Investigation on the Debonding Failure Model of Anchored Polyurea Coating under a High-Velocity Water Flow and Its Application

Abstract

1. Introduction

2. Debonding Failure Model under a High-Velocity Water Flow

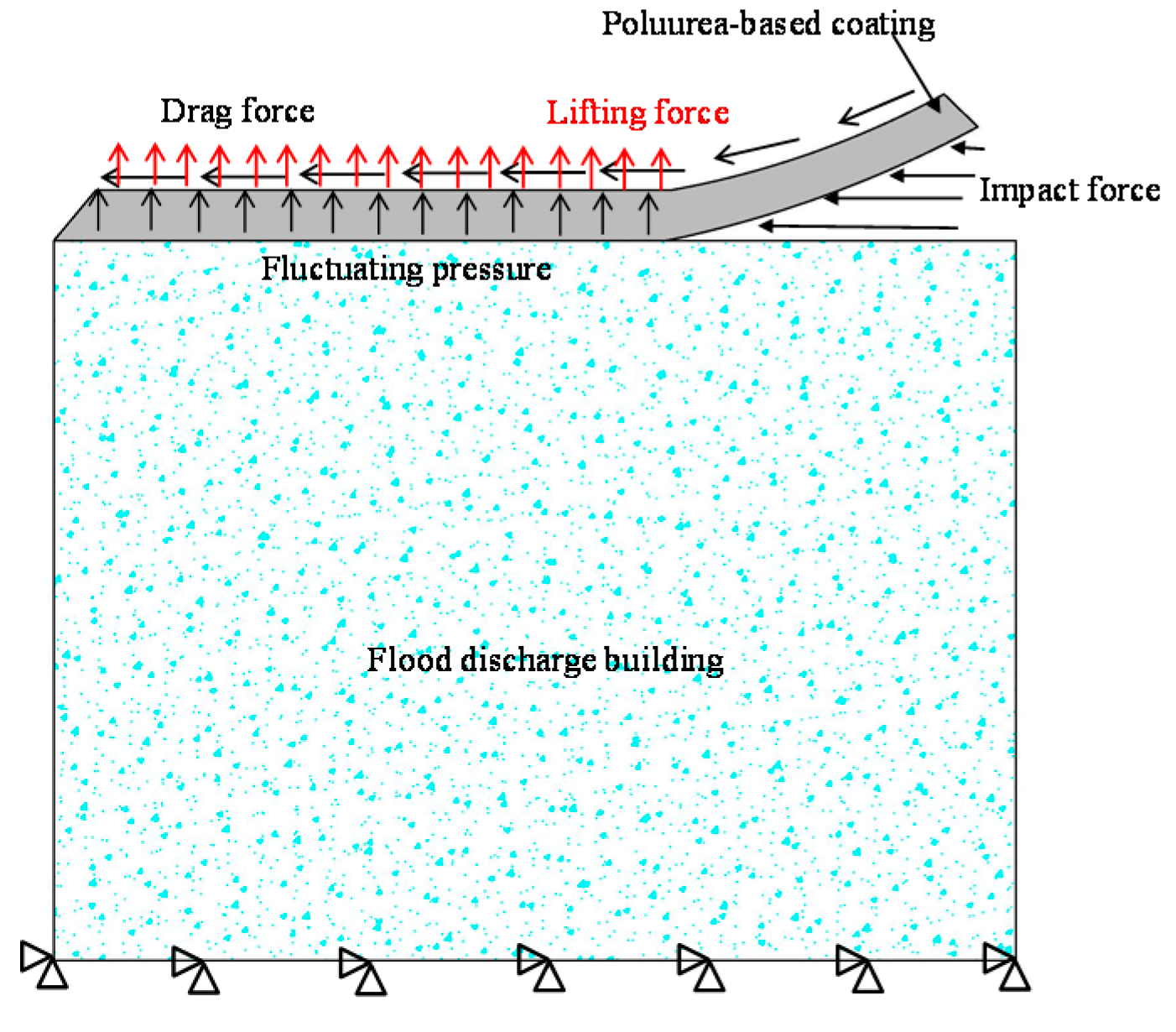

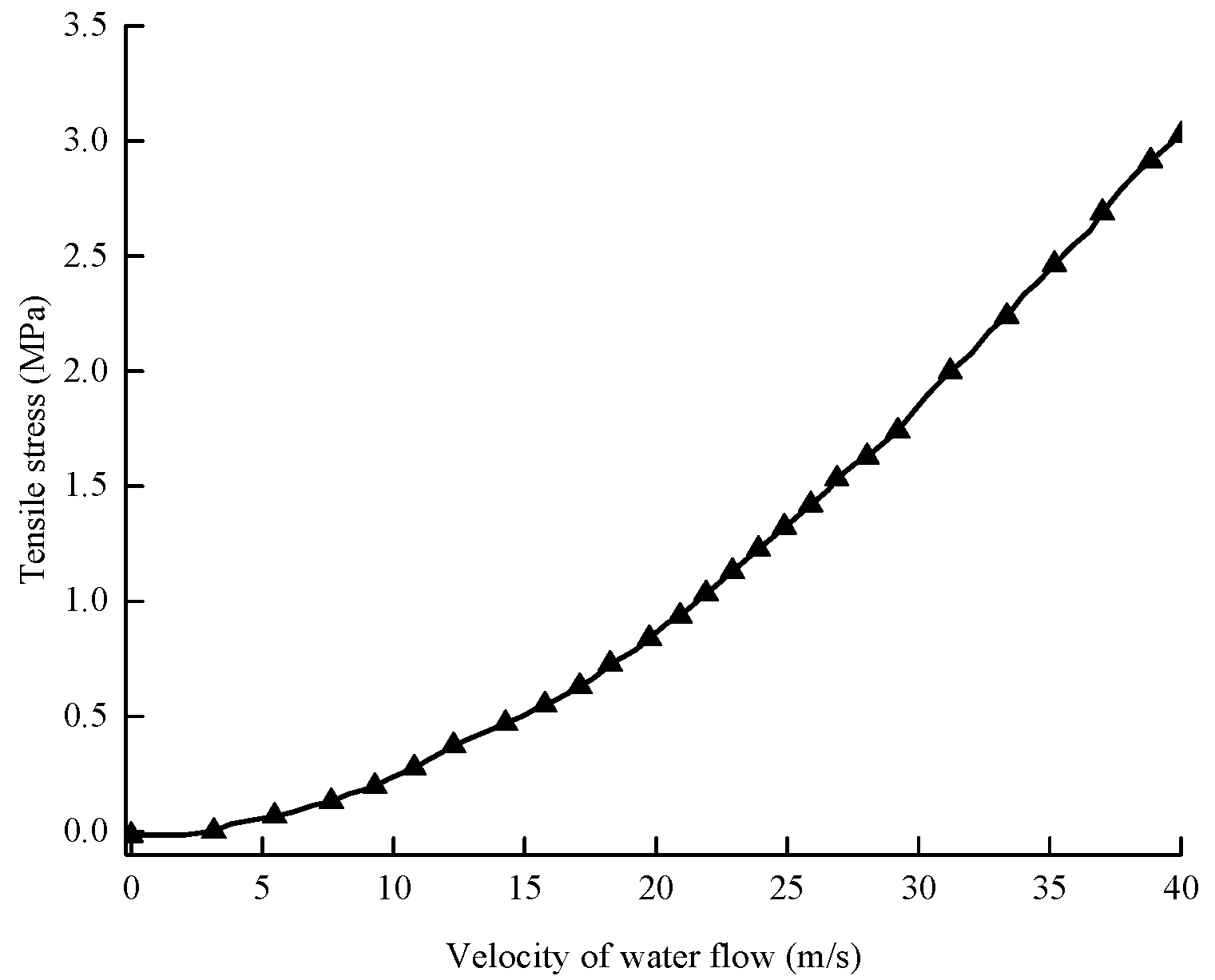

2.1. The Loading of a High-Velocity Water Flow

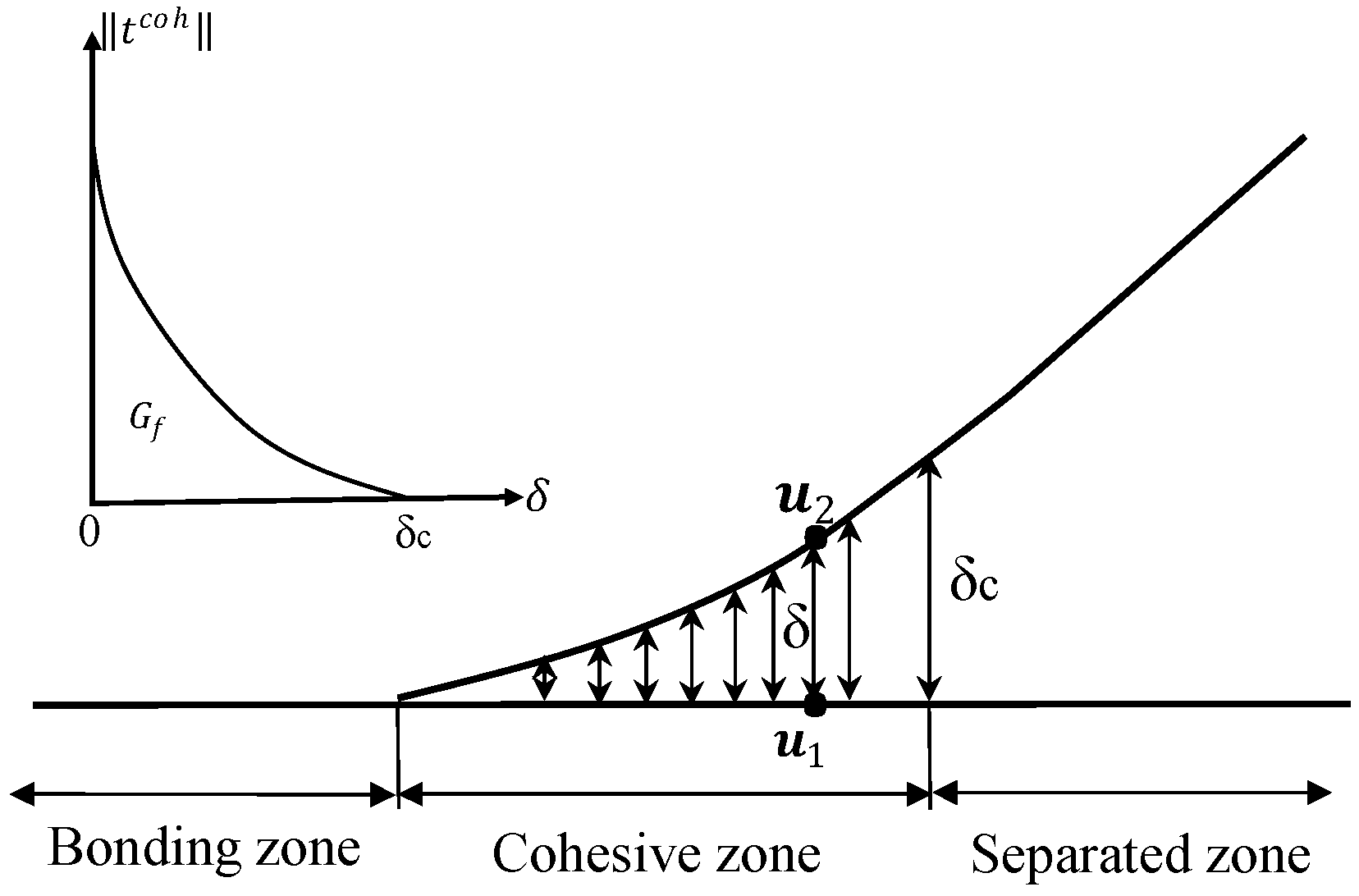

2.2. Debonding Failure Model

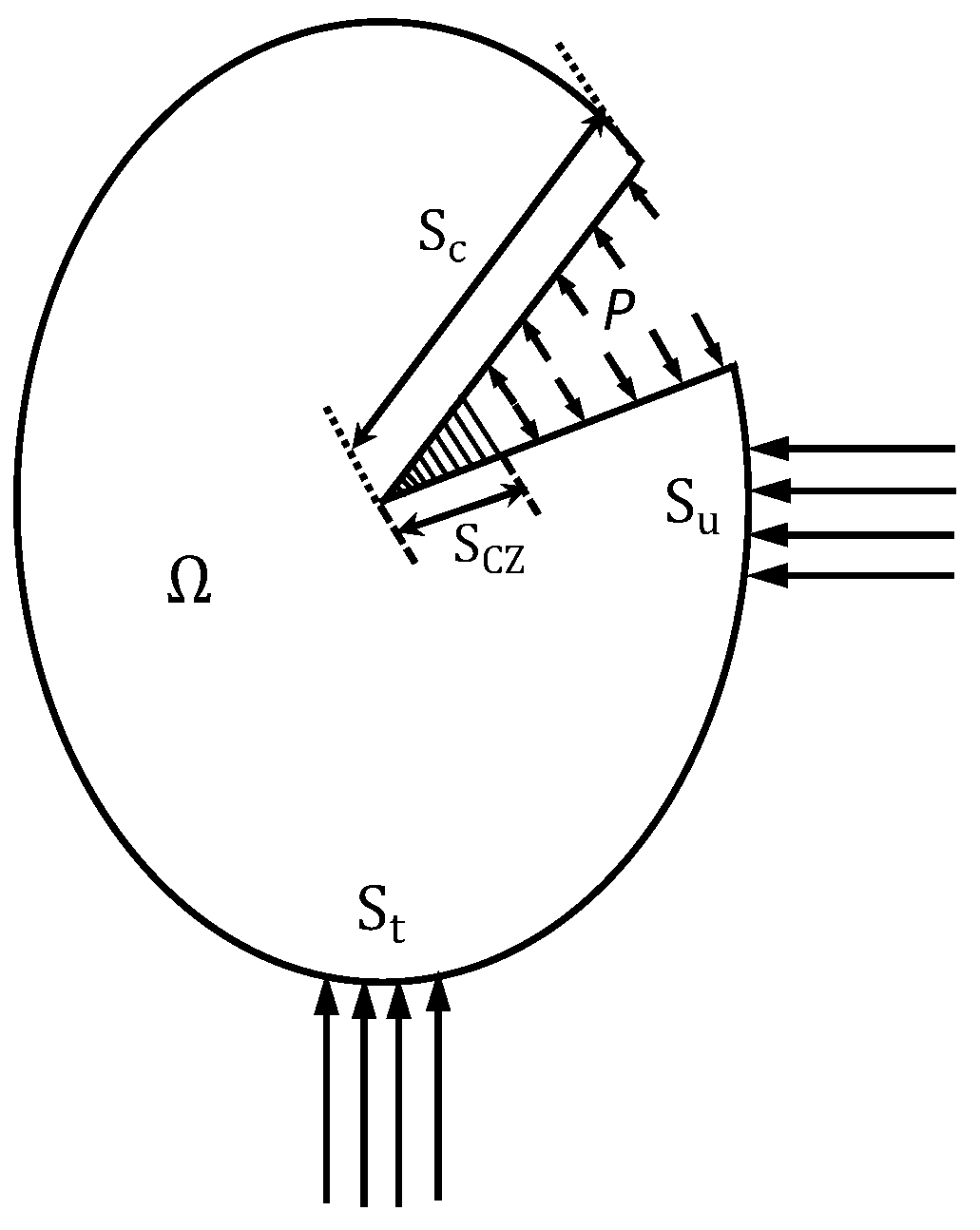

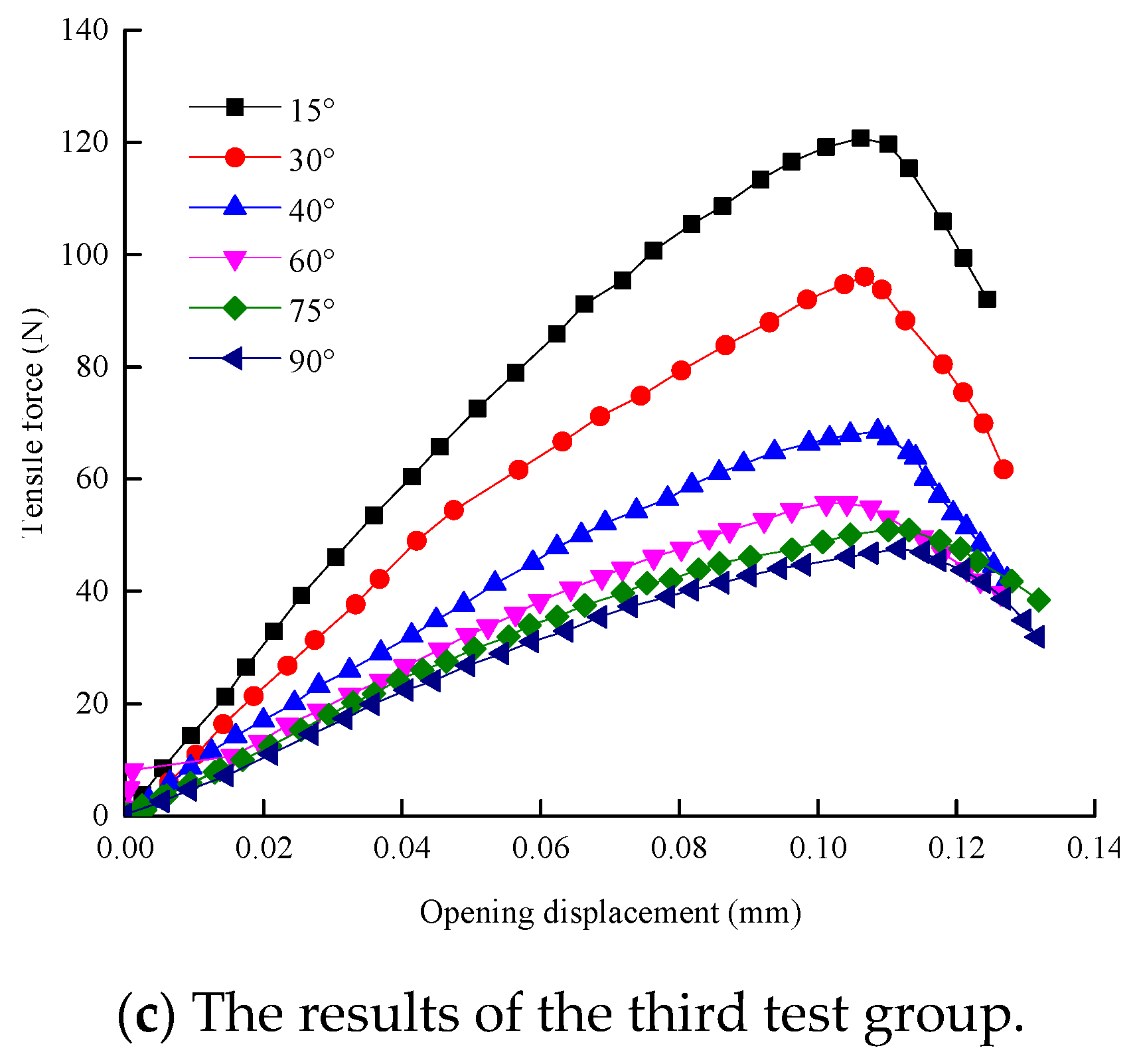

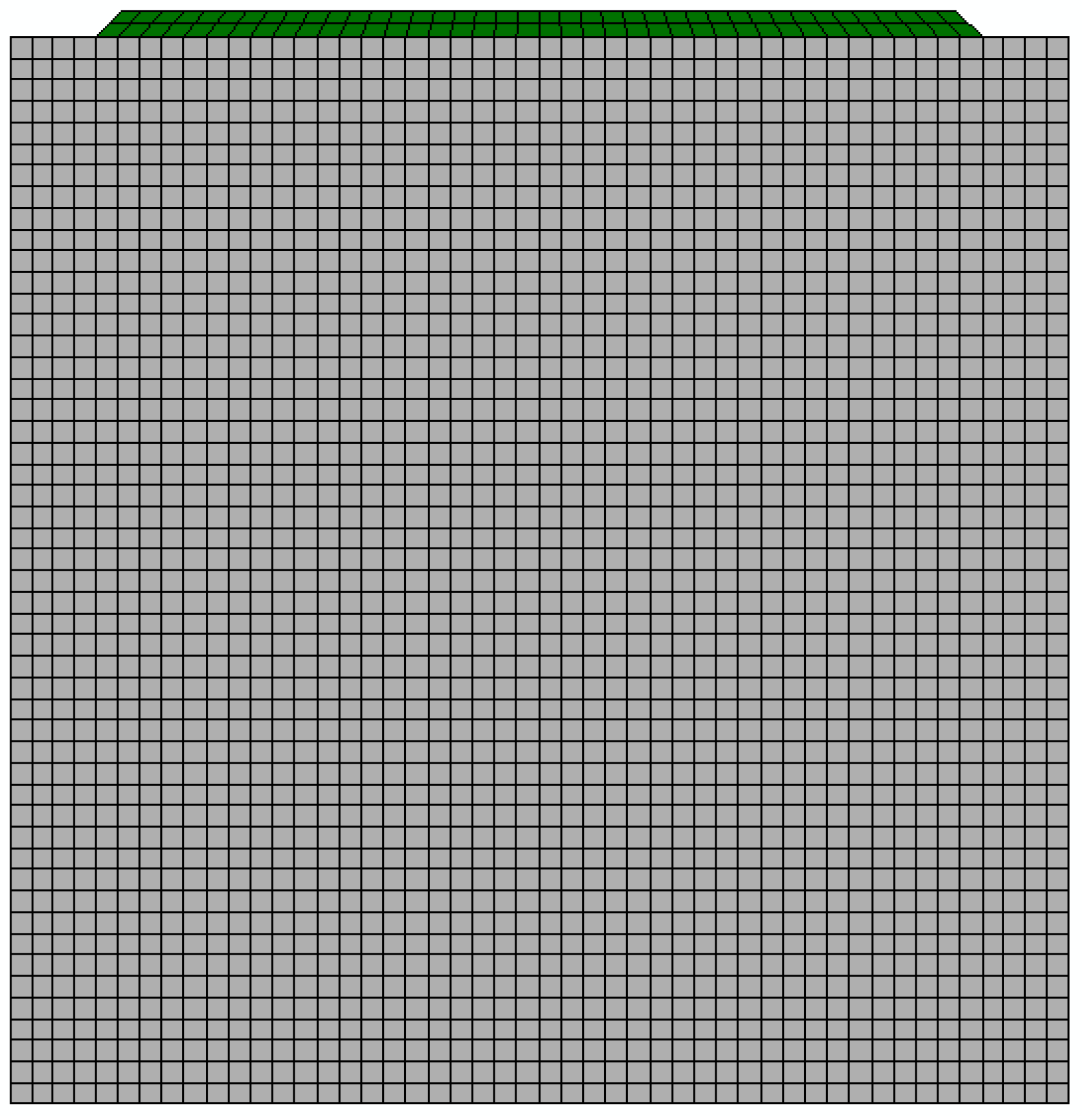

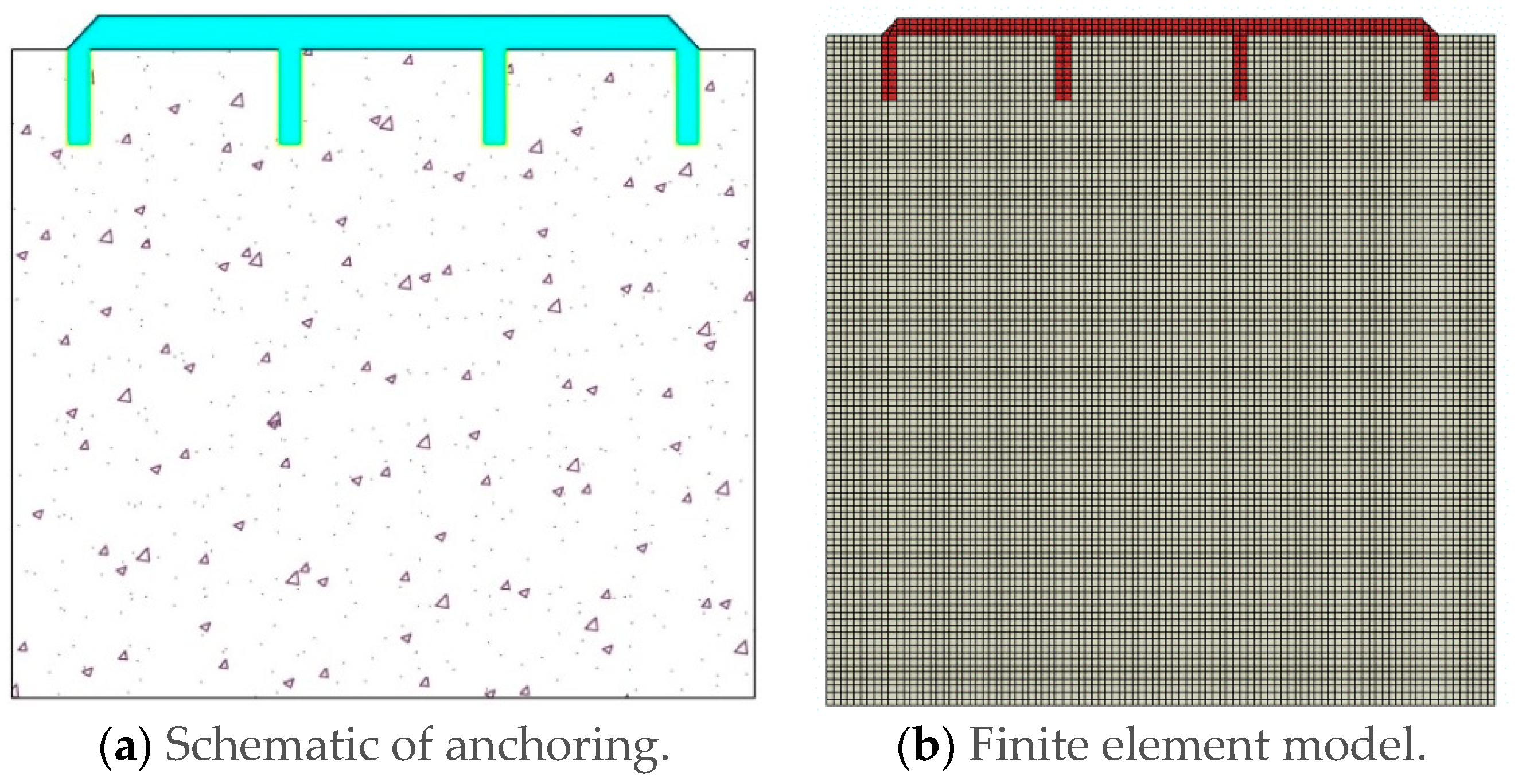

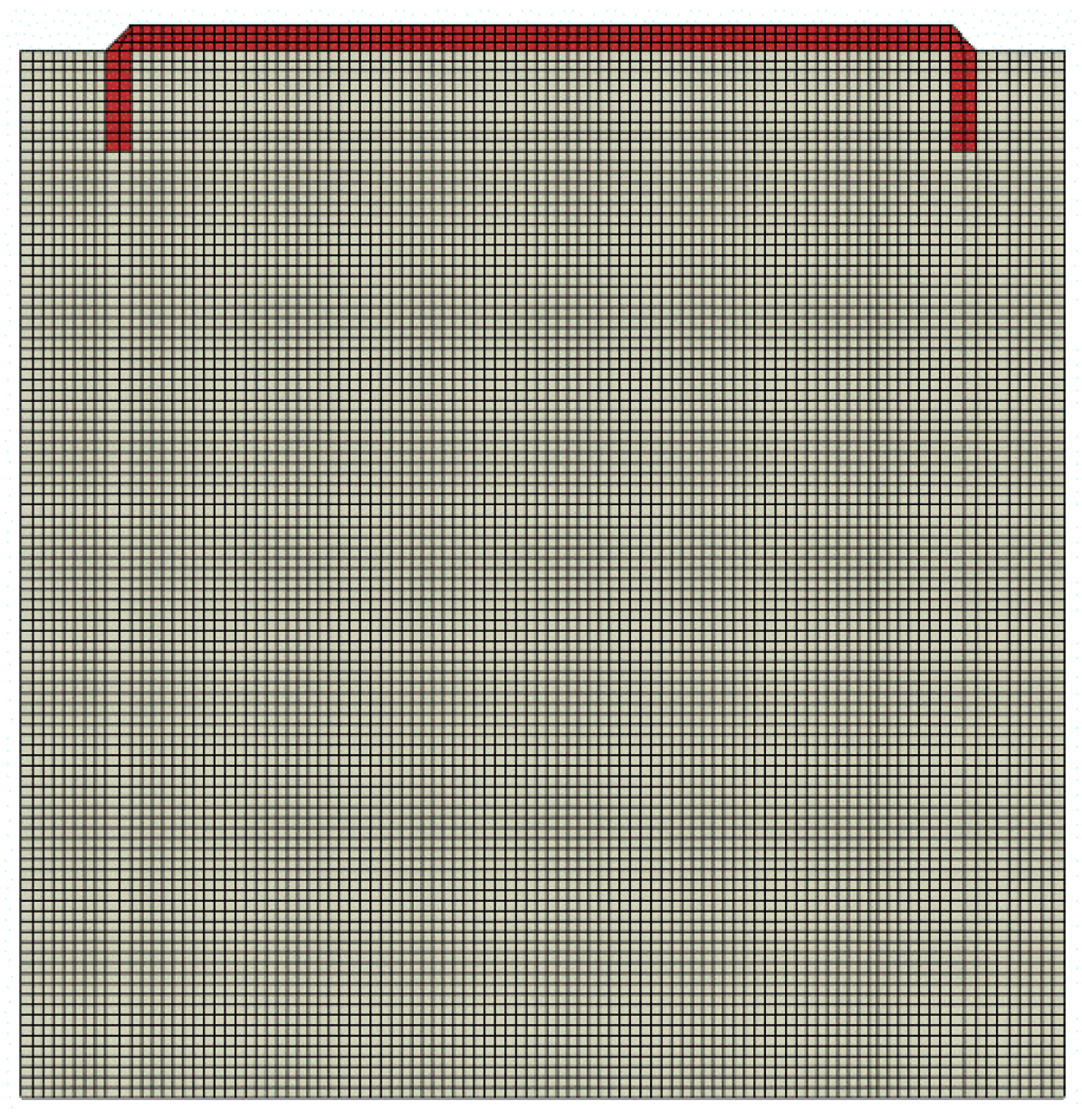

2.3. The Form of the Finite Element of the Model

h = 0, p > 0, contact surfaces are closed.

3. Model Verification

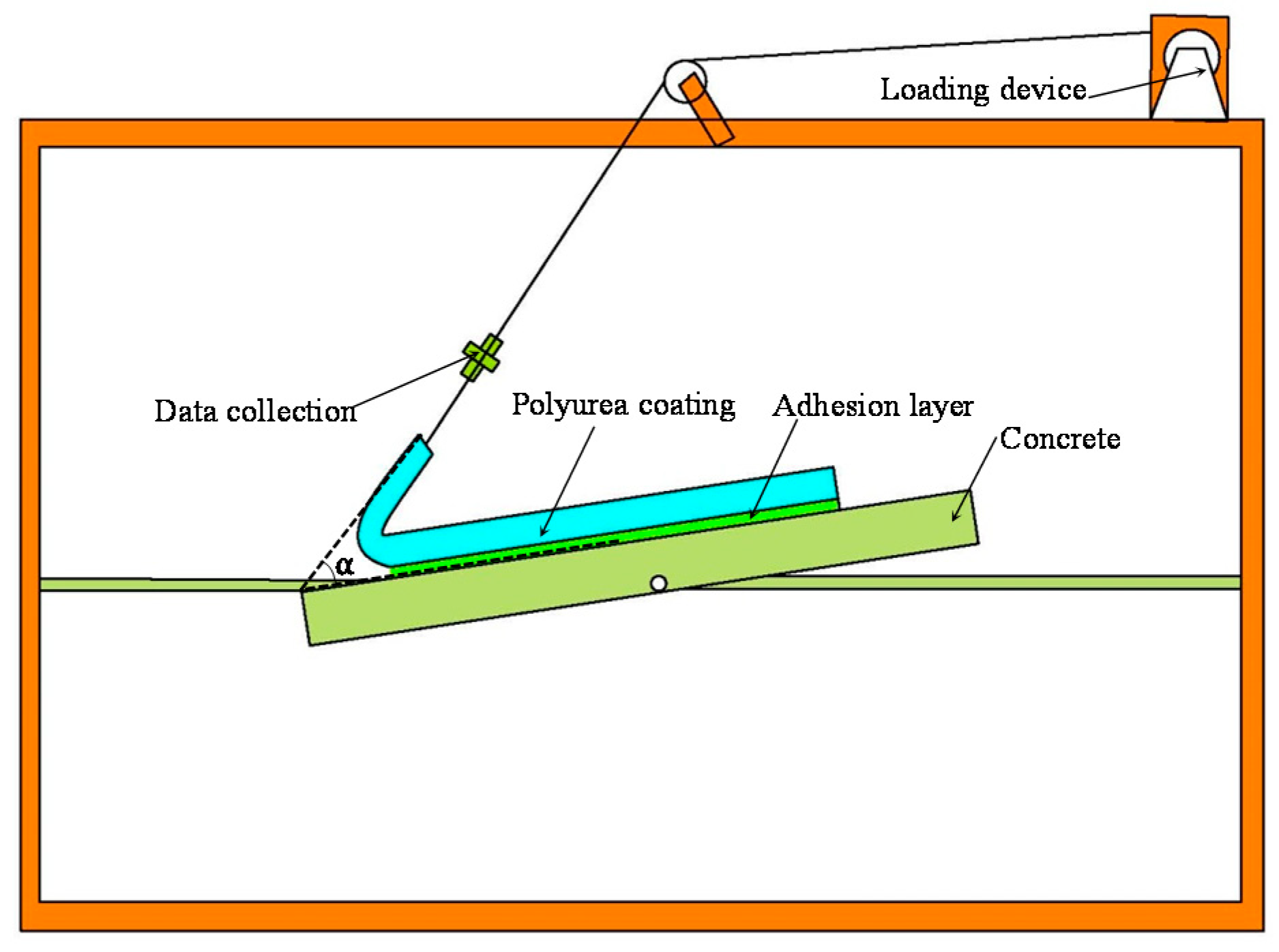

3.1. Debonding Failure Tests

3.1.1. Test Conditions

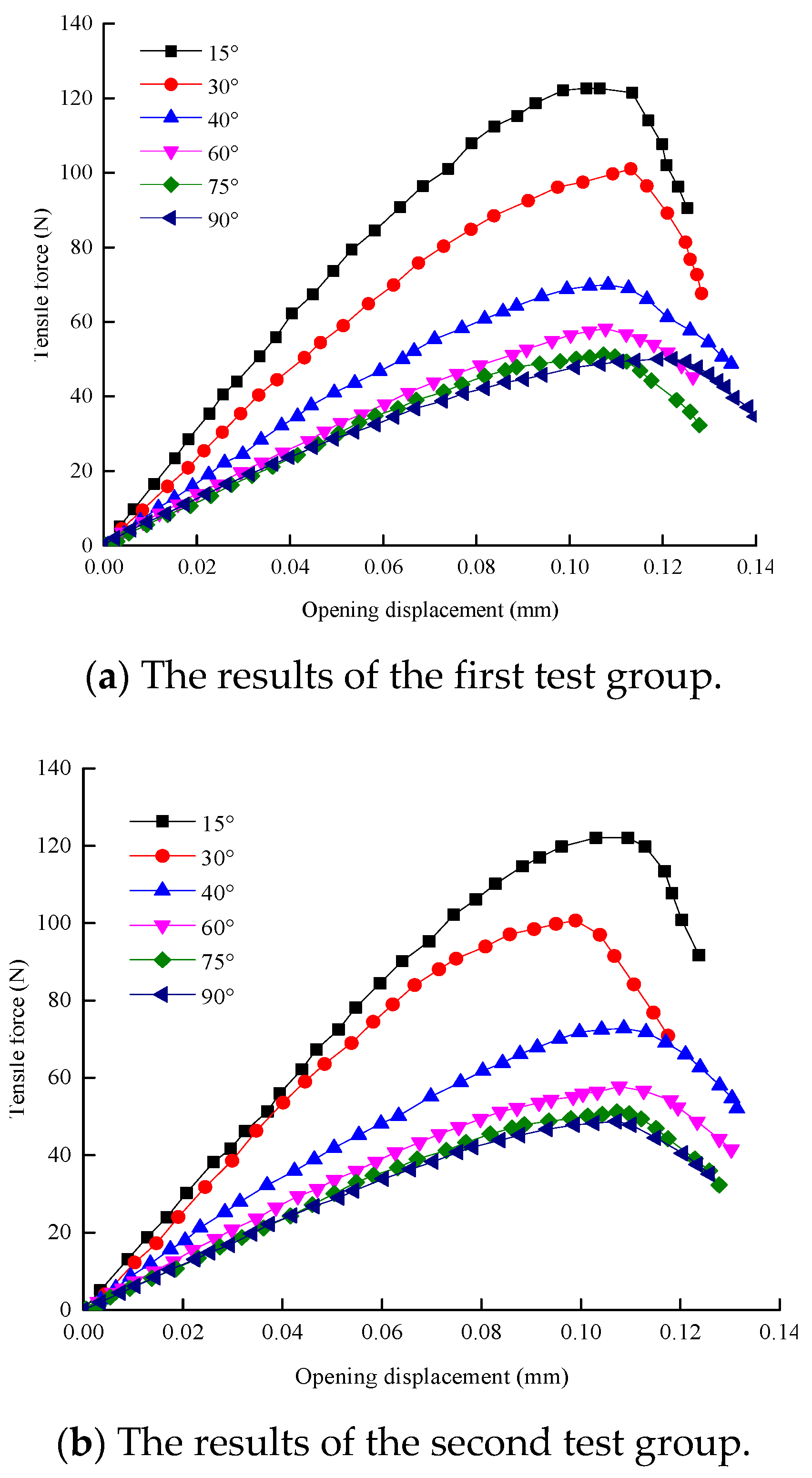

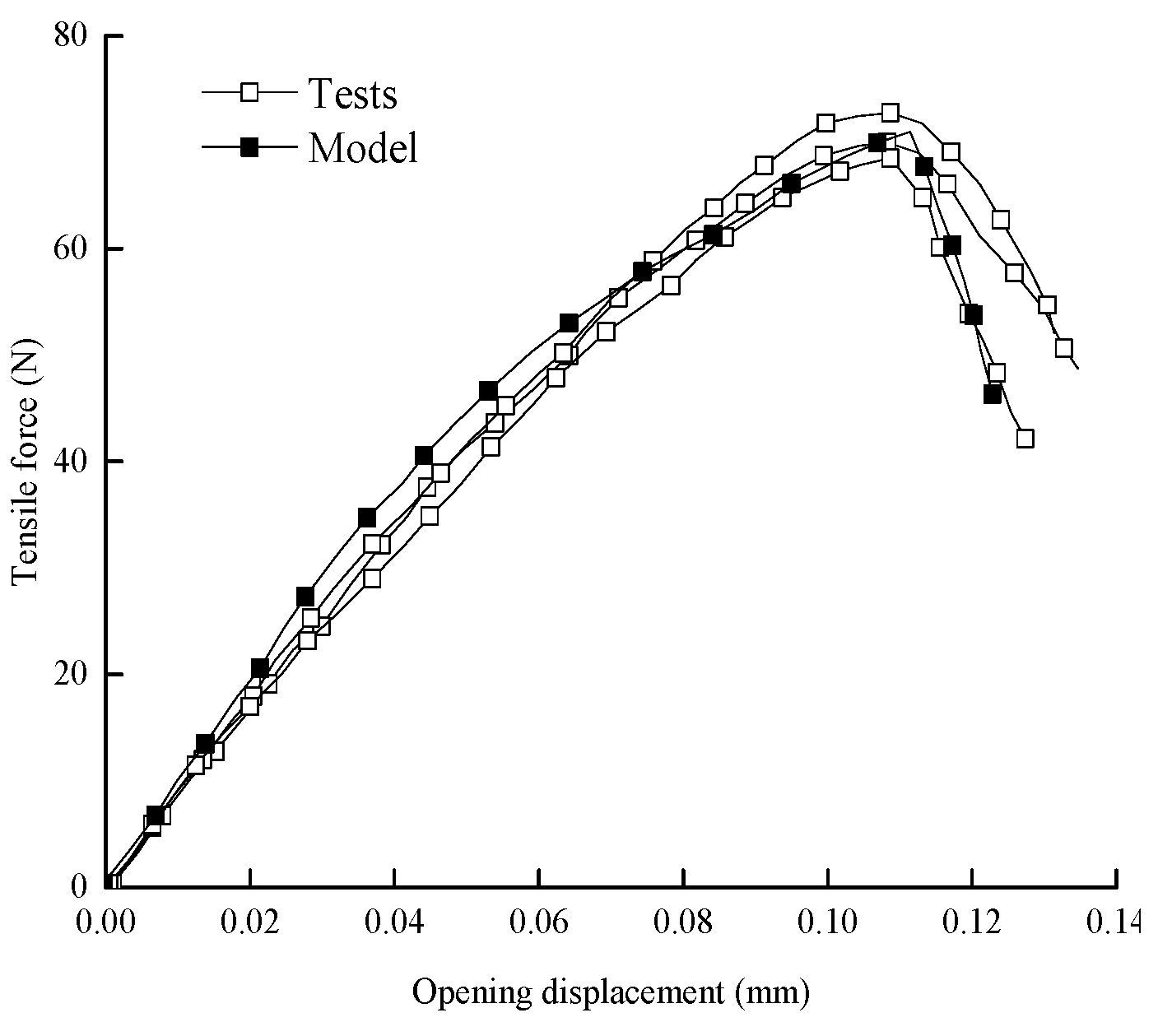

3.1.2. Test Results

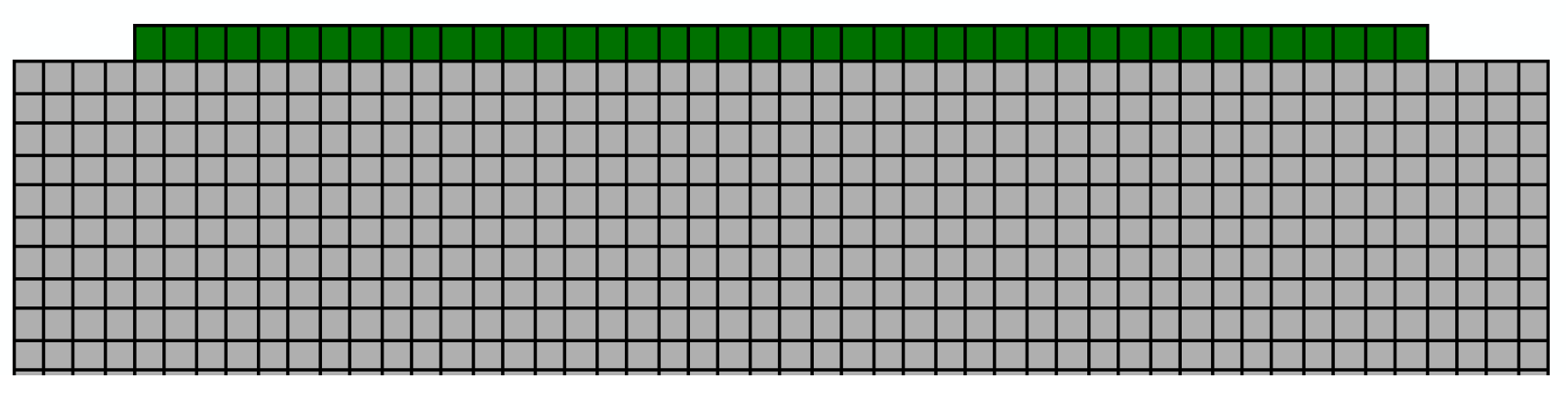

3.2. Model Verification

4. Numerical Calculation of the Anchored Polyurea-Based Coating under a High-Velocity Water Flow

4.1. Numerical Model

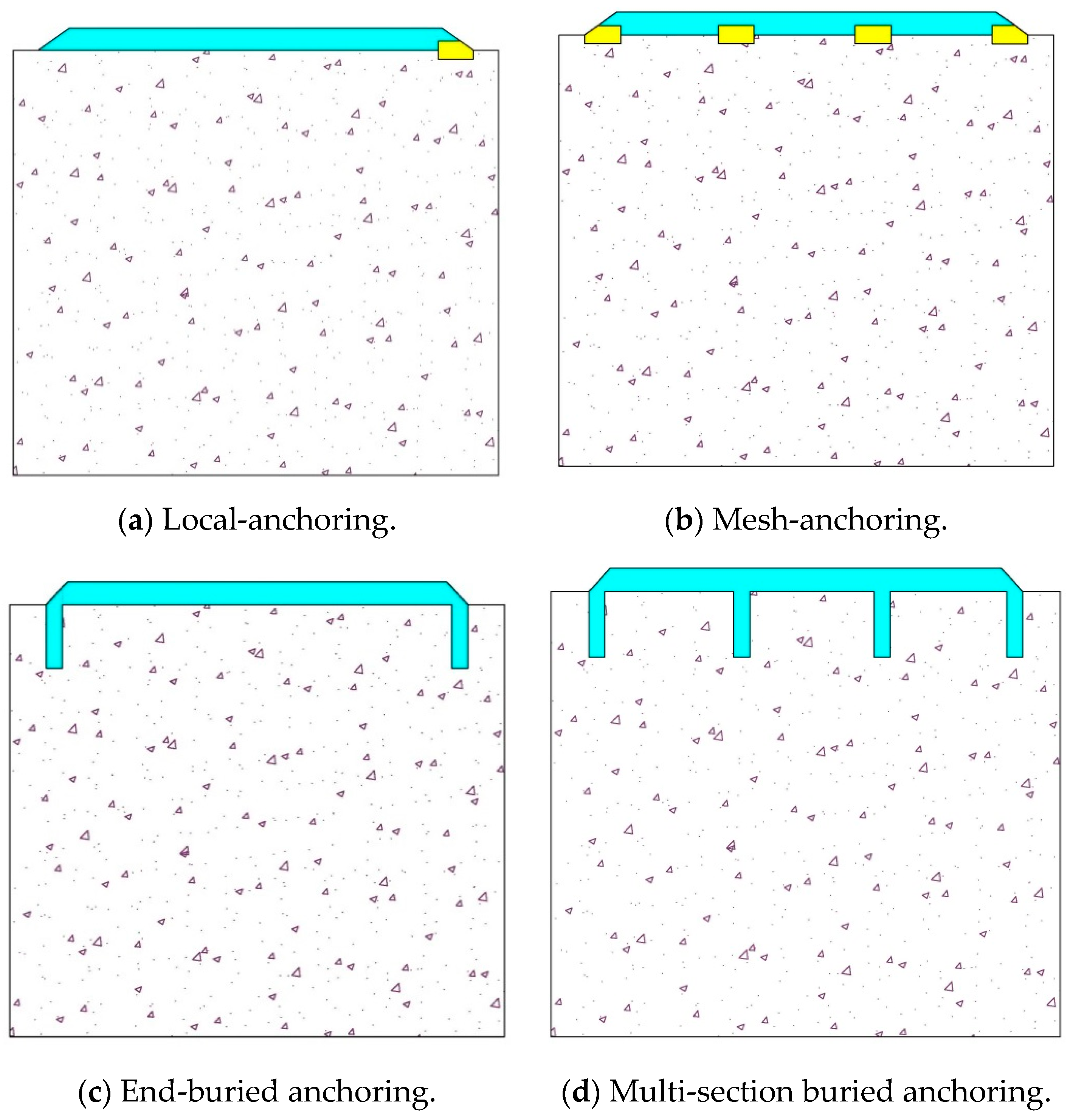

4.2. Case Studies

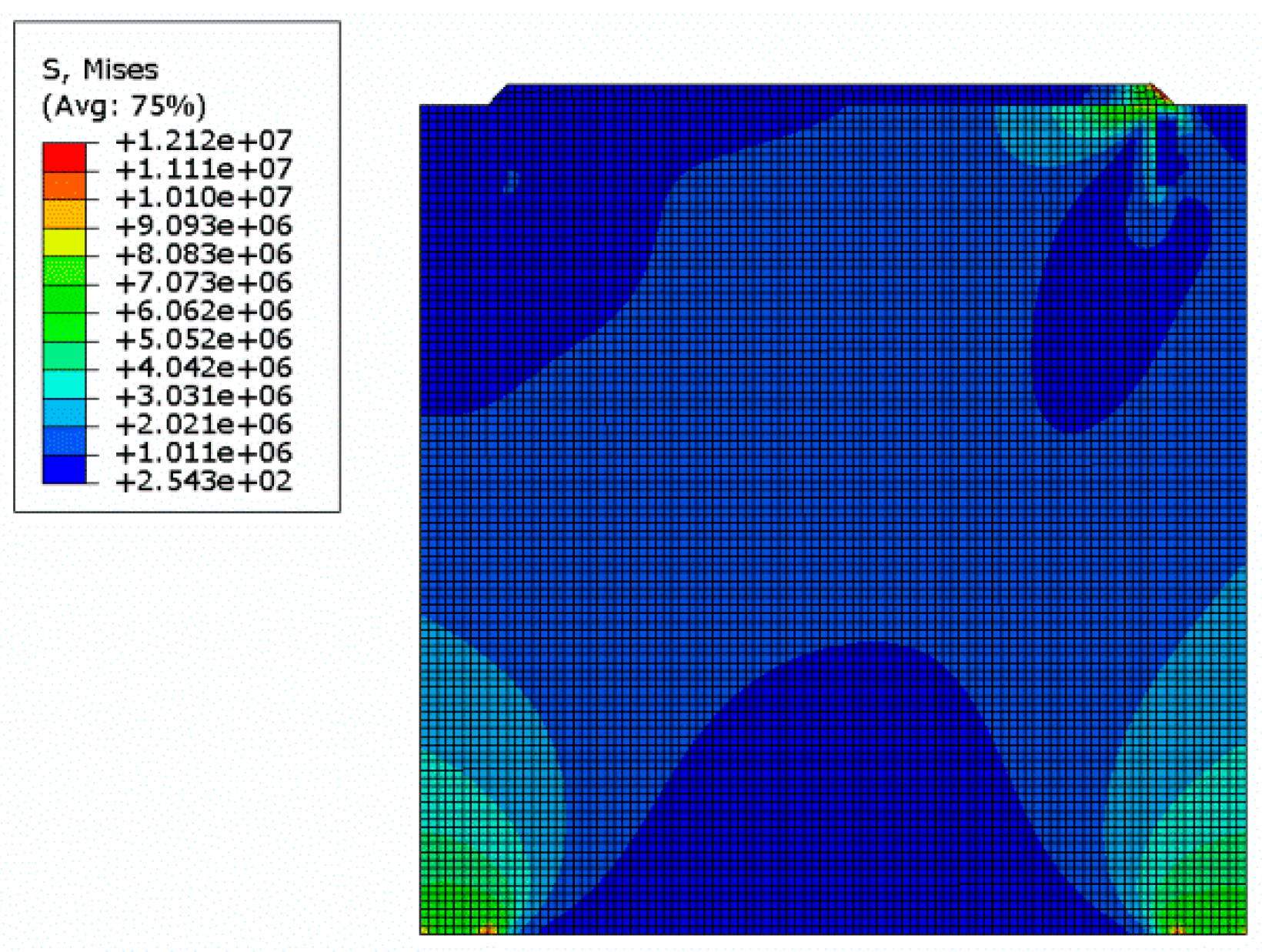

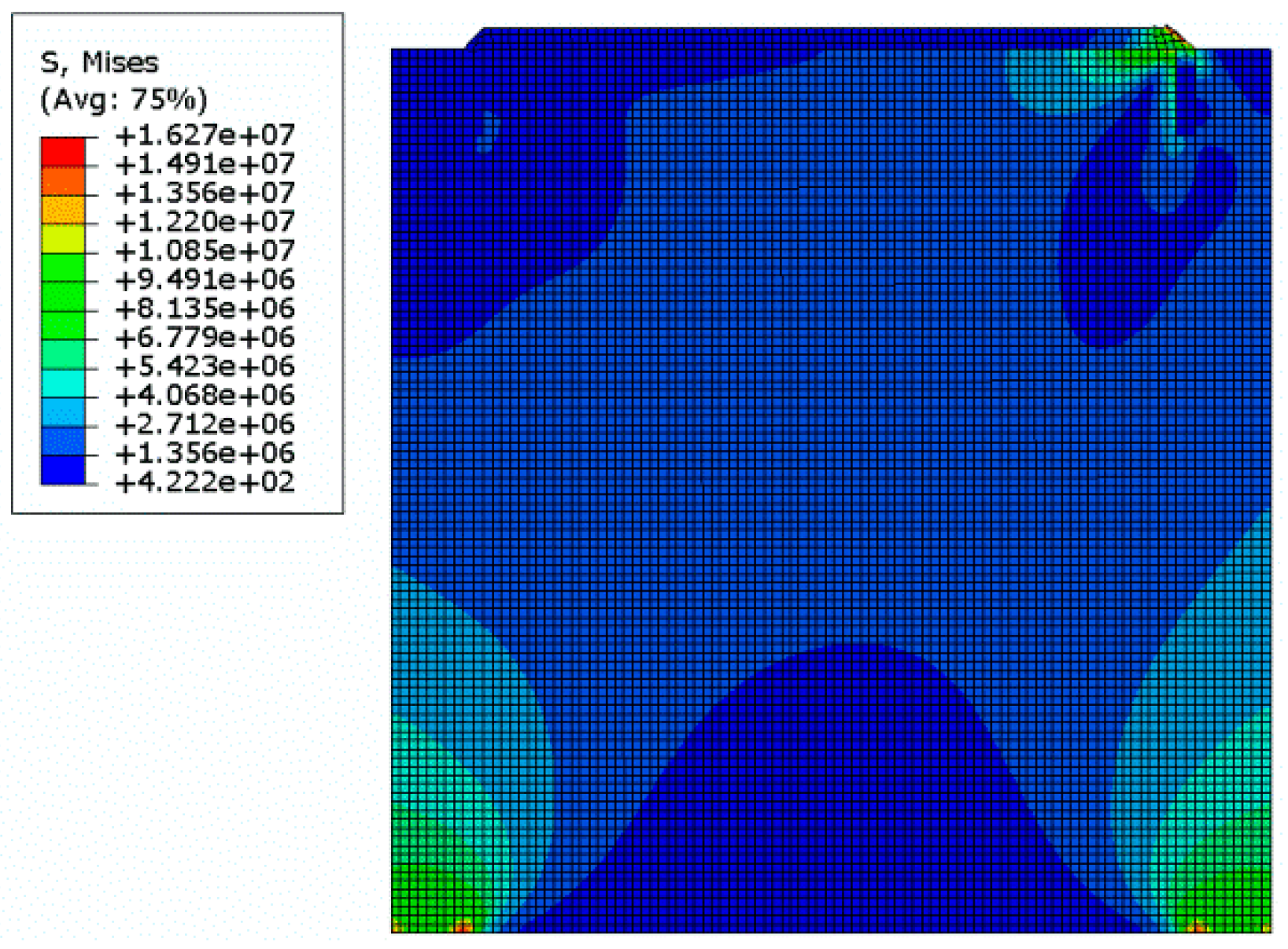

4.3. Results and Discussion

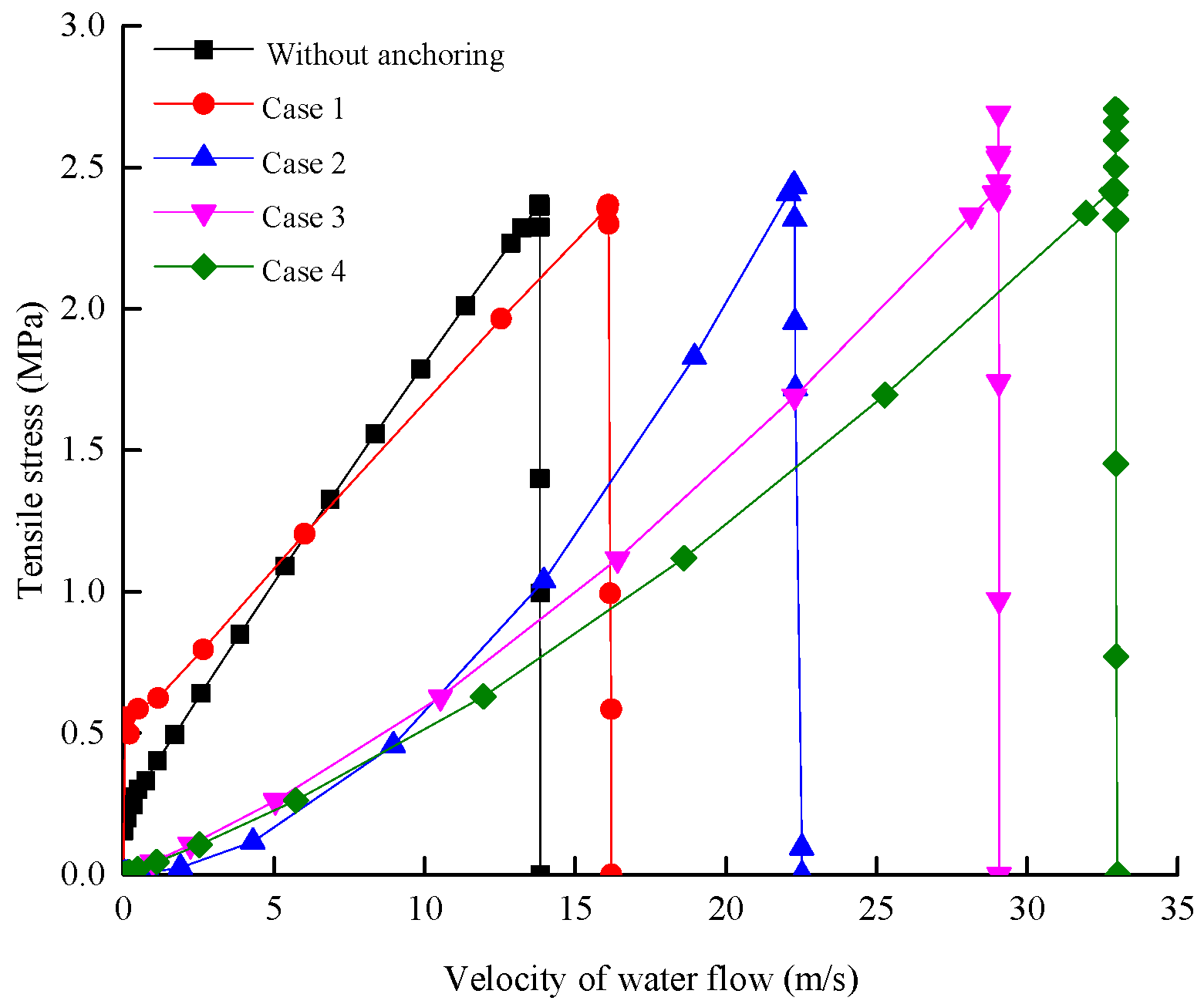

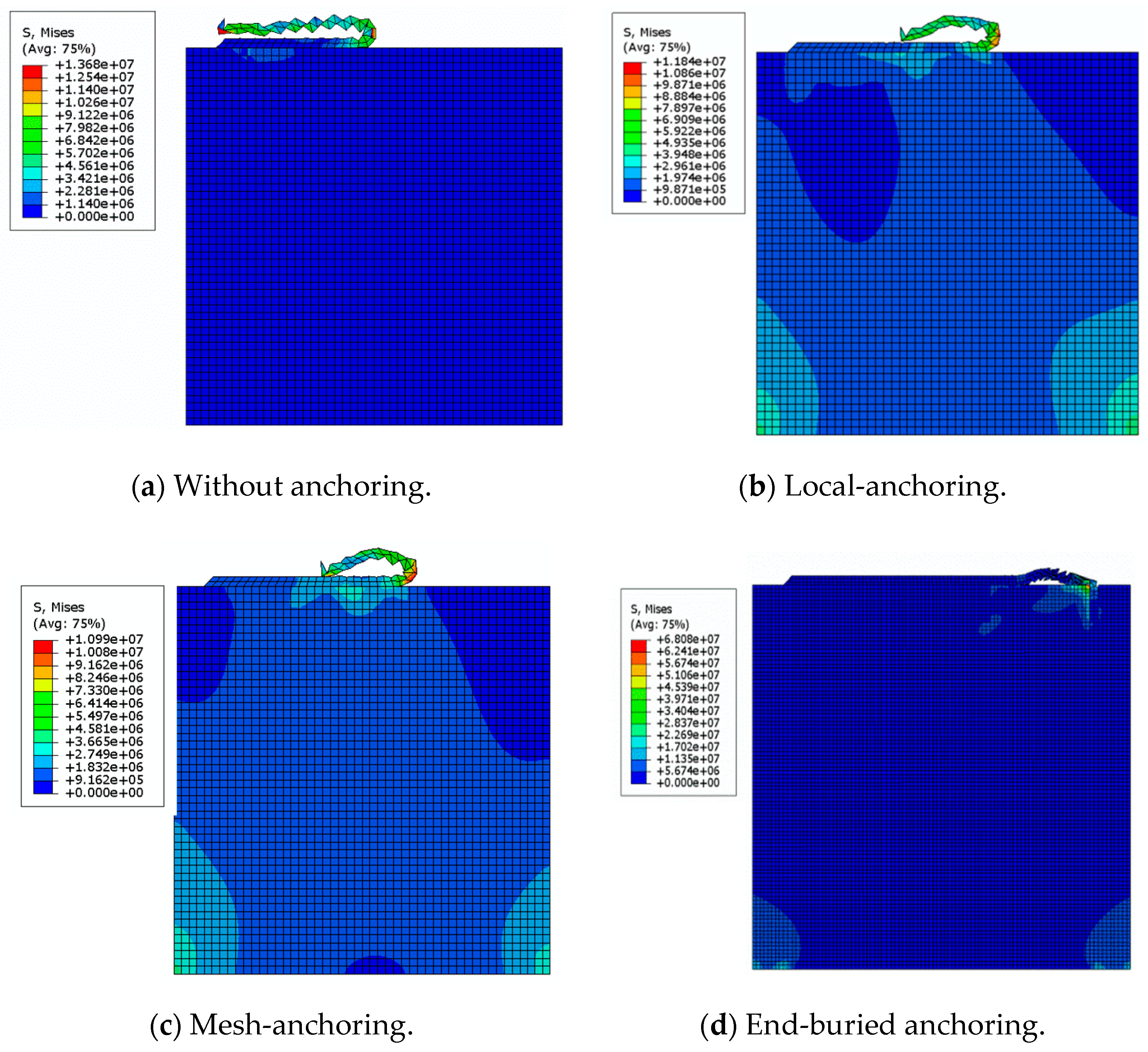

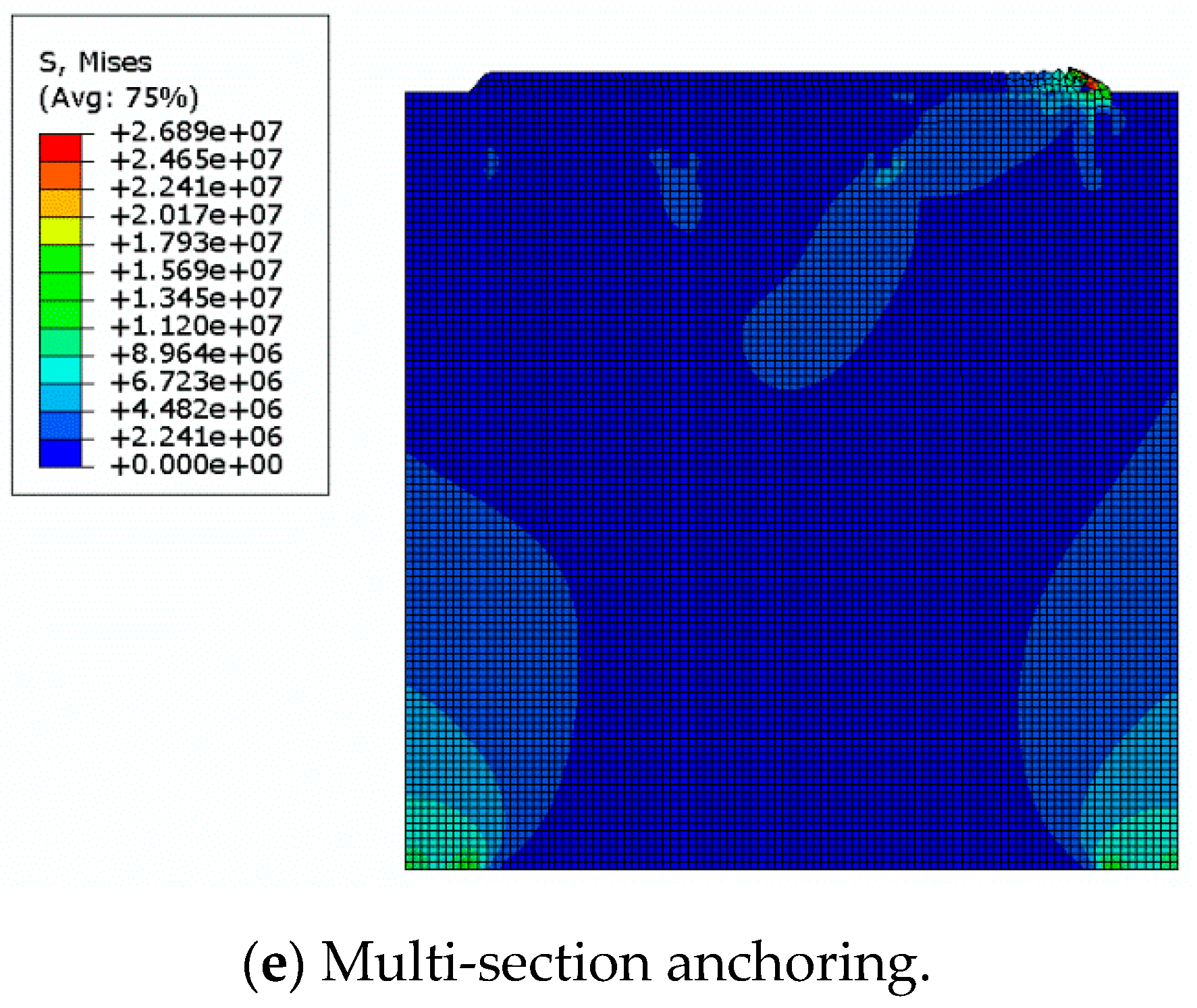

4.3.1. Impact Resistance with Different Anchoring Types

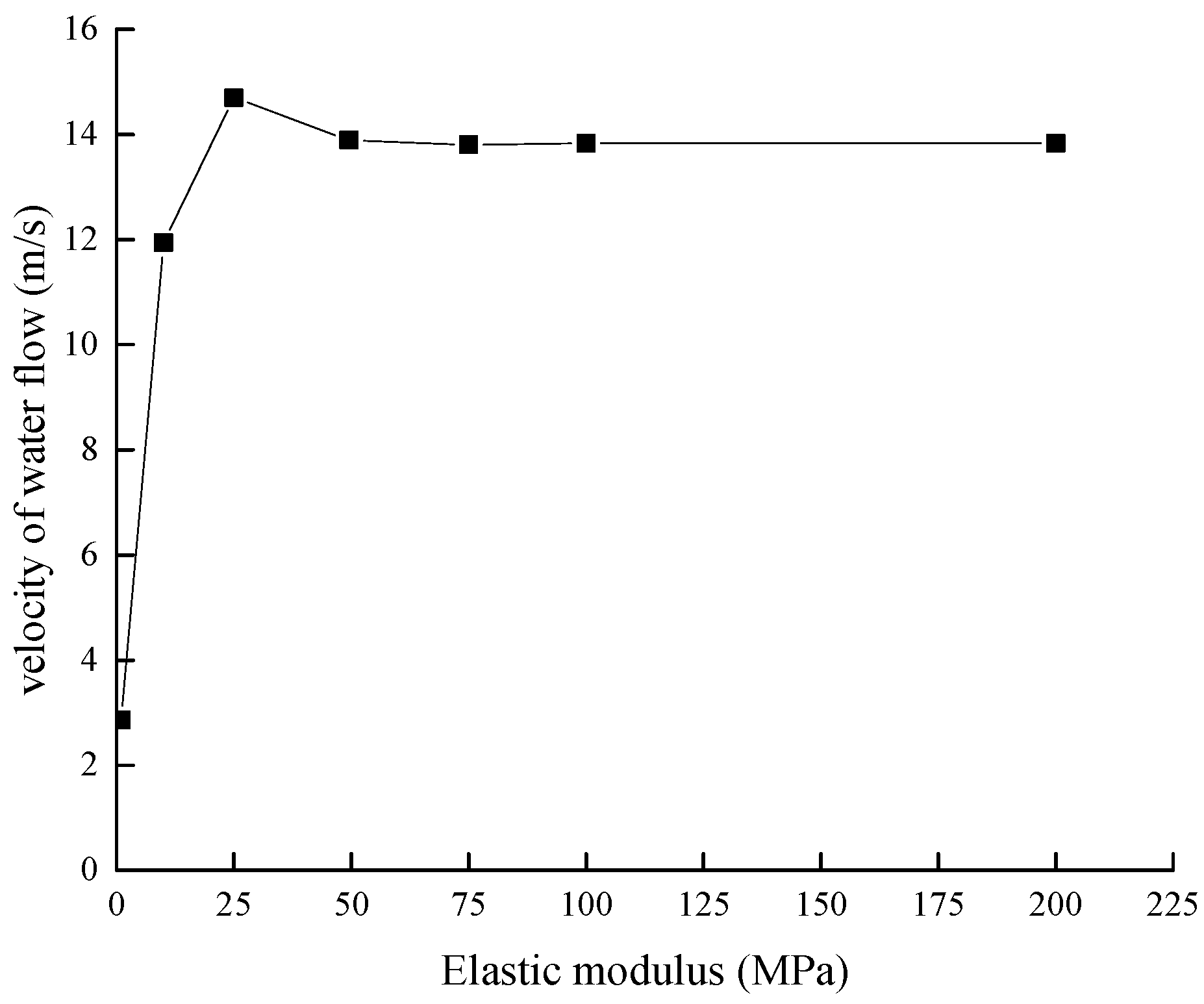

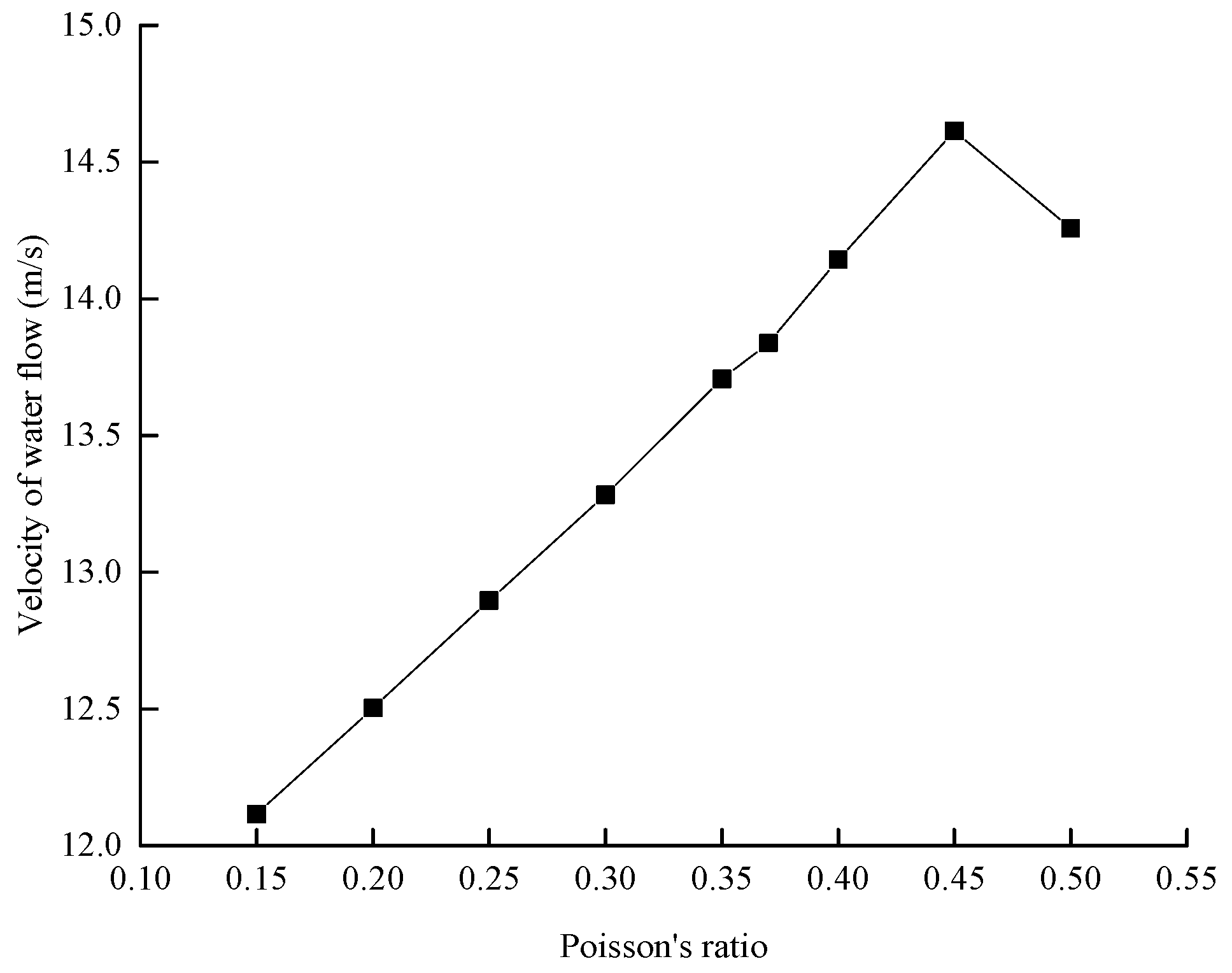

4.3.2. Sensitivity Analysis of Polyurea-Based Coating Material Parameters

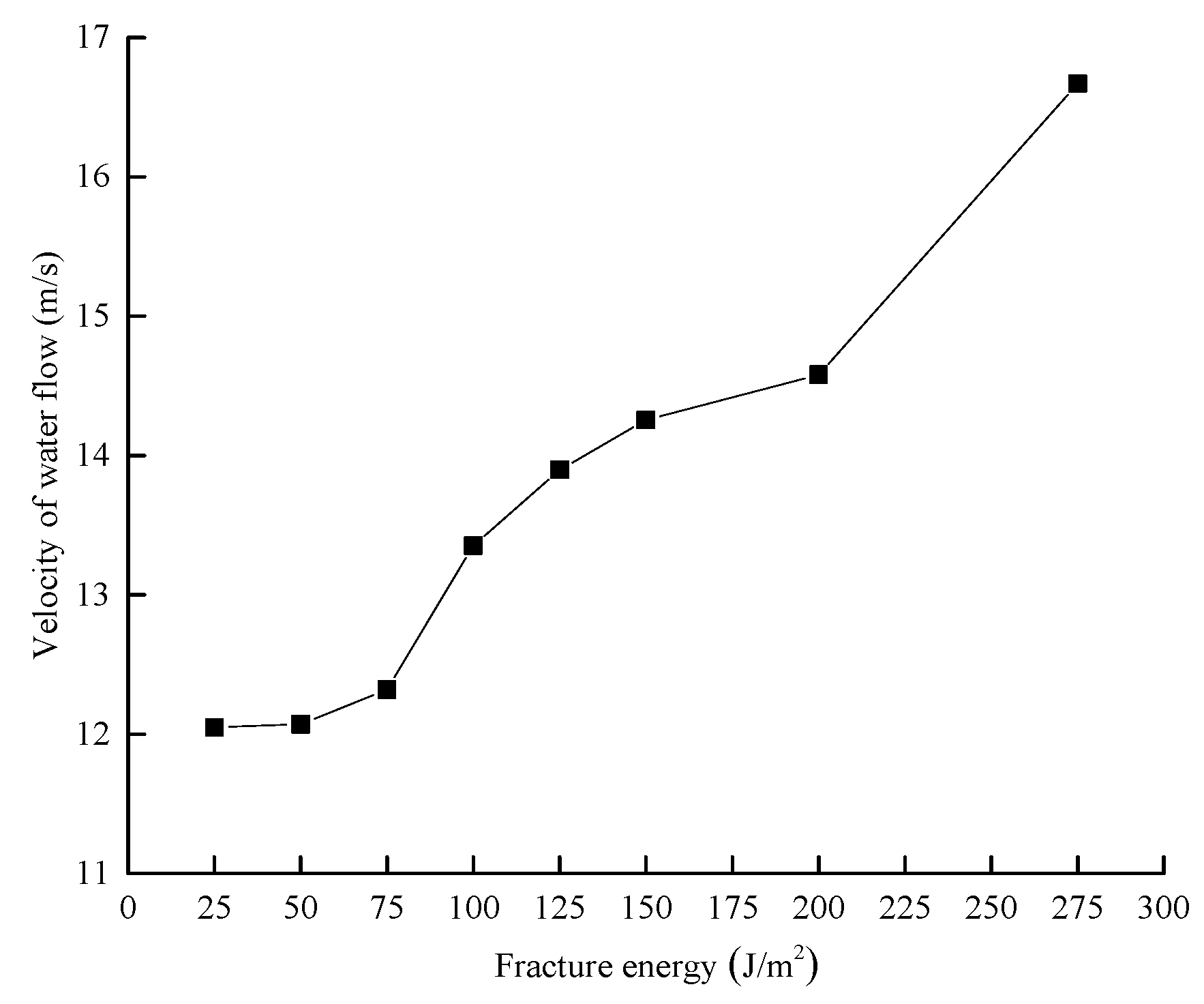

4.3.3. Sensitivity Analysis of Bonding Material Parameters

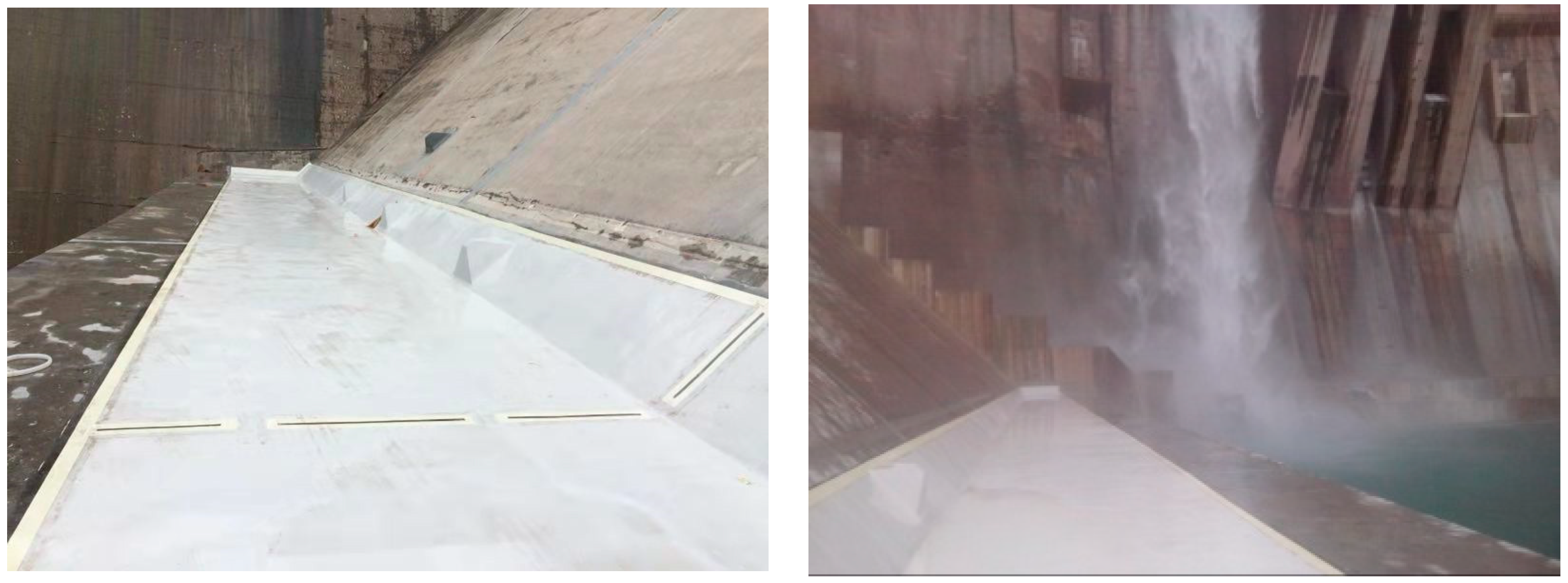

5. Engineering Applications of the Model

5.1. Engineering Application 1

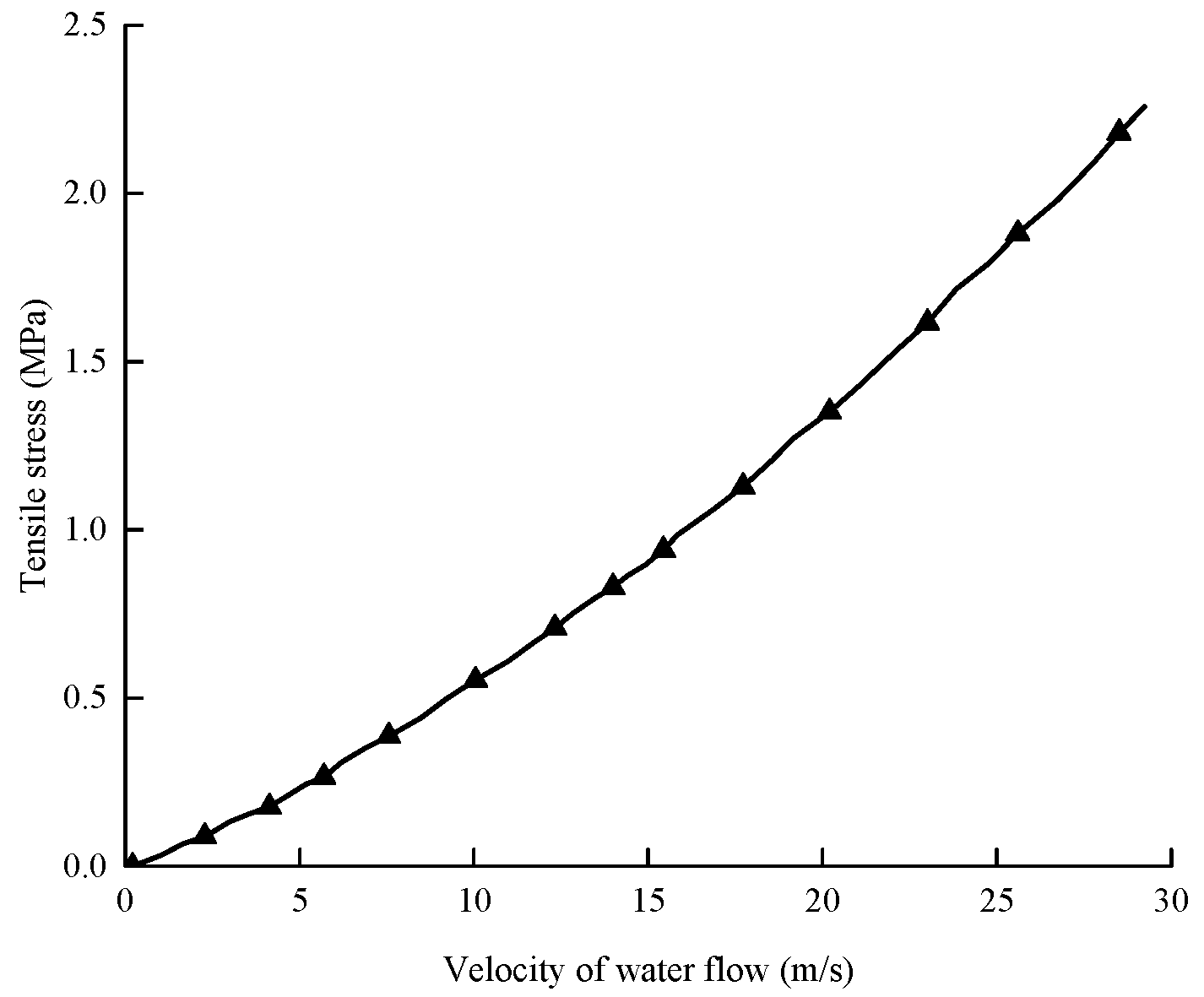

5.1.1. Study of the Impact Resistance Design of Flood Discharge Infrastructure

5.1.2. Analysis of Impact Resistance

5.2. Engineering Application 2

5.2.1. Research on the Impact Resistance Design of the Flood Discharge Tunnel

5.2.2. Analysis of Impact Resistance

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Urgessa, G.S.; Esfandiari, M. Review of Polymer Coatings Used for Blast Strengthening of Reinforced Concrete and Masonry Structures. In Proceedings of the International Congress on Polymers in Concrete; Springer: Cham, Switzerland, 2018; pp. 713–719. [Google Scholar]

- Buchan, P.A.; Chen, J.F. Blast resistance of FRP composites and polymer strengthened concrete and masonry structures. Compos. Part B Eng. 2007, 38, 509–522. [Google Scholar] [CrossRef]

- McCall, R.T.; Masselink, G.; Poate, T.G.; Roelvink, J.A.; Almeida, L.P.; Davidson, M.; Russell, P.E. Modelling storm hydrodynamics on gravel beaches with XBeach-G. Coast. Eng. 2014, 91, 231–250. [Google Scholar] [CrossRef]

- Buckley, M.L.; Wei, Y.; Jaffe, B.E.; Watt, S.G. Inverse modeling of velocities and inferred cause of overwash that emplaced inland fields of boulders at Anegada, British Virgin Islands. Nat. Hazards 2012, 63, 133–149. [Google Scholar] [CrossRef]

- Chanson, H. Embankment overtopping protection systems. Acta Geotech. 2015, 10, 305–318. [Google Scholar] [CrossRef]

- Chiganne, F.; Marche, C.; Mahdi, T.F. Evaluation of the overflow failure scenario and hydrograph of an embankment dam with a concrete upstream slope protection. Nat. Hazards 2014, 71, 21–39. [Google Scholar] [CrossRef]

- Schüttrumpf, H.; Oumeraci, H. Layer thicknesses and velocities of wave overtopping flow at seadikes. Coast. Eng. 2005, 52, 473–495. [Google Scholar] [CrossRef]

- Matsushima, K.; Mohri, Y.; Yamazaki, S.; Hori, T.; Ariyoshi, M.; Tatsuoka, F. Design of earth dams allowing temporary overtopping based on hydraulic failure experiments and flood analysis. In Geosynthetics in Civil and Environmental Engineering; Springer: Berlin/Heidelberg, Germany, 2008; pp. 757–762. [Google Scholar]

- Bomers, A.; Lopez, J.A.; Warmink, J.J.; Hulscher, S.J. Modelling effects of an asphalt road at a dike crest on dike cover erosion onset during wave overtopping. Nat. Hazards J. Int. Soc. Prev. Mitig. Nat. Hazards 2018, 93, 1–30. [Google Scholar]

- Quang, T.T.; Oumeraci, H. Numerical modelling of wave overtopping-induced erosion of grassed inner sea-dike slopes. Nat. Hazards 2012, 63, 417–447. [Google Scholar] [CrossRef]

- Alkhader, M.; Knauss, W.G.; Ravichandran, G. The influence of pressure on the large deformation shear response of a Polyurea. Time Depend. Const. Behav. Fract. Fail. Process. 2011, 3, 287–295. [Google Scholar]

- Ng, P.L.; Kwan, A.K.H. Improving concrete durability for sewerage applications. In Engineering Asset Management-Systems, Professional Practices and Certification; Springer: Cham, Switzerland, 2015; pp. 1043–1053. [Google Scholar]

- Raman, S.N.; Ngo TLu, J.; Mendis, P. Experimental investigation on the tensile behaviour of polyurea at high strain rates. Mater. Des. 2013, 50, 124–129. [Google Scholar] [CrossRef]

- Mohotti, D.; Ali, M.; Ngo, T.; Lu, J.; Mendis, P. Strain rate dependent constitutive model for predicting the material behaviour of polyurea under high strain rate tensile loading. Mater. Des. 2014, 53, 830–837. [Google Scholar] [CrossRef]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Barenblatt, G.I. The formation of equilibrium cracks during brittle fracture. General ideas and hypotheses. Axially-symmetric cracks. J. Appl. Math. Mech. 1959, 23, 622–636. [Google Scholar] [CrossRef]

- Zhang, Z.; Paulino, G.H. Cohesive zone modeling of dynamic failure in homogeneous and functionally graded materials. Int. J. Plast. 2005, 21, 1195–1254. [Google Scholar] [CrossRef]

- Paulino, G.H. Dynamic Fracture of Functionally Graded Composites Using an Intrinsic Cohesive Zone Model. Mater. Sci. Forum 2005, 492–493, 447–452. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M.; André, A. On the strength prediction of adhesively bonded FRP-steel joints using cohesive zone modelling. Theor. Appl. Fract. Mech. 2018, 93, 64–78. [Google Scholar] [CrossRef]

- Mohammed, I.K.; Kinloch, A.J.; Charalambides, M.N. Modelling the Peeling Behavior of Soft Adhesives. Procedia Struct. Integr. 2016, 2, 326–333. [Google Scholar] [CrossRef]

- Migliavacca, F. Modeling and Experimental Studies of Peeling of Polymer Coating for Biodegradable Magnesium Alloy Stents. Rare Met. Mater. Eng. 2014, 43, 2877–2882. [Google Scholar]

- Rahulkumar, P.; Jagota, A.; Bennison, S.J.; Saigal, S. Cohesive element modeling of viscoelastic fracture: Application to peel testing of polymers. Int. J. Solids Struct. 2000, 37, 1873–1897. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Petersson, P.E. Crack Growth and Development of Fracture Zones in Plain Concrete and Similar Materials; Report No. TVBM-1006; Division of Building Materials, Lund Institute of Technology: Lund, Sweden, 1981. [Google Scholar]

- Ortiz, M.; Pandolfi, A. Finite-deformation irreversible cohesive elements for three-dimensional crack-propagation analysis. Int. J. Numer. Methods Eng. 1999, 44, 1267–1282. [Google Scholar] [CrossRef]

- Ruiz, G.; Pandolfi, A.; Ortiz, M. Three-dimensional cohesive modeling of dynamic mixed-mode fracture. Int. J. Numer. Methods Eng. 2001, 52, 97–120. [Google Scholar] [CrossRef]

- Schoneboom, T.; Aberle, J.; Dittrich, A. Spatial Variability, Mean Drag Forces, and Drag Coefficients in an Array of Rigid Cylinders. In Experimental Methods in Hydraulic Research; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Lopardo, R.A.; Romagnoli, M. Pressure and Velocity Fluctuations in Stilling Basins. In Advances in Water Resources & Hydraulic Engineering; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Batchelor, G.K. Pressure fluctuations in isotropic turbulence. In Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1951; Volume 47, pp. 359–374. [Google Scholar]

- Anderson, J.D. Introduction to Flight, 7th ed.; McGraw-Hill Education: NewYork, NY, USA, 2004. [Google Scholar]

- Pike, J. Lift, drag and thrust at high flight Mach number. Philos. Trans. Math. Phys. Eng. Sci. 1999, 357, 2141–2149. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Taylor, R.L.; Zhu, J.Z. The Finite Element Method; Elsevier: Kidlington, UK, 2008. [Google Scholar]

- Steinhauser, M.O. Computational Mutiscale Modeling of Fluids and Solids: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Abaqus Analysis User’s Guide 6.14; Dassilt Simulia: Paris, France, 2014; pp. 827–915.

- Munjiza, A. The Combined Finite-Discrete Element Method; Wiley: Chichester, UK, 2004; pp. 35–129. [Google Scholar]

- Li, B.Q.; Zhang, Y.C.; Liu, X.N.; Li, Z.Y. Study on the polyurea-coat debonding failure of impervious structurein contraction joints. Shui Li Xue Bao 2017, 48, 70–77. (In Chinese) [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Zhang, Z.; Wang, X.; Liu, X. Investigation on the Debonding Failure Model of Anchored Polyurea Coating under a High-Velocity Water Flow and Its Application. Sustainability 2019, 11, 1261. https://doi.org/10.3390/su11051261

Li B, Zhang Z, Wang X, Liu X. Investigation on the Debonding Failure Model of Anchored Polyurea Coating under a High-Velocity Water Flow and Its Application. Sustainability. 2019; 11(5):1261. https://doi.org/10.3390/su11051261

Chicago/Turabian StyleLi, Bingqi, Zhenyu Zhang, Xiaogang Wang, and Xiaonan Liu. 2019. "Investigation on the Debonding Failure Model of Anchored Polyurea Coating under a High-Velocity Water Flow and Its Application" Sustainability 11, no. 5: 1261. https://doi.org/10.3390/su11051261

APA StyleLi, B., Zhang, Z., Wang, X., & Liu, X. (2019). Investigation on the Debonding Failure Model of Anchored Polyurea Coating under a High-Velocity Water Flow and Its Application. Sustainability, 11(5), 1261. https://doi.org/10.3390/su11051261