Abstract

The primary aim of this paper was to present and analyze practical solutions of Industry 4.0 as applied in the Re Alloys company. The research question was whether the implementation of the digitization process based on Industry 4.0 resulted in changes to the organizational structure of the company and whether this brought about an improvement in the energy and material efficiency of the company. The research method used in the paper was the case study method. In view of the project’s results, we concluded that implementation of the new solution based on digitalization caused increased energy and material efficiency, often forced by external factors stemming from the operation of competitive markets. Technological changes also require the application of IT technologies and communication systems in managing production. Access to this information is also a chance to gain a competitive advantage.

1. Introduction

Today, industrial production is driven by global competition and the need to quickly adapt to ever-changing market requirements [1,2,3]. Modern production was built on the experiences of the first industrial revolution, streamlining the operations of manufacturing plants; the second revolution, introducing electricity to industry; and the third revolution, automating uniform tasks for production workers [4,5,6]. The fourth industrial revolution—Industry 4.0—differs from its predecessors in that it applies to all areas of life [7], including the dangerous phenomenon of an ageing population and the consequent decline in the workforce [8,9,10,11]. This revolution is also connected with the fact that the opportunities for increasing the profit of industrial production are exhausted despite the use of the “lean” manufacturing concept and outsourcing [12,13,14,15]. Industry 4.0 determines changes in production—from mass production to personalized production—which make the production processes more flexible and provide the means to meet the individual needs of different customers more effectively [16].

In the digital age, an organization should adjust their production and logistics systems to meet new technologies. Business has evolved to improve in effectiveness and cost-efficiency. Production systems should be customer-centric and should drive agility within the business. To meet these objectives, the implementation of Industry 4.0 is needed. We can distinguish the following reasons for why the conception of Industry 4.0 is so important [17,18,19,20]:

- Cost efficiency;

- Agility and flexibility of the production system;

- Customer-centric production systems, with customization of products.

In the Industry 4.0 environment, producers should better understand the patterns of consumption and based on that, be able to adjust the product to the specified requirements of the end-users [21,22]. We can distinguish many technologies used in the Industry 4.0 concept. They may affect the methods of projecting, manufacturing, and delivering products to customers. The main technological conceptions supporting digitalization and servitization in Industry 4.0 are the following:

- Adaptive robotics [23,24];

- Cyber-physical infrastructure embedded systems [25,26];

- Additive manufacturing [27,28];

- Cloud technologies [29];

- Visualization technologies, such as virtual reality and augmented reality [30,31];

- Simulations [32,33];

- Data analytics and artificial intelligence [34];

- Industrial internet—communication and networking [35];

- RFID (Radio-frequency identification) and RTLS (Real-time locating system) technologies [36];

- Cybersecurity [37];

- Sensors and actuators [38];

- Mobile technologies [39].

The main objective of Industry 4.0 is to increase automation so as to contribute to the operational efficiency and effectiveness of the company [40,41,42,43]. Industry 4.0 is based on the integration of new technical solutions. Particularly important, in this case, is the process of combining smart machines and systems, as well as changes in the production processes [44].

The aim of applying innovative solutions in the Industry 4.0 concept is not only to bring about technological change but also to implement new ways of working and a new role for employers in the industry [45]. In Industry 4.0, it is essential to connect machines and equipment via the Internet and digitalize all production processes [46,47]. An essential aspect of implementing this new concept of the industry is to make it easier for smart factories to anticipate, identify, and solve issues [16].

Particularly important issues related to new, smart solutions based on Industry 4.0 are energy efficiency, material efficiency of production, and organizational changes in the company. The literature contains research on the relations between the implementation of Industry 4.0 solutions and changes in the company organizational structure [42,43,48], energy consumption [49,50,51], and increasing material efficiency [40,41]. The energy efficiency analysis proposed by Duflou is interesting in this respect [51].

Due to the importance of the problem of Industry 4.0 and, in particular, the digitalization of processes in organizations, we wanted to analyze the effects of these activities on the example of a particular organization. Based on this, we established the main aim of the paper [23,26,29], which was to present and analyze practical Industry 4.0 solutions applied in the company Re Alloys.

We also established a research question connected with the primary aim. The research question is whether the implementation of a process of digitalization based on Industry 4.0 resulted in changes in the organizational structure of the company and whether it brought about improvements in the energy and material efficiency of the company.

2. Literature Review

Industry 4.0 is based on the integration of new technical solutions. Particularly important in this case is the integration process of intelligent machines and systems and the changes in the production processes. The aim of the implementation of the Industry 4.0 concept is not only technological change, but also the implementation of new ways of working and the new role of employers in the industry [1,2,3,4,5,6,7]. In Industry 4.0, the connection of machines and devices via the Internet and the digitalization of all production processes is crucial [9,10,11,12,13]. An important issue in smart industry implementation is to enable factories to be sufficiently smart to be able to predict, identify, and resolve problems [14,15,16].

Industry 4.0 is not only a technological revolution. It is also now connected with the problem of linking different devices together for achieving traceability and trackability. We can distinguish the following dimensions of the Industry 4.0 concept [52,53,54]:

- Internet of Things—the ability to conveniently access data from anywhere and exchange data between devices. All production systems become interconnected. There are real-time flows between all elements of the supply chain.

- Common digitalization—the process of ensuring digitalized, constant communication between all people and all devices and between people and devices themselves.

- Autonomous manufacturing systems—creating intelligent factories that organize production processes autonomously and can react flexibly to changes to the requirements of the manufacturing processes. Smart factories perform virtually the entire production processes themselves with minimal human input.

- Customization of the product—delivering a customized product to the customer, precisely according to their orders.

- Robotization—implementation of flexible production sockets, based on industrial robots, using robots adapted to cooperate with humans.

- Implementation of architecture based on cyberphysical systems.

- Widespread use of disruptive innovations—these can allow a rapid increase in the efficiency and effectiveness of the socioeconomic and operation system in an organization.

Digitalization can be defined as restructuring of all the social and business processes around digital communication. It is an integration of digital technologies into business practice by the digitalization of all possible processes [55].

The use of digital technology in an industrial organization can lead to many changes in their business model [56]. In this paragraph we will describe the importance of implementing digitalization into an industrial organization. Turning many innovations into reality quickly is essential. To do this, the flexibility of the production must be increased. This can be achieved by the digitalization of the processes and by implementing state-of-the-art hardware and software solutions and the real-time evaluation of production data. The main aim of the implementation of digitalization in production firms is to increase productivity. This can be achieved by shortening the time between the development of the product and faster delivery to the customers on the market [57]. Increasing productivity also leads to greater flexibility, a better quality of product and processes, energy savings, time-savings, and so on. Implementation of the new, digitalized solutions in an organization can increase the competitiveness of the organization on the global market [58].

In the literature, there are many studies that indicate the positive effects of digitalization on energy consumption [59]. The implementation of digitalization in an organization can achieve increased energy efficiency. Digitalization also leads to an increase in labor and energy productivity.

The digitalization of the enterprise requires strong leadership. In this case, the collaboration of stakeholders is needed. Another critical factor is connected with personal data security and the avoidance of fraud [60]. Many of the effects achieved by the digitalization of processes also require organizational changes—for example, changes to the organizational structure. Using digitalization, we can conceptualize the operational performances of the organization [61]. The flexible working system and bidirectional flow of information can be a trigger for innovative solutions in the case of the product, process, and even the improvement of the entire production system [62,63,64].

To judge the successful adaptation of the Industry 4.0 concept, we considered three features: horizontal integration of the chains of value; vertical integration of the manufacturing systems or service systems and the network; and end-to-end engineering of the whole value chain [54].

The concept of Industry 4.0 was developed in the second decade of the 21st century in Germany. Industry 4.0 consists of using automation and digitization processes in industry to transform existing factories into self-controlled and self-adaptive social and technical systems (Smart Factories), allowing for the creation of intelligent value chains. This has already received many scientific studies [65,66,67] and implementations in many countries, becoming a global megatrend [68]. These challenges shape the new model of modern business and production that was defined by Lee, Lapir, Bagheri, and Kao as a 5M system in the context of Industry 4.0 [46]. On the one hand, it is integrated with the infrastructure based on the 5C functional model, and on the other hand, it is based on entirely new paradigms created on the basis of innovative trends and megatrends understood as directions of social, economic, environmental, political, cultural, and legal changes [69,70,71,72,73,74,75]. The Industry 4.0 concept also has an influence on environmental concerns [76].

The concept of Industry 4.0, although initialized in Germany [77,78], is spreading around the world, and the countries implementing the idea define it differently. In the United States and English-speaking countries, it is called the industrial Internet. In others, it is called the Internet of Things or a smart factory [79]. Apart from the non-uniform term, the terminology used for Industry 4.0 is not consistent either. The variations depend on how individual business circles interpret this term [80]. In the United States, it is seen as the integration of people with things and things among themselves, combining the analysis of large data sets with the Internet of Things [81,82].

In France, the concept of “Industrie du futur” is based on the cooperation between industry and science. It is built on five pillars, namely: (i) state-of-the-art technologies, including additive manufacturing, virtual factories, the Internet of Things, and augmented reality; (ii) support to French companies to adapt to the implementation of new technologies; (iii) intensive training of workers; (iv) strengthening international cooperation on industrial standards; and (v) promoting the French industry of the future [83,84]. In China, on the other hand, the concept consists of a comprehensive modernization of the Chinese industry, taking direct inspiration from the German concept of Industry 4.0 and adapting it to its own needs [85,86].

In Taiwan, the concept was named Productivity 4.0 [87]; the concept is also implemented in India [88], where it is named Skill India [88,89]; in Japan, it is named the IVI The Industrial Value Chain Initiative [90]; in the UK, it is named the High-Value Manufacturing Catapult (HMV Catapult) [91,92,93]; in Spain, it is named Industria Conectada 4.0. [94,95,96]; and in Poland, it is named Przemysł 4.0.

This diversity of interpretations of the Industry 4.0 concept in the scientific literature is seen by many researchers as collectively describing changes in technology and the organization of value chains [97,98,99,100,101,102,103]. These innovations, referred to as the Fourth Industrial Revolution (Industry 4.0), include the consolidation of information systems and the integration of people with digitally-controlled machines that make extensive use of wireless networking and digital technologies, such as virtual reality, augmented reality, and Big Data analytics [104,105,106,107]. They support the implementation of Industry 4.0 as they include real-time systems, controlled production, just-in-time supply, and perform AC (autonomic computing) processing based on self-managing computer systems, which are self-configuring, self-protecting, self-healing, self-optimizing, and process and analyze Big Data.

As indicated by Terziyan, Gryshko, and Golovianko [108], and Hermann et al. [97], the era of Industry 4.0 offers, above all, a new vision for the functioning of a company: the production of products, provision of services, management of assets, and business activity. Pereira and Romero [109] and other authors [110,111,112,113,114,115,116] added that Industry 4.0 represents a huge potential for many areas. The implementation will affect the entire value chain, improve production and engineering processes, improve the quality of products and services, and optimize the relationship between customers and organizations, while bringing new business opportunities and economic benefits and changes in educational requirements, and transforming the current working environment [117,118,119,120,121].

The concept of industry 4.0 is in accordance with the main goals of the European Green Deal. The digitalization of industry is an indispensable part of Industry 4.0 as an essential pre-condition to reach the climate targets set in the Green Deal. Sustainable manufacturing needs to be enabled, so as to ensure better use of the infrastructure and energy and better logistics and transportation. All these goals can be achieved when particular organizations implement Industry 4.0 principles connected with the digitalization of the production processes. The implementation of the Industry 4.0 concept can be a valuable aspect in establishing a European data economy.

The strategy of the organization should be based on the growth of high-quality data incorporation, which can be obtained through digitalization [122,123,124,125,126,127,128,129]. Such a great and multi-faceted impact of the fourth industrial revolution on the Re Alloys steel company makes it necessary to analyze the most critical areas of its operation in terms of the benefits resulting from the application of the Industry 4.0 concept and investigating whether the implementation of the digitalization process resulted in changes to the organizational structure of the company and its energy and material efficiency [130].

3. Materials and Methods

The research presented in this article was carried out at the Re Alloys steel company, which specializes in the production of ferrosilicon and silicon-based alloys. This company is the leading producer of ferroalloys in Europe. Re Alloys belongs to the Luma Holding Capital Group (Warsaw, Poland) which includes companies from the metallurgical industry, ventures, and automotive sectors in its portfolio. The primary research method used in this article was a case study analysis.

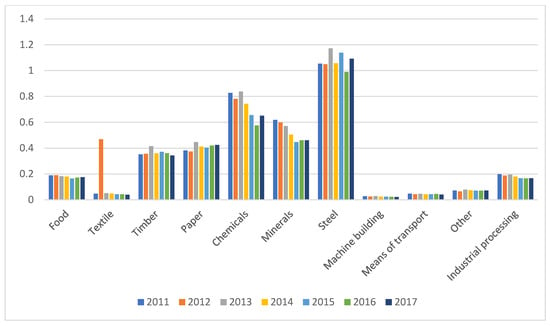

The steel industry worldwide, and in Europe and Poland, is still high energy, material, and cost intensive. This was confirmed by numerous studies showing that 60% of the total costs were feedstock, influenced by coke, energy, and iron ore prices. The European and Polish policy on reducing carbon dioxide emissions forces the implementation of technological investments in smelters and charges them with the additional costs of environmental protection. Polish statistics show that the steel industry is still the most energy-intensive; that is, it has a high ratio of final energy consumption to value-added (Table 1; Figure 1).

Table 1.

The energy intensity of industries in Poland, 2011–2017 (kgoe).

Figure 1.

Visualisation of the energy-intensive sectors of the economy in Poland for the years 2011–2017 (kgoe). Source: [131].

The main reason for applying the Industry 4.0 concept to the Re Alloys company was to reduce the production costs and thus increase its market competitiveness. An attempt was also made to adapt the overall equipment effectiveness (OEE) method to the area of truck management to increase the production efficiency. The consequence of these activities was the implementation of a project, No. ReA-1/8/2018: Optimization of key areas of the company’s business activity in terms of monitoring the location of assets and supervising the casting process in real-time (Vizum Factory) [132]. The implementation period, i.e., 2018–2021, was divided into two stages: 2018–2019 and 2019–2021.

The theoretical objective of this project was to verify the accuracy of the indications of particular radio technologies and sensor and location systems, as well as the accuracy of asset position calculation based on the evidence of appropriate location technologies in the real environment. The practical objective of the project was to continuously monitor the position and operation of 44 internal transport vehicles in order to analyze the possibilities of optimizing their use and to test the impact of monitoring devices on the power supply system of the monitored asset [132].

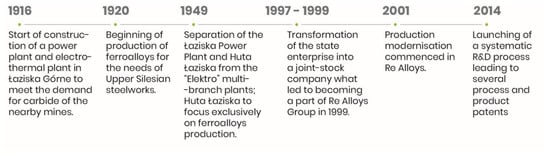

The primary information about the organization where the research was conducted is of relevance; in Figure 2, a historical background of the company is presented.

Figure 2.

Historical background of Re Alloys company. Source: own study.

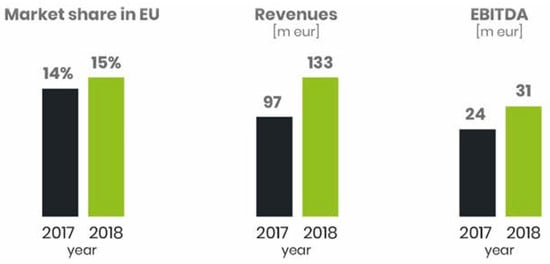

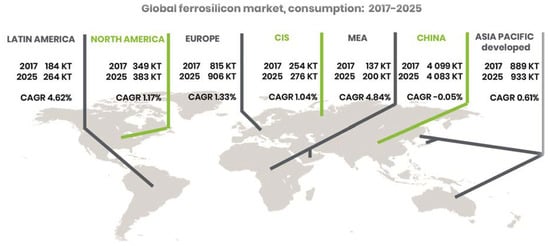

In Figure 3, key numbers regarding the company are presented, and in Figure 4 information about its market position is shown. In Figure 5, Figure 6 and Figure 7, we collected information regarding the macroeconomic context of the Re Alloys operations.

Figure 3.

Key numbers regarding Re Alloys. Source: own study.

Figure 4.

The market position of Re Alloys. Source: own study.

Figure 5.

The global ferrosilicon markets. Source: own study, based on CRU business intelligence

Figure 6.

The ferrosilicon long-term supply gap in selected regions. Source: own study, based on CRU.

Figure 7.

The global ferrosilicon long-term global supply gap. Source: own study, based on CRU.

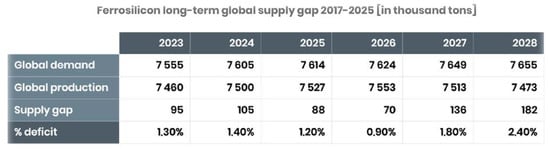

Crude steel production, including the production of both carbon and stainless steel, is the key indicator of demand for ferrosilicon. Europe is the second-largest producer of steel after China (Figure 8).

Figure 8.

Crude steel production in selected regions. Source: own study, based on CRU.

Customer relationships reach back to the beginning of the last century. All major European steel producers are currently long-standing end customers of Re Alloys products (Figure 9). These customer relationships extend to partnering in the development of new ferroalloy products for use in advanced steel offerings to the automotive and aerospace industries.

Figure 9.

The customer base of Re Alloys across Europe. Source: own study.

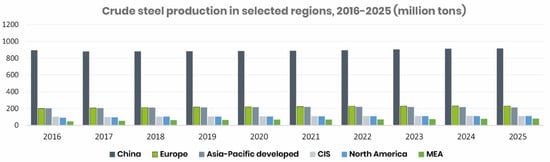

Re Alloys is significantly below the strict European Union emission limits—it is IPPC Directive and BAT (Best Available Techniques) compliant. Information regarding the level of Re Alloys emissions is presented in Figure 10.

Figure 10.

Re Alloys emission levels and energy consumption per ton of FeSi75. Source: own study.

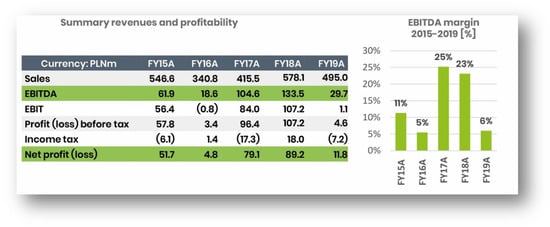

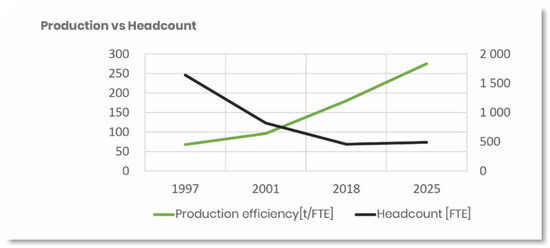

Figure 11 shows information regarding the revenues and profitability of Re Alloys, and Figure 12 shows information about the production of the organization connected with headcounts. Re Alloys management has consistently increased the efficiency of production and operations since the company’s privatization.

Figure 11.

The revenues and profitability of Re Alloys. Source: own study.

Figure 12.

Production vs. headcount. Source: own study.

Several Industry 4.0 initiatives are currently ongoing in the areas of asset and resource tagging. Indicative results point to further asset and staff optimization potential, which can be leveraged for planned production expansions (including a new furnace). The Industry 4.0 initiatives include:

- Implementation of a target-based bonus system for all staff.

- Strengthening the controlling framework, including monthly KPI (Key Performance Indicator) reviews.

- Centralization of the purchasing activities across the group.

- Ongoing CIT (Corporate Income Tax) optimization (special economic zone) and a “split-payment” VAT (Value-Added Tax) shield.

4. Results—The Practical Application of the Industrial 4.0 Concept in Re Alloys

To monitor the use of mobile assets in a company in both open and closed spaces, the Vizum Optitrack system was built. This system consists of three modules: Vizum Workforce—for crew monitoring, Vizum Vehicles—for vehicles monitoring, and Vizum Tools—for tools supervision. Vizum is based on Microsoft Azure secure cloud computing and is available as “Software as a Service” (SaaS) and “Infrastructure as a Service” (IaaS). The communication between cloud computing and IoT devices (smartphones, Vizum Assistant, Vizum Zone, and Vizum Box) is realized within the Internet connection using the MQTT (MQ Telemetry Transport) protocol. Additionally, to ensure maximum communication reliability, the Vizum Optitrack system is integrated with the Orange Live Objects service, which enables communication of cloud computing and IoT devices via the MQTT protocol realized directly in the software layer of the Orange operator’s infrastructure worldwide. The Vizum Workforce allows for the monitoring of employees in active (two-way communication with the employee) or passive (one-way communication) mode [132].

The active mode performs monitoring by means of a smartphone with a dedicated mobile application carried by the employee or by means of a dedicated Vizum Assistant device. The passive mode, on the other hand, performs monitoring by detecting so-called unmanned tags carried by employees whose presence is detected in the control zones designated on the company premises by means of Vizum Zone devices. The Vizum Workforce application can operate in an exclusive mode on a smartphone, i.e., the employee has no physical possibility to use any functionality of the device except those offered by the application: for instance, after the employee logs in to work, the application displays reminders with information important for the employee when their reaction is needed.

This application also enables the company to locate an employee: (i) in an open space, with repeatable accuracy of ±10 m using a GPS or equivalent signal offered by a given smartphone (e.g., Glonass); or (ii) in enclosed spaces (rooms) within control zones with a signal accuracy of ±5 m, determined by the unmanned Vizum beacon BT transmitters sending the signal in Bluetooth technology or ±1 m, determined by the Vizum beacon UWB transmitters sending the signal in ultrawide band technology. The application also allows for testing the state of the device’s movement (the detection of sudden impacts and accelerations, or random tests of an employee’s reaction), and in case of motionlessness (high acceleration or lack of an employee for a random test), it sends an alarm signal to the Vizum Workforce system.

This application also allows for voice contact with mobile phones and employees that can be found in the company-wide address book or the one designed for a specific group of employees (e.g., contacts to individual team leaders and shifts of the company fire brigade for groups of employees working on different shifts). As part of its improvement, at a later stage, the application is planned to expand with a dedicated device called the Vizum Assistant, enabling, in cooperation with the Vizum Tools module, the detection of tools and accessories that the employees have with them and checking if they have a full set of the required equipment.

The system is also capable of conducting random and continuous surveys of employees’ OHS (Occupational health and Safety) knowledge in the context of their type of work and places visited in the plant with feedback on the trend of the employees’ OHS knowledge level sent to their superiors [49]. Vizum Workforce is complemented by a Vizum ID tag (card or key fob). This is used for unmanned identification of a worker to determine their presence and the time they stay in a given zone, as well as for detecting the state of the card immobility, which is reported in the system as an emergency alarm (fainting, an accident, or a card left by a worker against factory regulations) [132].

On the other hand, Vizum Vehicles enables the monitoring of the operation of the trucks in two spaces: outdoor and indoor. In the outdoor space, using a GPS signal, it is possible to locate a truck with an accuracy of ±5 m. In the indoor system, the halls and rooms are equipped with iBeacon transmitters (Bluetooth technology) operating on the principle of a radio beacon (propagation of its identification number while the position of the transmitter in the Vizum system is defined in the plant layout), and signals from the accelerometer and gyroscope determine the position of the truck with an accuracy of several meters. If necessary, Ultra-Wide Band (UWB) technology is used where a higher position of accuracy (1 m) is required [132]. This solution allows for the monitoring of the operation of the truck: the distance travelled, effective working time, presence in individual zones at a given time, event log (stop, start-up), and the current location of the truck. The system also allows for detecting the state of its loading with the charge and monitors the quality of furnace filling. For the purposes of the project, the software of the control panel was devised for both furnaces 22 and 23, as shown in Figure 13.

Figure 13.

View of the VIZUM system administration panel. Source: authors’ own study [132].

Due to the use of deep-learning technology, the control panel allows for visualizing the area around the furnace in search of objects and people. Using neural network algorithms, the dispatcher can monitor, in real-time, the position of the truck filling the furnace, the degree of its filling in a given sector (1–2 m), and undesirable behaviors in the vicinity of the furnace (e.g., employees leaving certain permitted zones or entering a prohibited zone, loss of consciousness, and falls).

The control panel also facilitates the management coordination of the current operation of the furnace shop floor and the efficiency of the employees’ work through insights into the detailed employee log that shows the daily charts of the employees (periods of work and breaks, time and place in which they start and end work, and the time and place of preliminary and final warnings regarding potential risks) and the comparison of individual work and safety parameters between different groups of employees. Together with the human resources department, this allows collective reports to be compiled for groups of employees containing information about their work, safety, and breaches of applicable rules (including permitted and forbidden zones and the number and length of breaks) [132].

5. Discussion

As a result of the first stage of the Vizum Factory Project implementation, the functioning of Re Alloys’ infrastructure was rationalized. The optimum number of trucks necessary for the production process was determined. Their number was reduced from 44 to 36 at the beginning of the project’s implementation, which already made it possible to reduce the fixed costs related to the use of the company’s machinery. Their functioning in the open and closed space was improved by installing 39 iBeacon transmitters and configuring 70 control zones on the company premises: 40 inside buildings and 30 outside [133].

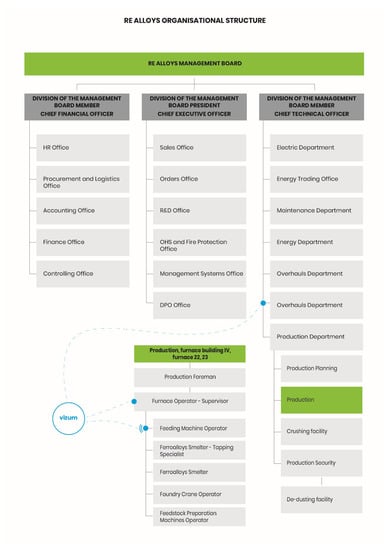

The implementation of solutions included in the project and originating from the concept of Industry 4.0 also resulted in changes in the organizational structure of Re Alloys, as presented in Figure 14.

Figure 14.

The organizational structure after the implementation of Vizum. Source: own work.

The organizational structure was flattened. Production, furnace building, and operating furnaces were submitted to the quality control department, which reports directly to the technical director. With this, the conditions for the operation of a learning organization were created.

The next point of analysis conducted after the completion of the first stage of the project was to assess the economic effectiveness of the implemented solutions, especially those related to energy and material consumption, which generates over 60% of the metallurgical production costs. Their rationalization after the implementation of the company’s own Industry 4.0 tools was to increase the competitiveness of the Re Alloys company on the market. After completing the first stage of the implementation of the project in 2019, an improvement in energy efficiency in relation to 2018 was noted. In the cases of furnace 22 and furnace 23, the efficiency was improved by 0.58% and 5.87%, respectively. Such a significant difference in the energy consumption for furnaces 23 and 22, was due to the fact that the latter furnace did not operate at full capacity during the audited period. The situation is comparable to other research [49,50,51]. The detailed data are presented in Table 2.

Table 2.

Electricity consumption: furnace 22, FeSi75 [t] and furnace 23, FeSi75 [t], 2016–2019.

During the period considered, a decrease in the consumption of raw materials used for production was also observed: by 2.3% for furnace 22 and 5.3% for furnace 23. This is further detailed in Table 3. A comparable decrease in raw material consumption was observed by [40,41].

Table 3.

Raw material consumption: furnace 22, FeSi75 [t] and furnace 23, FeSi75 [t], 2016–2019.

The implementation of solutions included in the project and coming from the concept of Industry 4.0 also resulted in changes in the organizational structure of Re Alloys.

The largest problem of the smelters was the charges for CO2 emissions (the carbon dioxide responsible for climate change). Today, this is approximately EUR 30 per ton on average. The effects obtained by saving energy and materials in Re Alloys are part of the climate and energy policies of the European Union and Poland, which assume a 20% reduction in CO2 emissions and a 20% use of energy from renewable sources. The results of the first stage of the project implementation inspired the managerial staff to include the remaining five furnaces operating on the premises of the smelter in the second stage of the project. This stage also provides for rationalizing the method of filling the furnace so that its operation is stable, which will allow for further improvement of the energy and material efficiency of production.

It is equally essential for the creators of the project to further increase the work safety of the smelter shop floor. Due to the implementation of Industry 4.0 tools, it will be possible—in cooperation with Protektor S.A., a leading manufacturer of protective, safe, and professional footwear—to create the project BR POIR.01.01.01-00-0194/19, with the aim to create a complete system for improving work safety and testing the working time with the use of footwear worn by employees. The footwear will be factory-fitted with Vizum Footwear IoT modules that will continuously broadcast an employee ID signal detected by Vizum Zone devices within the control zones on the plant premises for at least 24 months after activation. Additionally, the IoT module installed in the shoe will enable the detection of an employee’s immobility to send a signal in response to a potential threat to the user.

The digital transformation and new technologies of Industry 4.0 used in the project at Re Alloys also give the managers and employees the opportunity to further develop their new skills and competences, which facilitates the adaptation of business models important to the steel industry. This is expected to improve competitiveness and productivity through the increased interconnection, cooperation, and sharing of assets.

6. Conclusions

In the analyzed case study, we assumed that the implementation of the new solution based on digitalization caused increased energy and material efficiency, often forced by external factors stemming from the operation of the competitive markets: Chinese, Indian, Russian, and Turkish. Today, this is crucial, due to the mounting pressure to reduce costs induced by competition and environmental issues. Production companies are recommended to implement the new standards of Industry 4.0, such as production process digitalization or cloud computing, in order to improve production processes. This may boost their efficiency and bring positive financial results. A novelty in the article is the digitalization in a new sector—the steel industry—where the production process is still rarely fully digital. Therefore, it is critical that all the fields essential for the steel industry are identified: economic, political and legal, environmental, technical, and technological, as well as socio-demographic fields.

Technological changes also mean the application of IT technologies and communication systems in managing production. Access to information is a chance to gain a competitive advantage. Innovation and digitalization are vital for the development of metallurgy, and for companies such as Re Alloys. Steel companies in Poland amass information and data, though they only use approximately 1–2% of this information. The greater use of information in production management is an opportunity for more cost-effective production (production cycles analysis, set-up time metering, etc.). During the implementation of the project in Re Alloys, particular attention was paid to the need for the integration of IT and operating technologies and the extent to which such integration met the requirements of resistance to cyber-security in the broad sense. A growing number of cases of cyber-security breaches, which take advantage of production machinery weaknesses in the network, had adverse effects on the company’s efficiency. This entails a loss of confidentiality, integrity, and access to data, which, in turn, significantly affects the business competitiveness.

We applied a case study method, which was the result of project implementation in an organization, and was justified and representative, due to the repeatability of the many technical aspects of the production processes in the branch, as the same feeding system solutions were used. We believe that implementation of the presented solution in other companies, utilizing the same or similar technological processes, is a huge window of opportunity for them to join European and Polish policy in reducing their carbon dioxide emissions (EST). This is important, as the obtained environmental effects of reduced emissions of CO2 (and other pollutants) result from a decrease in energy consumption, which can be achieved through a change in the machinery efficiency regulation manner and the application of energy-saving solutions.

Author Contributions

Conceptualization, R.M. and R.W.; methodology, R.M. and R.W.; software, R.M. and R.W.; validation, R.M. and R.W.; formal analysis, R.M. and R.W.; investigation, R.M. and R.W.; resources, R.M. and R.W.; data curation, R.M. and R.W.; writing—original draft preparation, R.M. and R.W.; writing—review and editing, R.M. and R.W.; visualization, R.M. and R.W.; supervision, R.M. and R.W.; project administration, R.M. and R.W.; funding acquisition, R.M. and R.W. All authors have read and agreed to the published version of the manuscript.

Funding

Author’s own funds.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wolniak, R.; Grebski, M.E.; Skotnicka-Zasadzień, B. Comparative analysis of the level of satisfaction with the services received at the business incubators (Hazleton, PA, USA and Gliwice, Poland). Sustainability 2019, 11, 2889. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Wolniak, R.; Grebski, E.M.; Olkiewicz, A. Comparative analysis of the impact of the business incubator center on the economic sustainable development of regions in USA and Poland. Sustainability 2019, 11, 173. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A review. Engineering 2017, 3, 613–630. [Google Scholar] [CrossRef]

- Bauernhansl, T. Die Vierte Industrielle Revolution–Der Weg in einwertscha endes Produktionsparadigma. In Industrie 4.0 in Produktion, Automatisierung und Logistik – Anwendung, Technologien, Migration; Bauernhansl, T., ten Hompel, M., VogelHeuser, B., Eds.; Springer Fachmedien: Wiesbaden, Germany, 2014; pp. 5–35. [Google Scholar]

- Pilloni, V. How Data Will Transform Industrial Processes: Crowdsensing, Crowdsourcing and Big Data as Pillars of Industry 4.0. Future Internet 2018, 10, 24. [Google Scholar] [CrossRef]

- Zunino, C.; Valenzano, A.; Obermaisser, R.; Petersen, S. Factory Communications at the Dawn of the Fourth Industrial Revolution. Comput. Stand. Interfaces 2020, 71, 103433. [Google Scholar] [CrossRef]

- Herceg, I.V.; Kuč, V.; Mijušković, V.M.; Herceg, T. Challenges and Driving Forces for Industry 4.0 Implementation. Sustainability 2020, 12, 4208. [Google Scholar] [CrossRef]

- Nanterme, P.; Daugherty, P. Technology for People: The Era of the Intelligent Enterprise; Accenture: Dublin, Ireland, 2017. [Google Scholar]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the IEEE 2015 12th International Conferenceon Fuzzy Systemsand Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Saniuk, S.; Grabowska, S.; Gajdzik, B. Social expectations and market changes in the context of developing the Industry 4.0 concept. Sustainability 2020, 12, 1362. [Google Scholar] [CrossRef]

- Baden-Filler, C.; Haefliger, S. Business models and technological innovation. Long Range Plan. 2013, 46, 419–426. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.-A.; Yang, S. Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reißig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes–A literature review. J. Clean. Prod. 2020, 259, 120856. [Google Scholar] [CrossRef]

- Fareri, S.; Fantoni, G.; Chiarello, F.; Coli, E.; Binda, A. Estimating Industry 4.0 impact on job profiles and skills using text mining. Comput. Ind. 2020, 118, 103222. [Google Scholar] [CrossRef]

- Biel, K.; Glock, C.H. Systematic literature review of decision support models for energy-efficient production planning. Comput. Ind. Eng. 2016, 101, 243–259. [Google Scholar] [CrossRef]

- Ślusarczyk, B. Industry 4.0–are we ready? Pol. J. Manag. Stud. 2018, 17, 232–248. [Google Scholar] [CrossRef]

- Zezulka, F.; Marcon, P.; Vesely, I.; Sajdl, O. Industry 4.0–An Introduction in the phenomenon. IFAC PapersOnLine 2016, 49, 8–12. [Google Scholar] [CrossRef]

- Veselovsky, M.Y.; Pogodina, T.V.; Ilyukhina, R.V.; Sigunova, T.A.; Kuzovleva, N.F. Financial and economic mechanisms of promoting innovative activity in the context of the digital economy formation. Entrep. Sustain. Issues 2018, 5, 672–681. [Google Scholar] [CrossRef]

- Stverkova, H.; Pohludka, M. Business Organisational Structures of Global Companies: Use of the Territorial Model to Ensure Long-Term Growth. Soc. Sci. 2018, 7, 98. [Google Scholar] [CrossRef]

- Rao, S.K.; Prasad, R. Impact of 5G Technologies on Industry 4.0. Wirel. Pers. Commun. 2018, 100, 145–159. [Google Scholar] [CrossRef]

- Brozzi, R.; Forti, D.; Rauch, E.; Matt, D.T. The Advantages of Industry 4.0 Applications for Sustainability: Results from a Sample of Manufacturing Companies. Sustainability 2020, 12, 3647. [Google Scholar] [CrossRef]

- Wang, L.; Wang, G. Big data in cyber-physical systems, digital manufacturing and Industry 4.0. Int. J. Eng. Manuf. 2016, 4, 1–8. [Google Scholar]

- Wittenberg, C. Cause the trend Industry 4.0 in the automated industry to new requirements on user interface. In Human-computer interaction, Part III, HCII 2015, LNCS; Kurosu, M., Ed.; Springer: Cham, Switzerland, 2015; Volume 9171, pp. 238–245. [Google Scholar]

- Bagheri, B.; Yang, S.; Kao, H.; Lee, J. Cyber-physical systems architecture for self-aware machines in Industry 4.0 environment. IFAC Pap. Online 2018, 48, 1622–1627. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H. A cyber-physical systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Gaub, H. Customisationon of mass-produced parts by combining injection molding and additive manufacturing with Industry 4.0 technologies. Reinf. Plast. 2015, 60, 401–404. [Google Scholar] [CrossRef]

- Ford, S.L.N. Additive manufacturing technology: Potential implications for U.S. manufacturing competitiveness. J. Int. Commer. Econ. 2015, 6, 40. Available online: http://www.usitc.gov/journals (accessed on 10 April 2020).

- Thames, J.L.; Schaefer, D. Cybersecurity for Industry 4.0 and advanced manufacturing environments with ensemble intelligence. In Cybersecurity for Industry 4.0.1; Thames, L., Schaefer, D., Eds.; Springer (Springer Series in Advanced Manufacturing): Berlin, Germany, 2017; pp. 243–265. [Google Scholar]

- Paelke, V. Augmented reality in the smart factory supporting workers in an Industry 4.0. In Proceedings of the 2014 IEEE emerging technology and factory automation (ETFA), Barcelona, Spain, 16–19 September 2014. [Google Scholar]

- Syberfeldt, A.; Holm, M.; Danielsson, O.; Wang, L.; Brewster, R.L. Support systems on the industrial shop-floors of the future—Operators’ perspective on augmented reality. 6th CIRP Conference on Assembly Technologies and Systems (CATS). Procedia Cirp 2016, 44, 108–113. [Google Scholar] [CrossRef]

- Kühn, W. Digital factory—Simulation enhancing the product and production engineering process. In Proceedings of the 2006 Winter Simulation Conference, Monterey, CA, USA, 3–6 December 2006; Perrone, L.F., Wieland, F.P., Liu, J., Lawson, B.G., Nicol, D.M., Fujimoto, R.M., Eds.; IEEE: New York, NY, USA, 2006; pp. 1899–1906. [Google Scholar]

- Biegelbauer, G.; Vincze, M.; Noehmayer, H.; Eberst, C. Sensor based robotics for fully automated inspection of bores at low volume high variant parts. IEEE Int. Conf. Robot. Autom. 2004, 5, 4852–4857. [Google Scholar]

- Obitko, M.; Jirkovský, V. Big data semantics in Industry 4.0. In HoloMAS 2015, LNAI; Mařík, V., Ed.; Springer: Bern, Switzerland, 2015; Volume 9266, pp. 217–229. [Google Scholar]

- Blanchet, M.; Rinn, T.; von Thaden, G.; de Thieulloy, G. Industry 4.0: The new industrial revolution. How Europe will succeed. In Think Act, Roland Berger Strategy Consultants GmbH; Roland Berger: Germany, Munich, 2014. [Google Scholar]

- Borgia, E. The internet of things vision: Key features, applications and open issues. Comput. Commun. 2014, 54, 1–31. [Google Scholar] [CrossRef]

- Zuehlke, D. Smart factory towards a factory-of-things. Ann. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. A categorical framework of manufacturing for Industry 4.0 and beyond. Procedia Cirp 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Uckelmann, D.; Harrison, M.; Michahelles, F. An architectural approach towards the futurInternetet of things. In Architecting the Internet of Things; Uckelmann, D., Ed.; Springer: Berlin, Heidelberg, 2011. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material Efficiency: Providing Material Services with Less Material Production. 2013. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3575569/ (accessed on 15 April 2020).

- Shahbazi, S.; Wiktorsson, M.; Kurdve, M.; Jönsson, C.; Bjelkemyr, M. Material efficiency in manufacturing: Swedish evidence on potential, barriers and strategies. J. Clean. Prod. 2016, 127, 438–450. [Google Scholar] [CrossRef]

- Radel, J. Organizational Change and Industry 4.0 (id4). A Perspective on Possible Future Challenges for Human Resources Management. 2017. Available online: https://www.researchgate.net/publication/319102143_Organizational_Change_and_industry_40_id4_A_perspective_on_possible_future_challenges_for_Human_Resources_Management (accessed on 15 April 2020).

- Ziaei Nafchi, M.; Mohelská, H. Organizational Culture as an Indication of Readiness to Implement Industry 4.0. Information 2020, 11, 174. [Google Scholar] [CrossRef]

- Oluyisola, O.E.; Sgarbossa, F.; Strandhagen, J.O. Smart Production Planning and Control: Concept, Use-Cases and Sustainability Implications. Sustainability 2020, 12, 3791. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Z.; Lee, A.; Hua, Y. Measurement and analysis of corporate operating vitality in the age of digital business models. Appl. Econ. Lett. 2020, 27, 511–517. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.A. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Miśkiewicz, R. Industry 4.0 in Poland—Selected aspects of its implementation. Zesz. Nauk. Politech. Śląskiej 2019, 136, 403–413. [Google Scholar]

- Miśkiewicz, R. Organisational Structure in the Process of Integration on the Example of Iron and Steel Industry Enterprises in Poland. Process Digitisation in the Industry 4.0 Concept; PWN: Warsaw, Poland, 2019. [Google Scholar]

- Tesch da Silva, F.S.; da Costa, C.A.; Paredes Crovato, C.D.; da Rosa Righi, R. Looking at energy through the lens of Industry 4.0: A systematic literature review of concerns and challenges. Comput. Ind. Eng. 2020, 143, 106426. [Google Scholar] [CrossRef]

- Faheem, M.; Butt, R.A.; Raza, B.; Ashraf, M.W.; Begum, S.; Ngadi, M.A.; Gungor, V.C. Bio-inspired routing protocol for WSN-based smart grid applications in the context of Industry 4.0. Trans. Emerg. Telecommun. Technol. 2018. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP. Ann. Manuf. Technol. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; de Amicis, R.; Vallarino, I. Visual computing as a key enabling technology for industrie 4.0 and industriaInternetet. IEEE Comput. Graph. Appl. 2015, 35, 26–40. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 232–248. [Google Scholar] [CrossRef]

- Ustundag, A.; Cevican, E. Industry 4.0: Managing The Digital Transformation; Springer: Istanbul, Turkey, 2018. [Google Scholar]

- Grabowska, S. Improvement of the heat treatment process in the industry 4.0 context, METAL 2018. In Proceedings of the 27th International Conference on Metallurgy and Materials, Brno, Czech Republic, 23–25 May 2018; pp. 1985–1990. [Google Scholar]

- Vuksanović, D.; Ugarak, J.; Korčok, D. Industry 4.0: The future concept and new visions of factory of the future development. In Proceedings of the Advanced Engineering Systems, SINTEZA 2016 International Scientific Conference on ICT and e-Business Related Research, Belgrade, Serbia, 22 April 2016; pp. 293–298. [Google Scholar]

- Fonseca, L.M. Industry 4.0 and the digital society: Concepts, dimensions and envisioned benefits. Proc. 12th Int. Conf. Bus. Excell. 2018, 12, 386–397. [Google Scholar] [CrossRef]

- Gillani, F.; Chatha, K.A.; Sadiq Jajja, M.S.; Farooq, S. Implementation of digital manufacturing technologies: Antecedents and consequences, International. J. Prod. Econ. 2020, 229, 107748. [Google Scholar] [CrossRef]

- Lange, S.; Pohl, J.; Santarius, T. Digitalization and energy consumption. Does ICT reduce energy demand? Ecol. Econ. 2020, 54, 102153. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Cenamor, J.; Sjödin, D.R.; Parida, V. Adopting a platform approach in servitisation: Leveraging the value of digitalisation. Int. J. Prod. Econ. 2017, 192, 54–65. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A complex view of industry 4.0. SAGE Open 2016, 6, 56–74. [Google Scholar] [CrossRef]

- Saniuk, S.; Saniuk, A.; Cagánová, D. Cyber Industry Networks as an environment of the Industry 4.0 implementation. Wirel. Netw. 2019, 1–7. [Google Scholar] [CrossRef]

- Kagermann, H. Change Through Digitization—Value Creation in the Age of Industry 4.0. In Management of Permanent Change; Albach, H., Meffert, H., pinkwart, A., Rechwald, R., Eds.; Springer Gabler: Wiesbaden, Germany, 2015. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industrie 4.0: Bedarfssog und Technologiedruck als Treiber der vierten industriellen Revolution. Wirtschaftsinformatik 2014, 56, 239–242. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution: What It Means, How to Respond. Available online: https://www.weforum.org/agenda/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-to-respond/ (accessed on 10 January 2020).

- Kagermann, H. Chancen von Industrie 4.0 nutzen. In Vogel-Heuser: Industrie 4.0 in Produktion, Automatisierung und Logistik; Bauernhansl, T., ten Hompel, M., Eds.; Springer Fachmedien: Wiesbaden, Germany, 2014. [Google Scholar]

- Aceto, G.; Persico, V.; Pescapé, A. Industry 4.0 and Health: Internet of Things, Big Data, and Cloud Computing for Healthcare 4.0. J. Ind. Inf. Integr. 2020, 18, 100129. [Google Scholar] [CrossRef]

- Kim, D. A 2020 perspective on “A dynamic model for the evolution of the next generation Internet—Implications for network policies”: Towards a balanced perspective on the Internet’s role in the 5G and Industry 4.0 era. Electron. Commer. Res. Appl. 2020, 41, 100966. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an enabler of sustainability diffusion in supply chain: An analysis of influential strength of drivers in an emerging economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Chang, C.-W. Evaluation of smart alarm systems for industry 4.0 technologies. Appl. Sci. 2020, 10, 2022. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Ivanov, I.; Luk’yanova, T.; Belova, O. Digital economy: Knowledge in the logic of the industry 4.0 concept. Adv. Intell. Syst. Comput. 2020, 1100, 50–59. [Google Scholar]

- Olah, J.; Aburuman, N.; Popp, J.; Asif, M.K.; Haddad, H.; Kituktha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Nagaro, G.; Koc-Lem, A.; Vinces, L.; Ronceros, J.; Mesones, G. Acquiring, Monitoring, and Recording Data Based on the Industrie 4.0 Standard Geared Toward the Maca Drying Process. Adv. Intell. Syst. Comput. 2020, 1066, 42–53. [Google Scholar]

- Zimmermann, M.; Schellenberger, C.; Schotten, H.D. Dynamic live wireless communication monitoring for jamming and interference detection in industry 4.0 | [Dynamische Echtzeit-Überwachung von Funkkommunikation zur Erkennung von Jamming und Interferenzen für Industrie 4.0], 24. ITG Symp. Mob. Commun. Technol. Appl. 2020, 5, 52–57. [Google Scholar]

- García-Muiña, F.E.; Medina-Salgado, M.S.; Ferrari, A.M.; Cuchi, M. Sustainability Transition in Industry 4.0 and Smart Manufacturing with the Triple-Layered Business Model Canvas. Sustainability 2020, 12, 2364. [Google Scholar] [CrossRef]

- Schlaepfer, R.C.; Koch, M.; Merkofer, P. Challenges and Solutions for the Digital Transformation and Use of Exponential Technologies. Deloitte. 2015. Available online: https://www2.deloitte.com/content/dam/Deloitte/ch/Documents/manufacturing/ch-enmanufacturing-industry-4-0-24102014.pdf (accessed on 7 May 2020).

- Ashton, K. That ‘Internet of Things’ Thing. In the real world, things matter more than ideas. RFID J. 2009, 22, 97–144. Available online: http://www.rfidjournal.com/articles/pdf?4986 (accessed on 25 April 2020).

- Sittón-Candanedo, I.; Alonso, R.S.; Rodríguez-González, S.; García Coria, J.A.; De La Prieta, F. Edge Computing Architectures in Industry 4.0: A General Survey and Comparison. Adv. Intell. Syst. Comput. 2020, 950, 121–131. [Google Scholar]

- Presentation at the French Embassy in Germany. Ind. Future 2015. Available online: https://de.ambafrance.org/spip.php?page=recherche&id_rubrique=2&id_sous_secteur=2&recherche=Vorstellung-des-neuen-franzosischen-PlansIndustrie-du-Futur-in-der-Botschaft (accessed on 24 May 2020).

- Tran, T.K.; Yahoui, H.; Siauve, N. An interactive approach to teach automation in the training of the industry 4.0. In Proceedings of the 13th International Conference on Software, Knowledge, Information Management and Applications, SKIMA, Ukulhas, Maldives, 26–28 August 2019; p. 8982491. [Google Scholar]

- The State Council of the People’s Republic of China, “Made in China 2025”. Available online: http://english.gov.cn/2016special/madeinchina2025/ (accessed on 24 April 2020).

- Zhang, X. Intelligent Distribution System Based on “Internet +” Logistics. Adv. Intell. Syst. Comput. 2020, 1017, 1680–1684. [Google Scholar]

- Safar, L.; Sopko, J.; Dancakova, D.; Woschank, M. Industry 4.0—Awareness in South India. Sustainability 2020, 12, 3207. [Google Scholar] [CrossRef]

- Cheng, Y.-J.; Chen, M.-H.; Cheng, F.-C.; Lin, K.-P.; Yang, C.-J. Enhance the processing and management efficiency of dental laboratory by the strategy of productivity 4.0. In Proceedings of the 2017 IEEE International Conference on Applied System Innovation: Applied System Innovation for Modern Technology, ICASI, Sapporo, Japan, 13–17 May 2017; Volume 7988187, pp. 1098–1101. [Google Scholar]

- Tiwari, K.; Khan, M.S. Sustainability accounting and reporting in the industry 4.0. J. Clean. Prod. 2020, 258, 120783. [Google Scholar] [CrossRef]

- Pereira, A.G.; Lima, T.M.; Charrua-Santos, F. Society 5.0 as a result of the technological evolution: Historical approach. Adv. Intell. Syst. Comput. 2020, 1018, 700–705. [Google Scholar]

- Relf-Eckstein, J.E.; Ballantyne, A.T.; Phillips, P.W.B. Farming Reimagined: A case study of autonomous farm equipment and creating an innovation opportunity space for broadacre smart farming. NJAS Wagening. J. Life Sci. 2019, 90, 100307. [Google Scholar] [CrossRef]

- Grootel, A.; Chang, J.; Wardle, B.L.; Olivetti, E. Manufacturing variability drives significant environmental and economic impact: The case of carbon fiber reinforced polymer composites in the aerospace industry. J. Clean. Prod. 2020, 261, 121087. [Google Scholar] [CrossRef]

- Ward, M. Metal forming and forging—Finding a new place within high value manufacturing through advanced, industrial scale research. Ironmak. Steelmak. 2015, 42, 252–258. [Google Scholar] [CrossRef]

- Milošević, M.; Lukić, D.; Durdev, M.; Vukman, J. Digital Transformation of Manufacturing towards Industry 4.0 Concept. IOP Conf. Ser. Mater. Sci. Eng. 2020, 749, 012019. [Google Scholar] [CrossRef]

- Esquievel, J.C.C.; Lopez, R.N.O.; Encalada, J.M. Importancia de las competencias digitales directivas en los estudiantes de licenciatura para la industria 4.0. Lumina 2020. [Google Scholar] [CrossRef]

- Gutarra, R.; Valente, A. Las mipymes tecnológicas peruanas al 2030. Estrategias para su inserción a la industria 4.0. Nova Sci. 2018, 10, 754–778. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, O. Design principles for Industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Wang, Y.; Ma, H.S.; Yang, J.H.; Wang, K.S. Industry 4.0: A way from mass customisation to mass personalisation production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Tupa, J.; Simota, J.; Steiner, F. Aspects of Risk Management Implementation for Industry 4.0. Procedia Manuf. 2017, 11, 1223–1230. [Google Scholar] [CrossRef]

- Miśkiewicz, R. Knowledge Transfer in Merger and Acquisition Processes in the Metallurgical Industry; PWN: Warszawa, Poland, 2017. [Google Scholar]

- Berger, R. The Industrie 4.0 Transition Quantified. How the Fourth Industrial Revolution Is Reshuffling the Economic, Social and Industrial Model, Report. 2016. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjNwOT1rMfpAhXPk4sKHXyFAXwQFjAAegQIARAB&url=https%3A%2F%2Fwww.rolandberger.com%2Fpublications%2Fpublication_pdf%2Froland_berger_industry_40_20160609.pdf&usg=AOvVaw2rC6QBz3F2ubwaaqDKmdqj (accessed on 12 May 2020).

- Chiappetta Jabbour, C.J.; Fiorini, P.D.C.; Ndubisi, N.O.; Queiroz, M.M.; Piato, É.L. Digitally-enabled sustainable supply chains in the 21st century: A review and a research agenda. Sci. Total Environ. 2020, 725, 138177. [Google Scholar] [CrossRef]

- Reinhardt, I.C.; Oliveira, D.J.C.; Ring, D.D.T. Current Perspectives on the Development of Industry 4.0 in the Pharmaceutical Sector. J. Ind. Inf. Integr. 2020, 18, 100131. [Google Scholar] [CrossRef]

- Mittal, S.; Kahn, M.A.; Romero, D.; Wuest, T. Smart Manufacturing: Characteristics, Technologies and Enabling Factors. Proceedings of the Institution of Mechanical Engineers, Part B. J. Eng. Manuf. 2017. [Google Scholar] [CrossRef]

- Pfohl, H.-C.; Yahsi, B.; Kuznaz, T. The impact of Industry 4.0 on the Supply Chain. In Proceedings of the Hamburg International Conference of Logistic (HICL)-20, Hamburg, Germany, 10–12 August 2015; pp. 32–58. [Google Scholar] [CrossRef]

- Popkova, E.G.; Ragulina, Y.V.; Bogoviz, A.V. Industry 4.0: Industrial Revolution of the 21st Century; Springer International Publishing: Berlin, Germany, 2019. [Google Scholar]

- Raj, A.; Dwivedi, G.; Sharma, A.; Lopes de Sousa Jabbour, A.B.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Terziyan, V.; Gryshko, S.; Goloviank, M. Patented intelligence: Cloning human decision models for Industry 4.0. J. Manuf. Syst. 2018, 48, 204–217. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum: Davos, Switzerland, 2016. [Google Scholar]

- Manocha, T.; Sahni, M.; Satija, V.D. Adoption and awareness of industry 4.0 in logistics industry. Int. J. Adv. Sci. Technol. 2020, 29, 6334–6347. [Google Scholar]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 technologies on Lean principles. Int. J. Prod. Res. 2020, 58, 1644–1661. [Google Scholar] [CrossRef]

- Kipper, L.M.; Furstenau, L.B.; Hoppe, D.; Frozza, R.; Iepsen, S. Scopus scientific mapping production in industry 4.0 (2011–2018): A bibliometric analysis. Int. J. Prod. Res. 2020, 58, 1605–1627. [Google Scholar] [CrossRef]

- Stadnicka, D.; Litwin, P.; Antonelli, D. Human Factor in Industry of the Future – Knowledge Acquisition and motivation. Fme Trans. 2019, 44, 823–830. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Wolniak, R.; Grebski, M.E. Innovativeness and creativity as nature and nurture. Sci. Pap. Sil. Univ. Technol. Manag. Ser. 2018, 116, 215–226. [Google Scholar] [CrossRef]

- Grabowska, S.; Grebski, M.E.; Grebski, W.; Wolniak, R. Introduction to Engineering Concepts from a Creativity and Innovativeness Perspective; KDP Publishing: New York, NY, USA, 2019. [Google Scholar]

- Kadir, B.A.; Broberg, O. Human well-being and system performance in the transition to industry 4.0. Int. J. Ind. Ergon. 2020, 76, 102936. [Google Scholar] [CrossRef]

- Jerman, A.; Pejić Bach, M.; Aleksić, A. Transformation towards smart factory system: Examining new job profiles and competencies. Syst. Res. Behav. Sci. 2020, 37, 388–402. [Google Scholar] [CrossRef]

- Kabugo, J.C.; Jämsä-Jounela, S.-L.; Schiemann, R.; Binder, C. Industry 4.0 based process data analytics platform: A waste-to-energy plant case study. Int. J. Electr. Power Energy Syst. 2020, 115, 105508. [Google Scholar] [CrossRef]

- Lass, S.; Gronau, N. A factory operating system for extending existing factories to Industry 4.0. Comput. Ind. 2020, 115, 103128. [Google Scholar] [CrossRef]

- Ruff, C. A Stronger Digital Industrial Europe; Digital Europe: Brussels, Belgium, 2019. [Google Scholar]

- Ancygier, A. Poland and the European Climate Policy: An Uneasy Relationship. E Politikon 2013, 7, 76–93. [Google Scholar]

- Tamme, E. The European Green Deal: New Opportunities to Scale up Carbon Capture and Storage; Global CCS Institute: Tokyo, Japan, 2020. [Google Scholar]

- Michalski, G.; Rutkowska, M.; Sulich, A.; Rothe, R. The green jobs and the Industry 4.0. In Enterprises and Economies in the Face of Contemporary challenges. Management-Restructuring-Innovation; Global CCS Institute: Krynica, Poland, 2017; pp. 1–12. [Google Scholar]

- Pacana, A.; Radon-Cholewa, A.; Pacana, J. The study of stickiness of packaging film by Shainin method. Przemysł Chem. 2015, 94, 1334–1336. [Google Scholar]

- Pacana, A.; Czerwińska, K.; Bednarowa, L. Discrepancies analysis of casts of diesel engine piston. Metalurgija 2018, 57, 324–326. [Google Scholar]

- Malindzak, D.; Pacana, A.; Pacaiova, H. An effective model for the quality of logistics and improvement of environmental protection in a cement plant. Przesmysł Chem. 2017, 96, 1958–1962. [Google Scholar]

- Nagasawa, T.; Pillay, C.; Beier, G.; Fritzsche, K.; Pougel, F.; Takama, T.; Bobashev, I. Accelerating Clean Energy through Industry 4.0 Manufacturing the Next Revolution; United Nation Industrial development Organization: Vienna, Austria, 2017. [Google Scholar]

- Wolniak, R.; Saniuk, S.; Grabowska, S.; Gajdzik, B. Identification of energy efficiency trends in the context of the development of industry 4.0 using the Polish steel sector as an example. Energies 2020, 13, 2867. [Google Scholar] [CrossRef]

- GUS. Efektywność Wykorzystania Energii w Latach 2007–2017; GUS: Warszawa, Poland, 2019.

- ReA-1/8/2018 Project: Optimising the Key Areas of a Company’s Business Activity by Monitoring the Location of Its Assets and Supervising the Casting Process in Real Time. (In Polish) (Vizum Factory); ReAlloys: Laziska Gorne, Poland, 2018; Company internal documentation; Not published.

- Report on the Implementation of Stage 1 of the Project: Optimising the Key Areas of a Company’s Business Activity by Monitoring the Location of Its Assets and Supervising the Casting Process in Real Time. (In Polish) (Vizum Factory); ReAlloys: Laziska Gorne, Poland, 2019; Company internal documentation; Not published.

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).