Development of a Homogenous Cement Slurry Using Synthetic Modified Phyllosilicate while Cementing HPHT Wells

Abstract

:1. Introduction

2. Methods and Materials

2.1. Materials

2.2. Methods

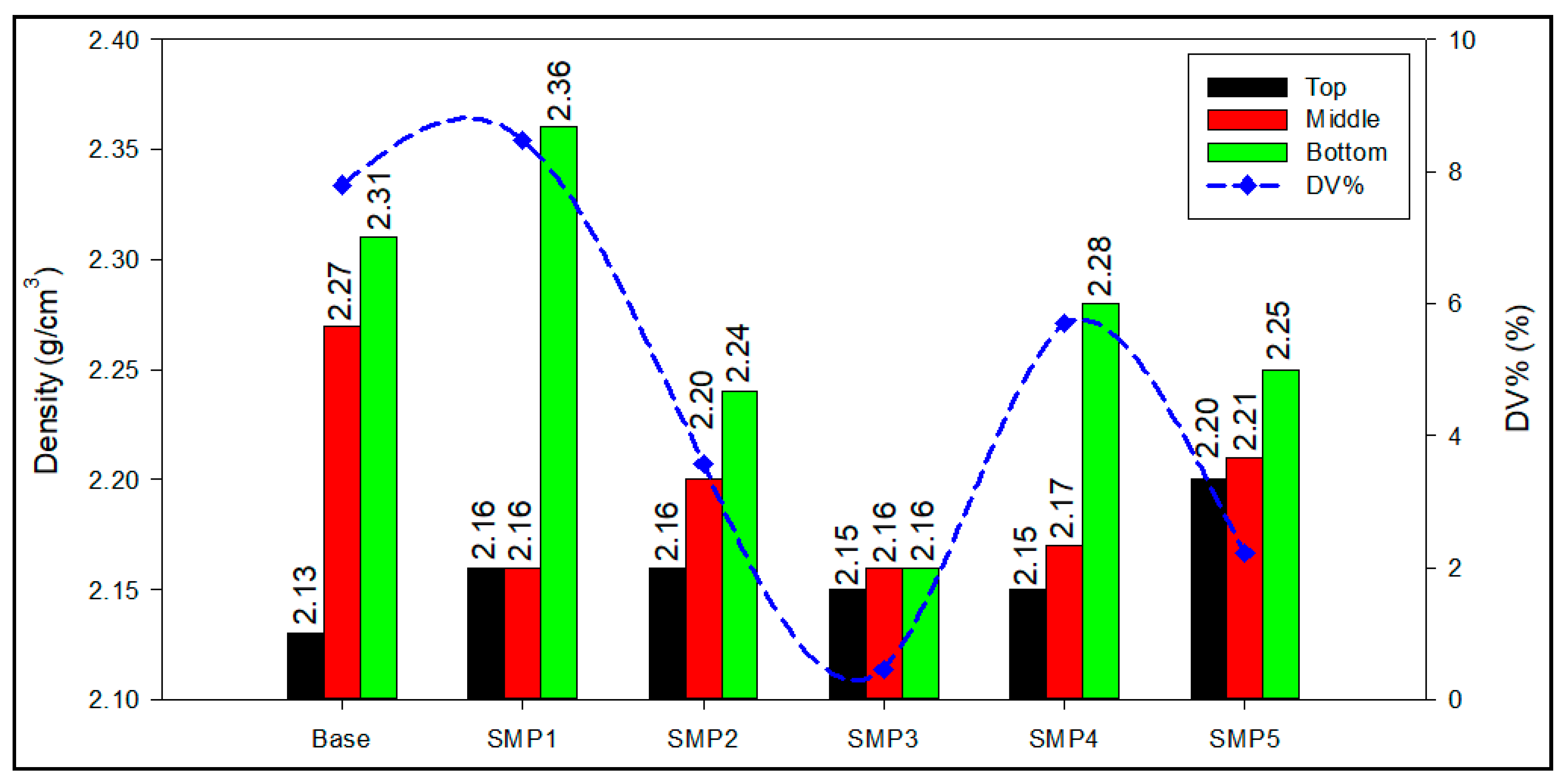

2.3. Density Variation

2.4. Rheology

2.5. Compressive Strength Test

2.6. Permeability

3. Results and Discussion

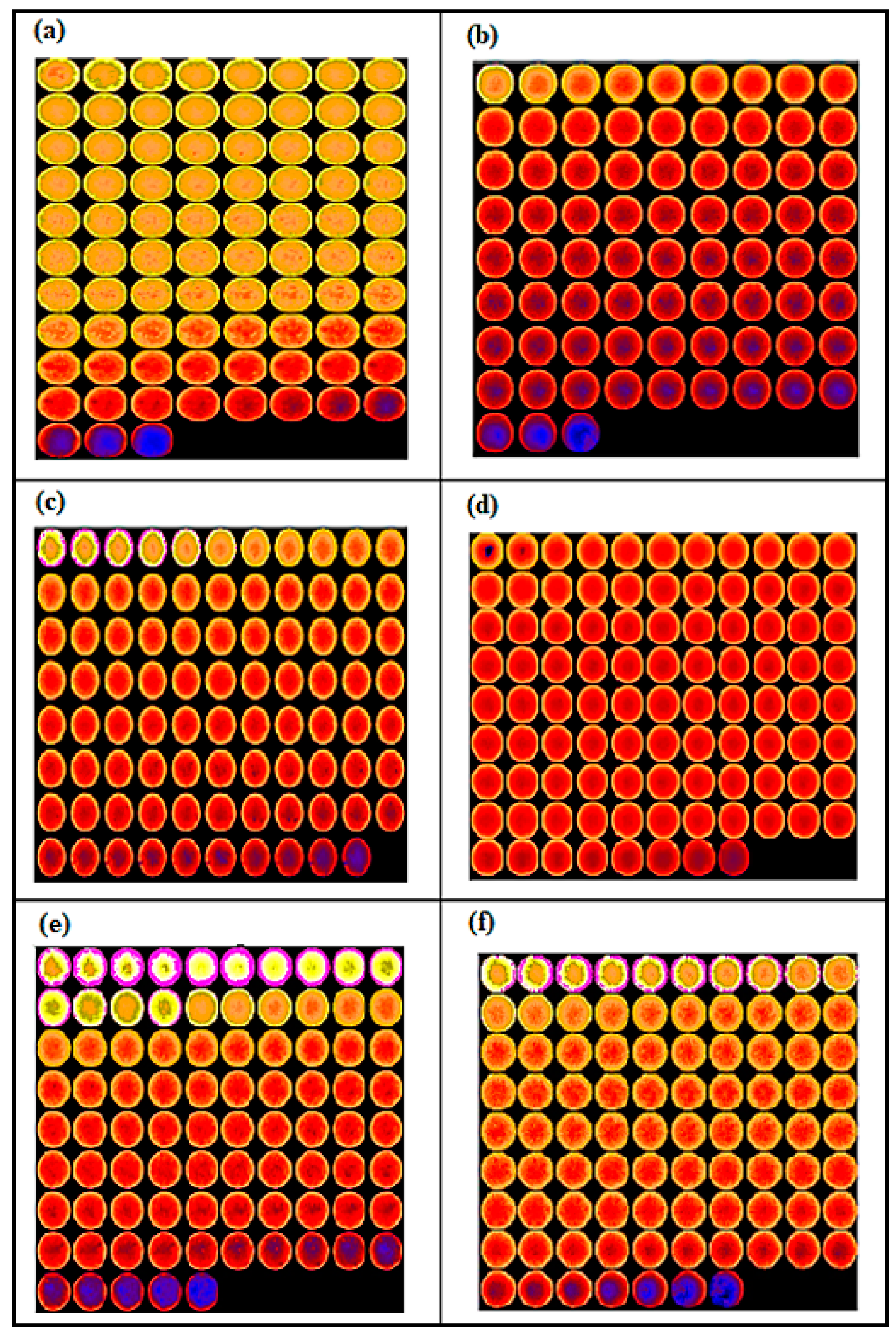

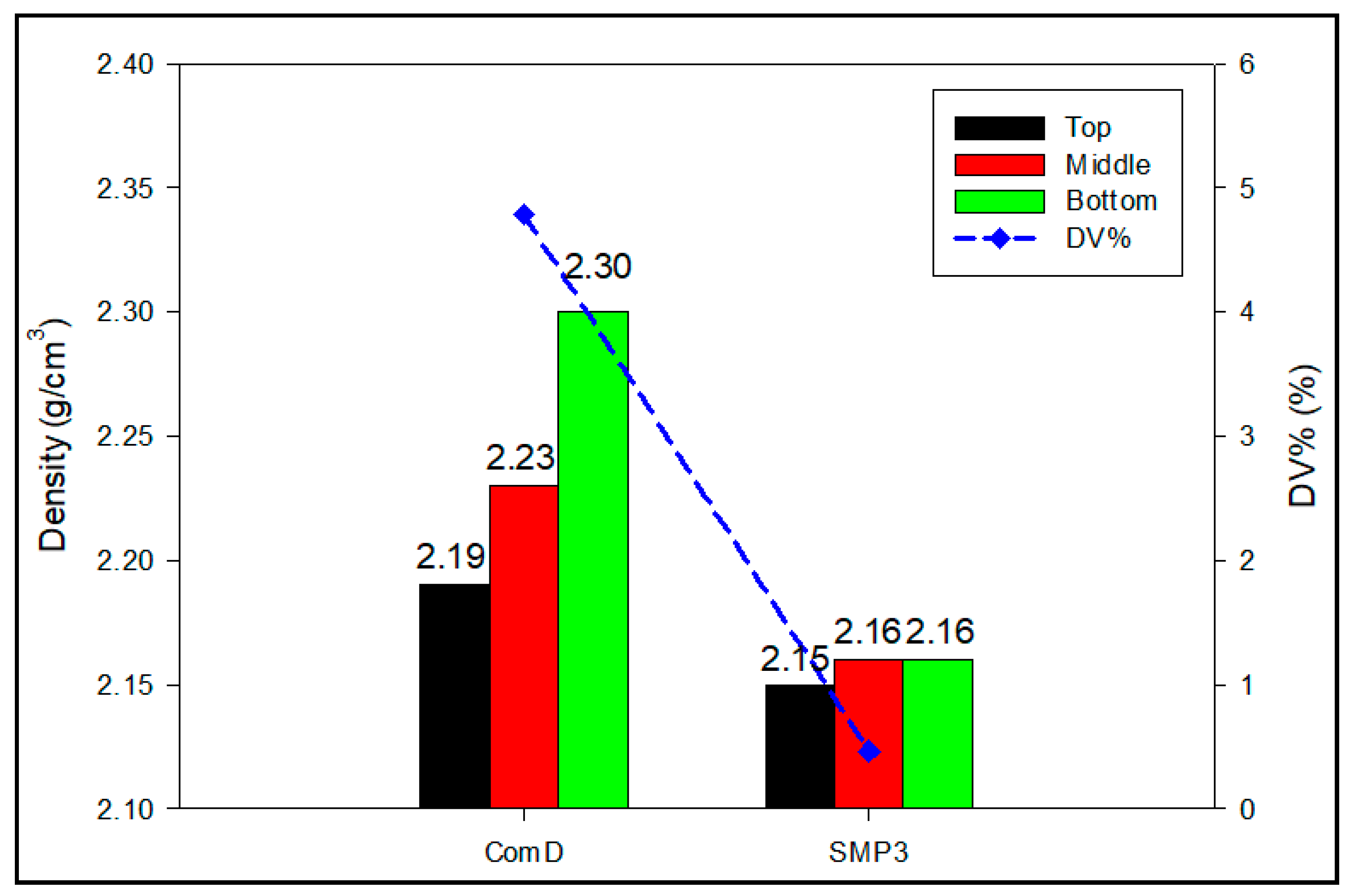

3.1. Density Variation

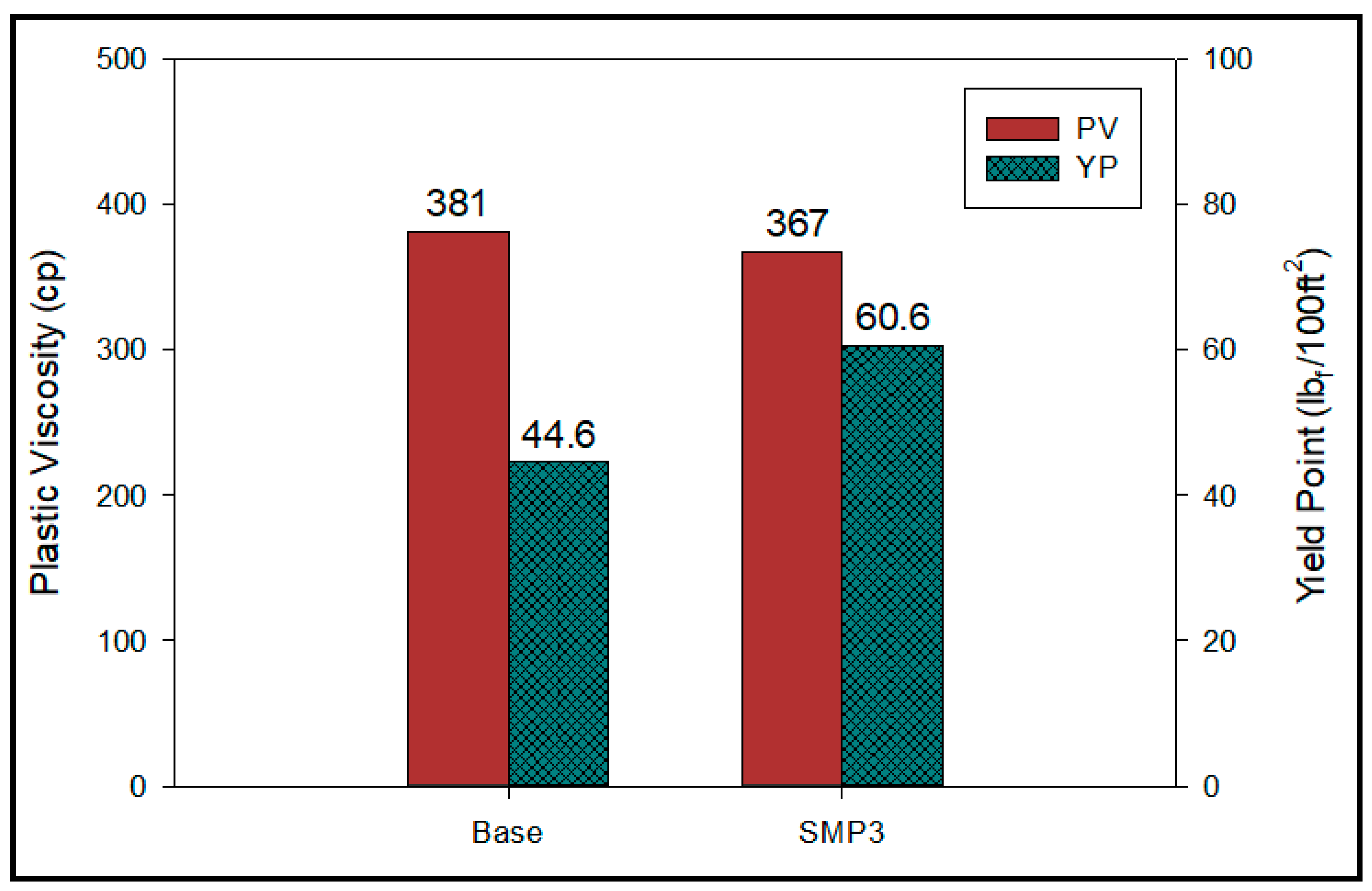

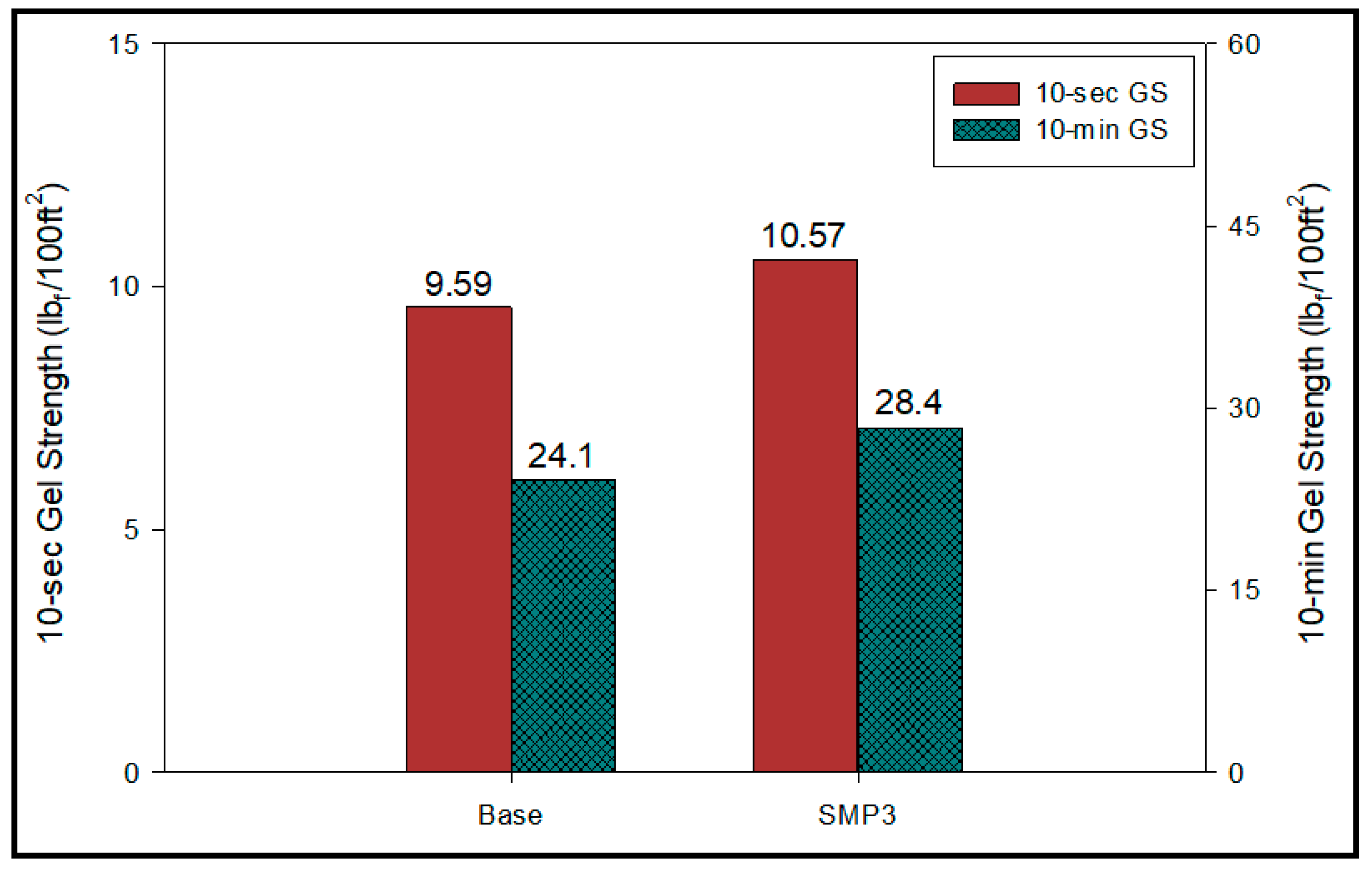

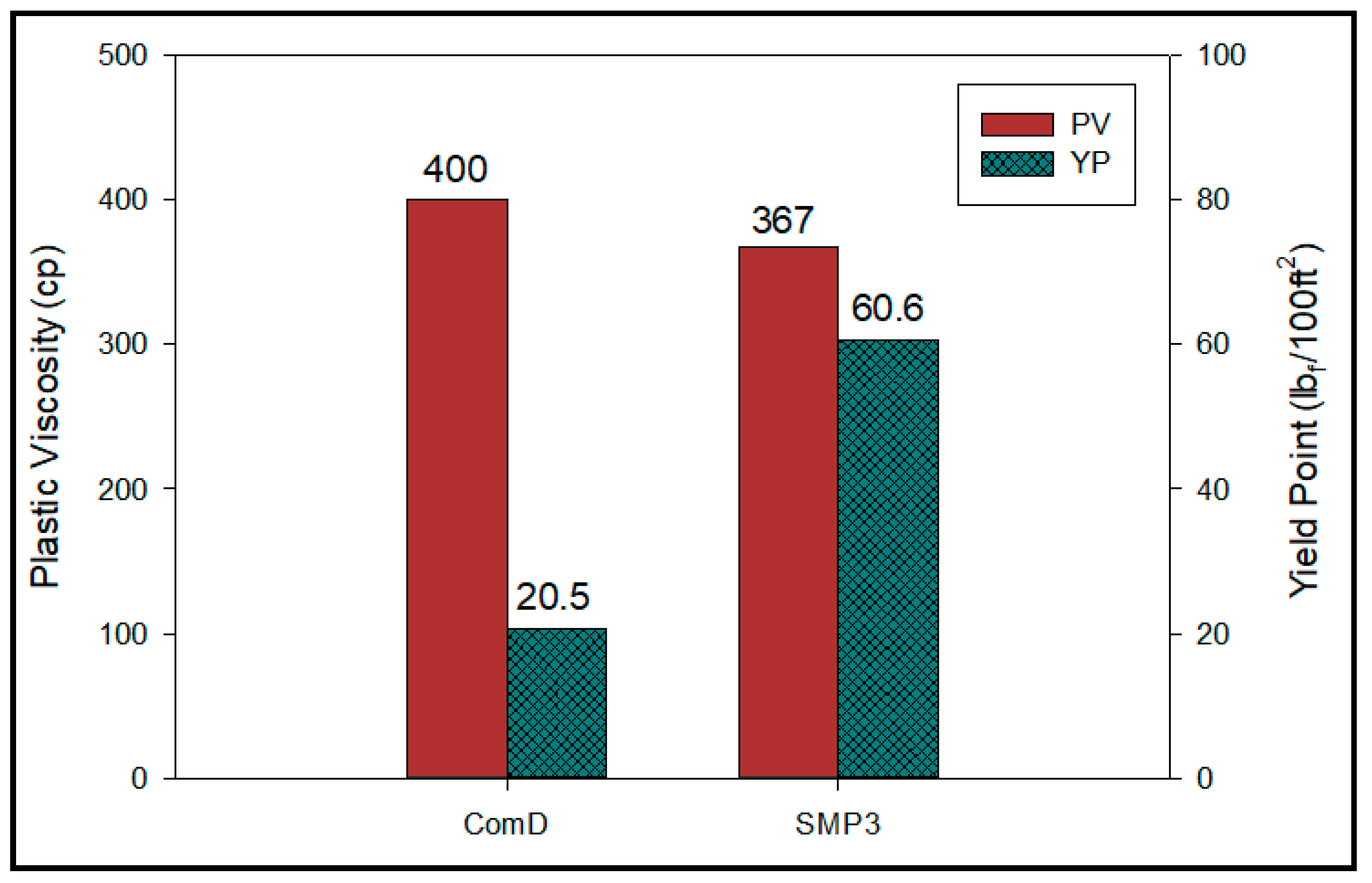

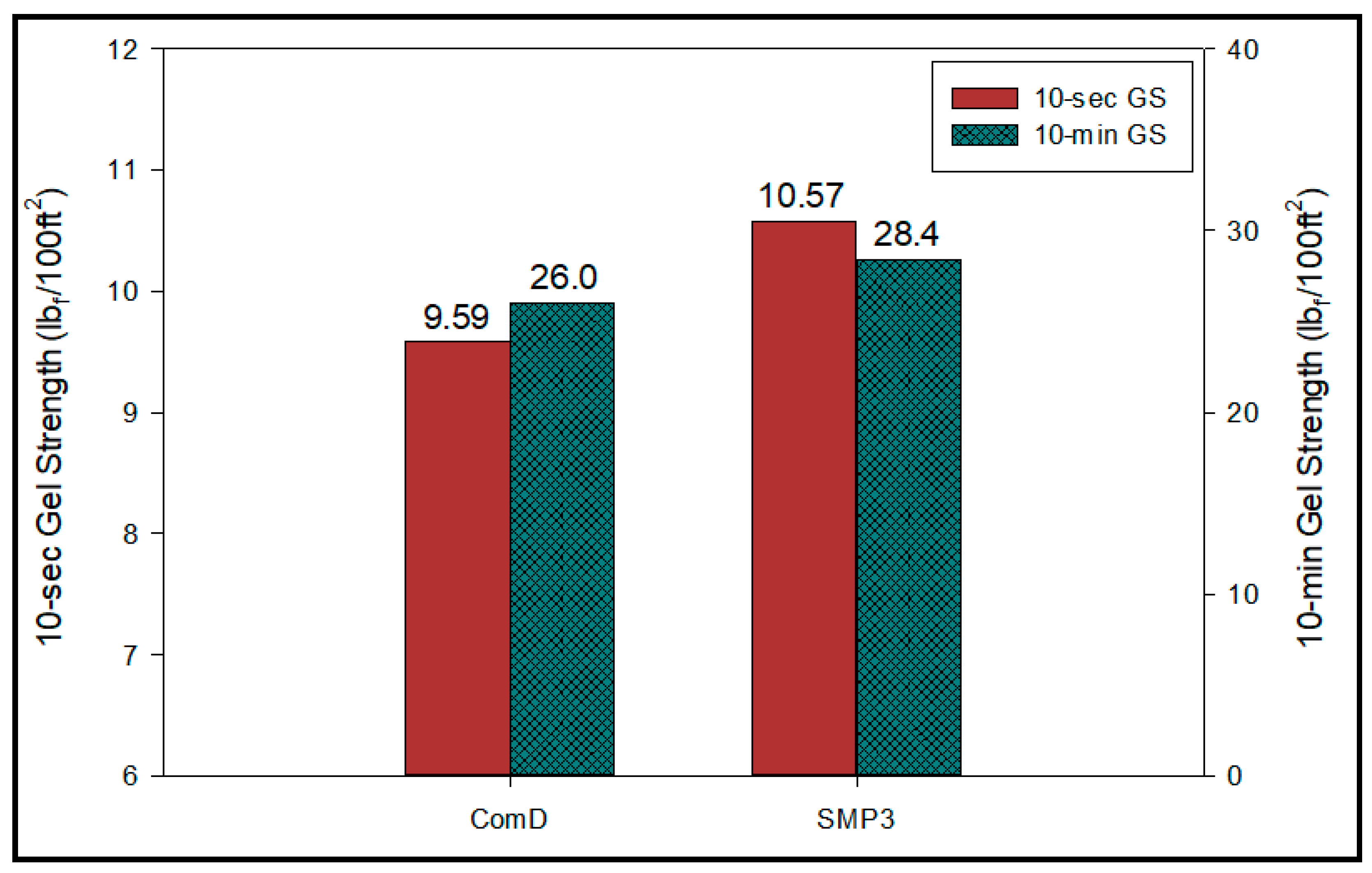

3.2. Effect on Rheological Parameters

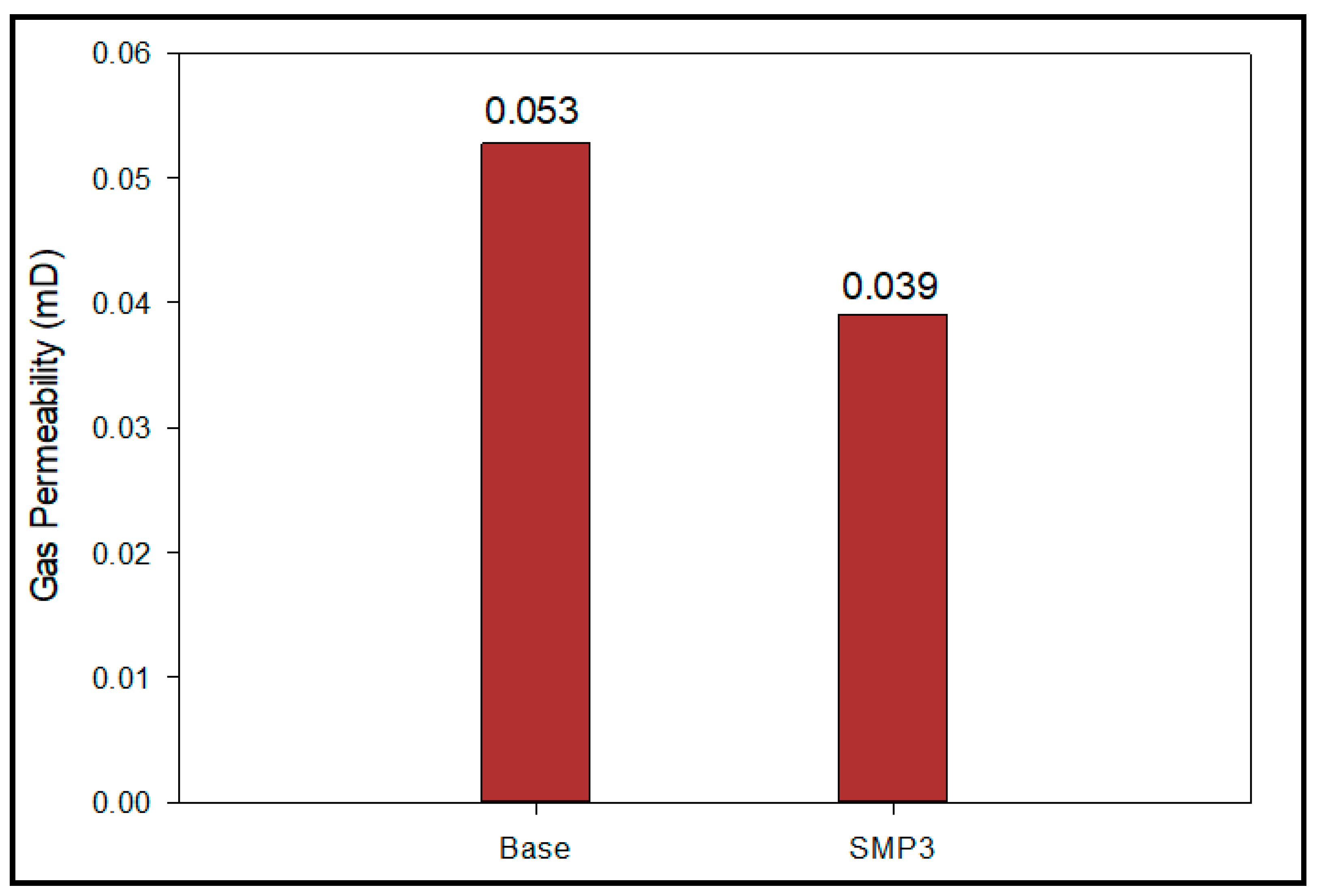

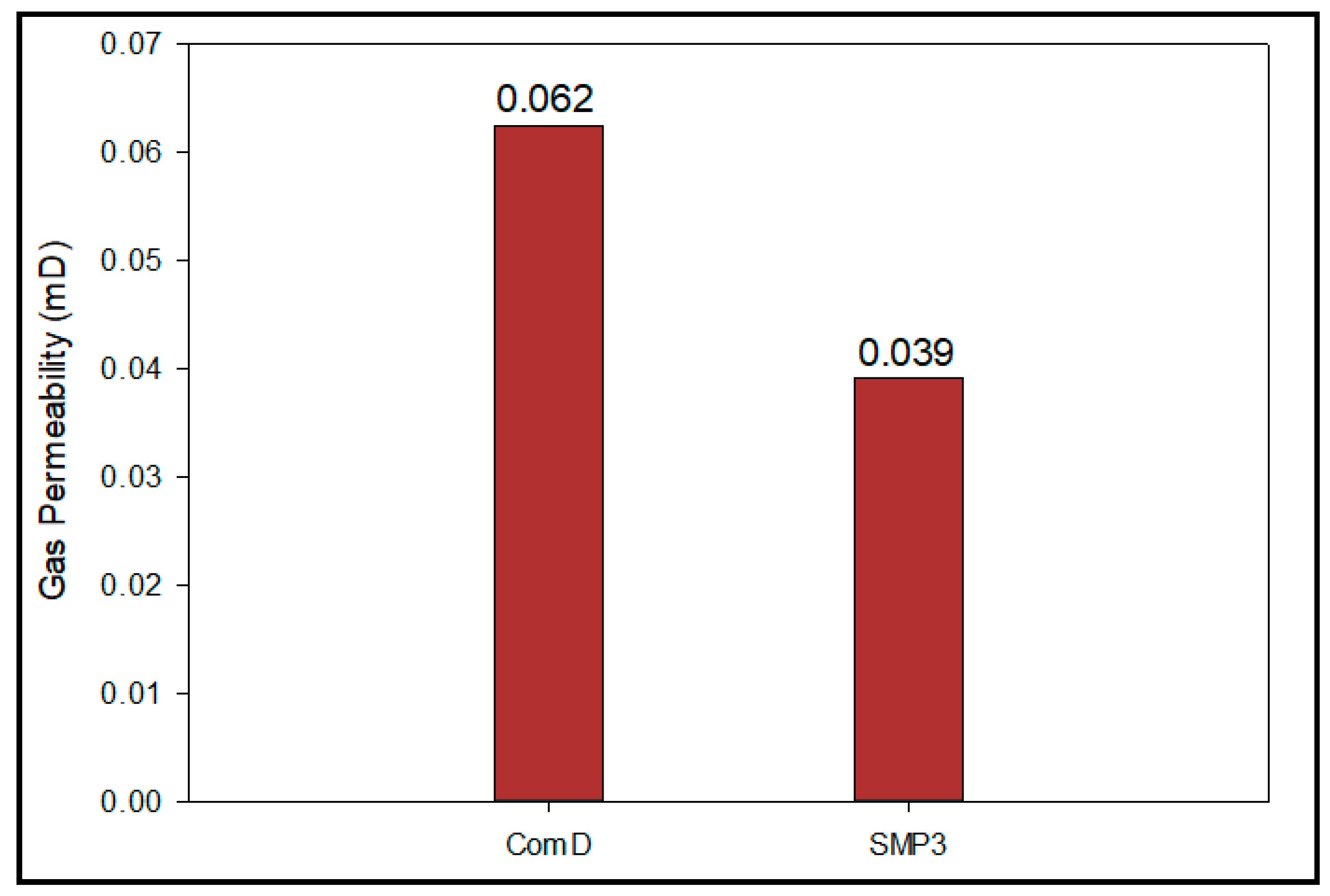

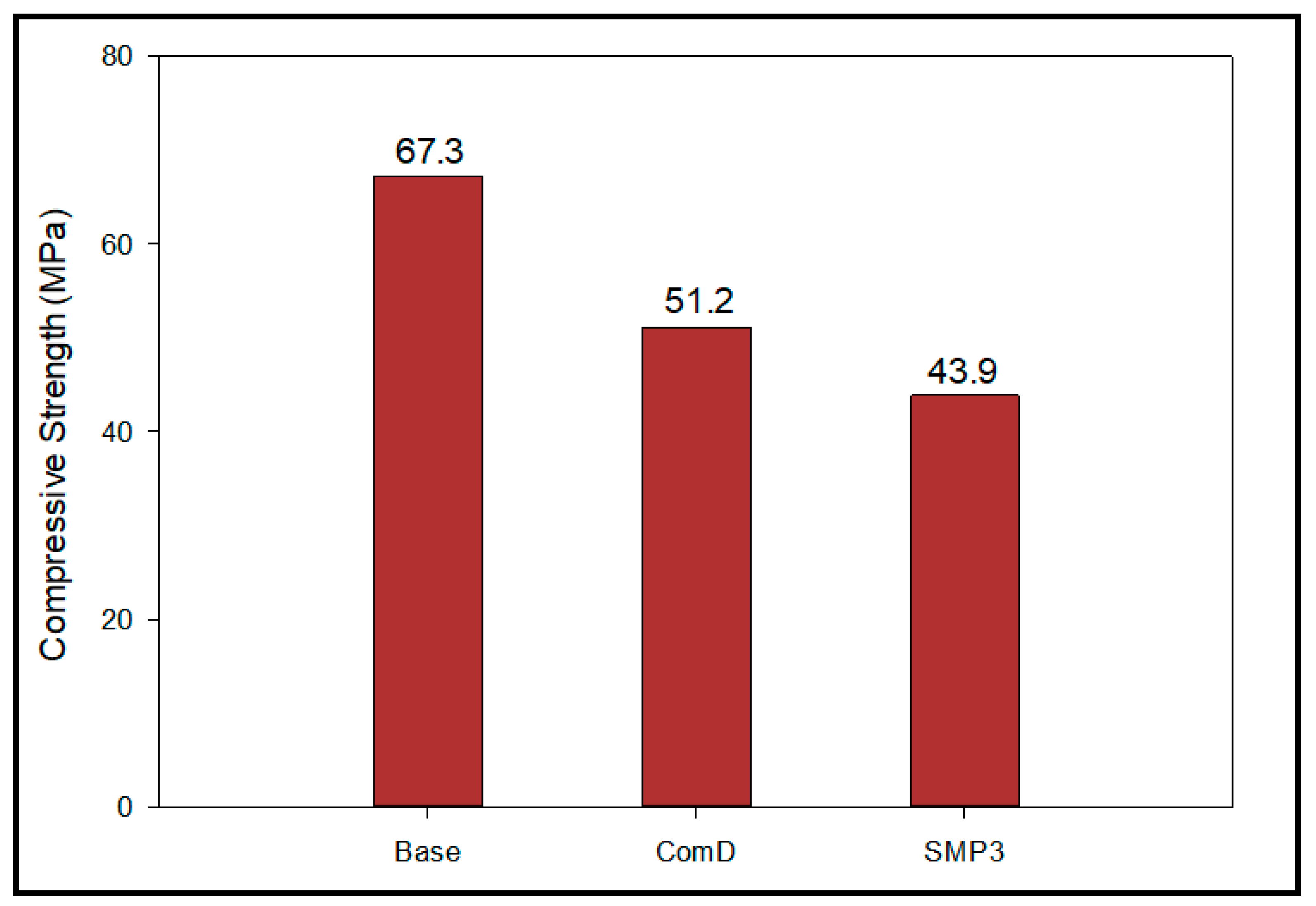

3.3. Effect on the Permeability

3.4. Comparison of the Synthetic Modified Phyllosilicate (SMP) with a Commercial Dispersant

4. Additional Cost to Prepare One Barrel of the New Cement

5. Conclusions

- 0.3% BWOC of SMP was found to prevent slurry segregation with density variation at the top and bottom of the cement column of 0.46% compared with a density variation of 4.78% for the cement incorporating the commercial dispersant.

- The CT scan imaging confirmed the homogeneous density distribution along the cement column for the samples incorporating 0.3% BWOC of SMP.

- The plastic viscosity, 10-sec, and 10-min gel strengths of the sample with the commercial dispersant and the sample with 0.3% BWOC of SMP are almost same.

- Addition of 0.3% BWOC of SMP increased the yield point of the cement slurry to 60.6 lbf/100 ft2 compared with 20.5 lbf/100 ft2 for the slurry with 0.25% BWOC of the commercial dispersant.

- Incorporating 0.3% BWOC of SMP decreased the permeability by 37.1% compared with the sample containing the commercial dispersant.

- Addition of both SMP and commercial dispersant decreased the cement compressive strength compared with the cement without dispersant. The sample with 0.3% BWOC of SMP has compressive strength of 43.9 MPa, which is still greater than the minimum acceptable compressive strength for an oil well cement matrix.

Funding

Conflicts of Interest

Abbreviations

| HPHT | High-pressure high-temperature |

| SMP | Synthetic modified phyllosilicate |

| BWOC | By weight of cement |

| CT | Computer tomography |

| OWC | Oil well cement |

| CS | Corn starch |

| CMS | Carboxymethyl starch |

| HPS | Hydroxypropyl starch |

| API | American petroleum institute |

| ComD | Commercial dispersant |

| DV | Density variation, % |

| PV | Plastic viscosity, cP |

| YP | Yield point, lb/ 100 ft2 |

| GS | Gell strength, lb/ 100 ft2 |

| ppg | pound per gallon |

References

- Pace, R.S.; McElfresh, P.M.; Cobb, J.A.; Smith, C.L.; Olsberg, M.A. Improved Bulk Blending Techniques for Accurate and Uniform Cement Blends. In Proceedings of the Paper SPE-13041-MS Presented at the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 16–19 September 1984. [Google Scholar]

- Cobb, J.A.; Pace, R.S. Elements Affecting Thickening Time of a Cement Blend. Paper SPE-14195-MS Presented at the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 22–26 September 1985. [Google Scholar] [CrossRef]

- Gerk, R.R.; Simon, J.M.; Logan, J.L.; Sabins, F.L. A-Study of Bulk Cement Handling and Testing Procedures. Soc. Pet. Eng. 1990. [Google Scholar] [CrossRef]

- Adams, N. Drilling Engineering: A Complete well Planning Approach; PennWell Publishing Company: Tulsa, OK, USA, 1985. [Google Scholar]

- Bourgoyne, A.T., Jr.; Chenevert, M.E.; Millheim Keith, K.; Young, F.S., Jr. Applied Drilling Engineering; Society of Petroleum Engineers, Inc.: Houston, Texas, USA, 1986. [Google Scholar]

- Rabia, H. Well Engineering and Construction; Entrac Consulting. Entrac Petroleum: London, UK, 2001. [Google Scholar]

- Minaev, K.; Gorbenko, V.; Ulyanova, O. Lightweight Cement Slurries based on vermiculite. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Tomsk, Russia, 7–11 April 2014; Volume 21. [Google Scholar]

- Hossain, M.; Al-Majed, A.A. Fundamentals of Sustainable Drilling Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Bourlon, A.J.G.; Roy-Delage, S.L.; Taoutaou, S. An Innovative Methodology to Assess Cement Blend Flowability and Proneness to Segregation—A Step Forward to Higher Quality. Soc. Pet. Eng. 2017. [Google Scholar] [CrossRef]

- Lavrov, A.; Torsæter, M. Physics and Mechanics of Primary Well Cementing, Chapter two. In Petroleum Geoscience & Engineering; SpringerBriefs: Berlin, Germany, 2016. [Google Scholar]

- Xu, H.; Ma, T.; Peng, N.; Yang, B. Influences of Fracturing Fluid Injection on Mechanical Integrity of Cement Sheath under Four Failure Modes. Energies 2018, 11, 3534. [Google Scholar] [CrossRef]

- Won, J.; Choi, H.; Lee, H.; Choi, H. Numerical Investigation on the Effect of Cementing Properties on the Thermal and Mechanical Stability of Geothermal Wells. Energies 2016, 9, 1016. [Google Scholar] [CrossRef]

- Xi, Y.; Li, J.; Liu, G.; Li, J.; Jiang, J. Mechanisms and Influence of Casing Shear Deformation near the Casing Shoe, Based on MFC Surveys during Multistage Fracturing in Shale Gas Wells in Canada. Energies 2019, 12, 372. [Google Scholar] [CrossRef]

- Tan, H.; Zheng, X.; Ma, L.; Huang, H.; Xia, B. A Study on the Effects of Starches on the Properties of Alkali-Activated Cement and the Potential of Starch as a Self-Degradable Additive. Energies 2017, 10, 1048. [Google Scholar] [CrossRef]

- Bourlon, A.J.G.; Roy-Delage, S.L.; Taoutaou, S. A Step Forward to Assess Cement Blend Flowability and Proneness to Segregation: Cases Histories. Soc. Pet. Eng. 2017. [Google Scholar] [CrossRef]

- Williams, J.C. Mixing and Segregation in Powders. In Principles of Powder Technology; Rhodes, M.J., Ed.; Wiley: Hoboken, NJ, USA, 1990; pp. 71–90. [Google Scholar]

- Williams, J.C. The Storage and Flow of Powders. In Principles of Powder Technology; Rhodes, M.J., Ed.; Wiley: Hoboken, NJ, USA, 1990; pp. 91–118. [Google Scholar]

- Nelson, E.B.; Guillot, D. Well Cementing; Schlumberger: Houston, TX, USA, 2006. [Google Scholar]

- Bassett, J.; Watters, J.; Combs, N.K.; Nikolaou, M. Lowering Drilling Cost, Improving Operational Safety, and Reducing Environmental Impact through Zonal Isolation Improvements for Horizontal Wells Drilled in the Marcellus Shale. Paper URTEC-1582346-MS Presented at the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013. [Google Scholar] [CrossRef]

- Negrete, H.N.; Letoffe, J.-M.; Putaux, J.-L.; David, L.; Bourgeat-Lami, E. Aqueous dispersions of silane-functionalized Laponite clay platelets. A first step toward the elaboration of water-based polymer/clay nanocomposites. Langmuir 2004, 20, 1564–1571. [Google Scholar] [CrossRef]

- Sun, K.; Kumar, R.; Falvey, D.E.; Raghavan, S.R. Photogelling colloidal dispersions based on light-activated assembly of nanoparticles. J. Am. Chem. Soc. 2009, 131, 7135–7141. [Google Scholar] [CrossRef] [PubMed]

- Ghadiri, M.; Hau, H.; Chrzanowski, W.; Agus, H.; Rohanizadeh, R. Laponite clay as a carrier for in situ delivery of tetracycline. RSC Adv. 2013, 3, 20193–20201. [Google Scholar] [CrossRef]

- Bienia, M.; Danglade, C.; Lecomte, A.; Brevier, J.; Pagnoux, C. Cylindrical Couette flow of Laponite dispersions. Appl. Clay Sci. 2018, 162, 83–89. [Google Scholar] [CrossRef]

- Thompson, D.W.; Butterworth, J.T. The nature of laponite and its aqueous dispersions. J. Colloid Interface Sci. 1990, 151, 236–243. [Google Scholar] [CrossRef]

- Mohanty, R.P.; Joshi, Y.M. Chemical stability phase diagram of aqueous Laponite dispersions. Appl. Clay Sci. 2016, 119, 243–248. [Google Scholar] [CrossRef]

- Loginov, M.; Lebovka, N.; Vorobiev, E. Laponite assisted dispersion of carbon nanotubes in water. J. Colloid Interface Sci. 2012, 365, 127–136. [Google Scholar] [CrossRef] [PubMed]

- Manilo, M.; Lebovka, N.; Barany, S. Characterization of the electric double layers of multi-walled carbon nanotubes, laponite and nanotube+laponite hybrids in aqueous suspensions. Colloids Surf. A Physicochem. Eng. Asp. 2014, 462, 211–216. [Google Scholar] [CrossRef]

- Manilo, M.V.; Lebovka, N.; Barany, S. Combined effect of cetyltrimethylammonium bromide and laponite platelets on colloidal stability of carbon nanotubes in aqueous suspensions. J. Mol. Liq. 2017, 235, 104–110. [Google Scholar] [CrossRef]

- Manilo, M.V.; Lebovka, N.I.; Barany, S. Stability of multi-walled carbon nanotube+laponite hybrid particles in aqueous suspensions. Colloids Surf. A Physicochem. Eng. Asp. 2015, 481, 199–206. [Google Scholar] [CrossRef]

- Silva, J.M.; Barud, H.S.; Meneguin, A.B.; Constantino, V.R.L.; Ribeiro, S.J.L. Inorganic-organic bio-nanocomposite films based on Laponite and Cellulose Nanofibers (CNF). Appl. Clay Sci. 2019, 168, 428–435. [Google Scholar] [CrossRef]

- American Petroleum Institute (API). Worldwide Cementing Practices; API: Dallas, TX, USA, 1991. [Google Scholar]

| Slurries | Cement | Water | Dispersion Agent | Silica Flour | Defoamer | Expandable Agent | Fluid Loss Controller |

|---|---|---|---|---|---|---|---|

| Base | 600 | 44 | 0 | 35 | 4.7E-07 | 1 | 0.75 |

| ComD | 600 | 44 | 0.25 * | 35 | 4.7E-07 | 1 | 0.75 |

| SMP1 | 600 | 44 | 0.1 | 35 | 4.7E-07 | 1 | 0.75 |

| SMP2 | 600 | 44 | 0.2 | 35 | 4.7E-07 | 1 | 0.75 |

| SMP3 | 600 | 44 | 0.3 | 35 | 4.7E-07 | 1 | 0.75 |

| SMP4 | 600 | 44 | 0.4 | 35 | 4.7E-07 | 1 | 0.75 |

| SMP5 | 600 | 44 | 0.5 | 35 | 4.7E-07 | 1 | 0.75 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elkatatny, S. Development of a Homogenous Cement Slurry Using Synthetic Modified Phyllosilicate while Cementing HPHT Wells. Sustainability 2019, 11, 1923. https://doi.org/10.3390/su11071923

Elkatatny S. Development of a Homogenous Cement Slurry Using Synthetic Modified Phyllosilicate while Cementing HPHT Wells. Sustainability. 2019; 11(7):1923. https://doi.org/10.3390/su11071923

Chicago/Turabian StyleElkatatny, Salaheldin. 2019. "Development of a Homogenous Cement Slurry Using Synthetic Modified Phyllosilicate while Cementing HPHT Wells" Sustainability 11, no. 7: 1923. https://doi.org/10.3390/su11071923

APA StyleElkatatny, S. (2019). Development of a Homogenous Cement Slurry Using Synthetic Modified Phyllosilicate while Cementing HPHT Wells. Sustainability, 11(7), 1923. https://doi.org/10.3390/su11071923