Abstract

The development of higher education has led to an increasing demand for campus buildings. To promote the sustainable development of campus buildings, this paper combines social willingness-to-pay (WTP) with the analytic hierarchy process (AHP) based on the characteristics of Chinese campus buildings to establish a life cycle assessment–life cycle cost (LCA–LCC) integrated model. Based on this model, this paper analyses the teaching building at a university in North China. The results show that the environmental impacts and economic costs are largest in the operation phase of the life cycle, mainly because of the use of electric energy. The environmental impacts and economic costs during the construction phase mainly come from the building material production process (BMPP); in this process, steel is the main source. Throughout the life cycle, abiotic depletion-fossil fuel potential (ADP fossil) and global warming potential (GWP) are the most prominent indexes. Further analysis shows that these two indexes should be the emphases of similar building assessments in the near future. Finally, this study offers suggestions for the proposed buildings and existing buildings based on the prominent problems found in the case study, with the aim to provide reference for the design, construction, and operation management of similar buildings.

1. Introduction

The university is an important place for social transformation, performing the functions of education, research, and governance, and it is a key place for promoting current and future development [1]. Many scholars have pointed out the important role played by universities in the process of achieving sustainable development goals [2,3,4]. Since the early 1970s, the academic community has recognized that the continued deterioration of the environment will affect economic and social development, and the concern for the internal environment and sustainability of higher education institutions is increasing. The rapid development of higher education in recent years has led to an increasing demand for university buildings, and the construction and operation of buildings have had a significant impact on the environment and the economy [5,6]. Therefore, to minimize the environmental impacts, construction cost, and operating cost of campus buildings, a comprehensive method for evaluating campus buildings is urgently needed.

As a special “product”, buildings have a long life, and the influence of different building phases on evaluation indexes is significant. Research has devoted gradually increasing attention to applying the life cycle concept to the evaluation and management of buildings, depicting the influence of different building phases and proposing management suggestions. Some developed countries have begun performing comprehensive building evaluations and produced results. For example, the UK’s BREEAM (Building Research Institute Environmental Assessment Methodology) uses the LCA&LCC (LCA, life cycle assessment; LCC, life cycle cost) tool to evaluate buildings in terms of building materials, energy, and management [7,8]. LEED (Leadership in Energy and Environmental Design) in the United States focuses on building materials LCA [9]. Japan’s CASBEE (Comprehensive Assessment System for Building Environmental Efficiency) assesses the life cycle carbon emissions of objects [7]. Germany’s BNB/DGNB (Bewertungs system Nachhaltiges Bauen/Deutsches Gutesiegel fur Nachhaltiges Bauen) emphasizes the quantitative assessment of resource consumption, environmental impacts and costs at various phases of the building life cycle [10,11]. In general, these assessment methods are comprehensive and quantitative and have good reference value.

LCA is a widely recognized environmental management method. In recent years, many experts and scholars have studied the building LCA methodology [12,13,14]. Some scholars have conducted case studies on specific buildings using the LCA method and put forward suggestions for addressing existing problems [15,16,17]. Due to the uncertainty of the decommissioning phase, Vitale et al. [18,19] conducted an in-depth study on this phase to further enhance building sustainability. Chhabra et al. [20,21] considered the impact of natural disasters in their evaluation, fully considering the flexibility of the LCA method in building evaluation. In addition, under many scholars’ unremitting efforts, the Chinese Life Cycle Database has been established; it includes life cycle data such as data on energy, raw materials, and transportation, and has created conditions for the application of LCA methods in the Chinese construction field [22,23,24]. In recent years, some popular LCA software and database companies in the world have started to develop the Chinese LCA database, which supports convenient LCA in China.

In addition to environmental impacts, economic costs are a key component of building development [25]. The LCC method can be used to evaluate the cost of each phase of the product life cycle. Scholars have carried out building LCC and LCA analyses [26,27]. However, although these studies considered the environmental and economic indexes of buildings, they carried out the evaluation process separately. These studies are limited in offering comprehensive indexes or supporting decision makers. Thus, research on LCA–LCC integration is needed.

Before this study was officially launched, over the course of one year, our research group collated and analyzed related studies on construction LCA published in recent years and completed a review entitled “Application and development of life cycle assessment (LCA) in the field of construction” [28]. In the literature review process, we identified the need to apply LCA and LCC methods to building evaluation. We also found that there is no related research on LCA–LCC integrated models at the building level, particularly in educational buildings. In the field of LCA–LCC integration research, some scholars have made contributions, some of which are summarized in Table 1. In general, there are relatively few LCA–LCC integration studies in the field of construction, and most of the LCA–LCC integration research focuses on developed countries with relatively complete basic data. Due to the different development levels of various aspects of Chinese buildings, these methods are difficult to apply in the evaluation of Chinese buildings. Therefore, it is urgent to establish a set of LCA–LCC integrated models applicable to the evaluation of Chinese buildings.

Table 1.

The summary of life cycle assessment–life cycle cost (LCA–LCC) integration studies.

Multiple criteria decision analysis (MCDA) is increasingly being used to facilitate stakeholder involvement in technology-selection processes and in decision support, and some recent studies have confirmed the advantages of this method for decision analysis [29,30]. It is undeniable that this evaluation method has a strong advantage in the flexibility of index selection, which is the mainstream method in current auxiliary decision analyses. However, the life cycle-based evaluation method has greater advantages in index quantification, and the evaluation results can better reflect the impact of each stage of the evaluation target. For the LCA–LCC integrated model, we refer to the idea of MCDA and comprehensively consider the environmental and economic impacts of buildings.

Table 1 shows that the current LCA and LCC integration methods mainly include the analytic hierarchy process (AHP), social willingness-to-pay (WTP), CO2 conversion and fuzzy inference. Among them, social WTP and AHP are the most widely used methods. The AHP has been widely used because of its flexibility and low data requirements. However, because of the complexity of the hierarchy model, establishing a judgment matrix is difficult. Based on the Chinese social background, Professor Li and his group [36] established an environmental impact assessment model and weight determination method based on social WTP and determined the currency factors of nine environmental impact categories, thus providing a basis for establishing a comprehensive assessment system of campus buildings in China. However, it is difficult to reflect the weight relationship between the environment and the economy using this method alone. To establish a practical comprehensive evaluation model, this study combines social WTP and the AHP. This model not only considers the influence of different social backgrounds on the evaluation model but also greatly reduces the complexity of the judgment matrix in the AHP and improves the pertinence and feasibility of the evaluation.

In recent years, a few scholars have conducted research on the evaluation of campus buildings. For example, Soares et al. [37] proposed an energy efficiency plan for a Portuguese higher education building. In this study, an energy audit was conducted, a monitoring campaign was carried out to measure and disaggregate electricity consumption, the consumption of natural gas and water were assessed, and the building envelope and heating and lighting systems were evaluated. However, the results of this study are restricted to the case study, and their generalization outside of the studied context is limited. Xiong et al. [38] used the LCA method to conduct a comparative analysis of teaching buildings with different structures. They found that the use of the timber structure instead of the RC-frame structure could result in good environmental performance, but economic factors were not considered in this study. Huang et al. [25] assessed university dormitories in terms of life cycle environmental impact and cost. The results showed that the consumption of electricity as well as windows, concrete, steel, and cement made the strongest contributions to life cycle environmental impacts, and the use phase was the dominant component of the environmental impacts and cost of university dormitories. The researchers thus proposed two major opportunities for reducing environmental impacts. This line of research closely follows the development trend of Chinese education, and the evaluation results are of high reference value. However, it did not link environmental and economic evaluation results. To better guide the construction and management of campus buildings, it is necessary to establish a comprehensive environmental and economic evaluation system for such buildings in order to provide a scientific theoretical basis for campus design, construction and management.

This paper is organized as follows. The second section describes the establishment of an LCA–LCC integrated model for campus buildings based on the AHP and social WTP. In the third section, the teaching building at a university in North China is taken as an example for analysis using the above model, and improvement suggestions are put forward based on the evaluation results. The fourth section summarizes the research results.

2. Method

This section defines the evaluation goals and boundaries, functional units, inventory contents, and life cycle impact assessment method based on the characteristics of Chinese campus buildings. Based on the investigation, the index weights were obtained based on the AHP and social WTP, and the LCA–LCC integrated model of the campus building was established. This LCA follows the ISO 14040/44 methodology [39,40], and the LCC refers to the ISO 15686-5 standard and the studies of Sun and Buyle et al. [26,41,42].

2.1. Establishment of LCA and LCC Models for Campus Buildings

2.1.1. Goal and Scope Definition

The goals of this LCA and LCC study of campus buildings are (1) to obtain quantitative values for environmental impacts and economic costs in different phases and to propose suggestions on outstanding issues at each phase; (2) to provide a scientific basis for future green campus construction, operation and management; and (3) to lay the foundation for LCA–LCC integration and the establishment of a comprehensive assessment index.

When establishing a comprehensive assessment index of campus buildings, the temporal and physical boundaries of the LCA and LCC should be consistent. Due to the high uncertainty of the building decommissioning phase and its relatively low environmental impact [43], this study does not consider this phase. The temporal boundaries are determined from the building materials acquisition phase to the end of the operation phase.

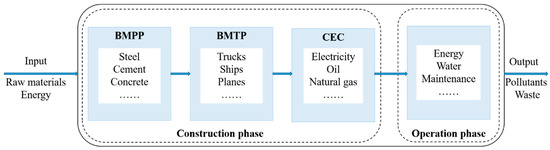

Construction projects can generally be divided into six phases: The investment decision phase, the design phase, the bidding phase, the construction phase, the operation phase, and the renovation and demolition phase. In this study, the purpose of establishing the LCA–LCC integrated model is to compare the different schemes for proposed buildings or to propose an environmental and economic management plan for existing buildings. Therefore, the physical boundary should contain certain environmental and economic contributions. However, the environmental impacts of the investment decision phase, the design phase and the bidding phase are relatively low [44,45], and these three phases are not considered in most current building LCA, such as Kamal et al. [46] applied a cradle-to-gate LCA to benchmark the environmental performance during the construction phase of residential buildings. In this study, the author only considered the materials and energy associated with the production of raw materials to the finished building. Morales et al. [47] performed an LCA that compared two types of public housing in southern Brazil. The construction phase of the public housing in this study included the building material production process, the transportation process and the construction and installation process. Petrovic et al. [48] recently evaluated a house in Sweden. The construction phase included both the material production process and the transportation process. To facilitate follow-up assessment, the physical boundaries of the research system distinguish the construction phase and the operation phase. The construction phase involves the building material production process (BMPP), the building material transportation process (BMTP), and construction energy consumption (CEC). The operation phase mainly involves operational energy consumption, water consumption and building maintenance. The system boundary is shown in Figure 1. To facilitate comparison between buildings of different scales, the functional unit is set to a use area of 1 m2.

Figure 1.

Campus building assessment system boundary. BMPP: building material production process; BMTP: building material transportation process; CEC: construction energy consumption.

Unlike most other products, buildings have a long service life, complex construction technology and a variety of materials. To facilitate follow-up assessment, in this paper, the following assumptions are made:

- Due to the large-scale and complex materials used to construct university buildings in China, it is difficult to obtain all the data on buildings and to perform an accurate evaluation of their life cycle. Therefore, this study focuses on the main raw materials in buildings.

- We consider only the consumption of energy, water, and building maintenance in the operation phase of buildings. The average annual consumption data are taken as the consumption of energy, water, and maintenance materials during the operation phase, and it is assumed that the level of consumption remains unchanged during the operation phase.

- We assume that buildings can operate for 50 years and that building technology will not change during these 50 years.

- Given the long operating life of a building, the time span of the construction phase can be neglected.

- Due to the lack of basic data in China, it is difficult to determine the currency factors of some evaluation indexes. Therefore, at this stage, it is infeasible to evaluate all LCA indexes in the integrated model. In this regard, we analyzed some building LCA cases, building materials LCA cases and some related studies and found that the indexes related to greenhouse gases, sulfur oxides, nitrogen oxides, photochemical oxidants, and resource consumption were concerned in the construction field [48,49,50,51]. Considering the limitations of actual conditions, at present, the selection of LCA indexes in the integrated model would focus on the environmental impact brought by the above substances. With the development of future construction technology and the improvement of relevant studies on currency factors, the LCA indexes can be further adjusted to improve the integrated model.

2.1.2. Inventory Analysis

Based on the characteristics of campus building construction and operation, Table 2 lists the inventory of campus building LCA and LCC requirements. Because the characterized results will be converted to social WTP, considering that money has a time value, the converted results should be discounted. Therefore, to facilitate integration, the operation phase inventory is collected based on annual consumption. For the inventory data for specific production processes, such as the different building materials and energy, refer to the background databases of evaluation software. The evaluation software and database can be selected according to the characteristics of the building and the habits of users. To make the evaluation results accurate, a local database is preferable.

Table 2.

Inventory of campus building life cycle assessment (LCA) and life cycle cost (LCC) requirements.

2.1.3. Impact Assessment

In our review entitled “Application and development of life cycle assessment (LCA) in the field of construction” [28], our group collated and analyzed evaluation indexes from studies related to construction LCA published in recent years and tried to classify these common indexes according to their damage types, as shown in Table 3. When selecting indexes, we should follow the assumption 5 mentioned in Section 2.1.1, and try to make selected indexes cover these four categories. In the end, we select: Global warming potential (GWP), photochemical oxidant creation potential (POCP), acidification potential (AP), eutrophication potential (EP), and abiotic depletion-fossil fuel potential (ADP fossil) as LCA indexes in this study.

Table 3.

Evaluation index classification in the field of construction (source [28]).

Considering the time value of money, the cost of each phase should be discounted. Given the long operating life of a building, the time span of the construction phase can be neglected. The cost of the operation phase should be calculated by the net present value and discounted to the initial phase of the project so that the following model can be established:

where LCC is the life cycle cost of the building, CC is the construction cost of the building, CO is the annual operating cost of the building, T is the life cycle, and i is the discount rate. Due to the long life cycle of campus buildings, a lower discount rate should be chosen for calculation. The discount rate for this study is set at 6% [52].

2.2. Establishment of a Comprehensive Index for Campus Building Assessment

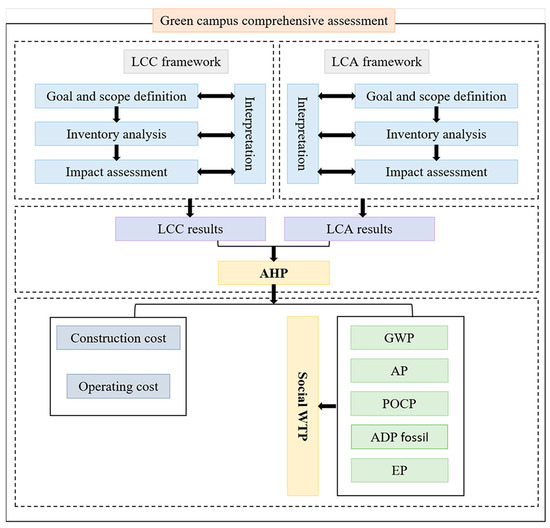

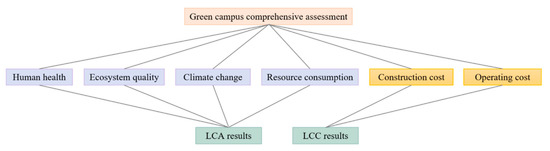

To establish a comprehensive assessment model that is easy to promote, we combine social WTP with the AHP. The LCA–LCC integrated framework for campus buildings is shown in Figure 2. Social WTP is used to monetize the environmental impact potential. The AHP is used only to judge the weight of the LCC results and the LCA results for the comprehensive index. The weight was determined by a questionnaire survey shown in Appendix A; the research objects include students, campus managers, and architectural design and construction firms. The hierarchical structural model is shown in Figure 3. Based on the survey, the weight for LCA results is 0.730, while the weight for LCC results is 0.270. (The establishment of the judgment matrix and its solution process can be found in monograph [53]).

Figure 2.

Campus building LCA–LCC integrated framework. GWP: global warming potential POCP: photochemical oxidant creation potential; AP: acidification potential; EP: eutrophication potential ADP fossil: abiotic depletion-fossil fuel potential.

Figure 3.

Hierarchical structural model.

Social WTP can be calculated from the following formula:

where is the th social WTP result, is the th environmental impact potential, and is the currency factor of the ith environmental impact.

Due to the particularity of the building, in the operation phase must be discounted to the initial phase of building construction, and the discounting method is the same as that of CO.

Based on Li’s research [36], we selected five of these currency factors and adjusted the currency factors corresponding to the EP and ADP fossil based on the characteristics of the integrated model and assessment goal. The currency factors involved in this study are shown in Table 4.

Table 4.

Currency factors of different environmental impact categories (source [36]).

3. Case Study

This section takes the teaching building of a university in North China as a case to study the building’s environmental impact, cost expenditure and comprehensive impact. The purpose is to identify the main problems in each phase of the teaching building and to put forward suggestions, providing a reference for similar research.

3.1. Case Overview

The teaching building was built in 2015 and is located in a coastal city with a monsoon climate and four distinct seasons. The average annual temperature is 12–15 °C, and the average annual sunshine hours are 2471–2769 h. The teaching building is open from March to July and from September to December every year, for a total of 9 months. Due to the winter and summer holiday periods in Chinese universities, the heating and cooling energy consumption of the building is low.

This teaching building has a multi-story reinforced concrete frame structure with a total construction area of 10,762.1 m2 and a total height of 15.75 m. It incorporates passive energy-saving technologies such as natural ventilation and natural lighting and mainly uses a centralized ground source heat pump air-conditioning system for heating and cooling, and the input inventory mainly includes water and electricity. This university has established a water-saving system that makes full use of reclaimed water and rainwater, reducing the consumption of water resources. This teaching building was awarded the green building design label certificate issued by the Chinese Society for Urban Studies in January 2017. The research results can provide further suggestions for the construction and operation of the teaching building and provide a reference for the construction and operation of campus buildings in the future.

3.2. Inventory Analysis

The main foreground system data during the construction phase originate from (1) the bill of quantities, (2) the main material equipment list, and (3) the engineering cost list. These lists are provided by the university’s infrastructure office, and the data quality is high.

Because the building materials transport data are difficult to obtain, this study assumes that all materials are supplied by the manufacturer nearest to the construction site and transported by a 22 t payload capacity truck, and the transport distance is calculated by Google Maps. Table 5 summarizes the main material consumption, energy consumption, cost and transportation distance information in the teaching building construction phase.

Table 5.

Main material consumption, energy consumption, cost and transportation distance information in the teaching building construction phase.

The main foreground system data during the operation phase originate from (1) water and energy bills of this building over the past 3 years and (2) damage and maintenance reports of this building over the past 3 years. These lists are provided by the university’s logistics departments, and the data quality is high. Table 6 summarizes the main material consumption, energy consumption and cost information in the operation phase of the teaching building. Because the transportation process of building maintenance materials has little influence, this study does not consider it.

Table 6.

Main material consumption, energy consumption, and cost information in the teaching building operation phase.

To meet the needs of Chinese customer groups, some popular LCA software and database companies in the world have started to develop a Chinese LCA database. We found that the Professional+Extension database in GaBi 8.7.1.30 software meets the needs of our case evaluation data. Given the conditions of our research group, we chose GaBi 8.7.1.30 software and the Professional+Extension database to analyze this case.

3.3. Results and Interpretation

3.3.1. Construction Phase

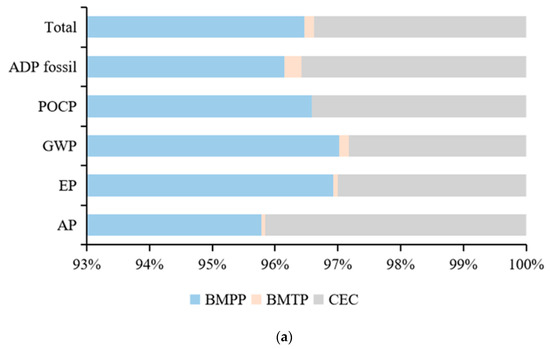

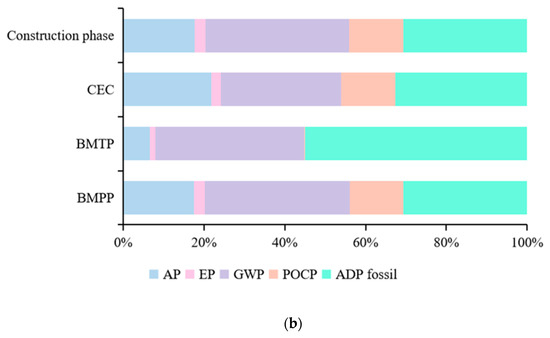

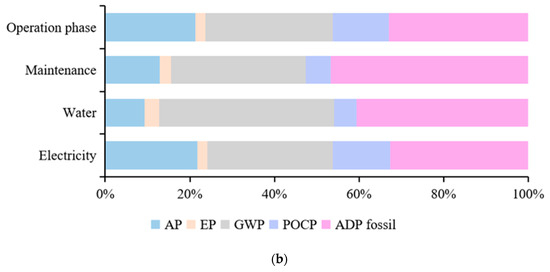

Based on the inventory collection, using GaBi software modelling and analysis, the environmental impact potential of the teaching building construction phase is shown in Table A2 (see Appendix B), and the normalized results are converted into the percentages shown in Figure 4. Figure 4a shows that the five types of environmental impacts in the BMPP account for more than 95% of the sum of the various environmental impact potentials during the construction phase, followed by CEC, and the proportion of all types of environmental impact potentials is approximately 3%. The environmental impact potentials of the BMTP are the lowest. According to the above analysis, the construction phase of similar buildings should focus on optimizing the BMPP, and the results of Kamali et al. [46] also confirm this conclusion to some extent. In addition, this case assumes that the building materials are transported from the manufacturer nearest to the construction site. If the transportation distance changes, the evaluation results will also change.

Figure 4.

Percentage results for the environmental impact potential during the construction phase. (a) Source composition of different environmental impact potentials; (b) the environmental impact potential composition of different construction processes.

Figure 4b shows that the environmental impact potentials during the construction phase are as follows (in descending order): GWP, ADP fossil, AP, POCP, and EP. Notably, the GWP and ADP fossil are particularly prominent during the BMTP; these two impact potentials account for 35.64% and 30.69% of the total environmental impact of BMTP, respectively. Further analysis revealed that under the assumptions of this case, the contributions of diesel production and vehicle transportation to the GWP during the BMTP are almost equal, indicating that the contribution of the vehicle transportation process cannot be ignored. Therefore, it is necessary for managers to consider the distance between the supply point of building materials and the construction site during the bidding phase.

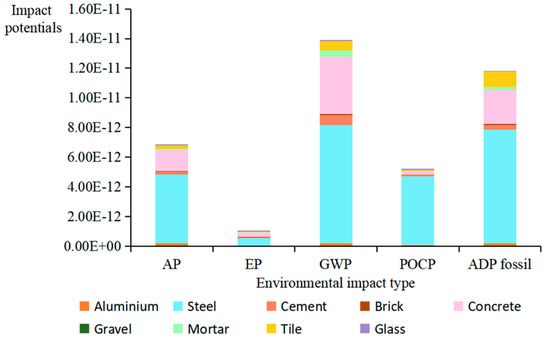

Based on the above analysis, BMPP is the main control process for reducing environmental impacts during the construction phase. Figure 5 shows that the environmental impacts of steel, which accounted for only 6.67% of building material consumption, are the largest. Liu’s [54] research also indicates that China’s steel companies need to improve their carbon management efforts. Among the five environmental impact potentials, the GWP and ADP fossil are the most prominent impacts in the BMPP. In this regard, steel, concrete and cement are the main sources contributing to the GWP, while steel, concrete and tile are the main sources contributing to ADP fossil.

Figure 5.

Environmental impact potential of BMPP.

The production of these building materials requires the consumption of a high amount of energy and fossil fuels. Power generation and the burning of fossil fuels are the main source of greenhouse gases and also cause non-living resource consumption. Therefore, for the construction phase of similar buildings, using environmentally friendly building materials and reducing the consumption of electricity and fossil fuels in the production of building materials should be the top priority for reducing the environmental impact in the construction phase.

Compared with the operation phase of the building, the building construction phase has a short time span; thus, the discount rate is not considered. The costs of the construction phase are the sum of the building materials costs, the energy charge and the transportation costs, that is, CC=1324.76 RMB/m2. The building materials costs accounted for 99% of the total construction costs, while the transportation costs and energy charge accounted for less than 1%.

3.3.2. Operation Phase

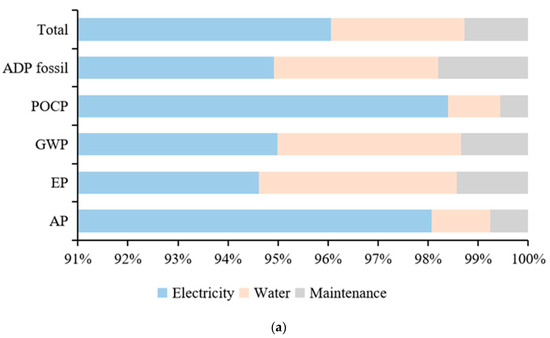

Based on the above inventories, the annual environmental impact of the operation phase as analysed by GaBi software is shown in Table A3 (see Appendix B); the normalized results in Table A3 are converted into the percentages shown in Figure 6. Figure 6a shows that electricity consumption has the largest environmental impact; its contribution to the five environmental impacts is more than 90%, and its total environmental impact potential accounts for 96.06% of the operation phase’s impact. Water consumption accounts for 2.67% and the maintenance process accounts for only 1.26% of the total environmental impact. Figure 6b shows that the environmental impacts during the operation phase are as follows (in descending order): ADP fossil, GWP, AP, POCP, and EP. The main reasons for these problems are resource consumption and environmental pollution in the power generation process. Therefore, we will conduct an in-depth analysis in the following.

Figure 6.

Percentage results for the environmental impact potential during the operation phase: (a) Source composition of different environmental impact potentials; (b) the environmental impact potential composition of different operation processes.

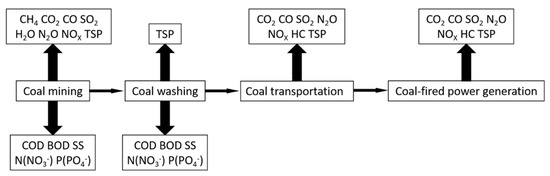

Coal-fired power generation accounts for a large proportion of power generation in China. The life cycle of the coal-fired power process can be divided into four stages: coal mining, coal washing, coal transportation, and coal-fired power generation; the main emissions at each stage are shown in Figure 7. The main contributor to ADP fossil is the consumption of coal resources. The main contributor to the GWP is the H2O (gas), CO2, N2O, and CH4 generated during power generation. The AP is mainly derived from SO2 and NOx emissions, and the EP is mainly derived from N (NO3–) and P (PO4–) discharged to bodies of water. The POCP is mainly derived from strong oxidants formed by photochemical reactions of NOx, CH and other substances under light conditions.

Figure 7.

Coal-fired power process and major pollutants.

At present, dust removal, denitration and desulfurization are required before the emission of flue gas from coal-fired power plants in China. Dust removal mainly uses electrostatic precipitation or bag filters, denitration mainly uses selective catalytic reduction technology, and desulfurization mainly uses wet desulfurization. These treatment processes can achieve great effects; thus, the dust, NOx and SO2 in the flue gas emitted by coal-fired power plants have been greatly reduced. In the coal mining and coal washing stages, wastewater will also be treated so that the COD, BOD, SS, N, and P of the treated water meet the emission standards. In this part of the assessment, we did not consider the flue gas treatment of coal-fired power plants or the wastewater treatment for coal mining and coal washing. It is assumed that flue gas and wastewater are directly discharged, so the actual AP and EP will be further reduced.

Coal remains the dominant fossil fuel in the power sector, accounting for 90% of the thermal power installed capacity [55]. The coal-fired power industry is an important field for carbon emission reduction, and the Ministry of Ecology and Environment of the People’s Republic of China is accelerating the construction of China’s carbon market infrastructure. However, there is still a long way to go before the comprehensive transformation of carbon emissions in the coal-fired power industry, which means that the emissions from coal-fired power plants will contain a large amount of greenhouse gases. Yu et al. [56] carried out LCA for different types of power plants in China, and their research results also reflect the impact of coal-fired power plants on climate change and resource consumption. In summary, the issue of fossil fuel consumption and global warming in the operation phase of similar buildings should be taken seriously.

The operation phase has a long time span, and the time value of money should be considered. The cost of the operation phase calculated by the method presented in 2.1.3 is 1309.97 RMB/m2. Electricity costs account for 58.47% of the operating cost, maintenance costs account for 20.86%, and water costs account for 20.67%.

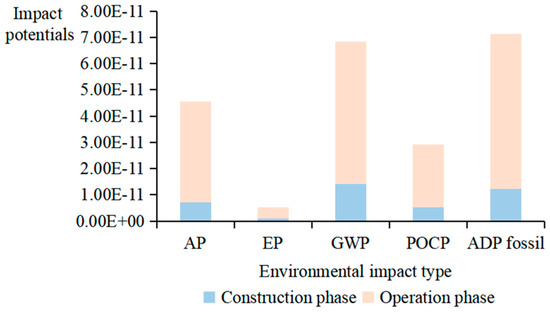

3.3.3. Full Life Cycle Impact and Integration Results

Table A4 shows the environmental impact potential in the full life cycle of the teaching building (see Appendix B); the normalized results in Table A4 are shown in Figure 8. Figure 8 shows that the environmental impacts in the operation phase are greater than those in the construction phase. The environmental impact potentials are as follows (in descending order): ADP fossil, GWP, AP, POCP, and EP; among them, ADP fossil and GWP are the most prominent. Based on the previous analysis, the main contributor to such environmental problems is the coal-fired power process.

Figure 8.

Coal-fired power process and major pollutants.

The construction cost and operating cost above are summarized in Table 7, which shows that the construction cost of the teaching building is greater than the operating cost when considering its 50-year lifespan. However, the lifespan of teaching buildings in Chinese universities is generally more than 50 years. Therefore, for teaching buildings, cost control in the operating phase is also very important.

Table 7.

The cost in the life cycle of the teaching building (unit: RMB/m2).

For this case, Formula (2) is used to calculate social WTP (Wi) in the construction phase and the operation phase. Wi during the construction phase and Wi during the operation phase after discounting are summed to obtain the social WTP results for the impact on the environment in the life cycle of the teaching building, as shown in Table 8.

Table 8.

The social WTP results for the impact on the environment in the life cycle of the teaching building (unit: RMB).

After weighting the environmental impact and economic costs, the comprehensive index is 927.31 RMB. This comprehensive index provides a reference for the selection of alternative scenarios in the future.

3.4. Improvement Suggestions

Based on the above analysis, it can be seen that the main environmental impacts and costs of the teaching building are derived from power consumption and BMPP. The main environmental impacts are ADP fossil and GWP. In this section, based on the above evaluation results, improvement suggestions for similar proposed buildings and existing buildings will be proposed. The purpose is to provide guidance for the operation management of this building and to provide a reference for the design, construction, and operation management of similar buildings.

3.4.1. Suggestions for the Proposed Buildings

Architects should mainly consider the selection of building materials and the energy consumption of building operation in the building design phase. Meanwhile, this study found that although the transportation process of building materials has relatively little impact, it has certain energy-saving potential. Therefore, we propose the following suggestions:

- Select suitable building materials. For the selection of building materials, environmentally friendly building materials are preferable. At the same time, regional characteristics should be considered in the selection of building materials to avoid transferring the environmental impact of the construction phase to the construction operation phase. Some scholars have compared building materials [26,57,58,59,60,61,62,63,64,65], and some scholars have considered the influence of the external environment when evaluating building materials [13,20,21,66] These studies can provide a reference for building designers to choose building materials.

- Design low-energy buildings. The “Design Standard for Energy Efficiency of Public Buildings” (GB50189-2015) should be strictly implemented during the process of building design. Appropriate heating and cooling methods should be determined based on local characteristics. Conditional areas can consider accessing the electricity generated by new energy, which can greatly reduce resource consumption and environmental pollution. However, the cost of some new energy generation methods is relatively high, so economic factors should be taken into consideration when making decisions. The LCA–LCC integrated model constructed in this study can be used for scheme comparison and selection.

- Improve the bidding scheme. In this study, we found that although the impact of the BMTP is small, the contributions of diesel production and vehicle transportation to the GWP during the BMTP are almost equal. The environmental impact and cost of vehicle transportation are directly related to the transportation distance. Therefore, it is necessary for managers to consider the distance between the supply point of building materials and the construction site during the bidding phase.

3.4.2. Suggestions for Existing Buildings

For existing buildings, the operational process is the primary concern. Our study shows that the impact potential brought by the electricity consumption in the operation phase accounts for a large proportion of the total impact. In this regard, we will put forward improvement suggestions based on the development planning and climate characteristics of the area where the teaching building is located. Suggestions are as follows:

- Renovate the power supply system of the teaching building. Based on the survey, we propose two alternative scenarios. Scenario 1: The teaching building is located in a coastal city in North China, where solar energy resources are relatively abundant. In addition, the school building roof area is large. Distributed photovoltaic power can be designed in combination with architectural features, and a photovoltaic unit can be installed on the roof. Therefore, distributed photovoltaic power can be considered. Scenario 2: Relevant departments intend to develop wind power in the area, which would make the use of wind power at the university possible. However, it is undeniable that the above two power generation methods have higher cost than the original power generation method [67]. Therefore, it is advisable for decision makers to evaluate the above alternative scenarios with the LCA–LCC integrated model before making a decision.

- Reduce the use of electrical energy. Reducing the use of electric energy can be achieved in the following three ways: a. Strengthening environmental education for students, b. formulating rules for the use of public resources on campus, and c. strengthening supervision and management. Ding et al. recently conducted a study on the behaviour of students in a Chinese university and proposed a strategy for reducing energy consumption via behavioural changes. The results of this study indicate that the improvement in energy-saving education for Chinese college students is imminent [68]. The teaching building is mainly open to college students. By strengthening students’ environmental education and cultivating energy-saving habits, the energy consumption of the teaching building can be reduced to some extent. In addition, relevant departments can formulate rules for the use of public resources on campus. For the teaching building, study lounges and other places, an appointment system can be adopted and an online point assessment system can be established. A user needs to turn off indoor electrical equipment after using it. If an administrator finds that the electrical equipment is not turned off, the user’s points will be deducted. After points are deducted to a certain point, the user will be restricted from using the public resources. Through this approach, administrators can strengthen supervision and effectively reduce the waste of electric energy.

4. Conclusions

Based on the actual situation of campus buildings in China, this study combined social WTP with the AHP to establish the LCA–LCC integrated model for the comprehensive assessment of campus buildings. The model can obtain quantitative environmental and economic indexes, which can be used for comprehensive evaluation of campus buildings and comparative analysis of alternative scenarios.

This study used the above integrated model to evaluate the teaching building at a university in North China. The results show that during the building’s life cycle, the environmental impacts and economic costs of the operation phase were the largest, mainly because of the use of electric energy. The environmental impacts and economic costs during the construction phase mainly came from the BMPP; in this process, steel was the main source. Although the environmental impact during the BMTP was small, it also had a certain energy-saving potential. Overall, the sources of the life cycle impact of the teaching building are as follows (in descending order): ADP fossil, GWP, AP, POCP, and EP. Further analysis shows that ADP fossil and GWP should be the emphases of similar building assessments in the near future.

This paper can help guide the construction and operation of campus buildings and provide assistance for campus management and operations. In addition, the results of the study provide a reference for the improvement of environmental and economic evaluation in China’s green campus evaluation standards and relevant green campus policies in China. However, due to the lack of basic data in China, it is difficult to determine the currency factors for some evaluation indexes, so there are relatively few LCA indexes in this study. We will conduct in-depth studies on currency factors in the future to improve the evaluation model.

Author Contributions

Conceptualization, Z.X., H.L., Q.Z., J.W., J.F., and X.Z.; Formal analysis, Z.X., H.L., and Q.Z.; Funding acquisition, H.L.; Investigation, Z.X., H.L., Q.Z., J.W., J.F., and X.Z.; Methodology, Z.X., H.L., Q.Z., J.W., J.F., and X.Z.; Supervision, Z.X. and H.L.; Writing—original draft, Z.X. and Q.Z.; Writing—review and editing, H.L., J.W., J.F., and X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Project for School Green Development Research of the Chinese Ministry of Education, grant number LSFZ1601.

Acknowledgments

The authors would like to thank American Journal Experts for English editing services.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Questionnaire

LCA results and LCC results weight determination questionnaire based on analytic hierarchy process

Instruction:

Please utilize the pairwise comparison to determine the importance of the six indexes (Human health, Ecosystem quality, Climate change, Resource consumption, Construction cost, Operating cost) for the green campus comprehensive assessment and fill in Table A1. For example, if A (Human health) is moderately important, fill in “A” in the corresponding bracket under “Moderate importance”. Conversely, if you think that B (Ecosystem quality) is strongly important, fill in “B” in the corresponding bracket under “Strong importance”. If you think that A (Human health) is as important as B (Ecosystem quality), then fill in “AB” in the corresponding brackets under “Equal importance”. Pairwise comparisons of each line can only be filled in “A”, “B”, or “AB” in one bracket. Thank you for your cooperation and support.

Table A1.

Importance judgment table.

Table A1.

Importance judgment table.

| Comparative Indexes | Equal Importance | Between Equal Importance and Moderate Importance | Moderate Importance | Between Moderate Importance and Strong Importance | Strong Importance | Between Strong Importance and Very Strong Importance | Very Strong Importance | Between Very Strong Importance and Extreme Importance | Extreme Importance |

|---|---|---|---|---|---|---|---|---|---|

| A (Human health) B (Ecosystem quality) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Climate change) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Resource consumption) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Climate change) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Resource consumption) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Climate change) B (Resource consumption) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Climate change) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Climate change) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Resource consumption) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Resource consumption) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Construction cos) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

Appendix B. The Environmental Impact Potentials at Various Phases in the Case Study

Table A2.

The environmental impact potential of the teaching building construction phase.

Table A2.

The environmental impact potential of the teaching building construction phase.

| Item | AP | EP | GWP | POCP | ADP Fossil | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Characterization (kg SO2 eq.) | Normalization | Characterization (kg Phosphate eq.) | Normalization | Characterization (kg CO2 eq.) | Normalization | Characterization (kg Ethene eq.) | Normalization | Characterization (MJ) | Normalization | |

| Building materials production | 1.63 | 6.81 × 10−12 | 0.157 | 9.94 × 10−13 | 5.80 × 102 | 1.39 × 10−11 | 0.19 | 5.17 × 10−12 | 4.50 × 103 | 1.18 × 10−11 |

| Building materials transportation | 9.65 × 10−4 | 4.04 × 10−15 | 1.28 × 10−4 | 8.11 × 10−16 | 0.952 | 2.27 × 10−14 | 2.81 × 10−6 | 7.62 × 10−17 | 12.8 | 3.38 × 10−14 |

| Construction energy consumption | 7.07 × 10−2 | 2.96 × 10−13 | 4.87 × 10−3 | 3.08 × 10−14 | 16.9 | 4.03 × 10−13 | 6.74 × 10−3 | 1.83 × 10−13 | 1.67 × 102 | 4.41 × 10−13 |

Table A3.

The annual environmental impact potential of the teaching building operation phase.

Table A3.

The annual environmental impact potential of the teaching building operation phase.

| Item | AP | EP | GWP | POCP | ADP Fossil | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Characterization (kg SO2 eq.) | Normalization | Characterization (kg Phosphate eq.) | Normalization | Characterization (kg CO2 eq.) | Normalization | Characterization (kg Ethene eq.) | Normalization | Characterization (MJ) | Normalization | |

| Electricity | 0.18 | 7.53 × 10−13 | 1.24 × 10−2 | 7.83 × 10−14 | 43 | 1.03 × 10−12 | 1.72 × 10−2 | 4.67 × 10−13 | 4.27 × 102 | 1.12 × 10−12 |

| Water | 2.14 × 10−3 | 8.97 × 10−15 | 5.19 × 10−4 | 3.28 × 10−15 | 1.66 | 3.97 × 10−14 | 1.83 × 10−4 | 4.97 × 10−15 | 14.8 | 3.90 × 10−14 |

| Maintenance | 1.40 × 10−3 | 5.88 × 10−15 | 1.88 × 10−4 | 1.19× 10−15 | 0.609 | 1.45 × 10−14 | 9.83 × 10−5 | 2.67 × 10−15 | 8.09 | 2.13 × 10−14 |

Table A4.

The environmental impact potential of the full life cycle of the teaching building.

Table A4.

The environmental impact potential of the full life cycle of the teaching building.

| Item | AP | EP | GWP | POCP | ADP Fossil | ADP Fossil | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Characterization (kg SO2 eq.) | Normalization | Characterization (kg Phosphate eq.) | Normalization | Characterization (kg CO2 eq.) | Normalization | Characterization (kg Ethene eq.) | Normalization | Characterization (MJ) | Normalization | |

| Construction phase | 1.70 | 7.11 × 10−12 | 0.162 | 1.03 × 10−12 | 5.98 × 102 | 1.42 × 10−11 | 0.197 | 5.36 × 10−12 | 4.68 × 103 | 1.23 × 10−11 |

| Operation phase | 9.18 | 3.84 × 10−11 | 0.655 | 4.14 × 10−12 | 2.26 × 103 | 5.42 × 10−11 | 0.874 | 2.37 × 10−11 | 2.25 × 104 | 5.90 × 10−11 |

| Grand total | 10.9 | 4.55 × 10−11 | 0.817 | 5.16 × 10−12 | 2.86 × 103 | 6.85 × 10−11 | 1.07 | 2.91 × 10−11 | 2.72 × 104 | 7.13 × 10−11 |

References

- Finlay, J.; Massey, J. Eco-Campus: Applying the Ecocity Model to Develop Green University and College Campuses. Int. J. Sustain. High. Educ. 2012, 13, 150–165. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, K.; Xue, B.; Fujita, T. Creating a “Green University” in China: A Case of Shenyang University. J. Clean. Prod. 2013, 61, 13–19. [Google Scholar] [CrossRef]

- Findler, F.; Schönherr, N.; Lozano, R.; Stacherl, B. Assessing the Impacts of Higher Education Institutions on Sustainable Development—An Analysis of Tools and Indicators. Sustainability 2019, 11, 59. [Google Scholar] [CrossRef]

- Anand, C.K.; Bisaillon, V.; Webster, A.; Amor, B. Integration of Sustainable Development in Higher Education—A Regional Initiative in Quebec (Canada). J. Clean. Prod. 2015, 108, 916–923. [Google Scholar] [CrossRef]

- Alghamdi, A.; Haider, H.; Hewage, K.; Sadiq, R. Inter-University Sustainability Benchmarking for Canadian Higher Education Institutions: Water, Energy, and Carbon Flows for Technical-Level Decision-Making. Sustainability 2019, 11, 2599. [Google Scholar] [CrossRef]

- Akhanova, G.; Nadeem, A.; Kim, J.R.; Azhar, S.A. Framework of Building Sustainability Assessment System for the Commercial Buildings in Kazakhstan. Sustainability 2019, 11, 4759. [Google Scholar] [CrossRef]

- Alyami, S.H.; Rezgui, Y. Sustainable Building Assessment Tool Development Approach. Sustain. Cities Soc. 2012, 5, 52–62. [Google Scholar] [CrossRef]

- Lee, W.L.; Burnett, J. Benchmarking Energy Use Assessment of HK-BEAM, BREEAM and LEED. Build. Environ. 2008, 43, 1882–1891. [Google Scholar] [CrossRef]

- USGBC. Available online: http://www.usgbc.org/displaypage.aspx?cmspageid=220 (accessed on 10 September 2019).

- Wei, Y.; Wang, S. German Building Sustainability Assessment System Based on Integrated Lca Methodology. Arch. J. 2014, 11, 92–96. (In Chinese) [Google Scholar]

- Konig, H.; De Cristofaro, M.L. Benchmarks for Life Cycle Costs and Life Cycle Assessment of Residential Buildings. Build. Res. Inf. 2012, 40, 558–580. [Google Scholar] [CrossRef]

- Tecchio, P.; Gregory, J.; Olivetti, E.; Ghattas, R.; Kirchain, R. Streamlining the Life Cycle Assessment of Buildings by Structured Under-Specification and Probabilistic Triage. J. Ind. Ecol. 2019, 23, 268–279. [Google Scholar] [CrossRef]

- Hennequin, T.; Dong, Y.; Arnbjerg-Nielsen, K.; Sørup, H. Life Cycle Assessment of a Typical European Single-Family Residence and its Flood Related Repairs. J. Clean. Prod. 2019, 228, 1334–1344. [Google Scholar] [CrossRef]

- Zabalza, I.; Scarpellini, S.; Aranda, A.; Llera, E.; Jáñez, A. Use of LCA as a Tool for Building Ecodesign. A Case Study of a Low Energy Building in Spain. Energies 2013, 6, 3901–3921. [Google Scholar] [CrossRef]

- Lessard, Y.; Anand, C.; Blanchet, P.; Frenette, C.; Amor, B. LEED v4: Where are we Now? Critical Assessment through the LCA of an Office Building Using a Low Impact Energy Consumption Mix. J. Ind. Ecol. 2018, 22, 1105–1116. [Google Scholar] [CrossRef]

- Vitale, P.; Arena, U. An Attributional Life Cycle Assessment for an Italian Residential Multifamily Building. Environ. Technol. 2017, 39, 3033–3045. [Google Scholar] [CrossRef] [PubMed]

- Kofoworola, O.F.; Gheewala, S.H. Environmental Life Cycle Assessment of a Commercial Office Building in Thailand. Int. J. Life Cycle Assess. 2008, 13, 498–511. [Google Scholar] [CrossRef]

- Marique, A.F.; Rossi, B. Cradle-To-Grave Life-Cycle Assessment within the Built Environment: Comparison between the Refurbishment and the Complete Reconstruction of an Office Building in Belgium. J. Environ. Manag. 2018, 224, 396–405. [Google Scholar] [CrossRef]

- Vitale, P.; Arena, N.; Di Gregorio, F. Life Cycle Assessment of the End-Of-Life Phase of a Residential Building. Waste Manag. 2017, 60, 311–321. [Google Scholar] [CrossRef]

- Chhabra, J.P.S.; Hasik, V.; Bilec, M.M.; Warn, G.P. Probabilistic Assessment of the Life-Cycle Environmental Performance and Functional Life of Buildings due to Seismic Events. J. Archit. Eng. 2018, 24, 04017035. [Google Scholar] [CrossRef]

- Welsh-Huggins, S.J.; Liel, A.B. A Life-Cycle Framework for Integrating Green Building and Hazard-Resistant Design: Examining the Seismic Impacts of Buildings with Green Roofs. Struct. Infrastruct. Eng. 2017, 13, 19–33. [Google Scholar] [CrossRef]

- Liu, X.L.; Wang, H.T.; Chen, J. Method and basic model for development of Chinese reference life cycle database. Acta Sci. Circumstantiae 2010, 30, 2136–2144. (In Chinese) [Google Scholar]

- Gong, X.; NIE, Z.; Wang, Z.; Zuo, T. Research and Development of Chinese LCA Database and LCA Software. Rare Met. 2006, 25, 101–104. [Google Scholar] [CrossRef]

- Ma, X.; Wang, H.T. Research and Application of Life Cycle Assessment in China. Chem. Eng. Equip. 2015, 2, 164–166. (In Chinese) [Google Scholar]

- Huang, L.; Liu, Y.; Krigsvoll, G.; Johansen, F. Life Cycle Assessment and Life Cycle Cost of University Dormitories in the Southeast China: Case Study of the University Town of Fuzhou. J. Clean. Prod. 2018, 173, 151–159. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability Assessment of Circular Building Alternatives: Consequential LCA and LCC for Internal Wall Assemblies as a Case Study in a Belgian Context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Li, Q.Y. BIM Enabled Life Cycle Environmental and Cost Analysis of a Prototype of Small Scalezero Energy House. Master’s Thesis, Tianjin University, Tianjin, China, 2017. (In Chinese). [Google Scholar]

- Liu, H.B.; Xue, Z.Y.; Fan, J.L.; Wang, J.X.; Wang, H.N.; Zhang, R.S. Application and Development of life cycle assessment (LCA) in the Field of Construction. J. Saf. Environ. Forthcoming.

- Campisi, D.; Gitto, S.; Morea, D. An Evaluation of Energy and Economic Efficiency in Residential. Int. J. Energy Econ. Policy 2018, 8, 185–196. [Google Scholar]

- Gong, X.; Michel, P.; Cantin, R. Multiple-Criteria Decision Analysis of BIM Influences in Building Energy Management. Build. Simul. 2019, 12, 641–652. [Google Scholar] [CrossRef]

- Tian, Z.W. The Research on Assessment of Environment and Economic Performance for Recycled Concrete Based on LCA–LCC. Master’s Thesis, Zhejiang University, Hangzhou, China, 2012. (In Chinese). [Google Scholar]

- Kim, S.H.; Choi, M.S. Environmental Impact Assessment and Eco-Friendly Decision-Making in Civil Structures. Environ. Manag. 2013, 126, 105–112. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Fan, S.; Ma, Q.; Jin, H. An Integrated Environment and Cost Assessment Method Based on LCA and LCC for Mechanical Product Manufacturing. Int. J. Life Cycle Assess. 2019, 24, 64–77. [Google Scholar] [CrossRef]

- Opher, T.; Friedler, E.; Shapira, A. Life Cycle Sustainability Assessment of Urban Water Reuse at Various Centralization Scales. Int. J. Life Cycle Assess. 2018, 24, 1319–1332. [Google Scholar] [CrossRef]

- Kouloumpis, V.; Azapagic, A. Integrated Life Cycle Sustainability Assessment Using Fuzzy Inference: A Novel FELICITA Model. Sustain. Prod. Consum. 2018, 15, 25–34. [Google Scholar] [CrossRef]

- Li, X.D.; Wu, X.; Zhang, Z.H. Study on Social WTP for Environmental Impacts Based on the LCA Theory. J. Harbin Inst. Technol. 2005, 11, 51–54. (In Chinese) [Google Scholar]

- Soares, N.; Pereira, L.D.; Ferreira, J.; Conceicao, P.; da Silva, P.P. Energy Efficiency of Higher Education Buildings: A Case Study. Int. J. Sustain. High. Educ. 2015, 16, 669–691. [Google Scholar] [CrossRef]

- Xiong, H.B.; Zhang, C.; Yeo, J.T.; Zhao, Y. Environmental Impact Comparison of Different Structure Systems Based on Life Cycle Assessment Methodology. In Advanced Materials Research; Li, H., Liu, Y.F., Guo, M., Zhang, R., Du, J., Eds.; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; Volume 374, p. 405. [Google Scholar]

- Environmental Management—Life Cycle Assessment-Principles and Framework (ISO 14040); International Standardization Organization: Geneva, Switzerland, 2016.

- Environmental Management—Life Cycle Assessment-Requirements and Guidelines (ISO 14044); International Standardization Organization: Geneva, Switzerland, 2016.

- Buildings and Constructed Assets—Service-Life Planning—Part 5: Life-Cycle Costing (ISO 15686-5); International Standardization Organization: Geneva, Switzerland, 2008.

- Sun, Y.F. The Research of Energy-Saving Buildings Cost Management Based on the Theory of Whole Life Cycle. Master’s Thesis, Shandong University of Technology, Qingdao, China, 2014. (In Chinese). [Google Scholar]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Life Cycle Assessment of Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Robati, M.; Kokogiannakis, G.; McCarthy, T.J. Impact of Structural Design Solutions on the Energy and Thermal Performance of an Australian Office Building. Build. Environ. 2017, 124, 258–282. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life Cycle Analysis in the Construction Sector: Guiding the Optimization of Conventional Italian Buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional Versus Modular Construction Methods: A Comparative Cradle-to-Gate LCA for Residential Buildings. J. Clean. Prod. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Morales, M.; Moraga, G.; Kirchheim, A.P.; Passuello, A. Regionalized Inventory Data in LCA of Public Housing: A Comparison between Two Conventional Typologies in Southern Brazil. J. Clean. Prod. 2019, 238, 117869. [Google Scholar] [CrossRef]

- Petrovic, B.; Myhren, J.A.; Zhang, X.; Wallhagen, M.; Eriksson, O. Life Cycle Assessment of a Wooden Single-Family House in Sweden. Appl. Energy 2019, 251, 113253. [Google Scholar] [CrossRef]

- Laiblova, L.; Pesta, J.; Kumar, A.; Hajek, P.; Fiala, C.; Vlach, T.; Koci, V. Environmental Impact of Textile Reinforced Concrete Facades Compared to Conventional Solutions-LCA Case Study. Materials 2019, 12, 319419. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Yv, H.; Zhang, Z.Y. A Comparative Study on Life Cycle Environmental Impacts of Building Insulation Materials. New Build. Mater. 2017, 44, 101–105. (In Chinese) [Google Scholar]

- Sustainability of Construction Works. Environmental Product Declarations. Product Category Rules for Concrete and Concrete Elements (EN 16757: 2017); CEN: Brussels, Belgium, 2017.

- Sun, Y.F. The Research of Energy-Saving Buildings Cost Management Based on the Theory of Whole Life Cycle Cost-Taking High-Rise Residential Buildings as an Example. Master’s Thesis, Shandong University of Technology, Qingdao, China, 2014. [Google Scholar]

- Xu, S.B. Practical Decision Method: Analytic Hierarchy Process. Principle; Tianjin University Press: Tianjin, China, 1988. (In Chinese) [Google Scholar]

- Liu, X.; Gao, X. A Survey Analysis of Low Carbon Technology Diffusion in China’s Iron & Steel Industry. J. Clean. Prod. 2016, 129, 88–101. [Google Scholar]

- Zhang, Y.; Bo, X.; Zhao, Y.; Nielsen, C.P. Benefits of Current and Future Policies on Emissions of China’s Coal-Fired Power Sector Indicated by Continuous Emission Monitoring. Environ. Pollut. 2019, 251, 415–424. [Google Scholar] [CrossRef]

- Yu, P.; Luo, Z.Y.; Wang, Q.H.; Fang, M.X. Life Cycle Assessment of Transformation from a Sub-critical Power Plant into a Polygeneration Plant. Energy Convers. Manag. 2019, 198, 111801. [Google Scholar] [CrossRef]

- Paik, I.; Na, S.; Yoon, S. Assessment of CO2 Emissions by Replacing an Ordinary Reinforced Concrete Slab with the Void Slab System in a High-Rise Commercial Residential Complex Building in South Korea. Sustainability 2019, 11, 82. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Martin-Morales, M.; Bonoli, A. Environmental Assessment of Masonry Mortars Made with Natural and Devoted Aggregates. Int. J. Life Cycle Assess. 2019, 24, 191–210. [Google Scholar] [CrossRef]

- Talang, R.P.N.; Sirivithayapakorn, S. Comparing Environmental Burdens, Economic Costs and Thermal Resistance of Different Materials for Exterior Building Walls. J. Clean. Prod. 2018, 197, 1508–1520. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Habert, G.; Correal Daza, J.; Archilla, H.; Echeverry Fernández, J.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- Ahmed, I.M.; Tsavdaridis, K.D. Life Cycle Assessment (LCA) and Cost (LCC) Studies of Lightweight Composite Flooring Systems. J. Build. Eng. 2018, 20, 624–633. [Google Scholar] [CrossRef]

- Saleem, M.; Chhipi-Shrestha, G.; Andrade, M.; Dyck, R.; Ruparathna, R.; Hewage, K.; Sadiq, R. Life Cycle Thinking–Based Selection of Building Facades. J. Archit. Eng. 2018, 24, 04018029. [Google Scholar] [CrossRef]

- Hossain, Y.; Marsik, T. Conducting Life Cycle Assessments (LCAs) to Determine Carbon Payback: A Case Study of a Highly Energy-Efficient House in Rural Alaska. Energies 2019, 12, 1732. [Google Scholar] [CrossRef]

- Cruz Rios, F.; Grau, D.; Chong, W.K. Reusing Exterior Wall Framing Systems: A Cradle-To-Cradle Comparative Life Cycle Assessment. Waste Manag. 2019, 94, 120–135. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, E.; Arslan, H.; Bideci, A. Environmental Performance Analysis of Insulated Composite Facade Panels Using Life Cycle Assessment (LCA). Constr. Build. Mater. 2019, 202, 806–813. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Bin Marsono, A.K.; Gohari, A. Sustainable Materials Selection Based on Flood Damage Assessment for a Building Using LCA and LCC. J. Clean. Prod. 2019, 222, 844–855. [Google Scholar] [CrossRef]

- Cai, J. Research on Cost Control and Optimization of Power Generation Industry under the Background of Supply Side Reformation-Based on the Case of C Power Plant. Master’s Thesis, Anhui University, Hefei, China, 2018. (In Chinese). [Google Scholar]

- Ding, Z.K.; Hu, T.; Li, M.; Xu, X.X.; Zou, P.X.W. Agent-Based Model for Simulating Building Energy Management in Student Residences. Energy Build. 2019, 198, 11–27. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).