Recent Developments in Luffa Natural Fiber Composites: Review

Abstract

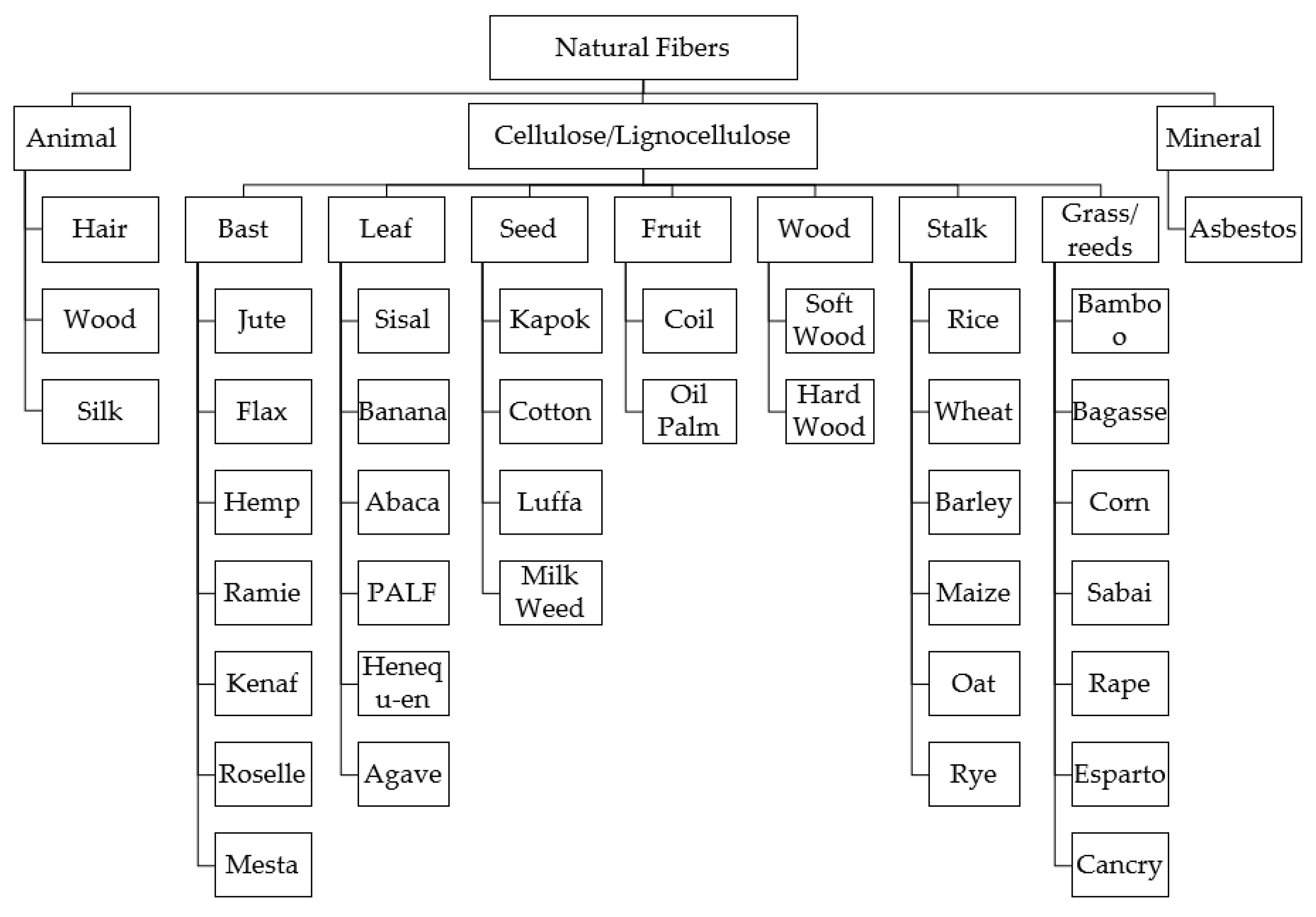

1. Introduction

2. Luffa and Its Composite Materials

2.1. Fiber Treatment

2.2. Matrices Selected for LNFCs

3. Characteristics of LNFCs

3.1. Morphology of LNFCs

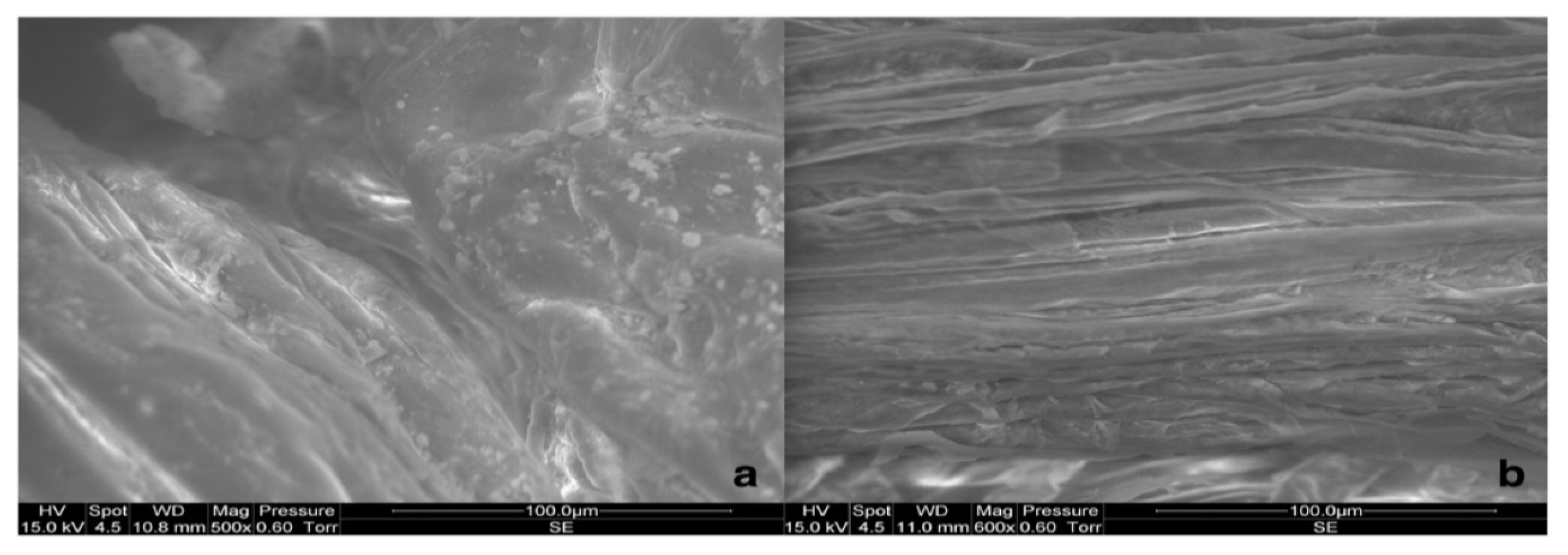

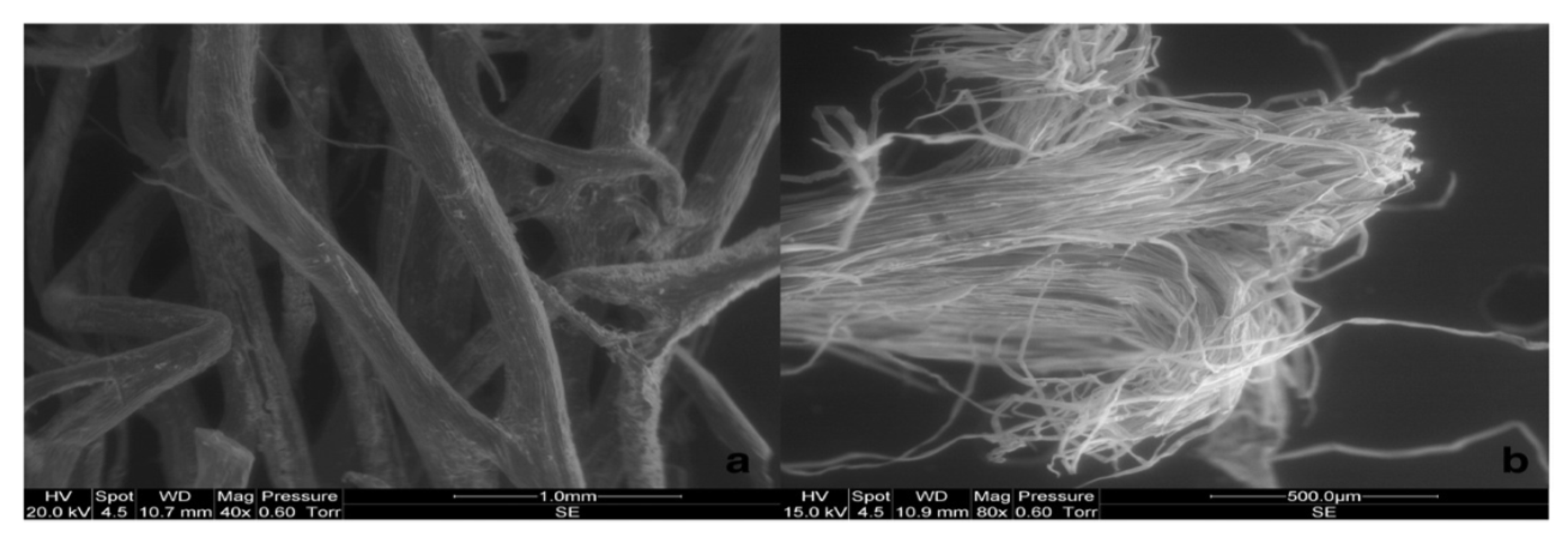

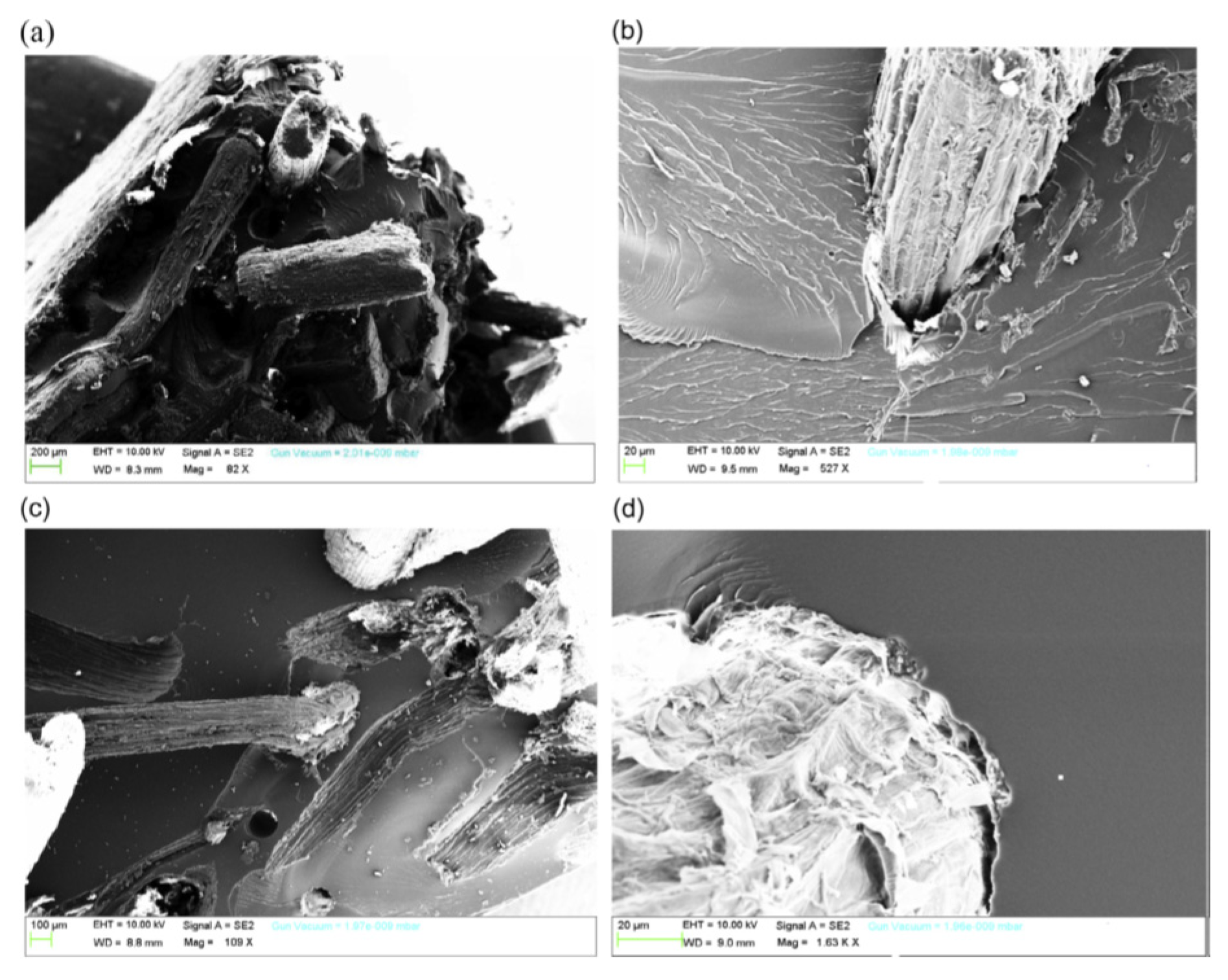

3.1.1. Microscopy

3.1.2. X-ray Diffraction

3.2. Physical Properties

3.2.1. Density

3.2.2. Water Absorption

3.2.3. Thickness Swelling

3.2.4. Acoustic Resistance

3.3. Mechanical Properties

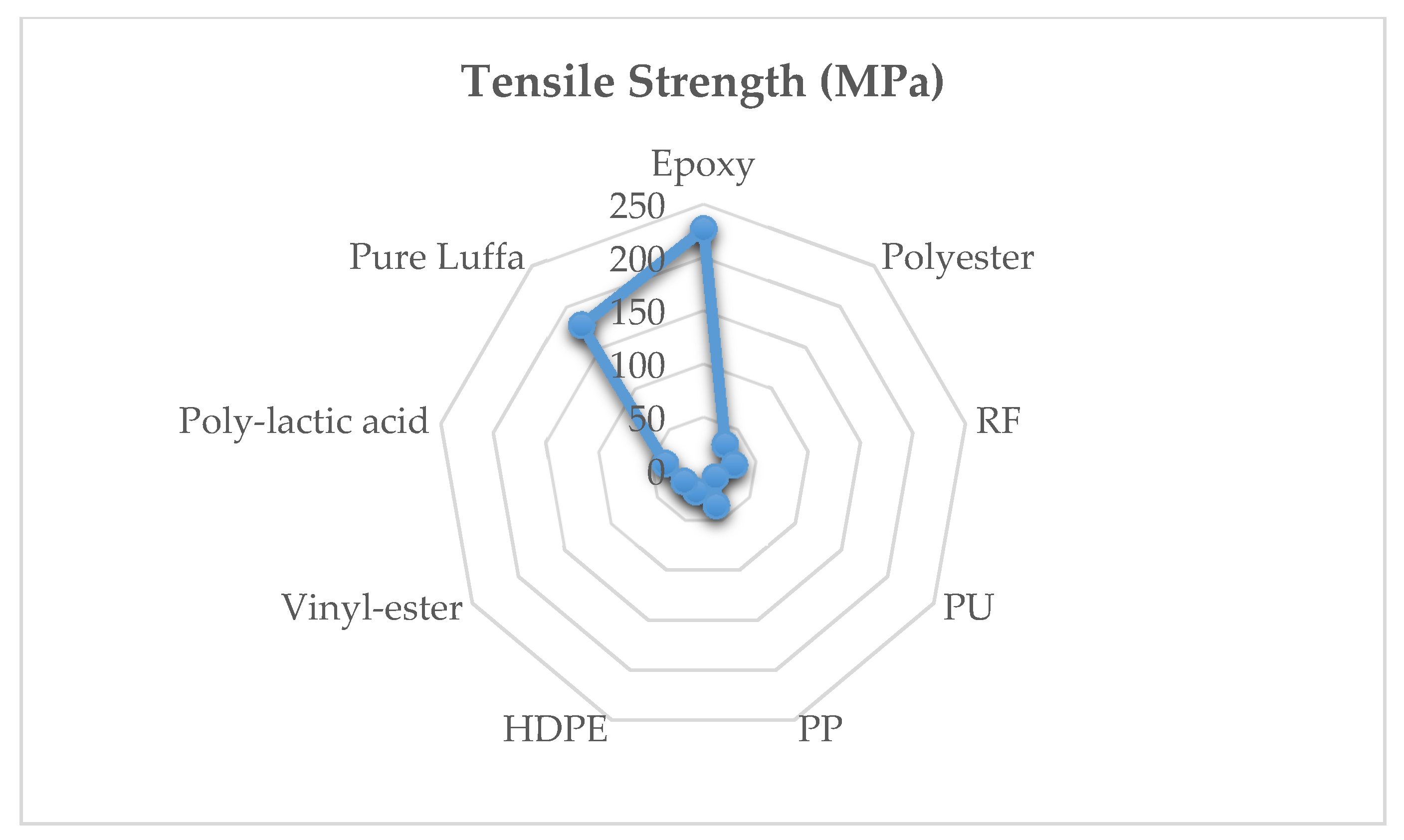

3.3.1. Tensile Properties

3.3.2. Flexural Properties

3.3.3. Compression Properties

3.3.4. Impact Properties

3.3.5. Hardness

3.3.6. Wear, Shear, Vibration, and Dynamic Mechanical Analysis

3.4. Chemical, Thermal, and Electrical Properties

3.4.1. Fourier-Transform Infrared Spectroscopy

3.4.2. Chemical

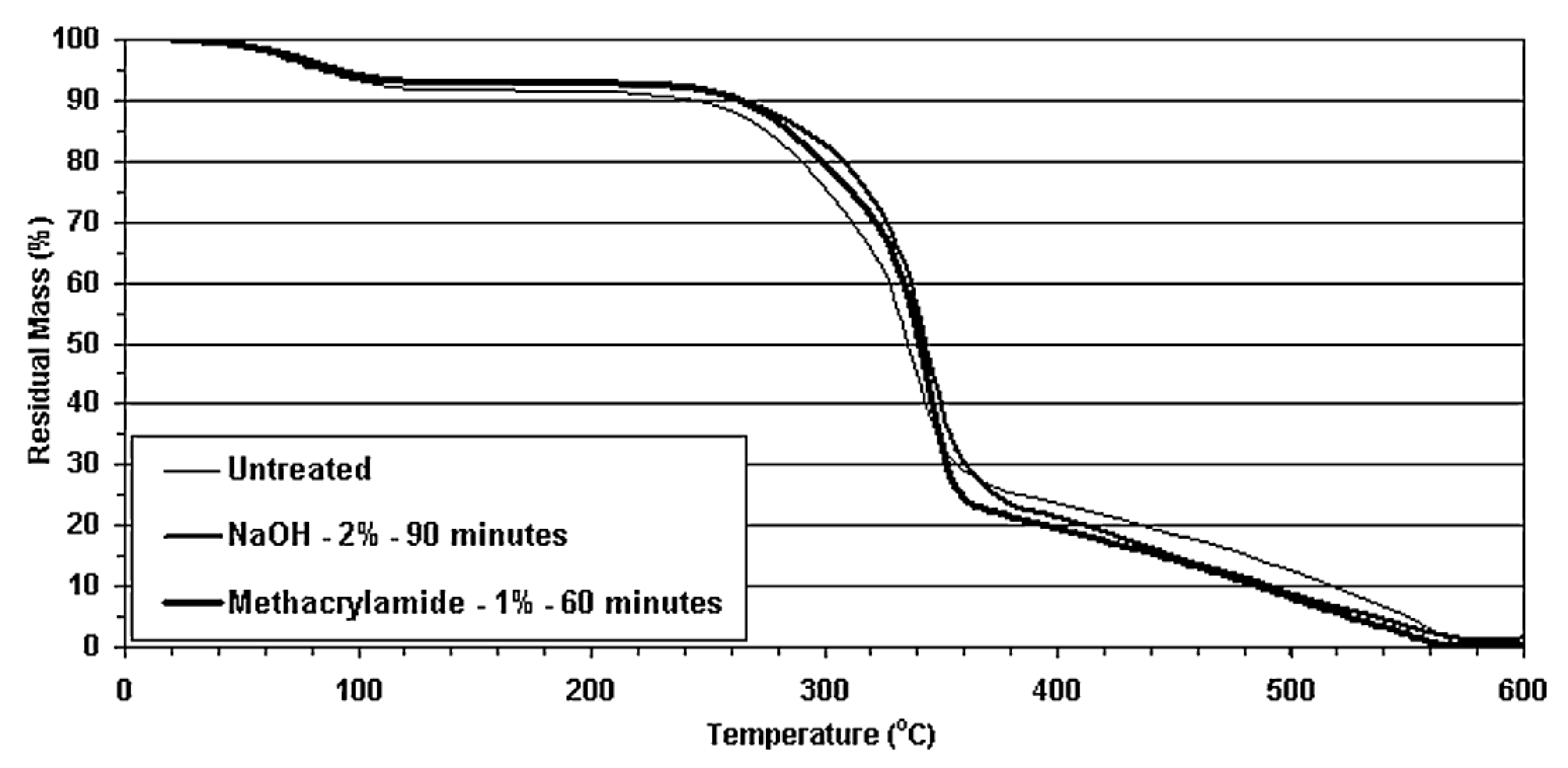

3.4.3. Thermogravimetric

3.4.4. Differential Scanning Calorimetric

3.4.5. Dielectric

4. Hybrid

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yusuf, S.; Islam, N.; Ali, H.; Akram, W.; Siddique, A. Impact Strength of Natural Fiber Reinforced Composites: Taguchi Method. Adv. Mater. Sci. 2020, 20, 54–70. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, K.; Zhao, Y.; Sahmani, S.; Safaei, B. Couple stress-based nonlinear buckling analysis of hydrostatic pressurized functionally graded composite conical microshells. Mech. Mater. 2020, 148, 103507. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, K.; Han, Y.; Sahmani, S.; Safaei, B. Nonlinear oscillations of composite conical microshells with in-plane heterogeneity based upon a couple stress-based shell model. Thin-Walled Struct. 2020, 154, 106857. [Google Scholar] [CrossRef]

- Mitra, B. Environment friendly composite materials: Biocomposites and green composites. Def. Sci. J. 2014, 64, 244. [Google Scholar] [CrossRef]

- Safaei, B. The effect of embedding a porous core on the free vibration behavior of laminated composite plates. Steel Compos. Struct. 2020, 35, 659–670. [Google Scholar]

- Rajkumar, D.R.; Santhy, K.; Padmanaban, K.P. Influence of Mechanical Properties on Modal Analysis of Natural Fiber Reinforced Laminated Composite Trapezoidal Plates. J. Nat. Fibers. 2020, 1–17. [Google Scholar] [CrossRef]

- Navaneethakrishnan, G.; Karthikeyan, T.; Saravanan, S.; Selvam, V.; Parkunam, N.; Sathishkumar, G.; Jayakrishnan, S. Structural analysis of natural fiber reinforced polymer matrix composite. Mater. Today 2020, 21, 7–9. [Google Scholar] [CrossRef]

- Javanbakht, Z.; Hall, W.; Virk, A.S.; Summerscales, J.; Öchsner, A. Finite element analysis of natural fiber composites using a self-updating model. J. Compos. Mater. 2020, 54, 3275–3286. [Google Scholar] [CrossRef]

- Fan, F.; Lei, B.; Sahmani, S.; Safaei, B. On the surface elastic-based shear buckling characteristics of functionally graded composite skew nanoplates. Thin-Walled Struct. 2020, 154, 106841. [Google Scholar] [CrossRef]

- Huzaifah, M.; Sapuan, S.; Leman, Z.; Ishak, M.; Maleque, M. A review of sugar palm (Arenga pinnata): Application, fibre characterisation and composites. Multidiscip. Model. Mater. Struct. 2017, 13, 678–698. [Google Scholar] [CrossRef]

- Behdinan, K.; Moradi-Dastjerdi, R.; Safaei, B.; Qin, Z.; Chu, F.; Hui, D. Graphene and CNT impact on heat transfer response of nanocomposite cylinders. Nanotechnol. Rev. 2020, 9, 41–52. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; Ruiz de Ballesteros, O.; Mollica, F.; Filippone, G. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Davoodi, M.; Sapuan, S.; Ahmad, D.; Aidy, A.; Khalina, A.; Jonoobi, M. Effect of polybutylene terephthalate (PBT) on impact property improvement of hybrid kenaf/glass epoxy composite. Mater. Lett. 2012, 67, 5–7. [Google Scholar] [CrossRef]

- Alhijazi, M.; Zeeshan, Q.; Safaei, B.; Asmael, M.; Qin, Z. Recent Developments in Palm Fibers Composites: A Review. J. Polym. Environ. 2020. [Google Scholar] [CrossRef]

- Ishak, M.; Leman, Z.; Sapuan, S.; Rahman, M.; Anwar, U. Chemical composition and FT-IR spectra of sugar palm (Arenga pinnata) fibers obtained from different heights. J. Nat. Fibers. 2013, 10, 83–97. [Google Scholar] [CrossRef]

- Moghaddam, M.K.; Mortazavi, S.M. Physical and chemical properties of natural fibers extracted from typha australis leaves. J. Nat. Fibers. 2016, 13, 353–361. [Google Scholar] [CrossRef]

- Saravanakumar, S.; Kumaravel, A.; Nagarajan, T.; Moorthy, I.G. Investigation of physico-chemical properties of alkali-treated Prosopis juliflora fibers. Int. J. Polym. Anal. Charact. 2014, 19, 309–317. [Google Scholar] [CrossRef]

- Vignesh, V.; Balaji, A.; Karthikeyan, M. Extraction and characterization of new cellulosic fibers from Indian mallow stem: An exploratory investigation. Int. J. Polym. Anal. Charact. 2016, 21, 504–512. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Safaei, B.; Fattahi, A.; Chu, F. Finite element study on elastic transition in platelet reinforced composites. Microsyst. Technol. 2018, 24, 2663–2671. [Google Scholar] [CrossRef]

- Lau, K.-T.; Hung, P.-Y.; Zhu, M.-H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M.K. Review on mechanical properties of natural fiber composites. Mater. Today 2018, 5, 1785–1790. [Google Scholar] [CrossRef]

- Dhanola, A.; Bisht, A.S.; Kumar, A.; Kumar, A. Influence of natural fillers on physico-mechanical properties of luffa cylindrica/ polyester composites. Mater. Today 2018, 5, 17021–17029. [Google Scholar] [CrossRef]

- Bisen, H.B.; Hirwani, C.K.; Satankar, R.K.; Panda, S.K.; Mehar, K.; Patel, B. Numerical Study of Frequency and Deflection Responses of Natural Fiber (Luffa) Reinforced Polymer Composite and Experimental Validation. J. Nat. Fibers. 2018, 17, 505–519. [Google Scholar] [CrossRef]

- Kiruthika, A.V. A review on physico-mechanical properties of bast fibre reinforced polymer composites. J. Build. Eng. 2017, 9, 91–99. [Google Scholar] [CrossRef]

- Chen, Y.; Su, N.; Zhang, K.; Zhu, S.; Zhao, L.; Fang, F.; Ren, L.; Guo, Y. In-Depth Analysis of the Structure and Properties of Two Varieties of Natural Luffa Sponge Fibers. Materials 2017, 10, 479. [Google Scholar] [CrossRef]

- Chandramohan, D.; Presin Kumar, A.J. Experimental data on the properties of natural fiber particle reinforced polymer composite material. Data Brief 2017, 13, 460–468. [Google Scholar] [CrossRef]

- Jauhari, N.; Mishra, R.; Thakur, H. Natural fibre reinforced composite laminates—A review. Mater. Today 2015, 2, 2868–2877. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Węcławski, B.T.; Fan, M.; Hui, D. Compressive behaviour of natural fibre composite. Compos. B Eng. 2014, 67, 183–191. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R.; Rajini, N. Characterization of natural fiber and composites—A review. J. Reinf. Plast. Compos. 2013, 32, 1457–1476. [Google Scholar] [CrossRef]

- Nguong, C.; Lee, S.; Sujan, D. A review on natural fibre reinforced polymer composites. Proc. World Acad. Sci. Eng. Technol. 2013, 7, 52–59. [Google Scholar]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Alothman, O.Y.; Jawaid, M.; Sapuan, S.; Es-Saheb, M. Processing and properties of date palm fibers and its composites. In Biomass Bioenergy; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–25. [Google Scholar]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Ho, M.-p.; Wang, H.; Lee, J.-H.; Ho, C.-k.; Lau, K.-t.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Joining of natural fiber reinforced composites using microwave energy: Experimental and finite element study. Mater. Des. 2012, 35, 596–602. [Google Scholar] [CrossRef]

- Rokbi, M.; Osmani, H.; Imad, A.; Benseddiq, N. Effect of Chemical treatment on Flexure Properties of Natural Fiber-reinforced Polyester Composite. Procedia Eng. 2011, 10, 2092–2097. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Alves, C.; Silva, A.; Reis, L.; Freitas, M.; Rodrigues, L.; Alves, D. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. SM&T 2020, 23, e00132. [Google Scholar] [CrossRef]

- Dawit, J.B.; Regassa, Y.; Lemu, H.G. Property characterization of acacia tortilis for natural fiber reinforced polymer composite. Results Mater. 2020, 5, 100054. [Google Scholar] [CrossRef]

- Jino, R.; Pugazhenthi, R.; Ashok, K.G.; Ilango, T.; Chakravarthy, P.R.K. Enhancement of Mechanical Properties of Luffa Fiber/Epoxy Composite Using B4C. J. Adv. Microsc. Res. 2017, 12, 89–91. [Google Scholar] [CrossRef]

- Ekici, B.; Kentli, A.; Küçük, H. Improving Sound Absorption Property of Polyurethane Foams by Adding Tea-Leaf Fibers. Arch. Acoust. 2012, 37, 515–520. [Google Scholar] [CrossRef]

- Shen, J.; Min Xie, Y.; Huang, X.; Zhou, S.; Ruan, D. Mechanical properties of luffa sponge. J. Mech. Behav. Biomed. Mater. 2012, 15, 141–152. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, Q.; Gorb, S.N.; Li, Z. A multiscale study on the structural and mechanical properties of the luffa sponge from Luffa cylindrica plant. J. Biomech. 2014, 47, 1332–1339. [Google Scholar] [CrossRef]

- Sinnott, E.W.; Bloch, R. Development of the fibrous net in the fruit of various races of Luffa cylindrica. Bot. Gaz. 1943, 105, 90–99. [Google Scholar] [CrossRef]

- Sabarinathan, P.; Rajkumar, K.; Gnanavelbabu, A. Investigation of mechanical properties of Luffa cylindrical and flax reinforced hybrid polymer composite. J. Adv. Eng. Res. 2016, 3, 124–127. [Google Scholar]

- Saw, S.K.; Purwar, R.; Nandy, S.; Ghose, J.; Sarkhel, G. Fabrication, characterization, and evaluation of luffa cylindrica fiber reinforced epoxy composites. BioResources 2013, 8, 4805–4826. [Google Scholar] [CrossRef]

- Mohanta, N.; Acharya, S.K. Fiber surface treatment: Its effect on structural, thermal, and mechanical properties of Luffa cylindrica fiber and its composite. J. Compos. Mater. 2016, 50, 3117–3131. [Google Scholar] [CrossRef]

- Porterfield, W. Loofah—The sponge gourd. Econ. Bot. 1955, 9, 211–223. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Rana, A.; Bose, N.R. Effect of alkali treated jute fibres on composite properties. Bull. Mater. Sci. 2001, 24, 129–135. [Google Scholar] [CrossRef]

- Jino, R.; Sriraman, M.; Arthika, B.; Ashok, K. Studies on mechanical properties of luffa acutangula/lignite fly ash reinforced composites. Int. J. Eng. Technol. 2018, 7, 251–254. [Google Scholar] [CrossRef]

- Chen, Y.; Su, N.; Zhang, K.; Zhu, S.; Zhu, Z.; Qin, W.; Yang, Y.; Shi, Y.; Fan, S.; Wang, Z.; et al. Effect of fiber surface treatment on structure, moisture absorption and mechanical properties of luffa sponge fiber bundles. Ind. Crop. Prod. 2018, 123, 341–352. [Google Scholar] [CrossRef]

- Thangaraju, R.; Aravindakumar, A. Experimental study on the characteristics of surface treated luffa fiber composites. Int. J. Chem. Pharm. Rev. Res. 2016, 9, 646–651. [Google Scholar]

- Parida, C.; Dash, S.K.; Das, S.C. Effect of Fiber Treatment and Fiber Loading on Mechanical Properties of Luffa-Resorcinol Composites. Indian J. Eng. Mater. Sci. 2015, 2015, 1–6. [Google Scholar] [CrossRef]

- Parida, C.; Dash, S.K.; Chaterjee, P. Mechanical properties of injection molded poly (lactic) Acid—Luffa fiber composites. SNL 2015, 5, 65. [Google Scholar] [CrossRef]

- Anbukarasi, K.; Kalaiselvam, S. Study of effect of fibre volume and dimension on mechanical, thermal, and water absorption behaviour of luffa reinforced epoxy composites. Mater. Des 2015, 66, 321–330. [Google Scholar] [CrossRef]

- Tanobe, V.; Flores-Sahagun, T.; Amico, S.; Muniz, G.; Satyanarayana, K. Sponge Gourd (Luffa Cylindrica) Reinforced Polyester Composites: Preparation and Properties. Def. Sci. J. 2014, 64, 273–280. [Google Scholar] [CrossRef]

- Srinivasan, C.; Sathish, S.; Vignesh, K. Mechanical properties of chemically treated Luffa Aegyptiaca fiber reinforced epoxy matrix composites. Int. J. Sci. Res. Manag. 2014, 2, 1515–1524. [Google Scholar]

- Panneerdhass, R.; Gnanavelbabu, A.; Rajkumar, K. Mechanical Properties of Luffa Fiber and Ground nut Reinforced Epoxy Polymer Hybrid Composites. Procedia Eng. 2014, 97, 2042–2051. [Google Scholar] [CrossRef]

- Panneerdhass, R.; Baskaran, R.; Rajkumar, K.; Gnanavelbabu, A. Mechanical Properties of Chopped Randomly Oriented Epoxy-Luffa Fiber Reinforced Polymer Composite. Appl. Mech. Mater. 2014, 591, 103–107. [Google Scholar] [CrossRef]

- Botaro, V.R.; Novack, K.M.; Siqueira, É.J. Dynamic mechanical behavior of vinylester matrix composites reinforced by Luffa cylindrica modified fibers. J. Appl. Polym. Sci. 2012, 124, 1967–1975. [Google Scholar] [CrossRef]

- Ghali, L.H.; Aloui, M.; Zidi, M.; Daly, H.B.; Msahli, S.; Sakli, F. Effect of chemical modification of luffa cylindrica fibers on the mechanical and hygrothermal behaviours of polyester/luffa composites. BioResources 2011, 6, 3836–3849. [Google Scholar]

- Ghali, L.; Msahli, S.; Zidi, M.; Sakli, F. Effects of Fiber Weight Ratio, Structure and Fiber Modification onto Flexural Properties of Luffa-Polyester Composites. Adv. Mater. Phys. Chem. 2011, 1, 78–85. [Google Scholar] [CrossRef][Green Version]

- Ghali, L.; Msahli, S.; Zidi, M.; Sakli, F. Effect of pre-treatment of Luffa fibres on the structural properties. Mater. Lett. 2009, 63, 61–63. [Google Scholar] [CrossRef]

- Demir, H.; Atikler, U.; Balköse, D.; Tıhmınlıoğlu, F. The effect of fiber surface treatments on the tensile and water sorption properties of polypropylene–luffa fiber composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 447–456. [Google Scholar] [CrossRef]

- Tanobe, V.O.A.; Sydenstricker, T.H.D.; Munaro, M.; Amico, S.C. A comprehensive characterization of chemically treated Brazilian sponge-gourds (Luffa cylindrica). Polym. Test. 2005, 24, 474–482. [Google Scholar] [CrossRef]

- Boynard, C.; Monteiro, S.; d’Almeida, J. Aspects of alkali treatment of sponge gourd (Luffa cylindrica) fibers on the flexural properties of polyester matrix composites. J. Appl. Polym. Sci. 2003, 87, 1927–1932. [Google Scholar] [CrossRef]

- Kalusuraman, G.; Siva, I.; Munde, Y.; Selvan, C.P.; Kumar, S.A.; Amico, S.C. Dynamic-mechanical properties as a function of luffa fibre content and adhesion in a polyester composite. Polym. Test. 2020, 87, 106538. [Google Scholar] [CrossRef]

- Dharmalingam, S.; Meenakshisundaram, O.; Kugarajah, V. Effect of Degree of Silanization of Luffa on the properties of Luffa-Epoxy Composites. Colloids Surf. A Physicochem. Eng. Aspects 2020, 603, 125273. [Google Scholar] [CrossRef]

- Ashok, K.; Kalaichelvan, K.; Damodaran, A. Effect of Nano Fillers on Mechanical Properties of Luffa Fiber Epoxy Composites. J. Nat. Fibers. 2020, 1–18. [Google Scholar] [CrossRef]

- Mohana Krishnudu, D.; Sreeramulu, D.; Reddy, P.V.; Rajendra Prasad, P. Influence of Filler on Mechanical and Di-electric Properties of Coir and Luffa Cylindrica Fiber Reinforced Epoxy Hybrid Composites. J. Nat. Fibers. 2020, 17, 1–10. [Google Scholar] [CrossRef]

- Chakrabarti, D.; Islam, M.S.; Jubair, K.; Sarker, M.R.H. Effect of Chemical Treatment on the Mechanical Properties of Luffa Fiber Reinforced Epoxy Composite. J. Eng. Adv. 2020, 1, 37–42. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.; Zhao, Y.; Xu, L.; Wang, T.; Zhang, X. Preparation of recyclable BiOI/luffa fiber composite and its highly efficient visible light photocatalytic properties. J. Clean. Prod. 2018, 200, 945–953. [Google Scholar] [CrossRef]

- Shen, J.; Xie, Y.M.; Huang, X.; Zhou, S.; Ruan, D. Behaviour of luffa sponge material under dynamic loading. Int. J. Impact Eng. 2013, 57, 17–26. [Google Scholar] [CrossRef]

- Parida, C.; Das, S.C.; Dash, S.K. Mechanical Analysis of Bio Nanocomposite Prepared from Luffa cylindrica. Procedia Chem. 2012, 4, 53–59. [Google Scholar] [CrossRef][Green Version]

- Pires, C.; Motta, L.A.d.C.; Ferreira, R.A.d.R.; Caixeta, C.d.O.; Savastano, H. Thermomechanical and Thermo-hydro-mechanical Treatments of Luffa Cylindrical Fibers. J. Nat. Fibers. 2020, 17, 1–13. [Google Scholar] [CrossRef]

- Kakar, A.; Jayamani, E.; Soon, K.H.; Bakri, M.K.B. Study of dielectric properties of luffa-polylactide quadratic splint composites: The effect of cyclic absorption and desorption of water. J. Vinyl. Addit. Technol. 2018, 24, 388–394. [Google Scholar] [CrossRef]

- Al-Mobarak, T.; Mina, M.; Gafur, M. Improvement in mechanical properties of sponge-gourd fibers through different chemical treatment as demonstrated by utilization of the Weibull distribution model. J. Nat. Fibers. 2020, 17, 573–588. [Google Scholar] [CrossRef]

- Yin, S.; Wang, H.; Li, J.; Ritchie, R.O.; Xu, J. Light but tough bio-inherited materials: Luffa sponge based nickel-plated composites. J. Mech. Behav. Biomed. 2019, 94, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wang, L.; Chen, Y.; Luo, P.; Chen, T. Properties of luffa fiber reinforced phbv biodegradable composites. Polymers 2019, 11, 1765. [Google Scholar] [CrossRef] [PubMed]

- Sivakandhan, C.; Balaji, R.; Loganathan, G.B.; Madan, D.; Murali, G. Investigation of mechanical behaviour on sponge/ridge gourd (Luffa aegyptiaca) natural fiber using epoxy and polyester resin. Mater. Today 2020, 22, 705–714. [Google Scholar] [CrossRef]

- Kalusuraman, G.; Kumaran, S.T.; Siva, I.; Kumar, S.A. Cutting performance of luffa cylindrica fiber–reinforced composite by abrasive water jet. J. Test. Eval. 2020, 48, 20180330. [Google Scholar] [CrossRef]

- Daniel-Mkpume, C.; Ugochukwu, C.; Okonkwo, E.; Fayomi, O.; Obiorah, S. Effect of Luffa cylindrica fiber and particulate on the mechanical properties of epoxy. Int. J. Adv. Manuf. Technol. 2019, 102, 3439–3444. [Google Scholar] [CrossRef]

- Koruk, H.; Genc, G. Investigation of the acoustic properties of bio luffa fiber and composite materials. Mater. Lett. 2015, 157, 166–168. [Google Scholar] [CrossRef]

- Mohanta, N.; Acharya, S. Tensile, flexural and interlaminar shear properties of Luffa cylindrica fibre reinforced epoxy composites. Int. J. Macromol. Sci 2013, 3, 6–10. [Google Scholar]

- Genc, G.; Körük, H. Investigation of the vibro-acoustic behaviors of luffa bio composites and assessment of their use for practical applications. In Proceedings of the 23rd International Congress on Sound and Vibration 2016, ICSV 2016, Athens, Greece, 10–14 July 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Mohanta, N.; Acharya, S.K. Mechanical and tribological performance of Luffa cylindrica fibre-reinforced epoxy composite. BioResources 2015, 10, 8364–8377. [Google Scholar] [CrossRef]

- Mohanta, N.; Acharya, S.K. Investigation of mechanical properties of luffa cylindrica fibre reinforced epoxy hybrid composite. Int. J. Eng. Sci. Technol. 2015, 7. [Google Scholar] [CrossRef]

- Genc, G.; Sarikas, A.; Kesen, U.; Aydin, S. Luffa/Epoxy composites: Electrical properties for PCB application. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 933–940. [Google Scholar] [CrossRef]

- Saygili, Y.; Genc, G.; Sanliturk, K.Y.; Koruk, H. Investigation of the acoustic and mechanical properties of homogenous and hybrid jute and luffa bio composites. J. Nat. Fibers. 2020, 17, 1–9. [Google Scholar] [CrossRef]

- Boynard, C.A.; D’Almeida, J.R.M. Morphological Characterization and Mechanical Behavior of Sponge Gourd (Luffa Cylindrica)–Polyester Composite Materials. Polym. Plast. Technol. Eng. 2000, 39, 489–499. [Google Scholar] [CrossRef]

- Boynard, C.; d’Almeida, J. Water absorption by sponge gourd (luffa cylindrica)-polyester composite materials. J. Mater. Sci. Lett. 1999, 18, 1789–1791. [Google Scholar] [CrossRef]

- NagarajaGanesh, B.; Muralikannan, R. Extraction and characterization of lignocellulosic fibers fromLuffa cylindricafruit. Int. J. Polym. Anal. Charact. 2016, 21, 259–266. [Google Scholar] [CrossRef]

- Akgül, M.; Korkut, S.; Çamlıbel, O.; Ayata, Ü. Some chemical properties of luffa and its suitability for medium density fiberboard (MDF) production. BioResources 2013, 8, 1709–1717. [Google Scholar] [CrossRef]

- Escocio, V.A.; Visconte, L.L.Y.; Cavalcante, A.d.P.; Furtado, A.M.S.; Pacheco, E.B.A.V. Study of mechanical and morphological properties of bio-based polyethylene (HDPE) and sponge-gourds (Luffa-cylindrica) agroresidue composites. In AIP Conference Proceedings; AIP: Cleveland, OH, USA, 2015; p. 060012. [Google Scholar] [CrossRef]

- Jamaluddin, J.; Firouzi, A.; Islam, M.; Yahaya, A. Effects of luffa and glass fibers in polyurethane-based ternary sandwich composites for building materials. SN Appl. Sci. 2020, 2, 1–10. [Google Scholar] [CrossRef]

- Alshaaer, M.; Mallouh, S.A.; Al-Kafawein, J.a.; Al-Faiyz, Y.; Fahmy, T.; Kallel, A.; Rocha, F. Fabrication, microstructural and mechanical characterization of Luffa Cylindrical Fibre-Reinforced geopolymer composite. Appl. Clay Sci. 2017, 143, 125–133. [Google Scholar] [CrossRef]

- Kaewtatip, K.; Thongmee, J. Studies on the structure and properties of thermoplastic starch/luffa fiber composites. Mater. Des. 2012, 40, 314–318. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, F.; Guo, Y.; Hu, D.; Zhu, Z.; Zhang, K.; Zhu, S. A novel mattress filling material comprising of luffa fibers and EVA resin. Ind. Crops Prod. 2018, 124, 213–215. [Google Scholar] [CrossRef]

- Quadri, A.I.; Alabi, O. Assessment of Sponge Gourd (Luffa Aegyptical) Fiber as a Polymer Reinforcement in Concrete. J. Civ. Eng. Mater. Appl. 2020, 4, 125–132. [Google Scholar]

- NagarajaGanesh, B.; Ganeshan, P.; Ramshankar, P.; Raja, K. Assessment of natural cellulosic fibers derived from Senna auriculata for making light weight industrial biocomposites. Ind. Crops Prod. 2019, 139, 111546. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S.; Jatti, V.S. A review on natural and waste material composite as acoustic material. Polym. Test. 2019, 80, 106142. [Google Scholar] [CrossRef]

- Mittal, V.; Saini, R.; Sinha, S. Natural fiber-mediated epoxy composites–a review. Compos. B Eng. 2016, 99, 425–435. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Yang, Q.; Zhai, Y.; Li, X.; Li, H. Synthesis of Fe3O4/Pr-BiOCl/Luffa composites with enhanced visible light photoactivity for organic dyes degradation. Mater. Res. Bull. 2018, 106, 409–417. [Google Scholar] [CrossRef]

- Satankar, R.K.; Sharma, N.; Panda, S.K.; Mohapatra, S.S. Experimental and simulation study of eigen frequency responses of Luffa cylindrica sponge fibre polymer composite. Mater. Today 2020. [Google Scholar] [CrossRef]

- Shih, Y.-J.; Dong, C.-D.; Huang, Y.-H.; Huang, C. Electro-sorption of ammonium ion onto nickel foam supported highly microporous activated carbon prepared from agricultural residues (dried Luffa cylindrica). Sci. Total Environ. 2019, 673, 296–305. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, W.; Xie, R.; Liu, X.; Yang, D.; Chen, P.; Zhang, J.; Zhang, F. Composite of nano-goethite and natural organic luffa sponge as template: Synergy of high efficiency adsorption and visible-light photocatalysis. Inorg. Chem. Commun. 2018, 98, 115–119. [Google Scholar] [CrossRef]

- Sreeramulu, D.; Ramesh, N. Synthesis, characterization, and properties of epoxy filled Luffa cylindrica reinforced composites. Mater. Today 2018, 5, 6518–6524. [Google Scholar]

- Saw, S.K. Effect of stacking patterns on morphological and mechanical properties of luffa/coir hybrid fiber-reinforced epoxy composite laminates. In Hybrid Polymer Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 313–333. [Google Scholar]

- Mohanta, N.; Acharya, S.K. Effect of alkali treatment on the flexural properties of a Luffa cylindrica-reinforced epoxy composite. Sci. Eng. Compos. Mater. 2018, 25, 85–93. [Google Scholar] [CrossRef]

- Malkapuram, R.; Kumar, V.; Negi, Y.S. Recent development in natural fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 28, 1169–1189. [Google Scholar] [CrossRef]

- O’donnell, A.; Dweib, M.; Wool, R. Natural fiber composites with plant oil-based resin. Compos. Sci. Technol. 2004, 64, 1135–1145. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, H.; Chu, B.; Hsiao, B.S. Super-hydrophobic modification of porous natural polymer “luffa sponge” for oil absorption. Polymer 2017, 126, 470–476. [Google Scholar] [CrossRef]

- Saraiva, A.B.; Pacheco, E.B.; Gomes, G.M.; Visconte, L.L.; Bernardo, C.; Simoes, C.L.; Soares, A.G. Comparative lifecycle assessment of mango packaging made from a polyethylene/natural fiber-composite and from cardboard material. J. Clean. Prod. 2016, 139, 1168–1180. [Google Scholar] [CrossRef]

- Kocak, D.; Mistik, S.; Akalin, M.; Merdan, N. The use of Luffa cylindrica fibres as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 689–699. [Google Scholar]

- Premalatha, N.; Saravanakumar, S.; Sanjay, M.; Siengchin, S.; Khan, A. Structural and thermal properties of chemically modified Luffa Cylindrica fibers. J. Nat. Fibers. 2019, 16, 1–7. [Google Scholar] [CrossRef]

- Bera, T.; Mohanta, N.; Prakash, V.; Pradhan, S.; Acharya, S.K. Moisture absorption and thickness swelling behaviour of luffa fibre/epoxy composite. J. Reinf. Plast. Compos. 2019, 38, 923–937. [Google Scholar] [CrossRef]

- Sewda, K.; Maiti, S. Mechanical properties of teak wood flour-reinforced HDPE composites. J. Appl. Polym. Sci. 2009, 112, 1826–1834. [Google Scholar] [CrossRef]

- Samanta, B.; Maity, T.; Dalai, S.; Banthia, A. Mechanical properties of modified epoxy: Effect of chain length. Pigment Resin Technol. 2006, 35, 216–223. [Google Scholar] [CrossRef]

- Krishnudu, D.M.; Sreeramulu, D.; Reddy, P.V. A study of filler content influence on dynamic mechanical and thermal characteristics of coir and luffa cylindrica reinforced hybrid composites. Constr. Build Mater. 2020, 251, 119040. [Google Scholar] [CrossRef]

- Chen, Y.; Yuan, F.; Su, Q.; Yu, C.; Zhang, K.; Luo, P.; Hu, D.; Guo, Y. A novel sound absorbing material comprising discarded luffa scraps and polyester fibers. J. Clean. Prod. 2020, 245, 118917. [Google Scholar] [CrossRef]

- Koruk, H.; Genç, G. Acoustic and mechanical properties of luffa fiber-reinforced biocomposites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 325–341. [Google Scholar]

- Keskin, O.; Yılmaz, S. Parameters affecting sound absorption in fiber composites: A case study for Luffa Cylindrica. In IDES’19 International Design and Engineering Symposium: Sustainability, Innovation, Production; Izmir Democracy University: Izmir, Turkey, 2019. [Google Scholar]

- Taiwo, E.M.; Yahya, K.; Haron, Z. Potential of using natural fiber for building acoustic absorber: A review. J. Phys. Conf. Ser. 2019, 1262, 012017. [Google Scholar] [CrossRef]

- Alhijazi, M.; Zeeshan, Q.; Qin, Z.; Safaei, B.; Asmael, M. Finite element analysis of natural fibers composites: A review. Nanotechnol. Rev. 2020, 9, 853–875. [Google Scholar] [CrossRef]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S. Mechanical properties of natural fiber/particulate reinforced epoxy composites—A review of the literature. Mater. Today 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Wang, X.; Shen, J.; Zuo, Z.H.; Huang, X.; Zhou, S.; Xie, Y.M. Numerical investigation of compressive behaviour of luffa-filled tubes. Compos. B Eng. 2015, 73, 149–157. [Google Scholar] [CrossRef]

- Ashok, K.; Kalaichelvan, K.; Elango, V.; Damodaran, A.; Gopinath, B.; Raju, M. Mechanical and morphological properties of luffa/carbon fiber reinforced hybrid composites. Mater. Today 2020. [Google Scholar] [CrossRef]

- Mani, P.; Dellibabu, G.; Anilbasha, K.; Anbukarsi, K. Tensile and flexural properties of Luffa fiber reinforced composite material. Int. J. Eng. Res. Technol. 2014, 3, 1882–1885. [Google Scholar]

- Paglicawan, M.A.; Cabillon, M.S.; Cerbito, R.P.; Santos, E.O. Loofah fiber as reinforcement material for composite. Philipp. J. Sci. 2005, 134, 113. [Google Scholar]

- Khan, M.A.; Hassan, M.M.; Drzal, L.T. Effect of 2-hydroxyethyl methacrylate (HEMA) on the mechanical and thermal properties of jute-polycarbonate composite. Compos. Part A Appl. Sci. Manuf. 2005, 36, 71–81. [Google Scholar] [CrossRef]

- White, J.E.; Catallo, W.J.; Legendre, B.L. Biomass pyrolysis kinetics: A comparative critical review with relevant agricultural residue case studies. J. Anal. Appl. Pyrolysis 2011, 91, 1–33. [Google Scholar] [CrossRef]

- Putson, C.; Jaaoh, D.; Muensit, N. Interface polarization effect on dielectric and electrical properties of polyurethane (PU)/polyaniline (PANI) polymer composites. Adv. Mater. Res. 2013, 770, 275–278. [Google Scholar] [CrossRef]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An overview: Natural fiber reinforced hybrid composites, chemical treatments and application areas. Mater. Today 2020, 27, 2828–2834. [Google Scholar] [CrossRef]

- Sreekala, M.; George, J.; Kumaran, M.; Thomas, S. The mechanical performance of hybrid phenol-formaldehyde-based composites reinforced with glass and oil palm fibres. Compos. Sci. Technol. 2002, 62, 339–353. [Google Scholar] [CrossRef]

- Arrakhiz, F.; Hamou, K.B.; Erchiqui, F.; Hammiche, D.; Kaddami, H. Development and characterization of hybrid composite laminate based on luffa and glass fibers. Mater. Today 2020. [Google Scholar] [CrossRef]

- Patel, V.K.; Dhanola, A. Influence of CaCO3, Al2O3, and TiO2 microfillers on physico-mechanical properties of Luffa cylindrica/polyester composites. Eng. Sci. Technol. Int. J. 2016, 19, 676–683. [Google Scholar] [CrossRef]

- Lai, S.-M.; Kao, Y.-H.; Liu, Y.-K.; Chiu, F.-C. Preparation and properties of luffa fiber-and kenaf fiber-filled poly (butylene succinate-co-lactate)/starch blend-based biocomposites. Polym. Test. 2016, 50, 191–199. [Google Scholar] [CrossRef]

| Physical Properties | Chemical Composition | ||||||

|---|---|---|---|---|---|---|---|

| Density (gm/cm3) | Diameter (μm) | Aspect ratio | Micro fibrillar angle (°) | Cellulose (%) | Lignin (%) | Hemi cellulose (%) | Ash (%) |

| 0.56−0.92 | 270 ± 20 | 340 ± 5 | 12 ± 2 | 63.0 ± 2.5 | 11.69 ± 1.2 | 20.88 ± 1.4 | 0.4 ± 0.10 |

| Treatment | Reference |

|---|---|

| Sodium Hydroxide (NaOH) | [25,44,49,50,51,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76] |

| Hydrogen Peroxide (H2O2) | [27,54,55,65,66,67] |

| Acetic Acid (CH3COOH) | [27,54,55] |

| Carbamide CO(NH2) | [55] |

| Methacrylamide | [60,69] |

| Benzoyl Chloride Permanganate (KMnO4) | [51,75] |

| Acetic Anhydride, and Acetone | [65] |

| Furfuryl Alcohol followed by oxidation (sodium chlorite + acetic acid) | [50] |

| CaCl2, H2SO4, and Na2HPO4 | [57] |

| Hypochlorite (NaClO) | [58] |

| Ethanol, BTDA Dianhydrides | [64] |

| HCl | [56] |

| Chlorine Bleach | [46,77] |

| CalciumPhosphate and Calcium Carbonate | [78] |

| CaOH2 and Silane | [71] |

| Thermo-mechanical treatment and thermo-hydromechanical treatment | [79] |

| Heat treatment | [80] |

| Matrix | Reference |

|---|---|

| Epoxy | [25,44,49,50,51,54,59,61,62,63,72,73,74,75,84,87,88,89,90,91,92,93] |

| Polyester | [24,56,60,65,66,70,71,84,94,95,96] |

| Resorcinol-formaldehyde | [57,78,97] |

| Polylactic acid | [58,80] |

| Bio-based polyethylene (HDPE) | [98] |

| Vinyl ester | [7,64] |

| Polyurethane foam | [45] |

| Polyurethane (PU) | [99] |

| Polypropylene | [68] |

| Geopolymer | [100] |

| Pre-gelatinized cassava starch | [101] |

| Eva resin | [102] |

| Bismuth nitrate pentahydrate (Bi(NO3)3·5H2O) and potassium iodide | [76] |

| Concrete | [103] |

| Resin/Coupling Agent/Hardener | Fiber Treatment | Fiber Size/Shape | Fiber Composition Vf/wt.% | Hybrid/Filler | Density g/cm3 | Reference |

|---|---|---|---|---|---|---|

| Epoxy/Hardener HY951 | Rectangular mat | 19.87–30.86% Vf | Glass fiber | 1.009–1.297 | [91] | |

| Epoxy/hardener K-6 | NaOH | 2–5 mm | 3.2–9.6 wt.% | 1.1142–1.1501 | [25] | |

| Formaldehyde | Mat in medium density fireboard | Pine, beech, and oak | 0.717–0.721 | [97] | ||

| Geopolymer (metakaolin activated with sodium silicate and sodium hydroxide solutions) | Fiber’s D: 200 μm. L: 160 mm | 10 vol.% | 1.38 | [100] |

| Resin/Fiber Treatment | Fiber Size, Shape, and Composition Vf/wt.% | Hybrid/Filler | Tensile (MPa) | Flexural (MPa) | Compression (MPa) | Impact | Hardness | Other | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Epoxy/NaOH | Particles, short fibers, and mat shaped fibers (0.3–0.5 Vf) | 23 | 115 | 107 | 27 KJ/m2 | [59] | |||

| Epoxy/NaOH | 10–20 mm (10%, 20%, 30%, 40% and 50% Vf) | Ground nut (1:1) | 20 | 72 | 52.22 | 1.3 J | [62] | ||

| Epoxy/NaOH | Mat (30% Vf) | Flax | 24 | 59 | 1.9 J | [49] | |||

| Epoxy/NaOH | Ceramic B4C (10 wt.%) | 13.56 E: 73.29 | 34.39 | 18000 J | 91 HRc | [44] | |||

| Epoxy | Rectangular mat (8, 13 and 19 wt.%) | 18 E: 699 | 28 | 4.90 KJ/m2 | 217.20 MPa | Interlaminar shear stress (ILSS):1.38 MPa Erosion: 45% to 60% IA | [90] | ||

| Epoxy | Rectangular mat (19.87–30.86% Vf) | Glass fiber | 35.34 | 108.36 | 53.825 Hv | ILSS: 5.628 MPa | [91] | ||

| Epoxy/NaOH, and furfuryl alcohol followed by oxidation (sodium chlorite + acetic acid) | 100 × 100 mat (30 wt.%) | 226.40 E:5865.70 | 7 KJ/m2 | [50] | |||||

| Epoxy/NaOH, benzoyl chloride, and potassium permanganate KMnO4 | Rectangular mat (13 wt.%) | 28 E: 910 | 54 Ef: 3800 | 7.3 KJ/m2 | ILSS: 2 MPa | [51] | |||

| Epoxy/NaOH | Chopped randomly (30%, 40% and 50% Vf) | 18 | 55 | 105 | 0.68 J | [63] | |||

| Epoxy/NaOH | 6 cm (30% Vf) | Silica nanoparticles | 13 E: 3284 | 28.9 | 81 | 0.9 J | [61] | ||

| Epoxy/NaOH, acetic acid | 2 mm (8, 9, 9.5 and 10 wt.%) | Lignite Fly Ash filler | 17.28 | 46.87 | 48.13 | 98 RHN | [54] | ||

| Epoxy | Rectangular mat (8, 13, and 19 wt.%) | 16.76 | 24.825 | ILSS: 1.38 MPa | [88] | ||||

| Epoxy/NaOH | 2–5 mm (3.2–9.6 wt.%) | E: 5560 | Vibration: 325.108 Hz | [25] | |||||

| Epoxy | Ceramic fibers | 140.68 | 8.22 KN | 2 J | 77.3 RHN | [84] | |||

| Epoxy/NaOH | 2 mm | Carbon fibers | 60.48 | 98.71 | 78.46 | 92 RHN | [133] | ||

| Polyester | 30 wt.% | Natural fillers (ground nut shell, rice husk, and wood powder) (3, 7 and11 WT.%) | 31.5 | 9 J | 13.3 Hv | Wear: 0.0284150 mm3/Nm | [24] | ||

| Polyester/NaOH, hydrogen peroxide, acetic anhydride, and acetone | 52.3 Ef: 3290 | [65] | |||||||

| Polyester/NaOH, meth-acrylamide | Short fibers and mat (24.5–42.6% Vf) | 22 E: 5200 | 3.71 KJ/m2 | [60] | |||||

| Polyester | 20 mm (15–30% Vf) | E-glass | 30.1 Ef: 1710 | [94] | |||||

| Polyester | Mat (10, 20, 30 and 40 wt.%) | 1.12 J | [96] | ||||||

| Polyester/NaOH | Strips 120 × 25 mm (30% Vf) | 46.4 Ef: 3220 | [70] | ||||||

| Polyester/methyl ethyl ketone peroxide | Mat 250 × 100 mm | 23.893 | [56] | ||||||

| Polyester/NaOH, hydrogen peroxide acetic anhydride, and acetone | Mat (5–15 wt.%) | 41.96 Ef: 2690 | [66] | ||||||

| RF/Calcium phosphate and calcium carbonate | 50 wt.% | 14.88 E: 680 | 80.67 Ef: 3338 | 70.28 | [78] | ||||

| RF/NaOH, CaCl2, H2SO4, and Na2HPO4 | 2 cm (10–50 wt.%) | 29.438 E: 1662 | 81.00 | [57] | |||||

| Formaldehyde | Mat in medium density fireboard | Pine, beech and oak | 50.91 | [97] | |||||

| Polyurethane | Mat | Glass fiber | 12.7 | [99] | |||||

| PP/NaOH and silane coupling agent | 2–15 wt.% | 35 | [68] | ||||||

| Bio-based polyethylene (HDPE) | (10, 20, 30 and 40 wt.%) | 21.2 E: 2082 | 37.7 | 33.3 J/m | [98] | ||||

| Vinyl ester/ethanol, NaOH, BTDA dianhydrides | Mat (15 wt.%) | 21.2 | DMA: | [64] | |||||

| Polylactic acid/NaClO | 2 cm (2, 5 and 10 wt.%) | 36.44 E: 2997.45 | 48.64 Ef: 3939 | 28.19 J/m | [58] | ||||

| Geopolymer | Fiber’s D: 200 μm. L: 160 mm. (10 vol.%) | 14.2 | 31 | [100] | |||||

| Concrete | Mat | 10.2 | 25.8 | [103] | |||||

| Pre-gelatinized cassava starch | 3–5 mm (5, 10, 15, and 20 wt.%) | 1.24 | [101] | ||||||

| Pure luffa/NaOH, H2O2, CH3COOH, | 30–40 mm/Bundle | 74.23 E: 820 | [55] | ||||||

| Pure luffa/glacial acetic acid and hydrogen peroxide | 2 20 and 30 mm | 91.63 E: 1897 | [27] | ||||||

| Pure luffa/thermo-hydromechanical treatment | 177.93 | ||||||||

| Pure Luffa | 0.74 | [77] | |||||||

| Pure luffa | 120 E: 2300 | 0.37 | [47] | ||||||

| Pure luffa | Specimen’s D: 42–81 mm | 0.40 | [46] |

| Resin/Coupling Agent/Hardener | Hybrid/Filler | Reference |

|---|---|---|

| Epoxy | Ground nut (1:1) | [62] |

| Epoxy | Flax | [49] |

| Epoxy | Jute | [93] |

| Epoxy | Ceramic B4C (10 wt.%) | [44] |

| Epoxy | Glass fiber | [91] |

| Epoxy | Glass fiber | [141] |

| Epoxy | Carbon fiber | [133] |

| Epoxy | Silica nanoparticles | [61] |

| Epoxy | Lignite fly ash filler | [54] |

| Epoxy | Lead oxide nanofiller | [73] |

| Epoxy | Coir | [74] |

| Polyester | Natural fillers (ground nut shell, rice husk, and wood powder) (3, 7, and 11 wt.%) | [24] |

| Polyester | E-glass | [94] |

| Polyester | TiO2, Al2O3, and CaCO3 | [142] |

| PU foams | Tea leaf (main in the study) | [45] |

| PU | Glass fiber | [99] |

| formaldehyde | Pine, beech, and oak | [97] |

| Poly (Butylene Succinate-Co-Lactate)/starch blends | Kenaf | [143] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhijazi, M.; Safaei, B.; Zeeshan, Q.; Asmael, M.; Eyvazian, A.; Qin, Z. Recent Developments in Luffa Natural Fiber Composites: Review. Sustainability 2020, 12, 7683. https://doi.org/10.3390/su12187683

Alhijazi M, Safaei B, Zeeshan Q, Asmael M, Eyvazian A, Qin Z. Recent Developments in Luffa Natural Fiber Composites: Review. Sustainability. 2020; 12(18):7683. https://doi.org/10.3390/su12187683

Chicago/Turabian StyleAlhijazi, Mohamad, Babak Safaei, Qasim Zeeshan, Mohammed Asmael, Arameh Eyvazian, and Zhaoye Qin. 2020. "Recent Developments in Luffa Natural Fiber Composites: Review" Sustainability 12, no. 18: 7683. https://doi.org/10.3390/su12187683

APA StyleAlhijazi, M., Safaei, B., Zeeshan, Q., Asmael, M., Eyvazian, A., & Qin, Z. (2020). Recent Developments in Luffa Natural Fiber Composites: Review. Sustainability, 12(18), 7683. https://doi.org/10.3390/su12187683