Abstract

Design, implementation, and operation of any project are affected by the environment where it is developed; at the same time, the project will influence the environment, since during its life cycle it can cause an impact on it. This impact can lead to social, economic, and environmental results. Directive 2014/52/EU, on the assessment of the effects of certain public and private projects on the environment, reflects the obligation for the project promoter to consider, in the Environmental Impact Study (EIS) of the project, their vulnerability (exposure and resilience) to major accidents and/or disasters, evaluating both the risk and their effects on the environment, in case these major accidents and/or disasters appear. The IEC 31.010:2019 Risk management—Risk assessment techniques standard defines 45 risk appreciation techniques that are useful when analysing the risks, in general. The objective of this paper is to review these 45 techniques, and establish which ones can be used for the assessment of accidents or disasters required in the specific environmental impact assessment process to accomplish with the regulation. After the revision, the authors propose five risks appreciation techniques that could be used for the assessment of major accidents and or disasters in projects for which EIA has to be carried out.

1. Introduction

The process of economic globalisation, together with the development of new technologies and population growth in the second half of twentieth century, has caused several environmental problems that have had effects far beyond national boundaries, becoming worldwide problems. This has brought with it a scientific movement aimed at the achievement of a new production model, more sustainable for the environment. The concept of “sustainable development” was originally defined by the European Commission in the paper “Our Common Future” as “the kind of development that meets the needs of the present without compromising the ability of future generations to meet their own needs” [1].

Sustainability includes social, environmental, and economic aspects to make a rational use of the resources and meet the current needs without compromising the ability of future generations to meet their own needs [2,3].

Traditionally, meeting human needs has been carried out through the development of projects, both for the construction of necessary buildings and infrastructure and for the development of products that the society demands. This satisfaction has been accompanied, nevertheless, by an excessive consumption of natural and non-renewable resources, which has contributed to environmental degradation, derived from the increased pollution, the damage to vulnerable ecosystems, and the release of greenhouse gases to the atmosphere [4]. Because of this, conventional project management techniques do not appear to be the most appropriate to manage portfolio, program, and projects in a sustainable manner. It is necessary to include the principles of sustainability in the concept of project management [5].

Design, implementation, and operation of any project are affected by the environment where it is developed; at the same time, the project will influence the environment, since during its life cycle it can cause an impact on it. This impact can lead to social, economic, and environmental results. According to them, we will get to know how sustainable the project is [6].

Projects, as defined in the “Guide to the Project Management Body of Knowledge” (PMBOK® Guide), are a “temporary endeavour undertaken to create a unique product, service, or result. Projects are undertaken to fulfil objectives by producing deliverables” [7]. Sustainability, as a study field, can provide project management with new prospects for improvement, since it considers environmental, economic, and social impacts at the same time, both for the life cycle of the project and for the life cycle of the product or good generated [6,8]. This relationship between sustainability and project management has caught the eye of many researchers and professionals, becoming a new research field for project management [9,10,11].

In fact, this new approach has been included in the concept “Sustainable Project Management” (SPM), defined by Silvius and Shipper [12] as “the planning, monitoring and controlling of project delivery and support processes, with consideration of the environmental, economic and social aspects of the life cycle of the project’s resources, processes, deliverables and effects, aimed at realising benefits for stakeholders, and performed in a transparent, fair, and ethical way that includes proactive stakeholder participation”.

The consideration of the sustainability dimensions in the practices of projects managers results in much more interesting large projects and/or projects with a significant social and environmental impact, such as the construction or civil works projects subject to the Environmental Impact Assessment procedure (EIA).

EIA is a legal, administrative procedure which consists of the identification, description, and assessment, in the light of each individual case, of the direct and indirect significant effects of a project on the environment in case it is put into operation, in order to prevent, correct, and evaluate the impacts, for the approval, modification, or rejection of the project if the amendment was not possible [13].

Spanish Law 9/2018 amending Law 21/2013 of Environmental Impact Assessment [14] came into force on 7 December 2018 [15]. This Law transposed to Spanish Law Directive 2014/52/EU, of 16 April 2014 [13] on the assessment of the effects of certain public and private projects on the environment. In its single article, point 14, paragraph d), the Law reflects the obligation for the project promoter to consider, in the Environmental Impact Study (EIS) of the project, their vulnerability (exposure and resilience) to major accidents and/or disasters, evaluating both the risk and their effects on the environment, in case these major accidents and/or disasters appear.

Article 1, point 2, includes the definitions for major accident and disaster:

“Major accident: occurrence such as a major emission, fire or big explosion resulting from a uncontrolled developments in the course of the implementation, operation, dismantling or demolition or a project, and leading to serious danger to human health or the environment, immediate or delayed.”

“Disaster: natural events such as floods, rising sea levels or earthquakes, external to the project, that produces severe destruction or damages on the people or the environment.”

It also includes the definition of vulnerability:

“Vulnerability of the Project: physical characteristics of a Project that may affect the possible significant adverse effects on the environment as a consequence of a major accident or a disaster.”

With this structure, EIA procedure of projects is linked to the European regulation for the control of major accidents hazards, Directive 2012/18/UE (known as Seveso III Directive) [16], and, at Spanish level, to the Royal Decree 840/2015 [17], relative to the control of risks inherent to the major accident involving dangerous substances.

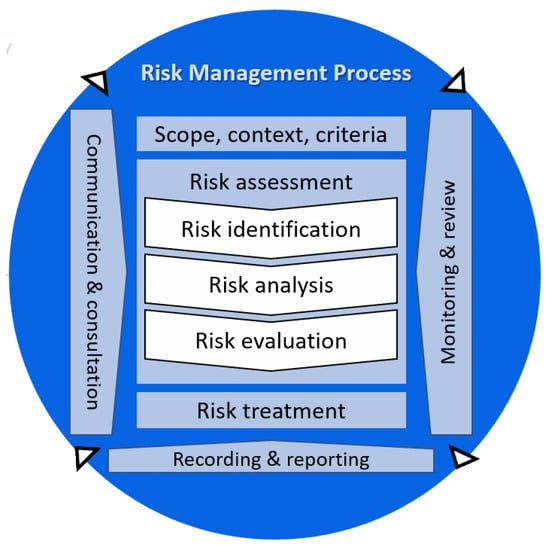

This new structure of the EIA regulation forces an identification, analysis, and evaluation of risks, this is to say, a risks appreciation procedure, as the ISO 31.000:2018 standard [18] indicates (see Figure 1).

Figure 1.

Model of risk management. Source: ISO 31.000:2018 [18].

Risk appreciation allows decision-makers to understand the risks that could affect the achievement of the goals of the project, providing a basis as well for making decisions on the more adequate approach to afford the risks. The way the identification, analysis, and evaluation of risks are performed not only depends on the context of the project, but also on the methods and techniques used to carry out the risk’s appreciation [19].

EIA and Risk Assessment (RA) have a similar procedural framework, since they try to predict impacts that can appear in the future. The need for their aggregated analysis was proposed by Gough in 1989 [20], although studies in this field are not very common. Demidova and Cherp proposed a model for the integration of RA into the process of EIA for thermal power plants, dams and water deposits, waste treatment plants, and landfills [21], integrating techniques from RA in the stages of the EIA process. In Australia, in 2010, the Department of Health of Western Australia presented a risk-based approach for EIA [22]. Subsequent to the publication of the European Directive 2014/52/EU on the assessment of the effects of certain public and private projects on the environment and its consequent transposition into national laws, different proposals for the consideration of RA into the EIA process have appeared, such as that proposed by Zelenákova and Zvijáková in Slovakia [23].

Driven by increasing pressure from government regulators, community activists, and non-governmental organisations [24], environmental practices are gaining attention from both academia and industry. However, much still needs to be done concerning this research topic, as the identification of risks caused by inadequately addressing environmental hazards remains poorly explored in the literature [25].

In [26], the authors analysed 767 abstracts and 70 full papers to identify 14 environmental risks, 3 main consequences, and 19 strategies to manage the environmental risks, and as a result they presented an Environmental Supply Chain Risk Management taxonomy.

In 2019, the International Electrotechnical Commission (IEC) published the International Standard 31.010:2019. Risk management. Risk assessment techniques [27], including 45 techniques appropriate to use within a risk management process, leading to actions to treat risk. Nevertheless, when performing an environmental impact assessment, risks can be very different, and it is necessary to choose the right one, depending on the type of project and circumstances of the risks.

Although the identification of environmental risks is a relatively new research field (EU Directive is from 2014), different authors have proposed methods to address the environmental risks within the environmental impact assessment process [28,29]. Nevertheless, there is little published about the convenience of the techniques identified as risk assessment techniques to identify and evaluate the environmental risks arising during the EIA process.

The objective of this paper consists of the revision of the 45 risk appreciation techniques, defined in the IEC 31.010:2019 Risk management—Risk assessment techniques standard, choosing the ones which could be used for the assessment of accidents or disasters required in the process of EIA, showing the baseline conditions (availability of data, stakeholders, and so on), the application conditions, and the robustness of their results. After the revision, five techniques have been chosen as the more adequate to assess the vulnerability of a project to major accidents or disasters in the EIA process, accomplishing the European regulatory framework for this process stated above.

2. Theoretical Framework

2.1. The Risk Appreciation Procedure

ISO 31.000:3018 standard defines risk assessment as “the overall process of risk identification, risk analysis and risk evaluation” [18].

Risk identification is the stage where risks are found, recognized, and described. This process includes the identification of causes and origin of the risks, events, situations, or circumstances that might have a potential impact on the objectives and may result in a variety of tangible or intangible consequences [30].

The risk analysis stage implies the development of an understanding of the risk; in other words, it consists of determining the consequences and probabilities for identified risks events, considering the existence (or not) and the effectiveness of all the existing controls. The consequences and their probabilities will be combined afterwards to determine the level of risk.

The risk evaluation stage implies the comparison of the estimated risk levels with the risk criteria defined when the context was established, with the aim of determine the importance of the level and type of risk.

During the risk evaluation stage, knowledge about the risk obtained during the risk analysis stage is applied. This makes it possible to make decisions about future actions, for example, if the risk needs to be addressed, which is the priority level of the treatment, if an action is necessary, or the path that it should follow.

Decision about if a risk must be addressed, and how, may depend on the costs and benefits of taking the risk, and on the costs and benefits of the implementation of improved controls to avoid it. A common approach in all the processes of risks appreciation involves dividing the risks into three groups:

- An upper range, where the level of risk is considered unacceptable, whatever the benefits of the activity. For this group, the treatment of the risk is essential, independently of its cost;

- A medium range, where the costs and benefits are considered, and the opportunities are compensated with regards to the potential consequences;

- A bottom range, where the level of risk is considered insignificant or so small that it is not necessary to take actions for its treatment.

2.2. The Risk Appreciation Techniques

Risk appreciation can be done according to various degrees of depth and detail, using one or more methods, varying from the simplest to the most complex ones, according to the available information, to the characteristics of the context and/or to the application cost of the methods [31,32].

Standard IEC 31.010:2019 [27] includes some characteristics that should be considered when selecting one or more techniques to use:

- Application;

- Scope;

- Time horizon;

- Decision level;

- Starting info/data needs;

- Specialist expertise;

- Qualitative–quantitative;

- Effort to apply.

There is no “prescription” to select the correct method or technique for risk appreciation, but there are some guidelines, in a manner that:

- It is justifiable and suitable for the project or organisation considered;

- The results make it possible to understand the nature of risk and how to address it;

- The application or the method or technique can be traceable, verifiable, and replicable.

With these characteristics about the selection of techniques for risk appreciation, considering their application in an Environmental Impact Study (which is developed at the same time as the preliminary project or basic plan of the facility), where the knowledge about the characteristics of receiving environment and the infrastructure is emerging or under development, this paper studies the main risk appreciation techniques included in IEC 31.010:2019 standard, analysing the possibility of their application to perform the vulnerability assessments in EIS.

3. Material and Methods

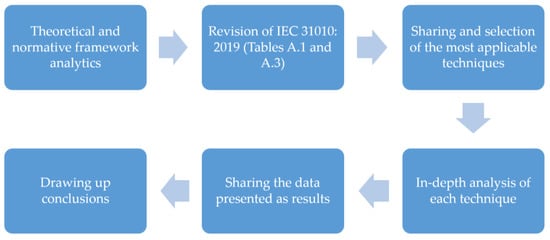

The procedure followed for the assessment of the suitability of risks appreciation techniques for the EIA process was structured in four steps. Initially, as a first step, an initial and individual review of IEC 31010:2019 standard was made by the authors. In particular, all the information included in tables A.1. and A.3. of the standard (which summarize the characteristics of the risk appreciation techniques that should be considered when selecting which technique or techniques to use) was analysed, and the information included in table A.2. of the standard, where a brief description of the 45 techniques is included, indicating for each of them the analysis regarding the characteristics indicated in tables A.1. and A.3.

In the second step, all the collected information was shared, and a first selection of techniques was made that, according to the authors, could more appropriately be applied to assess the vulnerability of a project to major accidents or disasters in the EIA process.

In the third step, an individual and deeper analysis of each technique was carried out.

Finally, at the fourth step, individual results were shared. These results are presented in the following section.

Figure 2 shows a schematic vision of the methodology followed for this study.

Figure 2.

Step-by-step methodology applied for this study. Source: Prepared by the authors.

4. Results

This section presents the techniques that, according to the authors, could be used to analyse the vulnerability of a project to major accidents or disasters in the EIA process.

After initial analysis of appreciation risk techniques, the authors made the following remarks:

- Application of quantitative techniques in the initial phases of a project, when the characteristics of all systems and subsystems are not yet completely defined, results complex, and it is in these phases when projects are to subject to the EIA process;

- There are no failure consequences or failure probabilities databases available for all types of projects subject to EIA. Originally, many of these techniques originated for chemical or petrochemical factories projects, and for these kinds of projects there is a lot of published scientific literature that has collected probabilities or frequencies of failure [33,34]; however, such data do not exist for events that can appear, for example, in linear infrastructures projects (roads or railway tracks);

- As the identification and analysis of risks is in fact a complex and multidisciplinary process where the actions of the project can influence several aspects of the environment (geology, hydrogeology, atmosphere, flora, fauna, employment, services, and so on), it will be convenient, in order to analyse the vulnerability of the project to major accidents or disasters, to have a selection of techniques that make it possible to perform both the identification and the analysis of the risk at the same time.

According to this, an initial selection of the following techniques was made, and a case-by-case analysis was carried out, including a description of every technique and an example of its possible application to the analysis of vulnerability of a project to major accidents or disasters.

The five selected techniques were the following:

- SWIFT Technique (Structured What IF Technique);

- Cause and Effect Analysis Technique;

- Scenario Analysis Technique;

- Failure Mode and Effects Analysis, FMEA Technique;

- Consequence/Likelihood Matrix Technique.

4.1. SWIFT Technique

This is a technique developed as an alternative to the HAZard and OPerability Study technique (HAZOP), consisting of a systematic study of the project carried out for an expert panel with a facilitator, with the goal of identifying possible hazardous scenarios that can result in accidents or working system problems, predicting their possible consequences [35,36].

The facilitator uses a list of questions or sentences with immediate effect and usually starting with “What if…”, “What would happen if…”, “Could somewhat or someone…”, “Has someone or somewhat about…”, to lead the workshop participants systematically through the identification of the risks. This technique is applied to systems with a minor detail level than the HAZOP technique, and consequently it could be applicable early in the design process of the projects, when there is less detailed information, and when the projects are subject to environmental evaluation.

To apply this technique, description of the project (systems, procedures, and so on) is needed, as well as an experienced project team with knowledge about the infrastructure or facility to evaluate.

The process of the application of this technique is established in workshops where the members of the team, based on the previous data (risks and hazards known, previous incidents, existing and known controls, legal requirements, and so on), and through the use of the sentences indicated by the facilitator, identify the risks, their causes, their consequences, and their planned controls, as well as the need for additional measures. Sometimes, a qualitative or semiquantitative technique is used to prioritize the measures identified in the SWIFT technique.

Table 1 shows an example of application of the SWIFT technique for a medium-voltage overhead power line installation project. In this example, the risk of a fire in a forest area following a lightning strike on the medium-voltage power line of a solar photovoltaic installation is analysed. Through a series of “what if” questions, the possible situations and consequences that could happen have been identified. The most serious consequence would be a fire affecting the forest area, and depending on the season of the year, also affecting the surrounding agricultural area. Due to this analysis, the initial preventive measures are reinforced by increasing the safety distance on each side of the power line projection by 10 m.

Table 1.

Example of the application of the SWIFT (Structured What IF Technique) technique. Source: Prepared by the authors.

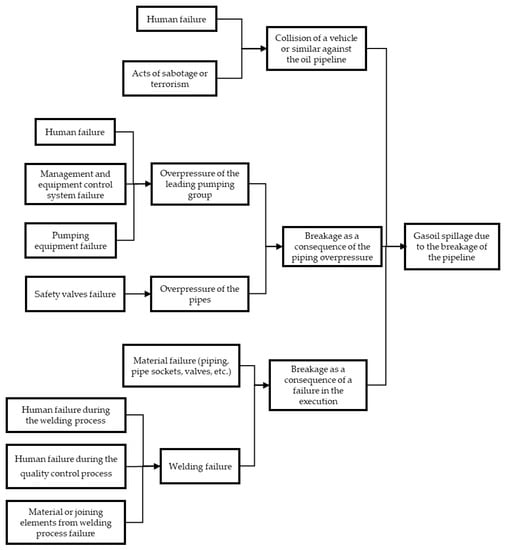

4.2. Cause and Effect Analysis Technique

The Cause and Effect Analysis technique is a structured and qualitative method to identify possible causes of an event or undesired problem, with no quantitative values for the probability of occurrence of the main event. This technique allows the organisation of possible factors contributing to a cause in categories, so all the possible hypotheses that may cause the event can be considered. Information is organized in a tree structure (see Figure 2), or in an Ishikawa or herringbone diagram.

For the application of this technique, a work team with knowledge about the project or system to be analysed is needed. Initially, the effect to analyse will be defined and situated in a box (the effect may be positive, namely a goal, or negative, namely a problem). This effect will have some main causes, and these causes will be formed by several causes or sub-causes. Finally, a diagram representing possible factors contributing to the effect will be obtained.

Figure 3 shows an example of the application of the Cause and Effect Analysis Technique, where an event consisting of a gasoil spillage of an oil pipeline during its operation is evaluated. In this case, the gasoil spillage could be caused by three main events: collision of a vehicle or similar against the gasoil pipeline, breakage because of the piping overpressure, and breakage as a consequence of a failure in the execution. These events in turn have causes that generate them until they reach simpler events, such as human failures or material failure (valves, piping, etc.).

Figure 3.

Example of the application of the Cause and Effect Analysis Technique. Source: Prepared by the authors.

4.3. Scenario Analysis Technique

The Scenario Analysis Technique consists of the development of descriptive models of what could happen in the future, enabling the identification of the risks through the consideration of possible future developments and the search for their implications [37]. For the analysis of the risks, scenarios including “the best scenario”, “the worst scenario”, and “the most probable scenario” can be considered, to analyse the possible consequences and probabilities of each scenario. This technique is employed in the planification of strategic actions such as urban planning and sectoral plans, or even in the EIA process, when evaluating the situation in the null or preoperational status of the environment and its future evolution if the project is implemented.

For the application of this technique, it is necessary to have a work team with knowledge about the project as well as the capacity to know how the surrounding environment has evolved, the technology to apply, and so on, and also the creativity to determine how it could evolve in the future. As it occurs when predicting the future, the shorter the terms, the more reliable the data and the more truthful the scenarios considered.

The operation principle of the technique is based in workshops where, once the context of the problem and the issues to consider are established, the nature of changes that could occur is identified (technological changes, needs of stakeholders, demographic changes, and so on), and several scenarios are proposed, describing how these scenarios will be reached from the current status and with which changes in the corresponding variables. In this case, when several scenarios are evaluated, a qualitative or semiquantitative method to express the probability of occurrence of each proposed scenario should be used.

Table 2 shows an example of the application of the Scenario Analysis technique for the case of an earthquake occurring in an area close to a wind farm. Three scenarios are contemplated. First, the most probable scenario, an earthquake with a medium-low intensity that affects some elements of the installation, without causing a breakdown in any of them, but forcing some repair and maintenance tasks to make the wind farm work again. Secondly, the best scenario, an earthquake with a low intensity that would not affect to the surrounding people or environment. Finally, the worst scenario, an earthquake with a medium intensity, which could generate collapse of wind towers, fall electric lines, possibly affect wind farm staff or people in general, or affect the environment (oil spills of the transformation centers, fire on forest areas, and so on).

Table 2.

Example of the application of the Scenario Analysis Technique. Source: Prepared by the authors.

4.4. Failure Mode and Effects Analysis, FMEA Technique

This technique is employed to identify the reasons why components, systems, or processes can fail regarding the fulfilment of the goals of their study. This technique allows the identification of all the possible failure modes of a system, the effects of these failures, the mechanisms of the failure, and how to avoid the failures and/or mitigate their effects over the system [38].

This technique is applicable during the design, manufacturing, or operation of a system, so it would be applicable during the EIA process stage and could feed back the design regarding its robustness with respect to major accidents or disasters. Results of this technique may be the starting point to other quantitative risk analysis techniques, such as the Fault Tree Analysis, and also, if actual failure estimations are available, it is possible to get a hierarchy of failure modes according to their importance or criticality. In this case, the technique is called Failure Mode Effects and Criticality Analysis, FMECA.

For the application of FMEA, it is necessary to constitute a work team expert in the technique, but mainly in the process, as well as to have all the possible information about the systems, subsystems, components, and so on. After breakdown of the system is made (similar to a Project Breakdown Structure, when referring to Project Management), the next step consists of identifying how each node or component could fail, what mechanisms could generate those failure models, what would be the effects if the damage was done, if the failure is harmful or harmless, how the failure would be detected, and so on. With all this information, necessary arrangements to compensate the failure would be determined.

Table 3 shows an example of the application of this technique for a failure mode of a component of a high-speed railway line project. The overpass over existing roads on the mountainside of a hillock is assessed. The failure mode identified is the outage of the normal operation of the line due to a flash flood because of the surface run-off from the mountainside of the hillock located close to the overpass. The application of the FMEA technique allows the identification of the failure mode, the failure mechanism, the failure type, the failure detection, and the corrective or additional measures to be implemented. In this case, the cleaning and maintenance of the perimeter ditches are the main preventive measures, completed with an increase of the monitoring of the node through surveillance cameras.

Table 3.

Example of the application of the Failure Mode and Effects Analysis (FMEA) Technique. Source: Prepared by the authors.

4.5. Consequence/Likelihood Matrix Technique

The Consequence/Likelihood Matrix is a technique that allows the combination of different qualitative and semiquantitative classifications of the consequences and likelihood to obtain a level of risk or a classification of the risk.

This method allows prioritisation of the risk, that is to say, to classify the identified risks and to determine if they are acceptable or unacceptable, and also if it is necessary to perform additional or deeper analysis, or prioritize the mitigating actions. It is a technique that can be used independently or in combination with other techniques of identification, analysis, and evaluation of risks.

Risks are usually analysed by combining estimates of consequence (also described as severity or outcome) and likelihood (frequency or probability) in the context of existing control measures. In general, the magnitude or rating of a given risk is established using a two-dimensional grid or matrix, with consequence as one axis and likelihood as the other. In this context, consequence is defined as the outcome or the potential outcome of an event [39].

The scale of consequence must have different levels, varying from maximum to minimum consequences, usually employing scales with three, four, or five levels. The likelihood scale can be numerical or descriptive and must cover a range from the minimum to the maximum likelihood of occurrence. As in the case of consequence scales, usually three, four, or five levels are employed.

The level of risk results from the combination of both variables, likelihood, and consequences, as follows:

where Li is the likelihood of the occurrence of a certain situation of risk and Ci is the consequences in case that situation occurs.

RLi=Li · Ci,

Table 4 shows a possible Consequence/Likelihood matrix, with a four-level qualitative and numerical scale for both variables (likelihood and consequences). For each combination of different possibilities for each variable, the risk level is shown (varying from I to V as the risk decreases).

Table 4.

Consequence/Likelihood Matrix. Source: Prepared by the authors.

At the bottom of the table, all the possible levels of likelihood and consequence scales are described.

Table 5 shows an example of the application of the Consequence/Likelihood matrix for a sewage treatment plant project. In this case, the risk analysed is the partial or total breakage of an underwater sanitary because of a shipwreck. The likelihood of this risk is considered “unlikely”, because a shipwreck is an unusual event and the underwater sanitary is a lineal infrastructure with a low width. The consequence classification for this risk is “Serious”, because a spillage of treated water would increase the concentration of some organic pollutants, and swimming at the surrounding beaches could be prohibited; also, fauna and flora could be affected. An “Unlikely” likelihood and a “Serious” consequence, according to the method explained in the Table 4, classify the risk as a level IV.

Table 5.

Example of the application of the Consequence/Likelihood Matrix. Source: Prepared by the authors.

5. Discussion

As indicated in the Introduction section, EIA, and Risk Assessment (RA) have a similar procedural framework. Subsequent to the publication of the European Directive 2014/52/EU, different proposals for the consideration of RA in the EIA process have appeared, but EIA and RA processes are still rarely used to complement each other, despite the potential benefits of such integration [29].

Due to this, taking advantage of recent publication of the update of ISO 31.000:2018 standard, the authors decided to perform an analysis of the 45 risk appreciation techniques included in it, with the aim of determining its greater or lesser suitability to be used for the identification and assessment of the vulnerability of the projects to major accidents and disasters, into the EIA process. After the analysis, 5 out of the 45 techniques were selected (SWIFT, Cause and Effect Analysis, Scenario Analysis, FMEA, and Consequence/Likelihood Matrix) that, in the authors’ view and according to their experience, could be suitable to help the evaluation of risks in the EIA process. The application of these techniques has been illustrated through their implementation in five specific projects. For each of the projects presented here, causes, failure mechanisms, possible scenarios, and consequences of major accident risk in the EIA process have been identified. Application of these techniques has been done by expert judgements, and in a qualitative manner. Maybe this is a major constraint of this proposal, since to apply these techniques an expert in the application of each technique is required. As well, quantitative techniques are difficult to use, because of the lack of data regarding frequencies or probabilities of occurrence of the assessed events.

This research is, in this sense, original, since there is no other general proposal like this, arising from the techniques validated and recommended by ISO 31.000: 2018 standard. This research represents a contribution in this direction, since our framework facilitated the integration and interpretation of risk appreciation techniques process and risk management practices into the EIA. The proposed assessment framework can serve as a useful guideline for practitioners to quantify the potential risks for sustainable projects and to facilitate the development of adequate risk monitoring and mitigation strategies.

Probably one of the main weaknesses of EIA is the subjectivity in some of the evaluation techniques. Although there is currently no single widely accepted risk assessment methodology, incorporating them into the EIA process can increase the objectivity of the process.

Once the 45 techniques included in [18] have been analysed, and after the selection of five techniques described in this article, future works can consist of the development of some of these techniques with the suitable purpose. In line with this approach, some authors have recently published works that explored the application of some of these techniques in the context of EIA [29]. In particular, authors have developed a method to facilitate the application of the Consequence/Likelihood Matrix for the EIA process of construction projects in Slovakia, but, as its authors indicate, it could be arranged for any other country considering national conditions, requirements, standards, and legislative.

Future research opportunities may include the development of even more detailed parameters for the evaluation of each vulnerability and risk management technique, and also the comparison of performance across projects with different risk profiles. Case studies should also consider different countries’ perspectives to yield interesting insights from other cultures. Moreover, case studies conducted in different economic and climatic regions may result in different perceptions and effects of environmental risks [26].

Finally, it would be interesting to apply a combination of some of the five techniques described in this research to a whole project in order to analyse the results regarding the evaluation of the vulnerability of the project to major accidents and or disasters.

6. Conclusions

The relationship between projects and their environments, together with the need to achieve a more sustainable development, has led to new approaches within Project Management, such as Sustainable Project Management. One of the pillars of sustainability is the environment, and in the case of the projects of big infrastructures of civil works and buildings, one of the main techniques for the analysis of the environmental impact is the EIA.

The new regulatory framework about EIA requires an analysis be made of the vulnerability of the project in the face of major accidents and or disasters, evaluating both the risk and the possible adverse effects on the environment in case these accidents or disasters occur. This new content must be included in the EIS, which opens a range of new opportunities of work for risk engineering in such a multidisciplinary field as environmental impact assessment.

This work proposed five risk appreciation techniques (from among those recommended in [18]) that could be used for the assessment of major accidents and or disasters in projects for which EIA has to be carried out: SWIFT, Cause and Effect Analysis, Scenario Analysis, FMEA, and Consequence/Likelihood Matrix.

The application of quantitative risk appreciation techniques to projects under EIA, particularly in the basic design of them, that is, when the EIA process is carried out, is often complicated, making the application of semi-quantitative or qualitative techniques more functional. By incorporating them, the objectivity of the EIA process would increase.

The proposed assessment framework can serve as a useful guideline for practitioners to quantify the potential accident risks in sustainable projects, thus reducing unacceptable risks to acceptable levels and enabling the best option among the proposed alternatives to be chosen.

Author Contributions

J.L.F.-B. conceived and designed the experiments. M.J.B.-C. analyzed the state of the art. M.C.G.-C., P.S.F.-G., M.J.B.-C. and J.L.F.-B. performed the analysis and obtained the results. All authors wrote the paper and revised the final version of the document. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by Universitat Politècnica de València, Spain.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Brundtland, G.H. Our Common Future; Oxford University Press: Oxford, UK, 1990; p. 420. [Google Scholar]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Singhal, K.; Van Wassenhove, L. Sustainable operations management. Prod. Oper. Manag. 2005, 14, 482–492. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Shen, L. Embedding “green” in project-based organizations: The way ahead in the construction industry? J. Clean. Prod. 2015, 107, 420–427. [Google Scholar] [CrossRef]

- Chofreh, A.G.; Goni, F.A.; Malik, M.N.; Khan, H.H.; Klemes, J.J. The imperative and research directions of sustainable project management. J. Clean. Prod. 2019, 238, 117810. [Google Scholar] [CrossRef]

- Armenia, S.; Dangelico, R.M.; Nomino, F.; Pompei, A. Sustainable Project Management: A Conceptualization-Oriented Review and a Framework Proposal for Future Studies. Sustainability 2019, 11, 2664. [Google Scholar] [CrossRef]

- PMI. A Guide to the Project Management Body of Knowledge, 6th ed.; Project Management Institute: Pennsylvania, PA, USA, 2017; pp. 4–9. [Google Scholar]

- Silvius, A.G.; Schipper, R.P. Sustainability in project management: A literature review and impact analysis. Soc. Bus. 2014, 4, 63–96. [Google Scholar] [CrossRef]

- Nidumolu, R.; Prahalad, C.K.; Rangaswami, M.R. Why sustainability is now the key driver of innovation. Harv. Bus. Rev. 2009, 87, 56–64. [Google Scholar]

- Kiron, D.; Unruh, G.; Reeves, M.; Kruschwitz, N.; Rubel, H.; ZumFelde, A.M. Corporate sustainability at a crossroads. MIT Sloan Manag. Rev. 2017, 58, 1–27. [Google Scholar]

- Dong, N.; Fu, Y.; Xiong, F.; Lujie, L.; Ao, Y.; Martek, I. Sustainable Construction Project Management (SCPM) Evaluation—A case study of the Guanghzou Metro Line-7, PR China. Sustainability 2019, 11, 5731. [Google Scholar] [CrossRef]

- Silvius, A.G.; Kampinga, M.; Paniagua, S.; Mooi, H. Considering sustainability in project management decision making; an investigation using Q-methodology. Int. J. Proj. Manag. 2017, 35, 1133–1150. [Google Scholar] [CrossRef]

- European Union, Directive 2014/52/EU of the European Parliament and of the Council of April 16 amending Directive 2011/92/EU on the assessment of the effects of certain public and private projects on the environment. Off. J. Eur. Union 2014, 124, 1–18.

- Spanish Ministry of the Presidency, Law 21/2013 of December 9 on Environmental Assessment. Off. State Gaz. Gov. Spain 2013, 296, 98151–98227.

- Spanish Ministry of the Presidency, Law 9/2018 of December 5 amending Law 21/2013 of December 9 on Environmental Assessment, Law 21/2015 of July 20 amending Law 43/2003 of November 21 of Forestry, and Law 1/2005 of March 9 on regulation of GHG Emissions Trading. Off. State Gaz. Gov. Spain 2018, 294, 119858–119905.

- European Union, Directive 2012/18/EU of the European Parliament and of the Council of July 4on the control of major-accident hazards involving dangerous substances, amending and subsequently repealing Council Directive 96/82/EC. Off. J. Eur. Union 2012, 197, 1–37.

- Spanish Ministry of the Presidency Royal. Decree 840/2015 of September 21, approving risk control measures regarding major accidents involving dangerous substances. Off. State Gaz. Gov. Spain 2015, 251, 97531–97567. [Google Scholar]

- International Standard Organization (ISO). International Standard ISO 31.000:2018. Risk Management. Guidelines; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Haimes, Y.Y. Risk Modelling, Assessment and Management, 3rd ed.; Wiley: New York, NY, USA, 2008; p. 1040. [Google Scholar]

- Gough, J.D. A Strategic Approach to the Use of Environmental Impact Assessment and Risk Assessment Within the Decision-Making Process; Information Paper nº 13; Centre for Resource Management: Canterbury, New Zealand, 1989; Available online: https://researcharchive.lincoln.ac.nz/handle/10182/1354 (accessed on 1 June 2019).

- Demidova, O.; Cherp, A. Risk assessment for improved treatment of health considerations in EIA. Environ. Impact Assess. Rev. 2005, 25, 411–429. [Google Scholar] [CrossRef]

- Spickett, J.; Goh, Y.; Katscherian, D.; Ellies, P. Health Risk Assessment (Scoping) Guidelines. A Health Risk Assessment Process for Risk Assessors for Use Within the Scoping Stages of Environmental and Health Impact Assessments; Environmental Health Directorate/Health Impact Assessment: Perth, Australia, 2010; p. 23. [Google Scholar]

- Zelenákova, M.; Zvijáková, L. Risk analysis within environmental impact assessment of proposed construction activity. Environ. Impact Assess. 2017, 62, 76–89. [Google Scholar] [CrossRef]

- Marconi, M.; Marilungo, E.; Papetti, A.; Germani, M. Traceability as a means to investigate supply chain sustainability: The real case of a leather shoe supply chain. Int. J. Prod. Res. 2017, 55, 6638–6652. [Google Scholar] [CrossRef]

- Torres-Ruiz, A.; Ravindran, A. Multiple criteria framework for the sustainability risk assessment of a supplier portfolio. J. Clean. Prod. 2018, 172, 4478–4493. [Google Scholar] [CrossRef]

- Negreiros de Oliveira, F.; Leiras, A.; Ceryno, P. Environmental risk management in supply chains: A taxonomy, a framework and future research avenues. J. Clean. Prod. 2019, 232, 1257–1271. [Google Scholar] [CrossRef]

- International Electrotechnical Commission (IEC). International Standard 31.010:2019. Risk management. Risk Assessment Techniques; IEC: Geneva, Switzerland, 2019. [Google Scholar]

- Chen, Z.; Li, H.; Ren, H.; Xu, Q.; Hong, J. A total environmental risk assessment model for international hub airports. Int. J. Proj. Manag. 2011, 29, 856–866. [Google Scholar] [CrossRef]

- Zelenáková, M.; Labant, S.; Zvijáková, L.; Weiss, E.; Cepelová, H.; Weiss, R.; Fialová, J.; Mindas, J. Methodology for environmental assessment of proposed activity using risk analysis. Environ. Impact Assess 2020, 80, 106333. [Google Scholar] [CrossRef]

- Center for chemical process safety (CCPS). Guidelines for Engineering Design for Process Safety, 2nd ed.; American Institute of Chemical Engineers: New York, NY, USA, 1993. [Google Scholar]

- Tixier, J.; Dusserre, G.; Salvi, O.; Gaston, D. Review of 62 analysis methodologies of industrial plants. J. Loss Prev. Process Ind. 2002, 15, 291–303. [Google Scholar] [CrossRef]

- Marhavilas, P.K.; Koulouriotis, D.; Gemeni, V. Risk analysis and assessment methodologies in the work sites: On a review, classification, and comparative study of the scientific literature of the period 2000–2009. J. Loss Prev. Process Ind. 2011, 24, 477–523. [Google Scholar] [CrossRef]

- Dexter, A.H.; Perkins, W.C. Component Failure-Rate Data with Potential Applicability to a Nuclear Fuel Reprocessing Plant; UNT Libraries Government Documents: Springfield, VA, USA, 1982; p. 42. [Google Scholar]

- Skelton, B. Process Safety Analysis: An Introduction; IChemE.: Rugby, UK, 1997; p. 214. [Google Scholar]

- Doerr, W.W. What-if analysis. In Risk Assessment and Risk Management for the Chemical Process Industry; Greenberg, H.R., Cramer, J.J., Eds.; Wiley: New York, NY, USA, 1991; pp. 75–90. [Google Scholar]

- Ayyub, B.M. Risk Analysis in Engineering and Economics; Chapman & Hall/CRC: New York, NY, USA, 2003; p. 600. [Google Scholar]

- Zheng, X.; Liu, M. An overview of accident forecasting methodologies. J. Loss Prev. Process Ind. 2009, 22, 484–491. [Google Scholar] [CrossRef]

- Price, C.J.; Taylor, N.S. Automated multiple failure FMEA. Reliab. Eng. Syst. Saf. 2002, 76, 1–10. [Google Scholar] [CrossRef]

- NPSA. A Risk Matrix for Risk Managers; National Patient Safety Agency: London, UK, 2008; p. 18.

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).