Occupant Comfort Management Based on Energy Optimization Using an Environment Prediction Model in Smart Homes

Abstract

1. Introduction

2. Related Works

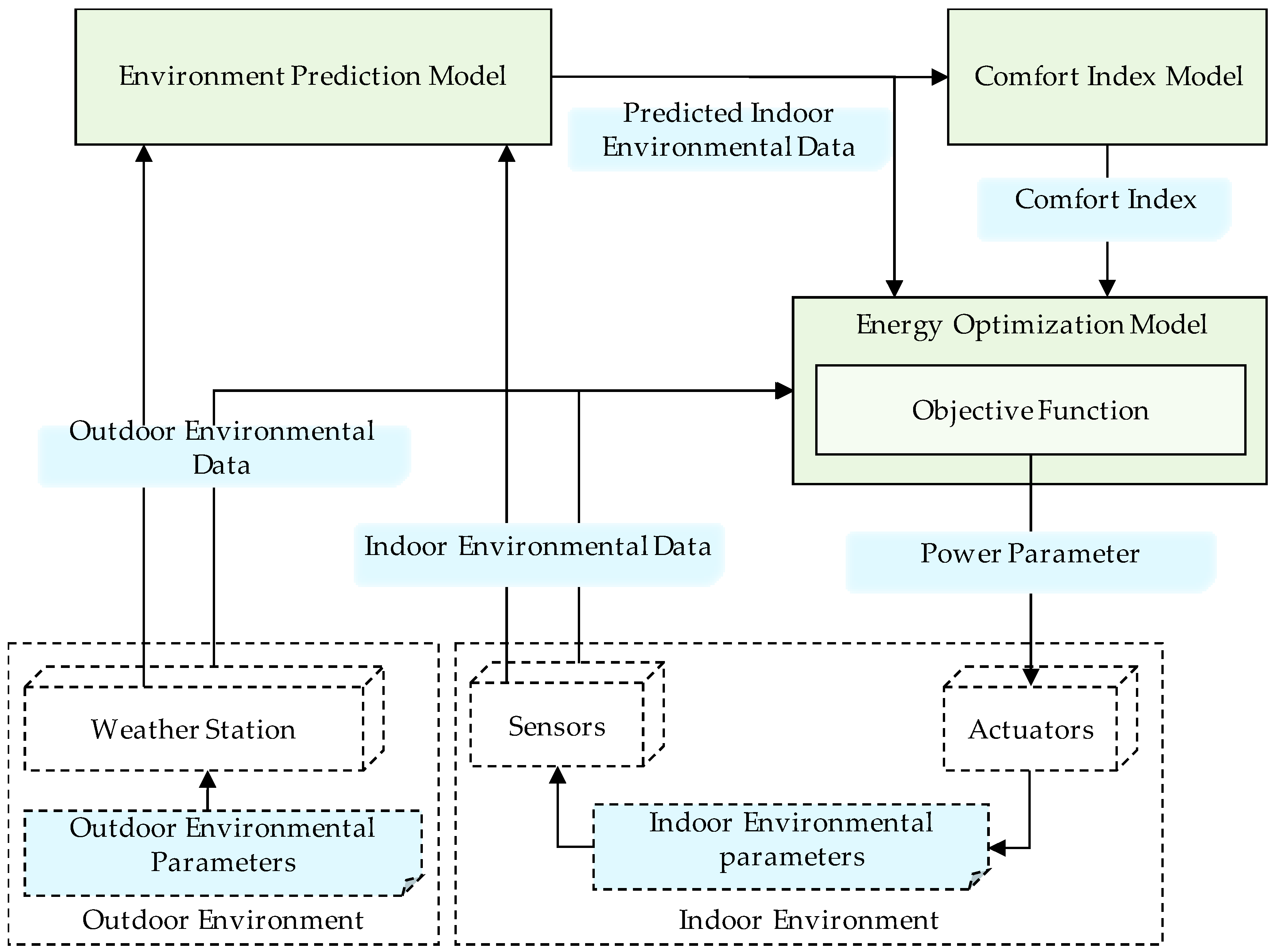

3. Proposed Occupant Comfort Management Methodology

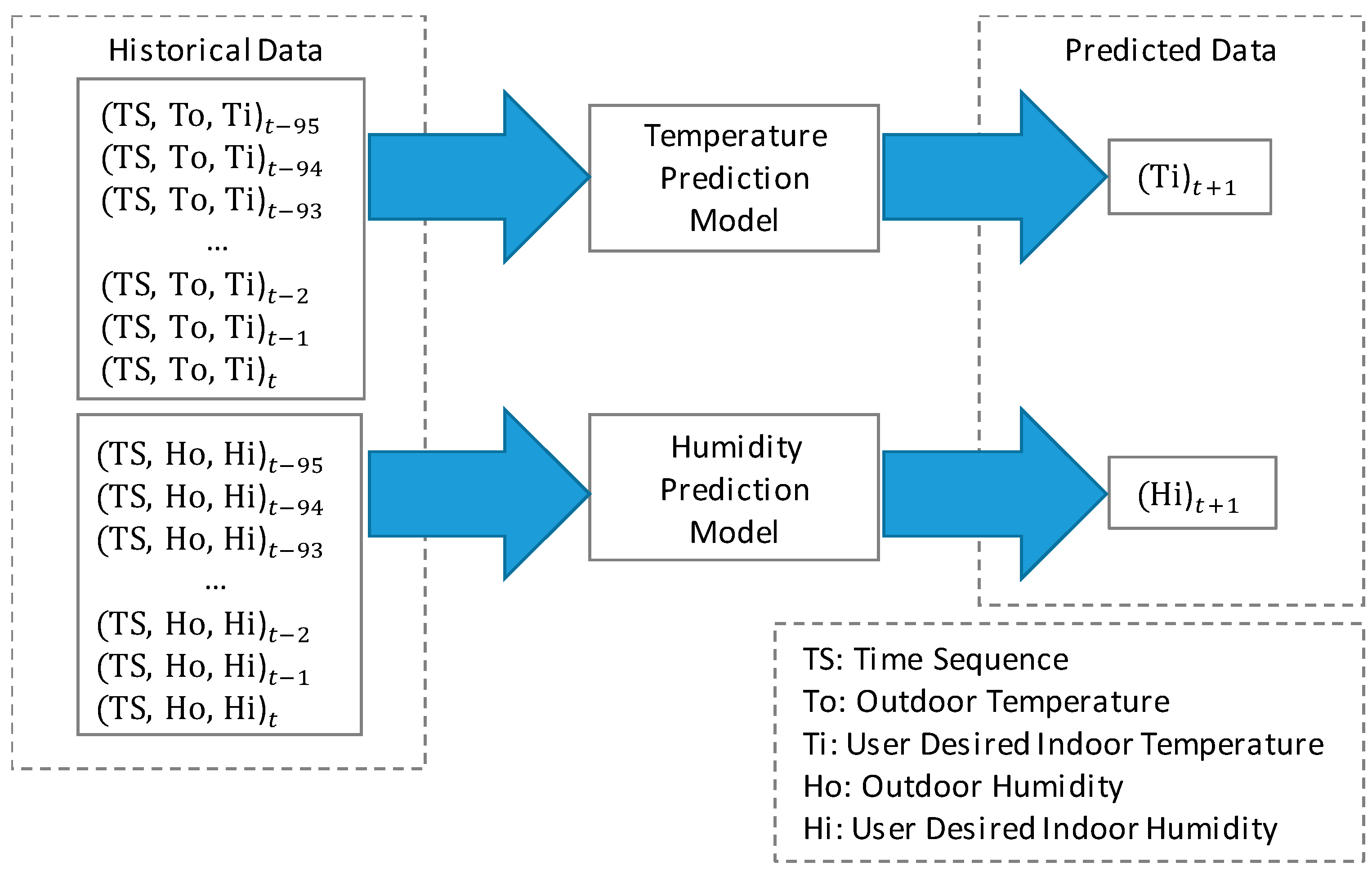

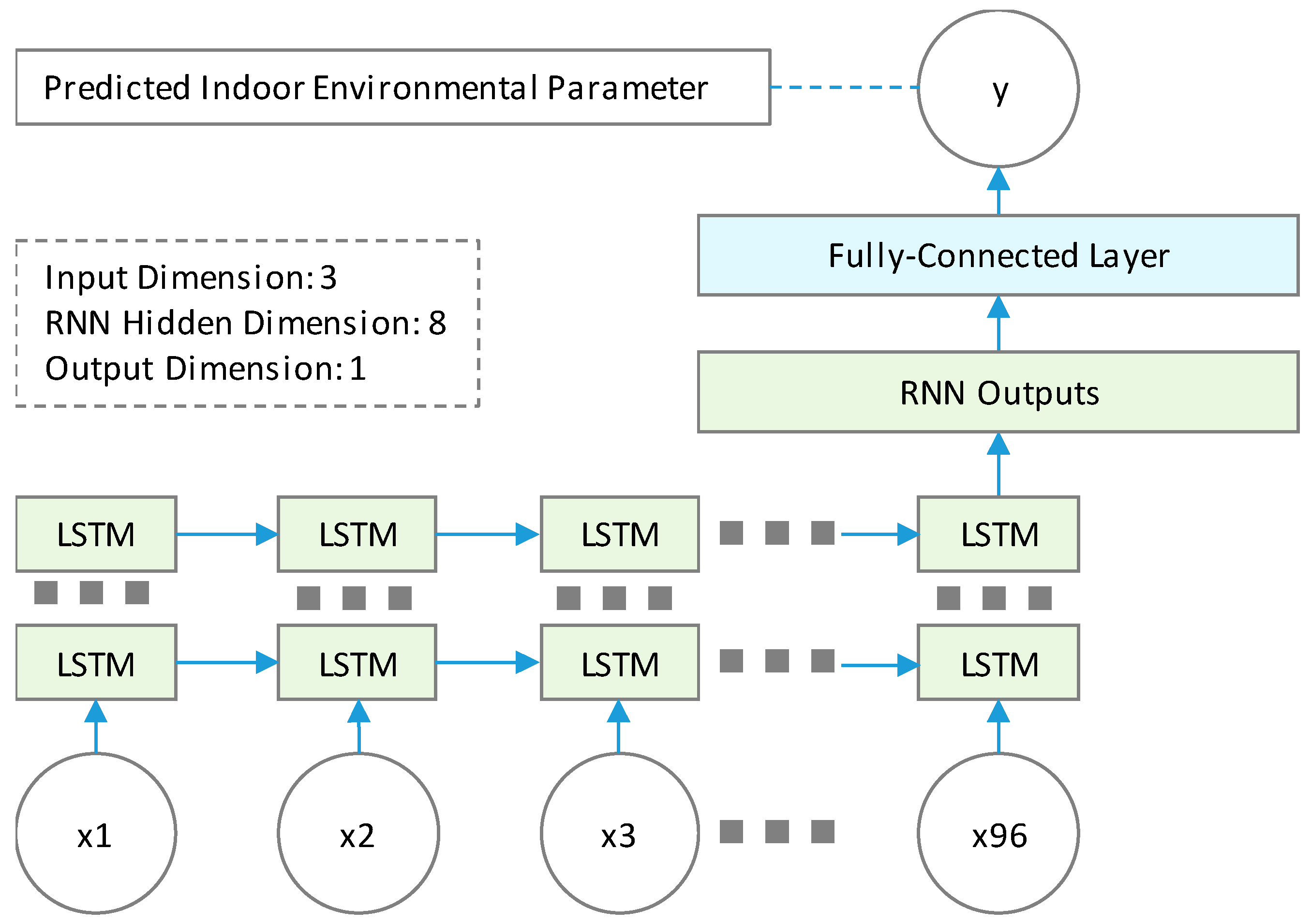

3.1. Environmental Parameter Prediction Model

3.2. Comfort Index Model

| Algorithm 1. Calculate PMV. | |

| 1: | function getPMV(M, W, Ta, Tr, Va, Rh, icl) |

| 2: | if icl > 0.078 then |

| 3: | fcl = 1.05 + 0.645 * icl; |

| 4: | else |

| 5: | fcl = 1.00 + 1.290 * icl; |

| 6: | end |

| 7: | if hc1 from Equation (6) > hc2 Equation (7) then |

| 8: | hc = hc1; |

| 9: | else |

| 10: | hc = hc2; |

| 11: | end |

| 12: | Pa = Get the value using Equation (8); |

| 13: | tcl = Algorithm 2(fcl, M, W, Ta, Tr, Va, icl); |

| 14: | Evaporation = Get the value using Equation (2); |

| 15: | Respiration = Get the value using Equation (3); |

| 16: | Radiation = Get the value using Equation (4); |

| 17: | Convection = Get the value using Equation (5); |

| 18: | PMV = Get the value using Equation (1); |

| 19: | return PMV; |

| 20: | end function |

| Algorithm 2. Calculate tcl. | |

| 1: | function getTcl(fcl, M, W, Ta, Tr, Va, icl) |

| 2: | ts = 35.7 − 0.028 * (M − W); |

| 3: | eps = 1e − 9; |

| 4: | q = {−50, 50}; |

| 5: | while (|q[0] − q[1]|) > eps) { |

| 6: | temp = (q[0] * getTclf(q[1], fcl, ts, Ta, Tr, Va, icl) |

| 7: | −q[1] * getTclf (q[0], fcl, ts, Ta, Tr, Va, icl)) |

| 8: | /( getTclf (q[1], fcl, ts, Ta, Tr, Va, icl) |

| 9: | −getTclf (q[0], fcl, ts, Ta, Tr, Va, icl)); |

| 10: | q[0] = q[1]; |

| 11: | q[1] = temp; |

| 12: | } |

| 13: | return (q[0] + q[1]) / 2; |

| 14: | end function |

| 15: | function getTclf(tcl, fcl, ts, Ta, Tr, Va, icl) |

| 16: | t1 = (tcl + 273)^(−4) − (Tr + 273)^(−4); |

| 17: | if hc1 from Equation (7) > hc2 Equation (8) then |

| 18: | hc = hc1; |

| 19: | else |

| 20: | hc = hc2; |

| 21: | end |

| 22: | tcle = ts − icl * (3.96 * 1e − 8 * fcl * t1 + fcl * hc * (tcl − Ta)); |

| 23: | return tcl − tcle; |

| 24: | end function |

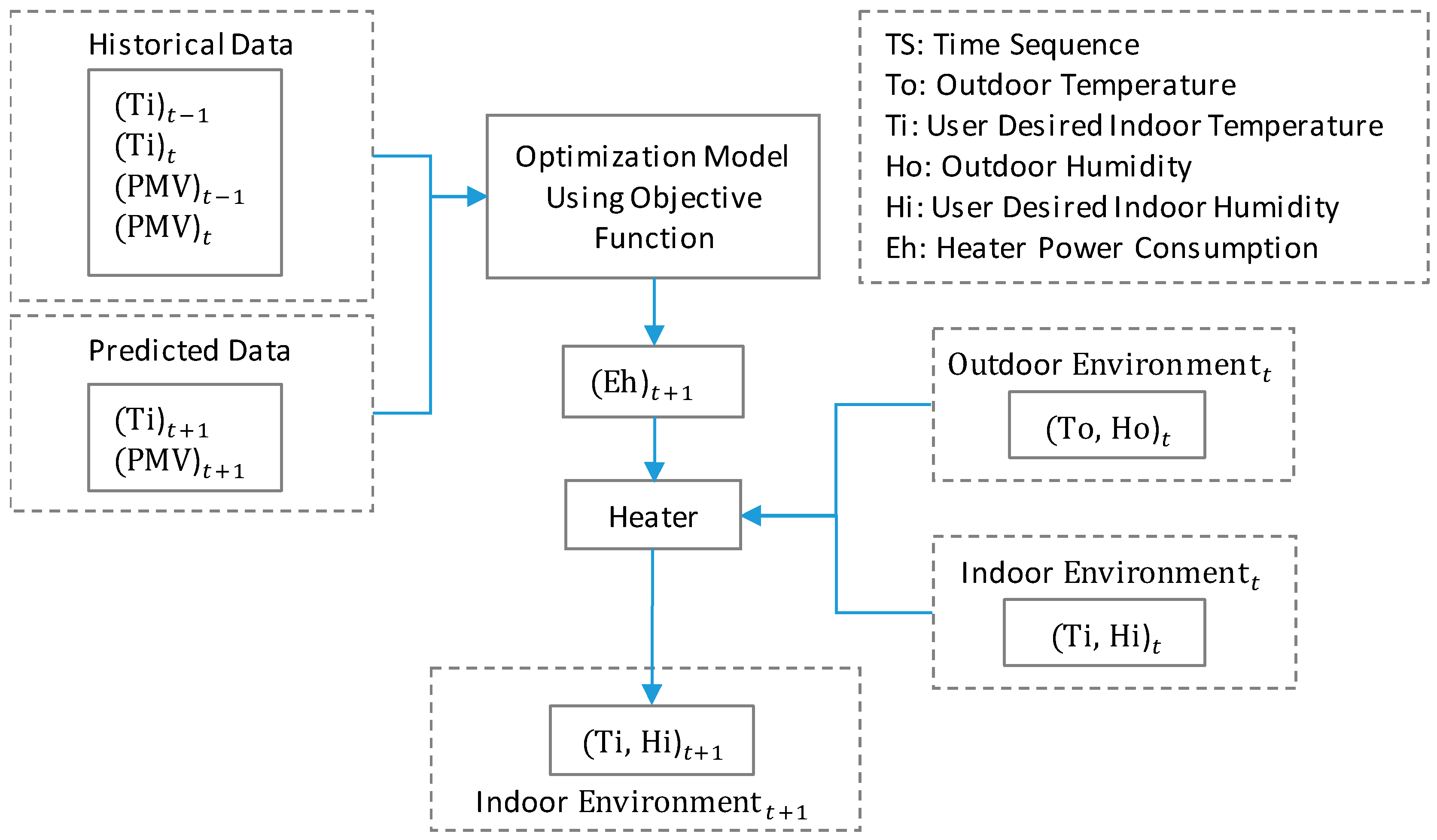

3.3. Energy Consumption Optimization Model

4. Experimental Results

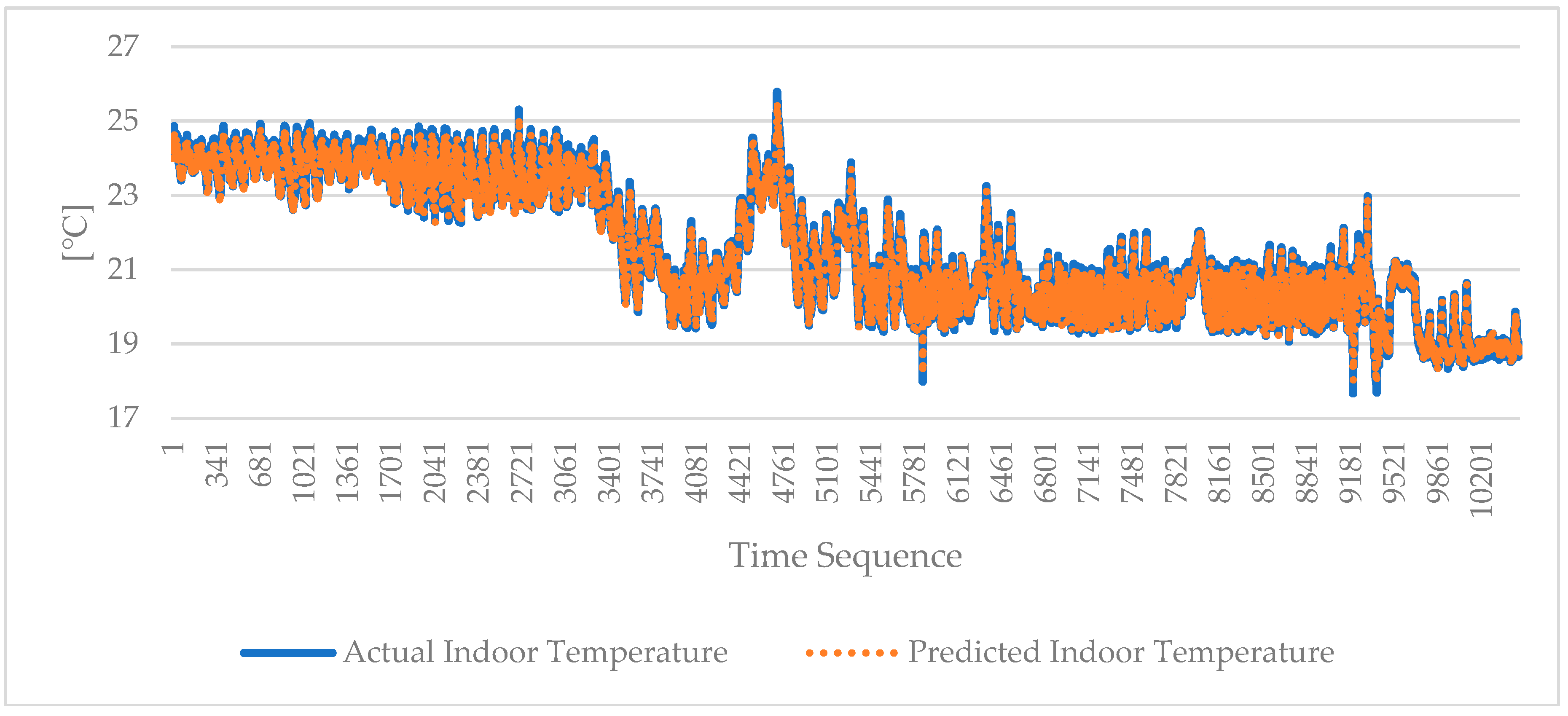

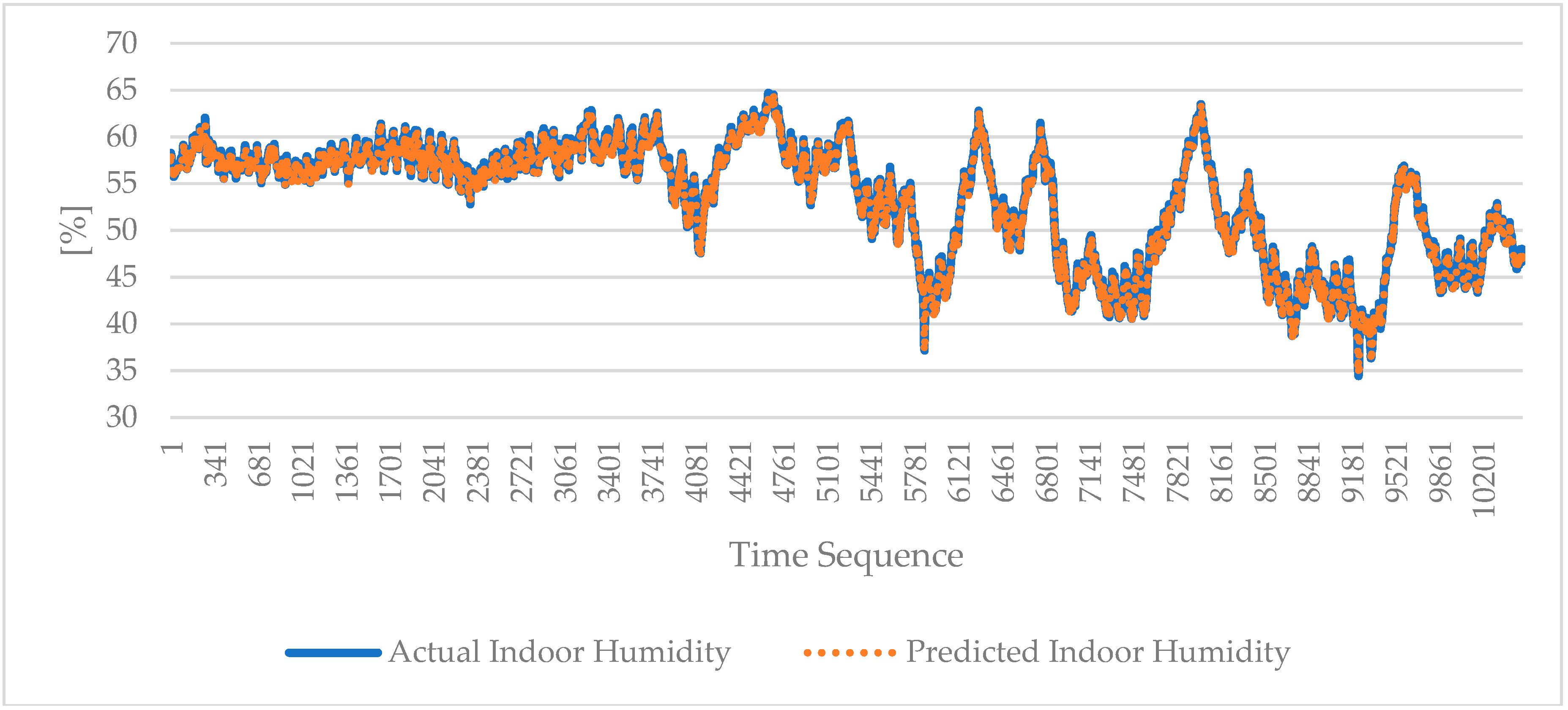

4.1. Indoor Environmental Parameters Predictions

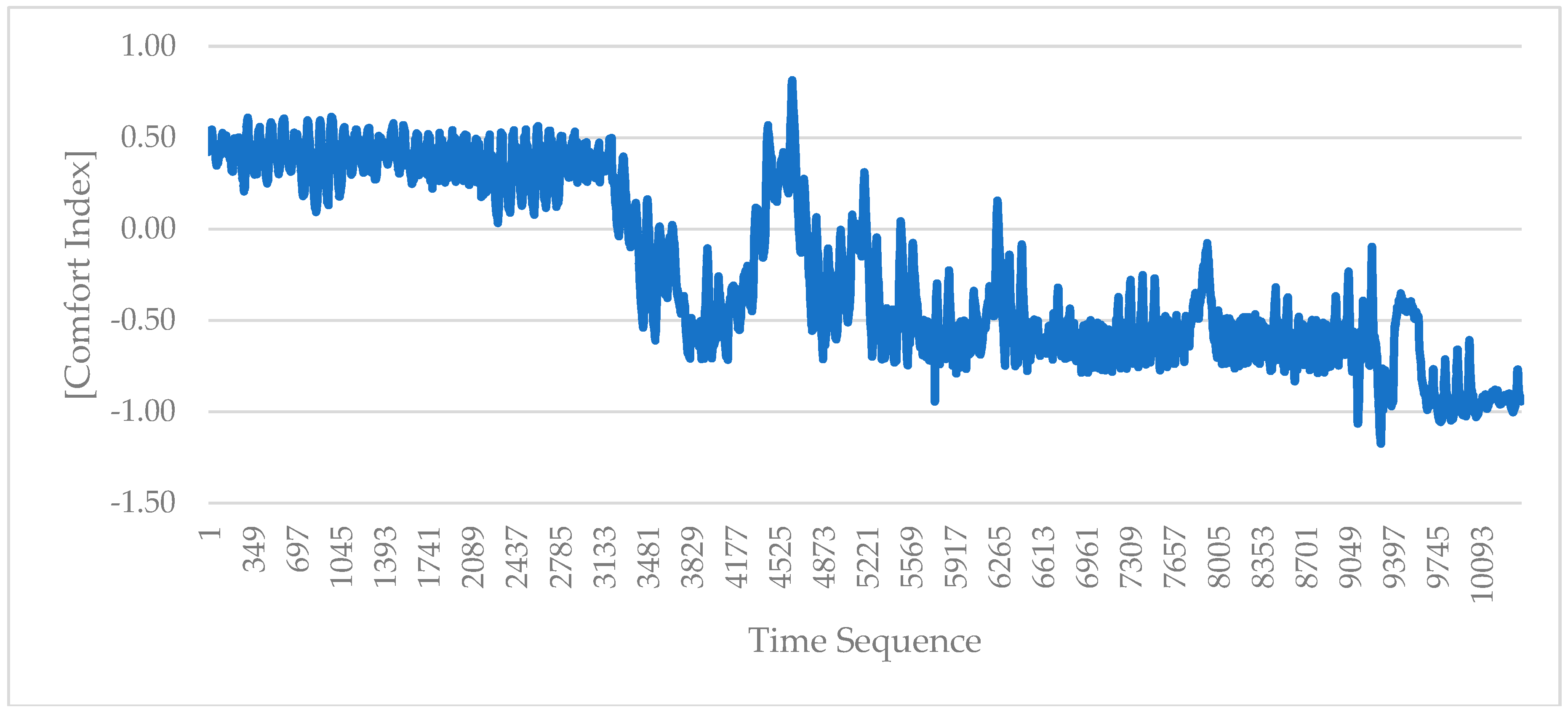

4.2. Indoor Environmental User Comfort Prediction

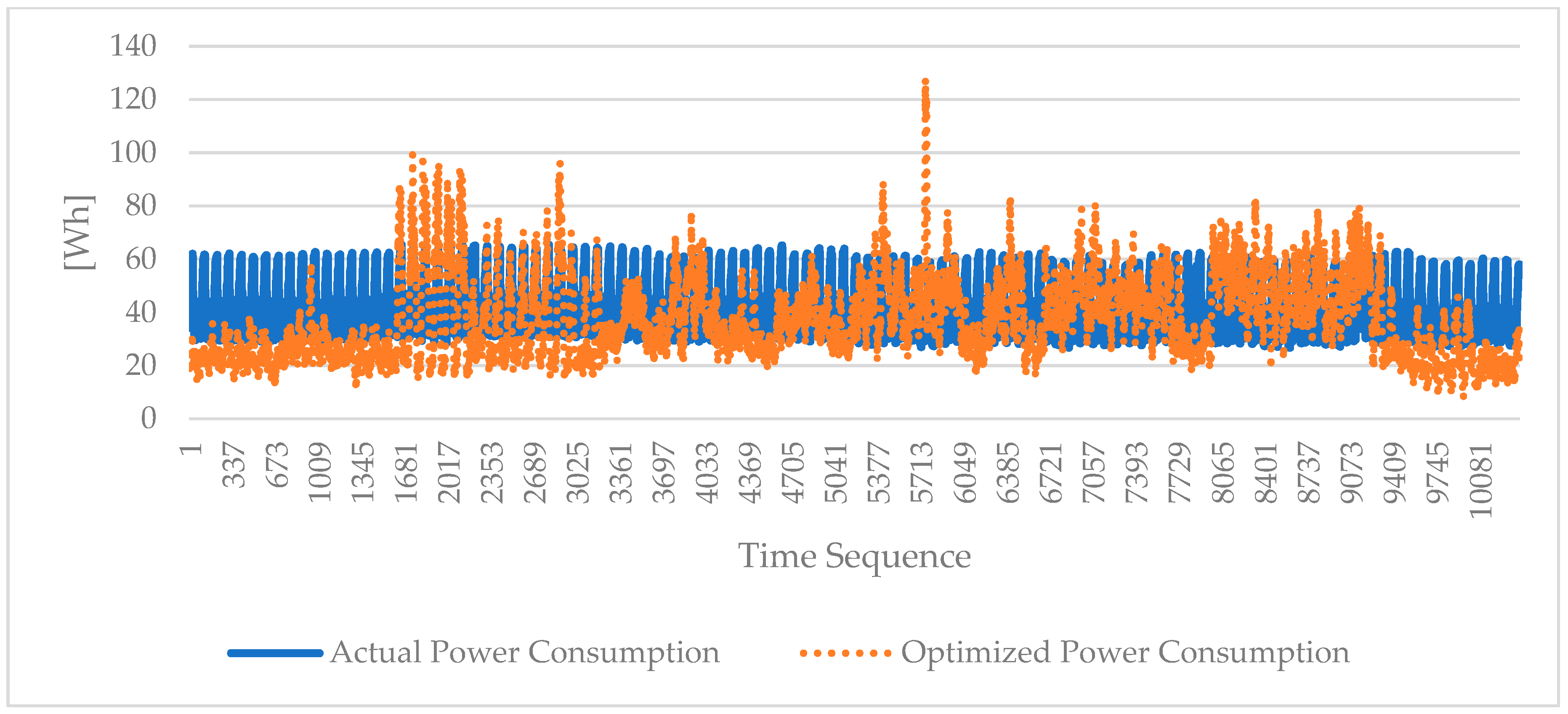

4.3. Optimal Energy Consumption

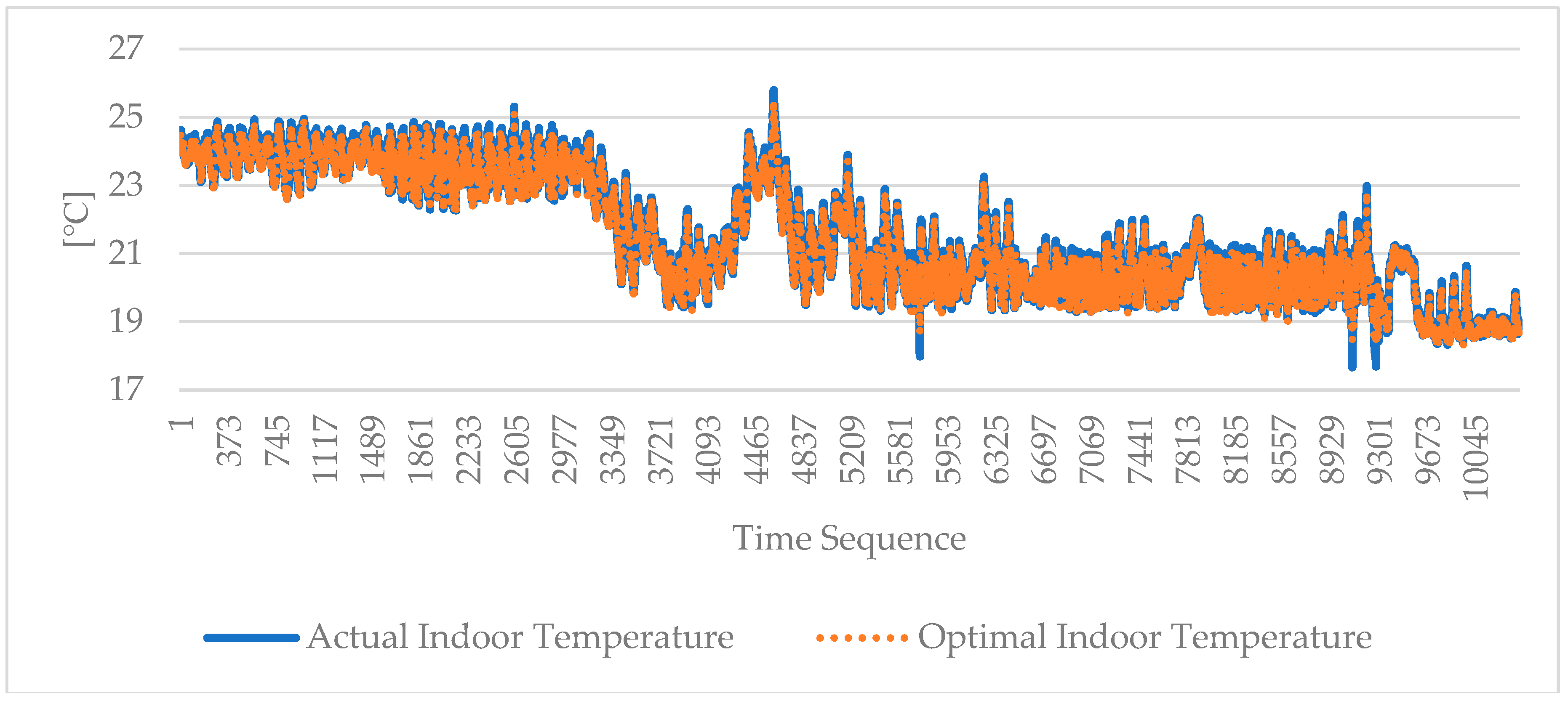

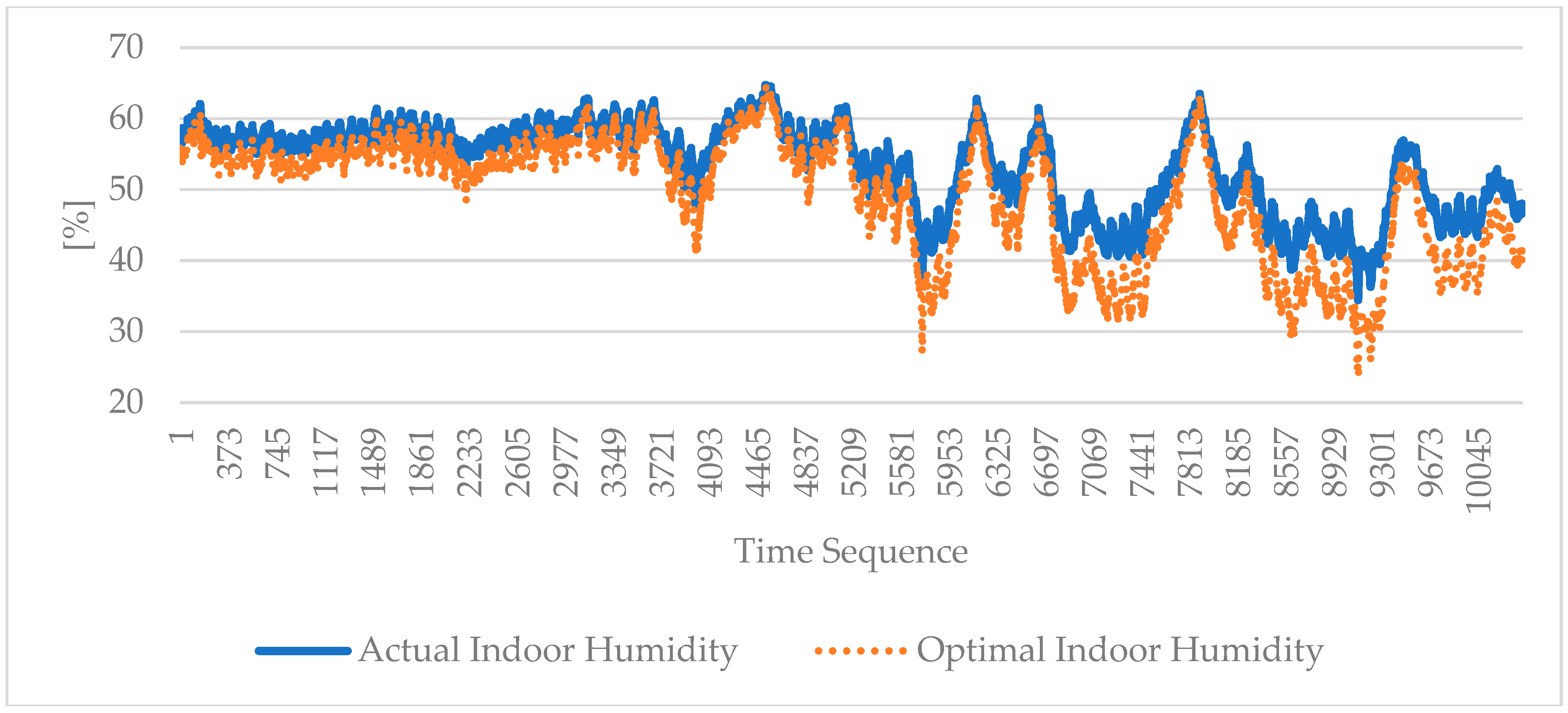

4.4. Indoor Environment Using Optimal Power Consumption

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rupp, R.F.; Vásquez, N.G.; Lamberts, R. A review of human thermal comfort in the built environment. Energy Build. 2015, 105, 178–205. [Google Scholar] [CrossRef]

- Yang, L.; Yan, H.; Lam, J.C. Thermal comfort and building energy consumption implications—A review. Appl. Energy 2014, 115, 164–173. [Google Scholar] [CrossRef]

- Chu, Y.; Xu, P.; Yang, Z.; Li, W. Existing building retrofitting for Indoor PM2.5 Concentration Control on Smog Days: Case study in China. Procedia Eng. 2017, 205, 3222–3227. [Google Scholar] [CrossRef]

- UN. World Urbanization Prospects: The 2014 Revision-Highlights; UN: New York, NY, USA, 2014. [Google Scholar]

- MacNaughton, P. Green Buildings and Health. 2016. Available online: https://dash.harvard.edu/handle/1/32644538 (accessed on 1 December 2018).

- Al Horr, Y.; Arif, M.; Kaushik, A.; Mazroei, A.; Katafygiotou, M.; Elsarrag, E. Occupant productivity and office indoor environment quality: A review of the literature. Build. Environ. 2016, 105, 369–389. [Google Scholar] [CrossRef]

- Haynes, B.; Suckley, L.; Nunnington, N. Workplace productivity and office type: An evaluation of office occupier differences based on age and gender. J. Corp Real Estate 2017, 19, 111–138. [Google Scholar] [CrossRef]

- Geng, Y.; Ji, W.; Lin, B.; Zhu, Y. The impact of thermal environment on occupant IEQ perception and productivity. Build. Environ. 2017, 121, 158–167. [Google Scholar] [CrossRef]

- Shaikh, P.H.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Ibrahim, T. A review on optimized control systems for building energy and comfort management of smart sustainable buildings. Renew. Sustain. Energy Rev. 2014, 34, 409–429. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, R.; Wang, L. Multi-agent intelligent controller design for smart and sustainable buildings. In Proceedings of the 2010 IEEE International Systems Conference, San Diego, CA, USA, 5–8 April 2010. [Google Scholar]

- Yang, R.; Wang, L. Optimal control strategy for HVAC system in building energy management. In Proceedings of the PES T&D 2012, Orlando, FL, USA, 7–10 May 2012; pp. 1–8. [Google Scholar]

- Dounis, A.; Caraiscos, C. Advanced control systems engineering for energy and comfort management in a building environment—A review. Renew. Sustain. Energy Rev. 2009, 13, 1246–1261. [Google Scholar] [CrossRef]

- Laftchiev, E.; Nikovski, D. An IoT system to estimate personal thermal comfort. In Proceedings of the 2016 IEEE 3rd World Forum on Internet of Things (WF-IoT), Reston, VA, USA, 12–14 December 2016; pp. 672–677. [Google Scholar]

- Farhan, A.A.; Pattipati, K.; Wang, B.; Luh, P. Predicting individual thermal comfort using machine learning algorithms. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 708–713. [Google Scholar]

- Afram, A.; Janabi-Sharifi, F.; Fung, A.S.; Raahemifar, K. Artificial neural network (ANN) based model predictive control (MPC) and optimization of HVAC systems: A state of the art review and case study of a residential HVAC system. Energy Build. 2017, 141, 96–113. [Google Scholar] [CrossRef]

- Zupančič, D.; Luštrek, M.; Gams, M. Trade-off between Energy Consumption and Comfort Experience in Smart Buildings. Inf. Technol. Control 2015, 44, 420–432. [Google Scholar] [CrossRef]

- Akkaya, K.; Guvenc, I.; Aygun, R.; Pala, N.; Kadri, A. IoT-based occupancy monitoring techniques for energy-efficient smart buildings. In Proceedings of the 2015 IEEE Wireless Communications and Networking Conference Workshops (WCNCW), New Orleans, LA, USA, 9–12 March 2015; pp. 58–63. [Google Scholar]

- Cannistraro, G.; Cannistraro, M.; Trovato, G. Island “Smart Energy” for Eco- Sustainable Energy—A Case Study “Favignana Island”. Int. J. Heat Techol. 2017, 35, S87–S95. [Google Scholar] [CrossRef]

- Suryadevara, N.K.; Mukhopadhyay, S.C.; Kelly, S.D.T.; Gill, S.P.S. WSN-Based Smart Sensors and Actuator for Power Management in Intelligent Buildings. IEEE/ASME Trans. Mechatron. 2015, 20, 564–571. [Google Scholar] [CrossRef]

- Cannistraro, M.; Lorenzini, E. The Applications of the New Techologies E-Sensing in Hospitals. Int. J. Heat Techol. 2016, 34, 551–557. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J. Forecasting energy market indices with recurrent neural networks: Case study of crude oil price fluctuations. Energy 2016, 102, 365–374. [Google Scholar] [CrossRef]

- Long-term energy/environment data for ORNL Research House #3. Available online: https://openei.org/datasets/dataset/ornl-research-house-3 (accessed on 1 July 2018).

- Kim, J.; Schiavon, S.; Brager, G. Personal comfort models—A new paradigm in thermal comfort for occupant-centric environmental control. Build. Environ. 2018, 132, 114–124. [Google Scholar] [CrossRef]

- Mossolly, M.; Ghali, K.; Ghaddar, N. Optimal control strategy for a multi-zone air conditioning system using a genetic algorithm. Energy 2009, 34, 58–66. [Google Scholar] [CrossRef]

- Peeters, L.; De Dear, R.; Hensen, J.; D’Haeseleer, W. Thermal comfort in residential buildings: Comfort values and scales for building energy simulation. Appl. Energy 2009, 86, 772–780. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Dounis, A.I.; Yang, R. Multi-agent control system with information fusion based comfort model for smart buildings. Appl. Energy 2012, 99, 247–254. [Google Scholar] [CrossRef]

- Molina-Solana, M.; Ros, M.; Ruiz, M.D.; Gómez-Romero, J.; Martin-Bautista, M. Data science for building energy management: A review. Renew. Sustain. Energy Rev. 2017, 70, 598–609. [Google Scholar] [CrossRef]

- Široký, J.; Oldewurtel, F.; Cigler, J.; Prívara, S. Experimental analysis of model predictive control for an energy efficient building heating system. Appl. Energy 2011, 88, 3079–3087. [Google Scholar] [CrossRef]

- Dounis, A.; Santamouris, M.; Lefas, C. Building visual comfort control with fuzzy reasoning. Energy Convers. Manag. 1993, 34, 17–28. [Google Scholar] [CrossRef]

- Jabłoński, K.; Grychowski, T. Fuzzy inference system for the assessment of indoor environmental quality in a room. Indoor Built Environ. 2017, 27, 1415–1430. [Google Scholar] [CrossRef]

- Aste, N.; Manfren, M.; Marenzi, G. Building Automation and Control Systems and performance optimization: A framework for analysis. Renew. Sustain. Energy Rev. 2017, 75, 313–330. [Google Scholar] [CrossRef]

- Manic, M.; Wijayasekara, D.; Amarasinghe, K.; Rodriguez-Andina, J.J. Building Energy Management Systems: The Age of Intelligent and Adaptive Buildings. IEEE Ind. Electron. Mag. 2016, 10, 25–39. [Google Scholar] [CrossRef]

- Shaikh, P.H.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I. Stochastic optimized intelligent controller for smart energy efficient buildings. Sustain. Cities Soc. 2014, 13, 41–45. [Google Scholar] [CrossRef]

- Hall, D.; Llinas, J. An introduction to multisensor data fusion. Proc. IEEE 1997, 85, 6–23. [Google Scholar] [CrossRef]

- Dounis, A.I.; Caraiscos, C. Intelligent coordinator of fuzzy controller-agents for indoor environment control in buildings using 3-D fuzzy comfort set. In Proceedings of the 2007 IEEE International Fuzzy Systems Conference, London, UK, 23–26 July 2007. [Google Scholar]

- Karaboga, D. An Idea Based on Honey Bee Swarm for Numerical Optimization; Technical Report-tr06; Computer Engineering Department, Engineering Faculty, Erciyes University: Talas, Turkey, 2005; Volume 200. [Google Scholar]

- Fong, K.; Hanby, V.; Chow, T. System optimization for HVAC energy management using the robust evolutionary algorithm. Appl. Therm. Eng. 2009, 29, 2327–2334. [Google Scholar] [CrossRef]

- Wright, J.A.; Loosemore, H.A.; Farmani, R. Optimization of building thermal design and control by multi-criterion genetic algorithm. Energy Build. 2002, 34, 959–972. [Google Scholar] [CrossRef]

- Soares, N.; Bastos, J.; Pereira, L.D.; Soares, A.; Amaral, A.; Asadi, E.; Rodrigues, E.; Lamas, F.; Monteiro, H.; Lopes, M.; et al. A review on current advances in the energy and environmental performance of buildings towards a more sustainable built environment. Renew. Sustain. Energy Rev. 2017, 77, 845–860. [Google Scholar] [CrossRef]

- Serale, G.; Fiorentini, M.; Capozzoli, A.; Bernardini, D.; Bemporad, A. Model Predictive Control (MPC) for Enhancing Building and HVAC System Energy Efficiency: Problem Formulation, Applications and Opportunities. Energies 2018, 11, 631. [Google Scholar] [CrossRef]

- Huang, W.; Lam, H. Using genetic algorithms to optimize controller parameters for HVAC systems. Energy Build. 1997, 26, 277–282. [Google Scholar] [CrossRef]

- Delgarm, N.; Sajadi, B.; Kowsary, F.; Delgarm, S. Multi-objective optimization of the building energy performance: A simulation-based approach by means of particle swarm optimization (PSO). Appl. Energy 2016, 170, 293–303. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, R.; Wang, L. Multi-agent control system with intelligent optimization for smart and energy-efficient buildings. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010. [Google Scholar]

- Ullah, I.; Kim, D. An Improved Optimization Function for Maximizing User Comfort with Minimum Energy Consumption in Smart Homes. Energies 2017, 10, 1818. [Google Scholar] [CrossRef]

- Cetin, K.; Tabares-Velasco, P.; Novoselac, A. Appliance daily energy use in new residential buildings: Use profiles and variation in time-of-use. Energy Build. 2014, 84, 716–726. [Google Scholar] [CrossRef]

- Ullah, I.; Ahmad, R.; Kim, D. A Prediction Mechanism of Energy Consumption in Residential Buildings Using Hidden Markov Model. Energies 2018, 11, 358. [Google Scholar] [CrossRef]

- Tripathy, M. Power transformer differential protection using neural network Principal Component Analysis and Radial Basis Function Neural Network. Simul. Model. Pract. Theory 2010, 18, 600–611. [Google Scholar] [CrossRef]

- Niu, H.; Wang, J. Financial time series prediction by a random data-time effective RBF neural network. Soft Comput. 2013, 18, 497–508. [Google Scholar] [CrossRef]

- Sermpinis, G.; Stasinakis, C.; Dunis, C. Stochastic and genetic neural network combinations in trading and hybrid time-varying leverage effects. J. Int. Financ. Mark. Inst. Money 2014, 30, 21–54. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep learning in neural networks: An overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef]

- Mudassar, L.; Byun, Y. Customer Prediction on Parking Logs Using Recurrent Neural Network. In International Conference on Software Engineering, Artificial Intelligence, Networking and Parallel/Distributed Computing; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Jain, V.; Seung, S. Natural image denoising with convolutional networks. In Proceedings of the Twenty-Second Annual Conference on Neural Information Processing Systems, Vancouver, BC, Canada, 8–11 December 2008. [Google Scholar]

- Fernández, S.; Graves, A.; Schmidhuber, J. Sequence labelling in structured domains with hierarchical recurrent neural networks. In Proceedings of the 20th International Joint Conference on Artificial Intelligence, IJCAI 2007, Hyderabad, India, 6–12 January 2007. [Google Scholar]

- Wu, Z.; Ma, X.; Yu, H.; Wang, S.; Wang, Y. Spatiotemporal Recurrent Convolutional Networks for Traffic Prediction in Transportation Networks. Sensors 2017, 17, 1501. [Google Scholar]

- Cheng, L.; Zang, H.; Ding, T.; Sun, R.; Wang, M.; Wei, Z.; Sun, G. Ensemble Recurrent Neural Network Based Probabilistic Wind Speed Forecasting Approach. Energies 2018, 11, 1958. [Google Scholar] [CrossRef]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Ahmed, R.; Emadi, A.; Kollmeyer, P. Long Short-Term Memory Networks for Accurate State-of-Charge Estimation of Li-ion Batteries. IEEE Trans. Ind. Electron. 2018, 65, 6730–6739. [Google Scholar] [CrossRef]

- Tam, Y.-C.; Shi, Y.; Chen, H.; Hwang, M.-Y. RNN-based labeled data generation for spoken language understanding. In Proceedings of the Sixteenth Annual Conference of the International Speech Communication Association, Dresden, Germany, 6–10 September 2015. [Google Scholar]

- Zhao, Z.; Chen, W.; Wu, X.; Chen, P.C.Y.; Liu, J. LSTM network: A deep learning approach for short-term traffic forecast. IET Intell. Transp. Syst. 2017, 11, 68–75. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Olesen, B.W.; Parsons, K.C. Introduction to thermal comfort standards and to the proposed new version of EN ISO 7730. Energy Build. 2002, 34, 537–548. [Google Scholar] [CrossRef]

- ISO EN7730:2005. Ergonomics of the Thermal Environment-Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- Chen, X.; Wang, Q.; Srebric, J. A data-driven state-space model of indoor thermal sensation using occupant feedback for low-energy buildings. Energy Build. 2015, 91, 187–198. [Google Scholar] [CrossRef]

- Ghahramani, A.; Castro, G.; Becerik-Gerber, B.; Yu, X. Infrared thermography of human face for monitoring thermoregulation performance and estimating personal thermal comfort. Build. Environ. 2016, 109, 1–11. [Google Scholar] [CrossRef]

- Ari, S.; Wilcoxen, P.; Khalifa, H.E.; Dannenhoffer, J.F.; Işik, C. A practical approach to individual thermal comfort and energy optimization problem. In Proceedings of the NAFIPS 2008—2008 Annual Meeting of the North American Fuzzy Information Processing Society, New York, NY, USA, 19–22 May 2008. [Google Scholar]

- Kawakami, K. Supervised Sequence Labelling with Recurrent Neural Networks. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2008. [Google Scholar]

- Cannistraro, M.; Cannistraro, G.; Restivo, R. The Local Media Radiant Temperature for the Calcuilation of Comfort in Areas Characterized by Radiant Surfaces. Int. J. Heat Techol. 2015, 33, 115–122. [Google Scholar] [CrossRef]

- Cannistraro, M.; Cannistraro, G.; Restivo, R. Some Observations on the Influence on Exchanges Radiative. Int. J. Heat Techol. 2015, 33, 79–84. [Google Scholar] [CrossRef]

- Cannistraro, M.; Cannistraro, G.; Restivo, R. Smart Controll of Air Climatization System in Function on the Values of the Mean Local Radiant Temperature. Smart Sci. 2015, 3. [Google Scholar] [CrossRef]

- Tetens, O. Uber einige meteorologische Begriffe. Z. Geophys. 1930, 6, 297–309. [Google Scholar]

- Snyder, R.L. Humidity Conversion; Biometeorology Program, University of California: Davis, CA, USA, 2005. [Google Scholar]

- CBE Thermal Comfort Tool. Available online: http://comfort.cbe.berkeley.edu (accessed on 12 December 2018).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, W.; Ullah, I.; Ahmad, S.; Kim, D. Occupant Comfort Management Based on Energy Optimization Using an Environment Prediction Model in Smart Homes. Sustainability 2019, 11, 997. https://doi.org/10.3390/su11040997

Jin W, Ullah I, Ahmad S, Kim D. Occupant Comfort Management Based on Energy Optimization Using an Environment Prediction Model in Smart Homes. Sustainability. 2019; 11(4):997. https://doi.org/10.3390/su11040997

Chicago/Turabian StyleJin, Wenquan, Israr Ullah, Shabir Ahmad, and Dohyeun Kim. 2019. "Occupant Comfort Management Based on Energy Optimization Using an Environment Prediction Model in Smart Homes" Sustainability 11, no. 4: 997. https://doi.org/10.3390/su11040997

APA StyleJin, W., Ullah, I., Ahmad, S., & Kim, D. (2019). Occupant Comfort Management Based on Energy Optimization Using an Environment Prediction Model in Smart Homes. Sustainability, 11(4), 997. https://doi.org/10.3390/su11040997