Corporate Social Responsibility of Companies Producing PFOA Containing Waxes for Cross-Country Skiing

Abstract

1. Introduction

2. Theoretical Framework

2.1. Corporate Social Responsibility

2.2. Responsible Businesses in the Chemical Industry

2.3. A Study of Fluorine and its Compounds

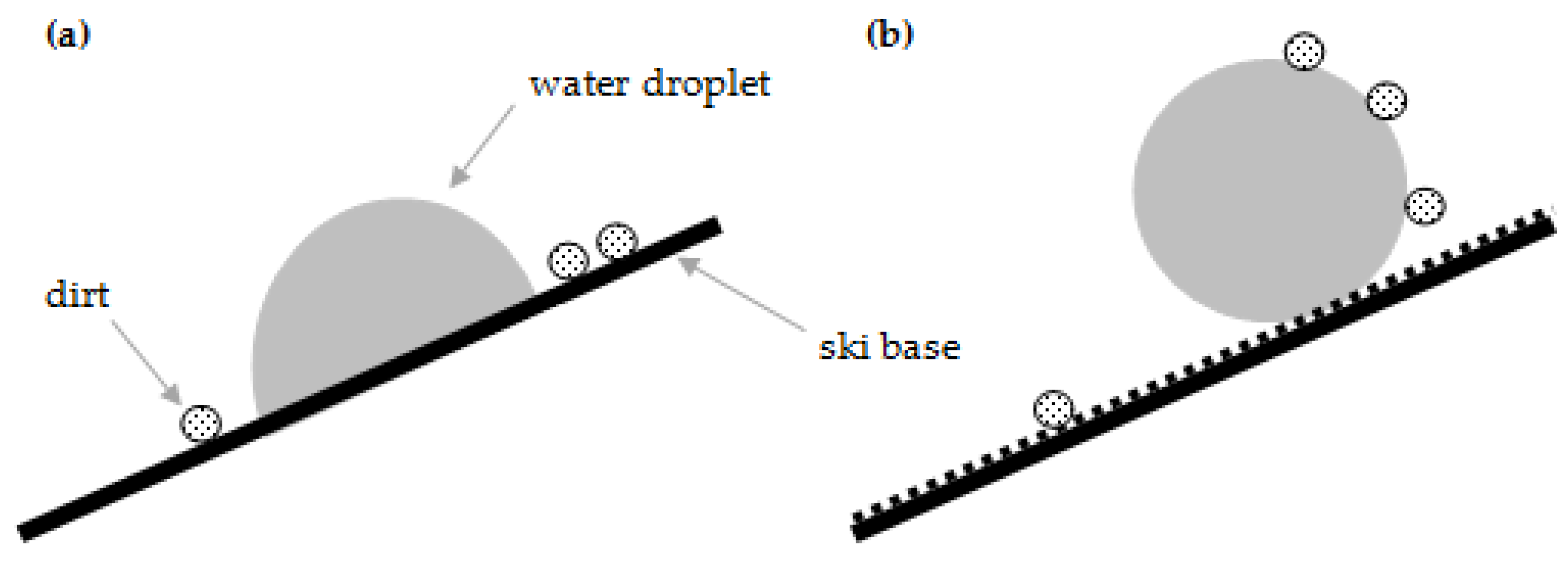

2.4. Ski Waxing

2.5. The Health Risk Posed by PFOA

2.6. Negative Effects of Perfluorinated Compounds in Ski Areas

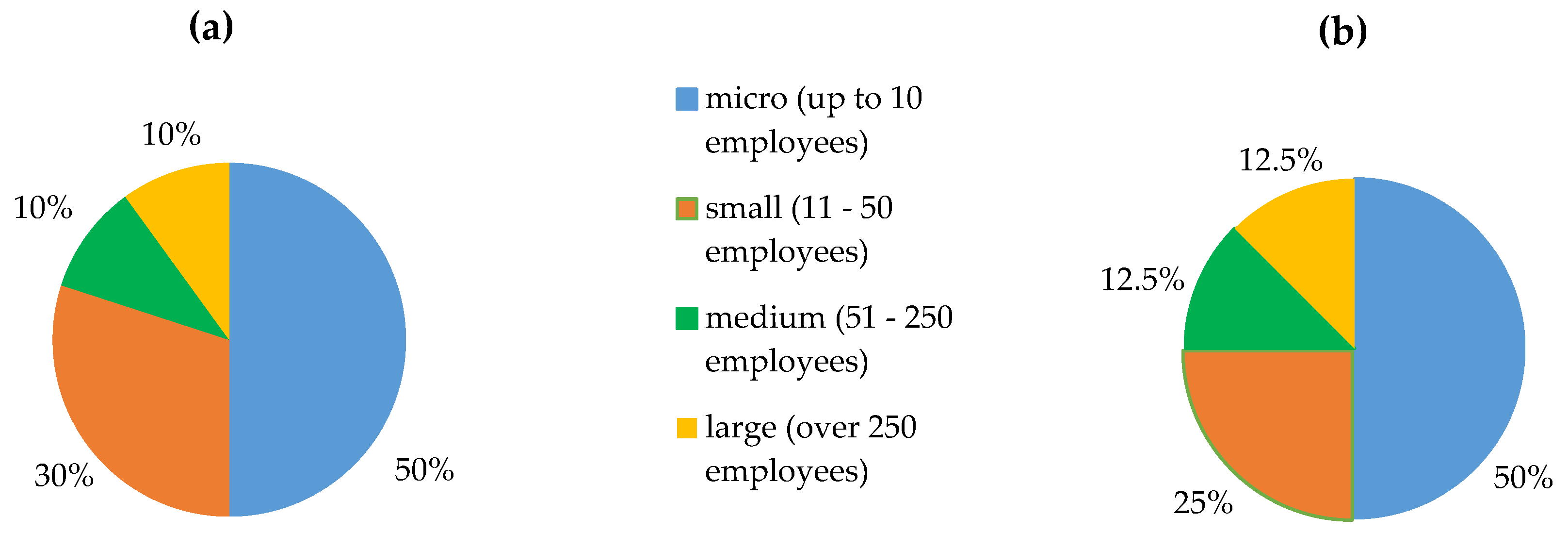

3. Methodology

The Corporate Social Responsibility of Companies Producing Paraffin Waxes

- Cramer’s V coefficient

- Correlation

4. Results and Discussion

4.1. General Awareness of CSR

4.2. Testing of the Hypotheses

4.3. Conclusion Related to CSR

4.4. The Norwegian Approach

4.5. Alternative Resources and Solutions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Svensson, G.; Ferro, C.; Høgevold, N.; Padin, C.; Carlos Sosa Varela, J.; Sarstedt, M. Framing the triple bottom line approach: Direct and mediation effects between economic, social and environmental elements. J. Clean. Prod. 2018, 197, 972–991. [Google Scholar] [CrossRef]

- Schlosberg, D.; Coles, R. The new environmentalism of everyday life: Sustainability, material flows and movements. Contemp. Polit. Theory 2016, 15, 160–181. [Google Scholar] [CrossRef]

- Regulation (EC) No 1005/2009 of the European Parliament and of the Council, of 16 September 2009. EUR-Lex-32009R1005-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32009R1005 (accessed on 29 June 2019).

- Ross, R. Facts about Fluorine. Available online: https://www.livescience.com/28779-fluorine.html (accessed on 16 June 2020).

- Posner, S. Perfluorinated Compounds: Occurrence and Uses in Products; Springer: Berlin/Heidelberg, Germany, 2012; pp. 25–39. [Google Scholar]

- Traverso, E.; Rinaldi, A. Ski Lubricant Comprising Paraffinic Wax and a Hydrocarbon Compound Containing a Perfluoro Segment. 1990. Available online: https://patents.google.com/patent/US5202041A/en (accessed on 16 June 2020).

- Katz, C. Ski Wax Chemicals Can Build Up in Blood. Available online: https://www.scientificamerican.com/article/ski-wax-chemicals-buildup-blood (accessed on 2 January 2019).

- UNEP. Stockholm Convention: Protecting Health and the Environment from Persistent Organic Pollutants. Available online: http://chm.pops.int/TheConvention/Overview/tabid/3351/Default.aspx (accessed on 3 August 2019).

- An, H.; Xiao, C.; Ding, M. The Spatial Pattern of Ski Areas and Its Driving Factors in China: A Strategy for Healthy Development of the Ski Industry. Sustainability 2019, 11, 3138. [Google Scholar] [CrossRef]

- Bazzanella, F. Perceptions and Role of Tourist Destination Residents Compared to Other Event Stakeholders in a Small-Scale Sports Event. The Case of the FIS World Junior Alpine Ski Championships 2019 in Val di Fassa. Sustainability 2019, 11, 6909. [Google Scholar] [CrossRef]

- Bowen, H.R. Social Responsibilities of the Businessman; University of Iowa Press: Iowa, IA, USA, 2013; ISBN 1609381963. [Google Scholar]

- CSR Europe. New EU Definition on CSR Mirrors Enterprise 2020 Aspirations. Available online: https://www.csreurope.org/new-eu-definition-csr-mirrors-enterprise-2020-aspirations (accessed on 1 July 2019).

- Delmas, M.A.; Montes-Sancho, M.J. An Institutional Perspective on the Diffusion of International Management System Standards: The Case of the Environmental Management Standard ISO 14001. Bus. Ethics Q. 2011, 21, 103–132. [Google Scholar] [CrossRef]

- Sundström, A.; Ahmadi, Z.; Mickelsson, K. Implementing Social Sustainability for Innovative Industrial Work Environments. Sustainability 2019, 11, 3402. [Google Scholar] [CrossRef]

- US EPA. Sources of Greenhouse Gas Emissions. Available online: https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions (accessed on 30 June 2019).

- Cefic aisbl, C. Facts & Figures of the European Chemical Industry; European Chemical Industry Council: Brussels, Belgium, 2018; p. 10. [Google Scholar]

- The Chemical Industry. Available online: http://www.essentialchemicalindustry.org/the-chemical-industry/the-chemical-industry.html (accessed on 2 August 2019).

- Novak, L. Bez Chemie Není Život; Technik—Business Media CZ: Prague, Czech Republic, 2015; p. 34. [Google Scholar]

- United Nations. Economic Commission for Europe. Inland Transport Committee. In Regulation (EC) No 1907/2006 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02006R1907-20140410 (accessed on 16 June 2020).

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: New York, NY, USA, 1998; p. 30. [Google Scholar]

- Ruiz-Real, J.L.; Uribe-Toril, J.; De Pablo Valenciano, J.; Gázquez-Abad, J.C. Worldwide Research on Circular Economy and Environment: A Bibliometric Analysis. Int. J. Environ. Res. Public Health 2018, 15, 2699. [Google Scholar] [CrossRef] [PubMed]

- Uribe-Toril, J.; Ruiz-Real, J.L.; Milán-García, J.; de Pablo Valenciano, J. Energy, Economy, and Environment: A Worldwide Research Update. Energies 2019, 12, 1120. [Google Scholar] [CrossRef]

- SusChem. Historie ČTP SusChem—Česká Technologická Platforma SusChem. Available online: https://www.suschem.cz/o-ctp-suschem/historie-ctp-suschem.html (accessed on 23 January 2019).

- SusChem. Technologický Foresight Chemického Průmyslu ČR v Kontextu Globálního Vývoje. Available online: https://www.suschem.cz/images/dokumenty/Technologicky_foresight_CTP_SusChem_2019_04.pdf (accessed on 16 June 2020).

- Liteplo, R.; Gomes, R.; Canada, H.; Howe, P.; Malcolm, H. Environmental Health Criteria 227. Fluorides; World Health Organization: Geneva, Switzerland, 2002. [Google Scholar]

- US EPA. Risk Information System Division, Fluorine (Soluble Fluoride); (CASRN 7782-41-4). Available online: https://cfpub.epa.gov/ncea/iris/iris_documents/documents/subst/0053_summary.pdf (accessed on 16 June 2020).

- Masia, S. Grip and Glide: A Short History of Ski Wax. Available online: https://www.skiinghistory.org/history/grip-and-glide-short-history-ski-wax (accessed on 23 January 2019).

- Tylenda, C.A. Toxicological Profile for Fluorides, Hydrogen Fluoride, and Fluorine (Update); U.S. Department of Health and Human Services—Agency for Toxic Substances and Disease Registry: Atlanta, GA, USA, 2003.

- Weinstein, L.H. Fluoride and plant life. J. Occup. Med. 1977, 19, 49–78. [Google Scholar] [CrossRef] [PubMed]

- Mezghani, I.; Elloumi, N.; Abdallah, F.B.; Chaieb, M.; Boukhris, M. Fluoride accumulation by vegetation in the vicinity of a phosphate fertiliser plant in Tunisia. Fluoride 2005, 38, 69–75. [Google Scholar]

- Vike, E. Uptake, deposition and wash off of fluoride and aluminium in plant foliage in the vicinity of an aluminium smelter in Norway. Water Air Soil Pollut. 2005, 160, 145–159. [Google Scholar] [CrossRef]

- Baunthiyal, M.; Bhatt, A.; Ranghar, S. Fluorides and its effects on plant metabolism. Int. J. Agric. Technol. 2014, 10, 1–27. [Google Scholar]

- Fornasiero, R.B. Phytotoxic effects of fluorides. Plant Sci. 2001, 161, 979–985. [Google Scholar] [CrossRef]

- NIOSH CDC. NIOSH Pocket Guide to Chemical Hazards—Hydrazine. Available online: https://www.cdc.gov/niosh/npg/npgd0289.html (accessed on 22 May 2019).

- Masia, S. Alpine Ski Maintenance and Repair; Contemporary Books: Chicago, IL, USA, 1987; ISBN 0809247186. [Google Scholar]

- Breitschädel, F.; Lund, Ø.; Løset, S. Cross country ski base tuning with structure imprint tools. In Procedia Engineering; Elsevier: Amsterdam, The Netherlands, 2010; Volume 2, pp. 2907–2911. [Google Scholar]

- Karlsson, N.P.E.; Laurell, H.; Lindgren, J.; Pehrsson, T.; Andersson, S.; Svensson, G. A cross-country comparison and validation of firms’ stakeholder considerations in sustainable business practices. Corp. Gov. 2018, 18, 408–424. [Google Scholar] [CrossRef]

- Knight, R. Boulder Nordic Sport (BNS); Natron Nordic Enterprises: Boulder, CO, USA, 2010; pp. 13–29. [Google Scholar]

- Dominator Educational Series—Wax Science Demystified. Available online: http://www.dominatorwax.com/technical-education (accessed on 13 April 2019).

- Walters, A.; Santillo, D. Uses of Perfluorinated Substances. Greenpeace Research Laboratories Technical Note 06/2006. Available online: http://www.greenpeace.to/publications_pdf/usesof-perfluorinated-chemicals.pdf (accessed on 16 June 2020).

- Jensen, A.A.; Poulsen, P.B.; Bossi, R. Survey and Environmental/Health Assessment of Fluorinated Substances in Impregnated Consumer Products and Impregnating Agents; University of Aarhus: Aarhus, Denmark, 2008. [Google Scholar]

- American Cancer Society. Teflon and Perfluorooctanoic Acid (PFOA). What Are Teflon and PFOA; ACS: Atlanta, GA, USA, 2018; pp. 1–5. [Google Scholar]

- US EPA. Health Effects Support Document for Perfluorooctanoic Acid (PFOA). Available online: https://www.epa.gov (accessed on 16 June 2020).

- Burmann, T. Race Guide Nordic; HOLMENKOL: Ludwigsburg, Germany, 2019. [Google Scholar]

- Waxing Irons|Star Ski Wax. Available online: https://www.starskiwax.com/laboratory/waxing-iron/ (accessed on 15 June 2019).

- Fujii, S.; Polprasert, C.; Tanaka, S.; Lien, N.P.H.; Qiu, Y. New POPs in the water environment: Distribution, bioaccumulation and treatment of perfluorinated compounds—A review paper. J. Water Supply Res. Technol. AQUA 2007, 56, 313–326. [Google Scholar] [CrossRef]

- Hekster, F.M.; Laane, R.W.P.M.; De Voogt, P. Environmental and toxicity effects of perfluoroalkylated substances. Rev. Environ. Contam. Toxicol. 2003, 179, 99–121. [Google Scholar] [CrossRef] [PubMed]

- Freberg, B.I.; Olsen, R.; Daae, H.L.; Hersson, M.; Thorud, S.; Ellingsen, D.G.; Molander, P. Occupational exposure assessment of airborne chemical contaminants among professional ski waxers. Ann. Occup. Hyg. 2014, 58, 601–611. [Google Scholar] [CrossRef][Green Version]

- Commission Regulation (EC) No 2017/1000, of 13 June 2017. EUR-Lex-32017R1000-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32017R1000 (accessed on 4 July 2019).

- Commission Regulation (EC) No 552/2009, of 22 June 2009. EUR-Lex-32009R0552-EN-EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32009R0552 (accessed on 4 July 2019).

- Øfsti, A.W. Holmenkollen er full av gift—NRK Viten—Nyheter Innen Vitenskap Og Forskning. Available online: https://www.nrk.no/viten/holmenkollen-er-full-av-gift-1.12658377 (accessed on 16 August 2019).

- Chropeňová, M.; Karásková, P.; Kallenborn, R.; Gregušková, E.K.; Čupr, P. Pine needles for the screening of perfluorinated alkylated substances (PFASs) along ski tracks. Environ. Sci. Technol. 2016, 50, 9487–9496. [Google Scholar] [CrossRef]

- Duglio, S.; Beltramo, R. Environmental Management and Sustainable Labels in the Ski Industry: A Critical Review. Sustainability 2016, 8, 851. [Google Scholar] [CrossRef]

- Zbuchea, A.; Pinzaru, F. Tailoring CSR Strategy to Company Size? Manag. Dyn. Knowl. Econ. 2017, 5, 415–437. [Google Scholar] [CrossRef]

- Survio. Ski Industry Companies. Available online: https://my.survio.com/T6H2J5T6V5J3E9F1X5T2/designer (accessed on 5 July 2019).

- Cramér, H. Mathematical Methods of Statitics; Princeton University Press: Princeton, NJ, USA, 1946; ISBN 9780691005478. [Google Scholar]

- Lock, I.; Seele, P. Analyzing sector-specific CSR reporting: Social and environmental disclosure to investors in the chemicals and banking and insurance industry. Corp. Soc. Responsib. Environ. Manag. 2015, 22, 113–128. [Google Scholar] [CrossRef]

- Svermova, P. The Environmental Pillar of CSR and Company Management. In International Conference on Science, Social Sciences and Management; ISTDS (The Institute of Science, Technology & Development Studies): Dubai, UAE, 2018. [Google Scholar]

- Plinke, E. The Sarasin Industry Rating: Methodology and Results of Sector Sustainability Analysis; Sarasin Bank: Basel, Switzerland, 2006. [Google Scholar]

- Graver, H.P. Business enterprises and the environmental information act in Norway. Front. Law China 2017, 12, 3–23. [Google Scholar] [CrossRef]

- European Commission. Corporate Social Responsibility—National Public Policies in the European Union; Office for Official Publications of the European Communities: Luxembourg City, Luxembourg, 2007. [Google Scholar]

- Ditlev-Simonsen, C.D.; von Weltzien Hoivik, H.; Ihlen, Ø. The Historical Development of Corporate Social Responsibility in Norway; Springer: Cham, Switzerland, 2015; pp. 177–196. [Google Scholar]

- Midttun, A.; Gjølberg, M.; Kourula, A.; Sweet, S.; Vallentin, S. Public Policies for Corporate Social Responsibility in Four Nordic Countries: Harmony of Goals and Conflict of Means. Bus. Soc. 2015, 54, 464–500. [Google Scholar] [CrossRef]

- Tøffest uten Fluor. Available online: https://toffestutenfluor.wordpress.com/om-oss/ (accessed on 15 August 2019).

- Adams, S. Alaska High Schools Call a “Wax Truce”—FasterSkier.com. Available online: https://fasterskier.com/fsarticle/alaska-high-schools-call-a-wax-truce/ (accessed on 5 July 2019).

- Herz, N. After Acquisition, Changes at Swix and Toko Will Be Behind the Scenes. Available online: https://fasterskier.com/fsarticle/after-acquisition-changes-to-swix-and-toko-will-be-behind-the-scenes/ (accessed on 6 July 2019).

- Swix. Code of Conduct. Available online: http://www.swixsport.com/Environment/society-responsibility/node_1638 (accessed on 25 January 2019).

- Swix. Skivoks og miljø. Available online: https://www.swix.no/no/barekraft/helse-og-miljo/skivoks-og-miljo (accessed on 30 January 2019).

- Robinson, M. How Do Skis Ski, and How Do Nanomaterials Make Skiing More Fun? Available online: http://sustainable-nano.com/2017/02/21/nanomaterials-make-skiing-more-fun (accessed on 13 September 2019).

| 3 Pillars (According to Assumptions) | Importance of Individual Factors of CSR | YES | Mostly YES | Maybe | Mostly NO | NO |

|---|---|---|---|---|---|---|

| Environmental pillar | Environmental protection (gentler production, waste sorting, etc.) | 100% | 0% | 0% | 0% | 0% |

| Social pillar | Customer service (loyalty programs, after-sales service, website accessibility, barrier-free shops, etc.) | 50% | 37.5% | 12.5% | 0% | 0% |

| Quality of products and services at an appropriate price | 12.5% | 37.5% | 50% | 0% | 0% | |

| Clear and accurate product or service information | 0% | 62.5% | 37.5% | 0% | 0% | |

| Code of Advertising compliance (true, decent and honest advertising) | 50% | 37.5% | 12.5% | 0% | 0% | |

| Cooperation with non-profit organizations in marketing activities | 37.5% | 50% | 12.5% | 0% | 0% | |

| Employee development, sophisticated evaluation and remuneration system, work-life balance, etc. | 50% | 37.5% | 12.5% | 0% | 0% | |

| Solvency towards suppliers, state and employees | 0% | 75% | 25% | 0% | 0% | |

| Economic pillar | Corporate foundations or endowment funds | 12.5% | 50% | 37.5% | 0% | 0% |

| Donorship (financial and non-financial donations to interest groups) | 0% | 62.5% | 25% | 12.5% | 0% |

| Q2-1 Environmental protection (gentler production, waste sorting, etc.) | ||||||||

| Q2-2 Customer service (loyalty programs, after-sales service, web site accessibility, barrier-free shops) | ||||||||

| Q2-3 Quality of products and services at an appropriate price | ||||||||

| Q2-4 Clear and accurate product or service information | ||||||||

| Q2-5 Code of advertising compliance (true, decent and honest advertising) | ||||||||

| Q2-6 Cooperation with non-profit organizations in marketing activities | ||||||||

| Q2-7 Corporate foundations or endowment funds (financial support for charitable activities) | ||||||||

| Q2-8 Donorship (financial and non-financial donations to interest groups) | ||||||||

| Q2-9 Employee development, sophisticated evaluation and remuneration system, work-life balance, etc. | ||||||||

| Q2-10 Solvency towards suppliers, state, employees | ||||||||

| A | Q2-3 | Q2-4 | Q2-5 | Q2-6 | Q2-7 | Q2-8 | Q2-9 | Q2-10 |

| Q2-2 | 0.55 | 0.42 | −0.03 | 0.07 | 0.78 | −0.13 | −0.03 | −0.10 |

| Q2-3 | 0.70 | 0.55 | 0.20 | 0.60 | 0.38 | 0.29 | 0.52 | |

| Q2-4 | 0.79 | 0.68 | 0.54 | 0.55 | 0.79 | 0.75 | ||

| Q2-5 | 0.61 | 0.32 | 0.64 | 0.74 | 0.73 | |||

| Q2-6 | 0.30 | 0.27 | 0.61 | 0.65 | ||||

| Q2-7 | 0.34 | 0.09 | 0.28 | |||||

| Q2-8 | 0.64 | 0.82 | ||||||

| Q2-9 | 0.73 | |||||||

| B | Q2-3 | Q2-4 | Q2-5 | Q2-6 | Q2-7 | Q2-8 | Q2-9 | Q2-10 |

| Q2-2 | −0.50 | −1.00 | −1.00 | −1.00 | 0.50 | −0.87 | −1.00 | −1.00 |

| Q2-3 | 0.50 | 0.50 | 0.50 | −1.00 | 0.00 | 0.50 | 0.50 | |

| Q2-4 | 1.00 | 1.00 | −0.50 | 0.87 | 1.00 | 1.00 | ||

| Q2-5 | 1.00 | −0.50 | 0.87 | 1.00 | 1.00 | |||

| Q2-6 | −0.50 | 0.87 | 1.00 | 1.00 | ||||

| Q2-7 | 0.00 | −0.50 | −0.50 | |||||

| Q2-8 | 0.87 | 0.87 | ||||||

| Q2-9 | 1.00 | |||||||

| C | Q2-3 | Q2-4 | Q2-5 | Q2-6 | Q2-7 | Q2-8 | Q2-9 | Q2-10 |

| Q2-2 | 0.82 | 0.90 | 0.52 | 0.17 | 0.82 | 0.17 | 0.52 | 0.17 |

| Q2-3 | 0.90 | 0.87 | 0.52 | 1.00 | 0.52 | 0.17 | 0.52 | |

| Q2-4 | 0.58 | 0.58 | 0.90 | 0.58 | 0.58 | 0.58 | ||

| Q2-5 | 0.33 | 0.87 | 0.33 | −0.33 | 0.33 | |||

| Q2-6 | 0.52 | 1.00 | 0.33 | 1.00 | ||||

| Q2-7 | 0.52 | 0.17 | 0.52 | |||||

| Q2-8 | 0.33 | 1.00 | ||||||

| Q2-9 | 0.33 | |||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Svermova, P.; Cernik, M. Corporate Social Responsibility of Companies Producing PFOA Containing Waxes for Cross-Country Skiing. Sustainability 2020, 12, 5141. https://doi.org/10.3390/su12125141

Svermova P, Cernik M. Corporate Social Responsibility of Companies Producing PFOA Containing Waxes for Cross-Country Skiing. Sustainability. 2020; 12(12):5141. https://doi.org/10.3390/su12125141

Chicago/Turabian StyleSvermova, Pavla, and Miroslav Cernik. 2020. "Corporate Social Responsibility of Companies Producing PFOA Containing Waxes for Cross-Country Skiing" Sustainability 12, no. 12: 5141. https://doi.org/10.3390/su12125141

APA StyleSvermova, P., & Cernik, M. (2020). Corporate Social Responsibility of Companies Producing PFOA Containing Waxes for Cross-Country Skiing. Sustainability, 12(12), 5141. https://doi.org/10.3390/su12125141