Abstract

Transitioning into a circular economy (CE) has been recently proposed as an agenda for reconciling global industrial systems with natural equilibria, but the current understanding of CE is ambiguous among scholars. Informed by recent growing CE literature, this study summarizes through three key propositions a set of indisputable insights emerging from the CE debate. In particular, the paper: remarks how CE takes stock of concepts of other schools of thought to drive policy interventions; depicts CE as a systemic transition of global industrial systems; and highlights the role of eco-effectiveness to upgrade business-centered approaches to sustainability. The proposed propositions are expected to contribute to reducing ambiguities in the CE debate and to convey coherence to future research.

1. Introduction

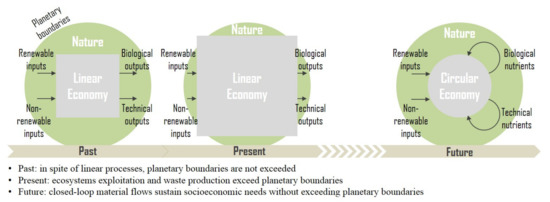

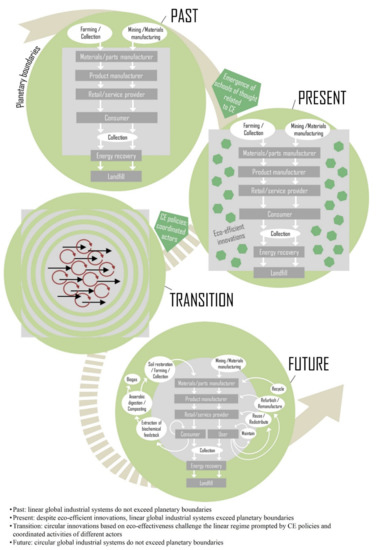

Over the last few years, the discourse on enhancing the sustainability of global industrial systems has increasingly focused on closed-loop supply chains and business models, and the idea that efforts should be made for a transition into a circular economy (CE) has gained momentum [1,2,3]. CE aims to reshape global industrial systems following the ideal objective of a zero-waste economy [4,5]. In general terms, a CE transition is seen as an agenda to redirect the path of economic development, and revert societal and environmental effects to earlier stages in which planetary boundaries were not exceeded [6]. The assumption is that linear production and consumption processes were feasible in the past when human activities did not require the current exploitation rates of natural resources (Figure 1) [7]. In the past, the natural environment was able to cope with the amount of natural resources extracted and of waste produced (inputs and outputs of the economic system in Figure 1) by human society on a global scale. Today, the effects of human activities exceed the resilience of ecosystems on a global scale. The CE narrative proposes a future in which the concept of “waste” is phased out. In this new economic system, by transforming waste into biological and technical “nutrients” circulating within ideally infinite loops, the extraction of natural resources and the waste produced to satisfy the needs of human societies will be significantly reduced [8].

Figure 1.

Timeline of the economy–nature relationship, including the transition from a linear to a circular economy (adapted from [7]; informed by [6,8]).

The spreading literature on CE has so far approached several aspects of the topic [9]. Studies have analyzed different strategies associated to CE through the ReSOLVE framework (regenerate, share, optimize, loops, virtualize, exchange) [10]. Several authors have highlighted CE managerial implications and the relevance of novel business models (e.g., [11,12]). People’s commitment to collaborative consumption has also been evidenced as a crucial factor for the success of CE schemes [13]. Scholars have shown that the CE concept has different implications depending on the level of analysis (micro, meso, supply chain, macro) to which it is applied [1]. Literature has also proven the cross-field relevance of CE, with studies applying circular principles to several sectors (e.g., metallurgy, agri-food, energy, construction, chemical) [9].

Although the perspective of reconciling global industrial systems with natural equilibria by means of closed-loop processes seems to be intuitive and reasonable, the current academic understanding of CE is prone to ambiguities, and thus criticism [14,15,16]. For example, although CE embraces different intellectual contributions, embedding concepts and principles from disparate disciplines, it is not clear how current research is producing original contributions useful for application. Among the schools of thought related to CE are the following: cradle-to-cradle [17], industrial ecology [18], biomimicry [19], laws of ecology [20], performance economy [21,22], blue economy [23], regenerative design [24], permaculture [25], the natural step [26], natural capitalism [27], industrial metabolism, symbiosis, and ecoparks [28,29]. This academic “melting pot” has had, during recent years, two main and related effects. First, it has generated numerous CE definitions. Although Kirchherr et al. [14] identify 114 definitions of CE, according to Gladek [30], “there is no single group with the undisputed authority to define what [CE] means exactly.” The lack of agreement in this domain undermines the possibility of building empirical studies grounded on a common theoretical background. Second, some authors have criticized or at least highlighted the lack of clarity of CE conceptual foundations (e.g., [16,31]), with Korhonen et al. ([32], p. 37) claiming that “the scientific and research content of the CE concept is superficial and unorganized” and that “CE seems to be a collection of vague and separate ideas from several fields and semi-scientific concepts.”

In addition, it remains undefined how CE and sustainability concepts relate and in what way, if any, CE improves and upgrades past approaches to reduce the negative effects of industrial systems. To illustrate, Geissdoerfer et al. ([33], p. 766) identify in the literature authors connecting CE and sustainability according to three different directions—namely, conditional (sustainability cannot be achieved without CE), beneficial (CE contributes to realizing sustainability goals), and trade-off—and classifies eight types of relationships. Millar et al. [34] list a set of shortcomings that limit the potential of CE to contribute to the sustainability debate. For example, these authors criticize CE for not explicitly targeting sustainable development goals, especially concerning the social dimension. In this regard, it has been noted that CE has the potential to contribute to the United Nations Sustainable Development Goals (SDGs) to different extents depending on the sustainability domain considered [3], ranging from a strong and direct contribution for SDGs that are close to the environment (e.g., SDG7 Affordable and clean energy and SDG12 Responsible consumption and production) and economic (e.g., SDG8 Decent work and economic growth) dimension of sustainability, to a weak or absent one for SDGs concerning certain social aspects (e.g., SDG5 Gender equality and SDG16 Peace, justice, and strong institutions).

Based on the recognition of these ambiguities and tensions in the current debate on CE transition, this study reviews key insights emerging from recent literature to provide a twofold contribution. First, it proposes a notion of CE meant as a systemic transition of multiple socio-technical regimes into alternatives to linear industrial systems. Second, it identifies CE peculiar features gravitating around the concept of eco-effectiveness and elaborates on their expected contribution to more sustainable global industrial systems. Notwithstanding the unclarified aspects of the CE concept, the CE debate has generated a set of indisputable insights that we summarize in our contribution through the following three key propositions:

- i.

- CE gathers the principles of other schools of thought and elaborates them in a narrative able to inspire policy actions.

- ii.

- CE is evoking a socio-technical transition into multiple regimes in which societal and material needs are fulfilled by innovative industrial systems.

- iii.

- CE contributes to the environmental and economic dimensions of sustainability by means of an eco-effectiveness approach to industrial systems.

Because of the lack of existing theorization on this subject, new propositions are needed to guide deductive research. To this aim, we identified a number of influential publications (e.g.: [32], for Section 2; [8], for Section 3; [35], for Section 4) and a number of articles conceptually connected to them. Starting from this baseline, we performed a literature review following a snowball searching method and based our conceptualization on the resulting group of papers. We complemented this method with a cursory quantitative analysis of Scopus articles including the word “circular economy” in their title, abstract, or keywords. Then, based on an inductive narrative approach [36], we summarized the present consolidated understanding of CE, informing practitioners interested in transitions, including researchers, managers, entrepreneurs, and policy-makers. CE is a multifaceted topic raising several critical questions that are still open [37], such as the timing needed for transitioning into circular systems, the comparison with other sustainability avenues (e.g., degrowth) [38], the technological and economic feasibility of circular processes [39,40], and issues of geographical equity with the global south [41]. These questions were excluded from our analysis. However, we sought to provide a clarifying point of view on a selection of misleading aspects of CE, able to represent a theoretical shortcut and a template for those who are engaged in this field.

The remainder of this paper is structured as follows. In Section 2, Section 3, and Section 4, we provide the argumentation supporting the three proposed propositions. In Section 5, we discuss implications of the propositions and provide some indications to guide future research. In the last section, Section 6, we elaborate on some conclusive considerations.

2. From Many Schools of Thought to a Unified Narrative Able to Inspire Policy Change

The current section informs the first proposition supported by the present study: CE gathers the principles of other schools of thought and elaborates them in a narrative able to inspire policy actions.

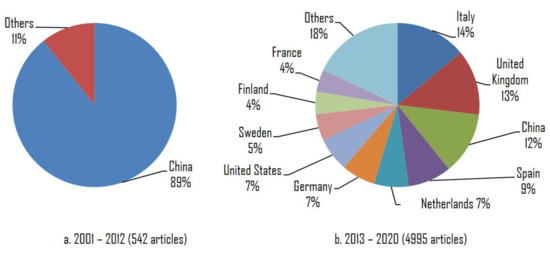

Over the last decades, influential reports such as The Limits to Growth [42], the codification of a novel ecological awareness into the ecological economics discipline [43], as well as the strong sustainability discourse [44], have supported the notion that natural capital cannot be entirely replaced by manufactured and technological capital. The idea that the proper functioning of Earth ecosystems may be jeopardized if human activities exceed a set of planetary boundaries has gained prominence [45]. In this evolving scenario, the term circular economy was coined [46] to describe systems in which economic activities and the environment interact in closed loops. However, only recently the CE concept has started to gain traction. To illustrate, taking the Scopus database as a reference, peer-reviewed CE articles may be separated into two main periods (Figure 2). A cursory glance at their publication years and authors reveals that, starting from the first article on the recycling of home electric appliances published in the Journal of the Japan Institute of Energy [47], nearly all of the first CE articles were published in China. China was the first country to adopt a CE law [48], and the main funding sponsor of articles published in Scopus is the National Natural Science Foundation of China. The turning point of this trend seems to occur after 2012, when the number of publications gradually started to rise and then to explode with the increasing interest in CE in Western countries, particularly in Europe. More specifically, among all Scopus documents including the words “circular economy” in their title, abstract, or keywords, about 86.2% are from authors having a European affiliation. Considering the period in which the exponential increase in the number of CE articles started, 2012 was selected as a turning point because it was the year the first CE report by the Ellen MacArthur Foundation (EMF) was published [8]. This is a key event for the emergence of recent CE research. The work of the EMF has thus far supported the growth of the CE debate, acting as a collaborative hub for business, policy-makers, and academics [33]. Strongly influenced by the work of authors such as Walter Stahel, Michael Braungart, and William McDonough [49], the role of the EMF has been crucial in influencing the CE narrative and generating knowledge with active report publication activity (e.g., [2,8,50,51,52]).

Figure 2.

Publication countries of CE articles (own elaborations on Scopus search results; retrieved on 13/02/2020).

Although the literature rarely highlights the legacy of CE in other inquiry fields (e.g., [53]), CE is actually informed by different schools of thought, which have evolved during the last decades and are listed in Table 1. The list includes approaches ranging from wide inquiry fields such as cleaner production [54]—generally referred to as environmentally friendly production methods—to specific product and organizational design innovations such as product-service systems [55]. Some of these approaches may be conceptually applied to any industrial sector (e.g. the Blue Economy, [23], and The Natural Step, [26]), whereas others are applicable only with regard to particular materials (e.g., biorefineries, [56]) or to specific fields (e.g., permaculture, [25]). However, some recursive topics are identifiable in this list. First, the CE principle “waste equals food” is borrowed by schools of thought that recognize the role of nature as a model to use for shaping production processes. For instance, biomimicry [19] and the laws of ecology [20] seem to inform the whole CE concept. Industrial ecology [57] and connected fields inform the notion that closed loops of resources may be structured by using waste and by-products of a production process as the input of another one. Permaculture [25] techniques implemented in agricultural production recall the CE principle of restoring the soil and its natural productivity. Second, the relevance of planning restorative systems and circular products at their design stage, which to an extent informs the CE notion, is emphasized by the cradle-to-cradle [17] and regenerative design [24] approaches. Third, the current CE narrative includes hints coming from the product-service systems (PSS) [55] and biorefineries [56] fields. In particular, CE considers servitization a tool to incentivize businesses to prolong product shelf life by transforming input resources into costs to avoid; furthermore, the CE narrative highlights the role of cascading processes as a means to produce high-value biomaterials (e.g., pharmaceuticals, food, and feed) before the residual biological matter is returned to the soil to feed agricultural ecosystems [58]. Fourth, the economic gains that a transition to CE may generate, for example, in terms of input cost savings, mitigation of supply risks, and reduced externalities, are frequently stressed by the CE narrative [8] (EMF 2012). Schools of thought such as the performance economy [21,22] and natural capitalism [27] may be easily associated with the CE notion that increasing resource productivity and usage efficiency are strategies to combine economic gains with environmental conservation.

Table 1.

Schools of thought related to the circular economy.

Despite the inheritance related to several conceptual and practical insights, CE detaches from these schools of thought for other aspects. For instance, the scale of application of CE can be extended to the system level, while cradle-to-cradle operates at the product/process level and The Natural Step at the organization level [59]. Among the systemic approaches, CE seems to be particularly oriented towards the conservation of the natural environment, while natural capitalism has been criticized for being too market-oriented [60]. As for the materials involved, recycling is a tenet of the CE approach, while fuel production in biorefineries starting from specialized energy crops remains controversial due to the so-called “food versus fuel” competition [61].

Based on this mixed theoretical background, some authors have recently sought to review CE literature to achieve a common understanding of the discipline or to question its usefulness in addressing sustainability goals. Among these, it has been noted that CE seems to be an “umbrella concept” [63] and that scholars do not agree on its basic notions [15,64], definition [65], and similarities with the sustainability concept [33]. CE’s potential contribution to sustainability has been questioned and studied by comparing it with other sustainability avenues [66] and with the SDGs framework [3] and by seeking to clarify CE operational principles [7]. Furthermore, the CE concept has been accused of being outdated, limited, deceptive, and superficial [16,31,32].

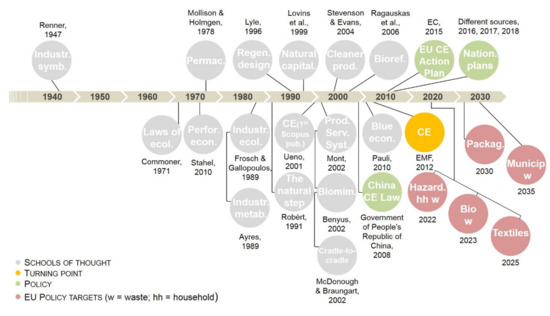

Unlike other schools of thought, however, the CE concept has been able to channel decades of scientific research outside academia. According to Korhonen et al. ([32], p. 37), “CE is important for its power to attract both the business community and policy-making community to sustainability work.” For instance, intergovernmental bodies such as the UNEP [67] and OECD, influential forums such as the World Economic Forum, large corporations such as Unilever, Danone, and Google, and consulting firms such as Accenture and Cisco are currently working on objectives related to CE [68]. Moreover, a number of actions have been enacted by the European Union (EU) to promote CE goals, such as the Circular Economy Action Plan [69] and the European Circular Economy Stakeholder Platform. In particular, the EU has set a number of ambitious targets to achieve within the next 15 years concerning the recycling of municipal (65%), packaging (70%), and hazardous household waste, biowaste, and textiles (mandatory separate collection) and taken actions directed toward the prevention of waste and governance of circular systems. EU actions are already taking effect at the national level, with several countries issuing strategic documents to lead future CE actions (Table 2). Policy actions seem to be guided by a general notion in which economic activities find a renewed equilibrium with the natural environment by means of closed-loop processes aimed to reduce the resources extracted and the waste produced by global industrial systems. This notion acts as an ideal that is “used to urge change and to mobilize resources” ([70], p. 60). Therefore, in addition to the varying CE definitions reported in the literature, the current CE debate catalyzes the emergence of top-down initiatives aimed at redirecting production and consumption patterns, acting in the domains of waste management and the adoption of secondary raw materials and stimulating the development of innovative technologies and organizational structures. Figure 3 presents a timeline reporting key references of the schools of thought related to CE and policies supporting actions towards circularity. The figure highlights the emergence of EU regulations and recycling targets after the publication of the first report of the Ellen MacArthur Foundation [8].

Table 2.

European CE national strategic plans.

Figure 3.

100 years of CE; schools of thought, regulations, and European Union (EU) recycling targets.

3. Transitioning Into Multiple Circular Socio-Technical Systems

The current section informs the second proposition supported by the present study: CE is evoking a socio-technical transition into multiple regimes in which societal and material needs are fulfilled by innovative industrial systems.

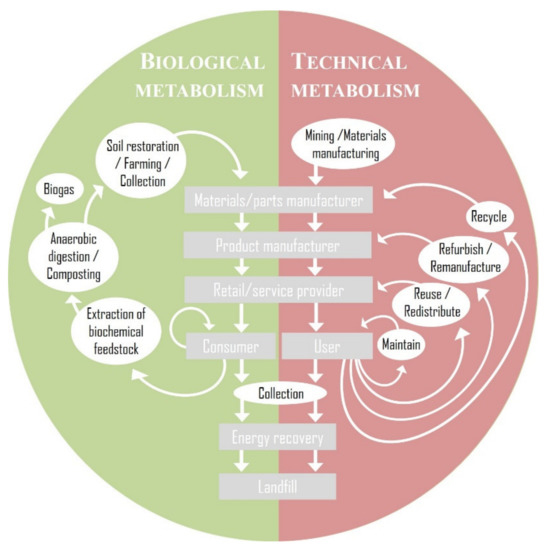

CE has been defined as an “industrial economy that is restorative or regenerative by intention and design” ([8], p. 7) and is based on closing, slowing, intensifying, narrowing, and dematerializing loops of resources [71]. Therefore, transforming biodegradable and nonbiodegradable waste into biological and technical nutrients moving throughout CE industrial metabolisms [8] would eventually lead to sustainably satisfying the needs of future human societies. The operational implications of this notion are represented in the butterfly graph of the Ellen MacArthur Foundation [8] (Figure 4).

Figure 4.

Butterfly graph of the circular economy (adapted from [8]).

Figure 4 classifies industrial production into two distinct types of materials, namely, biodegradable and nonbiodegradable. If one looks at supply chains with a “circular lens,” these materials (nutrients) may be recycled in sequential loops of reuse within biological and technical metabolisms. The adoption of the word “metabolism” to describe circular industrial systems recalls processes occurring in biological organisms and ecosystems, highlighting the CE intent to reconcile the economic and natural sphere. While nutrients of biological metabolism are designed to re-enter the biosphere after usage in “cascading” processes, technical nutrients remain in closed-loop systems of manufacture, reuse, and recovery throughout ideally infinite product life cycles. The butterfly graph provides a twofold heuristic value through including concepts coming from different approaches and extrapolating from these approaches the main innovative and practical insights. Therefore, it represents an attempt to re-propose and organize this knowledge into a scheme that fosters systemic thinking and facilitates operational adoptions. Figure 4 suggests a new way to make things, including a set of industrial solutions that reconfigure supply chains, thus envisioning a future in which material flows of extraction and disposal are minimized. CE calls for a complete reconfiguration of global industrial systems, entailing new business models, organizational structures, technologies, policy actions, and behaviors. It is crucial, for example, that technological advancements concerning recycling and valorization of by-products are combined with environmental life-cycle assessments, that resulting product innovations are supported by new business model approaches, and that political, social, and economic sciences contextually support these processes to foster the adoption and diffusion of new industrial systems. Furthermore, transitioning into CE should be a “coordinated and purposive change […] where several actors pursue a common goal in a coordinate manner” ([72], p. 223). To this end, research in disparate academic fields is providing contributions to increase CE insights (Table 3).

Table 3.

Subject areas of CE Scopus articles. Absolute frequency and exemplifying articles (data retrieved on 13/02/2020).

- N (Limit to subject area): applying this filter to Scopus, the refined outcome includes articles belonging also to other subject categories than the one at hand

- N (Exclude other subject areas): applying this filter to Scopus, the refined outcome includes articles belonging only to the subject category at hand

- Total: the total number of articles corresponding to the Scopus search “circular economy” in the field “Article title, Abstract, Keywords”

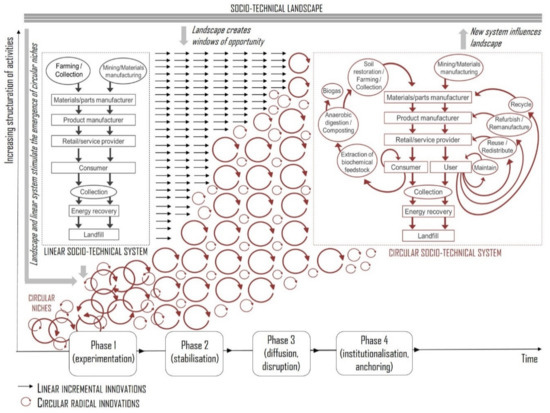

The CE concept thus represents an overarching label that includes trajectories of change for different industrial systems. The idea is that closed-loop-inspired innovations designed according to the waste-equals-food principle spread and replace their linear counterparts. Thus, in CE, different societal functions would be fulfilled sustainably after the enactment of multiple socio-technical transitions, which are incremental processes that technological innovations undergo before replacing the old ways in which humans fulfill their needs [73,74]. Because the CE narrative envisions a system transition involving many industrial systems with particular supply chain configurations, a CE transition may be represented by multiple technological innovations following a transition trajectory. These trajectories may be described by adopting the multilevel perspective (MLP) as a conceptual device [73,74] (Figure 5). The MLP focuses on how system transitions to sustainable configurations emerge over time from the interactions among processes at the niche level (pioneer activities promoting radical innovations), system level (technical, political, social, and cultural, business models, or infrastructural configurations), and landscape level (e.g., demographics, cultural repertoires, societal concerns, geopolitics, macroeconomic trends, ecological dynamics, wars, financial crises, and oil prices shocks). According to Geels ([74], p. 190), “(a) niche-innovations gradually build internal momentum, (b) niche innovations and landscape changes create pressure on the system and regime, and (c) destabilization of the regime creates windows of opportunity for niche-innovations, which then diffuse and disrupt the existing system.”

Figure 5.

Multilevel perspective of CE transition (adapted from [8,73,74]).

Following this perspective, several linear industrial systems are currently challenged by circular niche innovations stimulated by environmental and economic requests related to the increasing global population and diminishing stocks of natural resources. The current global landscape calls for solutions to cope with increasing worldwide consumption, insecure resource procurement, and volatile prices for which linear industrial systems seem to be no longer appropriate. Mirroring the MLP scheme, these environmental and economic burdens originating from the socio-technical landscape are inspiring niche outsiders, such as entrepreneurs, startups, and activists who are currently practicing in the domain of CE innovations (see [75] and [76] for examples of circular startups). In this experimentation stage (phase 1 of socio-technical transitions, Figure 5), practitioners are approaching circular niche innovations through trial-and-error learning processes. Furthermore, they face challenges such as uncertainty, competition, and failure and must cope with radical innovation performances, social acceptance, and political feasibility. The codification of learning processes occurred during phase 1 into standards, best practices, and design guidelines constitute phase 2 of the socio-technical transitions (stabilization). Despite the fact that most circular niches are currently experiencing phase 1, a circular “dominant design” ([74], p. 190) is identifiable in some industrial systems. If the CE transition happens, markets will show an increasing number of industrial systems having stabilized niche-innovation trajectories. Thereafter and before the eventual realization of a complete socio-technical transition into circular industrial systems (phase 4, institutionalization and anchoring), circular innovations will address diffusion processes into mainstream markets and struggles with linear regime elements and dynamics (phase 3, diffusion and disruption).

One example is the aquaculture and livestock feed industrial system, in which the insects-as-feed industry emerged to close agricultural material loops [77]. To illustrate, saprophagous insects can be efficiently used for bioconversion of waste into animal feed [78]. After first trials and pilot projects, standardized processes and product designs used to rear insects from biological materials have been extablished (e.g., [79]), as well as industry associations and intermediary actors (e.g., IPIFF) (phase 2, stabilization). Currently, this industry is experiencing its stabilisation phase, while its potential to reach in the future the third and fourth phases of socio-technical transitions is conditioned by several factors. For instance, the realization of further transition steps, such as the availability and economic convenience of future supplies of conventional feed, as well as the competition with other alternative feed sources, are among these factors [80].

While the replacement of traditional feed sources is yet to be achieved, other circular technologies now experience good opportunities to spread. Considering the plastic industry as a second example, one might speculate that the next decades will show the market diffusion of sustainable and circular alternatives to plastic materials. This spread might be led by windows of opportunity created by current landscape developments, such as radical normative changes (e.g., the single-use plastic directive, [81]) and increasing consumer awareness and environmental consciousness of the environmental effects of plastic [82].

4. From Eco-Efficiency to Eco-Effectiveness to Foster Sustainability

The current section informs about the third proposition supported in the present study: CE contributes to the environmental and economic dimensions of sustainability by means of an eco-effectiveness approach to industrial systems.

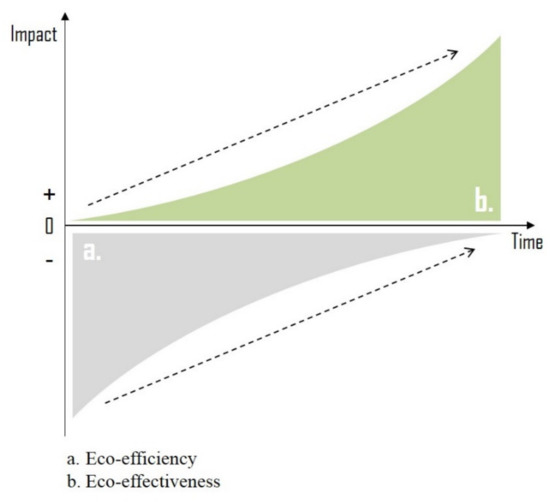

Widespread approaches to sustainability are often equated with eco-efficiency [35,83], an approach often considered managerialistic and business-centered [84,85]. Based on the well-known economic efficiency concept of “optimization of the production factors (inputs)” [86], eco-efficiency suggests that environmental impacts are a form of economic inefficiency [85]. Therefore, eco-efficiency is aimed at improving economic performance, for instance, by reducing energy, water, and resource inputs as well as waste and pollutants [83]. Although these kinds of actions are fundamental, they are still grounded on the assumption of industrial systems based on one-way linear flows of materials [35]. Although eco-efficient techniques are able to reduce the volume, velocity, and toxicity of the linear material flow, they continue to impact the environment. Because eco-efficiency strategies are aimed at reducing the environmental effects of industrial production (minimize negative effects), the ideal achievable goal entails zero impact (Figure 6). However, as observed by Young and Tilley ([84], p. 404), “Making a destructive system less destructive only serves to let industry continue to destroy ecosystems and to contaminate and deplete nature more slowly. Under the influence of eco-efficiency, a dystopian future lies ahead; destruction is the end game; the only choice remaining is the rate of destruction.” Consistently, transitioning into CE is expected to foster the adoption of sustainability strategies based on the concept of eco-effectiveness.

Figure 6.

Eco-efficiency versus eco-effectiveness (adapted from [35]).

The relevance of eco-effectiveness has been particularly highlighted in the past by cradle-to-cradle thinkers [17,35]. More recently, the concept has been described as “the transformation of products and their associated material flows such that they form a supportive relationship with ecological systems and future economic growth. The goal is not to minimize the cradle-to-grave flow of materials, but rather to generate cyclical, cradle-to-cradle ‘metabolisms’ that enable materials to maintain their status as resources” ([8], p. 23). Innovations constituting the CE transition should shape industrial systems that are able to generate positive values in terms of economic gains and enhance the quality of materials and the environment (maximize positive effects) (Figure 6). Therefore, whereas eco-efficiency strategies seek to reduce negative effects (“doing things right”), eco-effectiveness is based on envisioning new ways to produce materials, design products, and structure industrial systems and business models (“doing the right things”) [87]. Eco-effectiveness seems to be an emerging theme from the schools of thought of CE that conveys the idea of a synergistic relationship between ecological and economic systems able to restore and enhance the natural environment while allowing businesses to succeed. To illustrate, new businesses may impact the environment positively by acting as an emission sink for air and water pollutants or by using agricultural and food waste to regenerate the soil.

In contrast to eco-efficiency, the concept of eco-effectiveness addresses the crucial need to redesign the way in which materials flow across industrial systems [35]. CE entails a shift toward system thinking for the design and planning of global industrial systems. The aim is the creation of regenerative industrial metabolisms, mirroring natural processes, and not depleting the environment [84]. Therefore, the CE transition should be the result of a critical analysis of the status quo, ultimately leading to radical system innovations. Instead of addressing effects on the environment by means of an eco-efficiency approach based on the optimization of present linear systems, CE should be envisioned as an ideal state to strive for that requires the design of radically innovative solutions [88]. Indeed, designing products, processes, and systems based on eco-effectiveness requires abandoning the business-centered goal of short-term financial gain and instead focusing on innovations that can create long-term benefits [85]. Major contributions to the creation of eco-effective technologies occur in the early stages of their life cycles, namely R&D and customization [89]. Therefore, prior to manufacturing and production processes, CE-based design should be a crucial stage of industrial system management based on eco-effective strategies [90]. Figure 6 illustrates the conceptual difference between eco-efficiency and eco-effectiveness. Eco-efficiency approaches to sustainability work on “business-as-usual”; starting from negative environmental effects, they strive for zero impacts. On the contrary, based on novel design, eco-effective innovations are ideally conceived to have zero impact from the beginning and to produce positive effects over time.

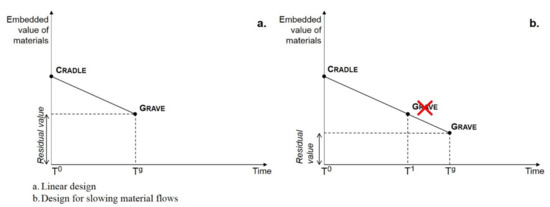

To illustrate, Den Hollander and colleagues [88] identified three circular product design approaches: resisting obsolescence by designing for long use (design for physical and emotional durability), postponing obsolescence by designing for extended use (design for maintenance and upgrading), and reversing obsolescence by designing for recovery (design for recontextualizing, repair, refurbishment, and remanufacture). Bocken et al. [11] proposed another categorization based on slowing (design long-life products or for product-life extension) or closing (design for a technological cycle, biological cycle, or dis- and re-assembly) material flows. A peculiarity of current affluent societies based on a linear economy, compared to past centuries and poor countries, is that products and materials have very short life spans because of planned or perceived obsolescence [90,91,92]. To stimulate the purchase of new products, goods are often conceived so that refurbishing, repairing, or even maintaining them is physically impossible. Furthermore, consumers often perceive products that are still intact and functioning as old-fashioned. Therefore, when people get rid of a product, the materials that compose it are still valuable but the product is not, or is not perceived as so. To address the issues of planned and perceived obsolescence, a company may produce designs that slow material flows to extend the product life span, thus maximizing the use of materials and minimizing their residual value at the life span end (Figure 7). To illustrate, Selvefors and colleagues [93] suggested countervailing planned obsolescence, making it easy to clean, maintain, repair, and replace product components (e.g., mobile phones produced by Fairphone), as well as perceived obsolescence by ensuring a long-term attractive appearance (e.g., designing jeans so they age well despite wear).

Figure 7.

Linear design and design for slowing material flows: materials’ embedded value at product end-life.

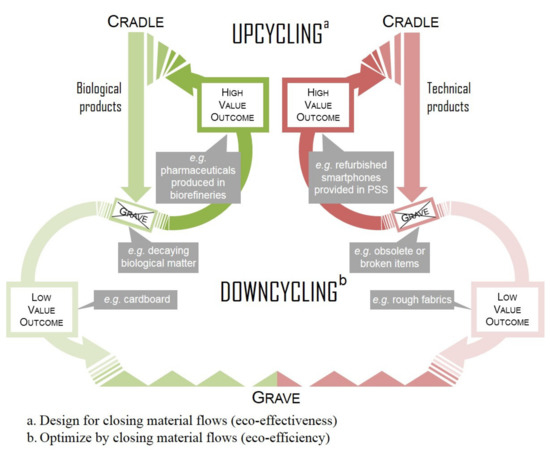

Alternatively, a company that designs for closing material flows creates new products, planning new purposes for wasted materials based on upcycling in an attempt to indefinitely delay disposal (Figure 8) [94,95,96]. The concept of “upcycling” is particularly relevant for the design of circular eco-effective products and materials. According to Singh et al. ([91], p. 1), “Upcycling is a process in which products and materials that are no longer in use, or are about to be disposed, are instead repurposed, repaired, upgraded, and remanufactured in a way that increases their value.” Upcycling envisions design strategies that offer many subsequent lives to material objects, potentially with completely different functionalities [90]. This is in contrast with other recycling activities in which value is often at least partially lost, thus creating secondary products and materials having lower values than those from which they originate (Figure 8). To illustrate, excluding quaternary processes concerned with the recovery of energy from materials, the plastic recycling terminology involves three categories: tertiary recycling, in which chemical constituents are recovered; secondary recycling (downcycling), that is, mechanical reprocessing into low-quality products; and primary recycling (upcycling), which can generate products having equal or improved properties [97]. Research and implementation of upcycling falls into a variety of fields, such as engineering and technology [98], business and creative entrepreneurship [99], design [100,101], art [102], and consumer behavior (“maker” movement) [103]. In particular, the concept of upcycling is implemented in the CE biological and technical metabolisms, for instance, and, respectively, in biorefineries and servitization processes. By means of consecutive recycling processes (cascades), biorefineries allow the upcycle of bio-based waste into different high-value outputs, such as pharmaceuticals, food, feed, chemicals, biofuels, compost, and energy [56,58,104]. Servitization is the strategy by which companies sell functions instead of products and transform consumers into users [55,62,93]. In addition to incentivizing companies to prolong the service life of products (as materials become costs to avoid), servitization extends materials’ life spans, allowing product redistribution and remanufacturing as well as component recycling (right side of Figure 4).

Figure 8.

Downcycling and upcycling: closing material flows by optimization or design.

Although it has been suggested that eco-effectiveness always creates value for companies [105], dominant business model logics are not tailored for CE innovations. The market success of a new product or technology is highly conditioned by the business model adopted [106], and this is even more true for radical innovation [107]. Hence, circular niche innovations require new ways of doing business to challenge linear socio-technical systems [11,71,108,109,110]. Furthermore, business model innovation and, particularly, circular business models (CBMs) are seen as required preconditions for a transition to more sustainable industrial production [33,111]. A CBM has been defined as “a business model in which the conceptual logic for value creation is based on utilizing economic value retained in products after use in the production of new offerings” ([112], p. 183). This means that CBMs should be able to reconceptualize the architecture of the firm and be able to create economic value from the design of upcycled products. This entails, in particular, rethinking perceptions of value conveyed to customers [109]. More specifically, whereas linear business models mainly gravitate around the ownership of products (value in exchange), CBMs are expected to focus on satisfying needs and on functionality (value in use), as well as the symbolic perception of enacting social roles by contributing to environmental protection (value in context) [113]. Furthermore, traditional business models should be redesigned, for example, in terms of collaborative partnerships and networks, lobbying, new activities (e.g., remanufacturing), logistics (e.g., warehouses and take-back systems), and consumer participation and incentives [12,39,114].

5. Discussion

Recent academic literature advocates CE as a strategy to reconcile global industrial systems with natural equilibria by means of closed-loop processes. However, this literature often falls short of justifying the prominence recently gained by CE. Why should researchers consider CE as something more than a buzzword? Why should the general public consider it something more than jargon used by researchers? It has become commonplace among scholars to adopt the term “circular economy” without questioning it. To illustrate, the definition of CE as “an industrial economy that is restorative or regenerative by intention and design” ([8], p. 7) has assumed the form of a meme, but few grasp the difference between the terms “regenerative” and “restorative” [115]. The scarce understanding of CE as a systemic transition based on the principle of eco-effectiveness undermines the possibility of producing sound studies grounded on a robust theoretical background and useful to inform practical implementations. Furthermore, it often leaves the utility of the CE debate for a more sustainable society unclear, thus making it prone to be considered either meaningless or a universal remedy.

The current study has sought to address these issues following the advice of Morseletto ([115], p. 8):

“Future research should explore how to specify better, improve, or complement the guiding principles of a CE because these are the constant reference points to inspire and orient actions of the framework. As theoretical core statements of a proposition, guiding principles must be clearly defined, consistent, and comprehensive. In a world dominated by buzzwords and dissonant meanings, clarity in language and consistent definitions of terms (not just in industrial ecology and sustainability discourse) are imperative to avoid misinterpretation, while facilitating effective implementation of frameworks like the CE one.”

The current study introduced three propositions to summarize CE’s potential, ambitions, and conceptual tools.

As for the first proposition, “CE gathers the principles of other schools of thought and elaborates them in a narrative able to inspire policy actions,” it has been argued that CE articles are comprised of elements coming from several schools of thought that are often randomly adopted under a new umbrella. It seems that CE cherry-picks from these schools of thought theoretical and practical insights, but the disorganized way in which these insights are reintroduced undermines CE theoretical solidity. However, the “persuasive and performative power” ([70], p. 60) of CE cannot be neglected. This power, which has been able to attract the commitment of international institutions, corporations, and other relevant actors, is linked to the ability of the CE concept to disclose an easy-to-use message: the way we make things is wrong and we must change it. Accordingly, CE conveys an appealing overview of a society in which economic systems have renewed their equilibrium with the natural environment by means of closed-loop processes, and in which waste and overexploited natural resources are no longer an issue. Analogous to “sustainable development,” which has become a political concept fueled by global growing environmental awareness despite its elusive meaning and undefined implementation tools [33,116,117], CE is thus already operating in the policy agenda. A potential implementation of the first proposition regards studies analysing strategies that CE borrows from specific schools of thought. We recommend that these studies recognise the influence of previous disciplines, considering their results and relevant insights. We also highlight the need for policy-makers to take stock of and look for consistency within the knowledge gathered throughout a period starting far before the spread of the circular economy concept.

As for the second proposition, “CE is evoking a socio-technical transition into multiple regimes in which societal and material needs are fulfilled by innovative industrial systems,” it has been argued that CE revitalizes past theoretical and practical insights, proposing them through a new inspirational framework for industrial design. More specifically, it organizes these insights in a toolkit for systemic transition [8], which seems to represent the core innovative power of the CE narrative. However, as pointed out by Webster ([49], p. 545), there is a temptation “to talk too much about things and too little about systems.” Therefore, CE is proposed as a transition into industries in equilibrium with natural systems, designed to have no impact or to restore and enhance the environment [68]. Circular niche innovations are expected to occur in future transition trajectories that are able to disrupt the current socio-technical linear system and to replace it by shaping a new circular regime. Supported by the coordinated action of various actors, the resulting novel industrial system configurations should actualize the goals of the schools of thought from which CE has evolved. The second proposition invites researchers to apply transition theory to the analysis of CE. Particularly, we recommend to follow the emergence and the transition pathway of circular niches in different industries, to identify regime constraints, as well as the expected timing for the transition. For those industries in which data are available and in order to assess the desirability of the transition, we also suggest the performance of life-cycle analysis comparing the environmental effects of their linear and circular counterparts.

As for the third proposition, “CE contributes to the environmental and economic dimensions of sustainability by means of an eco-effectiveness approach to industrial systems,” it has been argued that the CE transition requires political, practitioner, and research agendas to gravitate around insights that clearly distinguish and upgrade CE from past eco-efficiency approaches to environmental sustainability. Therefore, the current study posits that a CE socio-technical transition should be centered on innovation strategies based on eco-effectiveness, shifting from “doing things right” to “doing the right things.” Eco-effectiveness upgrades past business-centered approaches toward sustainability by creating supportive relationships between economic and environmental systems. In fact, product and business model designs based on eco-effectiveness can reduce environmental negative effects and improve the economic performance of firms. Moreover, upcycled products and materials are ideally able to indefinitely extend the life cycle of natural resources in economic systems. Indeed, this entails minimizing the exploitation of ecosystems through extractive activities, waste, and pollutants. Furthermore, economic gains are generated from the CE potential to create value by means of CBMs, as well as through the reduction of resource input costs. Highlighting the CE potential to address economic and environmental sustainability, the third proposition confirms the shortcomings of CE concerning social aspects [34,118]. Future studies are expected to work on this by focusing on the integration of social sustainability goals in CE transition pathways. We recommend that future research considers eco-effectiveness as an inspiring principle to guide circular design, supporting multiple niche implementions of this concept in biological and technical metabolisms.

Figure 9 illustrates a stylized timeline of the transition into CE including insights coming from the present analysis. At present, notwithstanding sustainability approaches based on eco-efficiency, the global linear economy exceeds planetary boundaries. The transition period is characterized by the emergence of eco-effective innovations catalysed by CE policies and the coordinated action of different actors. Future is envisioned as a global circular system as shaped by the EMF.

Figure 9.

Timeline of the economy-nature relationship, including main contents of the paper.

The three propositions call into question other CE elements that are still unclear. First, although policy-makers are already committed to moving in the CE direction, it remains unknown whether and how policy agendas are useful for and consistent with a CE transition. Furthermore, a historical process analysis is required to retrace and understand key events that have led to the current spread of the CE discourse. Second, once CE is defined as the transition of socio-technical systems, several questions arise. For instance, one can legitimately wonder whether this transition is really desirable, to what extent, and for which industrial systems. As noted by Corvellec and colleagues ([68], p. 100), it remains vague “what kind of answers it [CE] is able to provide to the manifold of ecological, economic and other social challenges in the Anthropocene.” Furthermore, strategies for a global CE agenda seem to be far from being defined: “how one is to build these circles across space and time remains an untold story” ([68], p. 100). Third, once it is clarified that eco-effectiveness distinguishes CE from previous sustainable approaches, product and business model designs are needed to transform this concept into practice, and a life-cycle analysis is crucial to assess the economic and environmental value created by circular solutions. In sum, the current work does not (and is not aimed to) obliterate the conjectures viewing the CE narrative as “revolutionary rhetoric” ([68], p. 98). However, it agrees with those who claim that “a linear economy has no real future” and that economy must be in “line with the workings of systems in which it is embedded” ([49], pp. 547, 553).

Therefore, assuming that CE is a potential pathway for future sustainability, the current study is expected to inform future research to act coherently with the proposed propositions. The three propositions are expected to contribute to the CE transition as a “coordinated and purposive change […] where several actors pursue a common goal in a coordinate manner” ([72], p. 223). If this is achieved, transforming biodegradable and nonbiodegradable waste into biological and technical nutrients moving throughout CE industrial metabolisms [8] might eventually lead to sustainably satisfying society’s future needs.

6. Conclusions

Despite criticisms and ambiguous views, through the proposed propositions we have highlighted how CE and its narrative are progressively assuming a dominant place in the academic and practitioner debate to inspire and foster ‘alternatives’ to current global industrial systems. As we have underlined in previous sections, transitioning into a new CE landscape has become a recognisible agenda attempting to reconcile global industrial systems with natural systems. The potentials of this agenda to tackle relevant challenges for humanity, and particularly to bring into a global scale feasible actions to address SDGs goals, are promising and should not be underestimated.

However, we have also highlighted that while the debate on the principles of CE has reached its maturity and has helped to firmly establish CE in the policy-making arena, as well as to define industrial and sustainability transition strategies worldwide, a new and more diverse debate on ways to implement CE practices still needs to take off. Perhaps, to facilitate this shift of the current debate, future research should focus more on establishing shared approaches and methodologies to collect data on both principles and practices. A further analysis and understanding of the meanings of these principles and practices in different geographies, for example comparing urban and rural contexts, Global North and South, core economies and peripheries, are highly dependent on developing measurable outcomes and impacts of the CE. Paradoxically, the tendency of CE narrative to become ‘impactful’ and ‘successful’ might be limited to its persistent ‘post-political’ and ‘uncontentious’ nature. While this has proved key to determine its emergence and dominance in the discourse on sustainable transitions of the current global economy, it is now risking to hamper its potentials, due to lack of clarity and excess of ambiguities. These are all sources of uncertainty and tensions that might limit actors to ‘translate’ principles into practices.

Moreover, while a post-political stand might have helped to gain consensus in the Global North, where CE is legitimised and adopted by almost all key economic and social actors, it has failed to bring up a clear and effective discussion in the Global South, and most notably around the fundamental contradictions that global economic systems provoke between these two ‘geographies.’ The capacity of the CE agenda to gain consensus has perhaps come by trading off a focus on planetary boundaries and critical natural equilibria at the expense of a more thorough criticism of the differences within the global economic and industrial systems. Facilitating any transition into circular systems within planetary boundaries should also imply a careful consideration of the social foundations of these systems, and to (re-)imagine the relations between societal and material needs, particularly in terms of fairness, equity, and justice at a global scale. We found the CE agenda and narrative particularly lacking in these elements and in desperate need of broadening and widening their perspectives, even risking to become more contentious and political.

Author Contributions

Conceptualization, M.B., S.P., and L.C.; methodology, M.B.; writing—original draft preparation, M.B.; writing—review and editing, S.P. and L.C.; supervision, L.C.; funding acquisition, L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received a grant from the Project PRIN DRASTIC “Driving The Italian Agri-Food System Into A Circular Economy Model,” PRIN-MIUR—Call 2017, funded by the Italian Ministry of Education, University and Research (MIUR).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- EMF (Ellen MacArthur Foundation). Achieving ‘Growth Within; Ellen MacArthur Foundation: Isle of Wight, UK, 2017. [Google Scholar]

- Schröder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2018, 23, 77–95. [Google Scholar] [CrossRef]

- Zwier, J.; Blok, V.; Lemmens, P.; Geerts, R.-J. The Ideal of a Zero-Waste Humanity: Philosophical Reflections on the Demand for a Bio-Based Economy. J. Agric. Environ. Ethic 2015, 28, 353–374. [Google Scholar] [CrossRef]

- Kerdlap, P.; Low, J.S.C.; Ramakrishna, S. Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour. Conserv. Recycl. 2019, 151, 104438. [Google Scholar] [CrossRef]

- Steffen, W.; Crutzen, P.J.; McNeill, J.R. The Anthropocene: Are Humans Now Overwhelming the Great Forces of Nature. Ambio 2007, 36, 614–621. [Google Scholar] [CrossRef]

- Eiroa, B.S.; Fernández, E.; Méndez, G.; Soto-Oñate, D. Operational principles of circular economy for sustainable development: Linking theory and practice. J. Clean. Prod. 2019, 214, 952–961. [Google Scholar] [CrossRef]

- Xu, F.J. The Studies of the Concept Plan of the Fengcheng Industrial Park towards the Circular Economy. Adv. Mater. Res. 2012, 598, 220–223. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- EMF (Ellen MacArthur Foundation). Delivering the Circular Economy-A Toolkit for Policy Makers; EMF (Ellen MacArthur Foundation): Isle of Wight, UK, 2015. [Google Scholar]

- Bocken, N.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustain. 2016, 8, 43. [Google Scholar] [CrossRef]

- Camacho-Otero, J.; Boks, C.; Pettersen, I.N. Consumption in the Circular Economy: A Literature Review. Sustain. 2018, 10, 2758. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Sandoval, J.V.P.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Skene, K.R. Circles, spirals, pyramids and cubes: Why the circular economy cannot work. Sustain. Sci. 2017, 13, 479–492. [Google Scholar] [CrossRef]

- Mc Donough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Sharfman, M.; Graedel, T.E.; Allenby, B.R. Industrial Ecology. Acad. Manag. Rev. 1995, 20, 1090. [Google Scholar] [CrossRef]

- Benyus, J.M. Biomimicry: Innovation Inspired by Nature; Harper Collins: New York, NY, USA, 2002. [Google Scholar]

- Commoner, B. The Closing Circle: Nature, Man, and Technology. Random House Inc: New York, NY, USA, 1971. [Google Scholar]

- Stahel, W.R.; Reday, G. The potential for substituting manpower for energy; report to DG V for Social Affairs; Commission of the EC: Brussels, Belgium, 1976. [Google Scholar]

- Stahel, W.R. The Performance Economy; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Pauli, G.A. The Blue Economy: 10 Years, 100 Innovations, 100 Million Jobs; Paradigm Publications: Boulder, CO, USA, 2010. [Google Scholar]

- Lyle, J.T. Regenerative Design for Sustainable Development; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Mollison, B.; Holmgren, D. Permaculture. Lesmurdie Progress Association: Australia, 1978. [Google Scholar]

- Robèrt, K.H. Educating A Nation: The Natural Step-A remarkable Nation-Wide Program Unites Sweden in Moving from Linear to Cyclic Processes-The Hallmark of Sustainability. Available online: https://www.context.org/iclib/ic28/robert/ (accessed on 15 January 2020).

- Lovins, A.B.; Lovins, L.H.; Hawken, P. A road map for natural capitalism. Harv. Bus Rev 1999, 77, 218–234. [Google Scholar] [CrossRef]

- Renner, G.T. Geography of Industrial Localization. Econ. Geogr. 1947, 23, 167. [Google Scholar] [CrossRef]

- Ayres, R.U. Industrial metabolism: Work in progress. Theory Implement. Econ. Models Sustain. Dev. 1998, 15, 195–228. [Google Scholar] [CrossRef]

- Gladek, E. The Seven Pillars of the Circular Economy. Available online: https://www.greenbiz.com/article/7-pillars-circular-economy (accessed on 15 January 2020).

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Millar, N.; McLaughlin, E.; Börger, T. The Circular Economy: Swings and Roundabouts? Ecol. Econ. 2019, 158, 11–19. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions–a strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Delmont, S.; Mason, J. Qualitative Researching; Sage Publications Limited: Thousand Oaks, CA, USA, 1978. [Google Scholar]

- Borrello, M.; Lombardi, A.; Pascucci, S.; Cembalo, L. The Seven Challenges for Transitioning into a Bio-based Circular Economy in the Agri-food Sector. Recent Pat. Food Nutr. Agric. 2016, 8, 39–47. [Google Scholar] [CrossRef]

- Schröder, P.; Bengtsson, M.; Cohen, M.; Dewick, P.; Hoffstetter, J.; Sarkis, J. Degrowth within—Aligning circular economy and strong sustainability narratives. Resour. Conserv. Recycl. 2019, 146, 190–191. [Google Scholar] [CrossRef]

- Borrello, M.; Caracciolo, F.; Lombardi, A.; Pascucci, S.; Cembalo, L. Consumers’ Perspective on Circular Economy Strategy for Reducing Food Waste. Sustainability 2017, 9, 141. [Google Scholar] [CrossRef]

- Pieroni, M.; McAloone, T.C.; Pigosso, D.C.A. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Gutberlet, J.; Carenzo, S.; Kain, J.-H.; De Azevedo, A.M.M. Waste Picker Organizations and Their Contribution to the Circular Economy: Two Case Studies from a Global South Perspective. Resources 2017, 6, 52. [Google Scholar] [CrossRef]

- Meadows, D.H.; Meadows, D.L.; Randers, J.; Behrens, W.W. The Limits to Growth: A report for the Club of Rome’s Project on the Predicament of Mankind; Universe Book: New York, NY, USA, 1972. [Google Scholar]

- Costanza, R. Ecological Economics: The Science and Management of Sustainability; Columbia University Pressp: New York, NY, USA, 1992. [Google Scholar]

- Neumayer, E. Weak Versus Strong Sustainability: Exploring the Limits of Two Opposing Paradigms; Edward Elgar Publishing: Cheltenham, UK, 2003. [Google Scholar]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.I.; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary Boundaries: Exploring the Safe Operating Space for Humanity. Ecol. Soc. 2009, 14. [Google Scholar] [CrossRef]

- Segerson, K.; Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment. Land Econ. 1991, 67, 272. [Google Scholar] [CrossRef]

- Ueno, K. Current status of home electric appliances recycling in Japan. Nihon Enerugi Gakkaishi/J. Jpn. Inst. Energy 2001, 80, 1100–1107. [Google Scholar]

- GPRC (Government of People’s Republic of China). Circular Economy Promotion Law of the People’s Republic of China. In Proceedings of the Fourth Session of the Standing Committee of the 11th National People’s Congress, Beijing, China, 29 August 2008. [Google Scholar]

- Webster, K. What Might We Say about a Circular Economy? Some Temptations to Avoid if Possible. World Futur. 2013, 69, 542–554. [Google Scholar] [CrossRef]

- EMF (Ellen MacArthur Foundation). Towards the Circular Economy Vol. 2: Opportunities for the consumer goods sector. EMF (Ellen MacArthur Foundation): Isle of Wight, UK, 2013. [Google Scholar]

- EMF (Ellen MacArthur Foundation). Towards the Circular Economy Vol. 3: Accelerating the scale-up across global supply chains. EMF (Ellen MacArthur Foundation): Isle of Wight, UK, 2014. [Google Scholar]

- EMF (Ellen MacArthur Foundation). Cities and Circular Economy for Food; EMF (Ellen MacArthur Foundation): Isle of Wight, UK, 2019. [Google Scholar]

- Saavedra, Y.M.; Iritani, D.R.; Pavan, A.L.R.; Ometto, A.R. Theoretical contribution of industrial ecology to circular economy. J. Clean. Prod. 2018, 170, 1514–1522. [Google Scholar] [CrossRef]

- Stevenson, R.S.; Evans, J. Editorial to: Cutting across interests: Cleaner production, the unified force of sustainable development. J. Clean. Prod. 2004, 12, 185–187. [Google Scholar] [CrossRef]

- Mont, O. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Ragauskas, A.; Williams, C.K.; Davison, B.H.; Britovsek, G.J.P.; Cairney, J.; Eckert, C.A.; Frederick, W.J.; Hallett, J.P.; Leak, D.J.; Liotta, C.L.; et al. The Path Forward for Biofuels and Biomaterials. Science 2006, 311, 484–489. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Berbel, J.; Posadillo, A. Review and Analysis of Alternatives for the Valorisation of Agro-Industrial Olive Oil By-Products. Sustainability 2018, 10, 237. [Google Scholar] [CrossRef]

- Mead, T.; Jeanrenaud, S. The elephant in the room: Biomimetics and sustainability? Bioinspired Biomim. Nanobiomaterials 2017, 6, 113–121. [Google Scholar] [CrossRef]

- Nyberg, D.; Wright, C. Corporate corruption of the environment: Sustainability as a process of compromise. Br. J. Sociol. 2013, 64, 405–424. [Google Scholar] [CrossRef]

- Esposito, D.; Antonietti, M. Redefining biorefinery: The search for unconventional building blocks for materials. Chem. Soc. Rev. 2015, 44, 5821–5835. [Google Scholar] [CrossRef] [PubMed]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.; Witjes, S. The circular economy: New or Refurbished as CE 3.0? — Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. SSRN Electron. J. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Nasr, N.; Russell, J.; Bringezu, S.; Hellweg, S.; Hilton, B.; Kreiss, C.; Von Gries, N. Re-defining Value–The Manufacturing Revolution. Remanufacturing, Refurbishment, Repair and Direct Reuse in the Circular Economy; A Report of the International Resource Panel; United Nations Environment Programme: Nairobi, Kenya, 2018. [Google Scholar]

- Corvellec, H.; Böhm, S.; Stowell, A.; Valenzuela, F. Introduction to the special issue on the contested realities of the circular economy. Cult. Organ. 2020, 26, 97–102. [Google Scholar] [CrossRef]

- The Communication from the Commission to the European Parliament, the Council. the European Economic and Social Committee and the Committee of the Regions: "Towards an EU Criminal Policy: Ensuring the effective implementation of EU policies through criminal law". Eur. Crim. Law Rev. 2011, 1, 311–318. [Google Scholar] [CrossRef]

- Lazarevic, D.; Valve, H. Narrating expectations for the circular economy: Towards a common and contested European transition. Energy Res. Soc. Sci. 2017, 31, 60–69. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Lammi, M.; Anttonen, M.T.; Bamford, I.; Antikainen, M.; Naumanen, M. Turning Finland into a Country of Circular Economy: What Kind of a Process of Change Should We Seek? In Proceedings of the Advances in Theory and Practice of Computational Mechanics; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 215–228. [Google Scholar]

- Geels, F.W. Technological transitions as evolutionary reconfiguration processes: A multi-level perspective and a case-study. Res. Policy 2002, 31, 1257–1274. [Google Scholar] [CrossRef]

- Geels, F.W. Socio-technical transitions to sustainability: A review of criticisms and elaborations of the Multi-Level Perspective. Curr. Opin. Environ. Sustain. 2019, 39, 187–201. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ulgiati, S. Circular economy transition in Italy. Achievements, perspectives and constraints. J. Clean. Prod. 2020, 243, 118360. [Google Scholar] [CrossRef]

- Henry, M.; Bauwens, T.; Hekkert, M.; Kirchherr, J. A typology of circular start-ups: An Analysis of 128 circular business models. J. Clean. Prod. 2020, 245, 118528. [Google Scholar] [CrossRef]

- Van Huis, A.; Van Itterbeeck, J.; Klunder, H.; Meretens, E.; Halloran, A.; Muir, G.; Vantomme, P. Edible insects: Future prospects for food and feed security (No. 171); FAO: Rome, Italy, 2013. [Google Scholar]

- Surendra, K.; Olivier, R.; Tomberlin, J.K.; Jha, R.; Khanal, S.K. Bioconversion of organic wastes into biodiesel and animal feed via insect farming. Renew. Energy 2016, 98, 197–202. [Google Scholar] [CrossRef]

- Urbanski, J.; Józefiak, D.; Mazurkiewicz, J.U.S. The Technological Line For Rearing Or Breeding Of Insects, The Modular System Of Technological Lines, The Method And Use Thereof. Publication Number WO/2018/029597Publication Date 15/02/2018International Application Number PCT/IB2017/054828. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2018029597 (accessed on 13 May 2020).

- Digiacomo, K.; Leury, B.J. Review: Insect meal: A future source of protein feed for pigs? Animal 2019, 13, 3022–3030. [Google Scholar] [CrossRef]

- EU (European Union). Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the reduction of the impact of certain plastic products on the environment (Text with EEA relevance) PE/11/2019/REV/1. Off. J. Eur. Union L CELEX n. 32019L0904. 2019. [Google Scholar]

- Van Rensburg, M.L.; Nkomo, S.L.; Dube, T. The ‘plastic waste era’; social perceptions towards single-use plastic consumption and impacts on the marine environment in Durban, South Africa. Appl. Geogr. 2020, 114, 102132. [Google Scholar] [CrossRef]

- Dyllick, T.; Hockerts, K. Beyond the business case for corporate sustainability. Bus. Strat. Environ. 2002, 11, 130–141. [Google Scholar] [CrossRef]

- Young, W.; Tilley, F. Can businesses move beyond efficiency? The shift toward effectiveness and equity in the corporate sustainability debate. Bus. Strat. Environ. 2006, 15, 402–415. [Google Scholar] [CrossRef]

- Burnett, R.D.; Skousen, C.J.; Wright, C.J. Eco-Effective Management: An Empirical Link between Firm Value and Corporate Sustainability. Account. Public Interest 2011, 11, 1–15. [Google Scholar] [CrossRef]

- Barbiroli, G. Eco-effectiveness to pursue resource valorisation and conservation: A new approach. Int. J. Environ. Technol. Manag. 2007, 7, 734. [Google Scholar] [CrossRef]

- Herrmann, C.; Blume, S.; Kurle, D.; Schmidt, C.; Thiede, S. The Positive Impact Factory–Transition from Eco-efficiency to Eco–effectiveness Strategies in Manufacturing. Procedia CIRP 2015, 29, 19–27. [Google Scholar] [CrossRef]

- Hollander, M.C.D.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Hofstra, N.; Huisingh, D. Eco-innovations characterized: A taxonomic classification of relationships between humans and nature. J. Clean. Prod. 2014, 66, 459–468. [Google Scholar] [CrossRef]

- Bridgens, B.; Powell, M.; Farmer, G.; Walsh, C.; Reed, E.; Royapoor, M.; Gosling, P.; Hall, J.; Heidrich, O. Creative upcycling: Reconnecting people, materials and place through making. J. Clean. Prod. 2018, 189, 145–154. [Google Scholar] [CrossRef]

- Singh, J.; Sung, K.; Cooper, T.; West, K.; Mont, O. Challenges and opportunities for scaling up upcycling businesses—The case of textile and wood upcycling businesses in the UK. Resour. Conserv. Recycl. 2019, 150, 104439. [Google Scholar] [CrossRef]

- Venkataraman, N.; Elangovan, N. Making the Best of Obsolescence—A Study on the Changing Landscape of Product Life-Cycle. In Advances in Theory and Practice of Computational Mechanics; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 223–233. [Google Scholar]

- Selvefors, A.; Rexfelt, O.; Renström, S.; Strömberg, H. Use to use–A user perspective on product circularity. J. Clean. Prod. 2019, 223, 1014–1028. [Google Scholar] [CrossRef]

- Ahn, S.H.; Lee, J.Y. Re-Envisioning Material Circulation and Designing Process in Upcycling Design Product Life Cycle. Arch. Des. Res. 2018, 31, 5–20. [Google Scholar] [CrossRef]

- Paras, M.K.; Curteza, A. Revisiting upcycling phenomena: A concept in clothing industry. Res. J. Text. Appar. 2018, 22, 46–58. [Google Scholar] [CrossRef]

- Sung, K.; Cooper, T.; Kettley, S. Factors Influencing Upcycling for UK Makers. Sustainability 2019, 11, 870. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B: Boil. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.P.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Cuc, S.; Tripa, S. Redesign and upcycling-A solution for the competitiveness of small and medium-sized enterprises in the clothing industry. Ind. Textila. 2018, 69, 31–36. [Google Scholar]

- Sung, K.; Cooper, T. Sarah Turner–Eco-artist and designer through craft-based upcycling. Cr Res. 2015, 6, 113–122. [Google Scholar] [CrossRef]

- Fischer, A.; Pascucci, S. Institutional incentives in circular economy transition: The case of material use in the Dutch textile industry. J. Clean. Prod. 2017, 155, 17–32. [Google Scholar] [CrossRef]

- Montana-Hoyos , C.; Scharoun, L. Adaptive reuse in craft, design, and art in the city. Int. J. Archit. Spat Environ. Des. 2014, 8, 1–20. [Google Scholar] [CrossRef]

- Anderson, C. Makers: The New Industrial Revolution; Random House Business: London, UK, 2012. [Google Scholar]

- Clark, J.H.; Luque, R.; Matharu, A.S. Green Chemistry, Biofuels, and Biorefinery. Annu. Rev. Chem. Biomol. Eng. 2012, 3, 183–207. [Google Scholar] [CrossRef]

- Figge, F.; Hahn, T. Sustainable Value Added—measuring corporate contributions to sustainability beyond eco-efficiency. Ecol. Econ. 2004, 48, 173–187. [Google Scholar] [CrossRef]

- Chesbrough, H. Business Model Innovation: Opportunities and Barriers. Long Range Plan. 2010, 43, 354–363. [Google Scholar] [CrossRef]

- Bhamra, T.; Lofthouse, V. Design for Sustainability: A Practical Approach; Gower Publishing, Ltd: Aldeshout, UK, 2007. [Google Scholar]

- Brennan, G.; Tennant, M.; Blomsma, F. Business and production solutions. In Sustainability; Informa UK Limited: London, UK, 2015; pp. 219–239. [Google Scholar]

- Fernando, L.; Evans, S. Competencies to Move beyond Eco-efficiency. Procedia CIRP 2016, 40, 365–371. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Rashid, A.; Asif, F.M.; Krajnik, P.; Nicolescu, C.M. Resource Conservative Manufacturing: An essential change in business and technology paradigm for sustainable manufacturing. J. Clean. Prod. 2013, 57, 166–177. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strat. Environ. 2015, 26, 182–196. [Google Scholar] [CrossRef]

- Peronard, J.-P.; Ballantyne, A.G. Broadening the understanding of the role of consumer services in the circular economy: Toward a conceptualization of value creation processes. J. Clean. Prod. 2019, 239, 118010. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Morseletto, P. Restorative and regenerative: Exploring the concepts in the circular economy. J. Ind. Ecol. 2020. [Google Scholar] [CrossRef]

- Hobsbawm, E.J. Age of extremes: The short twentieth century, 1914-London. Abacus: Hachette UK, 1995. [Google Scholar]

- Robert, K.W.; Parris, T.M.; Leiserowitz, A.A. What is Sustainable Development? Goals, Indicators, Values, and Practice. Environ. Sci. Policy Sustain. Dev. 2005, 47, 8–21. [Google Scholar] [CrossRef]

- Schröder, P.; Dewick, P.; Kusi-Sarpong, S.; Hofstetter, J. Circular economy and power relations in global value chains: Tensions and trade-offs for lower income countries. Resour. Conserv. Recycl. 2018, 136, 77–78. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).