Evaluation Research of Green Innovation Efficiency in China’s Heavy Polluting Industries

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Non-Radial DDF-DEA Three-Stage Model

3.1.1. First Stage: Non-Radial DDF-DEA Model

3.1.2. Second Stage: Input–Output Adjustment of the SFA Model

3.1.3. Third Stage: Revised DEA Model

3.2. Industry Data

3.3. Description of Input-Output Indicators and Influencing Factors

3.3.1. Input and Output Variables

3.3.2. Influencing Factors

Environmental Regulation

Technology Introduction Costs

Enterprise Scale

Government Support

4. Results

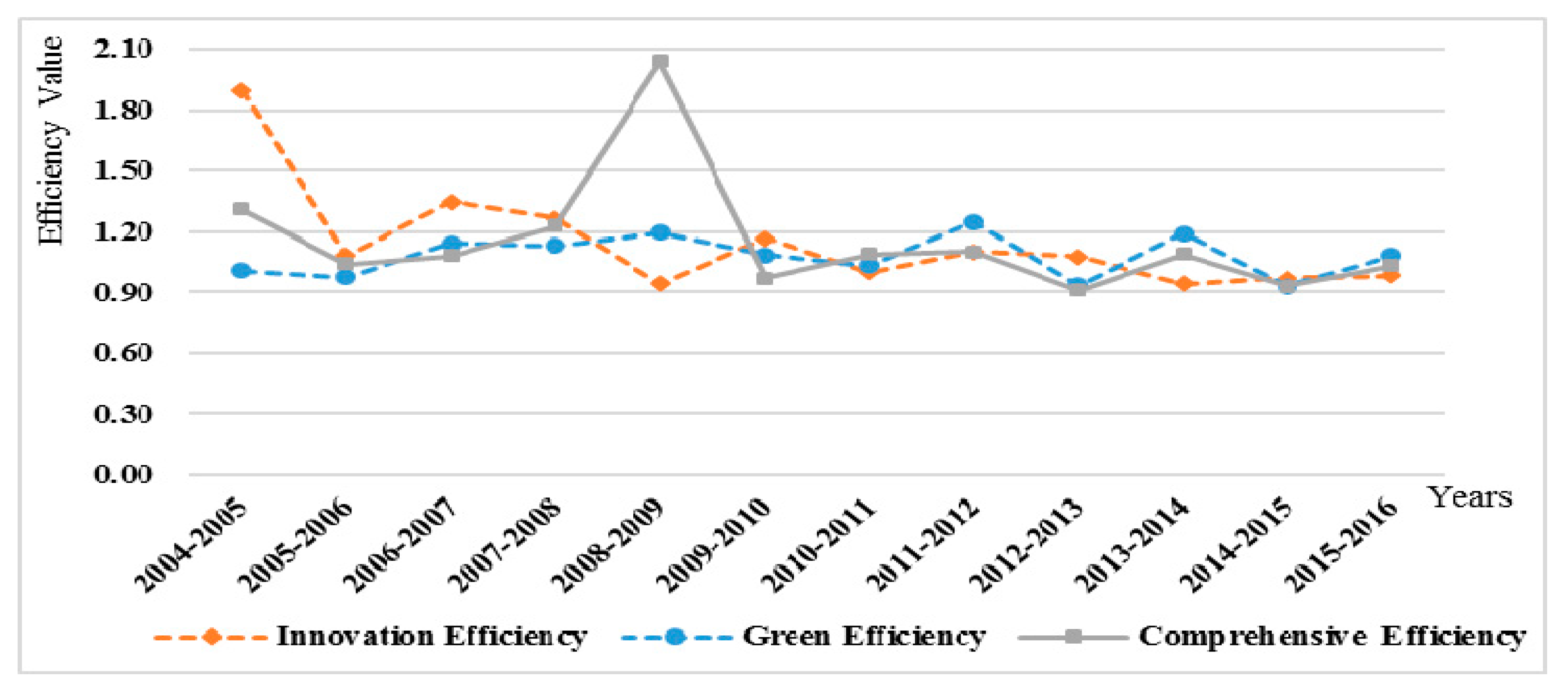

4.1. First Stage: A Comprehensive Green Innovation Efficiency Analysis

4.2. Second Stage: The Impact of External Environment on Green Innovation Efficiency

4.2.1. Environmental Regulation

4.2.2. Technology Introduction Cost

4.2.3. Enterprise Scale

4.2.4. Government Support

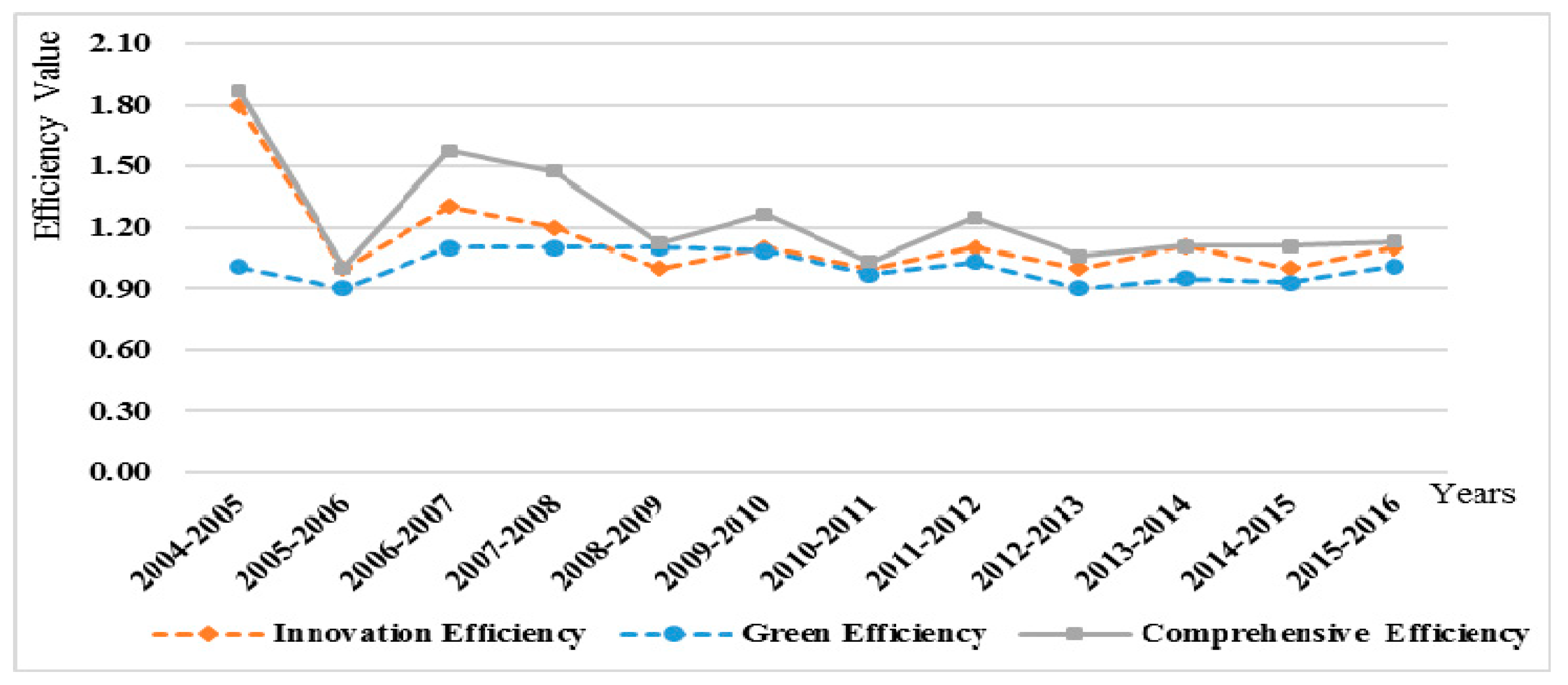

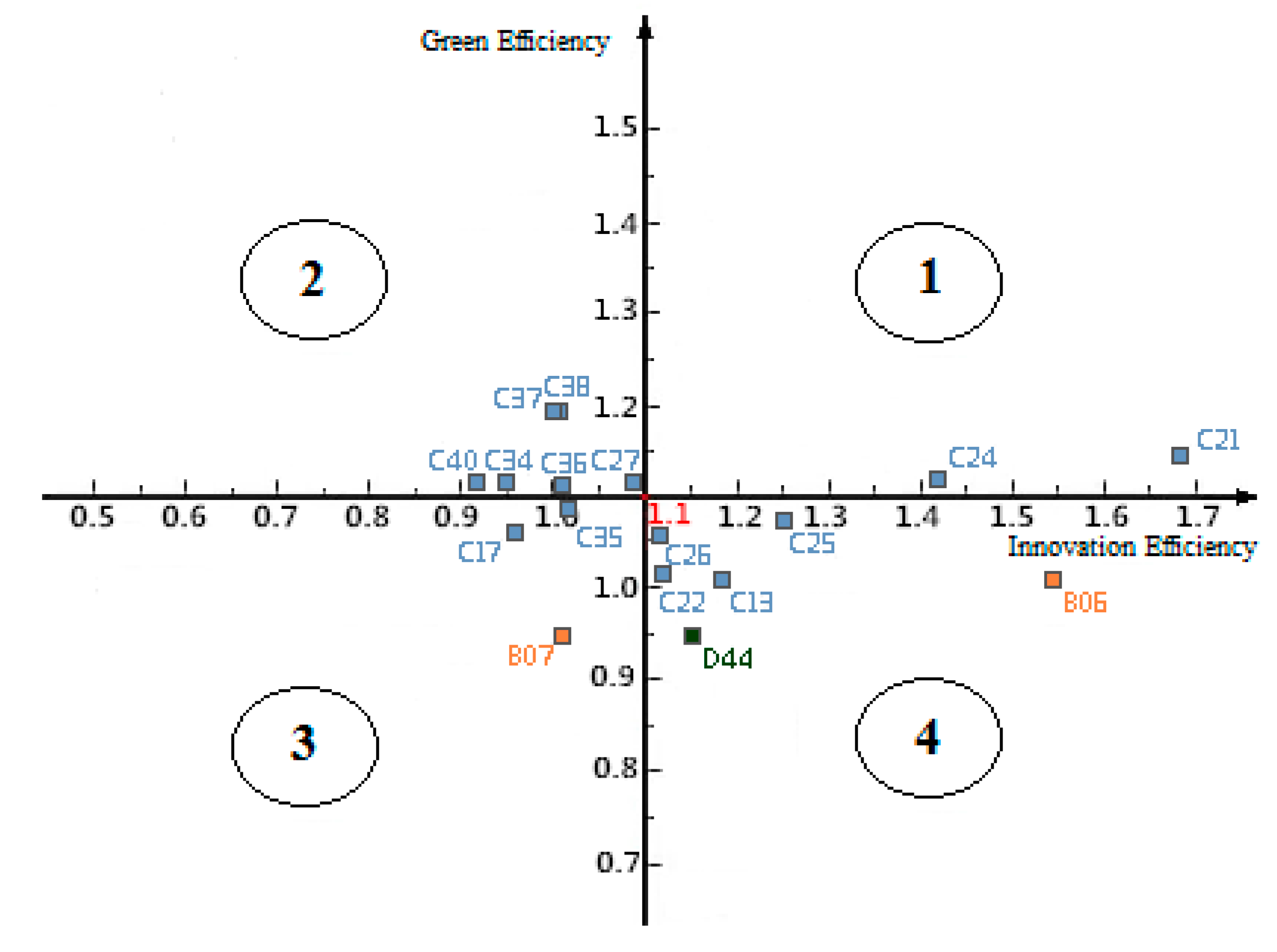

4.3. Third Stage: Real Green Innovation Efficiency Analysis

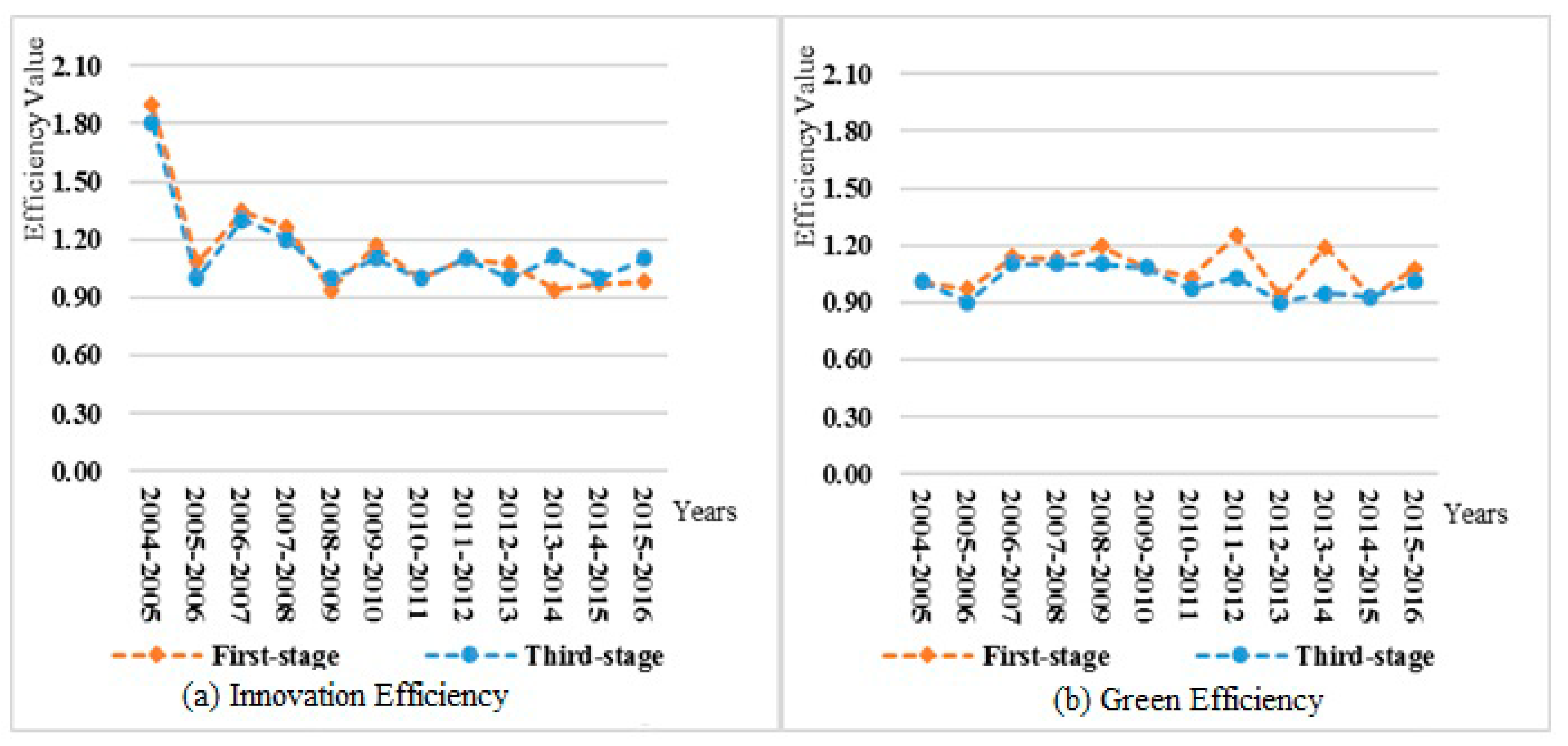

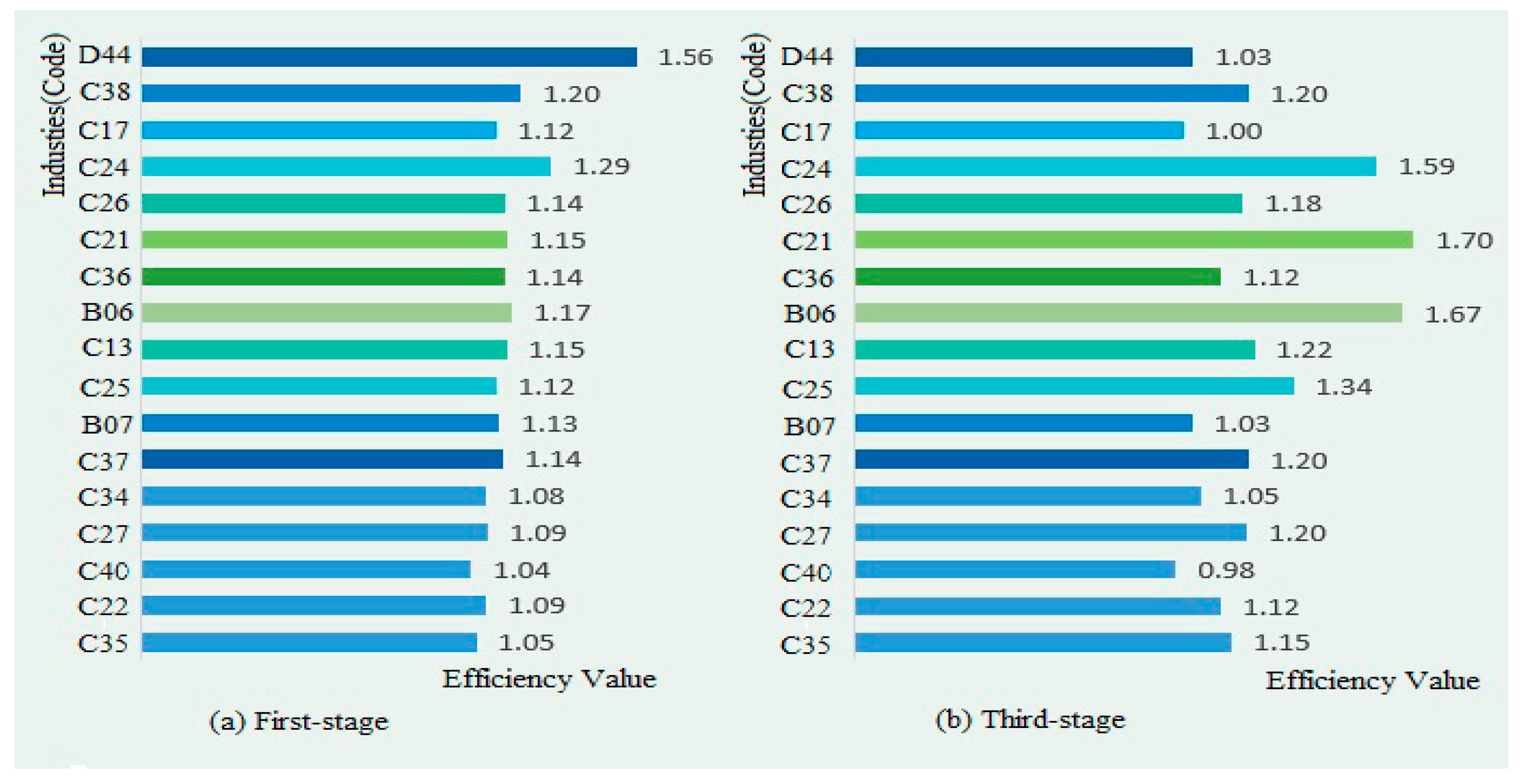

4.4. Comparative Analysis of the Results before and after Adjustment

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, J.S.; Liu, Y.M.; Chang, Y.; Zhang, L.X. Industrial eco-efficiency in China: A provincial quantification using three-stage data envelopment analysis. J. Clean. Prod. 2017, 143, 238–249. [Google Scholar] [CrossRef]

- Song, M.; Wang, S.H.; Sun, J. Environmental regulations, staff quality, green technology, R&D efficiency, and profit in manufacturing. Technol. Forecast. Soc. Chang. 2018, 133, 1–14. [Google Scholar]

- NBSC. China Statistical Yearbook; National Bureau of Statistics of People’s Republic of China (NBSC): Beijing, China, 2018.

- Li, K.; Lin, B. Impact of energy conservation policies on the green productivity in China’s manufacturing sector evidence from a three-stage DEA model. Apply Energy 2016, 168, 351–363. [Google Scholar] [CrossRef]

- NBSC. China Environmental Status Bulletin; National Bureau of Statistics of People’s Republic of China (NBSC): Beijing, China, 2018.

- Zhou, Y.; Xing, X.; Fang, K. Environmental efficiency analysis of power industry in China based on an entropy SBM Model. Energy Policy 2013, 57, 68–75. [Google Scholar] [CrossRef]

- Wong, S.K. Environmental requirements, knowledge sharing and green innovation: Empirical evidence from the electronics industry in China. Bus. Strategy Environ. 2013, 22, 321–338. [Google Scholar] [CrossRef]

- Yu, C.; Shi, L.; Wang, Y.; Chang, Y.; Cheng, B. The eco-efficiency of pulp and paper industry in China: An assessment based on slacks-based measure and Malmquist-Luenberger index. J. Clean. Prod. 2016, 127, 511–521. [Google Scholar] [CrossRef]

- Rennings, K.; Rammer, C. Increasing energy and resource efficiency through innovation: An explorative analysis using innovation survey data. ZEW-Leibniz Cent. Eur. Econ. Res. Discuss. 2009, 5, 442–459. [Google Scholar] [CrossRef]

- Worthington, I.; Patton, D. Strategic intent in the management of the green environment within SMEs: An analysis of the UK screen-printing sector. Long Range Plan. 2005, 38, 197–212. [Google Scholar] [CrossRef]

- Kiefer, C.P.; Carrillo-Hermosilla, J.; Del Río, P.; Barroso, F.J.C. Diversity of eco-innovations: A quantitative approach. J. Clean. Prod. 2017, 166, 1494–1506. [Google Scholar] [CrossRef]

- Sun, L.; Miao, C.; Yang, L. Ecological-economic efficiency evaluation of green technology innovation in strategic emerging industries based on entropy weighted TOPSIS method. Ecol. Indic. 2017, 73, 554–558. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, X.; Valdmanis, V.; Baležentis, T. Evaluating Economic and Environmental Performance of the Chinese Industry Sector. Sustainability 2019, 11, 6804. [Google Scholar] [CrossRef]

- Miao, Z.; Baležentis, T.; Tian, Z.Z.; Shao, S.; Geng, Y.; Wu, R. Environmental Performance and Regulation Effect of China’s Atmospheric Pollutant Emissions: Evidence from “Three Regions and Ten Urban Agglomerations”. Environ. Resour. Econ. 2019, 74, 211–242. [Google Scholar] [CrossRef]

- Fare, R.; Grosskopf, S. Productivity and intermediate products: A frontier approach. Econ. Lett. 1996, 50, 65–70. [Google Scholar] [CrossRef]

- Brown, M.A. Market failures and barriers as a basis for clean energy policies. Energy Policy 2001, 29, 1197–1207. [Google Scholar] [CrossRef]

- Miranda, M.L.; Hale, B.A. Taxing environment: Evaluating the multiple objectives of environmental taxes. Environ. Sci. Technol. 2002, 36, 5289–5295. [Google Scholar] [CrossRef]

- Yi, H.T.; Liu, Y. Green economy in China: Regional variations and policy drivers. Glob. Environ. Chang. 2015, 31, 11–19. [Google Scholar] [CrossRef]

- Du, L.; Hanley, A.; Zhang, N. Environmental technical efficiency, technology gap and shadow price of coal-fuelled power plants in China: A parametric meta-frontier analysis. Resour. Energy Econ. 2016, 43, 14–32. [Google Scholar] [CrossRef]

- Guo, C.; Shureshjani, R.A.; Foroughi, A.A.; Zhu, J. Decomposition weights and overall efficiency in two-stage additive network DEA. Eur. J. Oper. Res. 2017, 257, 896–906. [Google Scholar] [CrossRef]

- Hamamoto, M. Environmental regulation and the productivity of Japanese manufacturing industries. Resour. Energy Econ. 2006, 28, 299–312. [Google Scholar] [CrossRef]

- Porter, M.E. America’s green strategy. Sci. Am. 1991, 264, 168. [Google Scholar] [CrossRef]

- Popp, D. Entice: Endogenous technological change in the DICE model of global warming. J. Environ. Econ. Manag. 2004, 48, 742–768. [Google Scholar] [CrossRef]

- Feng, Z.; Zeng, B.; Ming, Q. Environmental regulation, two-way foreign direct investment, and green innovation efficiency in China’s manufacturing industry. Int. J. Environ. Res. Public Health 2018, 15, 2292. [Google Scholar] [CrossRef] [PubMed]

- Cainelli, G.; Mazzanti, M.; Montresor, M. Environmental innovations, local networks and internationalization. Ind. Innov. 2012, 19, 697–734. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Hansson, L.; Zhang, K.; Wang, R. Implementing stricter environmental regulation to enhance eco-efficiency and sustainability: A case study of Shandong province’s pulp and paper industry, China. J. Clean. Prod. 2011, 19, 303–310. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Gemar, G.; Gomez, T.; Caballero, R.; Sala-Garrido, R. Eco- efficiency assessment of wastewater treatment plants using a weighted Russell directional distance model. J. Clean. Prod. 2016, 137, 1066–1075. [Google Scholar] [CrossRef]

- Miranda, M.L.; Edwards, S.E.; Keating, M.H. Making the environmental justice grade: The relative burden of air polluted exposure in the United States. Int. J. Environ. Res. Public Health 2011, 8, 1755–1771. [Google Scholar] [CrossRef]

- Liang, X.; Si, D.; Zhang, X. Regional sustainable development analysis based on information entropy-Sichuan province as an example. Int. J. Environ. Res. Public Health 2017, 14, 1219. [Google Scholar] [CrossRef]

- Zaim, O.; Taskin, F. Environmental efficiency in carbon dioxide emissions in the OECD: A non-Parametric approach. J. Environ. Manag. 2000, 2, 95–107. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Yoshi, S.; Goto, M. DEA approach for unified efficiency measurement: Assessment of Japanese fossil fuel power generation. Energy Econ. 2011, 33, 292–303. [Google Scholar]

- Cooper, W.; Park, K.S.; Pastorj, T. RAM: A range adjusted measure of inefficiency for use with additive models, and relations to other models and measures in DEA. J. Prod. Anal. 1999, 11, 5–42. [Google Scholar] [CrossRef]

- Fried, H.; Lovell, C.K.; Schmidt, S.S. Accounting for environmental effects and statistical noise in data envelopment analysis. J. Prod. Anal. 2002, 17, 157–174. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, S.; Zhao, H.R. Provincial energy efficiency of China quantified by three-stage data envelopment analysis. Energy 2019, 166, 96–107. [Google Scholar] [CrossRef]

- Lin, S.F.; Sun, J.; Marinova, D.; Zhao, D.T. Evaluation of the green technology innovation efficiency of China’s manufacturing industries: DEA window analysis with ideal window width. Technol. Anal. Strateg. Manag. 2018, 30, 1166–1181. [Google Scholar] [CrossRef]

- Charnes, A.; Coopr, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 6, 429–444. [Google Scholar] [CrossRef]

- Fare, R.; Pasurka, C. Multilateral productivity comparisons when some outputs are undesirable: A nonparametric approach. Rev. Econ. Stat. 1989, 71, 90–98. [Google Scholar] [CrossRef]

- Luenberger, D.G. Benefit functions and duality. J. Math. Econ. 1992, 21, 461–481. [Google Scholar] [CrossRef]

- Picazo, T.A.J.; Prior, D. Environmental externalities and efficiency measurement. J. Environ. Manag. 2009, 90, 3332–3339. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Wang, H. Energy and CO2 emission performance in electricity generation: A non-radial directional distance function approach. Eur. J. Oper. Res. 2012, 221, 625–635. [Google Scholar] [CrossRef]

- Jondrow, J.; Lovell, C.K.; Materov, I.S.; Schmidt, P. On the estimation of technical inefficiency in the stochastic frontier production function model. J. Econom. 1982, 19, 233–238. [Google Scholar] [CrossRef]

- CSRC. Classification Index of Listed Companies; Securities Regulatory Commissionof People’s Republic of China (CSRC): Beijing, China, 2018.

- NBSC. Industrial Classification for National Economic Activities; National Bureau of Statistics of People’s Republic of China (NBSC): Beijing, China, 2011.

- NBSC. Environmental Statistical Yearbook; National Bureau of Statistics of People’s Republic of China (NBSC): Beijing, China, 2017.

- NBSC. Energy Statistical Yearbook; National Bureau of Statistics of People’s Republic of China (NBSC): Beijing, China, 2017.

- Yang, Z.S.; Wei, X.X. The measurement and influences of China’s urban total factor energy efficiency under environmental polluted: Based on the game cross -efficiency DEA. J. Clean. Prod. 2019, 209, 439–450. [Google Scholar] [CrossRef]

- Li, F.; Zhu, Q.; Liang, L. Allocating a fixed cost based on a DEA-game cross efficiency approach. Expert Syst. Appl. 2018, 96, 196–207. [Google Scholar] [CrossRef]

- Guan, A.; Shi, J.; Zhang, Q. Research on total factor energy efficiency in western region of China-based on super-DEA and Malmquist. J. Ind. Technol. Econ. 2014, 2, 32–40. [Google Scholar]

- Spirkova, D.; Kloudova, J.; Kljucnikov, A.; Stehlikova, B. Economy of heating and competitiveness of the state–the link between the life expectancy and the heating fuel type. The case of the slovak republic. J. Compet. 2019, 11, 116–134. [Google Scholar] [CrossRef]

- Mamedov, O.; Movchan, I.; Ishchenko-Padukova, O.; Grabowska, M. Traditional economy: Innovations, efficiency and globalization. Econ. Sociol. 2016, 9, 61–72. [Google Scholar] [CrossRef]

- Hnatyshyn, M. Decomposition analysis of the impact of economic growth on ammonia and nitrogen oxides emissions in the European Union. J. Int. Stud. 2018, 11, 201–209. [Google Scholar] [CrossRef]

- Štreimikienė, D.; Mikalauskienė, A.; Mikalauskas, I. Comparative assessment of sustainable energy development in the Czech Republic, Lithuania and Slovakia. J. Compet. 2016, 8, 31–41. [Google Scholar]

- Tvaronavičienė, M.; Prakapienė, D.; Garškaitė-Milvydienė, K.; Prakapas, R.; Nawrot, Ł. Energy efficiency in the long-run in the selected european countries. Econ. Sociol. 2018, 11, 245–254. [Google Scholar] [CrossRef]

- Jovovic, R.; Draskovic, M.; Delibasic, M.; Jovovic, M. The concept of sustainable regional development – institutional aspects, policies and prospects. J. Int. Stud. 2017, 10, 255–266. [Google Scholar] [CrossRef]

- Levinson, A. Environmental regulations and manufacturer’s location choices: Evidence from the Census of Manufactures. J. Public Econ. 1996, 62, 5–29. [Google Scholar] [CrossRef]

- Lanoie, P.; Patry, M.; Lajeunesse, R. Environmental regulation and productivity: Testing the porter hypothesis. J. Prod. Anal. 2008, 30, 121–128. [Google Scholar] [CrossRef]

- Yang, T.; Chen, W.; Zhou, K. Regional energy efficiency evaluation in China: A super efficiency slack-based measure model with undesirable outputs. J. Clean. Prod. 2018, 198, 859–866. [Google Scholar] [CrossRef]

- Marikina, M. The impact of ecological regulations and management on national competitiveness in the Balkan States. J. Compet. 2018, 10, 120–135. [Google Scholar] [CrossRef]

- Raszkowski, A.; Bartniczak, B. Towards sustainable regional development: Economy, society, environment, good governance based on the example of polish regions. Transform. Bus. Econ. 2018, 17, 225–245. [Google Scholar]

- Turturean, C.I.; Asandului, L.A.; Chirila, C.; Homocianu, D. Composite index of sustainable development of EU countries’ economies (ISDE-EU). Transform. Bus. Econ. 2019, 18, 586–605. [Google Scholar]

- Bian, Y.; Yang, F. Resource and environment efficiency analysis of provinces in China: A DEA approach based on Shannon’s entropy. Energy Policy 2010, 38, 1909–1917. [Google Scholar] [CrossRef]

- Chang, Y.T.; Zhang, N.; Danao, D.; Zhang, N. Environmental efficiency analysis of transportation system in China: A non-radial DEA approach. Energy Policy 2013, 58, 277–283. [Google Scholar] [CrossRef]

- Vlontzos, G.; Niavis, S.; Manos, B. A DEA approach for estimating the agricultural energy and environmental efficiency of EU countries. Renew. Sustain. Energy Rev. 2014, 40, 91–96. [Google Scholar] [CrossRef]

| Industries (Code) | Before | After |

|---|---|---|

| Production and distribution of electric power and heat power (D44) | 1.56 | 1.03 |

| Manufacture of electrical machinery and equipment (C38) | 1.20 | 1.20 |

| Manufacture of textiles (C17) | 1.12 | 1.00 |

| Manufacture of artwork and other manufacturing (C24) | 1.29 | 1.59 |

| Manufacture of chemical raw materials and chemical products (C26) | 1.14 | 1.18 |

| Manufacture of furniture (C21) | 1.15 | 1.70 |

| Manufacture of transportation equipment (C36) | 1.14 | 1.12 |

| Mining and washing of coal (B06) | 1.17 | 1.67 |

| Processing of food from agriculture products (C13) | 1.15 | 1.22 |

| Processing of petroleum, coking, processing of nuclear fuel (C25) | 1.12 | 1.34 |

| Extraction of petroleum and natural gas(B07) | 1.13 | 1.03 |

| Manufacture of communication equipment, computers and other electronic equipment (C37) | 1.14 | 1.20 |

| Manufacture of general purpose machinery (C34) | 1.08 | 1.05 |

| Manufacture of medicines(C27) | 1.09 | 1.20 |

| Manufacture of measuring instruments and machinery for cultural activity and office work (C40) | 1.04 | 0.98 |

| Manufacture of paper and paper products (C22) | 1.09 | 1.12 |

| Manufacture of special purpose machinery(C35) | 1.05 | 1.15 |

| Variables | Coefficients of R&D Input | Coefficients of Personnel Input | Coefficients of Energy Input |

|---|---|---|---|

| Constant | 4234.21 *** | 51,634.31 *** | 2377.92 *** |

| (423.42) | (201.90913) | (237.78) | |

| ER | −3071.680 | 5428.8986 * | −3071.68 *** |

| (−3,071,679.9) | (499.44) | (−3067.99) | |

| TC | −5.1077442 * | 0.92532736 *** | −0.3394 ** |

| (−9.36) | (8.31) | (−0.22) | |

| ES | −2101.92 *** | 21,608.45 *** | −3893.29 *** |

| (−2536.03) | (692.57) | (−351.93) | |

| GVM | −1,426,314.9 | 340,925.05 * | −1048.67 *** |

| (−1035.29) | (25,721.01) | (−1304.78) | |

| sigma-squared | 79,893,226 | 43,565,187 | 225,091,920 |

| gamma | 0.76 | 0.65 | 0.96 |

| log likelihood function | −352.03 | −267.07 | −215.51 |

| LR test | 43.57 | 67.87 | 36.21 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Z.; Bai, H.; Bilan, Y. Evaluation Research of Green Innovation Efficiency in China’s Heavy Polluting Industries. Sustainability 2020, 12, 146. https://doi.org/10.3390/su12010146

Fang Z, Bai H, Bilan Y. Evaluation Research of Green Innovation Efficiency in China’s Heavy Polluting Industries. Sustainability. 2020; 12(1):146. https://doi.org/10.3390/su12010146

Chicago/Turabian StyleFang, Zhong, Hua Bai, and Yuriy Bilan. 2020. "Evaluation Research of Green Innovation Efficiency in China’s Heavy Polluting Industries" Sustainability 12, no. 1: 146. https://doi.org/10.3390/su12010146

APA StyleFang, Z., Bai, H., & Bilan, Y. (2020). Evaluation Research of Green Innovation Efficiency in China’s Heavy Polluting Industries. Sustainability, 12(1), 146. https://doi.org/10.3390/su12010146