Abstract

China is the world’s largest coal producer country. However, large-scale coal mining has led to severe environmental pollution issues such as surface subsidence and gangue piling up. The gangue discharging amount has ranked the first in the world and coal mine enterprises are facing enormous discharging reduction pressure. This paper summarizes the research progress of the solid backfilling mining technology and then illustrates the realistic demands and significance of implementing underground coal-waste separation. It also focuses on the technical principles, systems and key equipment of the common underground coal-waste separation methods, such as the selective crushing method, the dense medium shallow groove method, the vibro-assisted jigging method and full-size water separation method and ray identification method. In addition, the selection steps of underground coal-waste separation method, the design process of large section separation chamber and the design principle of separation and backfilling system are proposed, finally, the mining-separating-backfilling + X for coal mining is put forward. By combining the technology of mining-separating-backfilling with other technologies, such as gob-side entry retaining with non-pillar mining, gas extraction, solid waste treatment, water protection mining, mining under buildings, railways and water bodies, the integrated mining methods, mining-separating-backfilling + setting pillars, gas drainage, treatment, protection and prevention methods are formed. It also introduced the ‘mining-separating-backfilling + gas extraction’ technology’s whole idea, system arrangement, separation equipment and practical engineering application effects based on the specific engineering case of pingmei no. 12 coal mine. The results indicate that the integration of underground coal-waste separation and solid backfilling technology could achieve gangue discharging reduction, underground washing and surface subsidence control. It is effective at realizing green mining.

1. Introduction

In recent years, with the continuous expansion of coal mining, mining-induced environmental problems are becoming increasingly serious, such as surface subsidence and gangue discharge. A large amount of gangue discharge not only polluted land resources but also produced hazardous gas and brought great pressure on ecological environmental protection in mining areas [1,2,3,4]. In the Coal Industry Development’s 13th Five-Year Plan, it was pointed out that the current annual gangue discharge was 795 million tons, the mine water was 6.004 billion cubic meters and the land subsidence was about 65,600 hectares. Table 1 [5,6,7,8,9] and Table 2 show the gangue discharge and the countermeasures in major coal producing countries. It can be seen that China’s annual gangue discharge and cumulative discharge came in first place. Serious harm has been caused and the gangue surface discharge has become a thorny problem for mines [10,11]. Domestic and foreign scholars have conducted a great deal of research on gangue treatments and have achieved certain results. The research mainly included power generation from coal gangue, chemical products manufacturing, building materials manufacturing and goaf backfilling. [12,13,14,15]. The most economical and effective method to backfill the goaf is to use the coal gangues directly, which could not only solve the problem of gangue surface discharge but also reduce upgrade costs of coal gangues. It is particularly effective during the mining of deep coal resources. With the development and maturity of solid backfilling mining technology, underground coal-waste separation and in situ backfilling technology have sprung up and become an important way of realizing the harmonious development of green mining [16], resource exploitation and the environment in modern mines.

Table 1.

Gangue discharge and countermeasures in major coal producing countries in the world.

Table 2.

Coal gangue discharge and treatment situations in China.

2. Research Progress of Solid Backfilling Mining Technology

Solid backfilling mining uses solid backfilling materials such as gangues, coal ashes, loess, aeolian sands or their mixtures to backfill the goaf. The backfilling methods are generally determined according to the backfilling methods of the backfilling materials including artificial backfilling, mechanical backfilling, pneumatic backfilling and hydraulic backfilling. Currently, the comprehensive mechanization mechanized solid backfilling [17,18,19] is widely used due to the advantages in respect of backfilling efficiency, resource protection and manpower savings. Its working face arrangement is basically the same as the traditional fully mechanized coal mining face. The backfilling mining face is arranged at the rear of mining working face. A ribbon conveyer used for solid backfilling material transportation is set in the railway laneway of the working face. Thus, the mining and backfilling can be operated at the same time [20,21,22,23]. At present, this technology has achieved rapid development in its process, equipment and basic theories. It has been applied and promoted in many mines, such as Pingdingshan Group, Yankuang Group, Cinwen Group, Huaibei Mining Group, Jizhong Energy Group, Kailuan Mining Group (Table 3). It has been used to exploit coal resources under buildings, water bodies and railways.

Table 3.

Application mines of solid backfilling mining technology in China (part).

2.1. Development of Solid Backfilling Mining Technology

The solid backfilling mining technology was firstly used in Zhaizhen Coal Mine since 1990s. After its successful industrial experiment, it has experienced four stages that include the initial underground gangue disposal, mining-backfilling operation, mining-separation-backfilling operation and the mining-separating-backfilling+X operation [24]. Among them, the underground gangue disposal was to achieve gangue emission reduction. The mining-filling operation could ensure the high efficiency and greening of the solid backfilling mining. The mining-separation-backfilling operation could meet the requirements of low environmental damage, while the popular mining-separating-backfilling+X operation aims to pursue low ecological environment impacts. Nowadays, the solid backfilling mining technology is gradually being used in mines with a depth of over a thousand meters, such as Tangkou Coal Mine and Xinjulong Coal Mine. Against this background, the mining-separating-backfilling+X method has become an inevitable trend, aiming to achieve green mining with low environmental damage, high production and high efficiency of backfilling mining. It has become the priority task in modern solid backfilling mining.

2.2. Backfilling Mining under Buildings, Water Bodies and Railways

At present, the difficulty of coal mining is increasing gradually—many enterprises are facing rapid depletion of coal resources and are seeking methods to exploit ‘under three’ coal resources (under buildings, railways and water bodies) which could not be mined by traditional technology. According to statistics, the amount of ‘under three’ coal resources exceeds 15 billion tons in China’s large-scale state-owned mines, What is worse, the ‘under three’ coal reserves in mines in eastern China are close to 50% of the recoverable reserves, especially the mines in Shandong province [25]. The solid backfilling mining could extract the ‘under three’ coal resources and achieve green mining. Therefore, it has good prospects [26,27].

2.2.1. Solid Backfilling Mining under Buildings

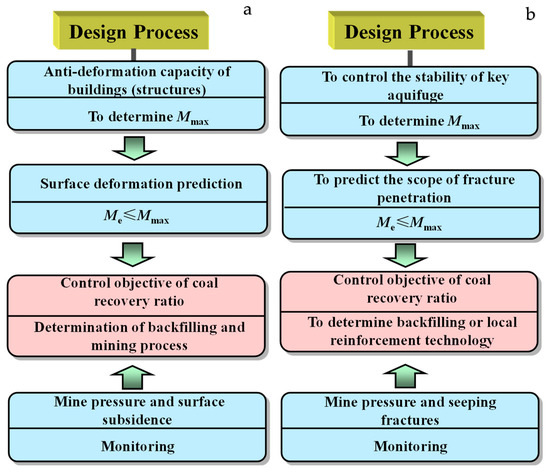

The key to solid backfilling mining under buildings is being able to fully protect surface buildings and structures by controlling compression density [28]. The concrete design process is shown. First, based on the structure of overlying strata and types of buried coal resources, the maximum fortification index of surface movement and deformation was determined by the non-deformability of buildings. Then, based on a probability integration model for surface subsidence prediction based on equivalent mining height theory, the maximum allowable equivalent mining height was obtained and the control indexes of compression ratio in theory. Next, key engineering parameters of solid backfilling mining were fixed after full consideration and the control indexes of the compression ratio were also fixed. Finally, the actual ground pressure and surface subsidence measurement could provide feedback to the equivalent mining height and compression ratio control indexes and the solid backfilling mining design was completed. The design flow is shown in Figure 1a.

Figure 1.

Solid backfilling mining design under buildings and under water bodies. (a) Under buildings, (b) Under water bodies.

The operations of solid backfilling mining under buildings were implemented in the No.12 mine in Pingdingshan Group, the Yangzhuang coal mine in Huaibei Group, the Dongping Coal in Dongping Coal Industry in Yu County, Shanxi, the Huayuan Coal Mine in Jining Mining Industry Group, the Tangkou Coal Mine of Zibo Mining Group and the Xijulong Coal Mine of Xinwen Mining Group. The No.12 mine was to exploit coal resources under villages. The Yangzhuang coal mine was to exploit coal resources under the ancient town of Suixi County. Dongping Coal was to exploit coal resources under the industrial square. Huayuan Coal Mine was to exploit coal resources under buildings around Jinxiang County. Tangkou Coal Mine and Xijulong Coal Mine were to exploit coal resources under villages. Taking the Huayuan Coal Mine as an example, the strip mining was originally designed to mine a 40 m strip and leave an 80 m coal pillar. By this method, the mining rate was less than 32%. It could reach 85% by using the pillarless mining method of solid dense backfilling mining with retained gateways along goaf. Moreover, the length of service increased from the original duration of less than 40 years to around 100 years. The solid backfilling mining was carried out in March 2011. So far, the actual maximum surface subsidence was 196 mm and the surface subsidence reduction ratio was more than 85%.

2.2.2. Solid Backfilling Mining under Water Bodies

The key to conducting solid backfilling mining under water bodies is to control the stability of water-resistant key strata and to strictly control the development height of water flowing fracture zone of overlying strata [29,30,31]. In the engineering design, the control standards of the stability of water-resistant key strata were used to determine the maximum equivalent mining height and predict the development height of water flowing fracture zone and the penetration range of fissures. Then, based on actual engineering geological conditions, the theoretical control indexes of the compression ratio could be obtained. Next, according to the concrete implementation process and strengthening technology, the engineering control indexes of the compression ratio were fixed. Finally, the real-time monitoring of seeping fractures provided feedback to the control indexes of the compression ratio and the solid backfilling mining process design was completed, as shown in in Figure 1b.

Jinan No.3 Coal Mine in Yankuang Group and Wugou Coal Mine of Wanbei Coal Electricity Group have conducted operations of solid backfilling mining under water bodies. Jinan No.3 Coal Mine was to mine coal resources under the riverbank of Nanyang Lake. The north levee of Nanyang Lakeis played an important role in flood control works. Considering the characteristics of the riverbank, the designed maximum allowable movement and deformation value was the horizontal deformation of 1.0 mm/m. The first mining face in this region was mined out. The second backfilling working face was under exploitation. After backfilling mining, the actual maximum surface subsidence was 340 mm [32] and no damage was monitored. The 272 m loose aquifers connecting to the surface water were above the main mining seams in Wugou Coal Mine. In the original design, 36.64 million tons of waterproof coal pillar remained. The coal seams within blocks of waterproof coal pillars were only 15 m away from the nearest area of the quaternary loose aquifers. The key to implementing solid backfilling mining was to control the immediate roof to become the key aquifuge strata.

2.2.3. Solid Backfilling Mining Under Railways

According to incomplete statistics, the amount of coal resources buried under railways has reached 1.918 billion tons in China. The railways affected by coal mining could be divided into special lines in mining areas, railway branches and railway mainlines [33,34]. In China, mining under the railway is mostly carried out under special lines in mining areas. The experiment is often conducted under railway branches and individual trials are implemented under railway mainlines. Compared with mining under buildings and water bodies, the major difference of the design of solid backfilling mining under railways is how to reasonably determine the fortification criterion.

So far, solid backfilling mining has been carried out under railways in mining areas such as Wuhai Taiyuan Coal Mine, Tangshan Mine of Kailuan Group. The railway special line from Tangshan Coal Mine to the air shaft passes through the three districts of Tangshan Mine. The area of the unexploited coal was about 2 km2 and the predicted influence area was 6 km2 after mining. The former Beijing-Shanhaiguan railway, named Jingshan Railway, and the affiliated buildings (structures) were affected. Taiyuan Coal Mine had the special Dongsheng-Wuhai railway for transporting coal, high-tension transmission line and Qipanjing-Shizuishan first class highway.

2.3. Underground Coal-Waste Separation and Solid Backfilling Situations

The combination of underground coal-waste separation and waste backfilling mining technology is the future development direction of backfilling coal mining technology. The surface transportation and feeding system will be replaced by an underground coal-waste separation system. The backfilling materials directly come from the mines and the intensification of the production system will become more concentrated. The underground coal-waste separation system needs to combine with the waste backfilling system, so it also has higher requirements for the mine production management level.

Many mines in China have used coal-waste separation methods such as the dense medium shallow groove method and the vibro-assisted jigging method to implement backfilling mining after underground coal-waste separation of the raw coal. These include the Zhaizhen Coal Mine of the Xinwen mining area, Xiezhuang Coal Mine, Xinjulong Coal Mine, the Tangshan Mine of Kailuan Group and the No.12 Coal Mine of Pingdingshan Group. Among them, the underground coal-waste separation project in Zhaizhen Coal Mine was approved by the Company in August 2010 and put into use in January 2011. The design processing capacity was 500,000 t/a and the maximum washing capacity was 150t per hour. The implementation of underground coal-waste separation avoided the waste during the transportation and achieved coal-waste separation and separate coal-waste storing and transporting as well as improved the quality of the raw coal. The electric charge could save about 200,000 RMB each year by the main and auxiliary shaft. The lifting capacity of the main shaft was increased by 100,000 t. In order to solve the piled gangue on the surface, Tangshan Mine used underground vibro-assisted jigging separation and solid backfilling mining technology. Eight hundred thousand t gangues could be separated each year. Some mining areas in Xinjulong Mine were exploited under buildings. The lifting pressure of the deep well transportation was large. The underground dense medium shallow groove system was used for coal-waste separation. After the separation, the gangues were used for solid backfilling. The separation capacity was 350~500t/h and the separable waste amount was 148,700 t every year.

2.4. The Significance of Underground Coal-Waste Separation

In traditional coal mining, coal mining and coal preparation are two relatively independent operating systems. That is, the mined raw coal resources are not stored underground for coal-waste separation processing. Instead, they will be directly transported to the ground and the gangue dumping operation is completed by the coal preparation plant. The transportation of gangues to the ground will increase the burden of the transport system, especially for mines with relatively long transport routes. The waste and gangues discharged from coal preparation plants are generally transported to the coal gangue hill for treatment, which also exacerbates the mining environment.

The underground coal-waste separation involves arranging coal-waste separation equipment underground to achieve the washing of waste and working face coal flow waste. Its significance is as follows:

Firstly, it could achieve the underground washing and in-situ backfilling of gangues. Secondly, it could relieve the burden of the underground transportation lifting system, especially for mines with relatively long transportation routes and a large mining depth. Thirdly, it could reduce the coal gangues piled up on the ground and protect the ecological environment. Fourthly, it could lower the costs of gangue lifting. Fifthly, it could alleviate the situation that the reserves of the backfilling materials such as gangue piped up on the ground become difficult to maintain the backfilling requirements of underground multi-working face.

3. Main Underground Coal-Waste Separation Methods and Equipment

The process of underground coal-waste separation should adapt to small underground spaces and meet the requirements of high security, production capacity and continuous production [35]. Therefore, the underground coal-waste separation equipment should have the characteristics of small volume, be explosion proof, and have strong practicability, good separation effects and high reliability. At present, the underground coal-waste separation methods include the coal-waste selective crushing methods, dense medium shallow groove methods, vibro-assisted jigging methods, water separation methods and ray identification methods [36,37].

3.1. Coal-Waste Selective Crushing Methods

Coal-waste selective crushing methods mainly include hydraulic automatic coal-waste separation, impact crushing coal-waste separation, rotor type coal-waste separation. They mainly use the hardness difference between coal and gangue and coal gangue crushers with different principles to realize the primary separation. They are suitable for mines without special size requirements for the coal products. They have disadvantages of low lump coal rate, small throughput, large noise, low accuracy, narrow promotion scope. So more research is needed.

3.2. Dense Medium Shallow Groove Methods

The dense medium shallow groove methods mainly use the configured suspension as the separation medium and carry out coal preparation according to the difference in particle size [38,39]. With large processing capacity and simple equipment, they have been widely used in domestic large-scale coal preparation plants. They have the highest separation efficiency. The shallow trough separator has a wide range of separation sizes and relatively high washing lower limits, so it is not suitable for coal-waste separation with diameter of less than 10mm. Therefore, the recovery and purification of media is necessary. Thus, the process system is relatively complex, covering a large area with more equipment and higher production costs.

3.3. Vibro-Assisted Jigging Methods

The principle of vibro-assisted jigging methods is to achieve separation by stratifying the particles according to the density under current effects of fluctuating medium (such as water and air) in the jig [40,41]. The moving sieve jig is mainly used for the separation of lump coal with the diameter of more than 50mm. Instead of manual separation, it could be divided into hydraulic and mechanical moving sieve jigs according to driving forms of the sieve plate. With the advantages of simple equipment, low costs, high production efficiency, less water consumption in the production and simple process system, this method is one of the preferred solutions for underground coal-waste separation. However, the current moving sieve jig has a larger machine body and a discharge device, the structures of which need to be optimized for underground applications.

3.4. Full-Size Water Separation Methods

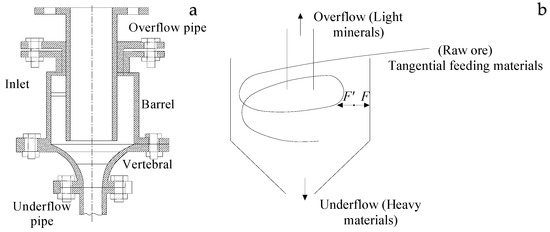

The water separation method (Figure 2) is to use a water-only cyclone for coal-waste separation. The water is taken as the medium and the particles are separated according to the density in centrifugal force field. The disadvantages of this method include low separation accuracy and poor effects and the advantage is the medium of water along with low costs and no pollution and simple configuration. With continuous improvement of the method, the separation effect has been greatly enhanced. For instance, Shandong University of Science and Technology has developed a new type of high-efficiency coarse slime tri-cone coal slurry cyclone. The method is developing in the direction of full-size water separation, which relies on the research and development of a fine classification of a water-only cyclone. It is predicted that 90% waste recovery rates and lower size limits of 0.25mm particles could be achieved.

Figure 2.

The full-size water separation method and process. (a) The tri-cone coal slurry cyclone, (b) Schematic diagram of water-only cyclone.

3.5. Ray Identification Method

The ray identification method is the latest technology and is mainly used for separating gangue from lump coal with a diameter of more than 30 mm. The size of particles is usually between 300 mm and 30 mm. Without water, it has a simple system and low cost. However, the production is unavailable in case of high amount of slack coal. Currently, this method is only suitable for the pre-exhaust of coarse coal [42].

3.6. Application of Underground Coal-Waste Separation

The coal-waste separation methods have been widely used in mines including Yixin Coal Mine of Hegang Branch of Longmei Mining Group, Zhaizhen Coal Mine of Xinwen Group, Xiezhuang Coal Mine of Xinwen Group, Xishan Duerping Coal Mine, Jiyang Coal Mine of Xinwen Group, Xingdong Mine of Jizhong Energy Group, Shandong Liangzhuang Mining Industry. The main separation methods include gravity separation methods, dense medium shallow groove methods and moving sieve jig methods. Table 4 shows the specific applications.

Table 4.

The application of underground coal-waste separation.

4. Underground Coal-Waste Separation and Backfilling Mining System Design

4.1. Selection of Coal-Gangue Separation Methods

(1) Analysis and comparison of underground coal-waste separation methods

Based on the existing technology of coal preparation plants, the coal-waste separation methods are to transport the designed surface equipment underground and to set the separation chamber to implement coal-waste separation. The common underground coal-waste separation methods include the selective crushing method, the vibro-assisted jigging method, the dense medium shallow groove separation method and the full-size water separation method. Table 5 shows their respective technical performances.

Table 5.

Comparison of main technical performance of different coal-waste separation methods.

(2) Selection principles

The underground coal-waste separation is different from that on the surface. The underground space is narrow, so the implementation of coal-waste separation underground has higher requirements for security, production capacity, efficiency and continuous production. Meanwhile, the separation equipment should have small volume, good explosion proof, strong practicability, sound separation effects and high reliability.

To select the underground coal-waste separation method, the main influencing factors should be determined first, generally including the coal flow refuse rate, particle size of gangues and separation equipment’s volume, allowable particle size range, efficiency, costs, dimension, capacity.

(3) Selection content and steps

The selection content and steps are as follows: to understand the situation of gangues (including refuse rate, particle size range, density.)→to determine the requirements of separation equipment (the requirements of cost, volume, security, reliability, adaptability, effects)→to determine the separation method (by contrastive analysis of the advantages and disadvantages of various separation methods)→to fix the specific parameters of the equipment (according to the requirements for the accuracy).

If the separation requirements could be satisfied for once or by one separation method, the grading method could be used. The separation process could be divided into primary concentration (grading according to particle size, unit weight.), cleaning (accurate cleaning of gangues) and washing (to remove residual media).

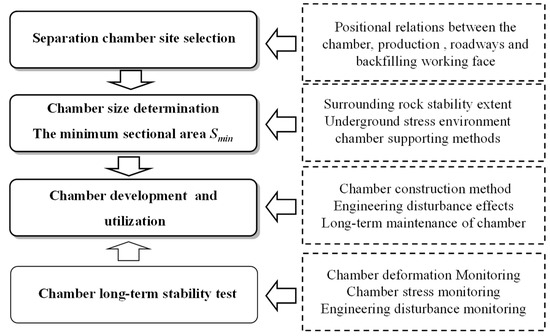

4.2. Large-Section Separation Chamber Design Methods

The underground coal-waste separation system is intended to move the surface separation system underground. The most fundamental difference is that the surface separation plants are replaced by underground roadways and chambers. Due to the limited underground space, unstable surrounding rocks and complex stress environment, the design of large-section separation chambers underground needs to consider the location and utilization. The influencing factors of location of chamber design mainly include the mutual positional relationship of the separation chamber and the existing production system, the mutual positional relationship among separation chambers, the distance between the separation chamber and mining and backfilling working face, sectional area of the chamber, the stability of surrounding rocks and the stress environment. The factors affecting the use of chamber mainly involve the long term stability of the surrounding rocks, the support patterns of the surrounding rocks and later construction impacts. Table 6 shows the dimensions of separation chambers in some mines in China.

Table 6.

Separation chambers in some mines in China.

The design process of underground separation chambers is illustrated in Figure 3, taking the location selection of the coal-waste system in the Tangshan Minging Branch of Kailuan Group as an example. Every year, 900,000 t gangues are produced underground in the Tangshan Mining Branch. To solve the problem of the underground discharge of gangues, the underground coal-waste separation system was established in the crosshead between 502 coal bunker and 5021 coal bunker in Tangkou coal mine. It has achieved a reasonable connection and matching with the existing production system and the gangue backfilling system. Moreover, it is reasonable in terms of the mine underground engineering, coal gangue transportation distance and separation chamber spatial distribution. Based on comprehensive consideration of the stability of the surrounding rocks, the underground stress environment and the maintenance of surrounding rock support, the underground coal-waste separation system was determined, which consisted of six roadways, seven chambers, one refuse bin, three milling coal holes and thirteen crossing points. The moving sieve jig jigging chamber’s length, width and height are 25.8m, 6.2m and 9.27m, respectively and is located in the large-section chamber. Considering the chamber construction design and difficulty level of support, the numerical simulation was used for analysis. Finally, the excavation of the separation chamber used the descending construction method and the combined support of anchor net spray, brick laying and inverted arch.

Figure 3.

Large-section separation chamber design process.

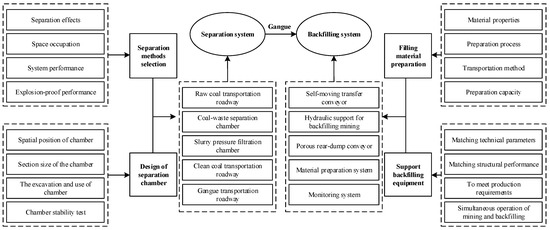

4.3. Separation and Backfilling System Design

The design of an underground coal-waste separation and backfilling system is intended to arrange a complete set of coal-waste separation systems and backfilling systems. The raw coal will be transported to the coal-waste separation system. Then the coal will be transported to the ground after separation. The gangues will be transported to the backfilling system and processed into backfilling materials for utilization. A close connection between the two systems is useful to achieve the underground coal-waste separation and backfilling and mining technology, thus achieving the goal of avoiding raising waste and instead directly replacing coal resources.

The key equipment of the backfilling system includes self-moving transfer conveyors, hydraulic supports for the backfilling mining, porous rear-dump conveyors. The self-moving transfer conveyor could transfer the backfilling materials from a low-position belt conveyor to a high-position porous rear-dump conveyor tail. The hydraulic supports for the backfilling mining could cover the working space of mining and backfilling at the same time and provide the hanging space for the porous rear-dump conveyor as well as offer compaction power for filling materials. The porous rear-dump conveyor could transport the solid backfilling materials in the goaf regularly in a fixed amount and unload them at a fixed point. The process of backfilling mining is completed under the orderly coordination of the self-moving transfer conveyor, hydraulic support for the backfilling mining and porous rear-dump conveyor. The underground coal-waste separation system is mainly made of transportation roadway, separation chambers and coal gangue storage bin. Firstly, the transportation roadway for raw coal will transport the raw coal at different mining positions to the separation chambers where the raw coal will be separated and the pressure filtration of slime and wastewater treatment will be completed. The transportation roadway for coal gangues is used to transport the coal and gangues after separation. The coal gangue storage bin could store quantitative coal and gangues to relieve coal gangue transportation pressure or facilitate the further utilization. The production capacity of the two systems matches each other with reasonable spatial distribution. Figure 4 shows the design principles of coal-waste separation system and the backfilling system.

Figure 4.

Design principles of underground coal-waste separation system and backfilling system.

5. Mining-Separating-Backfilling + X

5.1. The Concept of Mining-Separating-Backfilling + X Technology

The mining-separating-backfilling + X takes the underground mining, separation and backfilling as a whole and aims to achieve high coordination between mine development layouts, production system arrangements and mining-separation-backfilling equipment capacity. Then, according to the geological mining conditions and requirements, innovations can be made to the related technologies and processes to improve the control objectives or system’s intelligence level, thus becoming a highly integrated operation mode.

X could refer to the added technology or process, such as the gob-side entry retaining along the backfilling mining working face, the working face cooling or noise reduction and dust proofing. It also could refer to the systems of the backfilling working face, such as the gas drainage system, coal transportation system and the effects after the implementation of mining-separating-backfilling, such as dynamic disaster prevention, surrounding rock deformation control, surface subsidence reduction. In addition, it may include the improvement of intelligence level in whole or in part.

5.2. The Composition of Mining-Separating-Backfilling + X Technology

According to the basic connotations of mining-separating-backfilling + X and based on engineering requirements of safety coal seam mining, near zero discharge of gangue and gas, groundwater environmental protection, surface subsidence control and efficient coal seam mining, the technology of mining-separating-backfilling + X combines with other technologies, such as gob-side entry retaining non pillar mining, gas extraction, solid waste treatment, water protection mining, mining under buildings, railways and water bodies, to form integrated mining methods. They include the mining-separating-backfilling + setting pillars method, mining-separating-backfilling + gas drainage method, mining-separating-backfilling+treatment method, mining-separating-backfilling+protection, mining-separating-backfilling + prevention. During the simultaneous operations of mining, coal-waste separating and gangue backfilling, the integrated mining methods could combine with actual engineering requirements and achieve the multiple goals of coal resources’ exploitation, coordinated mining, waste-free emission, harmonious mining, lossless mining and safety mining, thus truly achieving green mining.

5.3. Advantages of Mining-Separating-Backfilling + X Technology

The technical advantages of mining-separating-backfilling + X include the following five aspects:

I The zero discharge of gangues could be achieved. As the representative technology of green mining, the mining-separating-backfilling + X technology is to backfill all mining-induced gangues to the goaf instead of transporting them to the surface by combining with coal-waste separation and gangue backfilling technology. The realization of zero discharge of gangues is useful to reduce land occupation due to gangue piling up and to avoid potential environmental damage due to spontaneous combustion in coal gangue dumps.

II The control of strata strike and inclination is more flexible. By the mining-separating-backfilling + X technology, the strata control uses the non-compact backfilling and non-precision control mainly for gangue treatment instead of the compact backfilling and precise control under conditions of ‘three under’ coal resources mining, so the control of strata strike and inclination has more flexible selectivity and the technology has wider applicability.

III The mining-separating-backfilling + X technology has various types. The mining may focus on a small amount of gangues due to mining. It also could be the mining of unconventional protective layers and pays attention to realizing pressure relief and permeability increasing of the protected seams. It may be the orderly mining of coal seam groups and lays emphasis on intensive production among coal seams and the influences of mine pressure superposition. The separating aims to achieve underground coal-waste separation and minimize the refuse rate. The separating methods include the selective crushing method, the dense medium shallow groove method, the vibro-assisted jigging method, the ray identification method and the full-size water separation method. The backfilling focuses on implementing the complete backfilling of gangues. The methods mainly include the solid backfilling, paste backfilling, ultra-high water backfilling, cemented backfilling. X refers to the related technologies determined by specific engineering requirements. The integration of different technical connotations of mining-separating-backfilling + X could form various technologies and carry out different implementations to achieve the ideas of green mining characterized as nearly zero ecological damage exploitation and nearly zero pollution emission.

IV The scientific combinations of multiple goals could be realized. The mining-separating-backfilling + X technology could achieve the combinations of multiple goals of coal resources’ more exploitation, coordinated mining, waste-free emission, harmonious mining, lossless mining and safety mining, which could provide a powerful technical support for the construction and development of green mines.

V The intensive underground production mode could be formed. The mining-separating-backfillling + X technology could simultaneously carry out coal mining, coal-waste separating and in-situ gangue backfilling combining with the specific X technology in accord with actual engineering requirements, thus forming intensive underground production mode which is favourable for the efficient production organization of large-scale mines and work employee efficiency.

6. The Engineering Application and a Typical Case of Mining-Separating-Backfilling + X Technology

6.1. The Engineering Application Situations

The green technology of mining-separating-backfilling has been applied in multiple mines in China, as shown in Table 7. It could be seen that mines had issues of difficult transportation and lifting of gangues and gangue piling up on the ground. After the implementation of the mining-separating-backfilling technology, the gangue transportation and lifting costs were greatly reduced. Moreover, the ‘three under’ coal resources were mined and substantial economic, social and environmental benefits were brought.

Table 7.

The engineering application situations of mining-separating-backfilling green technology.

6.2. A Typical Application Case in No.12 Mine of Pingdingshan Group

6.2.1. The Engineering Background

The production capacity of No.12 Mine under Pingdingshan Tianan Coal Mining Co., Ltd. in Henan province is 1.3 Mt/a. The buried depth of coal seams reached 1100 m. The remaining recoverable reserves were 23.849 million tons. Among them, the amount of ‘three under’ coal resources reached 12.343 million tons. The mine one level and two level were basically mined out. The total reserves of three level were 32.323 million tons and the recoverable reserves were 21.253 million tons, which was the main mining area. The original gas content of Ji15 coal seam of Group Ji was 15.256 m3/t, the original gas pressure was 1.78 MPa and the permeability coefficient was only 0.0776 m2/MPa2d. The thickness of Ji14 coal seam was only 0.5 m and the gas pressure was 0.26 MPa. It belonged to non-outburst coal seam and the occurrence was not stable.

The mining of Ji15 coal seam is facing the following problems: firstly, the mining depth was more than 1100 m and there were difficulties for the deep mining such as auxiliary lifting. Secondly, the gas has high content, low permeability and drainage rate. There are potential dangers and the safety of mining is severely challenged. Thirdly, the coal mine output is mainly from the exploitation of ‘three under’ coal resources, especially under buildings, so the output cannot be guaranteed.

Besides the above-mentioned problems urgently to be solved, the mining of Ji15 coal seam also faces serious eco-environmental pressure. The occurrence of the overlying Ji14 coal seam is not stable and the thickness is too thin to be mined, so it has no technical conditions of the mining of the conventional protective layers. However, if it was left unexploited, it would cause a serious waste of resources. If it is designed as the upper protective layer for mining, the mining of near whole rock protective layer inevitably leads to high refuse rate of 73.7%. The working faces of all protective layers would cause about 8.1 million m3 gangue. The piling up of gangues in quantities is bound to occupy large amounts of land. The gangue dumps will be washed away by the rain and will pollute water around the mining areas. What is worse, the spontaneous combustion in coal gangue dumps will release enormous amounts of toxic and hazardous gas. Therefore, how to exploit Ji15 coal seam safely and efficiently with low eco-environmental damage has become an urgent engineering problem to be solved.

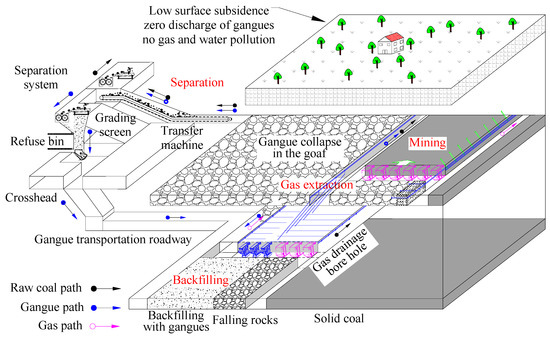

6.2.2. The Arrangement of Mining-Separating-Backfilling System

According to specific conditions, the No.12 Mine in Pingdingshan Group applied the integrated technology of ‘mining-separating-backfilling + gas extraction’ to solve the engineering problems. The basic idea of the integrated technology is as follows. For the mining of high gas low permeability coal seams, the integrated green recycling mining system of ‘mining-separating-backfilling-gas extraction’ was formed underground. The mining conditions of the protective layers were created based on essential requirements of the mining of the protected layer. The exploitation of the high gas low permeability Ji15 coal seam was carried out by mining the overlying No.14 coal seam protective layers. At the same time, the raw coal resources with a high refuse rate caused by the protective layer the mining of the Ji14 coal seam were separated by underground coal-waste separation system. Meanwhile, the mining-induced gangues were transported to the working face of Ji15 coal seam under mixing mining of solid backfilling mining and the traditional fully-mechanized mining and then used to backfill the goaf by the mining and backfilling technology. The protective layer mining led to an increase in the gas permeability of the protected layer, so the gas extraction system was arranged in the protective and protected layers to achieve the co-mining of Ji15 coal seam and high gas. Figure 5 shows the whole idea of the ‘mining-separating-backfilling + gas extraction’ integrated technology.

Figure 5.

The overall idea of ‘mining-separating-backfilling + gas extraction’ integrated technology.

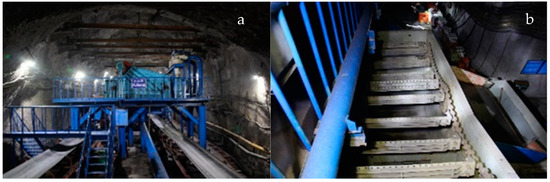

6.2.3. Key Separating Equipment

The coal flow refuse rate reached up to 73.7% in the working face of the Ji14 nearly total rock protective layer. Among them, the mass ratios of 0–13 mm screen underflow and ash content were 35.4% and 61.5%, respectively. The separation density grade was 1.7 kg/L. These characteristics were distinguished for coal-waste separation. Then, based on the actual conditions of No.12 Mine, the 13 mm and 250 mm three-product toothed roll screen were designed for primary concentration according to particle sizes. Next, the dense medium shallow groove separator was used for ultimate separation according to the density.

According to actual conditions of mines, the underground separation chamber was arranged at the connection point of gangue transportation roadway in the west wing of three level and gangue transportation inclined roadway. It had a length of 49.7 m in horizontal direction, a maximum height of 8.8 m and a width of 4m. The belt conveyor head chamber was arranged near the washing chamber with a length of 60 m in horizontal direction, a height of 6m and a width of 8.4 m. The separation chamber was armed with XCG-16/28 type three-product roll screen, roll crusher, XZQ1525 type dense medium shallow groove separator. The separator was suitable for 13~250 mm particle-size coal-waste separation and the separation capacity could reach 2.2 million t/a. Figure 6 shows the separation chamber and key equipment.

Figure 6.

Photos of key coal and gangue separation equipment. (a) Washing chamber, (b) Dense medium shallow groove separator.

6.2.4. The Application Effects

The integrated system of ‘mining-separating-backfilling + gas extraction’ has realized the integration of the mining system of the underground nearly total rock protective layer, the separation system of less coal and more gangues underground, the gas extraction system at low gas permeability coal seam and the mixed mining system of solid backfilling mining and the traditional fully-mechanized mining. They coordinated with each other and cooperated with each other in time and space during the mining, separating, gas extracting, backfilling and coal mining technology, thus ensuring the safe and efficient operation of the integrated system.

The mining of the nearly total rock working face of Ji14-31050 protective layer was started on 23 October 2014. By December 2015, a length of 600 m was mined. The maximum advance capacity of the working face was 120m each month. The produced raw coal was separated by the dense medium shallow groove separator and about 72,000 t coal and 347, 000 t gangues were separated. During the mining process of the protective layer, the gas extraction in the protected layer working face reached 9.6 million m3. The length of the mixed working face of the protected layer Ji 15-31010 reached 220 m. The coal production capacity could reach 1.2 million t/y and the highest yield per month reached 150,000 t. The gangue treatment capacity reached 600,000 t/y. It was mined between July 14 of 2014 and December of 2015 with a total coal production of 1.34 million t and the total gangue backfilling of 320,000 t as well as the gas extraction of 120 million m3. In general, the gangues discharged by a mine with the annual production of 1 million t will occupy about 7 hectares. According to the ratio measurement, the annual discharging reduction of gangues could reach 320,000 t by the backfilling mining working face of No.12 Mine of Pingdingshan Group. Moreover, about 9 hectares of lands occupied by gangue piling up could be reduced, thus eliminating water and air pollution in the mining area. Table 8 shows the remarkable environmental benefits brought by the application of the integrated technology of mining-separating-backfilling.

Table 8.

Benefit analysis.

7. Strata Control Theory in Backfilling Mining

The biggest technical advantage of backfill mining is to weaken strata movement. The main theories of strata control in backfilling mining include the equivalent mining height theory [43], the key strata stability control theory [44], the main roof control theory [45] and the cooperative roof control theory [46].

The equivalent mining height theory, which is mainly applied to the prediction and control design of surface subsidence, holds that the effect of strata movement in backfill mining is equivalent to that of mining in extremely thin coal seams by the traditional caving method.

The key strata stability control theory, which is mainly used to explain the bending deformation law of key strata, holds the following two points: (1) Compared with caving mining face, backfill mining face has obviously weakened rock pressure; (2) The maximum deflection of key strata decreases with the increase of elastic modulus of backfill body.

The main roof control theory, which clarifies that the elastic modulus of backfill body and the support strength of backfill support are the main factors controlling rock pressure in backfilling mining, holds the following two points: (1) Increasing the elastic modulus of backfill body can prevent the main roof from breaking; (2) Properly increasing the support strength of backfill support can well control the roof subsidence.

The cooperative roof control theory, which reveals the basic principle of stope stability in backfill mining, holds the following four points: (1) The degree of strata pressure in backfilling face is mainly controlled by coal wall, backfill support and backfill body; (2) Backfill support controls the roof subsidence within the roof control range and transfers roof load to floor; (3) Backfill body mainly bears overlying rock load and restrains roof displacement and the degree of restraint is strictly controlled by the elastic foundation coefficient of backfill body. The greater the elastic foundation coefficient is, the smaller the displacement of overlying rock is; (4) The overlying strata are controlled by backfill body with different densities within different critical states, which reflects the mechanism of backfill body in weakening rock pressure.

8. Conclusions

I The fully-mechanized solid backfilling mining technology has developed rapidly in terms of process, equipment and basic theory. It is being developed to the stage of ‘mining-separating-backfilling + X’ to achieve low eco-environmental damage. It has been widely used for the mining of coal resources buried under buildings, water bodies and railways in many coals of Pingdingshan Group, Yankuang Group, Xinwen Group.

II The design of underground coal-waste separation and solid backfilling mining systems mainly involves the gangue separation methods selection, large-section separation chamber design and the separation and backfilling system design. The basic principle is to form a complete set of coal-waste separation and solid backfilling mining systems which are tightly integrated with each other and realize the integrated mining-separating-backfilling technology. Thus, the gangues could avoid being transported to the ground and could directly replace coal resources.

III The integrated mining technology system of “mining-separating-backfilling + X” is put forward, the connotation of which is taking the underground mining, separation and backfilling as a whole and aims to achieve high coordination among mine development layout, production system arrangement, mining-separation-backfilling equipment capacity. Then, according to the geological mining conditions and requirements, it makes innovations of the related technologies and process and improves control objectives or system’s intelligence level, thus becoming a highly integrated operation mode. X could refer to the added technology or process, the systems of backfilling working face and the improvement of intelligence level in whole or in part.

IV The ‘mining-separating-backfilling + X’ integrated technology system has been put forward. The integrated technology of ‘mining-separating-backfilling + gas extraction’ was successfully carried out in No.12 Mine of Pingdingshan Group between July of 2014 and November 11 of 2015. A total of about 1.34 million t coal was mined and about 320,000 t gangues were used for backfilling. The amount of gas extraction reached 120 million m3. After the backfilling area is mined out, about 2.7 million t gangues are expected to be reduced. The reduction of land occupation by gangues could reach 72 hectares. 100 million m3 gas extraction could be reduced. Therefore, the green mining technology of the integration of ‘mining-separating-backfilling + gas extraction’ could provide significant environmental benefits.

V The main theories of strata control in backfilling mining include the equivalent mining height theory, the key strata stability control theory, the main roof control theory and the cooperative roof control theory.

Author Contributions

Q.Z. conceptualized, designed and analyzed the article; J.Z. conceptualized, analyzed the article; Z.W. performed the analysis and wrote the manuscript; Y.C. revised the manuscript. All of the authors reviewed the manuscript and approved it for submission.

Funding

This research was funded by the Fundamental Research Funds for the Central Universities, (2017XKZD13).

Acknowledgments

Thanks to the support of the Fundamental Research Funds for the Central Universities, (2017XKZD13) and thanks No.12 Mine of Pingdingshan Tianan Coal Mining Co., Ltd. for providing us the engineering application site. In addition, the authors are grateful to all the reviewers for their specific comments and suggestions.

Conflicts of Interest

The authors declare no conflict of the interest.

References

- Li, M.S. Ecological restoration of mineland with particular reference to the metalliferous mine wasteland in China: A review of research and practice. Sci. Total Environ. 2006, 357, 38–53. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.; Huang, Y.; Zhou, N. Effects of particle size of crushed gangue backfill materials on surface subsidence and its application under buildings. Environ. Earth Sci. 2017, 76, 603. [Google Scholar] [CrossRef]

- Zhao, T.B.; Ma, S.Q.; Zhang, Z.Y. Ground Control Monitoring in Backfilled Strip Mining under the Metropolitan District: Case Study. Int. J. Geomech. 2018, 18, 14. [Google Scholar] [CrossRef]

- Peng, B.; Li, X.; Zhao, W.; Yang, L. Study on the release characteristics of chlorine in coal gangue under leaching conditions of different pH values. Fuel 2018, 217, 427–433. [Google Scholar] [CrossRef]

- Gong, P.; Ma, Z.G.; Ni, X.Y.; Zhang, R.R. Floor Heave Mechanism of Gob-Side Entry Retaining with Fully-Mechanized Backfilling Mining. Energies 2017, 10, 2085. [Google Scholar] [CrossRef]

- Hasan, A.; Karrech, A.; Chareyre, B. Evaluating Force Distributions within Virtual Uncemented Mine Backfill Using Discrete Element Method. Int. J. Geomech. 2017, 17, 12. [Google Scholar] [CrossRef]

- Rukavishnikov, G.D.; Neverov, S.A.; Neverov, A.A. Substantiation of artificial composite-structure roof construction in top-down cut-and-fill stoping. In Geodynamics and Stress State of the Earth’s Interior; Kurlenya, M., Ed.; Iop Publishing Ltd.: Bristol, UK, 2018; Volume 134. [Google Scholar]

- Senapati, P.K.; Mishra, B.K. Design considerations for hydraulic backfilling with coal combustion products (ccps) at high solids concentrations. Powder Technol. 2012, 229, 119–125. [Google Scholar]

- Zhang, J.X.; Deng, X.J.; Zhao, X.; Ju, F.; Li, B.Y. Effective control and performance measurement of solid waste backfill in coal mining. Int. J. Min. Reclam. Environ. 2017, 31, 91–104. [Google Scholar] [CrossRef]

- Sun, Y.Z.; Fan, J.S.; Qin, P.; Niu, H.Y. Pollution extents of organic substances from a coal gangue dump of Jiulong Coal Mine, China. Environ. Geochem. Health 2009, 31, 81–89. [Google Scholar] [CrossRef]

- Zhang, H.; Ouyang, S. Release characteristics of heavy metals from coal gangue under simulation leaching conditions. Energy Explor. Exploit. 2014, 32, 413–422. [Google Scholar] [CrossRef]

- Li, N.; Han, B.Q. Chinese research into utilisation of coal waste in ceramics, refractories and cements. Adv. Appl. Ceram. 2006, 105, 64–68. [Google Scholar] [CrossRef]

- Liu, H.B.; Liu, Z.L. Recycling utilization patterns of coal mining waste in China. Resour. Conserv. Recycl. 2010, 54, 1331–1340. [Google Scholar]

- Xu, G.L.; Sun, C.M.; Sun, Y.; Liao, H. A New Comprehensive Utilization Method for Coal Gangue: Preparing Alite-Sulphoaluminate Cement. Adv. Mater. Res. 2013, 652, 1527–1532. [Google Scholar] [CrossRef]

- Yu, L.J.; Feng, Y.L.; Yan, W. The Current Situation of Comprehensive Utilization of Coal Gangue in China. Adv. Mater. Res. 2012, 524-527, 915–918. [Google Scholar] [CrossRef]

- Qian, M.G.; Miao, X.X.; Jia-Lin, X.U. Resources and Environment Harmonics (Green) Mining and Its Technological System. J. Min. Saf. Eng. 2006, 23, 1–5. [Google Scholar]

- Liu, J.-G.; Zhao, Q.-B. Comprehensive mechanized filling coal mining. J. China Coal Soc. 2010, 35, 1413–1418. [Google Scholar]

- Yan, H.; Zhang, J.X.; Zhou, N.; Zhang, S.; Dong, X.J. Shaft failure characteristics and the control effects of backfill body compression ratio at ultra-contiguous coal seams mining. Environ. Earth Sci. 2018, 77, 12. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Wang, J.; Zhou, N.; Zhang, S. Multi-fractal characteristics of particle size distribution of granular backfilling materials under different loads. Mater. Test. 2018, 60, 202–208. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Qiao, M.; Chen, Z.; Song, T.; Kong, G.; Gao, H.; Guo, L. Effects of Water Soaked Height on the Deformation and Crushing Characteristics of Loose Gangue Backfill Material in Solid Backfill Coal Mining. Processes 2018, 6, 64. [Google Scholar] [CrossRef]

- Huang, P.; Spearing, A.J.S.; Feng, J.; Jessu, K.V.; Guo, S. Effects of solid backfilling on overburden strata movement in shallow depth longwall coal mines in West China. J. Geophys. Eng. 2018, 15, 2194–2208. [Google Scholar] [CrossRef]

- Guo, Q.B.; Guo, G.L.; Lv, X.; Zhang, W.X.; Lin, Y.K.; Qin, S.Y. Strata movement and surface subsidence prediction model of dense solid backfilling mining. Environ. Earth Sci. 2016, 75, 11. [Google Scholar] [CrossRef]

- Guo, G.L.; Feng, W.K.; Zha, J.F.; Liu, Y.X.; Wang, Q. Subsidence control and farmland conservation by solid backfilling mining technology. Trans. Nonferrous Met. Soc. China 2011, 21, S665–S669. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Ju, F.; Zhou, N.; Li, M.; Zhang, W. Practice and technique of green mining with integration of mining, dressing, backfilling and X in coal resources. J. China Coal Soc. 2019, 44, 64–73. [Google Scholar]

- Teng, Y.H.; Wang, J.Z. China’s study on coal mining beneath surface buildings—State-of-the-art and developing trend. Trans. Nonferrous Met. Soc. China 2005, 15, 5–8. [Google Scholar]

- Pu, H.; Zhang, J. Research on protecting the safety of buildings by using backfill mining with solid. Procedia Environmental Sciences. 2012, 12, 191–198. [Google Scholar]

- Zhu, X.; Guo, G.; Zha, J.; Chen, T.; Fang, Q.; Yang, X. Surface dynamic subsidence prediction model of solid backfill mining. Environ. Earth Sci. 2016, 75, 1–9. [Google Scholar] [CrossRef]

- Li, H.Z.; Zha, J.F.; Guo, G.L.; Zhao, B.C.; Wang, B. Compression Ratio Design and Research on Lower Coal Seams in Solid Backfilling Mining Under Urban Areas. Soil Mech. Found. Eng. 2016, 53, 1–7. [Google Scholar]

- Zhang, J.; Shen, B. Coal mining under aquifers in China: A case study. Int. J. Rock Mech. Min. Sci. 2004, 41, 629–639. [Google Scholar] [CrossRef]

- Miao, X.; Cui, X.; Wang, J.A.; Xu, J. The height of fractured water-conducting zone in undermined rock strata. Eng. Geol. 2011, 120, 32–39. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, H.; Deng, X.; Ju, F. Prediction of the Height of the Water-Conducting Zone Above the Mined Panel in Solid Backfill Mining. Mine Water Environ. 2014, 33, 317–326. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.-X.; Deng, X.-J.; Zhou, N.; Zhang, Q. Method of water protection based on solid backfill mining under water bearing strata and its application. J. China Coal Soc. 2017, 42, 127–133. [Google Scholar]

- Yu, W.J.; Feng, T.; Chen, X.Y. Law of Ground Subsidence and Strata Movement Caused by Backfill Mining of “under Three” Coal. Adv. Mater. Res. 2013, 807, 2304–2308. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Sun, Q.; Gao, R.; Germain, D.; Abro, S. Surface subsidence control theory and application to backfill coal mining technology. Environ. Earth Sci. 2015, 74, 1–10. [Google Scholar] [CrossRef]

- Zheng, K.H.; Du, C.L.; Li, J.P.; Qiu, B.J. Coal and Gangue Underground Pneumatic Separation Effect Evaluation Influenced by Different Airflow Directions. Adv. Mater. Sci. Eng. 2016, 2016, 6465983. [Google Scholar] [CrossRef]

- Yang, D.L.; Li, J.P.; Zheng, K.H.; Du, C.L.; Liu, S.Y. Impact-Crush Separation Characteristics of Coal and Gangue. Int. J. Coal Prep. Util. 2018, 38, 127–134. [Google Scholar] [CrossRef]

- Zheng, K.; Du, C.; Li, J.; Qiu, B.; Yang, D. Underground pneumatic separation of coal and gangue with large size (≥ 50 mm) in green mining based on the machine vision system. Powder Technol. 2015, 278, 223–233. [Google Scholar] [CrossRef]

- Honaker, R.Q.; Singh, N.; Govindarajan, B. Application of dense-medium in an enhanced gravity separator for fine coal cleaning. Miner. Eng. 2000, 13, 415–427. [Google Scholar] [CrossRef]

- Chen, J.; Chu, K.W.; Zou, R.P.; Yu, A.B.; Vince, A.; Barnett, G.D.; Barnett, P.J. How to optimize design and operation of dense medium cyclones in coal preparation. Miner. Eng. 2014, 62, 55–65. [Google Scholar] [CrossRef]

- Peng, L.; Wang, Z.; Ma, W.; Chen, X.; Zhao, Y.; Liu, C. Dynamic influence of screening coals on a vibrating screen. Fuel 2018, 216, 484–493. [Google Scholar] [CrossRef]

- Fowler, R.T.; Lim, S.C. The influence of various factors upon the effectiveness of separation of a finely divided solid by a vibrating screen. Chem. Eng. Sci. 1959, 10, 163–170. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, C. Separating coal and gangue using three-dimensional laser scanning. Int. J. Miner. Process. 2017, 169, 79–84. [Google Scholar] [CrossRef]

- Miao, X.X.; Ju, F.; Huang, Y.L.; Guo, G.L. New development and prospect of backfilling mining theory and technology. J. China Univ. Min. Technol. 2015, 44, 391–399. [Google Scholar]

- Zhang, J. Study on Strata Movement Controlling by Raw Waste Backfilling with Fully-Mechanized Coal Winning Technology and Its Engineering Applications; China University of Mining & Technology: Xuzhou, China, 2008. [Google Scholar]

- Huang, Y. Ground Control Theory and Application of Solid Dense in Coal Mines; China University of Mining & Technology: Xuzhou, China, 2012. [Google Scholar]

- Zhang, Q. Roof Control Mechanism by Coordination with Backfilled Body and Backfill Support in Solid Backfill Mining Technology; China University of mining & Technology: Xuzhou, China, 2015. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).