Pelletization of Refuse-Derived Fuel with Varying Compositions of Plastic, Paper, Organic and Wood

Abstract

:1. Introduction

2. Material and Methods

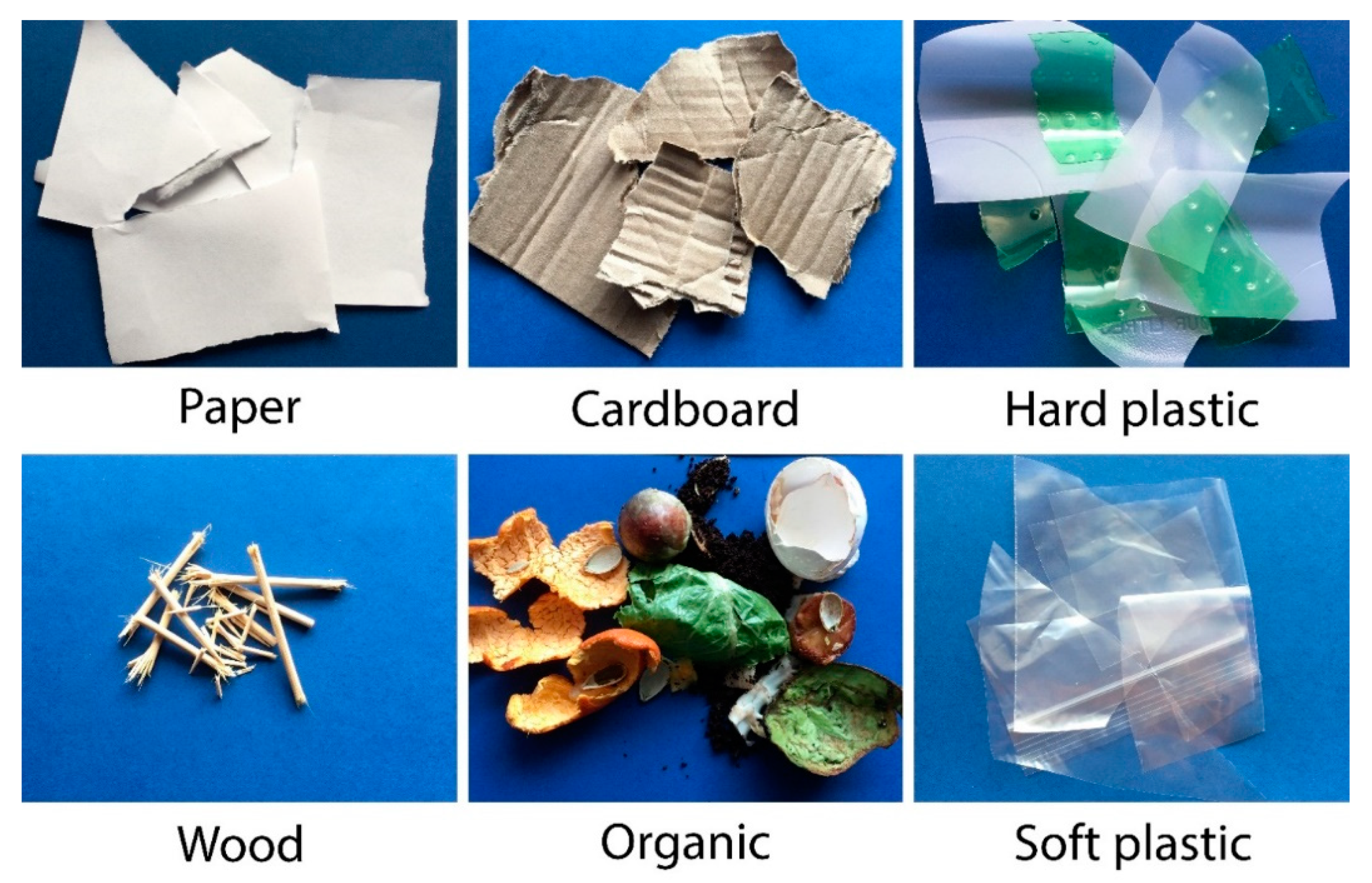

2.1. Preparation of RDF Compositions

2.2. Particle Size, Bulk Density, and Calorific Value

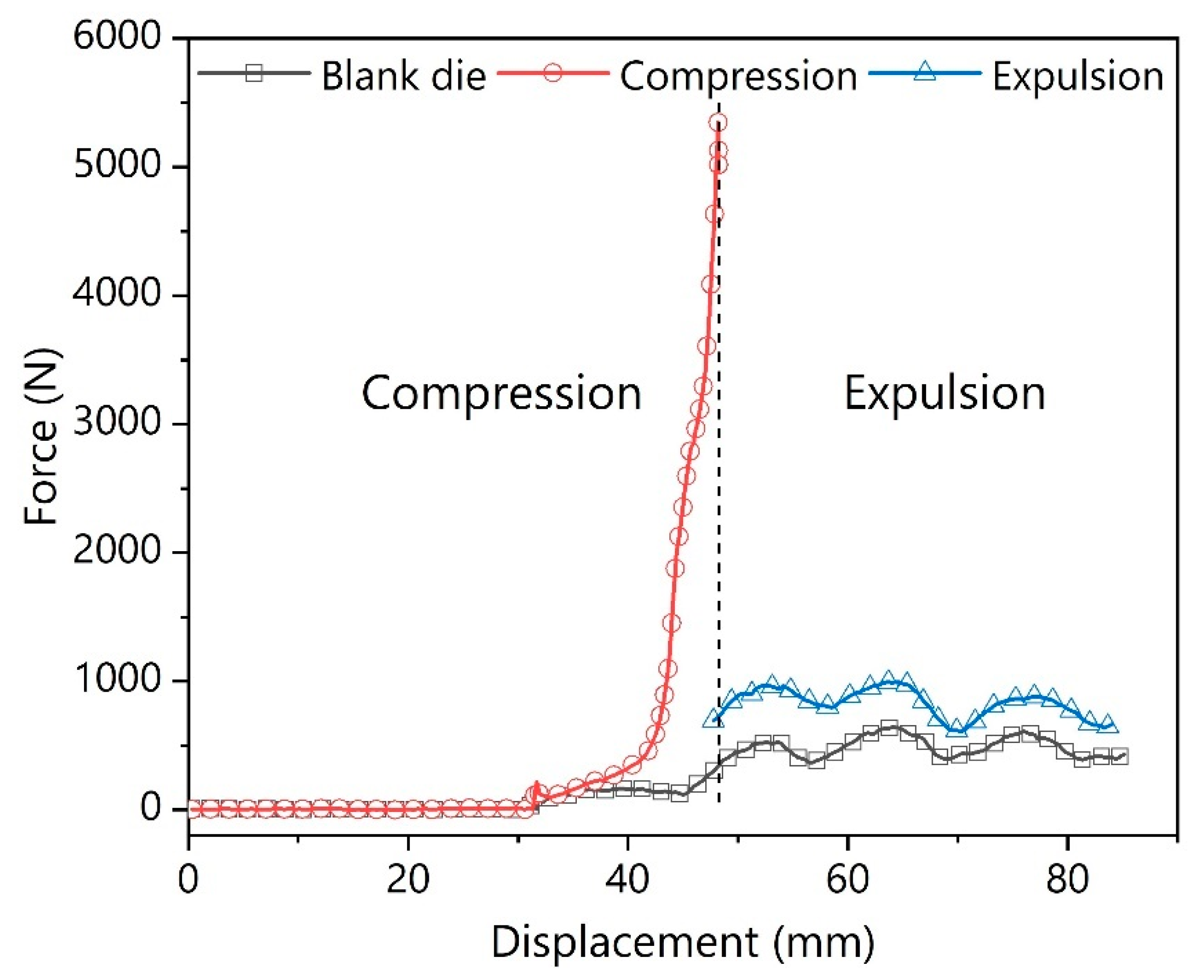

2.3. Pelletization

2.4. Pellet Durability

3. Results and Discussion

3.1. Ground Composition Characterization

3.2. RDF Compaction

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Caputo, A.C.; Pelagagge, P.M. RDF production plants: II Economics and profitability. Appl. Therm. Eng. 2002, 22, 439–448. [Google Scholar] [CrossRef]

- Sarc, R.; Lorber, K.E. Production, quality and quality assurance of Refuse Derived Fuels (RDFs). Waste Manag. 2013, 33, 1825–1834. [Google Scholar] [CrossRef] [PubMed]

- Alter, H. The “Recycling” of Densified Refuse-Derived Fuel. Waste Manag. Res. 1996, 14, 311–317. [Google Scholar] [CrossRef]

- Casado, R.R.; Rivera, J.A.; García, E.B.; Cuadrado, R.E.; Llorente, M.F.; Sevillano, R.B.; Delgado, A.P. Classification and characterisation of SRF produced from different flows of processed MSW in the Navarra region and its co-combustion performance with olive tree pruning residues. Waste Manag. 2016, 47, 206–216. [Google Scholar] [CrossRef] [PubMed]

- Grosso, M.; Dellavedova, S.; Rigamonti, L.; Scotti, S. Case study of an MBT plant producing SRF for cement kiln co-combustion, coupled with a bioreactor landfill for process residues. Waste Manag. 2016, 47, 267–275. [Google Scholar] [CrossRef]

- Tanigaki, N.; Ishida, Y.; Osada, M. A case-study of landfill minimization and material recovery via waste co-gasification in a new waste management scheme. Waste Manag. 2015, 37, 137–146. [Google Scholar] [CrossRef]

- Ayvaz-Cavdaroglu, N.; Coban, A.; Firtina-Ertis, I. Municipal solid waste management via mathematical modeling: A case study in İstanbul, Turkey. J. Environ. Manag. 2019, 244, 362–369. [Google Scholar] [CrossRef]

- Chang, Y.-H.; Chen, W.C.; Chang, N.-B. Comparative evaluation of RDF and MSW incineration. J. Hazard. Mater. 1998, 58, 33–45. [Google Scholar] [CrossRef]

- Rada, E.C. Present and future of SRF. Waste Manag. 2016, 47, 155–156. [Google Scholar] [CrossRef]

- Caputo, A.C.; Pelagagge, P.M. RDF production plants: I Design and costs. Appl. Therm. Eng. 2002, 22, 423–437. [Google Scholar] [CrossRef]

- Infiesta, L.R.; Ferreira, C.R.N.; Trovó, A.G.; Borges, V.L.; Carvalho, S.R. Design of an industrial solid waste processing line to produce refuse-derived fuel. J. Environ. Manag. 2019, 236, 715–719. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Li, Y.; Lou, X.; Guan, J.; Li, Y.; Mai, X.; Liu, H.; Zhao, C.X.; Wang, N.; Yan, C.; et al. Improved extraction of cobalt and lithium by reductive acid from spent lithium-ion batteries via mechanical activation process. J. Mater. Sci. 2018, 53, 13790–13800. [Google Scholar] [CrossRef]

- Tomasek, S.; Varga, Z.; Hancsók, J. Production of jet fuel from cracked fractions of waste polypropylene and polyethylene. Fuel Process. Technol. 2020, 197, 106197. [Google Scholar] [CrossRef]

- Alter, H. The history of refuse-derived fuels. Resour. Conserv. 1987, 15, 251–275. [Google Scholar] [CrossRef]

- Fyffe, J.R.; Breckel, A.C.; Townsend, A.K.; Webber, M.E. Use of MRF residue as alternative fuel in cement production. Waste Manag. 2016, 47, 276–284. [Google Scholar] [CrossRef]

- Georgiopoulou, M.; Lyberatos, G. Life cycle assessment of the use of alternative fuels in cement kilns: A case study. J. Environ. Manag. 2018, 216, 224–234. [Google Scholar] [CrossRef]

- Ko, A.S.; Chang, N.-B. Optimal planning of co-firing alternative fuels with coal in a power plant by grey nonlinear mixed integer programming model. J. Environ. Manag. 2008, 88, 11–27. [Google Scholar] [CrossRef]

- Seljak, T.; Katrašnik, T. Designing the microturbine engine for waste-derived fuels. Waste Manag. 2016, 47, 299–310. [Google Scholar] [CrossRef]

- Sever Akdağ, A.; Atımtay, A.; Sanin, F.D. Comparison of fuel value and combustion characteristics of two different RDF samples. Waste Manag. 2016, 47, 217–224. [Google Scholar] [CrossRef]

- Dunnu, G.; Maier, J.; Schnell, U.; Scheffknecht, G. Drag coefficient of Solid Recovered Fuels (SRF). Fuel 2010, 89, 4053–4057. [Google Scholar] [CrossRef]

- Soleimani, M.; Tabil, X.L.; Grewal, R.; Tabil, L.G. Carbohydrates as binders in biomass densification for biochemical and thermochemical processes. Fuel 2017, 193, 134–141. [Google Scholar] [CrossRef]

- Rezaei, H. Physical and Thermal Characterization of Ground Wood Chip and Ground Wood Pellet Particles. Ph.D. Thesis, University of British Columbia (UBC), Vancouver, BC, Canada, 2017. [Google Scholar]

- Larsson, S.H.; Lestander, T.A.; Crompton, D.; Melin, S.; Sokhansanj, S. Temperature patterns in large scale wood pellet silo storage. Appl. Energy 2012, 92, 322–327. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.T.; Lim, C.J.; Melin, S. Energy Input and Quality of Pellets Made from Steam-Exploded Douglas Fir (Pseudotsuga menziesii). Energy Fuels 2011, 25, 1521–1528. [Google Scholar] [CrossRef]

- Lam, P.Y.; Lam, P.S.; Sokhansanj, S.; Bi, X.T.; Lim, C.J.; Melin, S. Effects of pelletization conditions on breaking strength and dimensional stability of Douglas fir pellet. Fuel 2014, 117, 1085–1092. [Google Scholar] [CrossRef]

- Brigagão, G.V.; de Queiroz Fernandes Araújo, O.; de Medeiros, J.L.; Mikulcic, H.; Duic, N. A techno-economic analysis of thermochemical pathways for corncob-to-energy: Fast pyrolysis to bio-oil, gasification to methanol and combustion to electricity. Fuel Process. Technol. 2019, 193, 102–113. [Google Scholar] [CrossRef]

- Rajput, S.P.; Jadhav, S.V.; Thorat, B.N. Methods to improve properties of fuel pellets obtained from different biomass sources: Effect of biomass blends and binders. Fuel Process. Technol. 2020, 199, 106255. [Google Scholar] [CrossRef]

- Sprenger, C.J.; Tabil, L.G.; Soleimani, M.; Agnew, J.; Harrison, A. Pelletization of Refuse-Derived Fuel Fluff to Produce High Quality Feedstock. J. Energy Resour. Technol. 2018, 140, 042003. [Google Scholar] [CrossRef]

- Sprenger, C.; Tabil, L.G.; Soleimani, M. Compression and Relaxation Properties of Municipal Solid Waste Refuse-Derived Fuel Fluff. KONA Powder Part. J. 2018, 35, 200–208. [Google Scholar] [CrossRef] [Green Version]

- Rezaei, H.; Yazdanpanah, F.; Lim, C.J.; Sokhansanj, S. Pelletization properties of refuse-derived fuel—Effects of particle size and moisture content. Fuel Process. Technol. 2020, 205, 106437. [Google Scholar] [CrossRef]

- Bessi, C.; Lombardi, L.; Meoni, R.; Canovai, A.; Corti, A. Solid recovered fuel: An experiment on classification and potential applications. Waste Manag. 2016, 47, 184–194. [Google Scholar] [CrossRef]

- EPA Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2012; United States Environmental Protection Agency: Washington, DC, USA, 2012.

- Rezaei, H.; Sokhansanj, S. Physical and thermal characterization of ground bark and ground wood particles. Renew. Energy 2018, 129, 583–590. [Google Scholar] [CrossRef]

- Rezaei, H.; Lim, J.; Sokhansanj, S. Comparison of Drying Rates of Ground Western Red Cedar with Hemlock, Birch, Aspen and Spruce/Pine/Douglas Fir. Appl. Eng. Agric. 2020, 36, 159–165. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Rezaei, H.; Mandø, M.; Sokhansanj, S. Constitutive modelling of compression and stress relaxation in pine pellets. Biomass Bioenergy 2019, 130, 105370. [Google Scholar] [CrossRef]

- Schilling, C.; Wohler, M.; Yazdanpanah, F.; Bi, X.; Sokhansanj, S. Development of a Novel Wood Pellet Durability Tester for Small Samples Conference of World Sustainable Energy Days. In Proceedings of the World Sustainable Energy Days—Energy Efficiency & Biomass, At Wels, Austria, 25–27 February 2015; The OÖ Energiesparverband: Wels, Austria, 2015. [Google Scholar] [CrossRef]

- Chang, N.-B.; Chang, Y.-H.; Chen, W.C. Evaluation of heat value and its prediction for refuse-derived fuel. Sci. Total Environ. 1997, 197, 139–148. [Google Scholar] [CrossRef]

| Components | Composition (wt.%, w.b.) | Individual Components | ||||

|---|---|---|---|---|---|---|

| Comp 1 | Comp 2 | Comp 3 | Comp 4 | Moisture, as Received (%, w.b. 2) | Heating Value (MJ/kg, d.b. 2) | |

| Plastic | 20 | 30 | 40 | 30 | 1.9 | 46.5 ± 1.1 |

| Paper & cardboard | 50 | 40 | 30 | 50 | 3.5 | 15.8 ± 0.2 |

| Organic (food waste) | 20 | 20 | 20 | 10 | 4.1 | 21.2 ± 0.3 |

| Wood | 10 | 10 | 10 | 10 | 75.3 | 21.8 ± 0.2 |

| Overall moisture content (%, w.b.) 1 | 17.5 ± 0.1 | 17.4 ± 0.1 | 17.2 ± 0.1 | 10.5 ± 0.0 | - | - |

| Overall heating value (MJ/kg, d.b.) 1 | 23.6 ± 0.3 | 26.7 ± 0.5 | 29.8 ± 0.6 | 26.2 ± 0.2 | - | - |

| Parameter | Value |

|---|---|

| Die internal diameter | 6.35 mm |

| Maximum applied force | 5000 N |

| Maximum applied pressure | 158 MPa |

| Die temperature | 80 and 100 °C |

| Compression rate | 6 mm/min |

| Expulsion rate | 15 mm/min |

| Relaxation time | 30 s |

| Sample loading | 0.42 ± 0.01 g |

| Parameter | Composition | |||

|---|---|---|---|---|

| Comp 1 | Comp 2 | Comp 3 | Comp 4 | |

| Mass of RDF fed to die (g) | 0.42 ± 0.01 | 0.42 ± 0.01 | 0.42 ± 0.01 | 0.42 ± 0.01 |

| Density before pelletization (kg/m3) | 108.1 ± 3.2 | 133.3 ± 4.1 | 160.0 ± 2.8 | 117.6 ± 3.6 |

| Densification factor | 10.6 | 8.1 | 6.5 | 10.2 |

| Density of pellet (kg/m3) | 1145.8 ± 30.1 | 1079.7 ± 33.2 | 1040.0 ± 18.2 | 1199.5 ± 36.7 |

| Sample | Comp 1 | Comp 2 | Comp 3 | Comp 4 |

|---|---|---|---|---|

| Durability (%) | 92.25 ± 4.07 | 66.06 ± 6.05 | 50.96 ± 6.69 | 92.38 ± 4.74 |

| Source | DF | Adj SS 1 | Adj MS 2 | F-Value | p-Value |

|---|---|---|---|---|---|

| Pelletization energy consumption | |||||

| Regression | 2 | 13.7864 | 6.8932 | 3.38 | 0.359 |

| Plastic content (%) | 1 | 6.2118 | 6.2118 | 3.04 | 0.331 |

| Paper content (%) | 1 | 0.4736 | 0.4736 | 0.23 | 0.714 |

| Error | 1 | 2.0417 | 2.0417 | - | - |

| Total | 3 | 15.8281 | - | - | - |

| Regression equation | 40.2 − 0.337 (Plastic content, %) − 0.079 (Paper content, %) | ||||

| Pellet durability | |||||

| Regression | 2 | 1236.29 | 618.147 | 30.16 | 0.128 |

| Plastic content (%) | 1 | 2.13 | 2.135 | 0.10 | 0.801 |

| Paper content (%) | 1 | 383.86 | 383.861 | 18.73 | 0.145 |

| Error | 1 | 20.50 | 20.498 | - | - |

| Total | 3 | 1256.79 | - | - | - |

| Regression equation | −26.7 + 0.198 (Plastic content, %) + 2.262 (Paper content, %) | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezaei, H.; Yazdan Panah, F.; Lim, C.J.; Sokhansanj, S. Pelletization of Refuse-Derived Fuel with Varying Compositions of Plastic, Paper, Organic and Wood. Sustainability 2020, 12, 4645. https://doi.org/10.3390/su12114645

Rezaei H, Yazdan Panah F, Lim CJ, Sokhansanj S. Pelletization of Refuse-Derived Fuel with Varying Compositions of Plastic, Paper, Organic and Wood. Sustainability. 2020; 12(11):4645. https://doi.org/10.3390/su12114645

Chicago/Turabian StyleRezaei, Hamid, Fahimeh Yazdan Panah, C. Jim Lim, and Shahab Sokhansanj. 2020. "Pelletization of Refuse-Derived Fuel with Varying Compositions of Plastic, Paper, Organic and Wood" Sustainability 12, no. 11: 4645. https://doi.org/10.3390/su12114645

APA StyleRezaei, H., Yazdan Panah, F., Lim, C. J., & Sokhansanj, S. (2020). Pelletization of Refuse-Derived Fuel with Varying Compositions of Plastic, Paper, Organic and Wood. Sustainability, 12(11), 4645. https://doi.org/10.3390/su12114645