Competitive Priorities, Employee Management and Development and Sustainable Manufacturing Performance in Asian Organizations

Abstract

1. Introduction

1.1. Employee Management and Development

1.2. Theoretical Perspective of the Resource-Based View

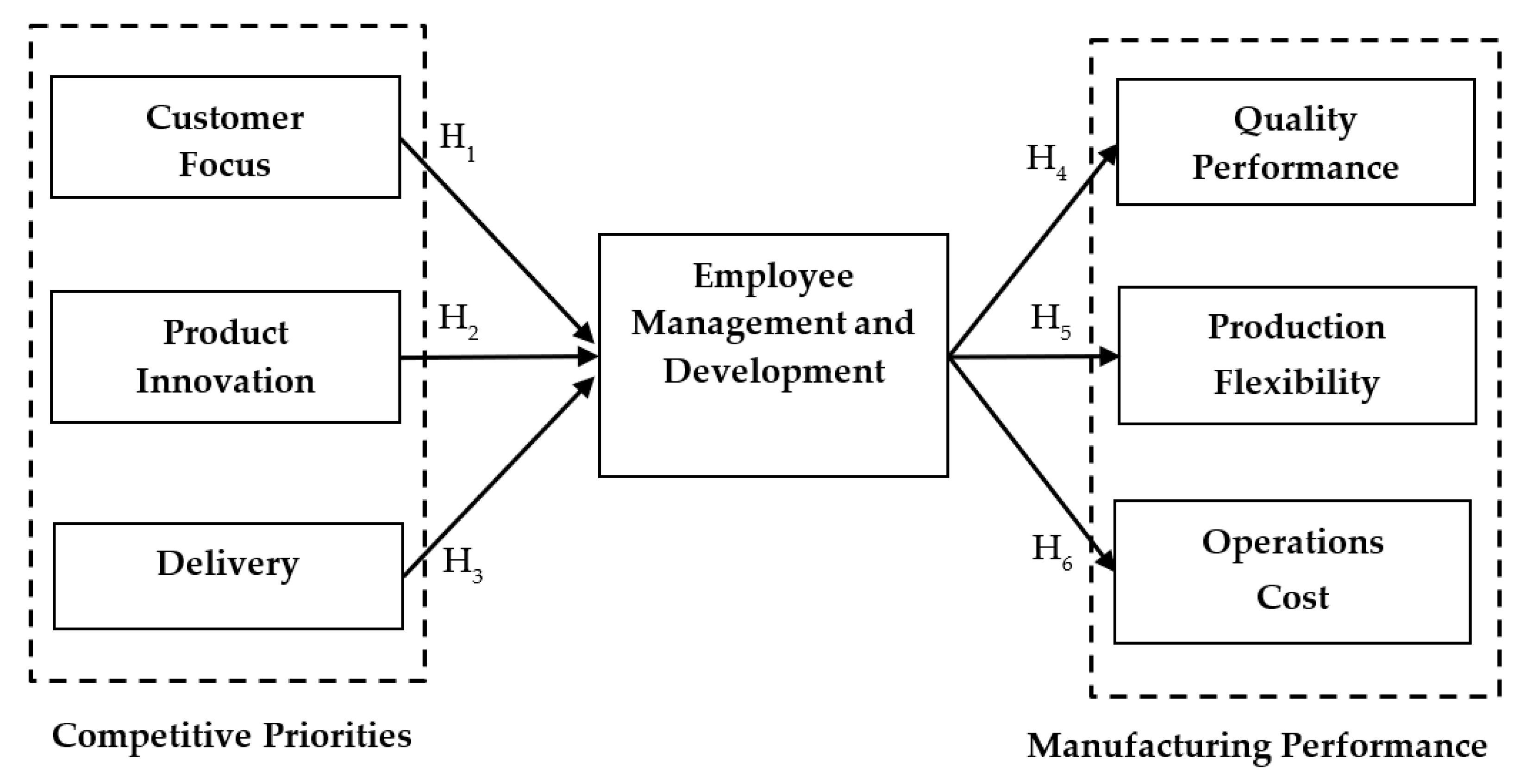

2. Hypotheses

2.1. Competitive Priorities and Employee Management and Development

2.2. The Importance of Employee Management and Development to Manufacturing Performance

3. Materials and Methods

Measures and Data Collection

4. Results

4.1. Data Validation

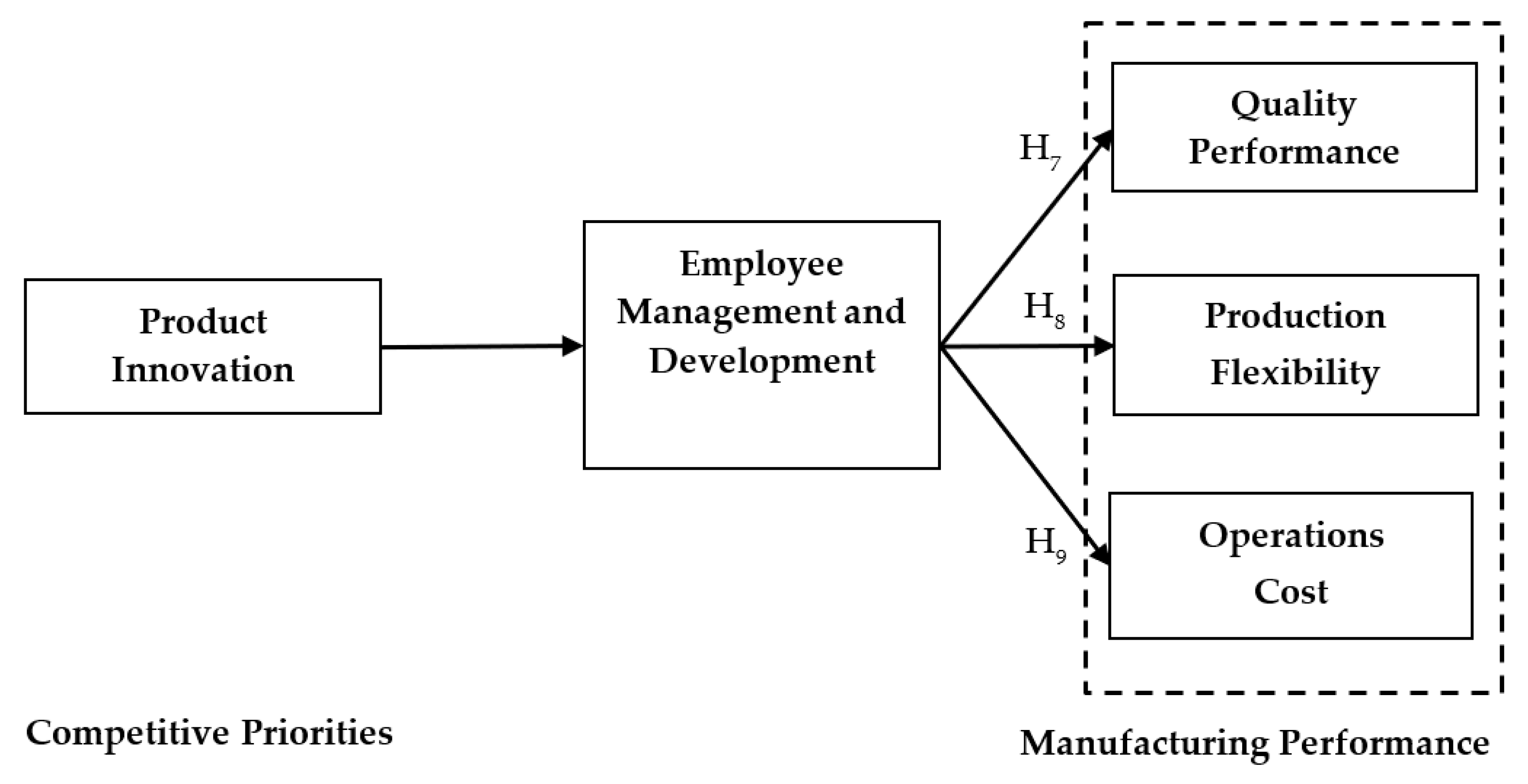

4.2. Mediation Effect of Employee Management and Development

5. Discussion

5.1. The Relationships between Competitive Priorities and Employee Management and Development

5.2. The Relationship between Employee Management/Development and Manufacturing Performance

5.3. The Mediating Role of Employee Management and Development

5.4. Impact on Sustainability in Asian Manufacturers

5.5. Study Implications

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, C.; Wang, Z.; Ding, K.; Chan, F.T.S.; Ji, W. An Energy-Aware Cyber Physical System for Energy Big Data Analysis and Recessive Production Anomalies Detection in Discrete Manufacturing Workshops. Int. J. Prod. Res. 2020, 1–19. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Qureshi, M.I.; Rasiah, R.; Al-Ghazali, B.M.; Haider, M.; Jambari, H.; Iswan; Sasmoko. Modeling Work Practices under Socio-Technical Systems for Sustainable Manufacturing Performance. Sustainability 2019, 11, 4294. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Ali, S.S. Exploring the Relationship between Leadership, Operational Practices, Institutional Pressures and Environmental Performance: A Framework for Green Supply Chain. Int. J. Prod. Econ. 2015, 160, 120–132. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K.H. Circular Economy Practices among Chinese Manufacturers Varying in Environmental-Oriented Supply Chain Cooperation and the Performance Implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable Supply Chain Management (SSCM) in Malaysia: A survey. Int. J. Prod. Econ. 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Wu, S.J. Assessing the Individual and Synergistic Effects of Quality Management Practices on Operations Performance. Int. J. Prod. Perform. Manag. 2020, 69, 297–320. [Google Scholar] [CrossRef]

- Zhao, X.; Sum, C.C.; Qi, Y.; Zhang, H.; Lee, T.S. A Taxonomy of Manufacturing Strategies in China. J. Oper. Manag. 2006, 24, 621–636. [Google Scholar] [CrossRef]

- Ward, P.T.; Duray, R.; Leong, G.K.; Sum, C.C. Business Environment, Operations Strategy, and Performance: An Empirical Study of Singapore Manufacturers. J. Oper. Manag. 1995, 13, 99–115. [Google Scholar] [CrossRef]

- Miller, J.G.; Roth, A.V. A Taxonomy of Manufacturing Strategies. Manag. Sci. 1994, 40, 285–304. [Google Scholar] [CrossRef]

- Berry, W.L.; Klompmaker, J.E.; Bozarth, C.C.; Hill, T.J. Factory Focus: Segmenting Markets from an Operations Perspective. J. Oper. Manag. 1991, 10, 363–387. [Google Scholar] [CrossRef]

- Prester, J. Competitive Priorities, Capabilities and Practices of Best Performers: Evidence from GMRG 4 Data. Total Qual. Manag. Bus. Excel. 2013, 24, 138–157. [Google Scholar] [CrossRef]

- Cai, S.; Yang, Z. On the Relationship between Business Environment and Competitive Priorities: The Role of Performance Frontiers. Int. J. Prod. Econ. 2014, 151, 131–145. [Google Scholar] [CrossRef]

- Kathuria, R.; Partovi, F.Y. Work Force Management Practices for Manufacturing Flexibility. J. Oper. Manag. 1999, 18, 21–39. [Google Scholar] [CrossRef]

- Lam, M.; O’Donnell, M.; Robertson, D. Achieving Employee Commitment for Continuous Improvement Initiatives. Int. J. Oper. Prod. Manag. 2015, 35, 201–215. [Google Scholar] [CrossRef]

- Lee, F.-H.; Lee, T.-Z.; Wu, W.-Y. The Relationship between Human Resource Management Practices, Business Strategy and Firm Performance: Evidence from Steel Industry in Taiwan. Int. J. Hum. Resour. Manag. 2010, 21, 1351–1372. [Google Scholar] [CrossRef]

- Mann, R.; Adebanjo, D.; Tickle, M. Deployment of Business Excellence in Asia: An Exploratory Study. Int. J. Qual. Reliab. Manag. 2011, 28, 604–627. [Google Scholar] [CrossRef]

- Laosirihongthong, T.; Teh, P.L.; Adebanjo, D. Revisiting Quality Management and Performance. Ind. Manag. Data Syst. 2013, 113, 990–1006. [Google Scholar] [CrossRef]

- Jagoda, K.; Kiridena, S. Operations Strategy Processes and Performance: Insights from the Contract Apparel Manufacturing Industry. J. Manuf. Technol. Manag. 2015, 26, 261–279. [Google Scholar] [CrossRef]

- Jayaram, J.; Droge, C.; Vickery, S.K. The Impact of Human Resource Management Practices on Manufacturing Performance. J. Oper. Manag. 1999, 18, 1–20. [Google Scholar] [CrossRef]

- Hayes, R.H.; Wheelwright, S.C. Restoring Our Competitive Edge: Competing through Manufacturing; John Wiley: New York, NY, USA, 1984. [Google Scholar]

- Phusavat, K.; Kanchana, R. Competitive Priorities for Service Providers: Perspectives from Thailand. Ind. Manag. Data Syst. 2008, 108, 5–21. [Google Scholar] [CrossRef]

- Prajogo, D. The Implementation of Operations Management Techniques in Service Organizations: An Australian Perspective. Int. J. Oper. Prod. Manag. 2006, 26, 1374–1390. [Google Scholar] [CrossRef]

- Thürer, M.; Godinho Filho, M.; Stevenson, M.; Fredendall, L.D. Competitive Priorities of Small Manufacturers in Brazil. Ind. Manag. Data Syst. 2013, 113, 856–874. [Google Scholar] [CrossRef]

- Foo, G.; Friedman, D.J. Variability and Capability: The Foundation of Competitive Operations Performance. AT T Technol. J. 1992, 71, 2–9. [Google Scholar] [CrossRef]

- Kathuria, R.; Porth, S.J.; Kathuria, N.N.; Kohli, T.K. Competitive Priorities and Strategic Consensus in Emerging Economies: Evidence from India. Int. J. Oper. Prod. Manag. 2010, 30, 879–896. [Google Scholar] [CrossRef][Green Version]

- Ward, P.T.; McCreery, J.K.; Ritzman, L.P.; Sharma, D. Competitive Priorities in Operations Management. Dec. Sci. 1998, 29, 1035–1046. [Google Scholar] [CrossRef]

- Leong, G.K.; Synder, D.L.; Ward, P.T. Research in the Process and Content of Manufacturing Strategy. OMEGA Int. J. Manag. Sci. 1990, 18, 109–122. [Google Scholar] [CrossRef]

- Verma, R.; Young, S.T. Configurations of Low-Contact Services. J. Oper. Manag. 2000, 18, 643–661. [Google Scholar] [CrossRef]

- Lee, V.H.; Ooi, K.B.; Chong, A.Y.L.; Sohal, A. The Effects of Supply Chain Management on Technological Innovation: The Mediating Role of Guanxi. Int. J. Prod. Econ. 2018, 205, 15–29. [Google Scholar] [CrossRef]

- Chan, H.K.; Yee, R.W.Y.; Dai, J.; Lim, M.K. The Moderating Effect of Environmental Dynamism on Green Product Innovation and Performance. Int. J. Prod. Econ. 2016, 181, 384–391. [Google Scholar] [CrossRef]

- Van Iwaarden, J.; van der Wiele, T. The Effects of Increasing Product Variety and Shortening Product Life Cycles on the Use of Quality Management Systems. Int. J. Qual. Reliab. Manag. 2012, 29, 470–500. [Google Scholar] [CrossRef]

- Laosirihongthong, T.; Tan, K.-C.; Adebanjo, D. Supply Chain Management in ASEAN Automotive Manufacturing Industry. Int. J. Logis. Res. App. 2011, 14, 317–333. [Google Scholar] [CrossRef]

- Ferdows, K.; De Meyer, A. Lasting Improvements in Manufacturing Performance: In Search of a New Theory. J. Oper. Manag. 1990, 9, 168–184. [Google Scholar] [CrossRef]

- Sanz-Valle, R.; Sabater-Sanchez, R.; Aragon-Sanchez, A. Human Resource Management and Business Strategy Links: An Empirical Study. Int. J. Hum. Resour. Manag. 1999, 10, 655–671. [Google Scholar] [CrossRef]

- Schuler, R.S.; Jackson, S.E. Linking Competitive Strategies with Human Resource Management Practices. Acad. Manag. Perspect. 1987, 1, 207–219. [Google Scholar] [CrossRef]

- Miles, R.E.; Snow, C.C. Designing Strategic Human Resources Systems; Institute of Industrial Relations, University of California: Oakland, CA, USA, 1984; pp. 36–52. [Google Scholar]

- Raghuram, S. Linking Staffing and Training Practices with Business Strategy: A Theoretical Perspective. Hum. Resour. Dev. Quar. 1994, 5, 237–251. [Google Scholar] [CrossRef]

- Medlin, B.; Green, K.W.; Wright, A.D. Comprehensive Management Practices and Policies Performance Model. Ind. Manag. Data Syst. 2016, 116, 1043–1060. [Google Scholar] [CrossRef]

- Indradevi, R. Training for Most Capable Workforce. Adv. Manag. 2010, 3, 49–54. [Google Scholar]

- Otoo, F.N.K.; Otoo, E.A.; Abledu, G.K.; Bhardwaj, A. Impact of Human Resource Development (HRD) Practices on Pharmaceutical Industry’s Performance: The Mediating Role of Employee Performance. Eur. J. Train. Dev. 2019, 43, 188–210. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, H. Exploring the Success Factors for Examining the Potential of Manufacturing System Output. Benchmarking Int. J. 2018, 25, 1171–1193. [Google Scholar] [CrossRef]

- Bandyopadhyay, C.; Srivastava, K. HR Signals in the Context of HRM-firm Performance Relationship: Development of a Conceptual Framework. Int. J. Prod. Perf. Manag. 2020. [Google Scholar] [CrossRef]

- Potnuru, R.K.G.; Sahoo, C.K. HRD Interventions, Employee Competencies and Organizational Effectiveness: An Empirical Study. Eur. J. Train. Dev. 2016, 40, 345–365. [Google Scholar] [CrossRef]

- Yu, W.; Ramanathan, R.; Wang, X.; Yang, J. Operations Capability, Productivity and Business Performance: The Moderating Effect of Environmental Dynamism. Ind. Manag. Data Syst. 2018, 118, 126–143. [Google Scholar] [CrossRef]

- Halley, A.; Beaulieu, M. Mastery of Operational Competencies in the Context of Supply Chain Management. Supply Chain Manag. Int. J. 2009, 14, 49–63. [Google Scholar] [CrossRef]

- Barney, J.; Griffin, R. The Management of Organization: Strategy, Structure, Behavior; Houghton Mifflin Co.: Boston, MA, USA, 1992. [Google Scholar]

- Amabile, T.M.; Conti, R.; Coon, H.; Lazenby, J.; Herron, M. Assessing the Work Environment for Creativity. Acad. Manag. J. 1996, 39, 1154–1184. [Google Scholar] [CrossRef]

- Steen, A.; Welch, D.; McCormack, D. Conflicting Conceptualizations of Human Resource Accounting. J. Hum. Resour. Costing Account. 2011, 15, 299–312. [Google Scholar] [CrossRef]

- Gannon, J.M.; Doherty, L.; Roper, A. The Role of Strategic Groups in Understanding Strategic Human Resource Management. Pers. Rev. 2012, 41, 513–546. [Google Scholar] [CrossRef]

- Woodall, J.; Scott-Jackson, W.; Newham, T.; Gurney, M. Making the Decision to Outsource Human Resources. Pers. Rev. 2009, 38, 236–252. [Google Scholar] [CrossRef]

- Peteraf, M.A. The Cornerstones of Competitive Advantage: A Resource-Based View. Strategic Manag. J. 1993, 14, 179–191. [Google Scholar] [CrossRef]

- Drohomeretski, E.; Gouvea da Costa, S.E.; Pinheiro de Lima, E.; Garbuio, P.A.D.R. Lean, Six Sigma and Lean Six Sigma: An Analysis based on Operations Strategy. Int. J. Prod. Res. 2014, 52, 804–824. [Google Scholar] [CrossRef]

- Boyer, K.K.; McDermott, C. Strategic Consensus in Operations Strategy. J. Oper. Manag. 1999, 17, 289–305. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, L. Evaluating and Developing Resource-Based Operations Strategy for Competitive Advantage: An Exploratory Study of Finnish High-Tech Manufacturing Industries. Int. J. Prod. Res. 2015, 53, 1019–1037. [Google Scholar] [CrossRef]

- Carranza, J.E. Product Innovation and Adoption in Market Equilibrium: The Case of Digital Camera. Int. J. Ind. Organ. 2010, 28, 604–618. [Google Scholar] [CrossRef]

- Verhees, F.J.H.M.; Meulenberg, M.T.G. Market Orientation, Innovativeness, Product Innovation, and Performance in Small Firms. J. Small Bus. Manag. 2004, 42, 134–154. [Google Scholar] [CrossRef]

- Thompson, A.A.; Strickland, A.J.; Gamble, J.E. Crafting and Executing Strategy: The Quest for Competitive Advantage: Concepts and Cases, 14th ed.; McGraw-Hill Education: Boston, MA, USA, 2005. [Google Scholar]

- Laosirihongthong, T.; Prajogo, D.; Adebanjo, D. The Relationships between Firm’s Strategy, Resources, and Innovation Performance: Resources-Based View Perspective. Prod. Plan. Control Manag. Oper. 2014, 25, 1231–1246. [Google Scholar] [CrossRef]

- Subramaniam, M.; Youndt, M.A. The Influence of Intellectual Capital on the Types of Innovative Capabilities. Acad. Manag. J. 2005, 48, 450–463. [Google Scholar] [CrossRef]

- Gumusluoğlu, L.; Ilsev, A. Transformational Leadership and Organizational Innovation: The Roles of Internal and External Support for Innovation. J. Prod. Innov. Manag. 2009, 26, 264–277. [Google Scholar] [CrossRef]

- Ren, S.; Eisingerich, A.B.; Tsai, H.-T. Search Scope and Innovation Performance of Emerging-Market Firms. J. Bus. Res. 2015, 68, 102–108. [Google Scholar] [CrossRef]

- Søndergaard, E.; Oehmen, J.; Ahmed-Kristensen, S. Extension of Internationalisation Models: Drivers and Processes for the Globalisation of Product Development—A Comparison of Danish and Chinese Engineering Firms. Prod. Plan. Control: Manag. Oper. 2016, 27, 1112–1123. [Google Scholar] [CrossRef][Green Version]

- Famiyeh, S.; Kwarteng, A.; Asante-Darko, D.; Dadzie, S.A. Green Supply Chain Management Initiatives and Operational Competitive Performance. Benchmarking Int. J. 2018, 25, 607–631. [Google Scholar] [CrossRef]

- Guillon, O.; Cezanne, C. Employee Loyalty and Organizational Performance: A Critical Survey. J. Organ. Change Manag. 2014, 27, 839–850. [Google Scholar] [CrossRef]

- Almatrooshi, B.; Singh, S.K.; Farouk, S. Determinants of Organizational Performance: A Proposed Framework. Int. J. Prod. Perform. Manag. 2016, 65, 844–859. [Google Scholar] [CrossRef]

- Sarfaraz, A.; Jenab, K.; Bowker, A. A View of Development in Management for Increasing Profitability in the Corporate Landscape. Benchmarking Int. J. 2015, 22, 120–134. [Google Scholar] [CrossRef]

- Melián-González, S.; Bulchand-Gidumal, J.; González López-Valcárcel, B. New Evidence of the Relationship between Employee Satisfaction and Firm Economic Performance. Pers. Rev. 2015, 44, 906–929. [Google Scholar] [CrossRef]

- Oakland, S.; Oakland, J.S. Current People Management Activities in World-Class Organizations. Total Qual. Manag. 2001, 12, 773–788. [Google Scholar] [CrossRef]

- Nasim, K. Role of Internal and External Organizational Factors in TQM Implementation: A Systematic Literature Review and Theoretical Framework. Int. J. Qual. Reliab. Manag. 2018, 35, 1014–1033. [Google Scholar] [CrossRef]

- Bourne, M.; Pavlov, A.; Franco-Santos, M.; Lucianetti, L.; Mura, M. Generating Organizational Performance: The Contributing Effects of Performance Measurement and Human Resource Management Practices. Int. J. Oper. Prod. Manag. 2013, 33, 1599–1622. [Google Scholar] [CrossRef]

- Hanna, M.D.; Newman, W.R.; Johnson, P. Linking Operational and Environmental Improvement through Employee Involvement. Int. J. Oper. Prod. Manag. 2000, 20, 148–165. [Google Scholar] [CrossRef]

- Thanyawatpornkul, R.; Siengthai, S.; Johri, L.M. Employee’s Perspective towards Strategy Execution in Facility Management in Thailand. Facilities 2016, 34, 682–702. [Google Scholar] [CrossRef]

- Walker, H.; Sisto, L.D.; McBain, D. Drivers and Barriers to Environmental Supply Chain Management Practices: Lessons from the Public and Private Sectors. J. Purchas. Sup. Manag. 2008, 14, 69–85. [Google Scholar] [CrossRef]

- Ahmad, S.; Schroeder, R.G. The Impact of Human Resource Management Practices on Operational Performance: Recognizing Country and Industry Differences. J. Oper. Manag. 2003, 21, 19–43. [Google Scholar] [CrossRef]

- Cagliano, R.; Acur, N.; Boer, H. Patterns of Change in Manufacturing Strategy Configurations. Int. J. Oper. Prod. Manag. 2005, 25, 701–718. [Google Scholar] [CrossRef]

- Cagliano, R.; Caniato, F.; Golini, R.; Longoni, A.; Micelotta, E. The Impact of Country Culture on the Adoption of New Forms of Work Organization. Int. J. Oper. Prod. Manag. 2011, 31, 297–323. [Google Scholar] [CrossRef]

- Sveiby, K.; Simons, R. Collaborative Climate and Effectiveness of Knowledge Work—An Empirical Study. J. Knowl. Manag. 2002, 6, 420–433. [Google Scholar] [CrossRef]

- Rogg, K.L.; Schmidt, D.B.; Shull, C.; Schmitt, N. Human Resource Practices, Organizational Climate, and Customer Satisfaction. J. Manag. 2001, 27, 431–449. [Google Scholar] [CrossRef]

- Cagliano, R.; Caniato, F.; Longoni, A.; Spina, G. Alternative Uses of Temporary Work and New Forms of Work Organization. Prod. Plan. Control Manag. Oper. 2014, 25, 762–782. [Google Scholar] [CrossRef]

- Sitkin, S.B.; Sutcliffe, K.M.; Schroeder, R.G. Distinguishing Control from Learning in Total Quality Management: A Contingency Perspective. Acad. Manag. Rev. 1994, 19, 537–564. [Google Scholar] [CrossRef]

- Garvin, D. Competing on the Eight Dimensions of Quality. Harv. Bus. Rev. 1987, 65, 101–109. [Google Scholar]

- Forza, C.; Filippini, R. TQM Impact on Quality Conformance and Customer Satisfaction: A Causal Model. Int. J. Prod. Econ. 1998, 55, 1–20. [Google Scholar] [CrossRef]

- Ahmed, J.U. Modern Approaches to Product Reliability Improvement. Int. J. Qual. Reliab. Manag. 1996, 13, 27–41. [Google Scholar] [CrossRef]

- Kimura, F.; Matoba, Y.; Mitsui, K. Designing Product Reliability Based on Total Product Lifecycle Modelling. CIRP Ann. Manuf. Technol. 2007, 56, 163–166. [Google Scholar] [CrossRef]

- Jack, E.P.; Raturi, A. Sources of Volume Flexibility and Their Impact on Performance. J. Oper. Manag. 2002, 20, 519–548. [Google Scholar] [CrossRef]

- Hallgren, M.; Olhager, J. Flexibility Configurations: Empirical Analysis of Volume and Product Mix Flexibility. OMEGA Int. J. Manag. Sci. 2009, 37, 746–756. [Google Scholar] [CrossRef]

- Woo, Y.Y.; Hsu, S.L.; Wu, S. An Integrated Inventory Model for a Single Vendor and Multiple Buyers with Ordering Cost Reduction. Int. J. Prod. Econ. 2001, 73, 203–215. [Google Scholar] [CrossRef]

- Rao, P. Greening the Supply Chain: A New Initiative in South East Asia. Int. J. Oper. Prod. Manag. 2002, 22, 632–655. [Google Scholar] [CrossRef]

- The International Manufacturing Strategy Survey. Available online: http://www.manufacturingstrategy.net/ (accessed on 7 June 2020).

- Hair, J.F.; Babin, B.J.; Anderson, R.E.; Black, W.C. Multivariate Data Analysis, 8th ed.; Cengage: Boston, MA, USA, 2018. [Google Scholar]

- Bagozzi, R.P.; Yi, Y. On the Evaluation of Structural Equation Models. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Preacher, K.J.; Hayes, A.F. SPSS and SAS Procedures for Estimating Indirect Effects in Simple Mediation Models. Behav. Res. Methods Instrum. Comput. 2004, 36, 717–731. [Google Scholar] [CrossRef] [PubMed]

- Peng, D.X.; Schroeder, R.G.; Shah, R. Competitive Priorities, Plant Improvement and Innovation Capabilities, and Operational Performance: A Test of Two Forms of Fit. Int. J. Oper. Prod. Manag. 2011, 31, 484–510. [Google Scholar] [CrossRef]

- Filho, A.G.A.; Nogueira, E.; Bento, P.E.G. Operations Strategies of Engine Assembly Plants in the Brazilian Automotive Industry. Int. J. Oper. Prod. Manag. 2015, 35, 817–838. [Google Scholar] [CrossRef]

- Yen, H.R.; Sheu, C. Aligning ERP Implementation with Competitive Priorities of Manufacturing Firms: An Exploratory Study. Int. J. Prod. Econ. 2004, 92, 207–220. [Google Scholar] [CrossRef]

- Chan, L.L.M.; Shaffer, M.A.; Snape, E. In Search of Sustained Competitive Advantage: The Impact of Organizational Culture, Competitive Strategy and Human Resource Management Practices on Firm Performance. Int. J. Hum. Resour. Manag. 2004, 15, 17–35. [Google Scholar] [CrossRef]

- Alagaraja, M.; Cumberland, D.M.; Choi, N. The Mediating Role of Leadership and People Management Practices on HRD and Organizational Performance. Hum. Resour. Dev. Int. 2015, 18, 220–234. [Google Scholar] [CrossRef]

- Zhu, Y.; Warner, M.; Rowley, C. Human Resource Management with ‘Asian’ Characteristics: A Hybrid People-Management System in East Asia. Int. J. Hum. Resour. Manag. 2007, 18, 745–768. [Google Scholar] [CrossRef]

- Kumar, S.; Teichman, S.; Timpernagel, T. A Green Supply Chain is a Requirement for Profitability. Int. J. Prod. Res 2012, 50, 1278–1296. [Google Scholar] [CrossRef]

- Testa, F.; Iraldo, F. Shadows and Lights of GSCM (Green Supply Chain Management): Determinants and Effects of These Practices Based on a Multi-National Study. J. Clean. Prod. 2010, 18, 953–962. [Google Scholar] [CrossRef]

| Constructs | Survey Items | Source |

|---|---|---|

| A Competitive Priority of Customer Focus | Consider the importance of the following attributes to win orders from your major customers. (Importance in the last three years: 1 = not important; 5 = very important) 1. Better conformance to customer specifications; 2. Superior customer service (training, information, help-desk); 3. Superior product assistance/support (after-sales and/or technical support). | Miller and Roth [10], Cagliano et al. [76] |

| A Competitive Priority of Product Innovation | Consider the importance of the following attributes to win orders from your major customers. (Importance in the last three years: 1 = not important; 5 = very important) 1. Better product design and quality; 2. Wider product range; 3. Offer new products more frequently; 4. Offer products that are more innovative. | Miller and Roth [10], Cagliano et al. [76] |

| A Competitive Priority of Delivery | Consider the importance of the following attributes to win orders from your major customers. (Importance in the last three years: 1 = not important; 5 = very important) 1. Faster deliveries; 2. More reliable deliveries; 3. Greater order size flexibility. | Miller and Roth [10], Cagliano et al. [76] |

| Employee Management and Development | Indicate the effort put in the current level of implementation of action programs related to: (Current level of implementation: 1 = none; 5 = high) 1. Delegation and knowledge of your workers (e.g., empowerment, training, encouraging solutions to work-related problems, pay for competence or incentives for improvement results); 2. Open communication between workers and managers (information sharing, encouraging bottom-up open communication, two-way communication flows); 3. Autonomous teams (e.g., team responsible for planning, execution and control, workers sharing experience, knowledge and skills, formalization of team composition and responsibilities, work group incentives); 4. Workers flexibility (e.g., multi-tasking, multi-skilling, job rotation); 5. Use of flexible forms of work (e.g., temporary workers, part time, job sharing, variable working hours). | Cagliano et al. [77], Sveiby and Simons [78], Rogg et al. [79], Cagliano et al. [80]. |

| Quality Performance | How does your current performance compare with that of your main competitor(s) 1? 1 Consider the average performance of the group of competitors that are the direct benchmark for the plant. (Relative to our main competitors, our performance is: 1 = much lower; 2 = lower; 3 = equal; 4 = higher; 5 = much higher) 1. Conformance quality; 2. Product quality and reliability. | Sitkin et al. [81], Garvin [82], Forza and Filippini [83], Ferdows and Meyer [34], Ahmed [84], Kimura et al. [85]. |

| Production Flexibility | How does your current performance compare with that of your main competitor(s) 1? 1 Consider the average performance of the group of competitors that are the direct benchmark for the plant. (Relative to our main competitors, our performance is: 1 = much lower; 2 = lower; 3 = equal; 4 = higher; 5 = much higher) 1. Volume flexibility; 2. Mix flexibility. | Jack and Raturi [86], Hallgren and Olhager [87]. |

| Operations Cost | How does your current performance compare with that of your main competitor(s) 1? 1 Consider the average performance of the group of competitors that are the direct benchmark for the plant. (Relative to our main competitors, our performance is: 1 = much higher; 2 = higher; 3 = equal; 4 = lower; 5 = much lower) 1. Unit manufacturing cost; 2. Ordering cost; 3. Materials, water and/or energy consumption. | Ferdows and Meyer [34], Woo et al. [88], Rao [89]. |

| Variables | Descriptions | Frequency (n = 259) | Percent (100%) |

|---|---|---|---|

| Countries | China | 127 | 49.0 |

| India | 91 | 35.1 | |

| Taiwan | 28 | 10.8 | |

| Malaysia | 13 | 5.0 | |

| International Standard Industrial Classification Code of Companies | 25: Manufacture of fabricated metal products, except machinery and equipment | 46 | 17.8 |

| 26: Manufacture of computer, electronic and optical products | 69 | 26.6 | |

| 27: Manufacture of electrical equipment | 40 | 15.4 | |

| 28: Manufacture of machinery and equipment not elsewhere classified | 53 | 20.5 | |

| 29: Manufacture of motor vehicles, trailers and semi-trailers | 36 | 13.9 | |

| 30: Manufacture of other transport equipment | 15 | 5.8 | |

| Job Title | Chief Executive Officer/Chief Financial Officer/Chief Information Officer /President/Chairman | 26 | 10.0 |

| Vice President/Director/General Manager | 65 | 25.1 | |

| Managers | 107 | 41.3 | |

| Senior Engineer/Technical Lead | 33 | 12.7 | |

| Other | 28 | 10.8 | |

| Years of Experience in Operations/Manufacturing in the Organization | Below 3 years | 42 | 16.2 |

| 3–5 years | 47 | 18.1 | |

| 6–10 years | 68 | 26.2 | |

| 11–15 years | 32 | 12.4 | |

| 16–20 years | 23 | 8.9 | |

| 21–30 years | 10 | 3.9 | |

| Above 30 years | 5 | 1.9 | |

| Unspecified | 32 | 12.4 |

| Variables | No. of Items | KMO | BTS | EV | Factor Loadings | ||||

|---|---|---|---|---|---|---|---|---|---|

| Item 1 | Item 2 | Item 3 | Item 4 | Item 5 | |||||

| CF | 3 | 0.591 | 190.963 *** | 1.919 | 0.652 | 0.887 | 0.841 | Nil | Nil |

| PI | 4 | 0.756 | 323.084 *** | 2.491 | 0.683 | 0.825 | 0.832 | 0.807 | Nil |

| DE | 3 | 0.585 | 196.500 *** | 1.924 | 0.841 | 0.892 | 0.649 | Nil | Nil |

| EMD | 5 | 0.795 | 442.974 | 2.886 | 0.807 | 0.779 | 0.800 | 0.727 | 0.678 |

| QP | 2 | 0.500 | 208.846 *** | 1.746 | 0.934 | 0.934 | Nil | Nil | Nil |

| PF | 2 | 0.500 | 189.426 *** | 1.723 | 0.928 | 0.928 | Nil | Nil | Nil |

| OC | 3 | 0.634 | 232.856 *** | 2.039 | 0.866 | 0.886 | 0.709 | Nil | Nil |

| Mean | Standard Deviation | Cronbach’s Alpha | Composite Reliability | Average Variance Extracted | |

|---|---|---|---|---|---|

| Customer Focus | 4.058 | 0.928 | 0.709 | 0.840 | 0.640 |

| Product Innovation | 3.873 | 0.912 | 0.798 | 0.868 | 0.623 |

| Delivery | 3.996 | 0.887 | 0.701 | 0.841 | 0.641 |

| Employee Management and Development | 3.599 | 0.783 | 0.807 | 0.872 | 0.577 |

| Quality Performance | 3.778 | 0.806 | 0.855 | 0.932 | 0.872 |

| Production Flexibility | 3.475 | 0.763 | 0.838 | 0.925 | 0.861 |

| Operations Cost | 3.116 | 0.764 | 0.761 | 0.863 | 0.679 |

| CF | PI | DE | EMD | QP | PF | OC | |

|---|---|---|---|---|---|---|---|

| CF | 0.800 | ||||||

| PI | 0.510 ** | 0.789 | |||||

| DE | 0.452 ** | 0.507 ** | 0.801 | ||||

| EMD | 0.219 ** | 0.254 ** | 0.254 ** | 0.760 | |||

| QP | 0.072 | 0.249 ** | 0.115 | 0.291 ** | 0.934 | ||

| PF | 0.128 * | 0.370 ** | 0.238 ** | 0.282 ** | 0.607 ** | 0.928 | |

| OC | 0.056 | 0.074 | 0.035 | 0.208 ** | 0.140 * | 0.241 ** | 0.824 |

| Hypotheses | Causal Path | Standard Path Coefficients | Standard Errors | Critical Ratios | p-Value |

|---|---|---|---|---|---|

| H1 | Customer Focus → Employee Management and Development | 0.006 | 0.167 | 0.088 | 0.930 |

| H2 | Product Innovation → Employee Management and Development | 0.314 | 0.170 | 3.043 | 0.002 ** |

| H3 | Delivery → Employee Management and Development | 0.157 | 0.079 | 1.653 | 0.098 |

| H4 | Employee Management and Development → Quality Performance | 0.448 | 0.076 | 6.293 | 0.000 *** |

| H5 | Employee Management and Development → Production Flexibility | 0.347 | 0.073 | 4.649 | 0.000 *** |

| H6 | Employee Management and Development → Operations Cost | 0.222 | 0.073 | 3.039 | 0.002 ** |

| Construct | Estimate | Lower 95% Confidence Interval | Upper 95% Confidence Interval |

|---|---|---|---|

| Employee Management and Development (Between Competitive Priority of Product Innovation and Quality Performance) | 0.141 | 0.040 | 0.228 |

| Employee Management and Development (Between Competitive Priority of Product Innovation and Production Flexibility) | 0.109 | 0.034 | 0.228 |

| Employee Management and Development (Between Competitive Priority of Product Innovation and Operations Cost) | 0.070 | 0.021 | 0.175 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adebanjo, D.; Teh, P.-L.; Ahmed, P.K.; Atay, E.; Ractham, P. Competitive Priorities, Employee Management and Development and Sustainable Manufacturing Performance in Asian Organizations. Sustainability 2020, 12, 5335. https://doi.org/10.3390/su12135335

Adebanjo D, Teh P-L, Ahmed PK, Atay E, Ractham P. Competitive Priorities, Employee Management and Development and Sustainable Manufacturing Performance in Asian Organizations. Sustainability. 2020; 12(13):5335. https://doi.org/10.3390/su12135335

Chicago/Turabian StyleAdebanjo, Dotun, Pei-Lee Teh, Pervaiz K Ahmed, Erhan Atay, and Peter Ractham. 2020. "Competitive Priorities, Employee Management and Development and Sustainable Manufacturing Performance in Asian Organizations" Sustainability 12, no. 13: 5335. https://doi.org/10.3390/su12135335

APA StyleAdebanjo, D., Teh, P.-L., Ahmed, P. K., Atay, E., & Ractham, P. (2020). Competitive Priorities, Employee Management and Development and Sustainable Manufacturing Performance in Asian Organizations. Sustainability, 12(13), 5335. https://doi.org/10.3390/su12135335