Design Guidelines Developed from Environmental Assessments: A Design Tool for Resource-Efficient Products

Abstract

:1. Introduction

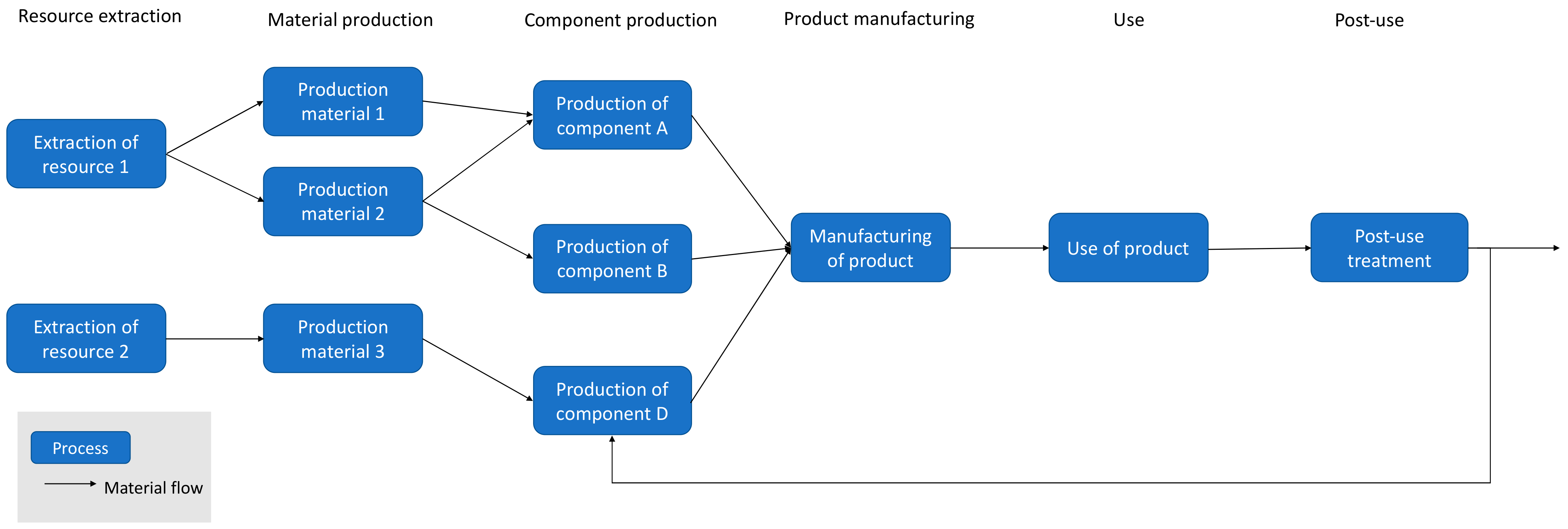

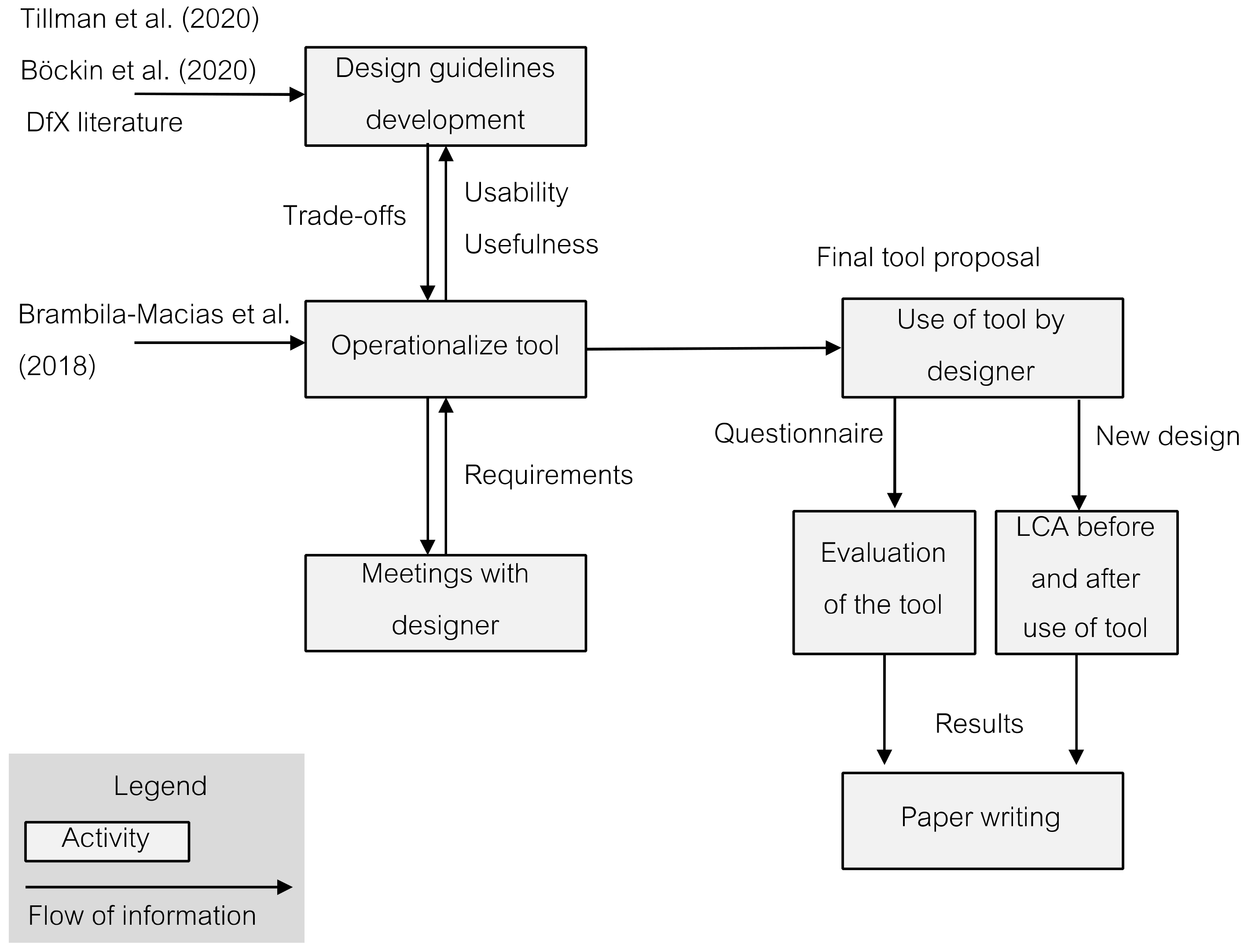

2. Methods

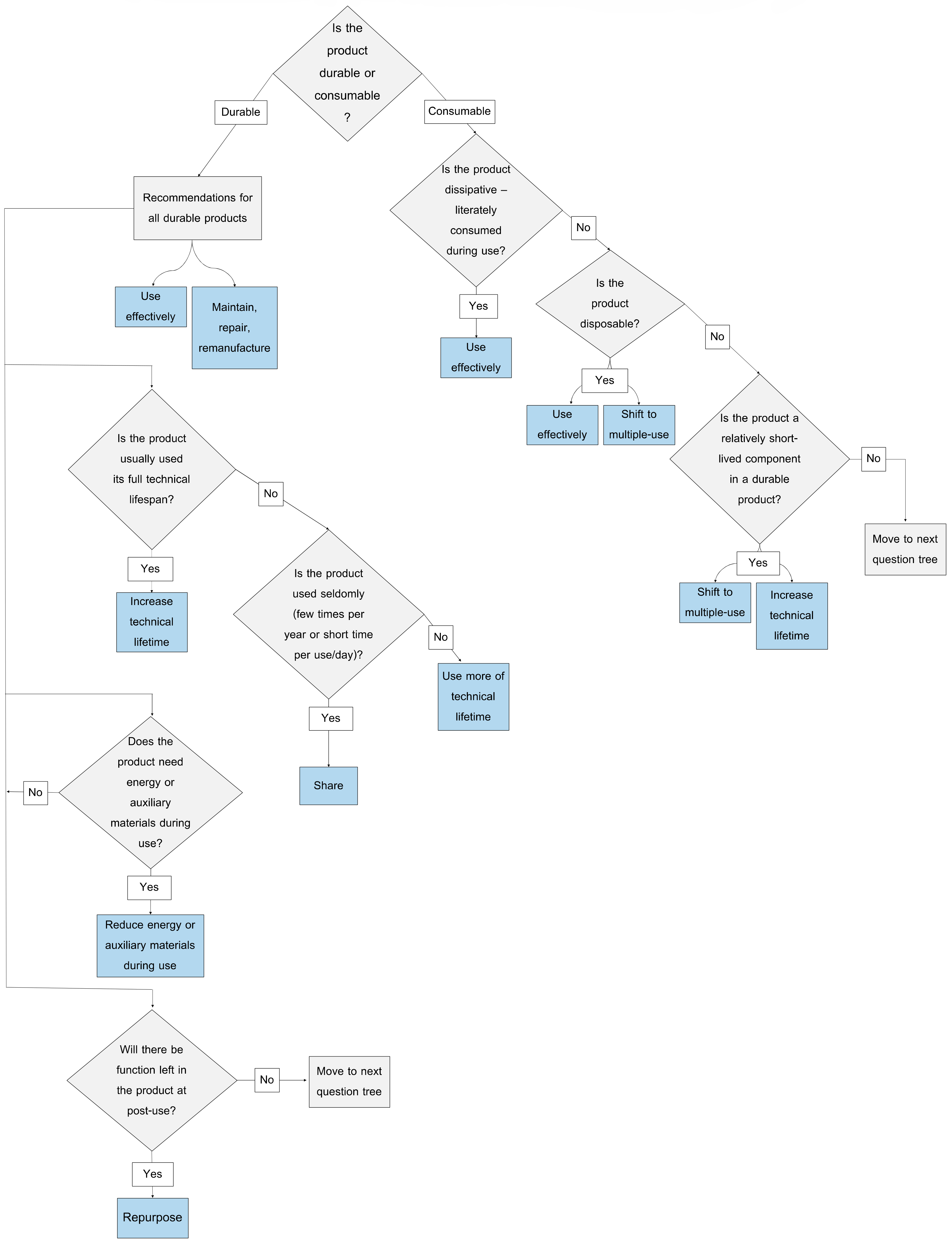

3. Design Guideline Tool

3.1. Tool Overview

3.2. Guidelines for Durable Products

3.2.1. General Guidelines for Durable Products

3.2.2. Products That Are Seldom Replaced

3.2.3. Products Typically Discarded before Wearing Out

3.2.4. Products Infrequently Used and Typically Discarded before Being Worn Out

3.2.5. Active Products

3.2.6. Function Partly Remains Post-Use

3.3. Guidelines for Consumable Products

3.3.1. Dissipative Products

3.3.2. Disposable Products and Components

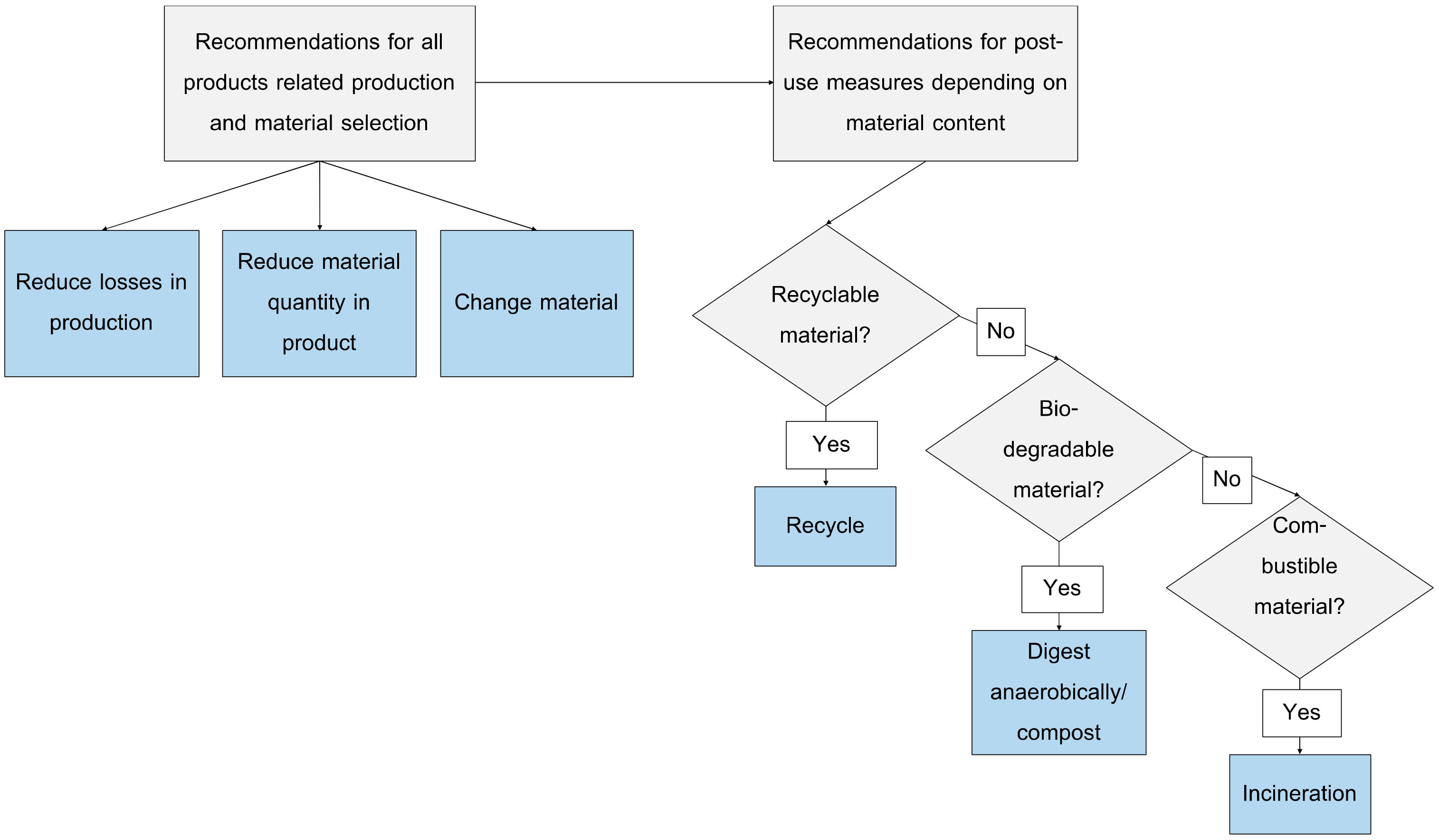

3.4. Guidelines for All Products

3.5. Guidelines for Post-Use Measures

4. Tool Evaluation

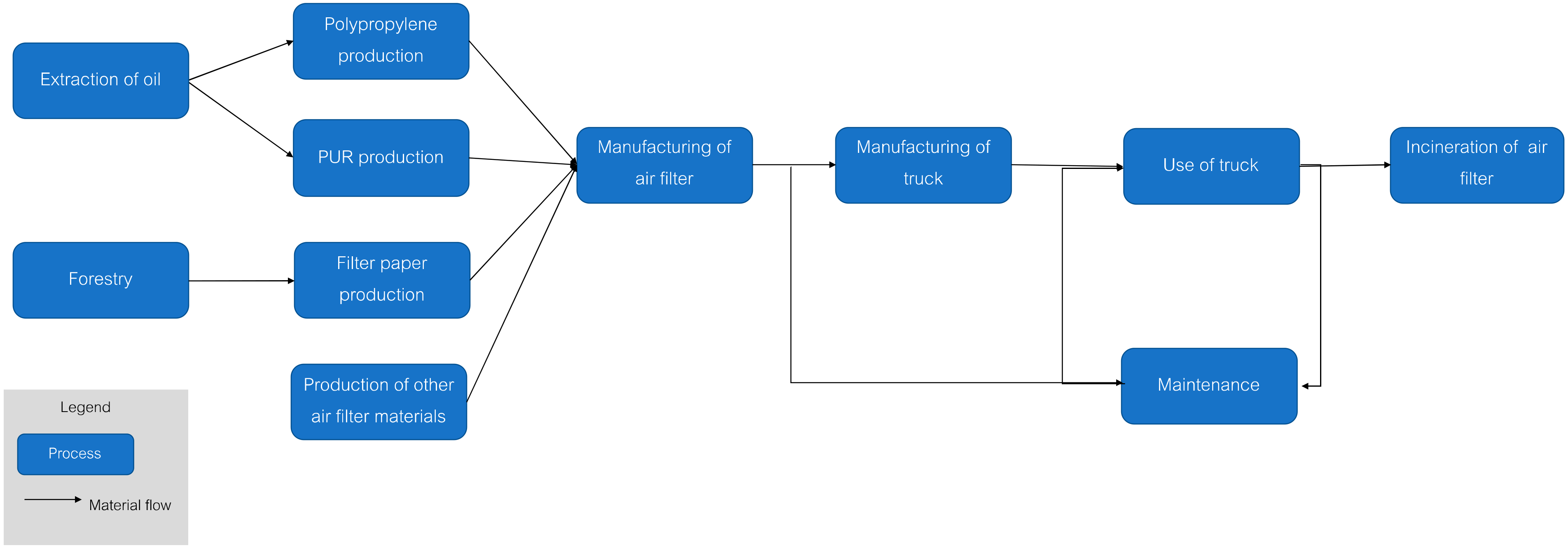

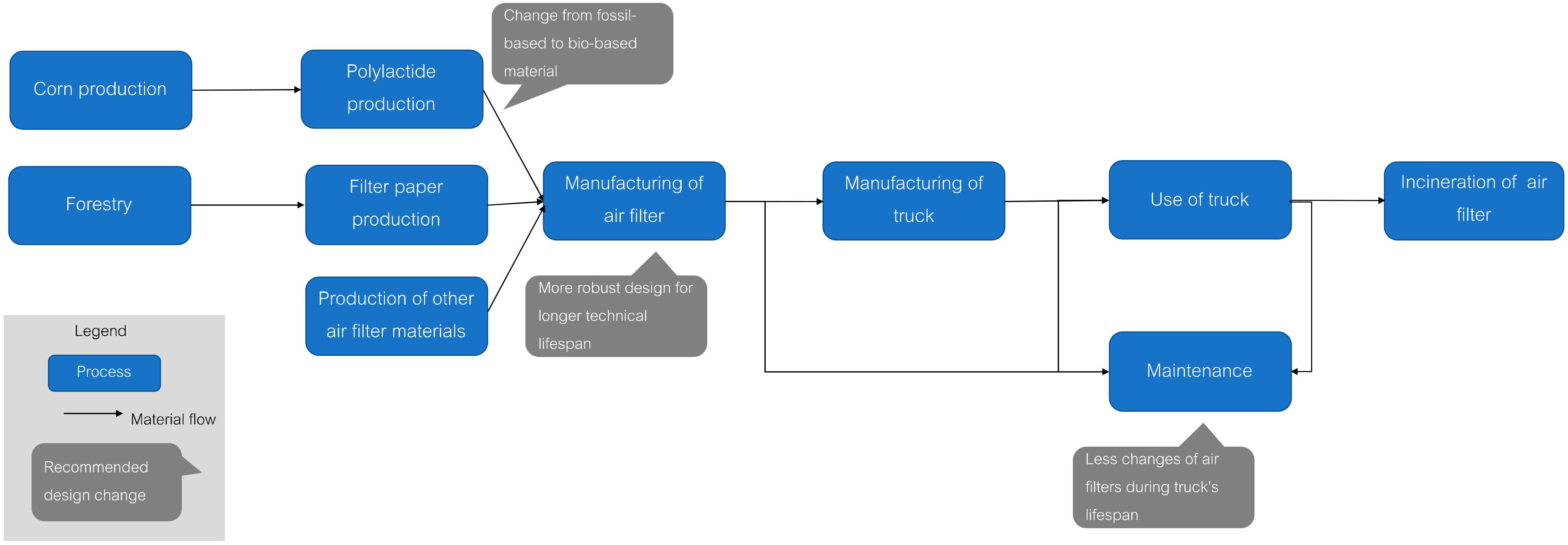

4.1. During Use

4.2. After-Use

4.2.1. LCA

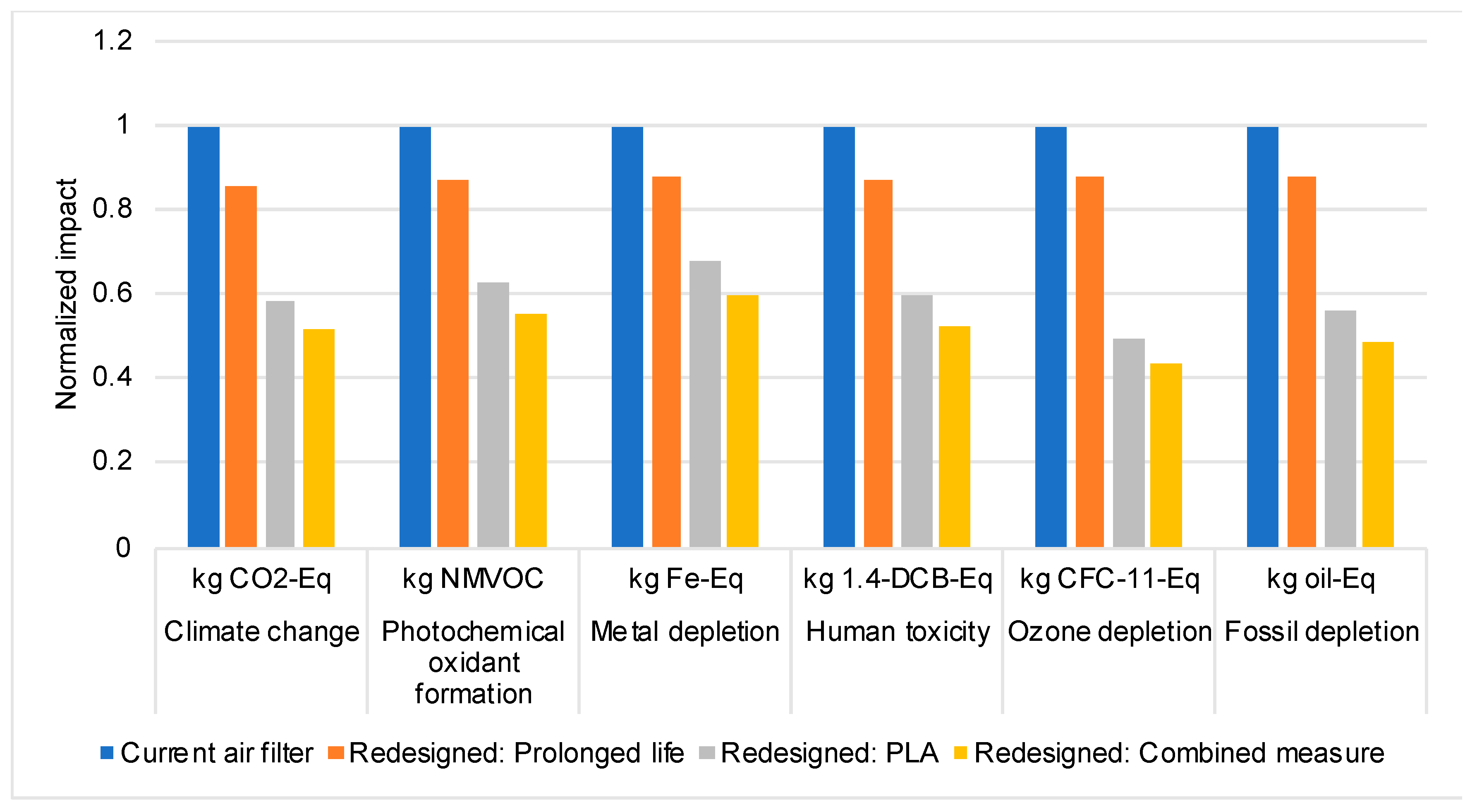

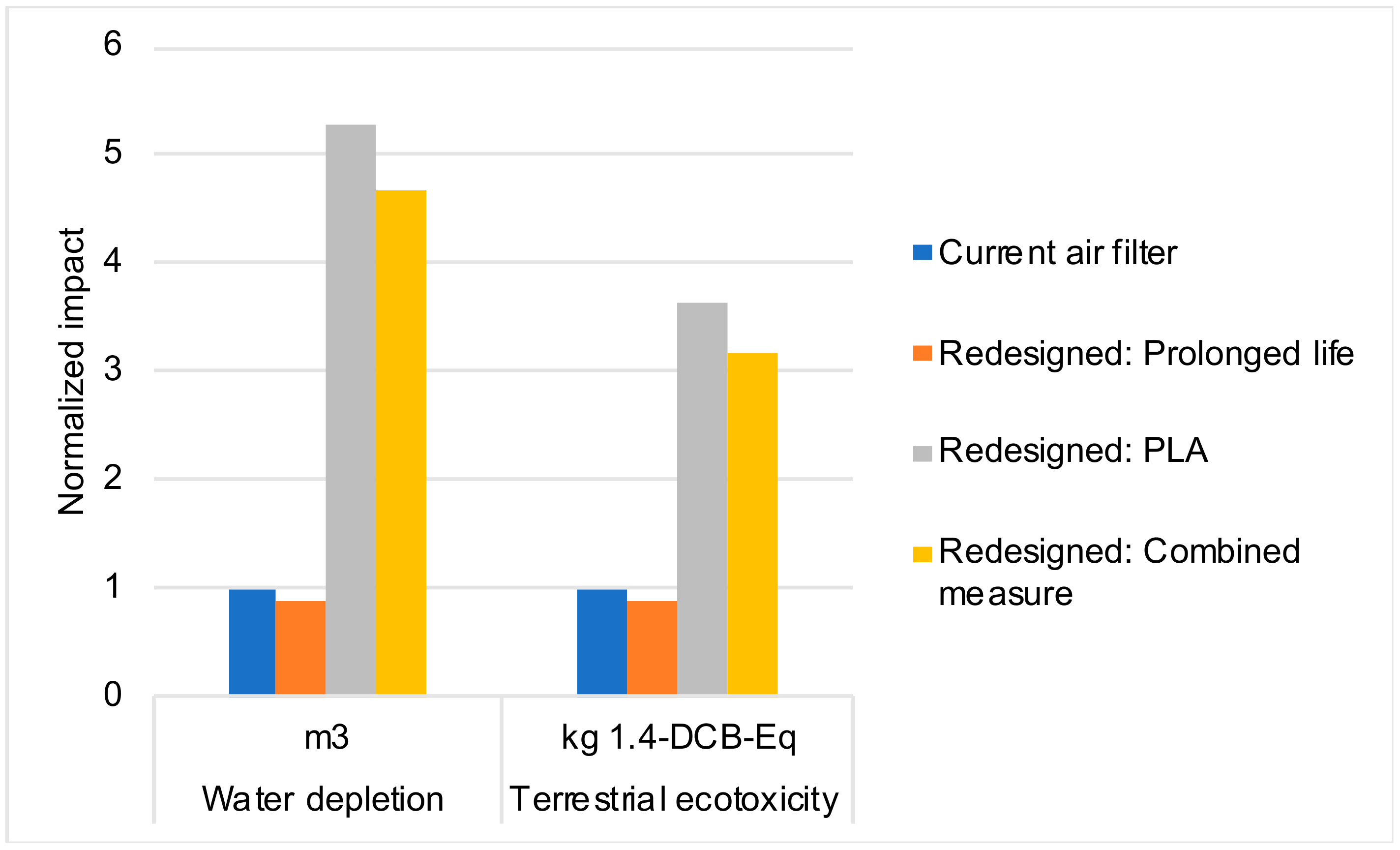

4.2.1.1. Impact Assessment Result

5. Discussion

5.1. Comparison with Other Tools and Methods

5.1.1. Ranking

5.1.2. Trade-Offs

5.1.3. Design Measures

- Use effectively: user-centered design and design for sustainable behavior through information, functionality matching, eco-feedback, forced functionality, portion control, and enable using all of the product;

- Maintain, repair, remanufacture: error-proofed design to enable desired behavior and reduce mistakes during use;

- Reduce the use of energy and auxiliary materials: eco-feedback;

- Increase lifespan of product: design for attachment and trust;

- Use for full technical lifespan: design for attachment, enable personalization and adaptability;

- Sharing: user-centered design in terms of understanding the requirements for sharing a product/willingness to share and error-proofed design; and

- Shift to multiple use: design for attachment.

5.1.4. Product Types

5.2. Practical Contributions

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Product Characteristic | Example Products | Recommended Design Measure | Example Measures | Potential Environmental Trade-Offs | Design Considerations |

|---|---|---|---|---|---|

| Durable products, irrespective of other characteristics | Machines, buildings, vehicles, furniture, household appliances, electronics and components thereof, clothes | Use effectively | Deliver/acquire only needed function, use for intended purpose, avoid losses using use | No identified trade-offs | User-centered design (understand how the user will use the product) e.g., functionality matching of user and product by design products with only needed function and not over-specifying |

| Maintain, repair, remanufacture | Maintain: inspect, maintain, and protect before failure Repair after wear, malfunction, or failure Remanufacture: restore product to functional state as good as new (or better) | – Maintenance, repair, and remanufacture can increase transportation – Products designed for disassembly may use more material – Benefits of longer use vs. impact from sensors For active products with technological development towards use-phase efficiency: – Use-phase efficiency vs. benefits of use extension | – Design for disassembly (particularly important for complex products), e.g., use standardized joins, minimize connectors, modular design, use fasteners instead of adhesives – Design “out” the need for maintenance by identifying possible failures and through error proof design (user cannot make mistakes) to reduce wear and tear – Design maintenance system (e.g., for energy efficiency, for preventive maintenance, and for easy and effective maintenance) | ||

| Durable products, typically used for full technical lifetime | Vehicles, machines, household appliances and their components, furniture | Increase technical lifetime by design | Products and components designed to last longer | – Durability vs. amount (or impact) of materials For active products with technological development towards use-phase efficiency: – Use-phase efficiency vs. benefits of use extension | – Design for durability (more material, more robust material) – Design for remanufacturing (make sure the product can be remanufactured) – Design for maintenance (improve the maintenance of the product) – Design for upgradability (make sure that the product can be upgraded and adapted to new needs of the user during the lifetime. If the product is active, this could be important to avoid trade-off where an inefficient product (in terms of energy use) is kept used for a long time |

| Durable products, typically discarded before being worn out | Furniture, household appliances, electronics, clothes | Use more of technical lifetime, including reuse | Use for longer by the same user and/or second-hand sales | – Second-hand sales risk inducing transportation out-weighing benefits of reuse For active products with technological development towards use-phase efficiency: – Use-phase efficiency vs. benefits of use extension | Design to avoid non-technical obsolescence: – Timeless design (avoid fashion trends) – Design for attachment: consumers exert considerable influence upon product lifespans, and may attach emotions to products; promote quality – Design for upgradability (e.g., modular design or disassemble to upgrade function or performance) – Design for adaptability (possibility to change design or functions during use) |

| Durable products, typically discarded before being worn out and infrequently used | Vehicles, washing machines, tools, clothes | Share | Use regularly by several users, e.g., clothes, library, rented tools, communal washing machines | Sharing can increase transportation for users accessing the shared stock | – Design for more robust and easier to use product and uniform design – Design for easy maintenance (e.g., modular design or disassembly) – User centered design (understand the requirements for sharing a product) – Error proof design (user cannot make mistakes) to reduce wear and tear |

| Durable products, active | Machines, buildings, vehicles, household appliances, electronics and active components thereof (for vehicles also passive components) | Reduce use of auxiliary materials and energy during use (use efficiently) | Energy efficient machines, vehicles, electronics, etc., energy- and water-efficient buildings and household appliances, e.g., turn off equipment when not in use, eco-driving | – Reduced use-phase impact vs. increased production-phase impact – Reduced use-phase impact vs. impact from sensors in cases when required | – Design for energy efficiency – Design for reduced consumption of auxiliary materials (e.g., water, detergents, lubricants) – Design for light weight (vehicles and machines) – Designs that promote efficient use of auxiliary materials and energy use (e.g., sensors and control units, eco-mode programs, monitoring and information) – Design for upgrading (if fast efficiency development, this is important) |

| Durable products for which function partly remains when no longer usable for original purpose | Automotive batteries, electronics | Repurpose | Reuse in a function other than the original one, e.g., reuse of automotive batteries for stationary energy storage | For active products with technological development towards use-phase efficiency: – Use-phase efficiency vs. benefits of use extension | – Design for disassembly – Design for cascades (plan for second life use of product/component) – Communication of specification to producer of repurposed product important (e.g., mark components with its content, provide information) |

| Product Characteristic | Example Products | Recommended Design Measure | Example Measure | Potential Environmental Trade-Offs | Design Considerations |

|---|---|---|---|---|---|

| Dissipative products | Food, fuels, water, electricity, cleaning agents | Use effectively | Deliver only needed function, avoid losses using use (e.g., smart dispensing), use for intended purpose, increase functionality to improve system efficiency (e.g., detergents allowing lower washing temperature and fuel additive increasing engine efficiency) | – Reduced use-phase impact vs. production of sensors in cases when required – Chemicals with higher functionality vs. risk of more hazardous constituents | – Design for smart distribution: – Packaging sizes – Packaging shape (possibility to empty packaging) – Smart dispensing (e.g., foam soap) – User-centered design (understand how the user will use the product and how resource waste can be reduced) – Designs that promote effective use (e.g., sensors and control units) – Error-proof design (user cannot make mistakes) and thus reduce losses |

| Disposable products | Single-use items, e.g., tissues, packaging, hygiene products. Disposable components in durable products, e.g., ink cartridges, single-use batteries, disposable machine components | Use effectively | Deliver/acquire only needed function, avoid losses using use (e.g., smart dispensing), use for intended purpose | – Reduced use-phase impact vs. production of sensors in cases when required | – User-centered design (understand how the user will use the product and how resource waste can be reduced) – Designs that enable correct use – User recommendations/ information – Indicators for remaining level – Smart dispensing (e.g., one napkin at the time) – Designs that promote effective use (e.g., sensors and control units) – Error-proof design (user cannot make mistakes) and thus reduce losses |

| Shift to multiple-use product | Reusable, e.g., washable, rechargeable, and refillable products | – Benefits from multiple use vs. increased impact from production and maintenance/cleaning, including transportation | – Redesign for multiple use (more durable product and handle maintenance) – Design for attachment: consumers exert considerable influence upon product lifespans, and may attach emotions to products which ensures that the product will be used for a long time; promote quality – Design for hygiene: the multiple-use product feels and is hygienic to reuse – Design maintenance system (energy efficient both in terms of maintenance activity) |

| Recommended Design Measure | Example Measures | Potential Environmental Trade-Offs | Design Considerations |

|---|---|---|---|

| Reduce losses in production (including valorizing by-product streams) | Reduce scrap rates and other material losses in production, increase energy efficiency in production, valorize by-product energy and material flows, internally (process integration) or externally (industrial symbiosis) | – Reduced losses of material in production vs. energy use for avoiding losses | Design for manufacturing: – Use operation materials with a long lifetime – Increase the material and energy efficiency of actions in the process, e.g., reduce losses due to leakage. – Close material and energy loops for water, solvents – Technology optimization (implement new technologies, improve process control, redesign processes) – Industrial symbiosis (one industry’ uses another industry’s waste/by-products as resource) Product design for reduced impact in production: – Avoiding complex product structure and many details to reduce losses when cutting materials |

| Reduce material quantity in product without material substitution | Thinner layers of specific materials, non-massive designs, e.g., truss and shell structures | – Risk for losing function, e.g., durability – Benefit of removing water vs impact of removing water for the concentrate | – Dematerialization (use less material for a specific function) – “Take out water” to reduce packaging material and impacts from transport – Design out the need for packaging |

| Change material in product | Change to/increase share of: – Bio-based material – Bio-degradable material – Recycled material Substitute/decrease share of: – Scarce materials – Hazardous constituents | – Risk for burden-shifting when substituting material – Changing material is often a precondition for other measures, e.g., use-phase efficiency or increased lifetime. Potential trade-off between the benefits of the enabled measure and impact of the new material | – Consider recycling implications during material selection: avoid hazardous materials; make sure scarce/ critical are easily liberated in recycling – Products made from fossil-based materials—change to bio-based – Attention needed to where and how biomaterial is cultivated and harvested to avoid land use-related impacts – Products that risk uncontrolled dispersion (littering, dissipative use of consumables, degradation of surfaces): use biodegradable and non-hazardous materials |

| Product Characteristic | Recommended Design Measure | Useful Output | Potential Environmental Trade-Offs | Design Considerations |

|---|---|---|---|---|

| All products, except consumables, used in a dissipative manner. Relevant in particular for products with significant impacts from material production | Recycle material | Recycled material | – Impacts from recycling need to be smaller than impacts from alternative material production – Risk of keeping hazardous substances in circulation | Design for recycling: – Few or uniform materials (locate same materials together) – Avoid molding or fusing incompatible materials – Easily liberated materials, e.g., use snap fits instead of adhesives – Easy to disassemble (no adhesive) |

| Biodegradable products | Digest anaerobically | Biogas, digestate (complete fertilizer and soil enhancer) | – Impacts from digestion need to be smaller than avoided impact from alternative production of its products – Risk of keeping hazardous substances in circulation | Requires whole product to be made from biodegradable materials, or/unless the non-biological material is easy to separate before treatment |

| Biodegradable products | Compost | Soil enhancer | – Impacts from composting need to be smaller than avoided impact from alternative production of its products (e.g., soil enhancers) – Risk of keeping hazardous substances in circulation | Requires whole product to be made from biodegradable materials, or/unless the non-biological material is easy to separate before treatment |

| Combustible products | Incinerate with energy recovery | Heat and/or electricity | – Impacts from incineration need to be smaller than avoided impact from alternative production of its products | – Strive for completely combustible products to reduce slag – Design for disassembly (separate parts to recycle and parts to combust) – Avoid hazardous metals (end up in flue gases and slag) – Avoid halogens (creates hazardous flue gases) |

| Dissipatively used products, collected as waste in sewers | Treat wastewater | Biogas, heat, sludge containing plant nutrients | – Impacts from digestion need to be smaller than avoided impact from alternative production of its products – Risk of introduction of hazardous substances in the food chain – Risk of dispersion of pathogens | Design that make sure only things that are supposed to end up in toilets end up there |

| All products and/or residues from other post-use processes | Landfill and control | Landfill gas, long term material source | Landfill impacts versus sink for carbon, materials, and hazardous substances |

| Design Measures | Definition | Sources |

|---|---|---|

| Industrial symbiosis | – Use by-products or waste from other companies as raw material – Generate by-products or waste that can be reused as raw material by other companies – Take advantage of other companies’ utilities in the production process (share utilities, e.g., energy, heat, and steam) | Mantesea, et al. [50] |

| Cleaner production | Production efficiency through optimization of productive use of natural resources (materials, energy, water) at all stages of the production cycle. General examples: – Use less of hazardous raw, auxiliary, or operating materials – Use operation materials with a longer lifetime – Increase the material and energy efficiency of actions in the process, e.g., reduce losses due to leakage – Close material and energy loops for water, solvents, etc. – Cascading of material and energy streams – Technology optimization (implement new technologies, improve process control, redesign processes) Minimizing energy consumption during pre-production and production: – Select materials with low energy intensity – Select processing technologies with the lowest energy consumption possible – Use energy-efficient machinery – Use the heat emitted in processes for preheating other determined process flows – Engage pump and motor speed regulators with dynamic configuration – Equip the machinery with smart power-off utilities – Optimize the overall dimensions of engines – Facilitate engine maintenance – Define accurately the tolerance parameters – Optimize the volumes of required batch; optimize transportation systems and scale down the weight and dimensions of all transportable materials and semi-products – Engage in efficient heating, illumination, and ventilation in buildings | Vezzoli [14] |

| Design for manufacturing and assembly | Design for manufacture and assembly (DFMA) was born after design for manufacturing (DFM) and design for assembly. DFA has been used by many companies around the world to develop product designs that use optimal manufacturing and assembly processes. The development of DFMA started in the 1990s with research into automatic assembly (DFA). The main goal is to minimize part count and reorientation of parts, standardize parts, encourage modular design, emphasize top-down assemblies, design for component symmetry, design parts with self-aligning and fastening features, and design parts for retrieval, handling, and insertion. Hence, DFA implies to: – Minimize the number of components – To simplify and reduce the number of manufacturing operations to use standard parts and materials – To design for efficient joining, for ease of part fabrication, for ease of packaging, and for ease of assembly – To use common parts across product lines, flexible components, and modular design – To eliminate or reduce adjustment required | Benabdellah, et al. [49] |

| Dematerialization | Dematerialization can be accomplished by more efficient use of a given material for a given function. | Karlsson [51] |

| Design for maintenance | Enable ease of maintenance. The process of product maintenance ensures the smooth performance of equipment, often at the cost of equipment downtime. Products that are easy to maintain, entail less downtime. Some guidelines are: – Accessibility: simplify access to and disassembly of components to be maintained. All equipment and subassemblies that require routine inspections should be located such that they can be accessed in a readily and easy manner. Additionally, they should be fitted with parts that can be connected rapidly to mechanical, air, electric, and electronic connections. Avoid narrow slits and holes to facilitate access for cleaning – Modularity: modularity requires grouping functionally similar parts into subassemblies, which then can be put together to form the product. Prearrange and facilitate the substitution of short-lived components. Effective modularization can be achieved only if interfaces are standard – Simplicity: simpler designs are inherently easier to maintain. Simplicity can be achieved by reducing the number of different parts or reducing the part variety – Standardization: allows for the easy replacement of faulty components. It also assures designers of a certain quality level – Fool proofing: precautions should be devised to prevent fitting to the wrong assembly – Inspectability: there should be an attempt to create a design that can be subjected to full, non-destructive, functional testing. Equip products with diagnostic and/or auto-diagnostic systems for maintainable components – Other: design products for easy on-site maintenance. Design complementary maintenance tools and documentation. Design products that need less maintenance | Chiu and Kremer [73], Desai and Mital [40] and Vezzoli [14] |

| Design for durability | Designing for appropriate lifespan, e.g.: – Design component with coherent lifespans, select the most appropriate materials and shapes to preserve performance in relationship with the foreseen usage conditions – Design equally useful lives for the different components – Design the lifespan of replaceable components according to scheduled durability – Enable separation of different components – Select durable materials according to product performance and lifespan Designing for reliability, e.g.: – Reduce overall number of components – Simplify products and eliminate weak links – Facilitate upgrading and adaptability (see design for upgrading and design for adaptability) – Facilitate maintenance (see design for maintenance) – Facilitate reuse (see design for reuse) – Facilitate repair and remanufacture (see design for remanufacturing) | Vezzoli [14] |

| Design for disassembly | It is NOT the exact opposite or a reversal of the assembly process. Some proposed guidelines include: – Product structure: create a modular design; minimize the component count; optimize component standardization; minimize product variants – Materials: minimize the use of different materials; use recyclable materials; eliminate toxic or hazardous materials – Fasteners, joints and connections: minimize the number of joints and connections; make joints visible and accessible; eliminate hidden joints; use joints that are easy to disassemble; mark non-obvious joints; use fasteners rather than adhesives – Characteristics of components for disassembly: good accessibility, low weight; robust; minimize fragile parts; non-hazardous; preferably unpainted – Disassembly conditions: design for automated disassembly; eliminate the need for specialized disassembly procedures; Design for disassembly with simple and standard tools | Bogue [38] |

| Design for remanufacturing | The usual product activities are: clean core, strip core (disassembly), clean components, remanufacture components, store components, build product (assembly), and test product Product features and guidelines facilitating remanufacturing: – Smooth surfaces – Corrosion resistance. However, this will depend on the materials, as some coating materials may peel, leaving debris that may damage components – Non-adhesive surfaces. However, it may be difficult to maintain the integrity of such surfaces – Design for excessive use of material for easily deteriorating surfaces – Design and facilitate the removal and substitution of easily expendable components, e.g., threaded fasteners and ‘‘breakable snap fits’’ – Design structural parts that can be easily separated from external/visible ones, e.g., through modularity – Novel disassembly techniques, e.g., soluble or shape memory fasteners – Easy to replace degrading elements to better deal with mechanical wear and aesthetic damage – Standard parts, ease of component condition identification and parts with ‘‘extra material’’ for rework and cascading parts – Provide easier access to components to be re-manufactured – Calculate accurate tolerance parameters for easily expendable connections – Design for excessive use of materials in places more subject to deterioration | Ijomah, et al. [39] and Vezzoli [14] |

| Design for upgrading | Products that fast become technologically obsolete can maintain their validity (remain in usage) by means of exchanging the parts that have become obsolete. Upgrading leaves the product up to date with technology but saves many components that do not have to be substituted – Enable and facilitate software and hardware upgrading – Design products that are upgradeable and adaptable onsite – Design complementary tools and documentation for product upgrading and adaptation | Vezzoli [14] |

| Design for energy efficiency | Design to reduce energy consumption during production and use by using more energy efficient components (light weight for vehicles) and processes, to ensure rapid warm up and power down – Minimize energy consumption during pre-production and production (see Cleaner production) – Minimize energy consumption during transportation and storage (design compact products with high storage density; scale down product and packaging weight; design concentrated products; equip products with on-site assembly) – Select the most efficient energy consumption systems during use – Enable a variable consumption of energy, to follow demand fluctuations – Minimize energy consumption during product development | Arnette, et al. [44] and Vezzoli [14] |

| Design for adaptability | Adaptability is understood in relation to the changing environment in which the product could be working continuously, as well as the various stages of physical and cultural evolution of individuals. Because of this, it is sound to design the products to be flexible, modular, and with dynamical dimensions, performance, and aesthetics. – Design modular and dynamically configured products to facilitate their adaptability for changing environments – Design multifunctional and dynamically configured products to facilitate their adaptability for the changing of individuals’ cultural and physical backgrounds – Design products that are upgradeable and adaptable onsite – Design complementary tools and documentation for product upgrading and adaptation | Vezzoli [14] |

| User-centered design | Based on Norman’s psychology of design, the following are some guidelines for products that are easy to use: – Build conceptual models, write manuals that are easily understood and that are written before the design is implemented – Make things visible: the user should be able to figure out the use of an object by seeing the right buttons or devices for executing an operation – Get the mappings right. One way to make things understandable is to use graphics. – Exploit the power of constraints, both natural and artificial, in order to give the user the feeling that there is one thing to do – Design for error. Plan for any possible error that can be made, this way the user will be allowed the option of recovery from any possible error made. Design mistake prevention into the process. Design mistake detection into the process. Design the process to fail safely. Design a work environment that prevents errors – When all else fails, standardize. Create an international standard if something cannot be designed without arbitrary mappings Error-proof design, also called “poka-yoke”, means reducing the potential for mistakes during use, thus reducing wear and tear, and ultimately repair and maintenance by: – Lock-ins, lockouts, and interlocks to prevent errors from occurring and by making it difficult to proceed until an error has been corrected – Warnings such as lights, information displays, and reminders that inform users of errors and desired behavior | Abras, et al. [46] |

| Lockton, et al. [41] | ||

| Design for sustainable behavior | For design for sustainable behavior: – Motivating behavior: motivating users to change behavior by education, incentives, and changing attitudes – Enabling behavior: enabling “desirable” behavior by making it easier for the user than the alternatives – Constraining behavior: constraining users to “desirable” behavior by making alternatives difficult or impossible – Make it easier for people to adopt a desired behavior – Make it harder for people to perform undesired behavior – Make people want a desired behavior – Make people not want an undesired behavior Thus, there are two main approaches to reduce environmental impacts during the use phases of functionality matching and behavior adaptation: – Functionality matching: aims at eliminating mismatches between delivered functionalities and desired functionalities. Redundant functionalities have an unnecessary impact, while missing functionalities can trigger unwanted behavior, with subsequent unsustainable effects. – Behavior adaptation by eco-feedback, scripting and forced functionality Eco-feedback: the user is presented with specific information on the impact of his or her current behavior, and it is left to the user to relate this information to his or her own behavior, and adapt this behavior, or not. Scripting: the product is designed in such a way that the design triggers the sustainable use by either creating hinderances for unsustainable use, or by making sustainable behavior so easy, it is performed almost without thinking about it by the user. Forced functionality: refers to either intelligent products that adapt automatically to changing circumstances, or to designing in strong hinderances to prevent unsustainable behavior. | Niedderer, et al. [47] |

| Wever, et al. [37] | ||

| Design for attachment | This is also called emotionally durable design, which strengthens the relationship between user and product to increase the product lifetime. Design products that evoke enjoyment, or facilitate the formation of associations between products and people, places, or events (memories): – Designs that enable product personalization – Designing products that age with dignity – Designs that allow the user to capture memories | Ceschin and Gaziulusoy [16] |

| Design for reuse | Reuse of a product “as-is” or harvesting working parts and components for reuse: – Increase the resistance of easily damaged and expendable components – Arrange and facilitate access to and removal of retrievable components – Design modular and replaceable components – Design components according to standards to facilitate substitution – Design reusable auxiliary parts – Design refillable and re-usable packaging – Design products for secondary use | Vezzoli [14] |

| Design for cascades | Adopting a cascade approach means pre-planning and designing the route of the component or material from one product or component to another, each with lower requirements. This strategy is based on the presupposition that, in comparison with primary raw materials, the recycled materials will inevitably lose some of their characteristics, either for economic or technological reasons. Therefore, we can imagine a route for cyclical recycling where materials are employed for components with gradually lower requirements. | Vezzoli [14] |

| Design for recycling | These guidelines affect the efficiency of the recycling process. They must be integrated in the conceptual design stage and applied simultaneously with the requirements of manufacturing, maintainability, reliability, and other design objectives. Some of the guidelines include: – Criteria regarding individual components and materials: avoid hazardous and otherwise environmentally harmful materials. Avoid materials and components incompatible with standard recycling processes. Prefer materials that can be reutilized easily. Allow for the reuse of recycled components. Minimize the number of different incompatible materials. Select materials that easily recover after recycling the original performance characteristics. Avoid composite materials or, when necessary, choose easily recyclable ones. Engage geometrical solutions, like ribbing, to increase polymer stiffness instead of reinforcing fibers – Criteria regarding disassembly operations: use joining elements that are easy to disassemble between subassemblies consisting of incompatible materials. Design easily accessible joining elements. Protect joining elements from corrosion and wear. Avoid the need of destructive disassembly techniques if they produce sharp edges. Facilitate cleaning – Criteria regarding the product as a whole: minimize the variety of materials. Minimize the number and variety of joining elements. Make harmful and valuable components/materials easily accessible – Criteria relevant to logistics: provide information relevant to recycling, for example, material content, disassembly procedures, available recycling options and processes, etc. Design the product in a way that it can be transported easily after usage, i.e., by allowing pre-disassembly. Encourage the consumers to begin the recycling process. Facilitate end-of-life collection and transportation. – Adopt the cascade approach: design by taking into consideration the secondary use of the materials once recycled. Arrange and facilitate the recycling of materials into components with lower mechanical requirements. Arrange and facilitate the recycling of materials into components with lower aesthetical requirements. Arrange and facilitate energy recovery from materials throughout combustion. | Kriwet, et al. [53] and Vezzoli [14] |

| Product service system | An integrated product and service offering that delivers value in use through customized solutions. For example, power by the hour, where a user pays for the outcome of a solution. | Vezzoli [14] |

Appendix B

Appendix B1. Feedback from the Designer

Appendix B2. Questionnaire for Evaluating Design Guideline Tool

- 1)

- How important is sustainability in your work?

- 2)

- How important is resource efficiency/circular economy in your work?

- 3)

- How many years have you been working with design?

- 4)

- How many years have you been working with eco-design?

- 5)

- What type of tools (both eco-design and others) do you usually use in your current work?

- 6)

- In short, how does your current process of developing a new product concept look like?

- 7)

- If you are to develop a more sustainable and resource efficient product concept, how do you usually decide which concept to go for?

- 1)

- How familiar were you with the design recommendations?

- 2)

- How informed were you about the trade-offs?

- 3)

- How relevant were the design recommendations?

- 4)

- How satisfied are you with the generated solution concepts from the application of the tool?

- 5)

- What were your expectations?

- 6)

- How easy was it to understand the tool during use?

- 7)

- How understandable were the design recommendations?

- 8)

- How understandable were the trade-offs?

- 9)

- How likely is it for you to incorporate the tool in your common design practice?

Appendix B3. Tool Evaluation: Before Use

References

- Meadows, D.H.; Meadows, D.l.; Randers, J.; Behrens, W.W., III. Limits to Growth; Universe Books: New York, NY, USA, 1972; Volume 102. [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- EMF. Towards the Circular Economy. Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Publishers: The Hague, The Netherlands, 2017. [Google Scholar]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- EMF the Circular Design Guide. Available online: https://www.circulardesignguide.com/ (accessed on 20 November 2019).

- Pozo Arcos, B.; Balkenende, A.R.; Bakker, C.A.; Sundin, E. Product Design for a Circular Economy: Functional Recovery on Focus. In Proceedings of the DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 2727–2738. [Google Scholar]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef] [Green Version]

- Byggeth, S.; Hochschorner, E. Handling trade-offs in Ecodesign tools for sustainable product development and procurement. J. Clean. Prod. 2006, 14, 1420–1430. [Google Scholar] [CrossRef]

- Ljunggren Söderman, M.; André, H. Effects of circular measures on scarce metals in complex products–Case studies of electrical and electronic equipment. Resour. Conserv. Recycl. 2019, 151, 104464. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Vezzoli, C. Design for Environmental Sustainability, Life Cycle Design of Products; Springer: Berlin, Germany, 2018. [Google Scholar]

- Böckin, D.; Willskytt, S.; André, H.; Tillman, A.-M.; Ljunggren Söderman, M. How product characteristics can guide measures for resource efficiency–A synthesis of assessment studies. Resour. Conserv. Recycl. 2020, 154C, 104582. [Google Scholar] [CrossRef]

- Ceschin, F.; Gaziulusoy, I. Evolution of design for sustainability: From product design to design for system innovations and transitions. Des. Stud. 2016, 47, 118–163. [Google Scholar] [CrossRef]

- Wastling, T.; Charnley, F.; Moreno, M. Design for Circular Behaviour: Considering Users in a Circular Economy. Sustainability 2018, 10, 1743. [Google Scholar] [CrossRef] [Green Version]

- Bakker, C.; den Hollander, M.; Van Hinte, E.; ZljLstra, Y. Products that Last: Product Design for Circular Buisness Models; TU Delft Library: Delft, The Netherlands, 2014. [Google Scholar]

- Bakker, C.; Wang, F.; Huisman, J.; den Hollander, M. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Bovea, M.D.; Perez-Belis, V. Identifying design guidelines to meet the circular economy principles: A case study on electric and electronic equipment. J. Environ. Manage. 2018, 228, 483–494. [Google Scholar] [CrossRef]

- Telenko, C.; Seepersad, C.; Webber, M. A compilation of design for environment principles and guidelines. In Proceedings of the ASME 2008 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, Brooklyn, NY, USA, 3–6 August 2008. [Google Scholar]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policyand business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Lofthouse, V. Ecodesign tools for designers: Defining the requirements. J. Clean. Prod. 2006, 14, 1386–1395. [Google Scholar] [CrossRef] [Green Version]

- Lindahl, M. Engineering designers’ experience of design for environment methods and tools—Requirement definitions from an interview study. J. Clean. Prod. 2006, 14, 487–496. [Google Scholar] [CrossRef]

- Vallet, F.; Eynard, B.; Millet, D. Requirements and features clarifying for eco-design tools. In Global Product Development; Bernard, A., Ed.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Dekoninck, E.A.; Domingo, L.; O’Hare, J.A.; Pigosso, D.C.A.; Reyes, T.; Troussier, N. Defining the challenges for ecodesign implementation in companies: Development and consolidation of a framework. J. Clean. Prod. 2016, 135, 410–425. [Google Scholar] [CrossRef] [Green Version]

- Dickson, G.; Stolterman, E. Why Design Method Development is Not Always Carried Out as User-Centered Design. In Proceedings of the CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016; pp. 4056–4060. [Google Scholar]

- ISO. Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040:2006; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef] [Green Version]

- Bhamra, T.A.; Evans, S.; McAloone, T.C.; Simon, M.; Poole, S.; Sweatman, A. Integrating environmental decisions into the product development process. In I. The early stages. In Proceedings of the First International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 1–3 February 1999; IEEE: Tokyo, Japan, 1999; pp. 329–333. [Google Scholar]

- Tillman, A.-M.; Willskytt, S.; Böckin, D.; Andre, H.; Ljunggren Soderman, M. What circular economy measures fit what kind of product. In Draft Chapter in Handbook on the Circular Economy; Brandão, M., Lazaveric, D., Finnveden, G., Eds.; Edward Elgar Publishing Ltd.: Cheltenham, UK, 2020. [Google Scholar]

- Schöggl, J.-P.; Baumgartner, R.J.; Hofer, D. Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. J. Clean. Prod. 2017, 140, 1602–1617. [Google Scholar] [CrossRef]

- Poulikidou, S.; Björklund, A.; Tyskeng, S. Empirical study on integration of environmental aspects into product development: Processes, requirements and the use of tools in vehicle manufacturing companies in Sweden. J. Clean. Prod. 2014, 81, 34–45. [Google Scholar] [CrossRef]

- Brambila-Macias, S.A.; Sakao, T.; Lindahl, M. Requirements for REES Design Support: A Survey among Large Companies and SMEs; Linköping University Electronic Press: Linköping, Sweden, 2018. [Google Scholar]

- Luttropp, C.; Brohammer, G. EcoDesign Roadmap, 1st ed.; Studentlitteratur: Lund, Sweden, 2014. [Google Scholar]

- Brezet, H.; van Hemel, C. Ecodesign: A Promising Approach to Sustainable Production and Consumption; UNEP: Paris, France, 1997. [Google Scholar]

- Wever, R.; van Kuijk, J.; Boks, C. User-centred design for sustainable behaviour. Int. J. Sustain. Eng. 2008, 1, 9–20. [Google Scholar] [CrossRef]

- Bogue, R. Design for disassembly: A critical twenty-first century discipline. Assem. Autom. 2007, 27, 285–289. [Google Scholar] [CrossRef]

- Ijomah, W.L.; McMahon, C.A.; Hammond, G.P.; Newman, S.T. Development of design for remanufacturing guidelines to support sustainable manufacturing. Robot. Comput. -Integr. Manuf. 2007, 23, 712–719. [Google Scholar] [CrossRef]

- Desai, A.; Mital, A. Design for maintenance: Basic concepts and review of literature. Int. J. Prod. Dev. 2006, 3, 77–121. [Google Scholar] [CrossRef]

- Lockton, D.; Harrison, D.; Stanton, N. Making the user more efficient: Design for sustainable behaviour. Int. J. Sustain. Eng. 2008, 1, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Selvefors, A.; Rexfelt, O.; Renström, S.; Strömberg, H. Use to use—A user perspective on product circularity. J. Clean. Prod. 2019, 223, 1014–1028. [Google Scholar] [CrossRef]

- Mont, O. Reducing Life-Cycle Environmental Impacts through Systems of Joint Use. Green. Manag. Int. 2004, 2004, 63–77. Available online: https://www.jstor.org/stable/greemanainte.45.63 (accessed on 16 June 2020). [CrossRef]

- Arnette, A.N.; Brewer, B.L.; Choal, T. Design for sustainability (DFS): The intersection of supply chain and environment. J. Clean. Prod. 2014, 83, 374–390. [Google Scholar] [CrossRef]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Abras, C.; Maloney-Krichmar, D.; Preece, J. User-centered design. In Encyclopedia of Human-Computer Interaction; Bainbridge, W., Ed.; Sage Publications: Thousand Oaks, CA, USA, 2004; Volume 37, pp. 445–456. [Google Scholar]

- Niedderer, K.; Cain, R.; Clune, S.; Lockton, D.; Ludden, G.; Mackrill, J.; Morris, A. Creating Sustainable Innovation through Design for Behaviour Change: Full Project Report; University of Wolverhampton: Wolverhampton, UK, 2014. [Google Scholar]

- Lilley, D.; Lofthouse, V.; Bhamra, T. Towards instinctive sustainable product use. In Proceedings of the 2nd International Conference in Sustainability, Creating the Culture, Aberdeen, UK, 2–4 November 2005. [Google Scholar]

- Benabdellah, A.C.; Bouhaddou, I.; Benghabrit, A.; Benghabrit, O. A systematic review of design for X techniques from 1980 to 2018: Concepts, applications, and perspectives. Int. J. Adv. Manuf. Technol. 2019, 102, 3473–3502. [Google Scholar] [CrossRef]

- Mantesea, G.; Bianchia, M.; Amarala, D. The industrial symbiosis in the product development: An approach through the DFIS. In Procedia Manufacturing, Proceedings of the Manufacturing Engineering Society International Conference 2017, MESIC 2017, Vigo, Spain, 28–30 June; Elsevier: Amsterdam, The Netherlands, 2018; Volume 21, pp. 862–886. [Google Scholar]

- Karlsson, S. Man and Materials Flows, Towards Sustainable Materials Management; Sessions of the series A Sustainable Baltic Region; Umeå Universitet: Umeå, Sweden, 1997. [Google Scholar]

- Napper, I.E.; Thompson, R.C. Environmental Deterioration of Biodegradable, Oxo-biodegradable, Compostable, and Conventional Plastic Carrier Bags in the Sea, Soil, and Open-Air Over a 3-Year Period. Environ. Sci. Technol. 2019, 53, 4775–4783. [Google Scholar] [CrossRef] [PubMed]

- Kriwet, A.; Zussman, E.; Seliger, G. Systematic integration of design-for-recycling into product design. Int. J. Prod. Econ. 1995, 38, 15–22. [Google Scholar] [CrossRef]

- Jönsson, H.; Eklind, Y.; Albihn, A.; Jarvis, Å.; Kylin, H.; Nilsson, M.-L.; Nordberg, Å.; Pell, M.; Schnürer, A.; Schönning, C.; et al. Samhällets organiska avfall—en resurs i kretsloppet. Fakta Jordbr. Sammanfattar Aktuell Forsk. 2003, 1, 1–8. [Google Scholar]

- Salomon, E. Fakta om Komposterat Eller Rötat Matavfall som Fosforgödselmedel. SLU Nyh. 2016. Available online: https://www.slu.se/ew-nyheter/2016/9/fakta-om-komposterat-eller-rotat-matavfall-som-fosforgodselmedel/ (accessed on 16 June 2020).

- Ecoinvent Ecoinvent 3.5. Available online: https://www.ecoinvent.org/database/older-versions/ecoinvent-35/ecoinvent-35.html (accessed on 16 January 2020).

- Ciroth, A. ICT for environment in life cycle applications openLCA—A new open source software for life cycle assessment. Int. J. Life Cycle Assess. 2007, 12, 209–210. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; de Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008-A Life Cycle Impact Assessment Method which Comprises Harmonized Category Indicators at the Midpoint and the Endpoint Level/Report I: Characterisation; Ministerie van VROM: Den Haag, Netherlands, 2009. [Google Scholar]

- Willskytt, S.; Tillman, A.-M. Resource efficiency of consumables—Life cycle assessment of incontinence products. Resour. Conserv. Recycl. 2019, 144, 13–23. [Google Scholar] [CrossRef]

- Luttropp, C.; Lagerstedt, J. EcoDesign and The Ten Golden Rules: Generic advice for merging environmental aspects into product development. J. Clean. Prod. 2006, 14, 1396–1408. [Google Scholar] [CrossRef]

- Ameri, F.; Dutta, D. Product Lifecycle Management: Closing the Knowledge Loops. Comput. Aided Des. Appl. 2005, 2, 577–590. [Google Scholar] [CrossRef]

- Yousnadj, D.; Jouanne, G.; Maranzana, N.; Segonds, F.; Bouchard, C.; Aoussat, A. Integration of Environmental Assessment in a PLM Context: A Case Study in Luxury Industry. In Product Lifecycle Management for a Global Market. PLM 2014. IFIP Advances in Information and Communication Technology; Fukuda, S., Bernard, A., Gurumoorthy, B., Bouras, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 442. [Google Scholar]

- Gmelin, H.; Seuring, S. Determinants of a sustainable new product development. J. Clean. Prod. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Yang, C.J.; Chen, J.L. Accelerating preliminary eco-innovation design for products that integrates case-based reasoning and TRIZ method. J. Clean. Prod. 2011, 19, 998–1006. [Google Scholar] [CrossRef]

- Romli, A.; Setchi, R.; Prickett, P.; de la Pisa, M.P. Eco-design case-based reasoning tool: The integration of ecological quality function deployment and case-based reasoning methods for supporting sustainable product design. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 1778–1797. [Google Scholar] [CrossRef] [Green Version]

- Kolodner, J.L. An Introduction to Case-Based Reasoning. Artif. Intell. Rev. 1992, 6, 3–34. [Google Scholar] [CrossRef]

- Germani, M.; Mandolini, M.; Marconi, M.; Morbidoni, A.; Rossi, M. A Case-Based Reasoning Approach to Support the Application of the Eco-Design Guidelines. In Proceedings of the 20th CIRP International Conference on Life Cycle Engineering, Singapore, 17–19 April 2013. [Google Scholar]

- Vargas Hernandez, N.; Okudan Kremer, G.; Schmidt, L.C.; Acosta Herrera, P.R. Development of an expert system to aid engineers in the selection of design for environment methods and tools. Expert Syst. Appl. 2012, 39, 9543–9553. [Google Scholar] [CrossRef]

- Rossi, M.; Germani, M.; Zamagni, A. Review of ecodesign methods and tools. Barriers and strategies for an effective implementation in industrial companies. J. Clean. Prod. 2016, 129, 361–373. [Google Scholar] [CrossRef]

- Moreno, M.; Ponte, O.; Charnley, F. A Taxonomy of design strategies for a circular design tool. In Proceedings of the 2nd Conference on Product Lifetimes and the Environment, Delft, The Netherlands, 8–10 November 2017; pp. 275–279. [Google Scholar]

- Salari, M.; Bhuiyan, N. A new model of sustainable product development process for making trade-offs. Int. J. Adv. Manuf. Technol. 2016, 94, 1–11. [Google Scholar] [CrossRef]

- Chiu, M.C.; Kremer, G.E.O. Investigation of the applicability of Design for X tools during design concept evolution: A literature review. Int. J. Prod. Dev. 2011, 13, 132–167. [Google Scholar] [CrossRef] [Green Version]

- Kjaer, L.L.; Pigosso, D.C.A.; McAloone, T.C.; Birkved, M. Guidelines for evaluating the environmental performance of Product/Service-Systems through life cycle assessment. J. Clean. Prod. 2018, 190, 666–678. [Google Scholar] [CrossRef] [Green Version]

- Selvefors, A.; Strömberg, H.; Renström, S. What a designer can change: A proposal for a categorisation of artefact-related aspects. In Proceedings of the 2016 Design Research Society 50th Anniversary Conferance, Brighton, UK, 27–30 June 2016; pp. 1–17. [Google Scholar]

- Kuzmina, K.; Prendeville, S.; Walker, D.; Charnley, F. Future scenarios for fast-moving consumer goods in a circular economy. Futures 2019, 107, 74–88. [Google Scholar] [CrossRef]

- Charnley, F.; Walker, D.; Kuzmina, K. Fast-Moving Circular Goods 2025; The Nexus Network: Brighton, UK, 2015. [Google Scholar]

- Haffmans, S.; van Gelder, M.; Van Hinte, E.; Zijlstra, Y. Products that Flow: Circular Business Models and Design Strategies for Fast-Moving Consumer Goods; BIS Publisher: Amsterdam, The Netherlands, 2018. [Google Scholar]

| Materials and Mass (kg) | Current Air Filter | Redesigned Air Filter |

|---|---|---|

| Polyurethane (PUR) | 1.65 | |

| Polypropylene (PP) | 0.75 | |

| Paper filter | 0.9 | 1 |

| Polylactide (PLA) | 2.64 | |

| Absorbed particles during use | 2.5 | 3 |

| Incinerated mass | 5.8 | 6.63 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Willskytt, S.; Brambila-Macias, S.A. Design Guidelines Developed from Environmental Assessments: A Design Tool for Resource-Efficient Products. Sustainability 2020, 12, 4953. https://doi.org/10.3390/su12124953

Willskytt S, Brambila-Macias SA. Design Guidelines Developed from Environmental Assessments: A Design Tool for Resource-Efficient Products. Sustainability. 2020; 12(12):4953. https://doi.org/10.3390/su12124953

Chicago/Turabian StyleWillskytt, Siri, and Sergio A. Brambila-Macias. 2020. "Design Guidelines Developed from Environmental Assessments: A Design Tool for Resource-Efficient Products" Sustainability 12, no. 12: 4953. https://doi.org/10.3390/su12124953

APA StyleWillskytt, S., & Brambila-Macias, S. A. (2020). Design Guidelines Developed from Environmental Assessments: A Design Tool for Resource-Efficient Products. Sustainability, 12(12), 4953. https://doi.org/10.3390/su12124953