The Effect of Selected Parameters on Spelt Dehulling in a Wire Mesh Cylinder

Abstract

:1. Introduction

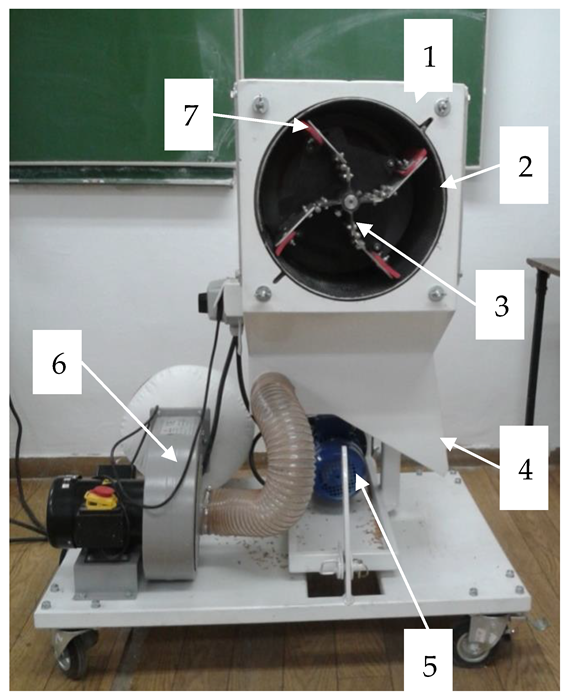

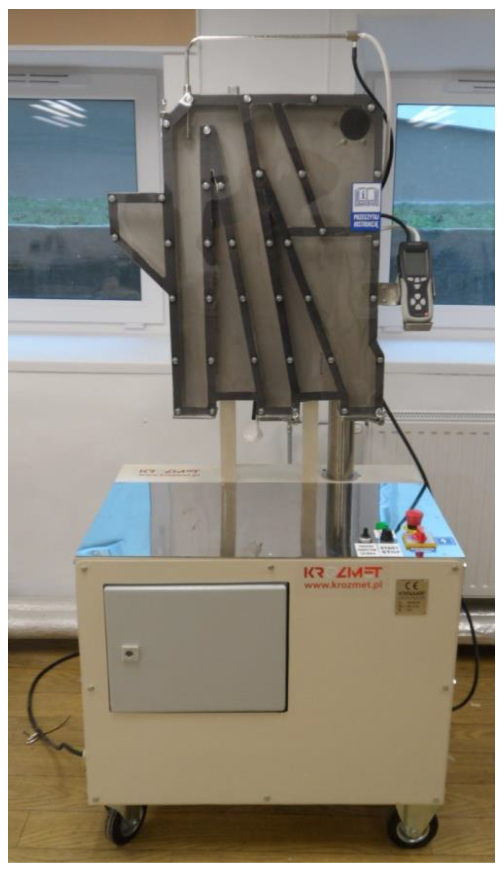

2. Materials and Methods

- Fixed parameters:

- –

- Width of the grain inlet sz = 10 mm;

- –

- Sample mass mp = 300 g;

- –

- Relative moisture content of the sample—11.56 ± 2.00%;

- –

- Rubber impeller blades (properties T-REX40 red natural rubber (T-Rex Rubber International, Netherlands): hardness: 40 ± 5° ShA, min. 600% elongation at break, tensile strength—16 MPa, max. abrasion resistance—210 mm3);

- –

- Distance between the cylinder and beaters sr = 2 mm.

- Independent variables:

- –

- Rotor blade angle αw—50° ÷ 90°, at intervals of 10°;

- –

- Rotational speed of the shaft nw—160 ÷ 400 rpm, at intervals of 60 rpm;

- Dependent variables:

- –

- Kernel separation efficiency ηz, %;

- –

- Husk separation efficiency ηp, %;

- –

- Proportion of damaged kernels Uz, %.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cegielska, A.; Gromulska, W. Różnorodność produktów z orkiszu (Diverse spelt products). Przegląd Zbożowo-Młynarski 2008, 5, 30–31. (In Polish) [Google Scholar]

- Majewska, K.; Dąbkowska, E.; Żuk-Gołaszewska, K.; Tyburski, J. Baking quality of flour obtained from grain of chosen spelt varieties (Triticum spelta L.). Żywność Nauka Technol. Jakość 2007, 2, 60–71. [Google Scholar]

- Capouchová, I. Technological quality of spelt (Triticum spelta L.) from ecological growing system. Sci. Agric. Biochem. 2001, 32, 307–322. [Google Scholar]

- Kohajdova, Z.; Karovicova, J. Nutritional Value and Baking Applications of Spelt Wheat. Acta Sci. Pol. Technol. Aliment. 2008, 7, 5–14. [Google Scholar]

- Wieser, H. Comparative investigations of gluten proteins from different wheat species. III. N–terminal amino acid sequences of a–gliadins potentially toxic for celiac patients. Eur. Food Res. Technol. 2001, 213, 183–186. [Google Scholar]

- Abdel-Aal, E.S.M.; Hucl, P. Amino acid composition and in vitro protein digestibility of selected ancient wheats and their end products. J. Food Comp. Anal. 2002, 15, 737–747. [Google Scholar] [CrossRef]

- Babalski, M.; Przybylak, Z.; Przybylak, K. Uzdrawiające Ziarna Zbóż (Cereal Grains with Healing Properties); Eko Media: Bydgoszcz, Poland, 2013; pp. 1–191. ISBN 9788363537128. (In Polish) [Google Scholar]

- Tyburski, J.; Babalski, M. Uprawa Pszenicy Orkisz (Spelt Cultivation); Centrum Doradztwa Rolniczego w Brwinowie, Oddział w Radomiu: Radom, Poland, 2006; pp. 1–25. ISBN 8360185263. (In Polish)

- Frączek, J.; Reguła, T. Method of evaluation of susceptibility of spelt grains to mechanical damages during the threshing process. Inżynieria Rol. 2010, 4, 51–58. [Google Scholar]

- Choszcz, D.J.; Konopka, S.; Zalewska, K. Characteristics of physical properties of selected varieties of spelt. Inżynieria Rol. 2010, 4, 23–28. [Google Scholar]

- Budzyński, W. (Ed.) Pszenice—Zwyczajna, Orkisz, Twarda: Uprawa i Zastosowanie (Common Wheat, Spelt and Durum Wheat: Cultivation and Applications); Powszechne Wydawnictwo Rolnicze i Leśne: Poznań, Poland, 2012; pp. 1–328. ISBN 9788309011354. (In Polish) [Google Scholar]

- Tudor, N. Farmer Built Spelt Dehuller. USDA Sustainable Agriculture Research and Education Report. 2012. Available online: http://mysare.sare.org/MySare/ProjectReport.aspx?do=viewRept&pn=FNE11–731&t=1&y=2014 (accessed on 18 November 2015).

- Kolankowska, E.; Choszcz, D. Urządzenie do Usuwania Plew z Ziarna Orkiszu (Device for Removing Chaff from Spelt Grain). Patent PL408757, 29 November 2019. (In Polish). [Google Scholar]

- Kolankowska, E.; Choszcz, D. Urządzenie do Usuwania Plew z Ziarna Orkiszu (Device for Removing Chaff from Spelt Grain). Utility Model Application No W123522, 31 May 2017. (In Polish). [Google Scholar]

- Kolankowska, E. Doskonalenie Procesu Usuwania Plew z Ziarna Orkiszu (Optimization of the Dehulling Process for Spelt Kernels). Ph.D. Thesis, Uniwersytet Warmińsko-Mazurki w Olsztynie, Wydział Nauk Technicznych, Olsztyn, Poland, 2019. (In Polish). [Google Scholar]

- Grochowicz, J. Maszyny do Czyszczenia i Sortowania Nasion (Seed Cleaning and Sorting Machines); Wydawnictwo Akademii Rolniczej: Lublin, Poland, 1994; pp. 1–326. ISBN 839016129X. (In Polish) [Google Scholar]

- Kolankowska, E.; Choszcz, D. Separator powietrzny (Air Separator). Utility Model Application No W124984, 31 December 2018. (In Polish). [Google Scholar]

- Stanisz, A. Przystępny kurs Statystyki w Oparciu o Program STATISTICA PL na Przykładach z Medycyny. Tom 1. Statystyki Podstawowe (Accessible Course in Statistics Based on the STATISTICA PL Software on Examples from Medicine. Tome 1. Basic Statistics); StatSoft Polska: Kraków, Poland, 2007; pp. 1–532. ISBN 8388724185. (In Polish) [Google Scholar]

| General Data: Correlation Coefficients are Significant at α < 0.05 N = 25 | ||||

|---|---|---|---|---|

| No. | Variable | Mean | Standard Deviation | Coefficient of Variation (%) |

| 1. | Rotor blade angle (°) | 70.00 | 14.43 | 20.62 |

| 2. | Rotational speed (rpm) | 280.00 | 86.60 | 30.93 |

| 3. | Proportion of damaged kernels (%) | 4.74 | 3.96 | 83.60 |

| Correlation Matrix | ||||

| 1 | 0 | 0.584 | ||

| 1 | 0.320 | |||

| 1 | ||||

| Variable | F-Statistic | Coefficient of Determination R2 | Standard Error of the Estimate | t-Statistic |

| Free term | 8.81 | 0.70 | 2.44 | −3.18 |

| 3.76 | ||||

| −3.84 | ||||

| −0.30 | ||||

| −0.04 | ||||

| 1.14 | ||||

| Quadratic equation for two independent variables: Stepwise regression did not decrease the degree of the polynomial function for two independent variables | ||||

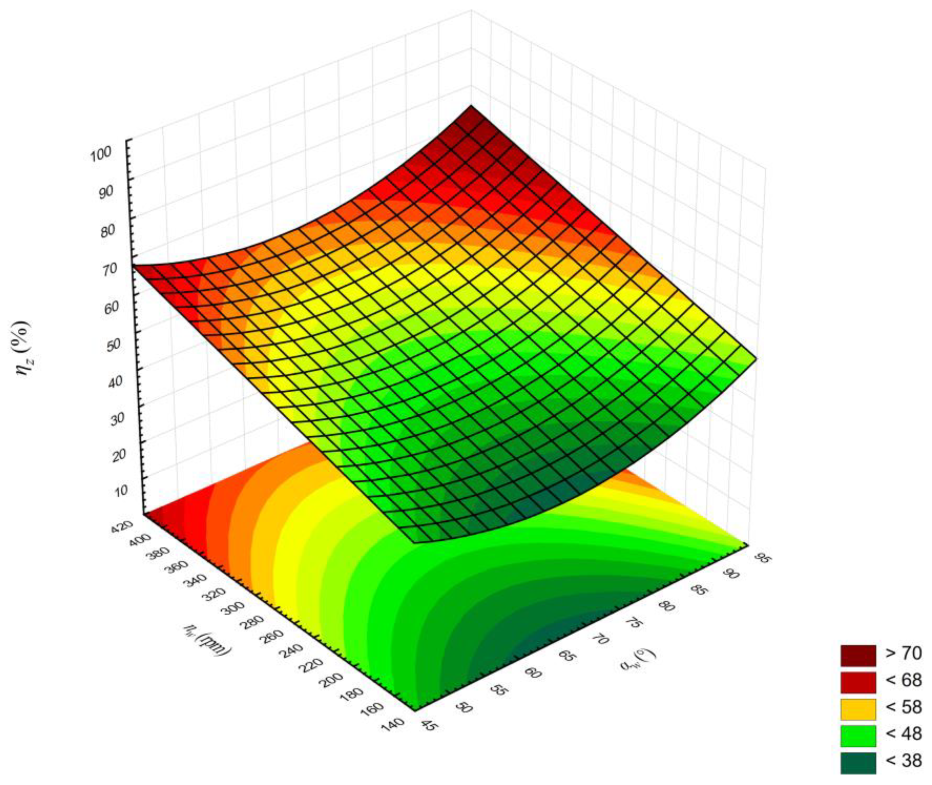

| General Data: Correlation Coefficients are Significant at α < 0.05 N = 25 | ||||

|---|---|---|---|---|

| No. | Variable | Mean | Standard Deviation | Coefficient of Variation (%) |

| 1. | Rotor blade angle (°) | 70.00 | 14.43 | 20.62 |

| 2. | Rotational speed (rpm) | 280.00 | 86.60 | 30.93 |

| 3. | Kernel separation efficiency (%) | 52.14 | 8.58 | 16.46 |

| Correlation Matrix | ||||

| 1 | 0 | 0.226 | ||

| 1 | 0.845 | |||

| 1 | ||||

| Variable | F-Statistic | Coefficient of Determination R2 | Standard Error of the Estimate | t-Statistic |

| Free term | 53.77 | 0.88 | 3.11 | 5.65 |

| −4.41 | ||||

| 4.68 | ||||

| 11.41 | ||||

| Quadratic equation for two independent variables: | ||||

| General Data: Correlation Coefficients are Significant at α < 0.05 N = 25 | ||||

|---|---|---|---|---|

| No. | Variable | Mean | Standard Deviation | Coefficient of Variation (%) |

| 1. | Rotor blade angle (°) | 70.00 | 14.43 | 20.62 |

| 2. | Rotational speed (rpm) | 280.00 | 86.60 | 30.93 |

| 3. | Husk separation efficiency (%) | 42.42 | 9.52 | 22.45 |

| Correlation Matrix | ||||

| 1 | 0 | 0.673 | ||

| 1 | 0.541 | |||

| 1 | ||||

| Variable | F-Statistic | Coefficient of Determination R2 | Standard Error of the Estimate | t-Statistic |

| Free term | 54.86 | 0.89 | 3.42 | 5.85 |

| −4.95 | ||||

| 5.36 | ||||

| . | 7.20 | |||

| Quadratic equation for two independent variables: | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anders, A.; Kolankowska, E.; Choszcz, D.J.; Konopka, S.; Kaliniewicz, Z. The Effect of Selected Parameters on Spelt Dehulling in a Wire Mesh Cylinder. Sustainability 2020, 12, 43. https://doi.org/10.3390/su12010043

Anders A, Kolankowska E, Choszcz DJ, Konopka S, Kaliniewicz Z. The Effect of Selected Parameters on Spelt Dehulling in a Wire Mesh Cylinder. Sustainability. 2020; 12(1):43. https://doi.org/10.3390/su12010043

Chicago/Turabian StyleAnders, Andrzej, Ewelina Kolankowska, Dariusz Jan Choszcz, Stanisław Konopka, and Zdzisław Kaliniewicz. 2020. "The Effect of Selected Parameters on Spelt Dehulling in a Wire Mesh Cylinder" Sustainability 12, no. 1: 43. https://doi.org/10.3390/su12010043

APA StyleAnders, A., Kolankowska, E., Choszcz, D. J., Konopka, S., & Kaliniewicz, Z. (2020). The Effect of Selected Parameters on Spelt Dehulling in a Wire Mesh Cylinder. Sustainability, 12(1), 43. https://doi.org/10.3390/su12010043