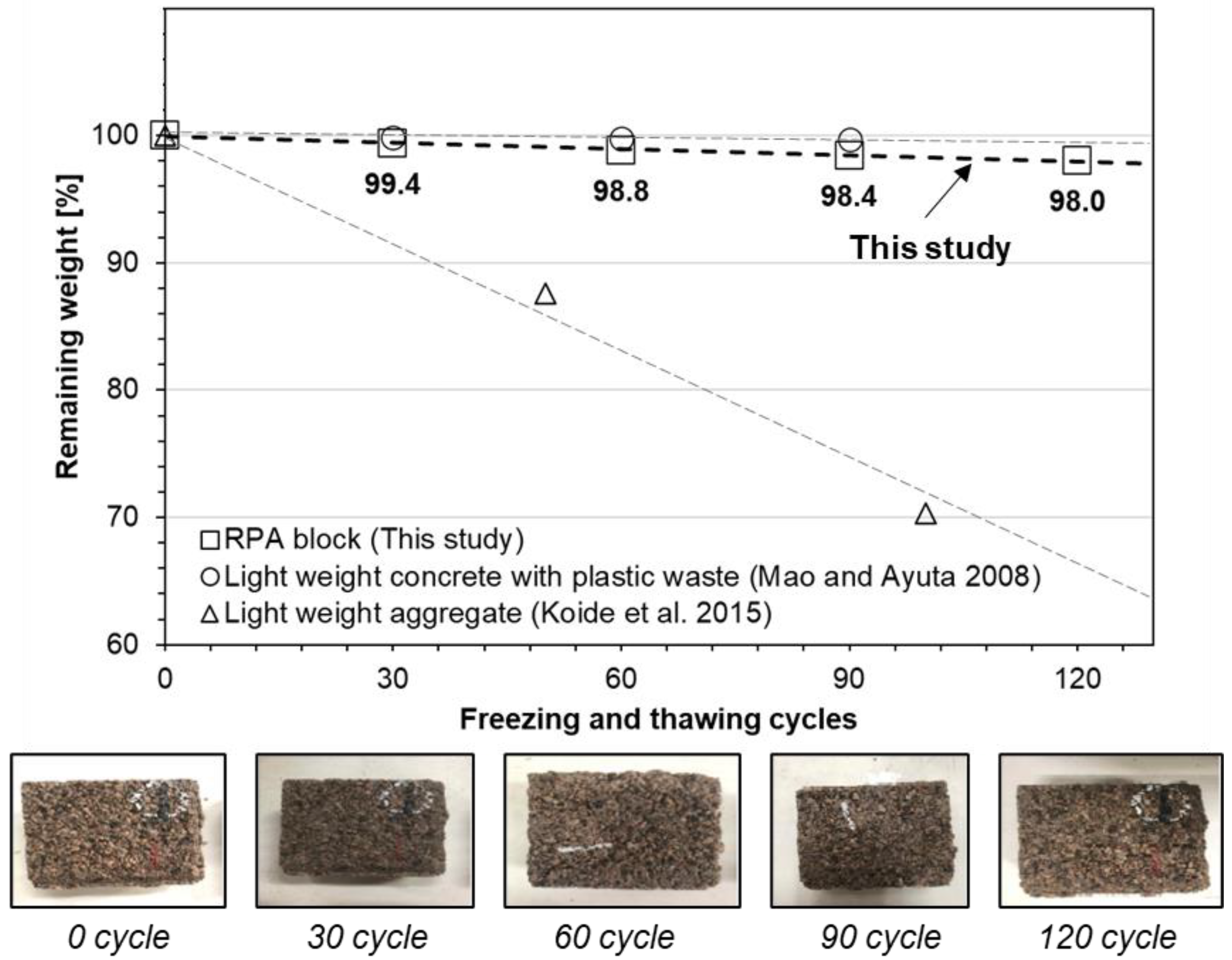

3.3. Durability

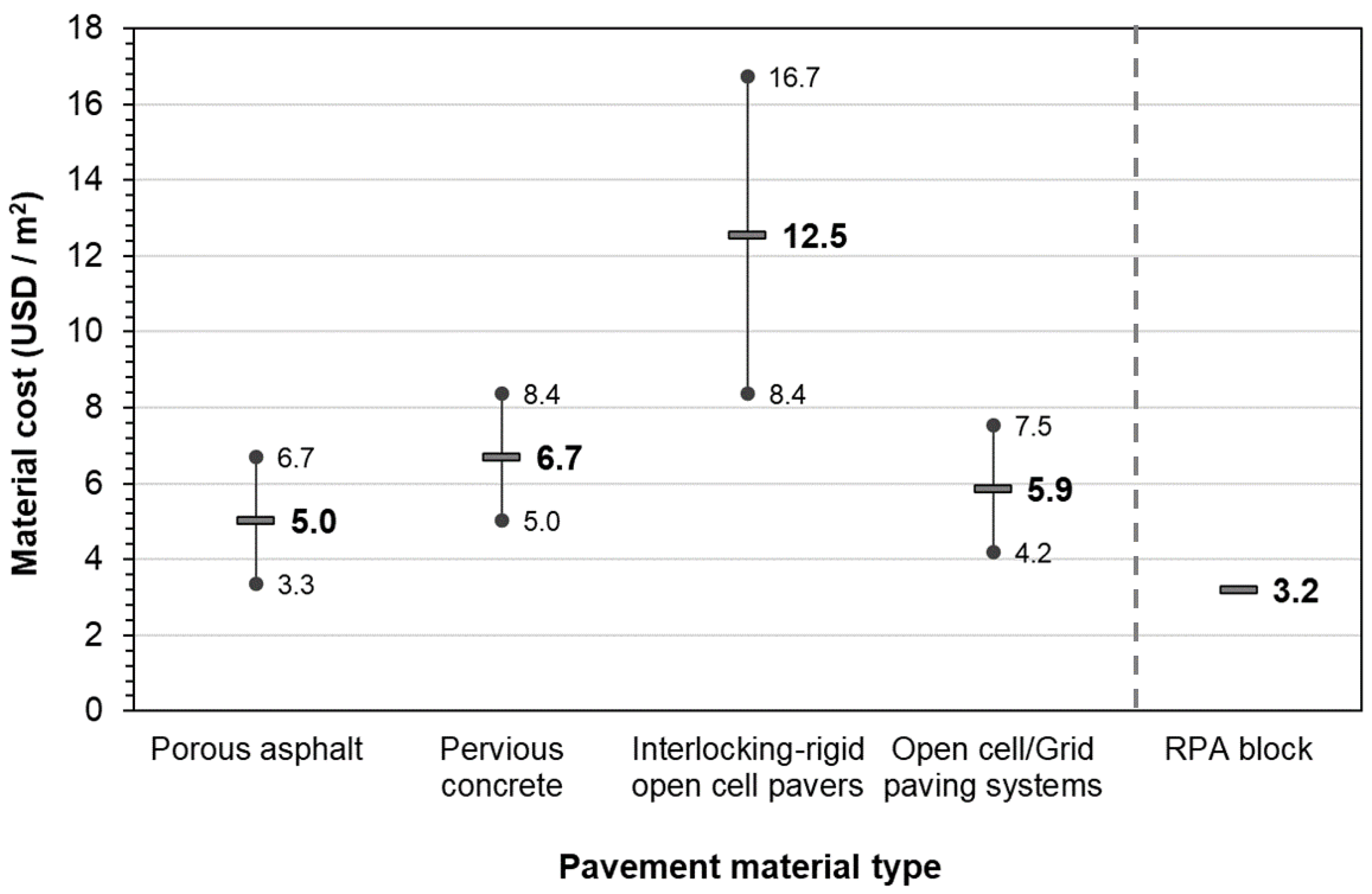

3.4. Performance Summary and Economic Feasiblity of RPA Block

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Haselbach, L.M.; Valavala, S.; Montes, F. Permeability predictions for sand-clogged Portland cement pervious concrete pavement systems. J. Environ. Manag. 2006, 81, 42–49. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Mullaney, J.; Lucke, T. Practical review of pervious pavement designs. Clean–Soil Air Water 2014, 42, 111–124. [Google Scholar] [CrossRef]

- Dreelin, E.A.; Fowler, L.; Ronald Carroll, C. A test of porous pavement effectiveness on clay soils during natural storm events. Water Res. 2006, 40, 799–805. [Google Scholar] [CrossRef] [PubMed]

- Scholz, M.; Grabowiecki, P. Review of permeable pavement systems. Build. Environ. 2007, 42, 3830–3836. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Cho, G.-C. Global CO2 emission-related geotechnical engineering hazards and the mission for sustainable geotechnical engineering. Energies 2019, 12, 2567. [Google Scholar] [CrossRef]

- Rahman, M.A.; Imteaz, M.A.; Arulrajah, A.; Piratheepan, J.; Disfani, M.M. Recycled construction and demolition materials in permeable pavement systems: Geotechnical and hydraulic characteristics. J. Clean. Prod. 2015, 90, 183–194. [Google Scholar] [CrossRef]

- Kelley, K.N. Use of Recycled Oyster Shells as Aggregate for Pervious Concrete; University of Florida: Gainesville, FL, USA, 2009. [Google Scholar]

- Nguyen, D.H.; Boutouil, M.; Sebaibi, N.; Baraud, F.; Leleyter, L. Durability of pervious concrete using crushed seashells. Constr. Build. Mater. 2017, 135, 137–150. [Google Scholar] [CrossRef]

- Tho-in, T.; Sata, V.; Chindaprasirt, P.; Jaturapitakkul, C. Pervious high-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2012, 30, 366–371. [Google Scholar] [CrossRef]

- Kuo, W.-T.; Liu, C.-C.; Su, D.-S. Use of washed municipal solid waste incinerator bottom ash in pervious concrete. Cem. Concr. Compos. 2013, 37, 328–335. [Google Scholar] [CrossRef]

- Gourmelon, G. Global plastic production rises, recycling lags. Vital Signs 2015, 22, 91–95. [Google Scholar]

- Uhrin, A.V.; Schellinger, J. Marine debris impacts to a tidal fringing-marsh in North Carolina. Mar. Pollut. Bull. 2011, 62, 2605–2610. [Google Scholar] [CrossRef] [PubMed]

- Browne, M.A.; Dissanayake, A.; Galloway, T.S.; Lowe, D.M.; Thompson, R.C. Ingested microscopic plastic translocates to the circulatory system of the mussel, Mytilus edulis (L.). Environ. Sci. Technol. 2008, 42, 5026–5031. [Google Scholar] [CrossRef] [PubMed]

- Rochman, C.M.; Browne, M.A.; Halpern, B.S.; Hentschel, B.T.; Hoh, E.; Karapanagioti, H.K.; Rios-Mendoza, L.M.; Takada, H.; Teh, S.; Thompson, R.C. Classify plastic waste as hazardous. Nature 2013, 494, 169–171. [Google Scholar] [CrossRef]

- Pauly, J.L.; Stegmeier, S.J.; Allaart, H.A.; Cheney, R.T.; Zhang, P.J.; Mayer, A.G.; Streck, R.J. Inhaled cellulosic and plastic fibers found in human lung tissue. Cancer Epidemiol. Prev. Biomark. 1998, 7, 419–428. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Donnini, J.; Nardinocchi, A. Lightweight plasters containing plastic waste for sustainable and energy-efficient building. Constr. Build. Mater. 2015, 94, 337–345. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Baskar, K. Recycling of E-plastic waste as a construction material in developing countries. J. Mater. Cycles Waste Manag. 2015, 17, 718–724. [Google Scholar] [CrossRef]

- Intini, F.; Kühtz, S. Recycling in buildings: An LCA case study of a thermal insulation panel made of polyester fiber, recycled from post-consumer PET bottles. Int. J. Life Cycle Assess. 2011, 16, 306–315. [Google Scholar] [CrossRef]

- Consoli Nilo, C.; Montardo Júlio, P.; Prietto Pedro Domingos, M.; Pasa Giovana, S. Engineering behavior of a sand reinforced with plastic waste. J. Geotech. Geoenviron. Eng. 2002, 128, 462–472. [Google Scholar] [CrossRef]

- Ji, L.N. Study on preparation process and properties of polyethylene terephthalate (PET). Appl. Mech. Mater. 2013, 312, 406–410. [Google Scholar] [CrossRef]

- Baghaee Moghaddam, T.; Karim, M.R.; Syammaun, T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr. Build. Mater. 2012, 34, 236–242. [Google Scholar] [CrossRef]

- ASTM. C67/67M Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM. C1701/1701M 17a Standard Test Method for Infiltration Rate of In Place Pervious Concrete; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Razzaghmanesh, M.; Beecham, S. A review of permeable pavement clogging investigations and recommended maintenance regimes. Water 2018, 10, 337. [Google Scholar] [CrossRef]

- ASTM. C666 Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Portland Cement Association. Pervious concrete mixtures and properties. Concr. Technol. Today 2004, 25, 3–4. [Google Scholar]

- New Jersey Stormwater. New Jersey Stormwater Best Management Practices Manual; New Jersey Department of Environmental Protection: Trenton, NJ, USA, 2004. [Google Scholar]

- Seoul Metropolitan Government. Pervious Pavement Installation, Construction, and maintenance Design Manul (Ver.2.0); Seoul Metropolitan Government: Seoul, Korea, 2013.

- Interlocking Concrete Pavement Institute. Tech Spec 23. Maintenance Guide for Permeable Interlocking Concrete Pavements. Available online: https://icpi.org/tech-specs (accessed on 16 February 2020).

- ASTM. C936 Solid Concrete Interlocking Pavering Units; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Chopra, M.; Stuart, E.; Hardinm, M.; Uju, I.; Wanielista, M. Pervious Pavements-Installation, Operation and Strength. Part 1: Pervious Concrete Systems; Florida Department of Transportation: Tallahassee, FL, USA, 2011. [Google Scholar]

- Medhani, R.; Khan, W.; Arhin, S. Evaluation of Mix Designs and Test Procedures for Pervious Concrete; District Department of Transportation: Washington, DC, USA, 2014. [Google Scholar]

- Uju, I. A Study of the Strength of Pervious Pavement Systems; University of Central Florida in Orlando: Orlando, FL, USA, 2010. [Google Scholar]

- Bean, E.Z.; Hunt, W.F.; Bidelspach, D.A. Field survey of permeable pavement surface infiltration rates. J. Irrig. Drain. Eng. 2007, 133, 249–255. [Google Scholar] [CrossRef]

- Chopra, M.B.; Stuart, E.; Wanielista, M.P. Pervious pavement systems in Florida-Research results. In Low Impact Development 2010; American Society of Civil Engineers: San Francisco, CA, USA, 2010; pp. 193–206. [Google Scholar]

- Andrés-Valeri, V.C.; Marchioni, M.; Sañudo-Fontaneda, L.A.; Giustozzi, F.; Becciu, G. Laboratory assessment of the infiltration capacity reduction in clogged porous mixture surfaces. Sustainability 2016, 8, 751. [Google Scholar] [CrossRef]

- Fwa, T.; Tan, S.; Guwe, Y. Laboratory evaluation of clogging potential of porous asphalt mixtures. Transp. Res. Rec. 1999, 1681, 43–49. [Google Scholar] [CrossRef]

- Mao, J.; Ayuta, K. Freeze–thaw resistance of lightweight concrete and aggregate at different freezing rates. J. Mater. Civ. Eng. 2008, 20, 78–84. [Google Scholar] [CrossRef]

- Koide, H.; Tomon, M.; Sasaki, T. Investigation of the use of waste plastic as an aggregate for lightweight concerte. In Proceedings of the Challenges of Concrete Construction, University of Dendee, Scotland, UK, 9–11 September 2002. [Google Scholar]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; İpek, S. Abrasion and freezing–thawing resistance of pervious concretes containing waste rubbers. Constr. Build. Mater. 2014, 73, 19–24. [Google Scholar] [CrossRef]

- Aubert, J.E.; Gasc-Barbier, M. Hardening of clayey soil blocks during freezing and thawing cycles. Appl. Clay Sci. 2012, 65, 1–5. [Google Scholar] [CrossRef]

- Tawfik, M.E.; Eskander, S.B. Chemical recycling of poly(ethylene terephthalate) waste using ethanolamine. Sorting of the end products. Polym. Degrad. Stab. 2010, 95, 187–194. [Google Scholar] [CrossRef]

- Demirel, B.; Yaraş, A.; Elçiçek, H. Crystallization behavior of PET materials. J. Balikesir Univ. Inst. Sci. Technol. 2011, 13, 26–35. [Google Scholar]

- Lu, X.F.; Hay, J.N. Isothermal crystallization kinetics and melting behaviour of poly(ethylene terephthalate). Polymer 2001, 42, 9423–9431. [Google Scholar] [CrossRef]

- Berdahl, P.; Bretz, S.E. Preliminary survey of the solar reflectance of cool roofing materials. Energy Build. 1997, 25, 149–158. [Google Scholar] [CrossRef]

- Cambridge Systematics, Inc. Cool Pavement Report: EPA Cool Pavements Study-Task 5; Environmental Protection Agency: Chevy Chase, MD, USA, 2005. [Google Scholar]

| Properties | RPA Block | International Criteria | ||

|---|---|---|---|---|

| Test Results | Test Method | Recommendation | Institution | |

| Flexural strength | 5.2 MPa | ASTM C67 | 1.0–3.8 MPa | Portland Cement Association (USA) |

| In situ permeability | 2365.2 mm/h | ASTM C1701 | 828.0 mm/h 2 | New Jersey Stormwater (USA) |

| 360.0 mm/h 2 | Seoul Metropolitan Government (Korea) | |||

| Sand-clogged permeability | 2.93 to 1.63 mm/s | ASTM C1701 1 | 0.14 mm/s 3 | Interlocking Concrete Pavement Institute (USA) |

| Durability (freezing and thawing) | 2.0% mass loss 4 per 120 cycles on average | ASTM C666 | 1% or less per 50 cycles | ASTM C936 |

| Reference | This Study | Gesoğlu et al. [42] | Aubert and Gasc-Barbier [43] | |

|---|---|---|---|---|

| Material | RPA block | Plane concrete | Rubberized pervious concrete | Clayey soil block |

| Weathered mass (%/cycles) | 2.0%/120 cycles | 34.0%/300 cycles | 3.5%/240 cycles | 0.7%/28 cycles |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, B.-H.; Lee, S.; Chang, I. Pervious Pavement Blocks Made from Recycled Polyethylene Terephthalate (PET): Fabrication and Engineering Properties. Sustainability 2020, 12, 6356. https://doi.org/10.3390/su12166356

Ryu B-H, Lee S, Chang I. Pervious Pavement Blocks Made from Recycled Polyethylene Terephthalate (PET): Fabrication and Engineering Properties. Sustainability. 2020; 12(16):6356. https://doi.org/10.3390/su12166356

Chicago/Turabian StyleRyu, Byung-Hyun, Sojeong Lee, and Ilhan Chang. 2020. "Pervious Pavement Blocks Made from Recycled Polyethylene Terephthalate (PET): Fabrication and Engineering Properties" Sustainability 12, no. 16: 6356. https://doi.org/10.3390/su12166356

APA StyleRyu, B.-H., Lee, S., & Chang, I. (2020). Pervious Pavement Blocks Made from Recycled Polyethylene Terephthalate (PET): Fabrication and Engineering Properties. Sustainability, 12(16), 6356. https://doi.org/10.3390/su12166356